Patents

Literature

42results about How to "Accurate torque value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

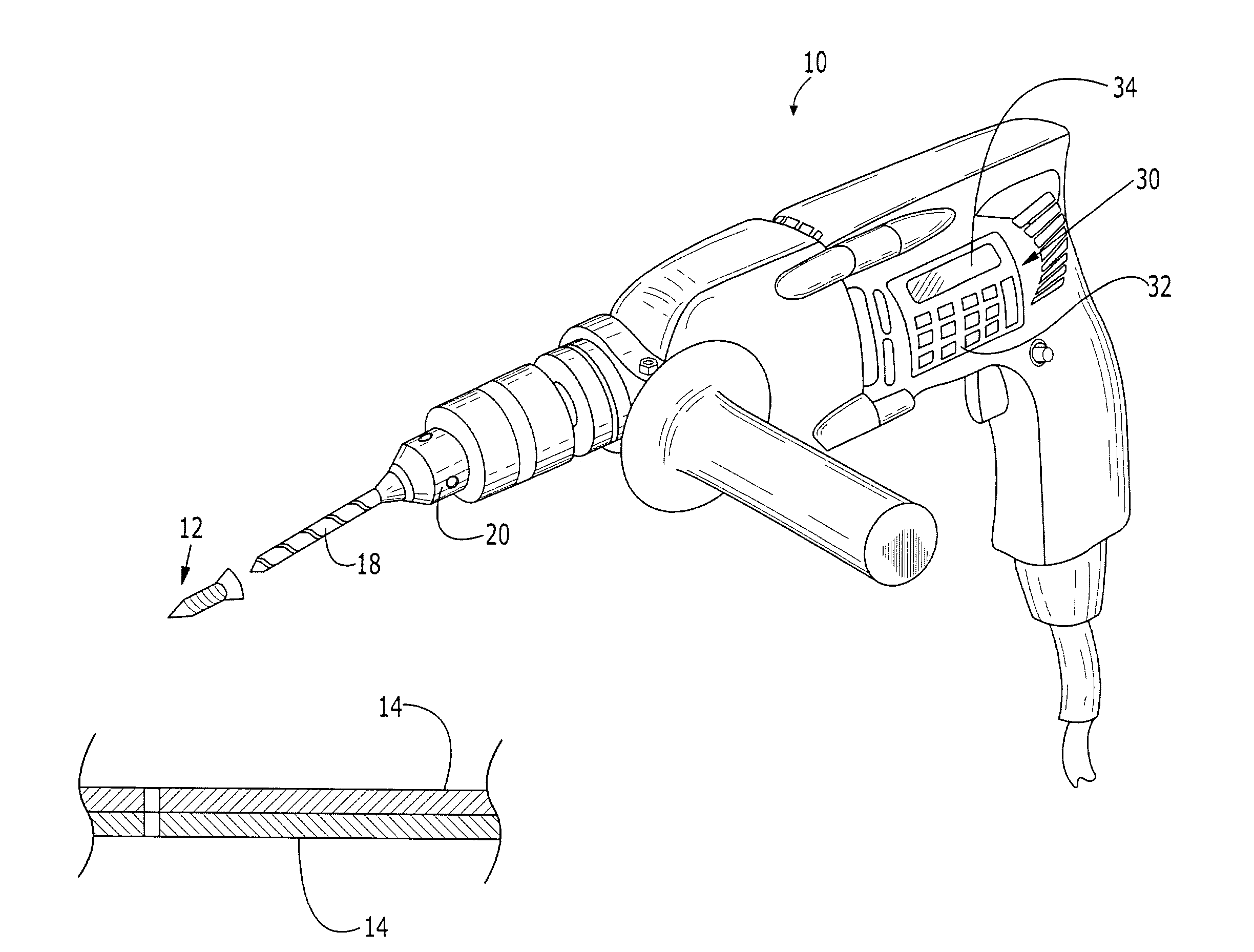

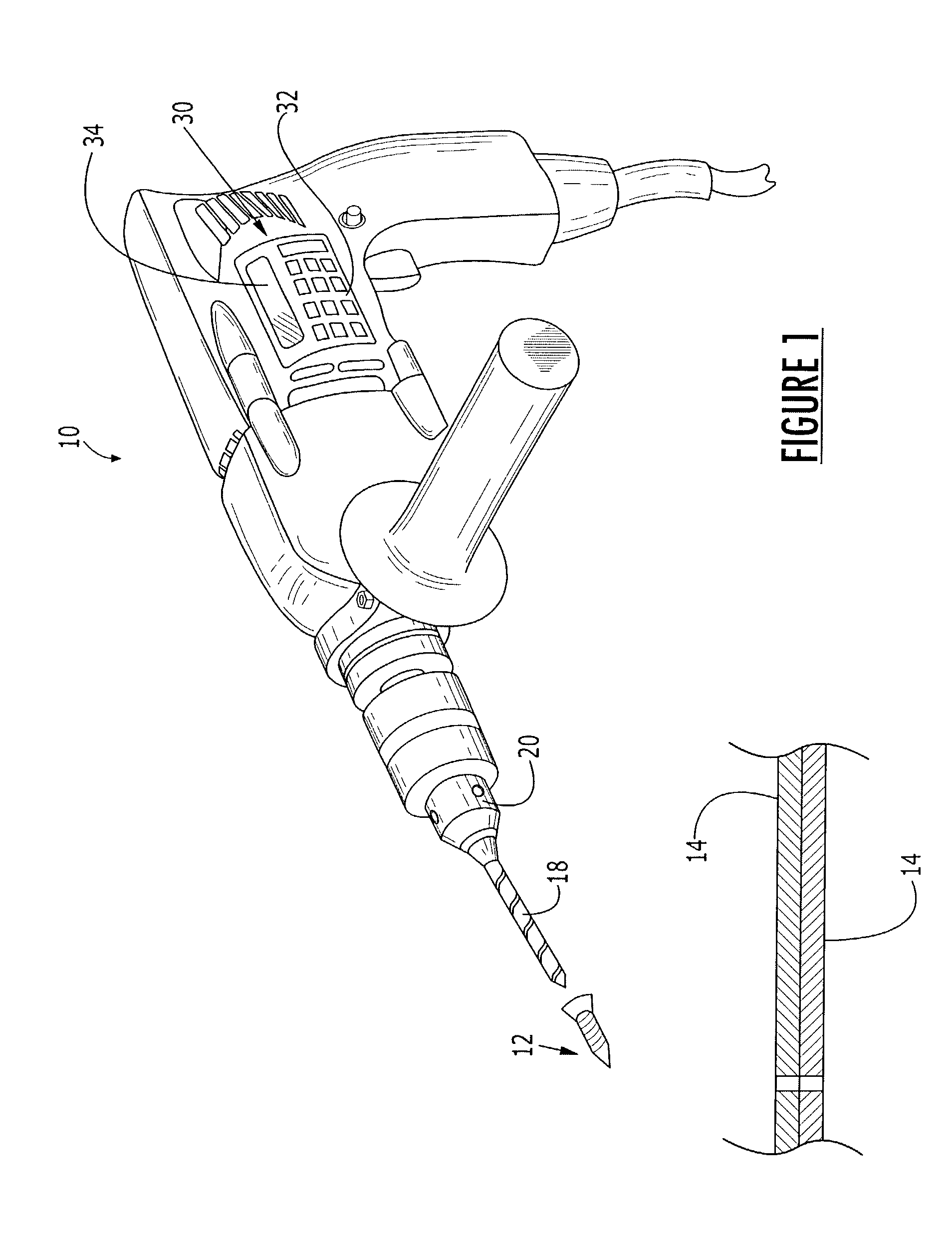

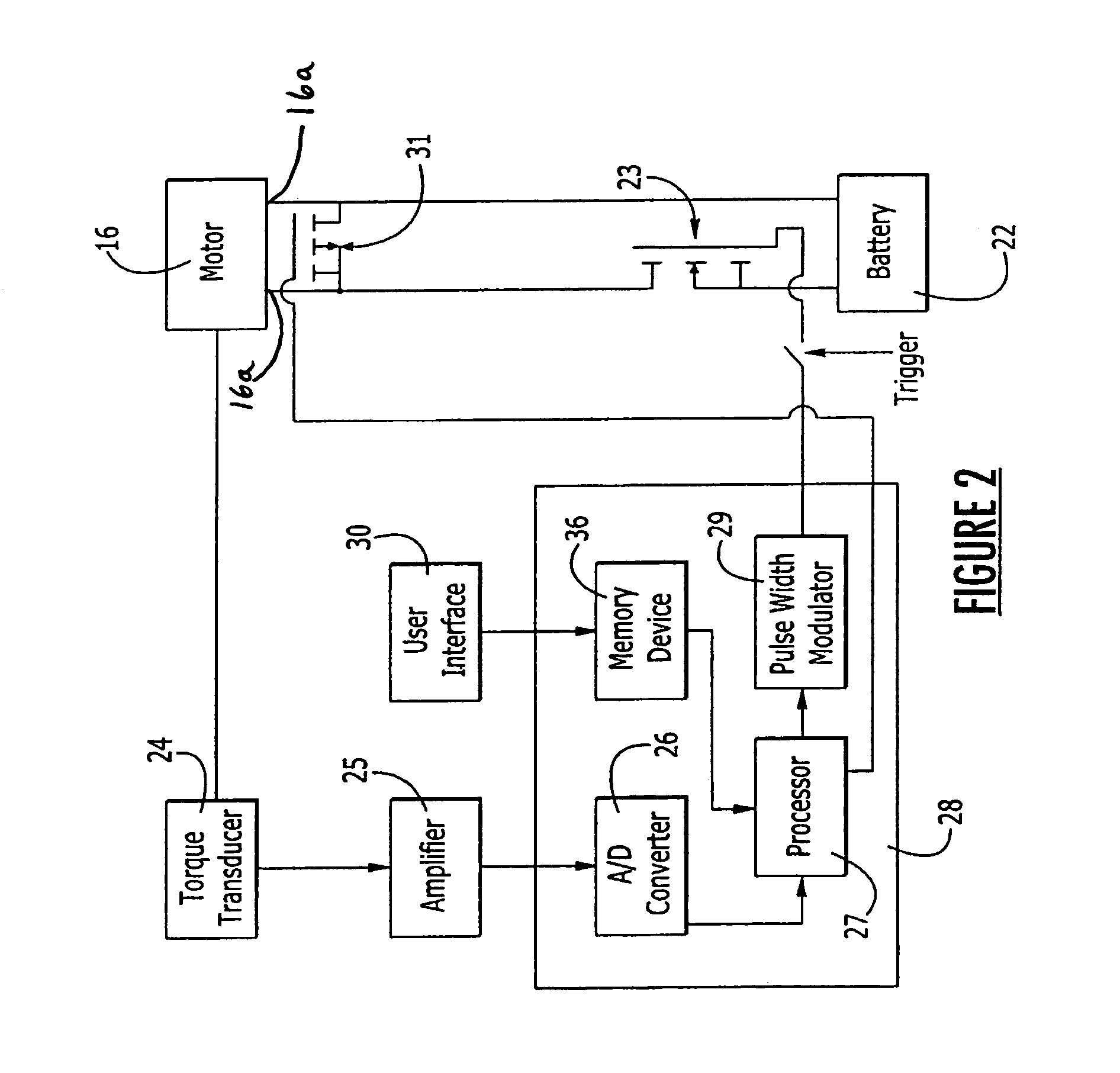

Tool and associated methods for controllably applying torque to a fastener

InactiveUS7062979B2Improve accuracyImprove consistencyMeasurement of torque/twisting force while tighteningWork measurementTransducerReference device

A torque tool and an associated method are provided which apply operator-defined levels of torque to a threaded fastener. In one aspect, a portable, battery powered torque tool controls the motor to slow further advancement of the threaded fastener once the torque that has been applied to the threaded fastener has reached a predefined threshold. In another aspect, a torque tool monitors a measure of torque applied to a threaded fastener more frequently once the torque applied to the threaded fastener has reached a predefined threshold. A method of defining a mathematical relationship between a first measure provided by a torque transducer of torque applied to a threaded fastener and a second measure provided by a torque measurement reference device of torque applied to the threaded fastener is also provided such that the measure of torque provided by the torque transducer can be calibrated.

Owner:THE BOEING CO

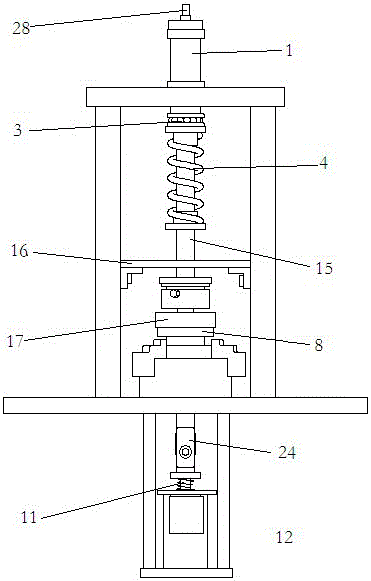

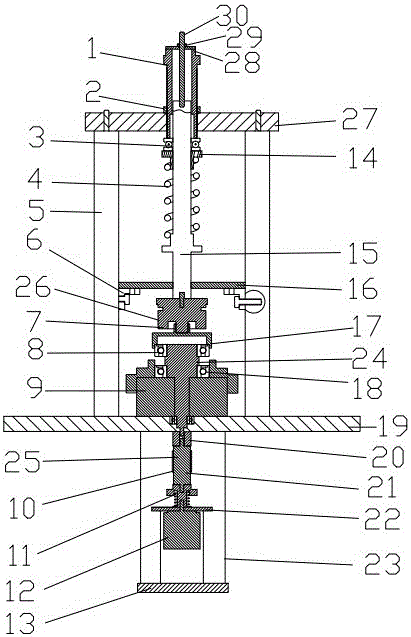

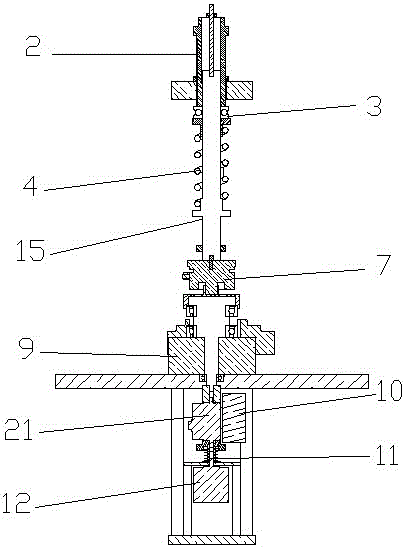

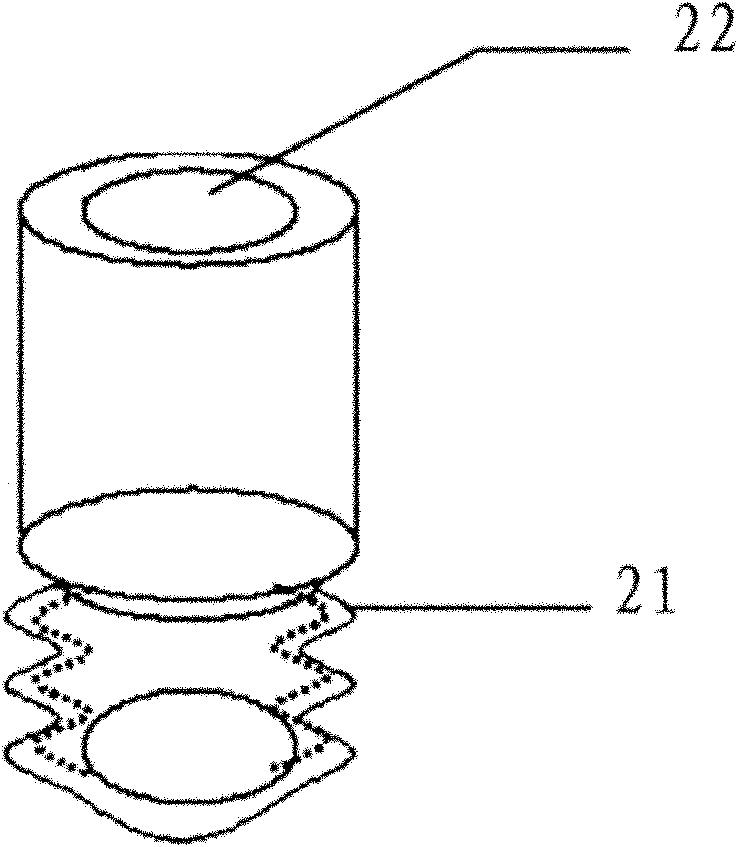

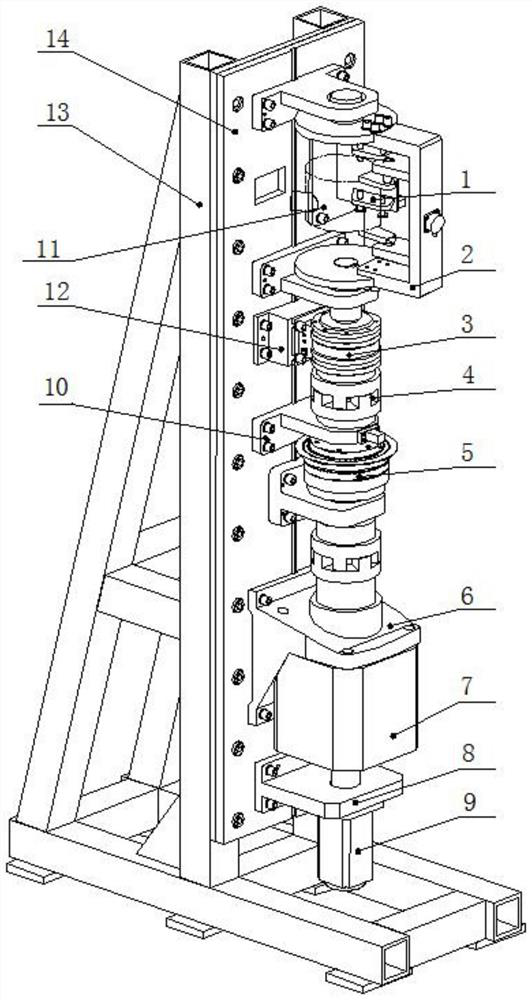

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

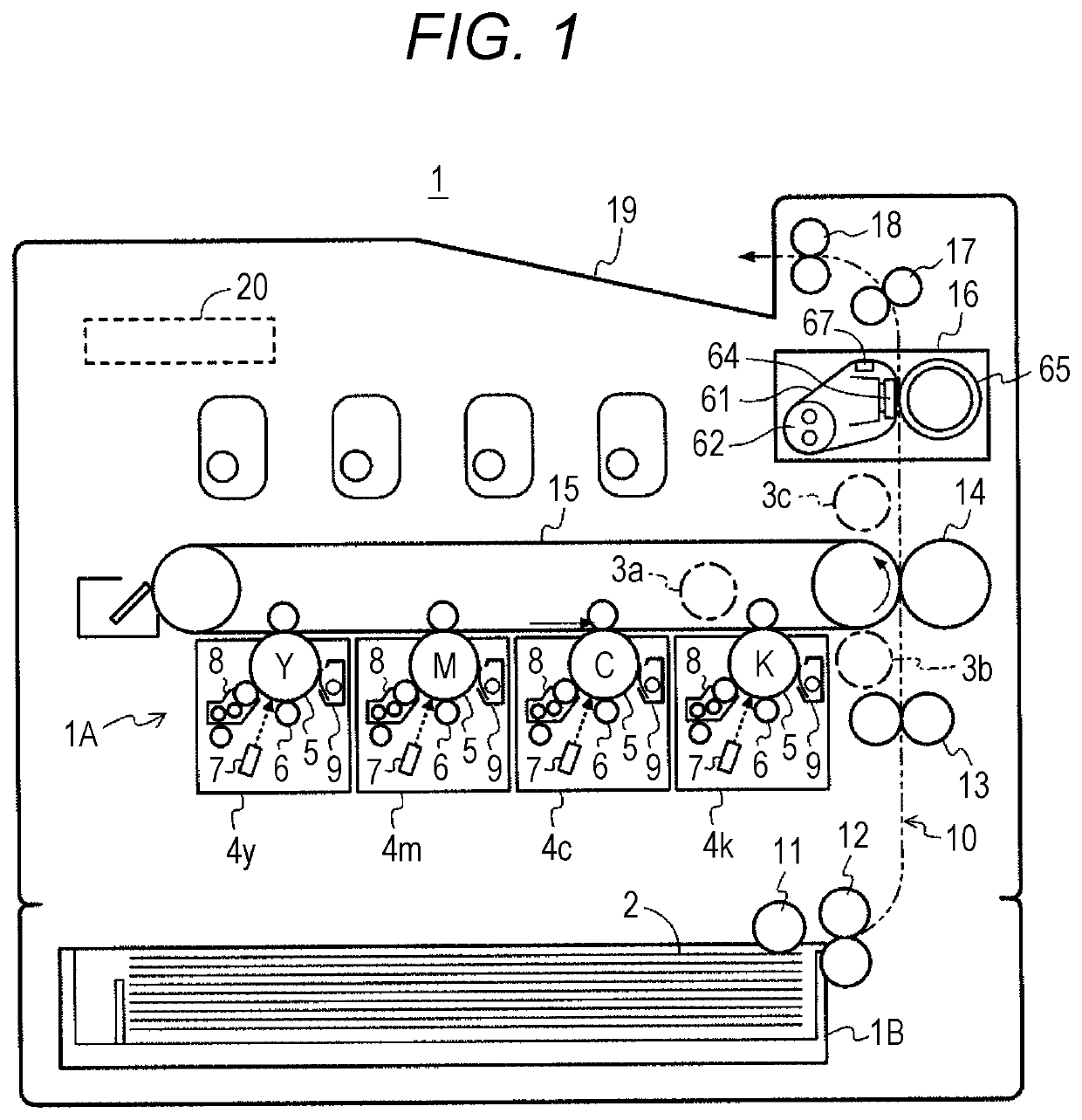

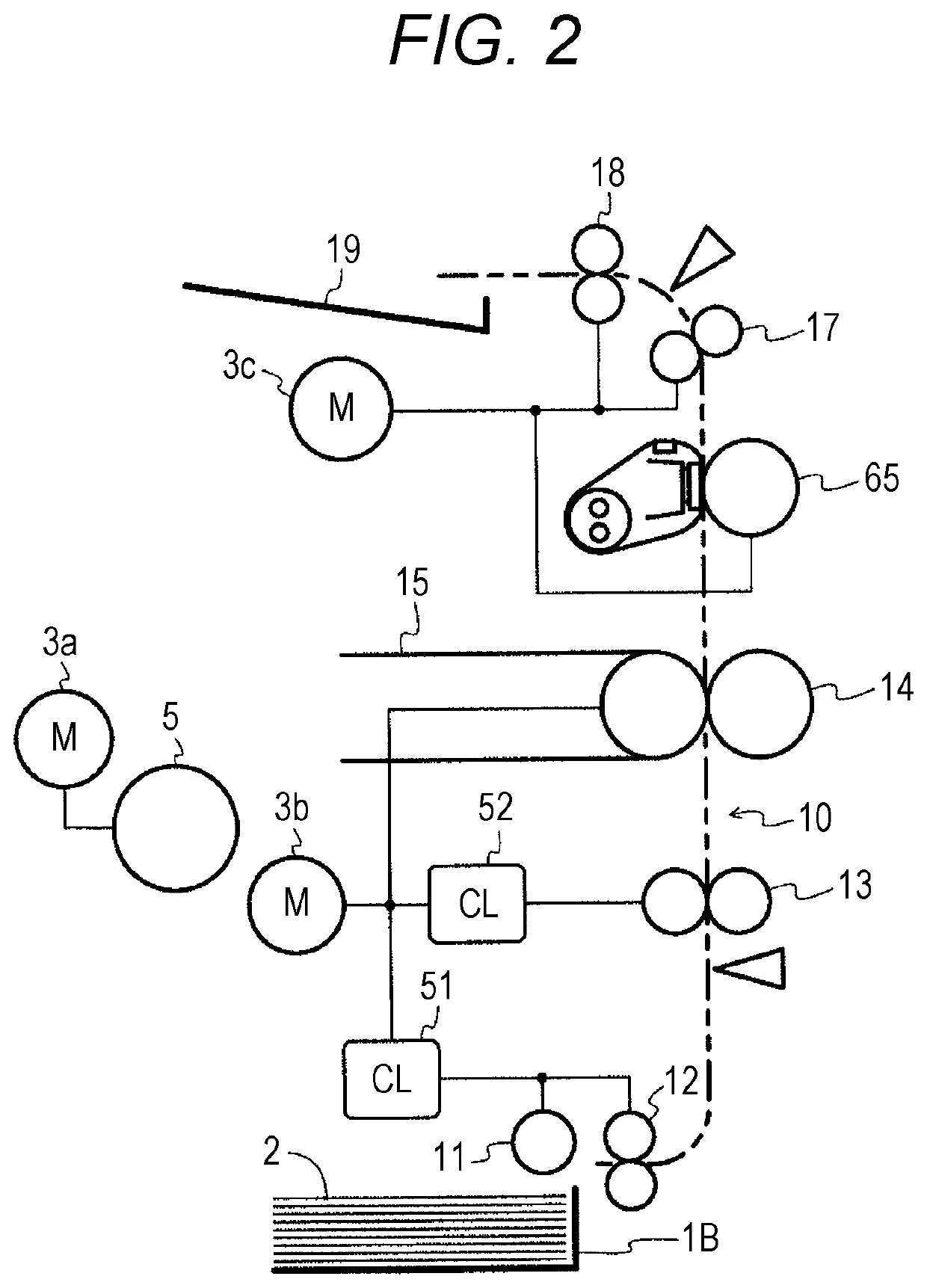

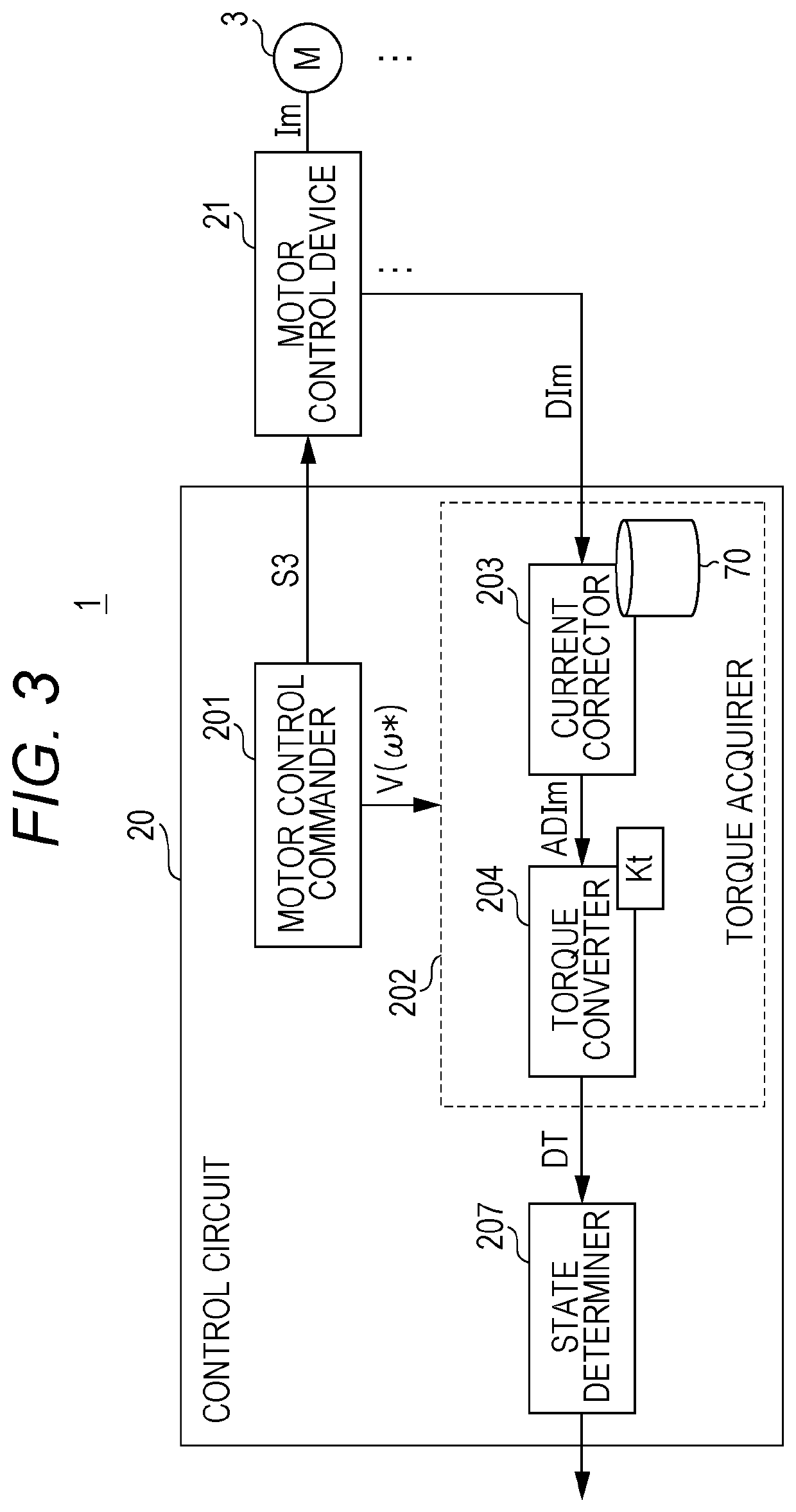

Image forming apparatus

ActiveUS20200073301A1Accurate torque valueElectrographic process apparatusMotor speedControl engineering

An image forming apparatus forms an image on a sheet, and includes: a rotator used to form the image; a motor that drives the rotator rotationally; a current measurer that measures motor current flowing through a current-carrying path including a winding of the motor, at measurement timing that is timing after the motor starts up; a torque acquirer that acquires a torque value of the motor based on a measured value of the motor current; and a corrector that performs correction for cancellation of an amount of error based on one or both of a variation in characteristic corresponding to motor speed of the motor and a variation in characteristic corresponding to the motor current at the measurement timing, at the acquisition of the torque value by the torque acquirer.

Owner:KONICA MINOLTA INC

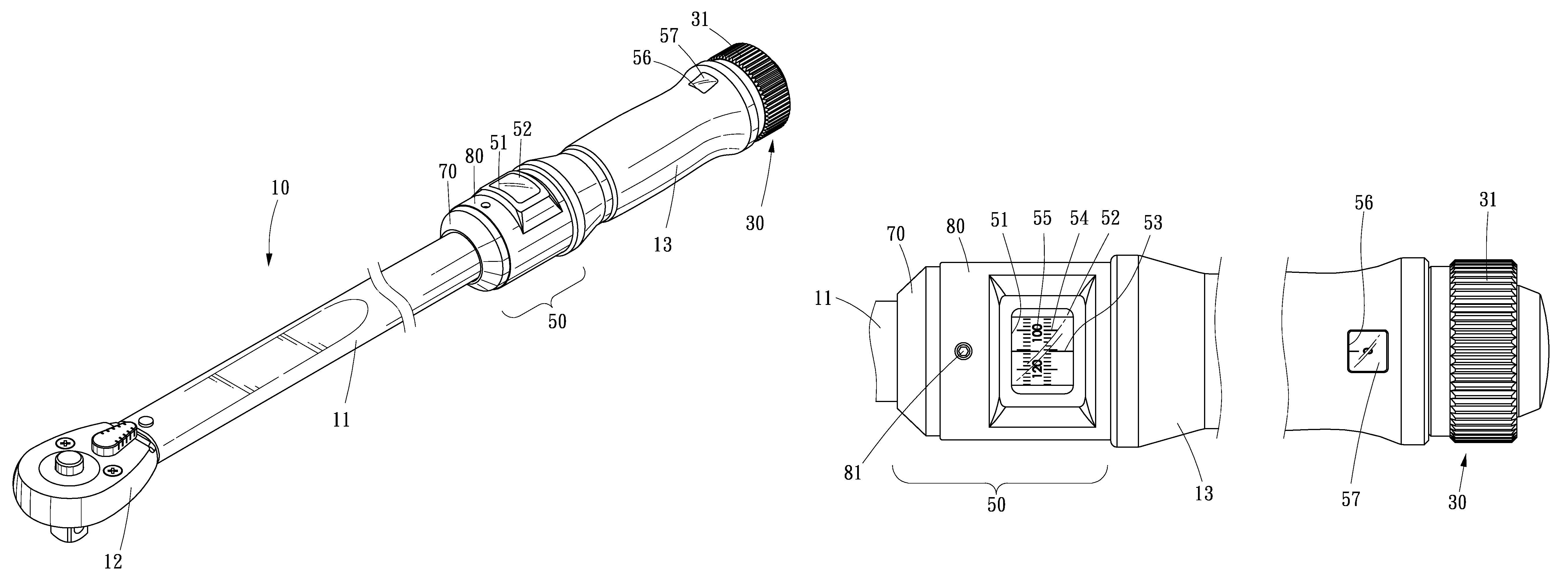

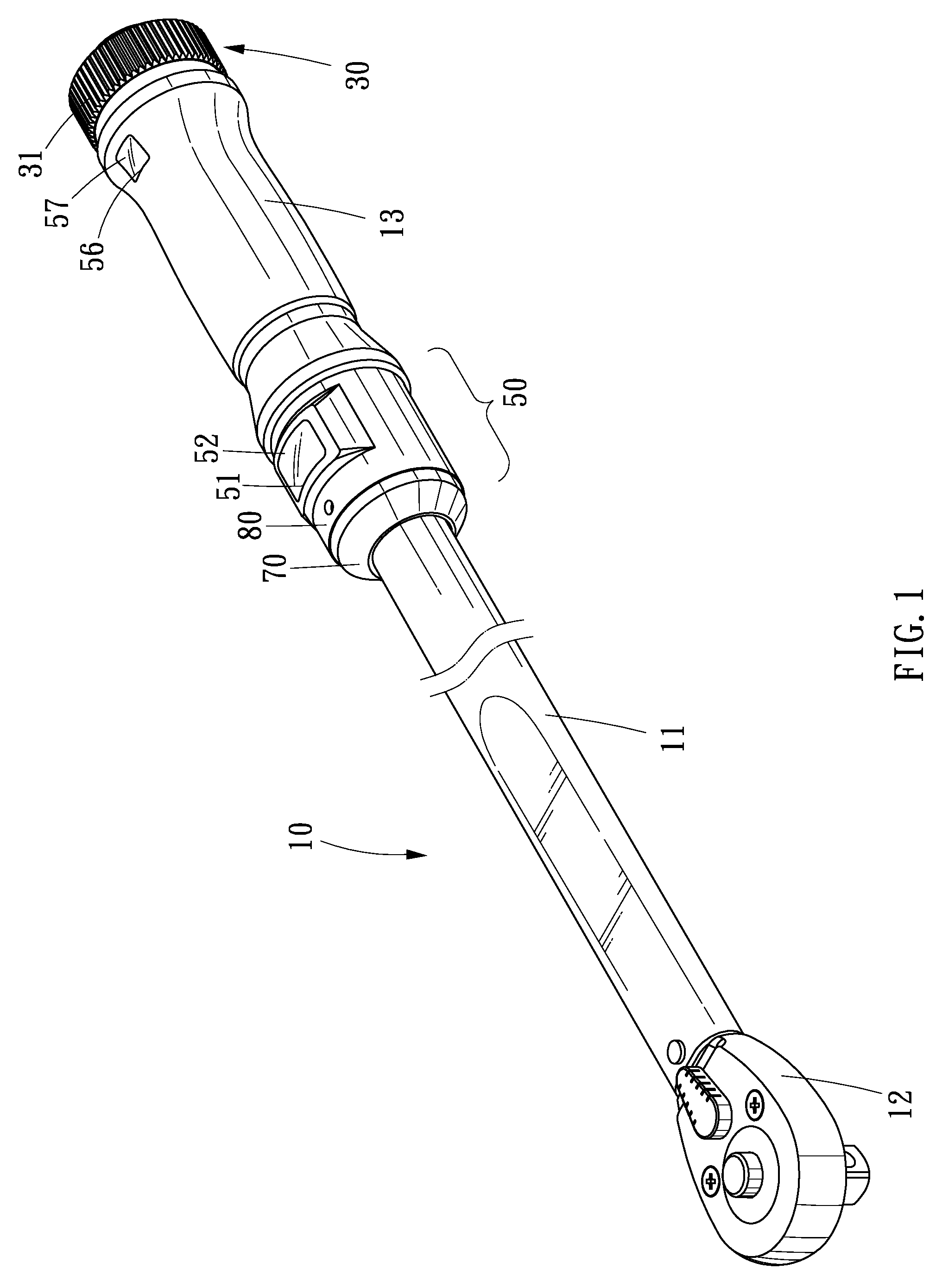

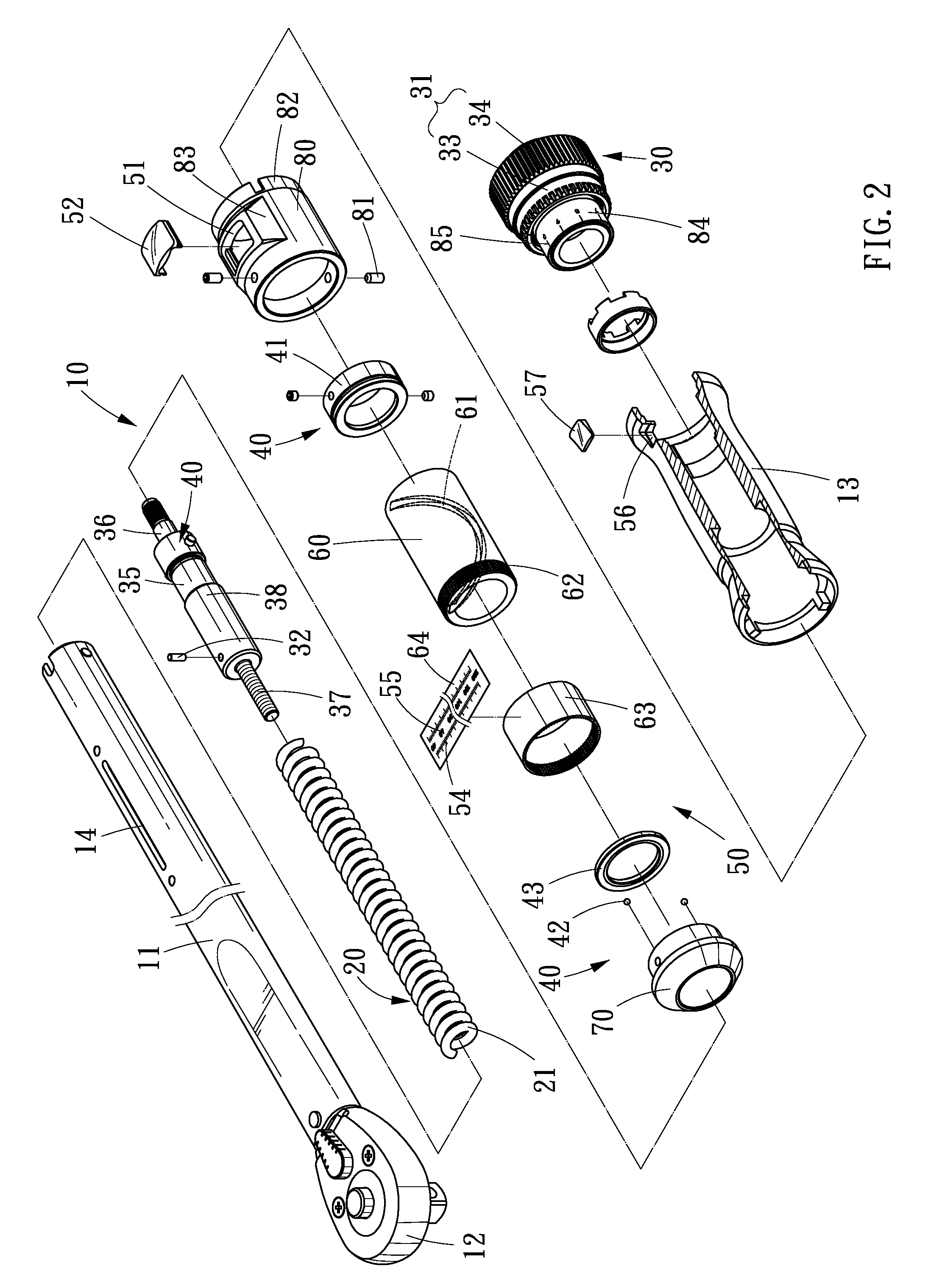

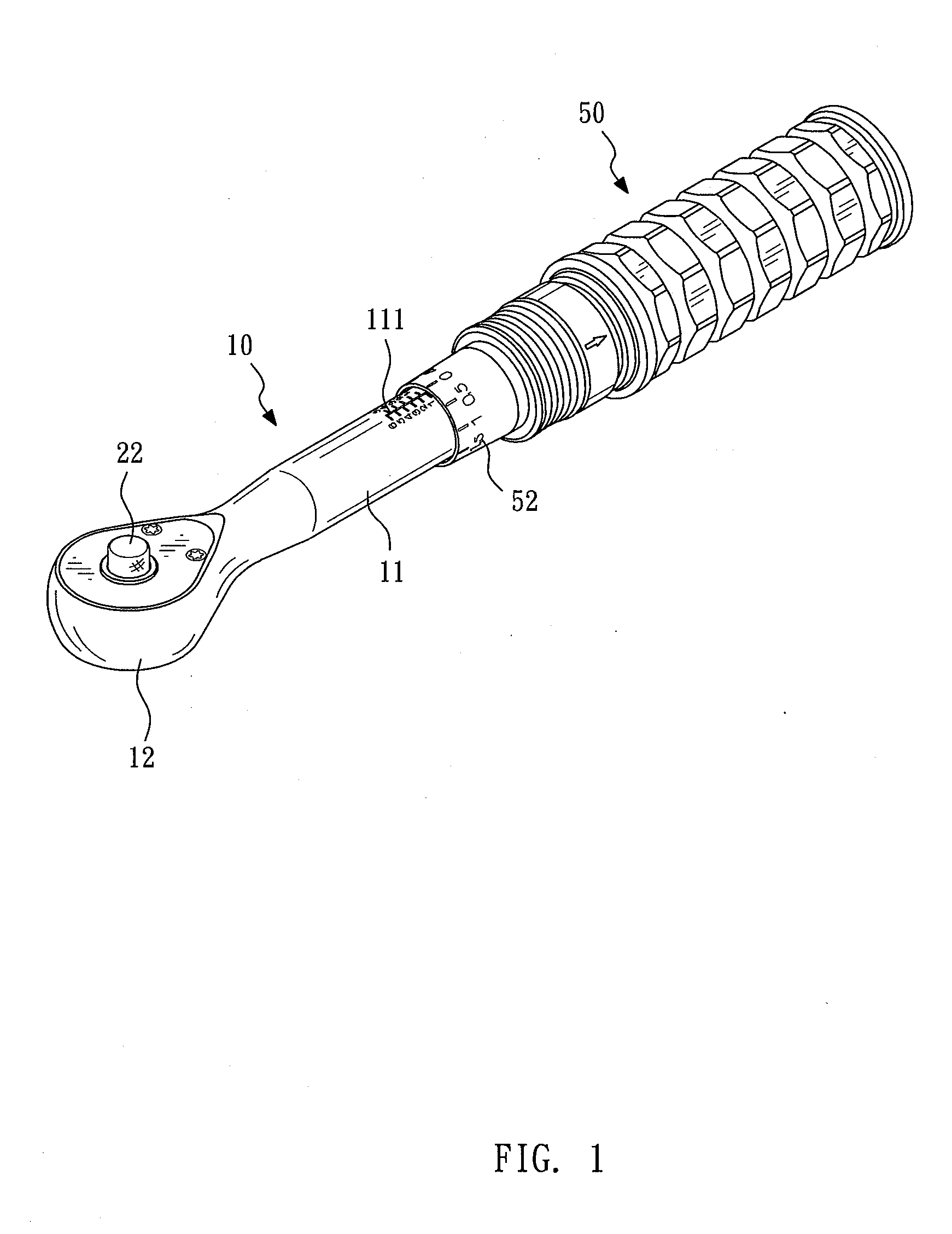

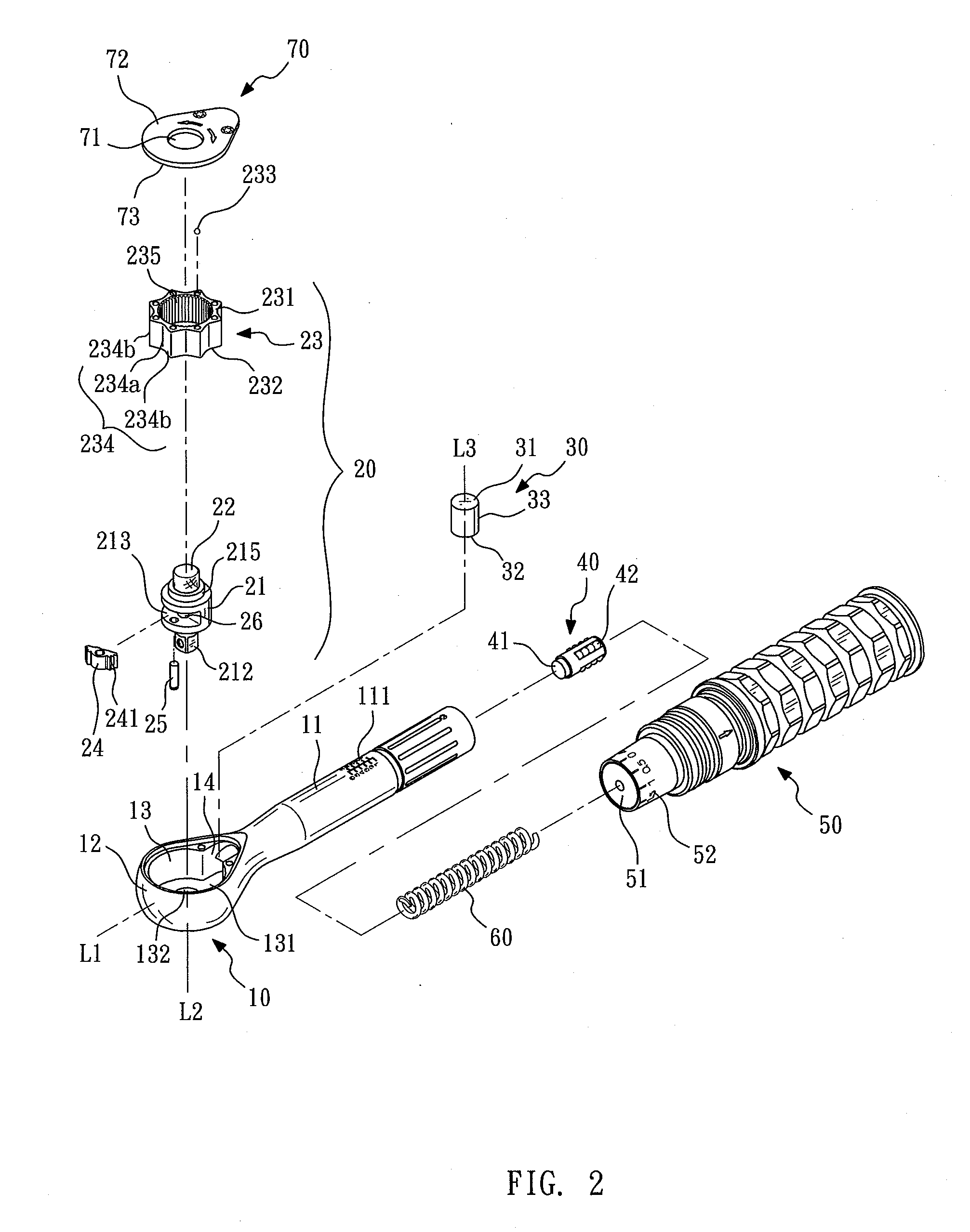

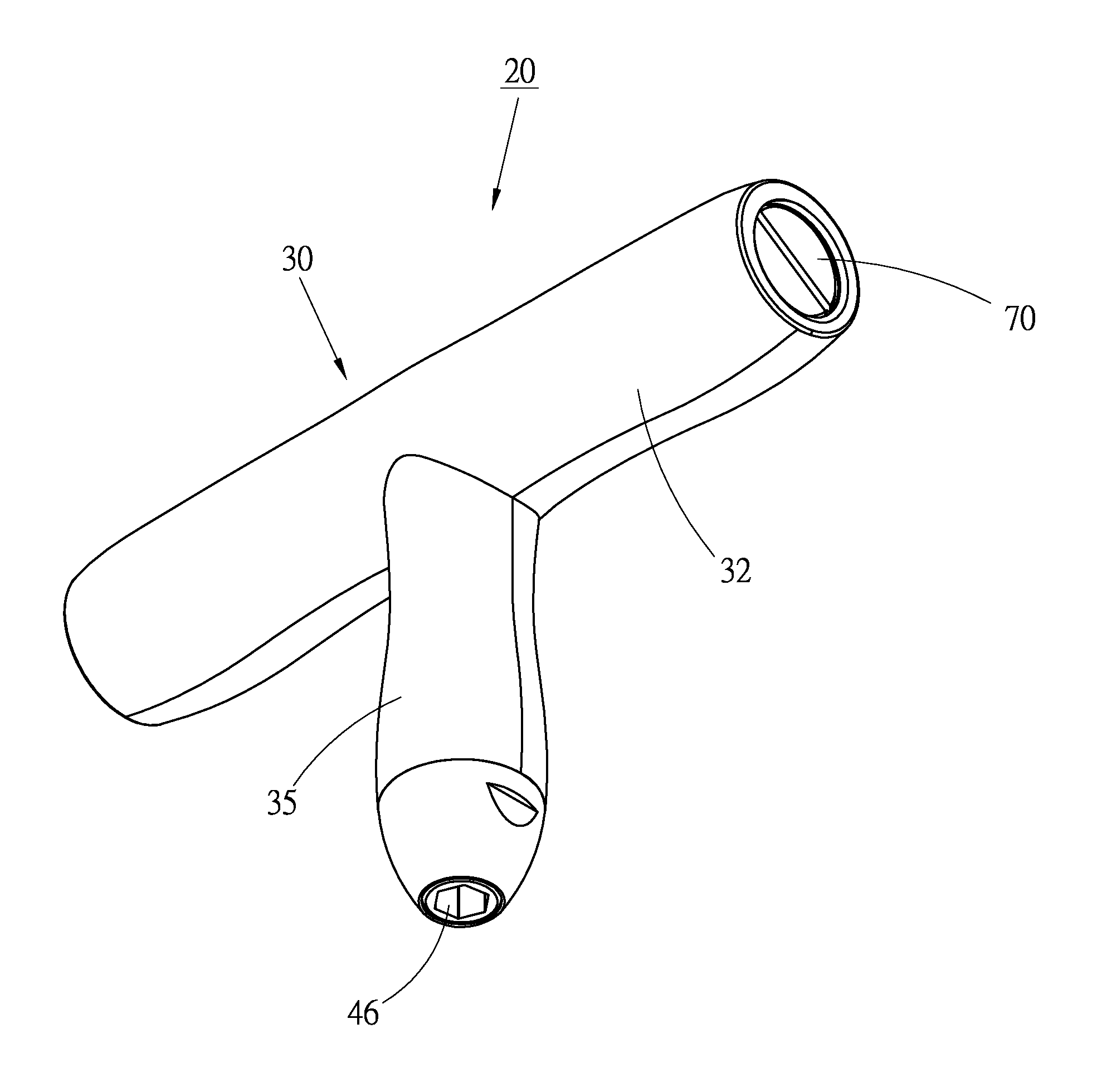

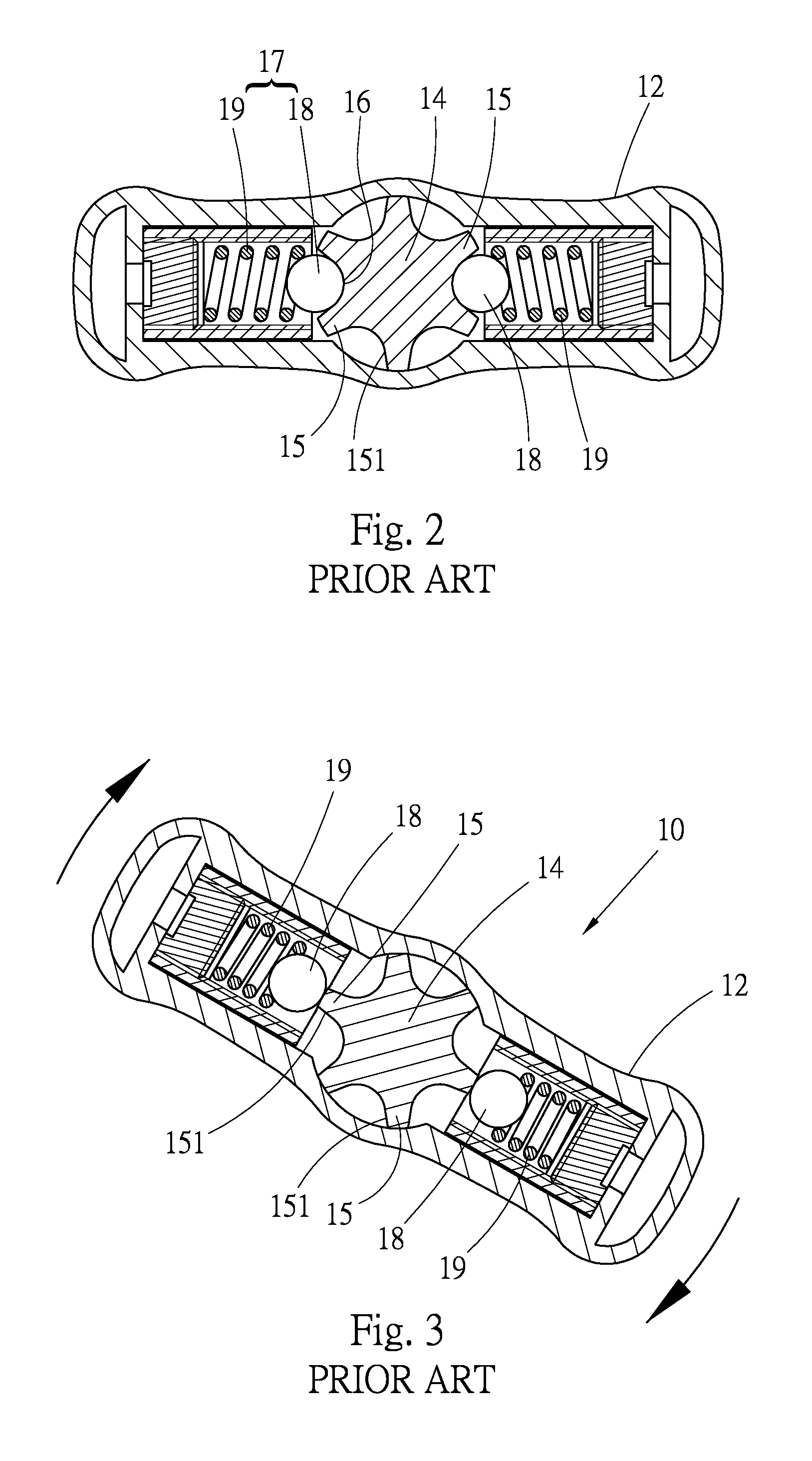

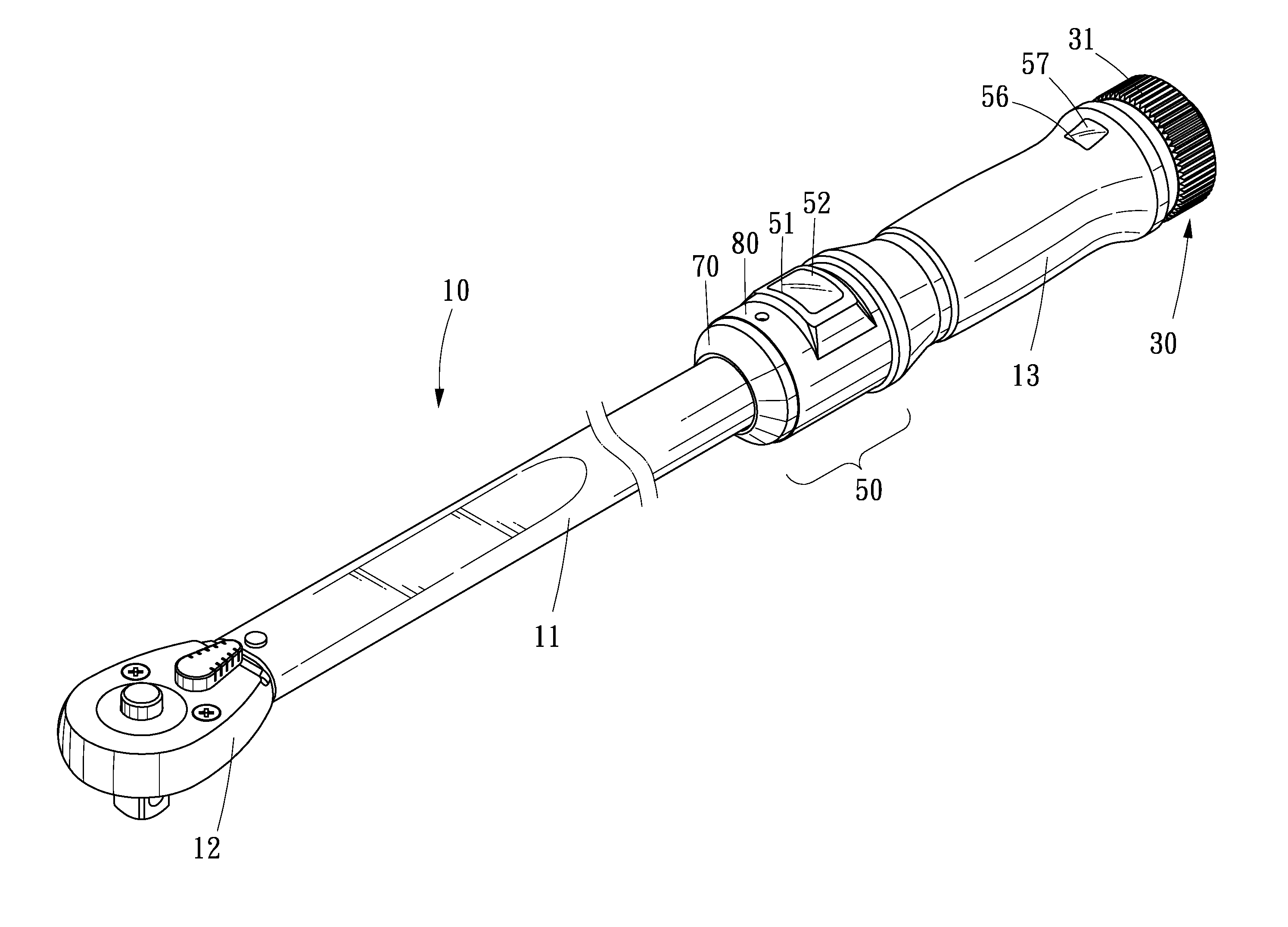

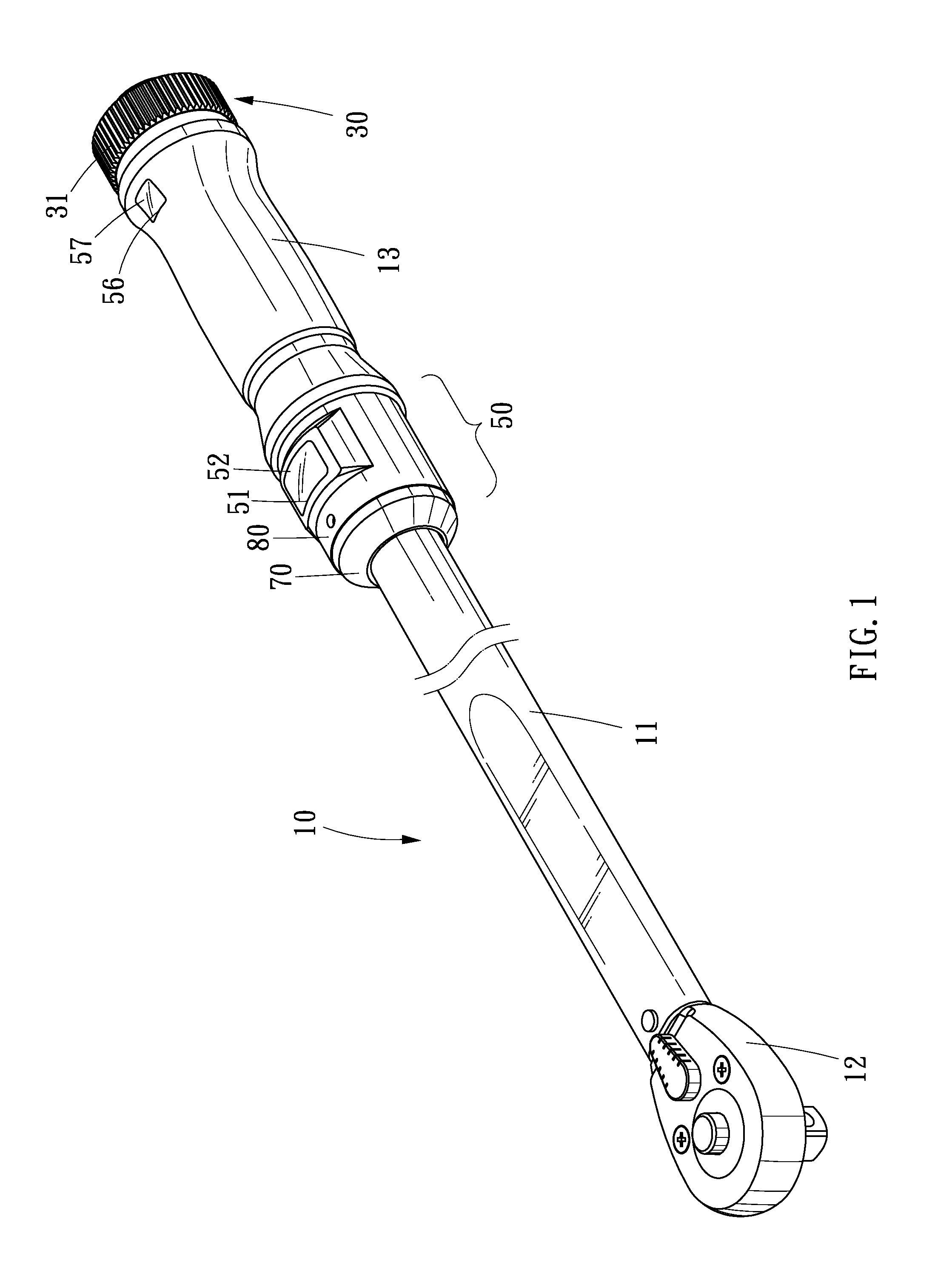

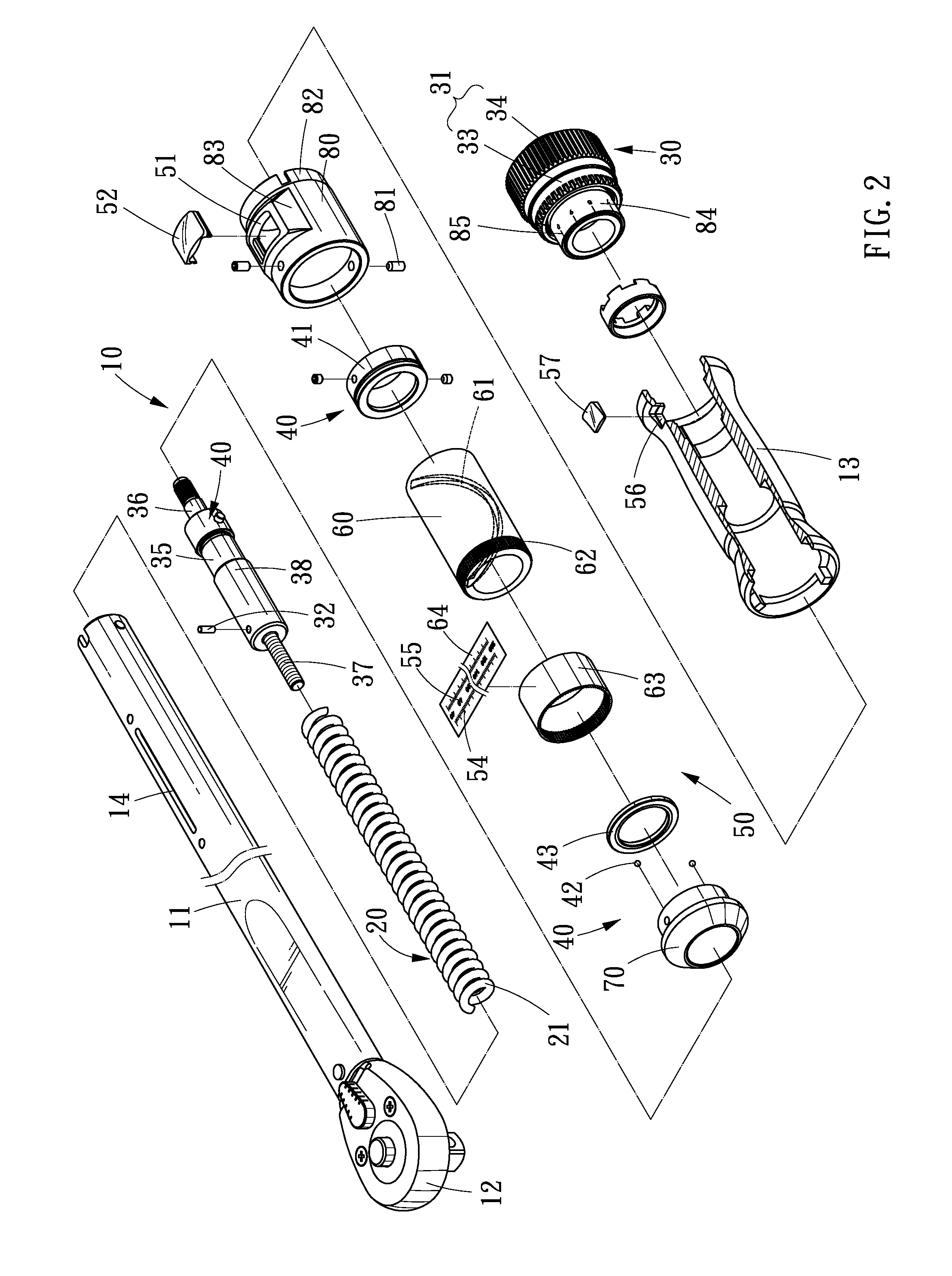

Wrench equipped with a precise torque-measuring device

A wrench includes a shank including a slot defined therein longitudinally, a handle attached to an end of the shank, a head, a torque assembly for connecting the head to another end of the shank, a torque-setting device and a torque-measuring device. The torque-setting device includes a knob inserted in the handle and a pin movable in and along the slot as the knob is spun. The torque-measuring device includes a measurement sleeve and a collar. The measurement sleeve is rotationally located around the shank and includes a helical groove defined in an internal side and a scale provided on an external side. A portion of the pin is movably inserted in the helical groove so that the measurement sleeve is spun as the pin is moved in and along the slot. The collar is located around the shank and includes a window through which the scale is observable.

Owner:MATATAKITOYO TOOL

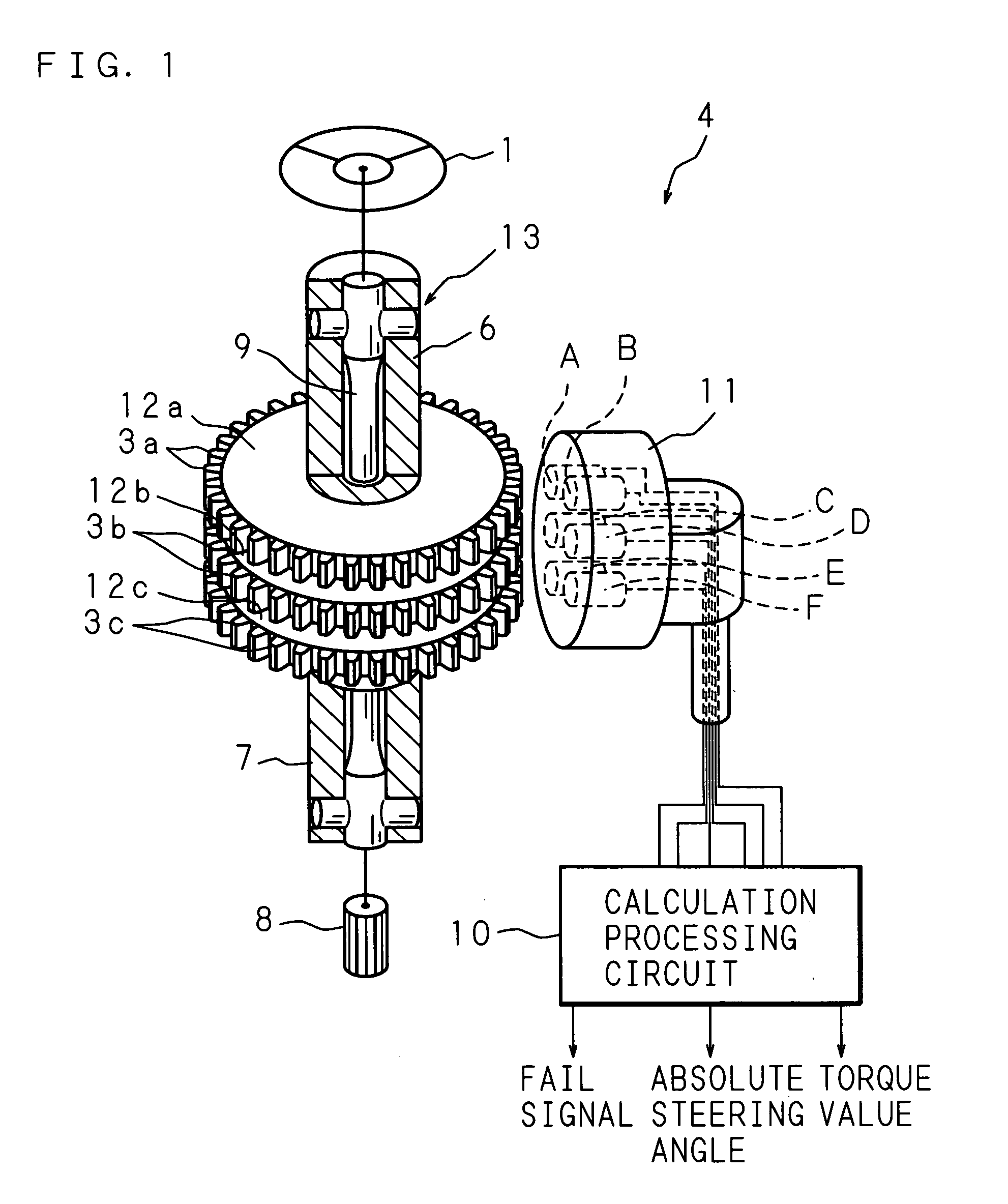

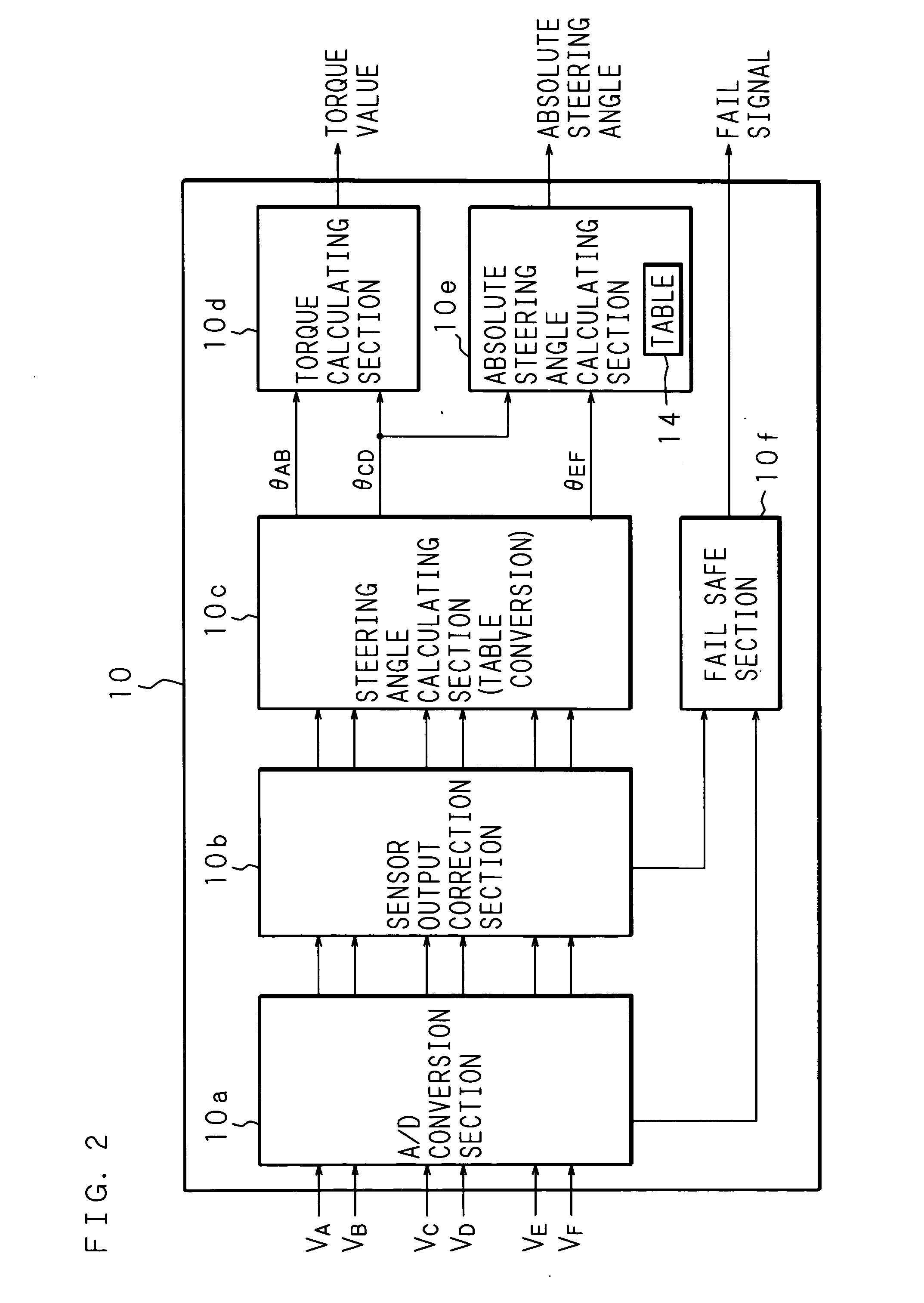

Rotational angle detecting apparatus and torque detecting apparatus

InactiveUS7201070B2Accurate acquisitionAccurate torque valueSteering linkagesWork measurementElectricityPhysics

Owner:JTEKT CORP

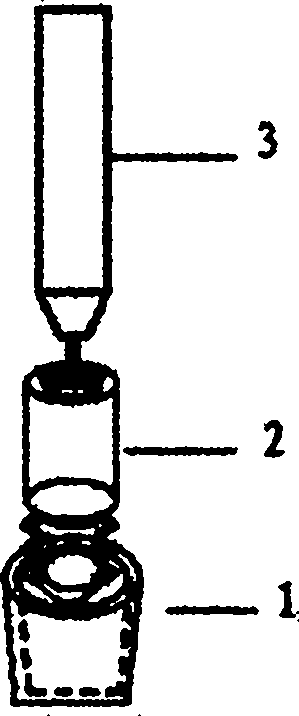

Screw lamp holder torsion testing device and torque testing method thereof

InactiveCN102692292ASimple structureEasy to operateMeasurement of torque/twisting force while tighteningControl theory

The invention discloses a screw lamp holder torsion testing device and a torque testing method thereof. The device comprises a fixing base, a connecting piece and an electric screwdriver with an adjustable torque. The fixing seat is used for fixing a screw lamp holder to be tested. One end of the connecting piece is provided with external thread. The other end of the connecting piece is provided with a groove. The electric screwdriver with the adjustable torque can be embedded into the groove. According to a set torque, the electric screwdriver with the adjustable torque screws the end of the connecting piece provided with the external thread into or out of the screw lamp holder to be tested. The torque testing method comprises the followings steps of: fixing the screw lamp holder to be tested into the fixing base; setting a torque of the electric screwdriver with the adjustable torque; embedding the electric screwdriver with the adjustable torque into the groove; placing the connecting piece into the screw lamp holder to be tested; according to the set torque, by using the electric screwdriver with the adjustable torque, and screwing the end of the connecting piece provided with the external thread into or out of the screw lamp holder to be tested. The device has the advantages of simple structure, rapid measurement, accurate torque value and no existence of a potential safety hazard.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

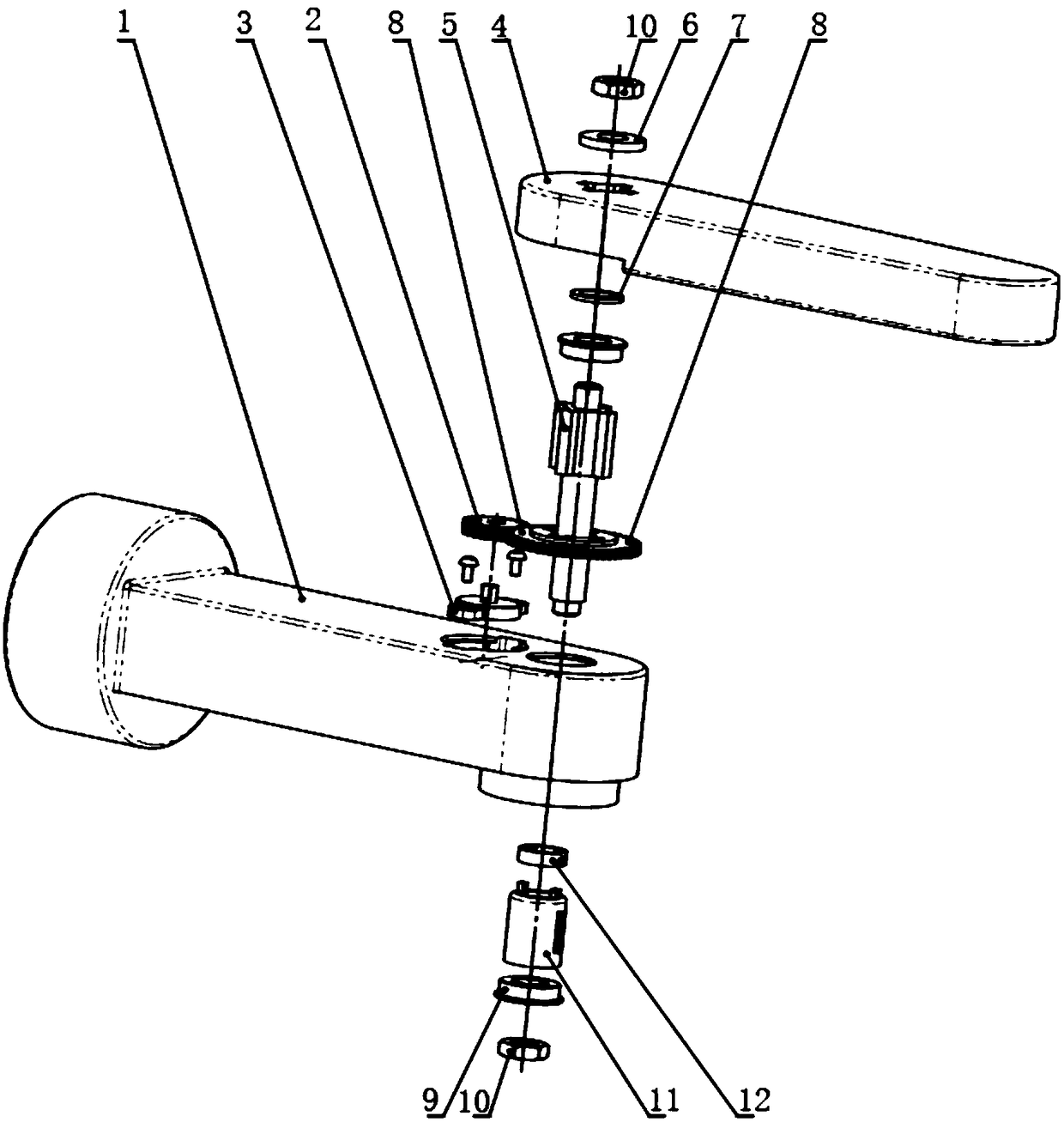

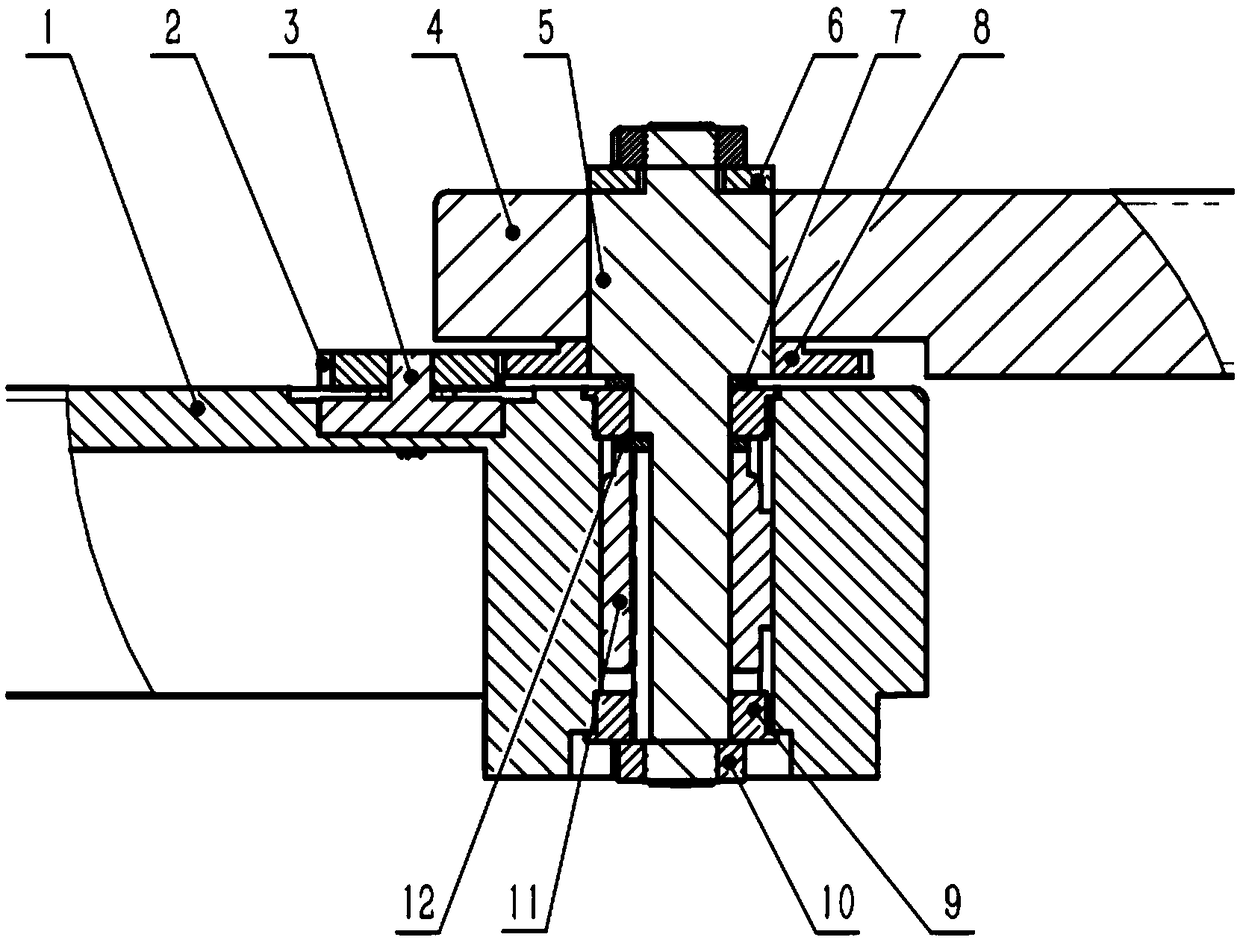

Damping joint for main manipulator

PendingCN109366519AImprove operating experienceImprove the safety of useJointsManipulatorShock absorber

The invention provides a damping joint for a main manipulator. The damping joint comprises a first connecting rod, a second connecting rod, a rotary shaft assembly and a damping assembly, wherein thesecond connecting rod is rotatably connected with the first connecting rod; the rotary shaft assembly comprises a key shaft and a bearing; the key shaft penetrates through the first connecting rod andthe second connecting rod and is locked and fixed in the axial direction; the key shaft comprises a spline section and a cylindrical section which are fixedly connected; the spline section is in keyconnection with the second connecting rod; the cylindrical section is fixedly connected with the first connecting rod through the bearing; the damping assembly comprises a first rotary damper; the cylindrical section of the key shaft is sleeved with the first rotary damper; the rotary damper comprises a shell and a rotary body which rotate relatively. The shell and the first connecting rod are fixed. The rotary body and the key shaft are fixed. The first connecting rod drives the second connecting rod to rotate through the key shaft. The key shaft drives the rotary body to rotate synchronously. The rotary body and the shell rotate relatively to achieve the damping effect. According to the damping joint provided by the invention, the rotary damper is arranged in the joint structure of the main manipulator to achieve the stable damping effect, and the operation precision of the main manipulator is ensured.

Owner:SUZHOU KANGDUO ROBOT

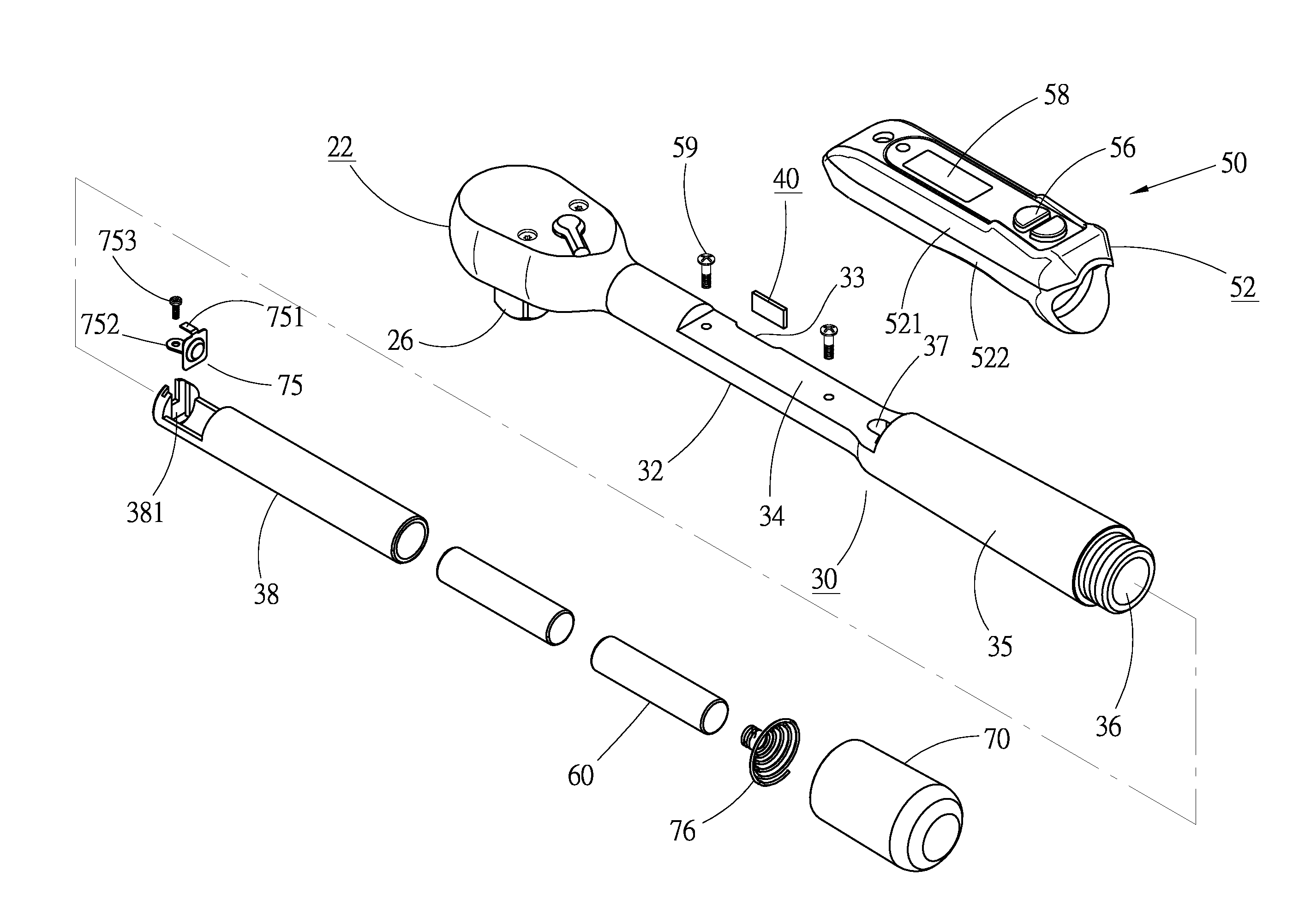

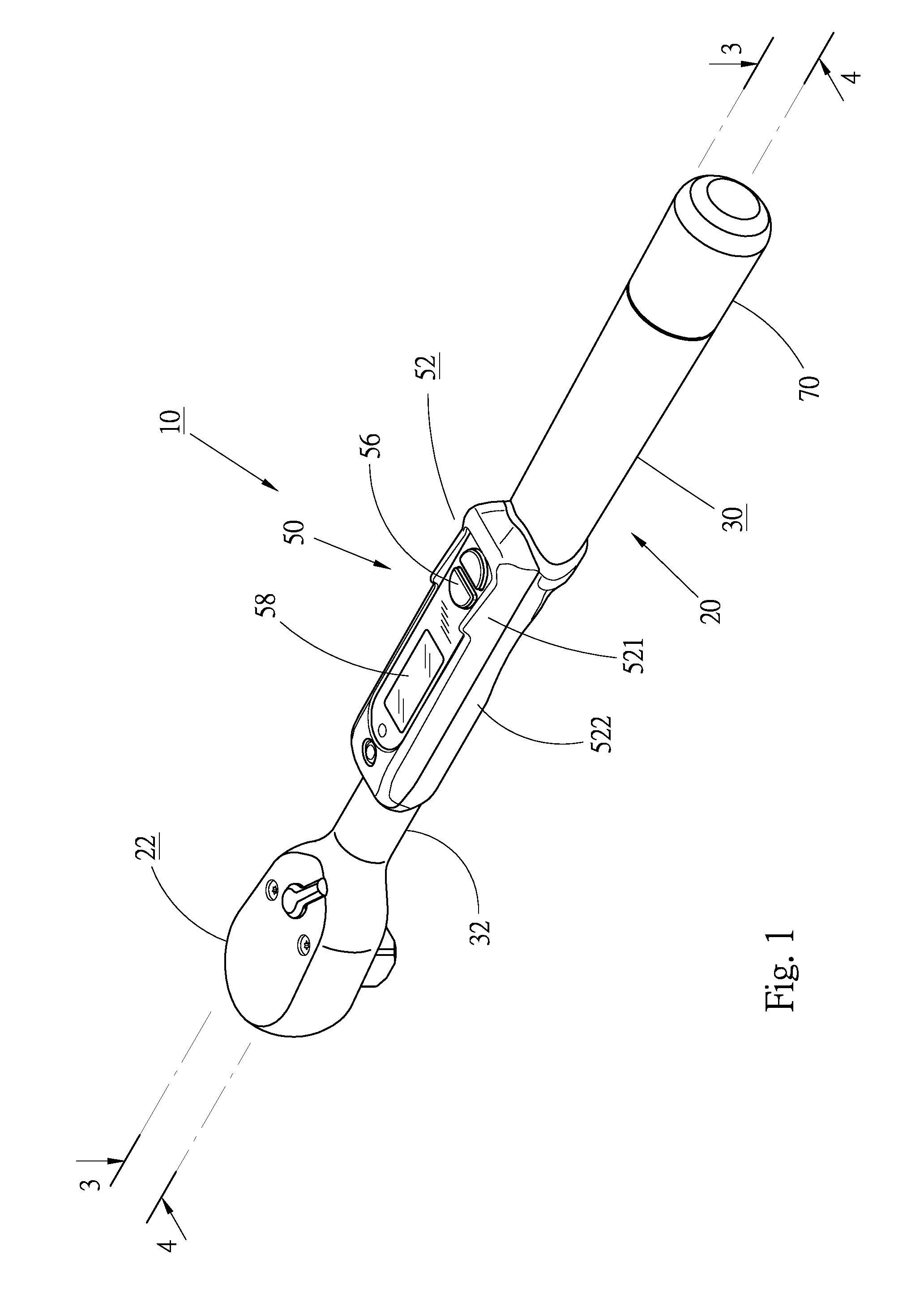

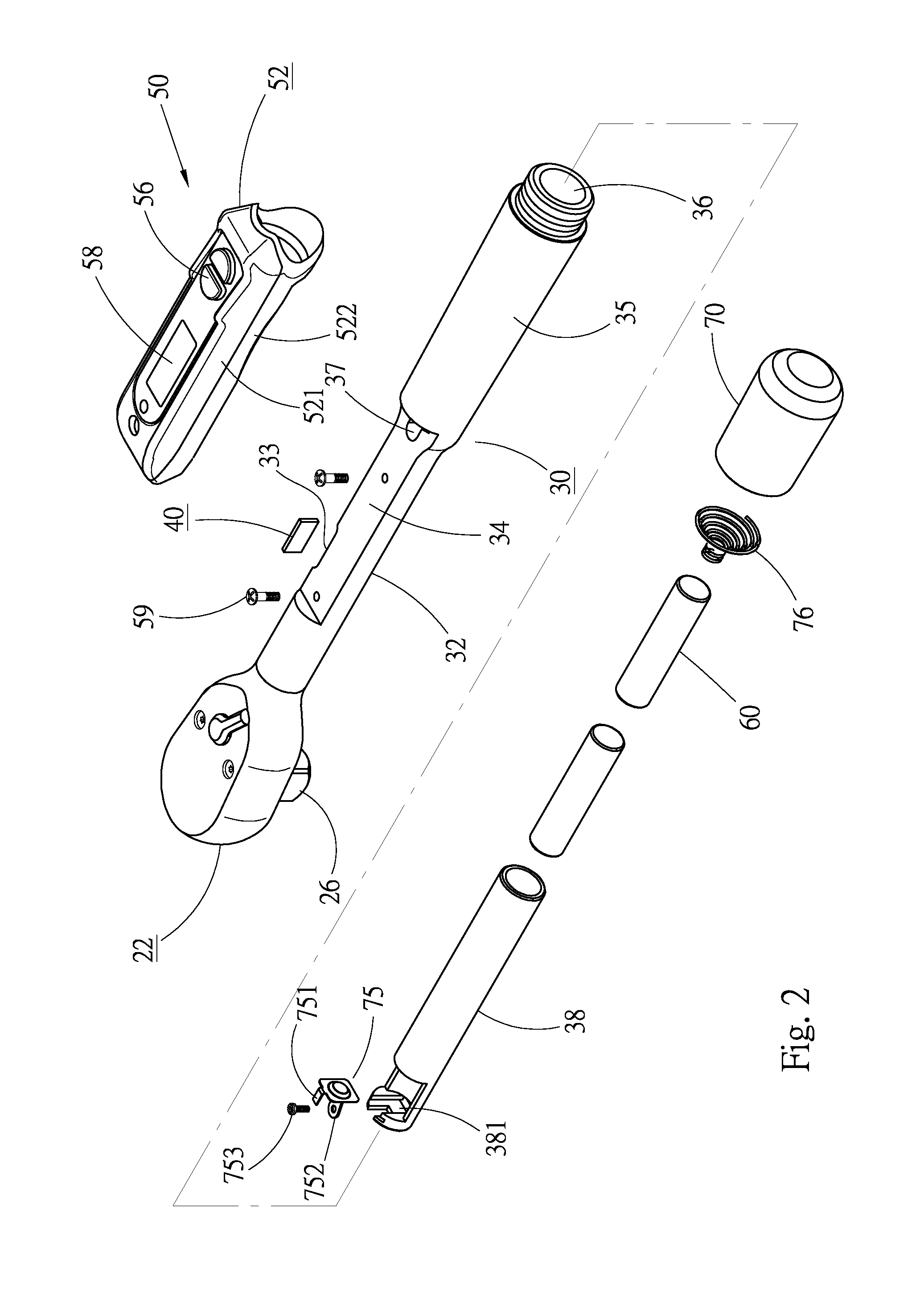

Electronic torque wrench

An electronic torque wrench includes: a wrench main body including ahead section and a shank body, at least one recess being formed on a wall face of one side of the shank body, a top face of the shank body being inward depressed to form a platform, a rear end of the shank body being inward recessed to form a cavity for placing cells therein, a through hole being formed on the shank body in communication with the platform and the cavity; at least one torque sensor disposed in the recess; and an electronic operation / control device disposed on the platform. The outward protruding volume of the operation / control device is reduced to minify the total volume of the wrench and the platform and the recess enhance the flexion of the shank body.

Owner:KABO TOOL COMPANY

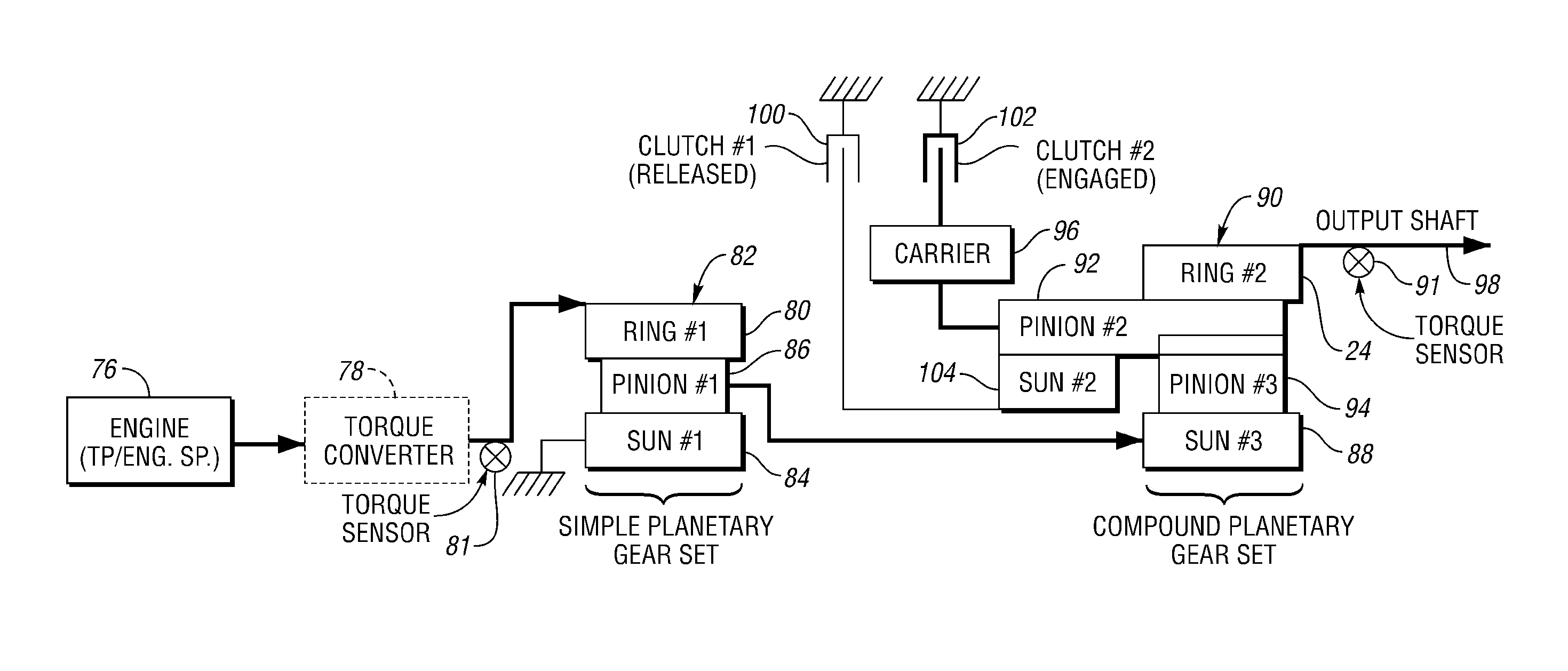

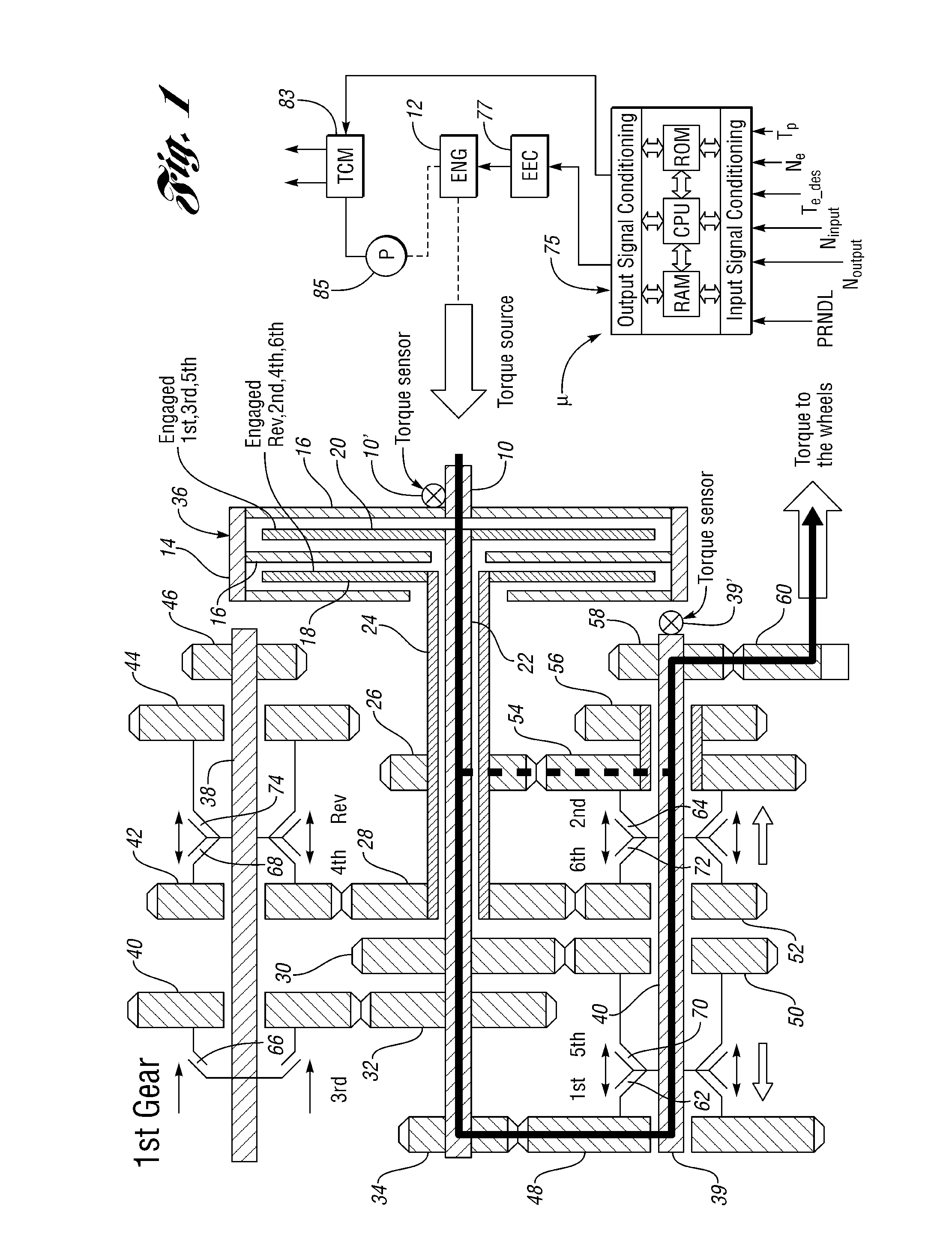

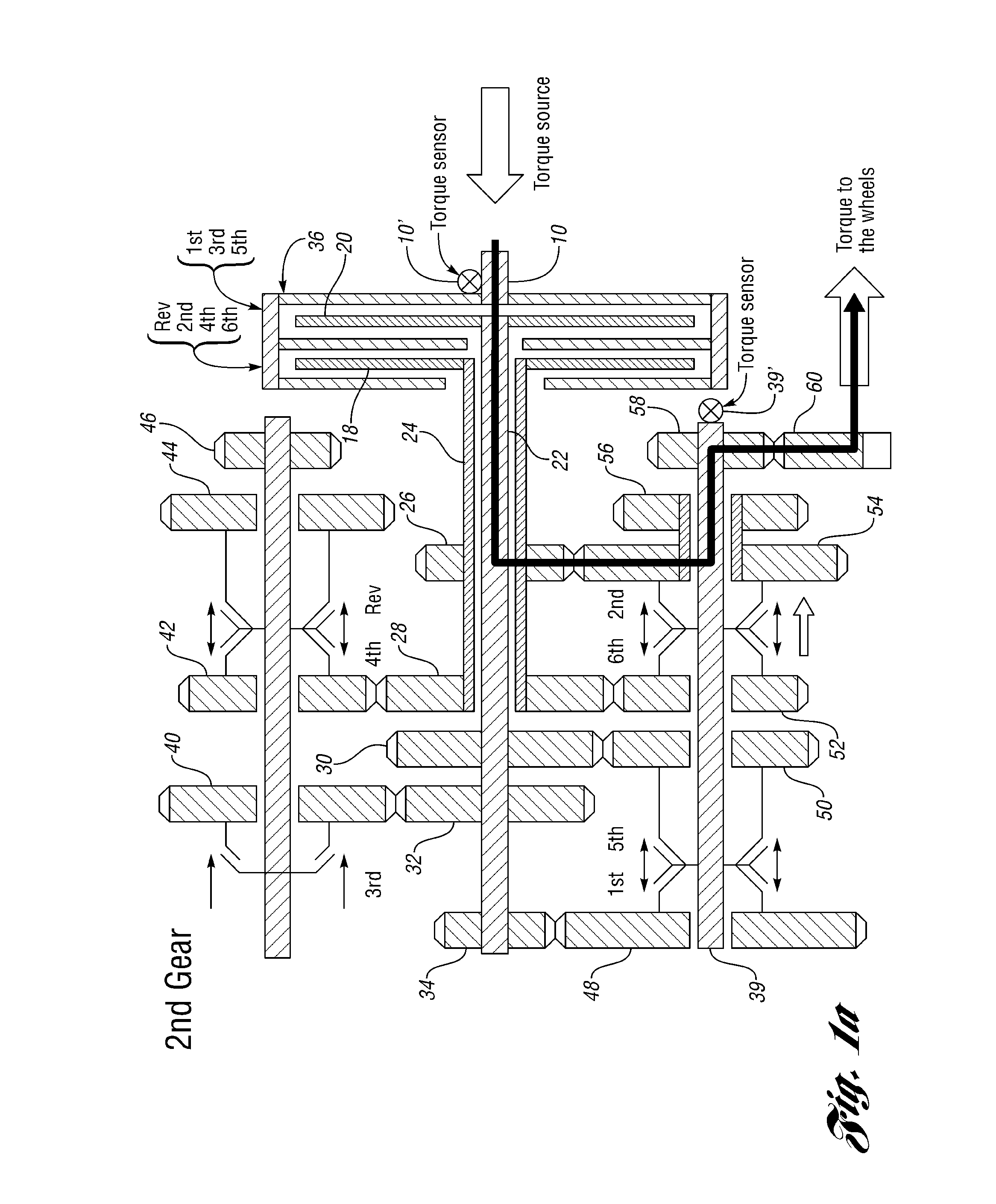

Clutch torque trajectory correction to provide torque hole filling during a ratio upshift

InactiveUS9260102B2Eliminate and reduce torque hole effectReducing transient torque disturbanceGearing controlEngine controllersFriction torqueAutomatic transmission

A control system and method for controlling a multiple gear ratio automatic transmission in a powertrain for an automatic transmission having pressure activated friction torque elements to effect gear ratio upshifts. The friction torque elements are synchronously engaged and released during a torque phase of an upshift event as torque from a torque source is increased while allowing the off-going friction elements to slip, followed by an inertia phase during which torque from a torque source is modulated. A perceptible transmission output torque reduction during an upshift is avoided. Measured torque values are used during a torque phase of the upshift to correct an estimated oncoming friction element target torque so that transient torque disturbances at an oncoming clutch are avoided and torque transients at the output shaft are reduced.

Owner:FORD GLOBAL TECH LLC

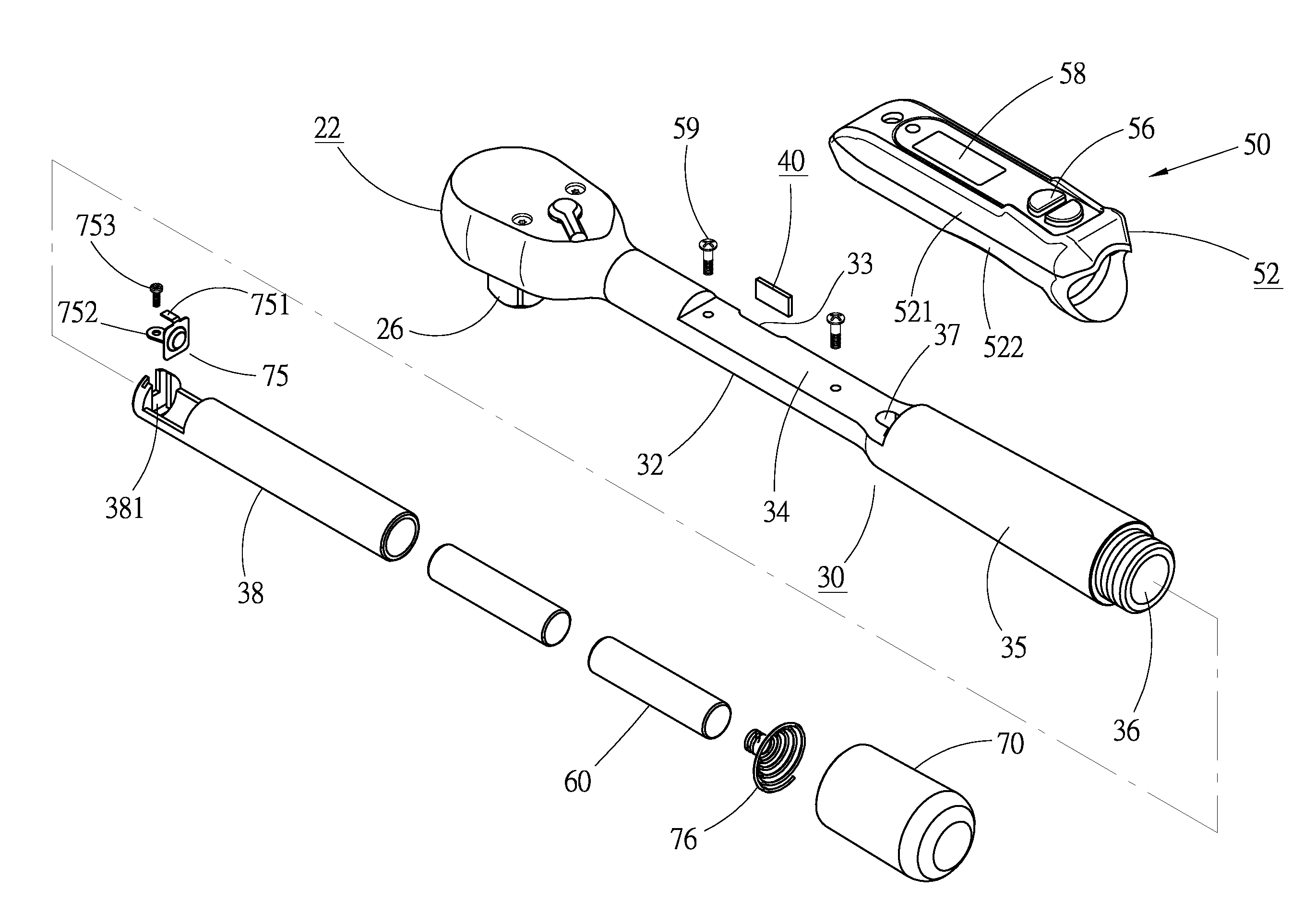

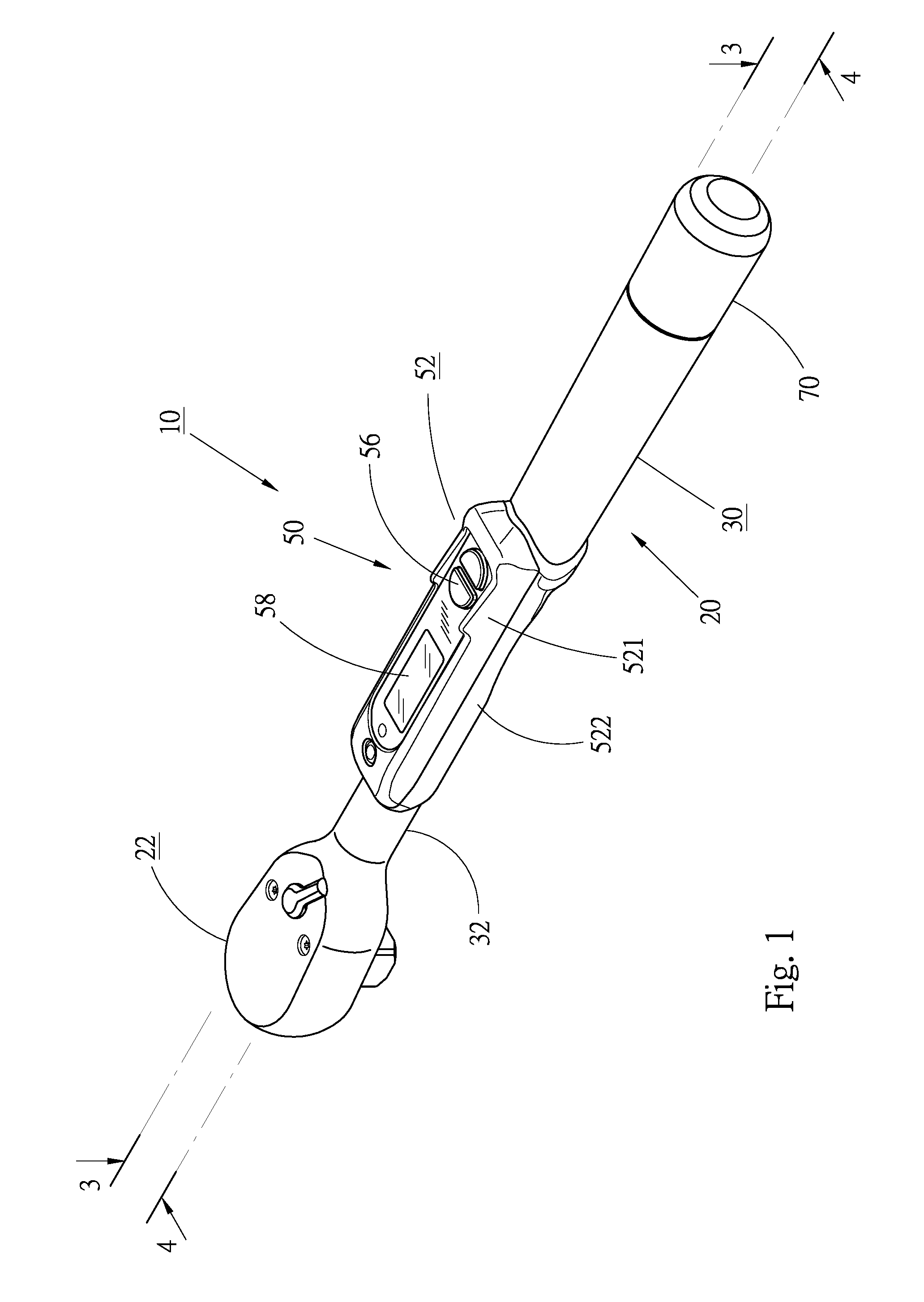

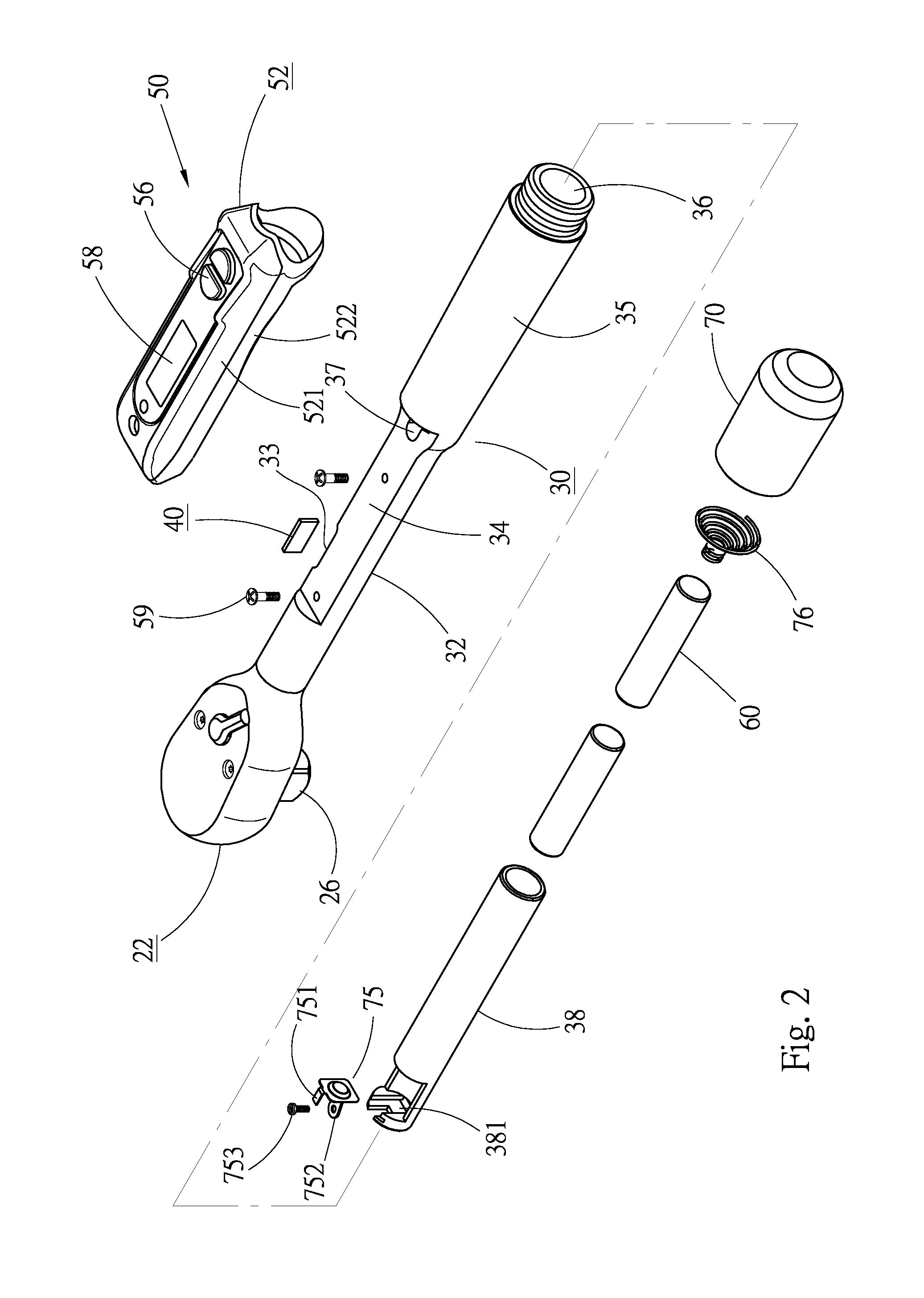

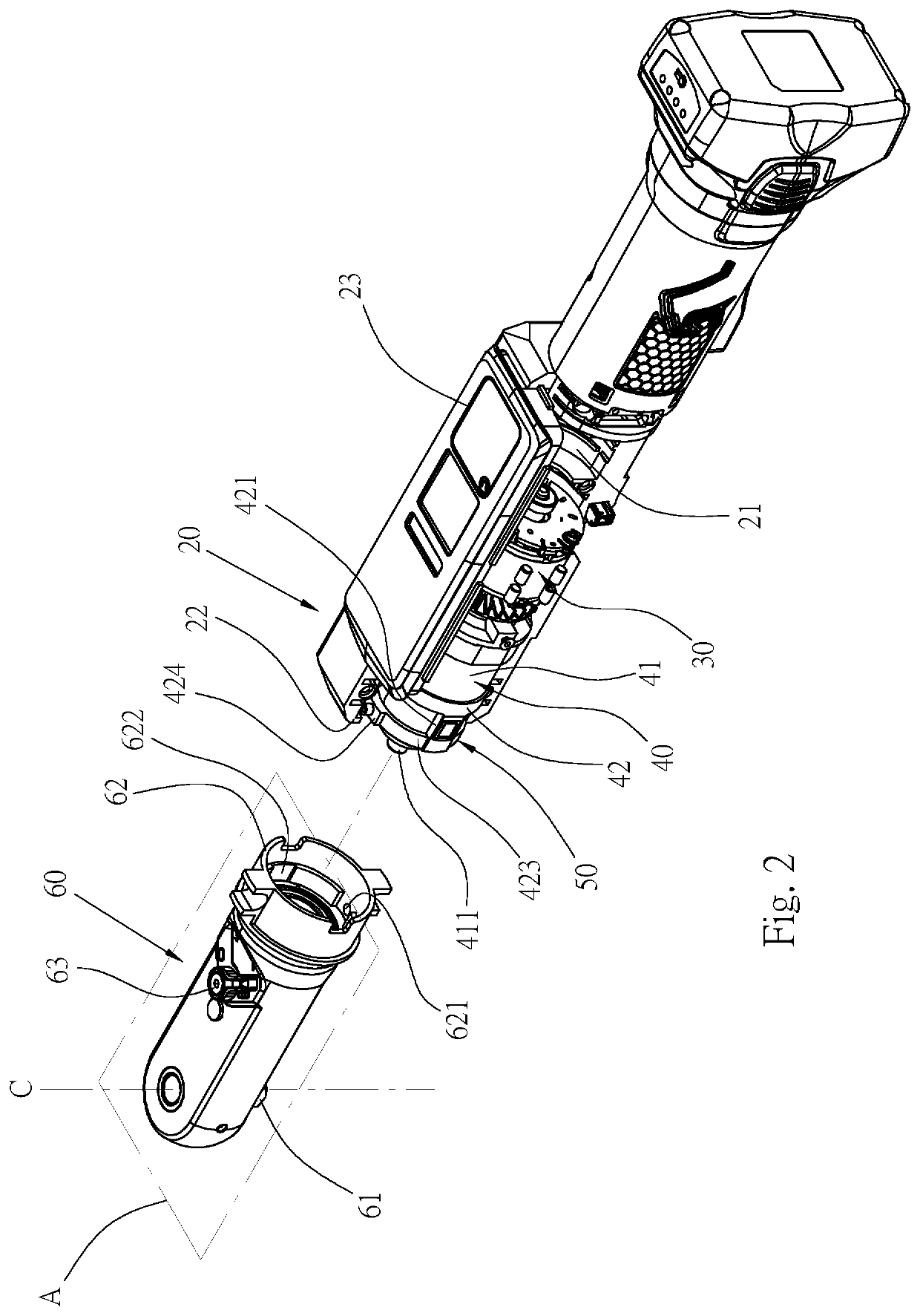

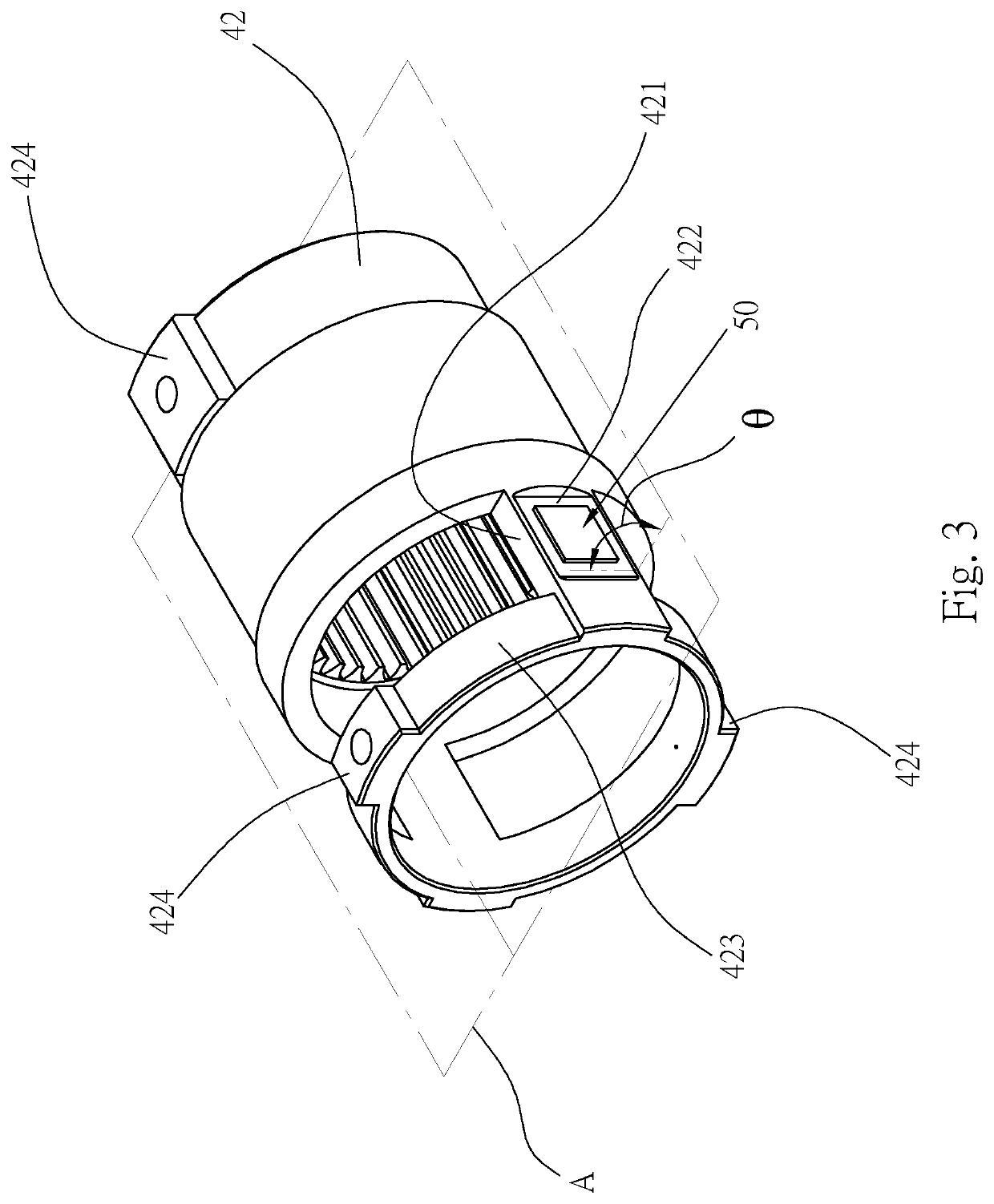

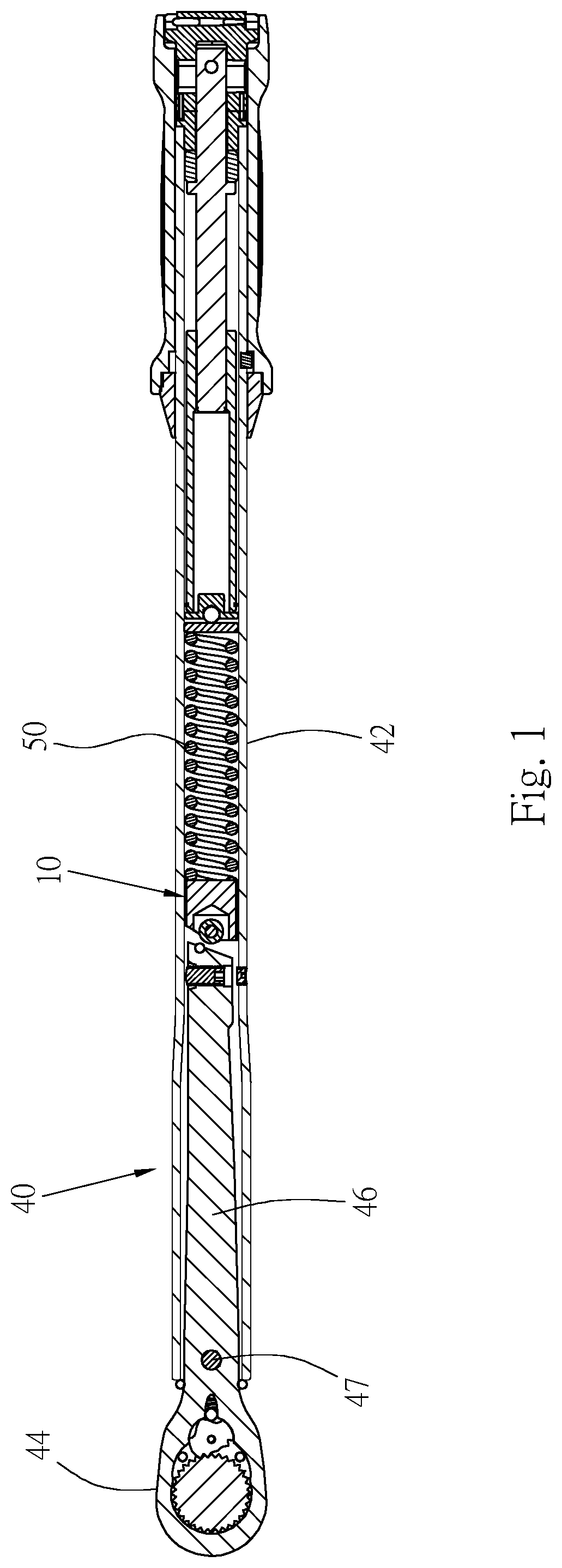

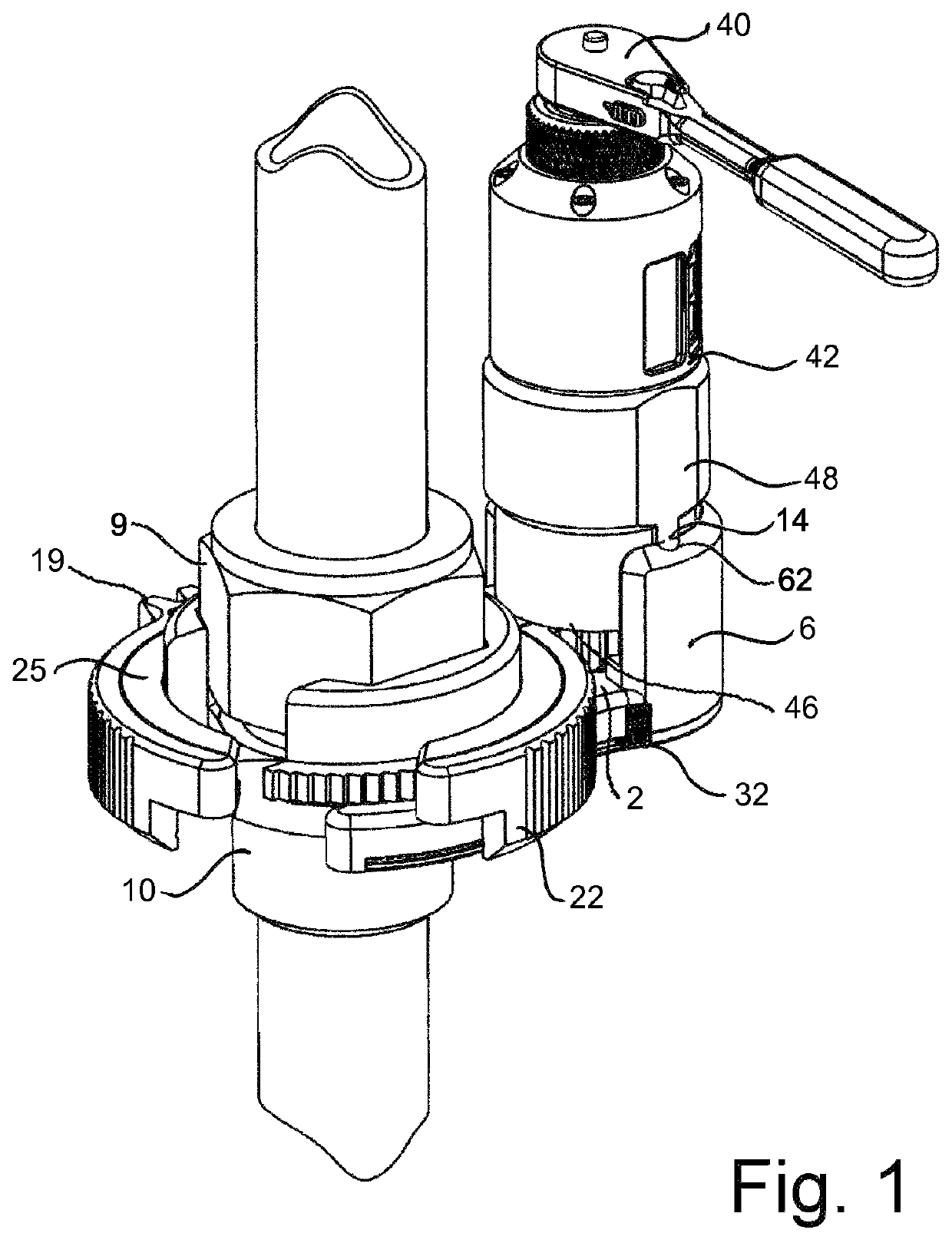

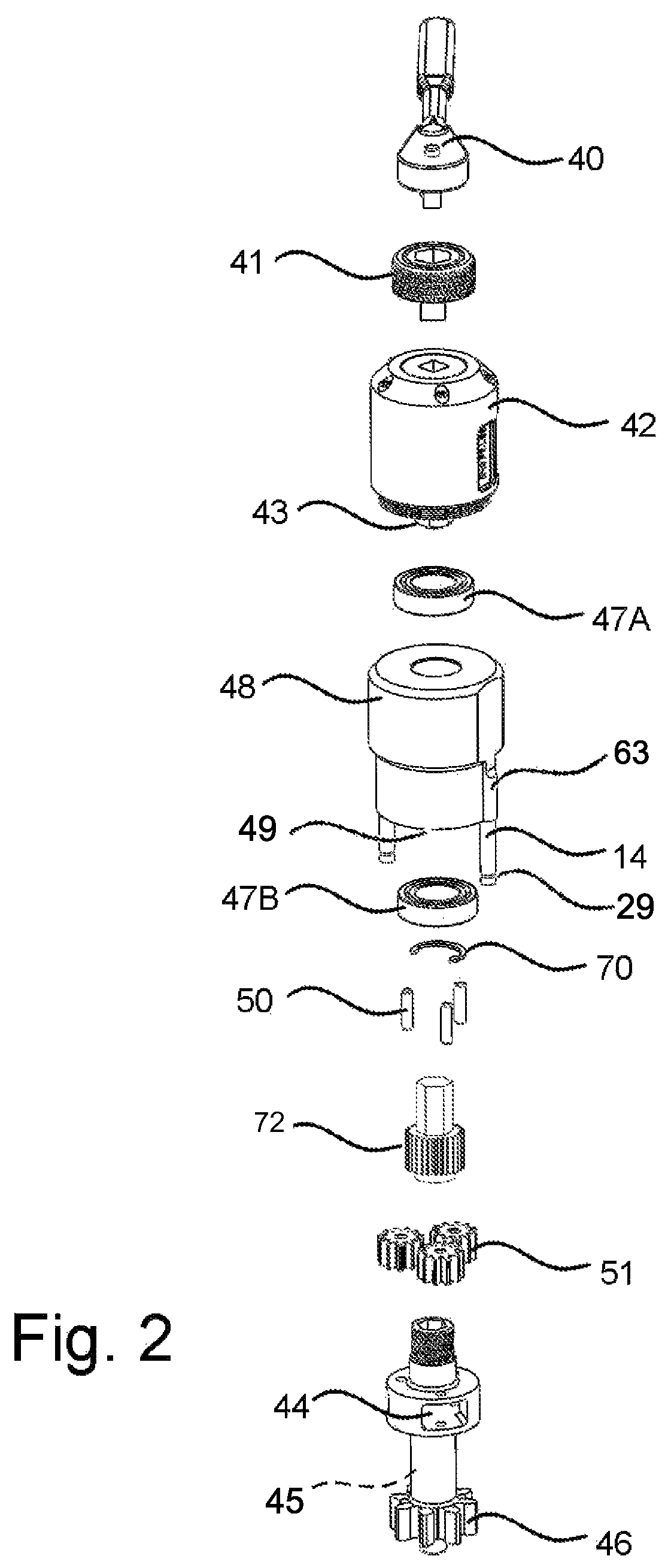

Electric torque wrench capable of sensing manual operating torque

ActiveUS20210122016A1Precise manual operating torque valueImprove production yieldSpannersWrenchesGear wheelControl engineering

An electric torque wrench capable of sensing a manual operating torque includes: an outer housing having an accommodating space at an internal thereof, a motor and a reduction device arranged therein; the reduction device having a reduction gear assembly with a hollow ring gear member; a front end of the ring gear member having at least one extension arm and at least one sensing plane formed thereon; a torque sensing unit arranged on the sensing plane; a driving device installed at the front end of the outer housing and having a working head arranged at the front end thereof; the extension arm of the ring gear member secured and attached onto the driving device. With the torque sensing unit installed on the extension arm, the electric torque wrench can be rotated manually with hand and is able to measure the torque value.

Owner:TECHWAY INDAL

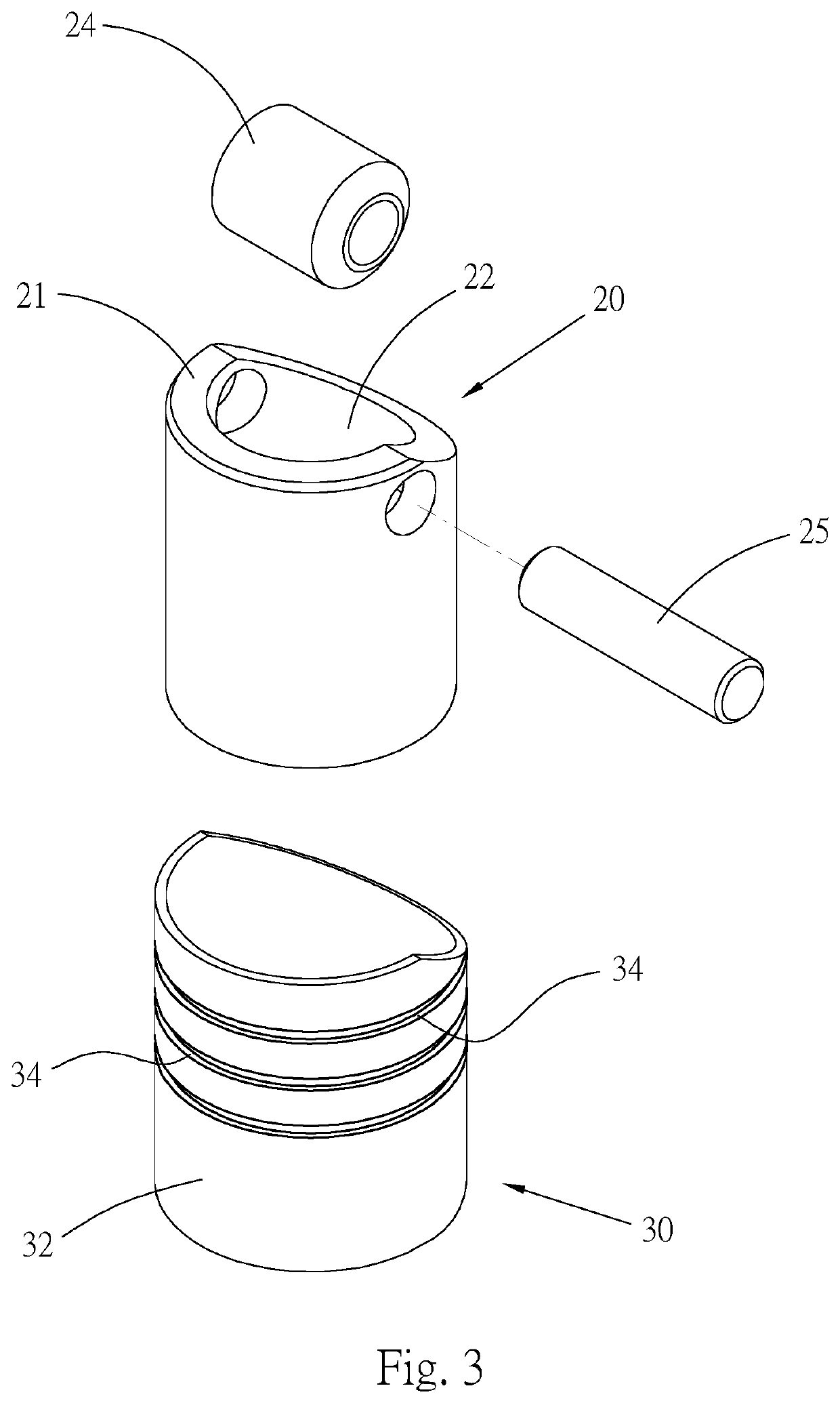

Sound base of torque wrench

InactiveUS20200269399A1Reduce frictional resistanceAccurate torque valueSpannersWrenchesEngineeringAcoustics

The present invention provides a sound base of torque wrench comprising a base and an outer sleeve, a hardness of the outer sleeve is lower than a hardness of the base, the outer sleeve is hollow with a peripheral wall, and the peripheral wall is sleeved around the base; and at least one oil accommodating groove disposed on an outer peripheral surface of the peripheral wall. Thereby, the sound base uses the oil accommodating groove to accommodate lubricating oil, so that the sound base has a long-term lubricating effect, and long-term lubrication can be achieved when the sound base is operated in a wrench in order to have low frictional resistance, and thus the wrench can maintain a certain precision on a long-term basis.

Owner:KABO TOOL COMPANY

Torque wrench with constant torque

A torque wrench with constant torque comprises a wrench body having a tube and a cavity, an adapter, a pillar, a clutching member, a handle, and a resilient member. Therein, the adapter is rotatably disposed in the cavity, with plural adapting parts disposed on the outer periphery thereof. The pillar is disposed between the tube and the cavity for resisting against the adapting part. The clutching member is disposed in the tube, with a first end resisting against the peripheral surface of the pillar, a second end and a peripheral edge rollingly contacting the inner edge of the tube. The handle is connected to one end of the tube. The resilient member is disposed inside the tube for resisting against the second end of the clutching member. Thus, the torque is transmitted directly and prevented from diminishing, maintain a precise torque value.

Owner:OGC TORQUE

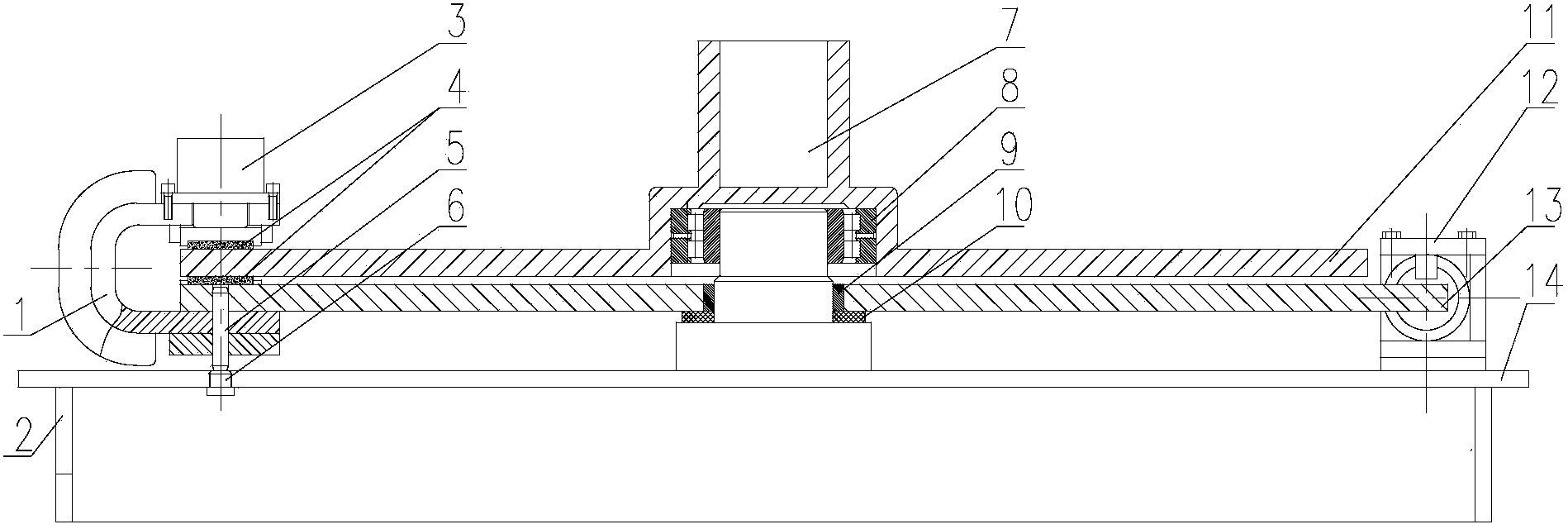

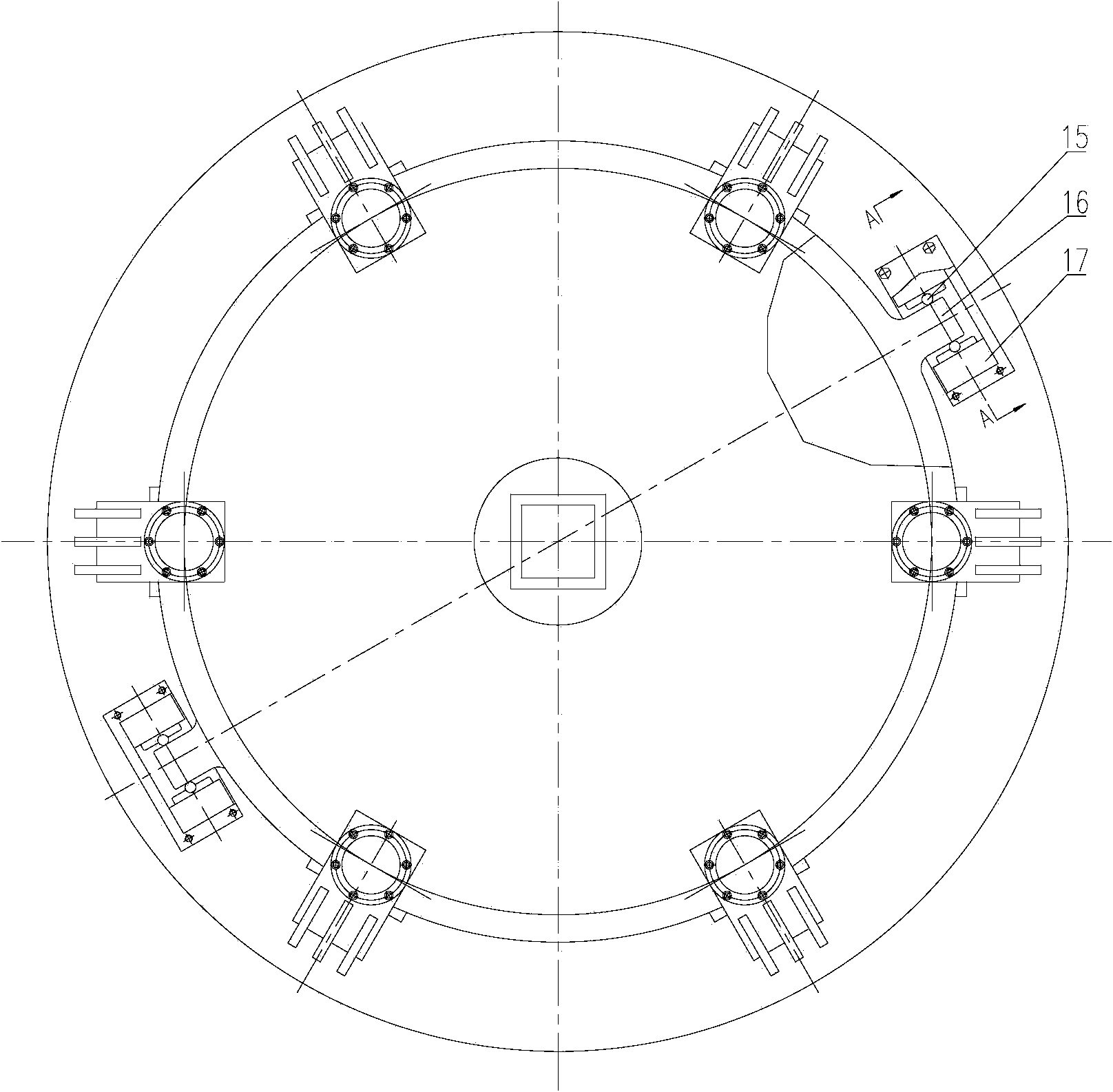

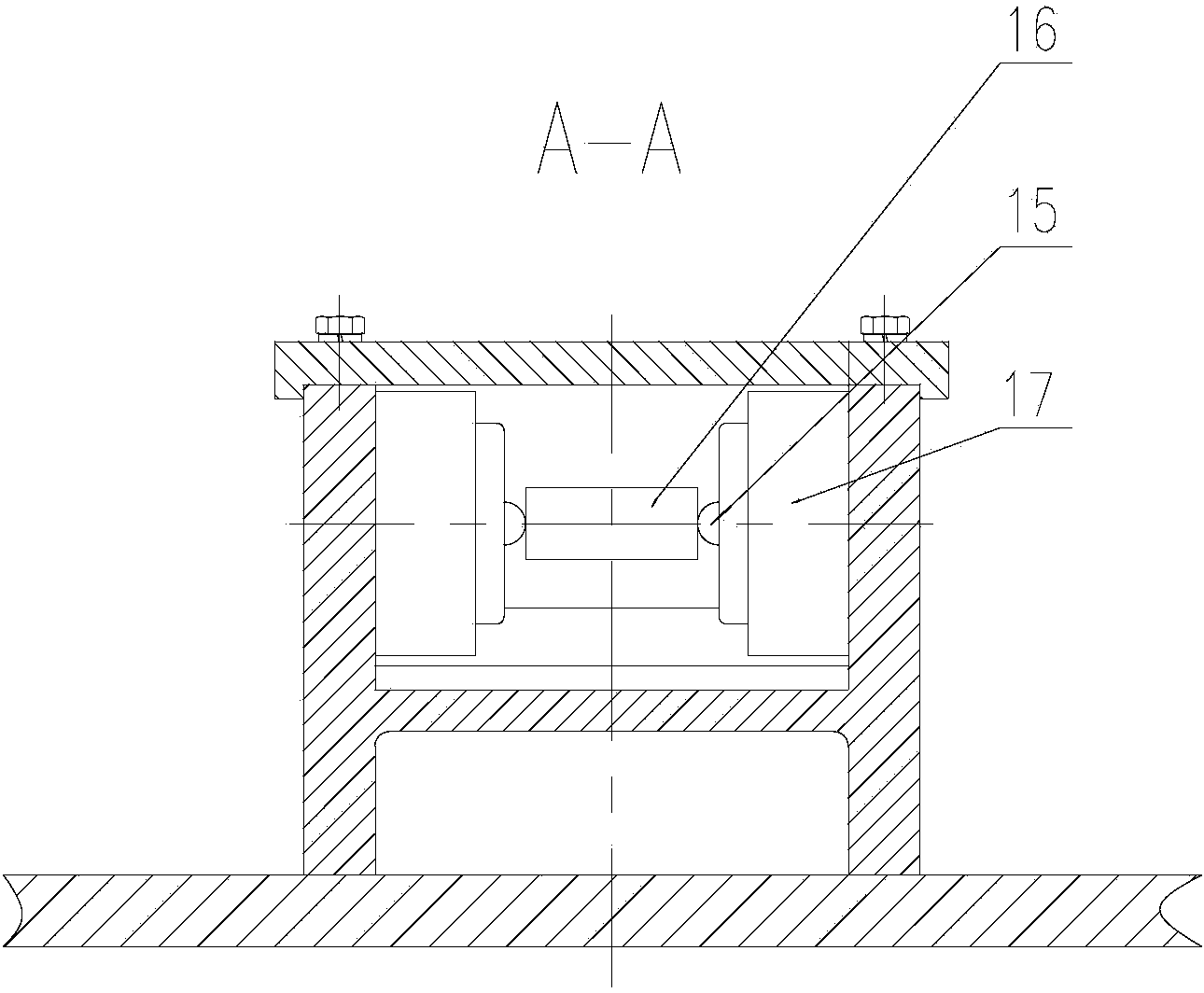

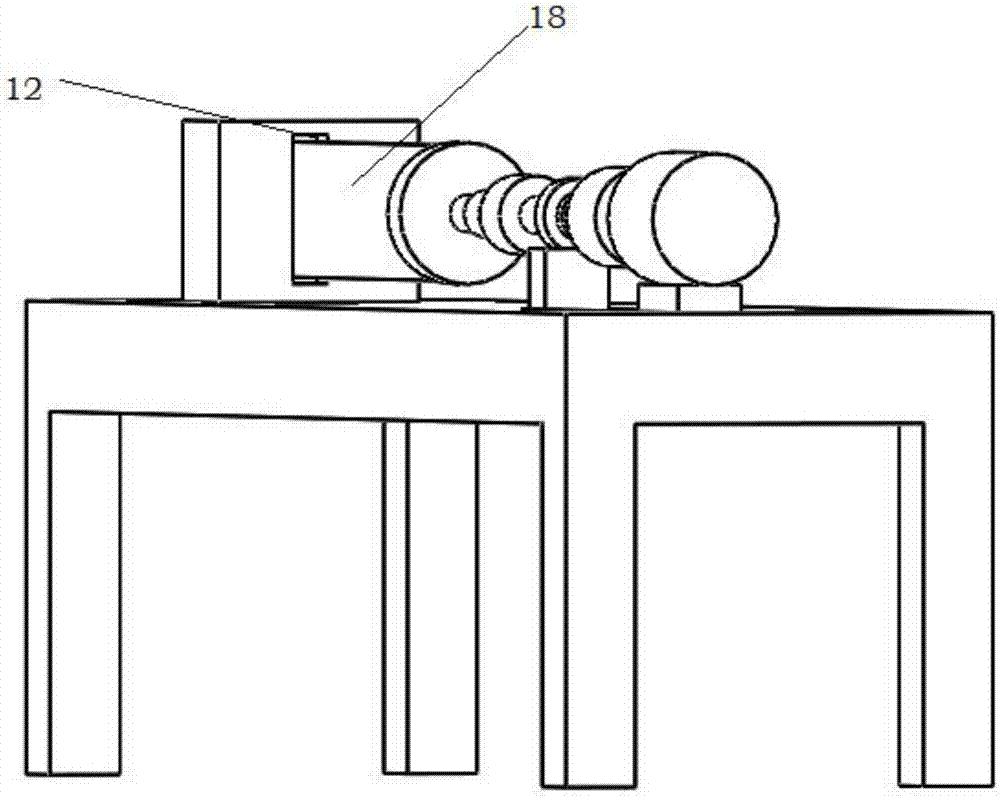

Large torque and super-large torque test system for engineering equipment

ActiveCN103528737AAvoid interferenceAccurate torque valueWork measurementTorque measurementDesign evaluationDirect test

The invention discloses a large torque and super-large torque test system for engineering equipment. The large torque and super-large torque test system for the engineering equipment comprises a friction disk, friction sheets and a dynamometry disk, wherein the friction disk is fixedly provided with a fixed part connected with a drill pipe; the dynamometry disk and the friction disk are coaxially installed and are not directly contacted; the friction disk is driven by the drill pipe connected with the fixed part to rotate; the dynamometry disk independently rotates; the dynamometry disk is provided with at least one pressure device to press the friction disk and the dynamometry disk; the friction sheets are respectively installed between the friction disk and the dynamometry disk as well as between the pressure device and the friction disk; the dynamometry disk is provided with at least one dynamometry disk extending end; and the dynamometry disk extending end is arranged in a dynamometry device and is connected with the dynamometry end of the dynamometry device via a fixed point transmission ball. According to the large torque and super-large torque test system for the engineering equipment, which is disclosed by the invention, the maximum value of the static torque can be directly tested, and the dynamic torque value can be directly tested, thereby being favorable for debugging a product system parameter, a predelivery test and design evaluation.

Owner:SUNWARD INTELLIGENT EQUIP

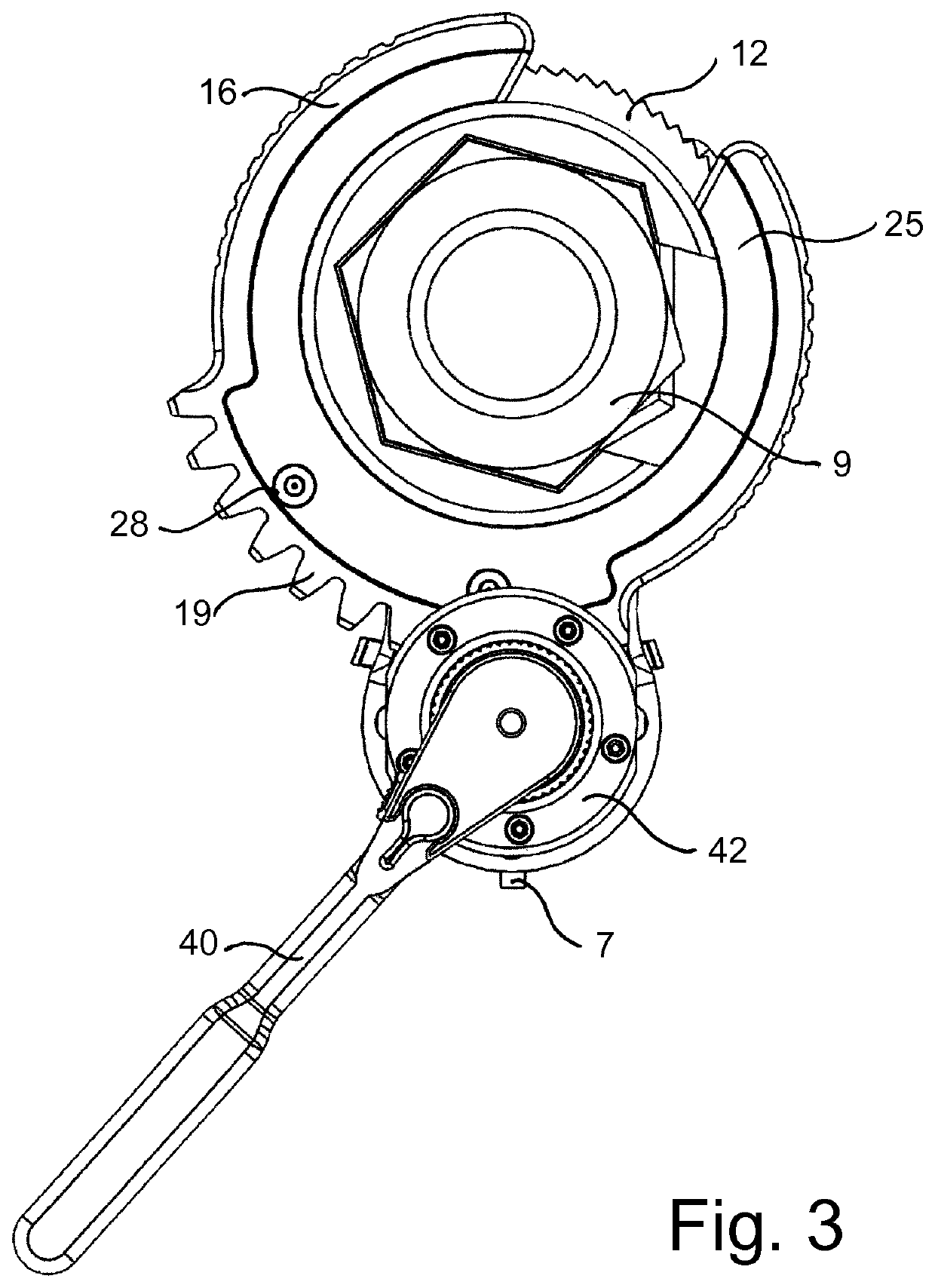

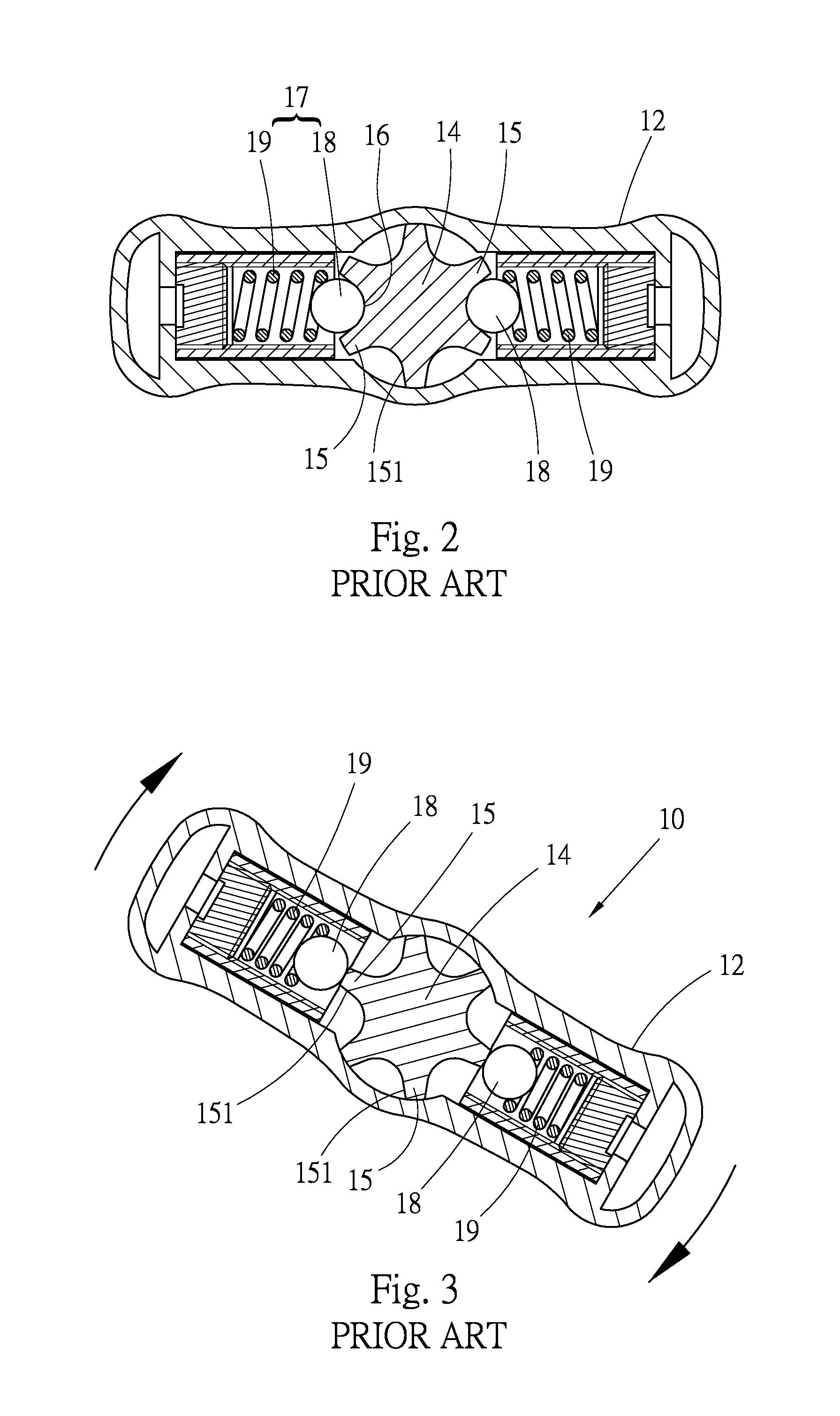

Torque tool

A reciprocating apparatus for high torque transfer to a fitting, including tightening or loosening, having two coaxially synchronized engageable drive members provided with a sector geared radial flange engageable with an engageable rotatable drive gear, one internally supported split ratchet gear and drive socket maintained in contact with a spring biased ratchet pawl, together simultaneously rotatable in a first driving direction and independently disengageable in a second direction for reciprocative advancement of a ratchet geared socket in driving engagement with a fitting.

Owner:WILSON JR DAVID

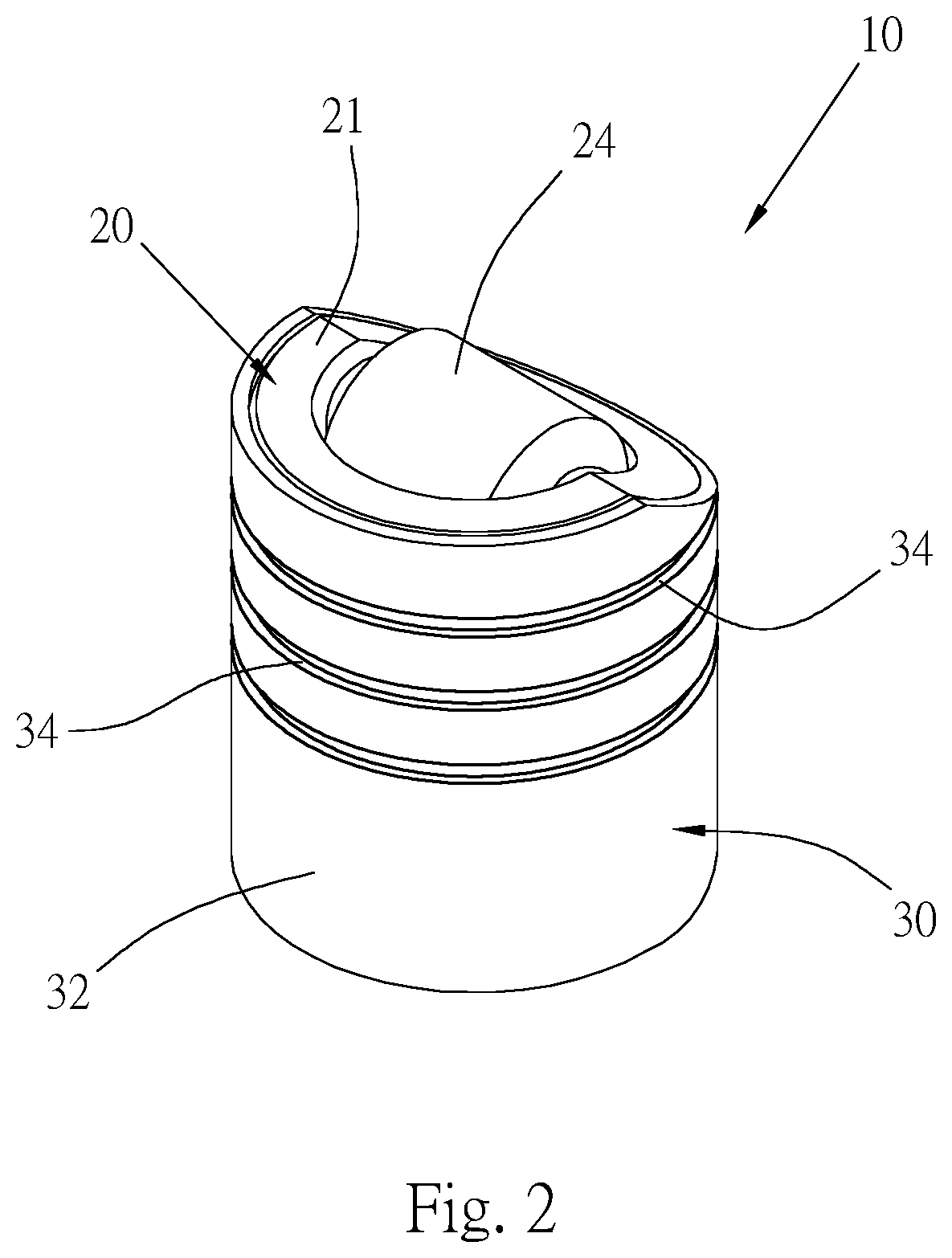

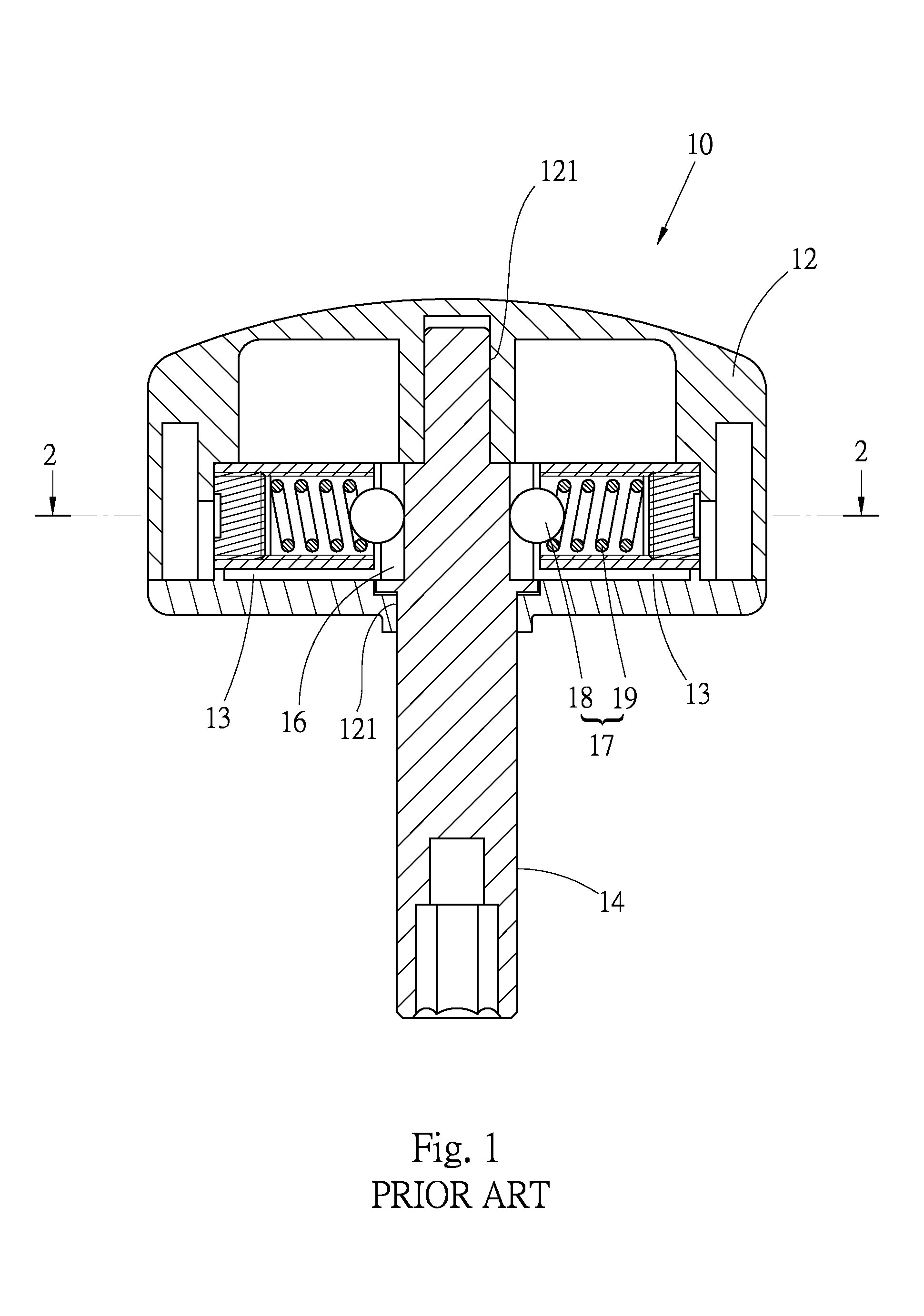

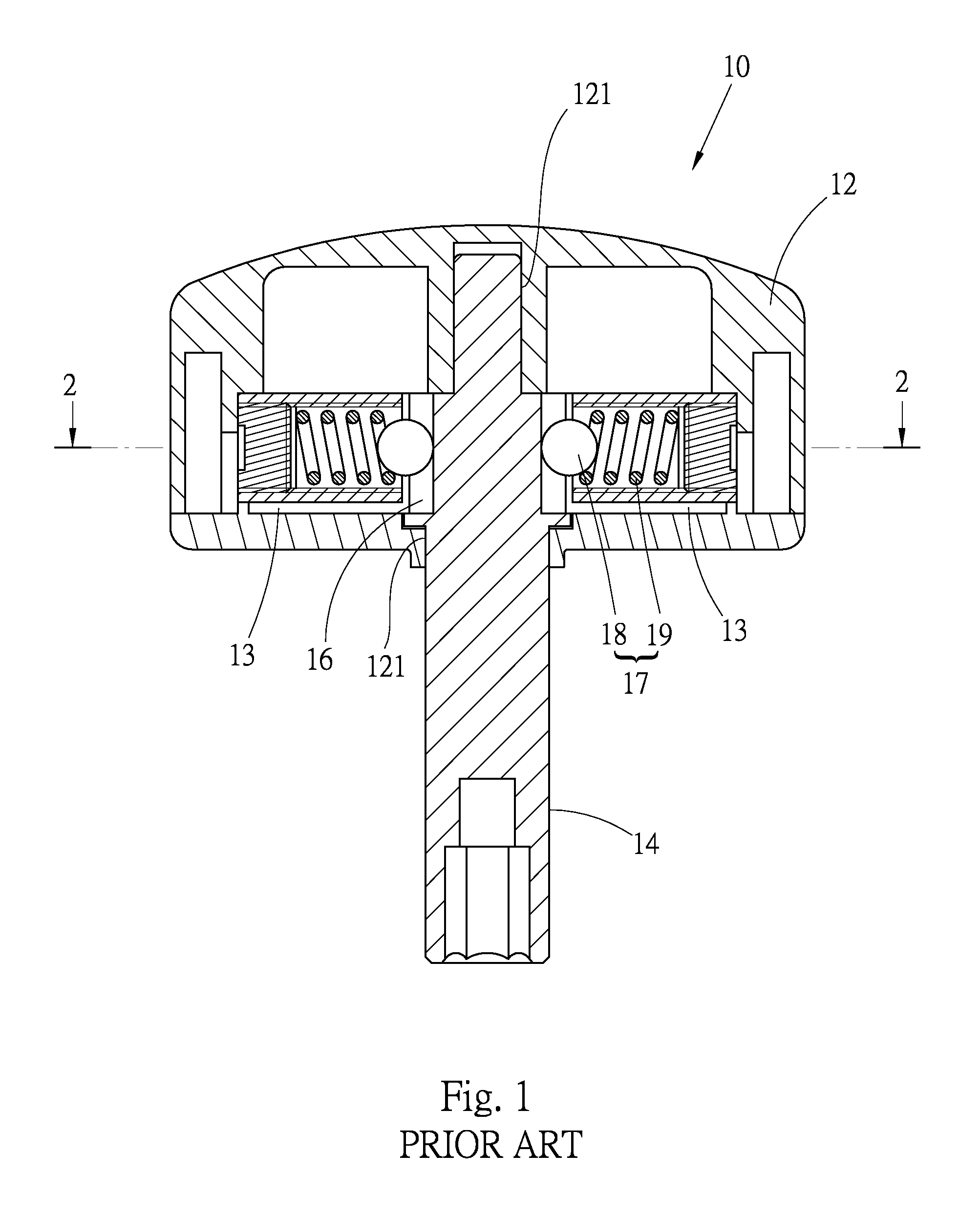

Torque screwdriver

ActiveUS20150239110A1Precise and stable torque valueAccurate torque valueSpannersWrenchesEngineeringMechanical engineering

A torque screwdriver includes: a main body having a transverse handle section and a vertical tubular section, the handle section being formed with an internal passage having two cavities respectively formed on two sides of the tubular section; the tubular section being formed with an internal axial space; an operation stem, several ratchets and several recesses being disposed at a top end of the operation stem, each ratchet having a long tooth face and a short tooth face, the long tooth face having a slope smaller than a slope of the short tooth face; the operation stem being mounted in the main body; two elastic abutment assemblies respectively mounted in the two cavities to elastically press two abutment members to elastically contact the operation stem; and at least two support rings disposed between the operation stem and the main body.

Owner:KABO TOOL COMPANY

Electronic torque wrench

An electronic torque wrench includes: a wrench main body including ahead section and a shank body, at least one recess being formed on a wall face of one side of the shank body, a top face of the shank body being inward depressed to form a platform, a rear end of the shank body being inward recessed to form a cavity for placing cells therein, a through hole being formed on the shank body in communication with the platform and the cavity; at least one torque sensor disposed in the recess; and an electronic operation / control device disposed on the platform. The outward protruding volume of the operation / control device is reduced to minify the total volume of the wrench and the platform and the recess enhance the flexion of the shank body.

Owner:KABO TOOL COMPANY

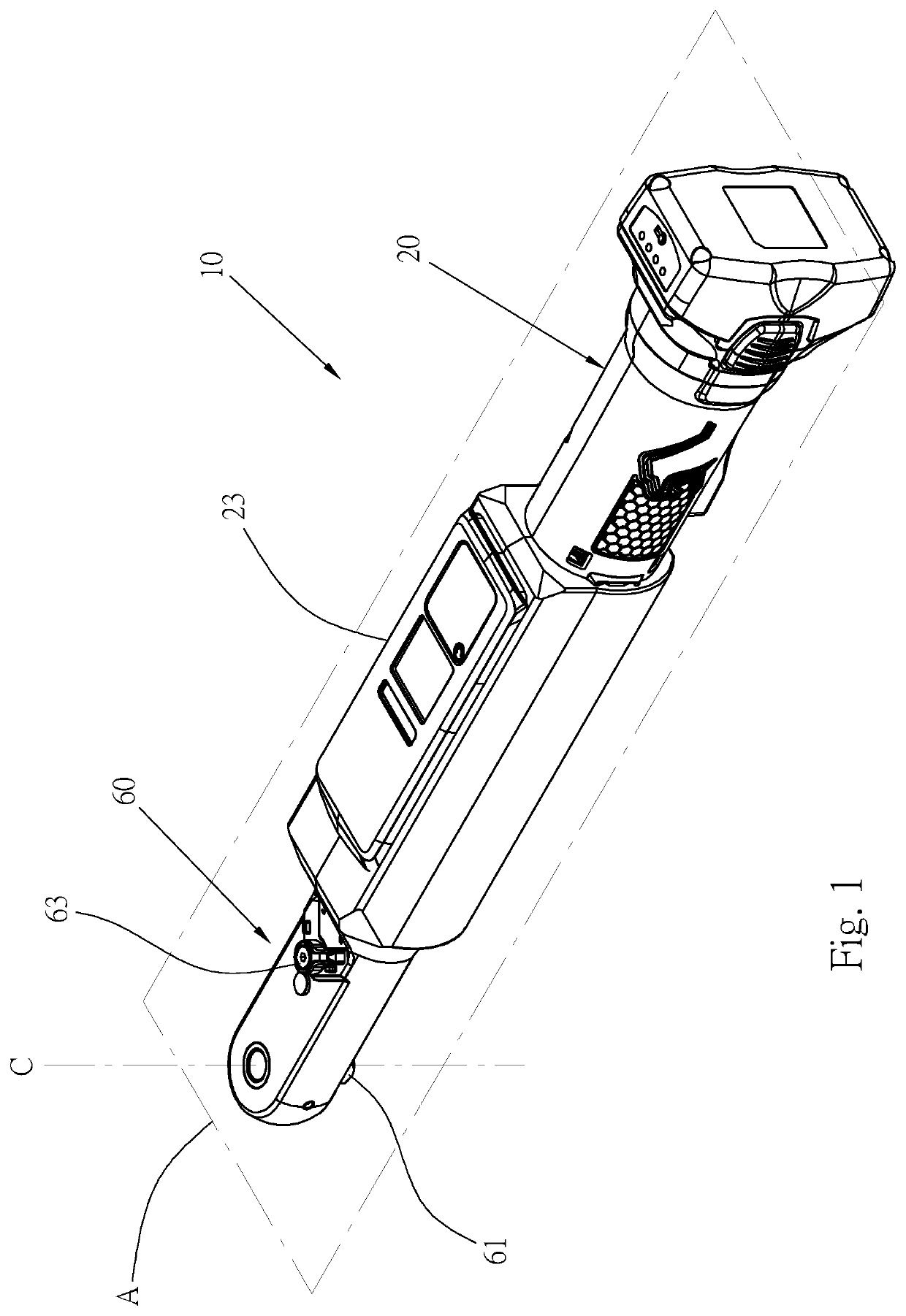

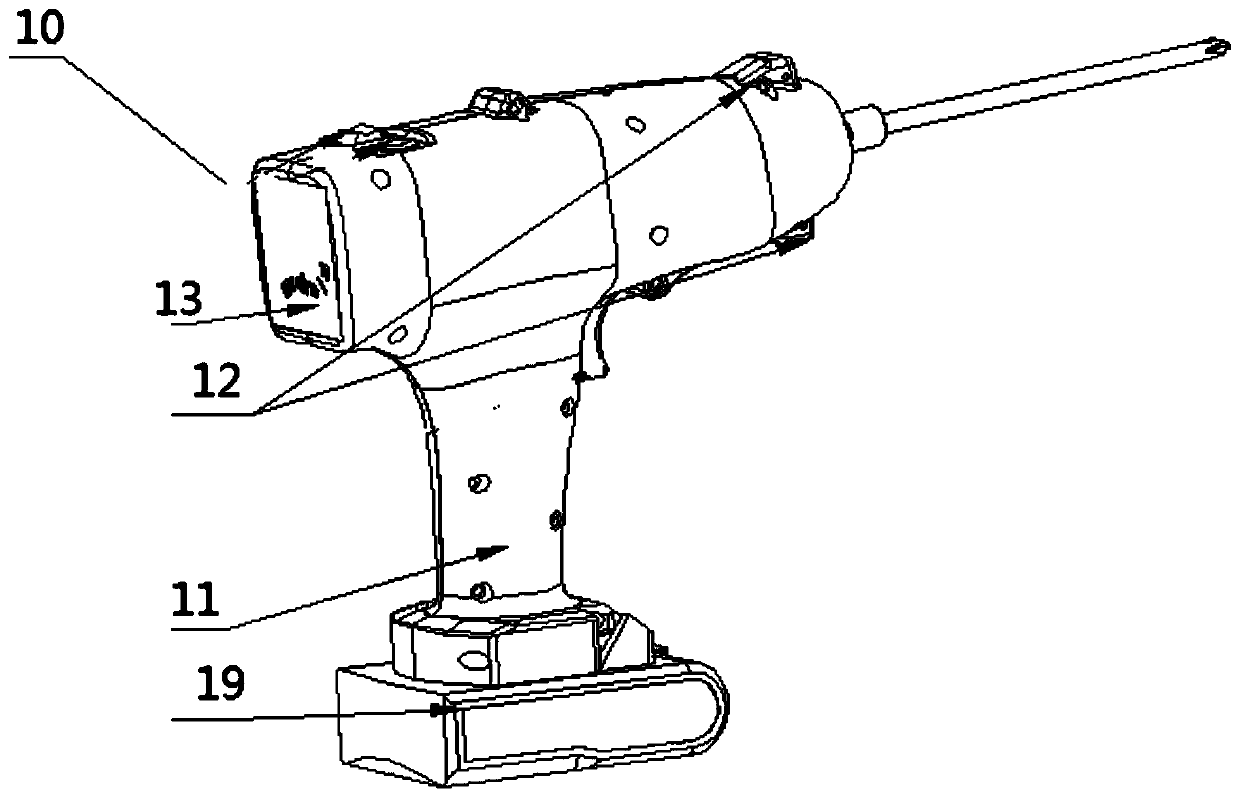

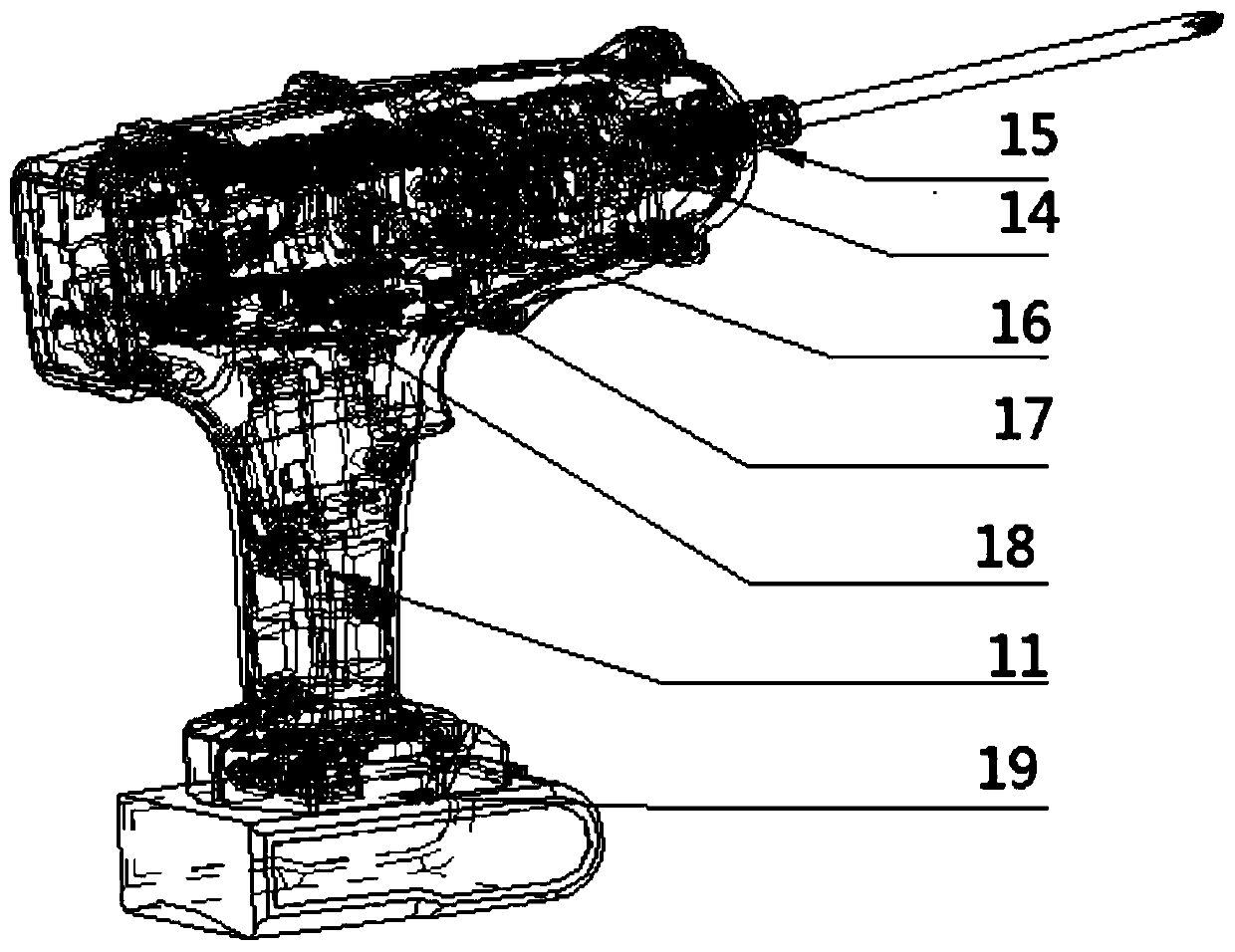

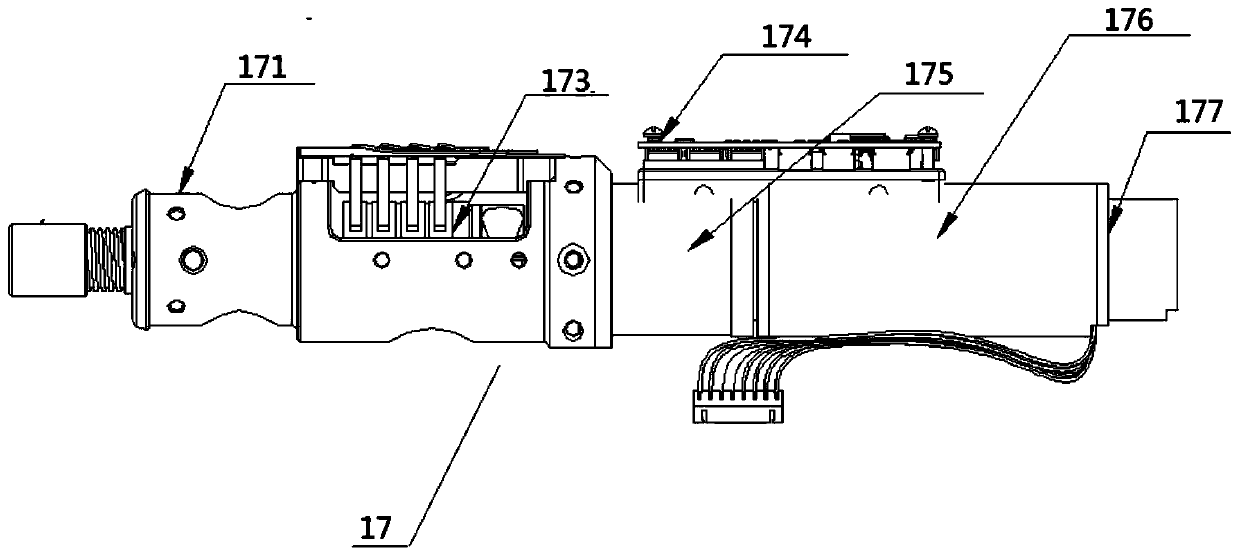

Intelligent tightening tool and intelligent management method

ActiveCN109940533AImprove efficiencyHigh precisionMechanical power/torque controlSpannersInformatizationComputer module

The invention discloses an intelligent tightening tool. The intelligent tightening tool comprises a tool body, a tightening power structure arranged on the upper part of the tool body, a main controlstructure component which is accommodated in the tool body and is used for correcting and recording positions of a working process by identifying assembly information, an electric driving control structure which is connected to the tightening power structure, an image acquiring module which is arranged on the front part of the tool body and is used for acquiring equipment positioning characteristics and a tightening execution mechanism; the tightening power structure is connected to the main control structure component; a quick-detaching structure used for assembling the tightening execution mechanism is arranged on the front part of the tightening power structure; torsion adjusting of the intelligent tightening tool is digitally controlled, so that tightening working efficiency and torsion precision are high; a vision and software algorithm is brought in; an electric screw driver has extremely high intelligent induction; outside products or cable connection information is intelligently scanned, so that a wiring fail-safe function and an assembly fail-safe function are provided; and AI informatization is combined with a database management system, so that flexible production process control is improved.

Owner:深圳市颐驰自动化有限公司

Torque wrench with constant torque

A torque wrench with constant torque comprises a wrench body having a tube and a cavity, an adapter, a pillar, a clutching member, a handle, and a resilient member. Therein, the adapter is rotatably disposed in the cavity, with plural adapting parts disposed on the outer periphery thereof. The pillar is disposed between the tube and the cavity for resisting against the adapting part. The clutching member is disposed in the tube, with a first end resisting against the peripheral surface of the pillar, a second end and a peripheral edge rollingly contacting the inner edge of the tube. The handle is connected to one end of the tube. The resilient member is disposed inside the tube for resisting against the second end of the clutching member. Thus, the torque is transmitted directly and prevented from diminishing, maintain a precise torque value.

Owner:OGC TORQUE

Torque screwdriver

ActiveUS9573256B2Precise and stable torque valueAccurate torque valueSpannersWrenchesMechanical engineeringEngineering

A torque screwdriver includes: a main body having a transverse handle section and a vertical tubular section, the handle section being formed with an internal passage having two cavities respectively formed on two sides of the tubular section; the tubular section being formed with an internal axial space; an operation stem, several ratchets and several recesses being disposed at a top end of the operation stem, each ratchet having a long tooth face and a short tooth face, the long tooth face having a slope smaller than a slope of the short tooth face; the operation stem being mounted in the main body; two elastic abutment assemblies respectively mounted in the two cavities to elastically press two abutment members to elastically contact the operation stem; and at least two support rings disposed between the operation stem and the main body.

Owner:KABO TOOL COMPANY

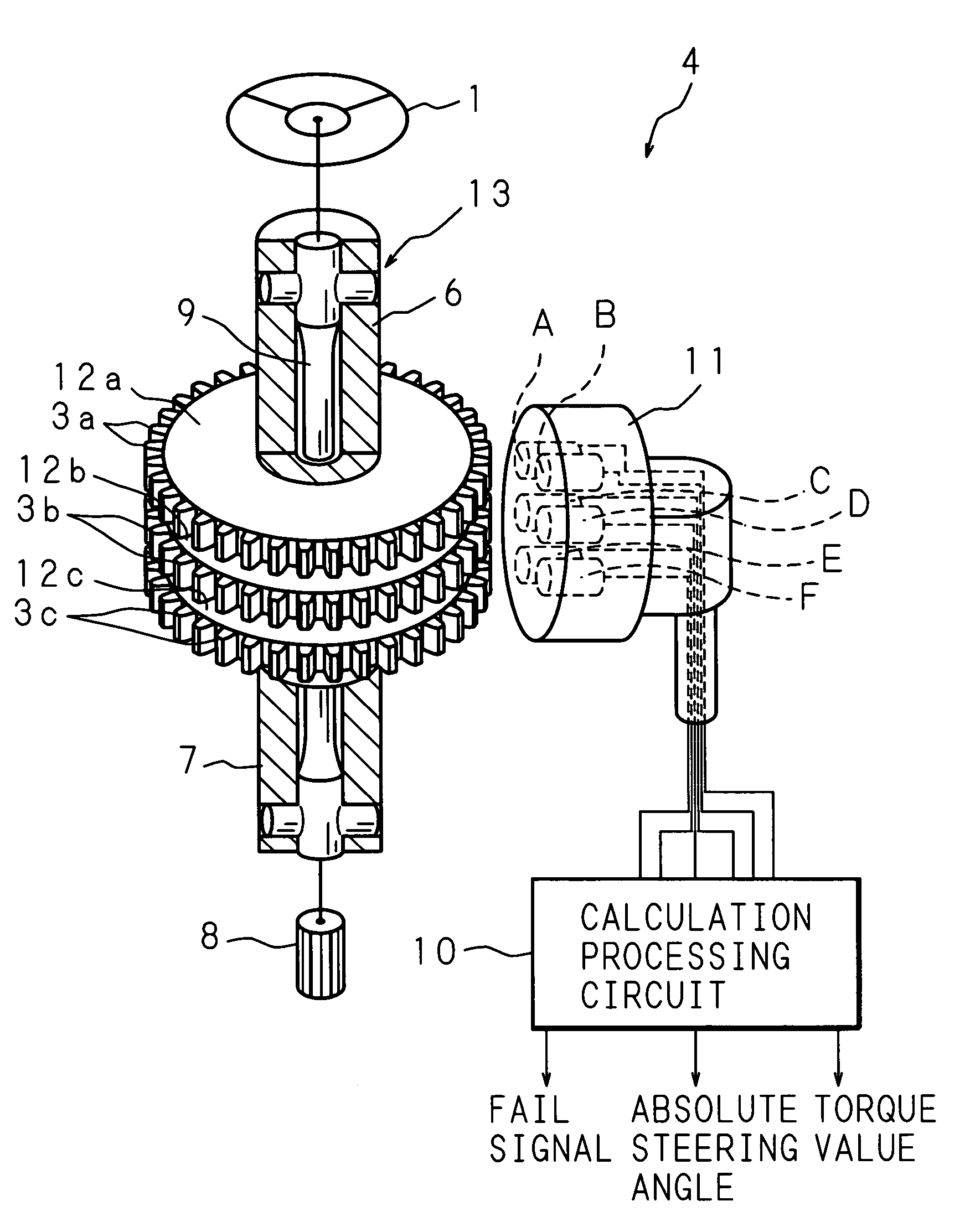

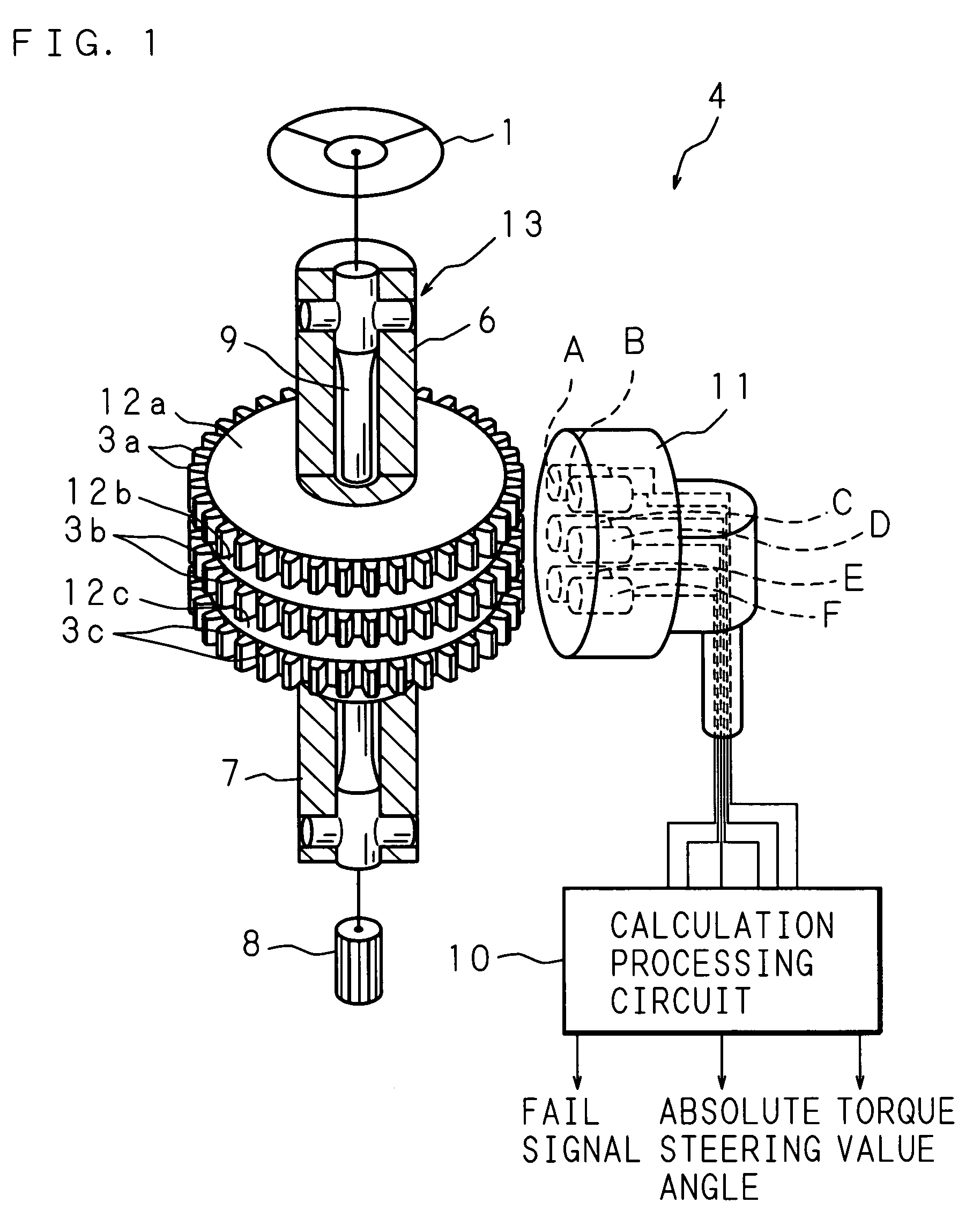

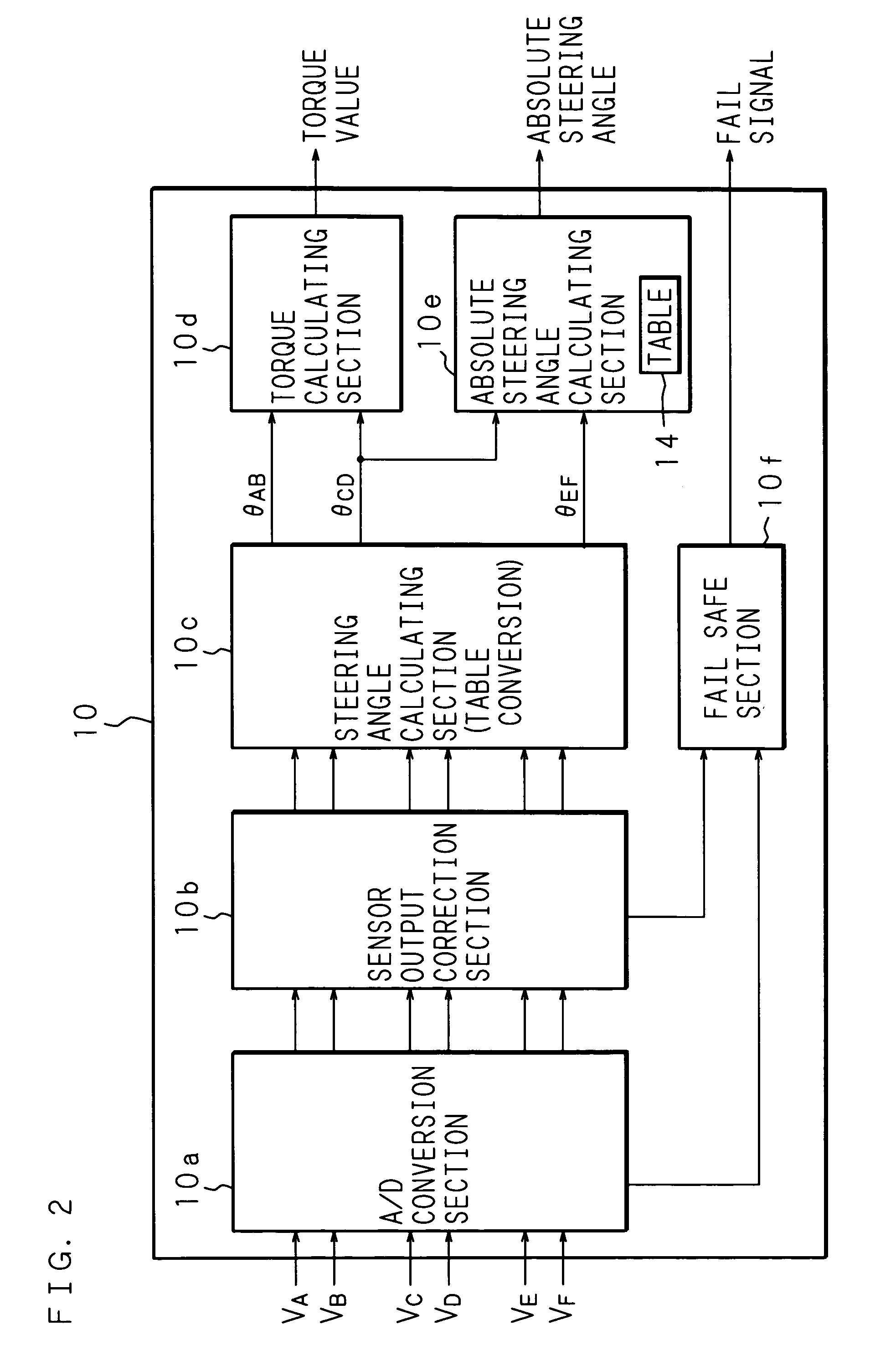

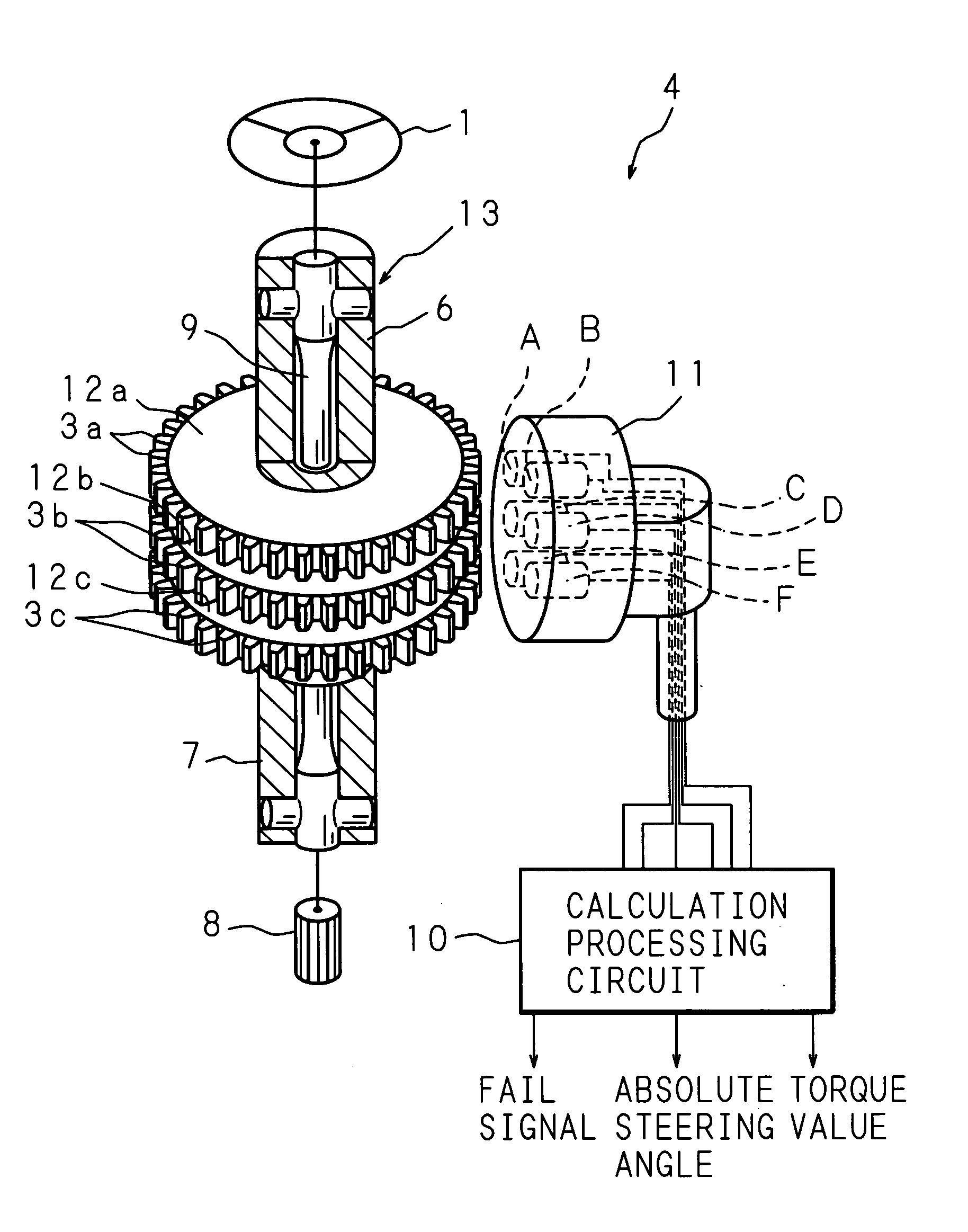

Rotational angle detecting apparatus and torque detecting apparatus

InactiveUS20050139017A1Accurate acquisitionAccurate torque valueSteering linkagesWork measurementElectricityPhysics

A rotational angle detecting apparatus, in which first targets and second targets, the number thereof is coprime with each other, are provided at the rotors rotating coaxially with each other. Rotational angle of the rotor is detected based on the detection signals from each of two sensors disposed opposite to the targets respectively, which output detection signals having phases different from each other as the rotor rotates. Based on a magnitude relation between one detection signal and the other detection signal from each of the two sensors, the range of the electrical angle of the other detection signals is determined. Relation between a detection signal and an electrical angle is stored in advance. Based on the determined electrical angle, and referring to the relation, the electrical angle of the other detection signal is obtained; thus, the rotational angle of the rotor is detected.

Owner:JTEKT CORP

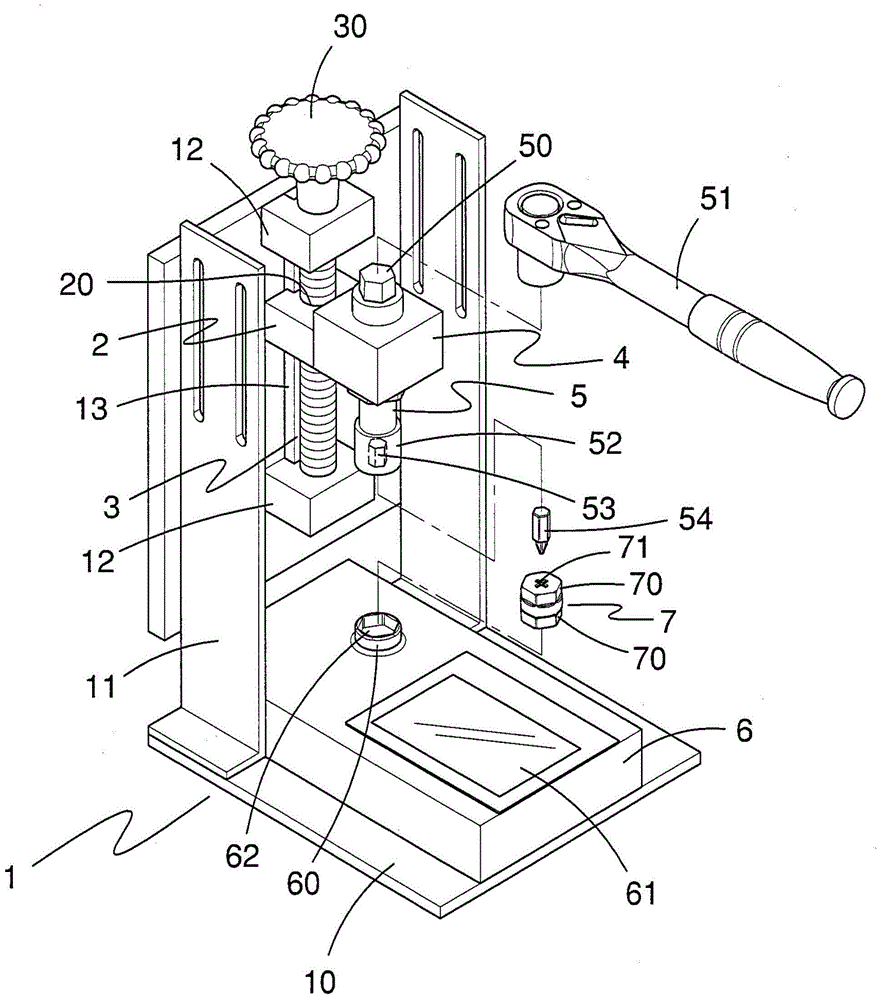

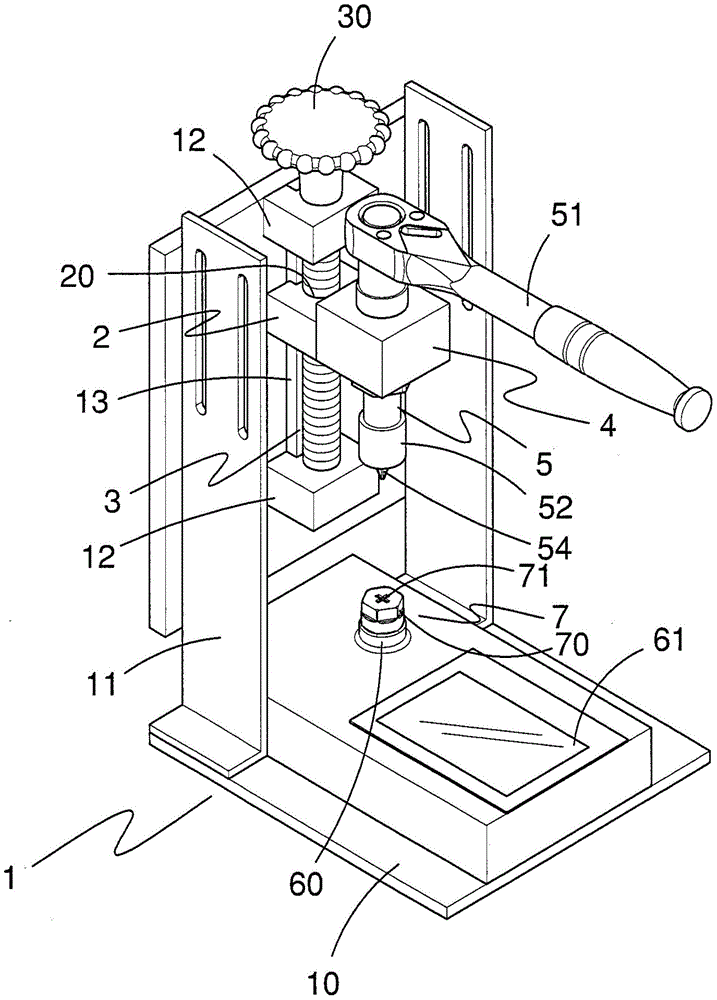

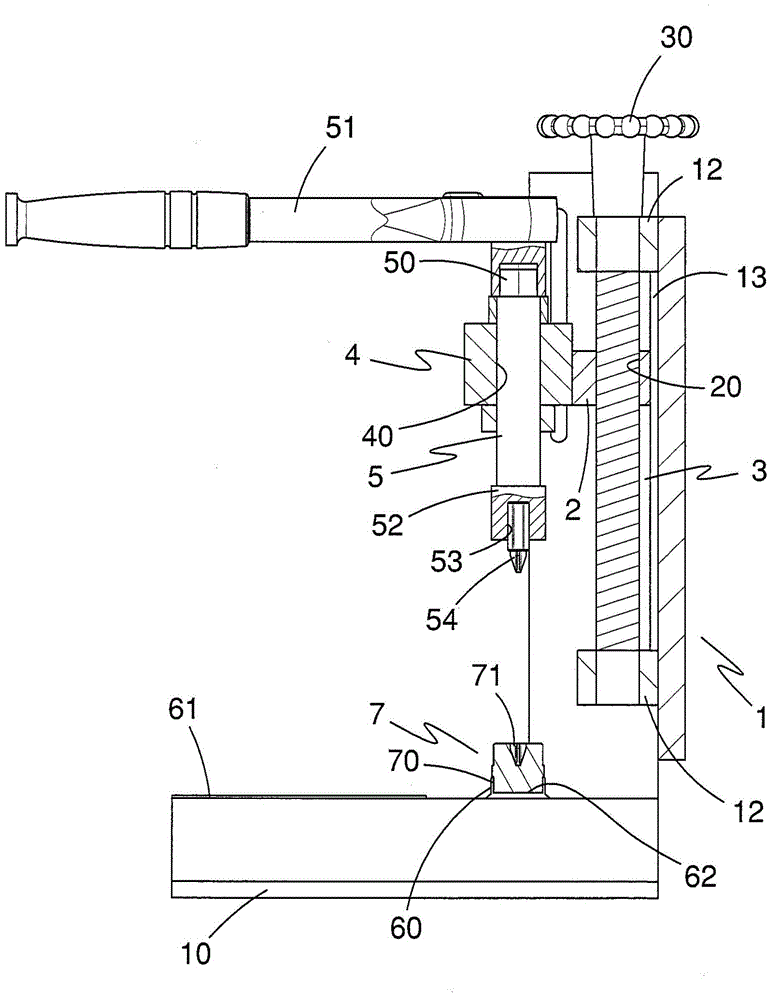

Torque test machine

InactiveCN104677544AEasy to operatePrecise positioningMeasurement of torque/twisting force while tighteningTest efficiencyWrench

The invention discloses a torque test machine, which comprises a machine table, a movable block, a leading screw, a lug and a shaft, wherein the machine table is provided with a base a frame body standing on the base; the movable block can rise and fall relative to the base at one side of the frame body, and a screw hole is formed in the movable block; the leading screw is rotatably combined with the frame body, and is vertical to the base; the leading screw penetrates through the screw hole of the movable block, so that the leading screw can move through rotation; the lug is combined with the movable block; the shaft is rotatably combined with the lug, and is parallel with the leading screw; one end, which is far away from the base, of the shaft is provided with a drive part, and the drive part can be used for driven to rotate by a spanner; one end, which is near the base, of the shaft is provided a bell and spigot joint part; the shaft is controlled to rise and fall through the rotation of the leading screw. The torque test machine is very simple in operation, and very accurate in positioning; the test efficiency can be greatly increased.

Owner:SICHUAN DITEL ELECTRONICS

Intensity testing device for cooling fin

InactiveCN107402157AAccurate torque valueAccurate outputMaterial strength using steady torsional forcesCouplingReducer

The invention discloses a heat sink strength testing device, which includes a bottom frame, a limit block, a driving turntable, a first rotating shaft, a first coupling, a torque sensor, a second coupling, a second rotating shaft, a reducer, motor and sliding device; the lower end of the underframe is fixedly connected with a column, the top of the underframe is fixedly connected with a limit block, the end face of the limit block is provided with a first bar-shaped groove, and the driving turntable is provided with a first Two bar-shaped grooves, the first groove and the second groove are facing each other, the driving turntable is coaxially fixed with the first rotating shaft, and the first rotating shaft is connected with one end of the torque sensor through the first shaft coupling. shaft, the other end of the torque sensor is coaxially fixed with the second shaft through a second coupling, and a bearing is sleeved on the second coupling, and the output of the second shaft and the reducer The output end of the motor is connected to the input end of the reducer; the strength of the heat sink can be detected.

Owner:重庆钜途机电有限公司

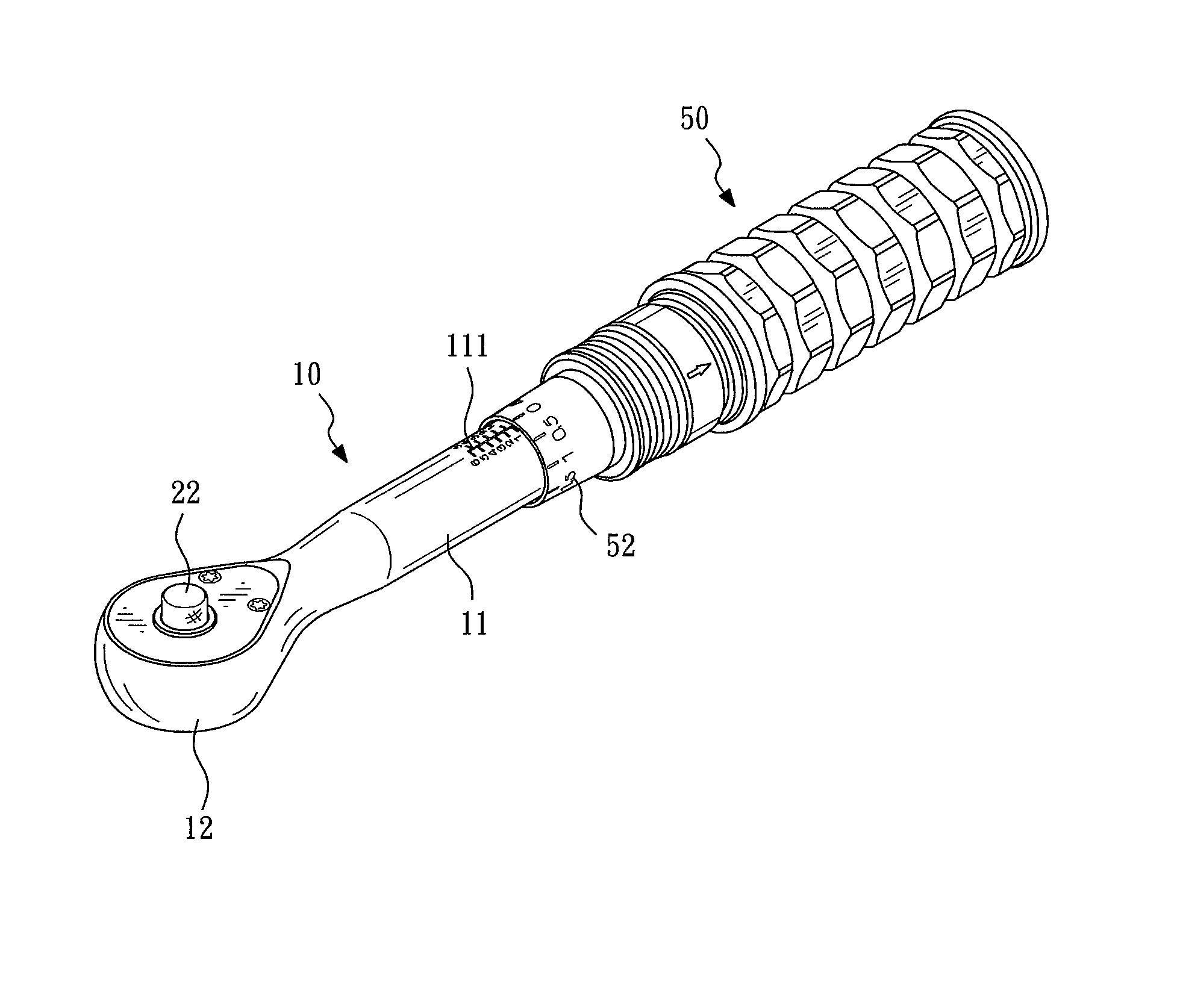

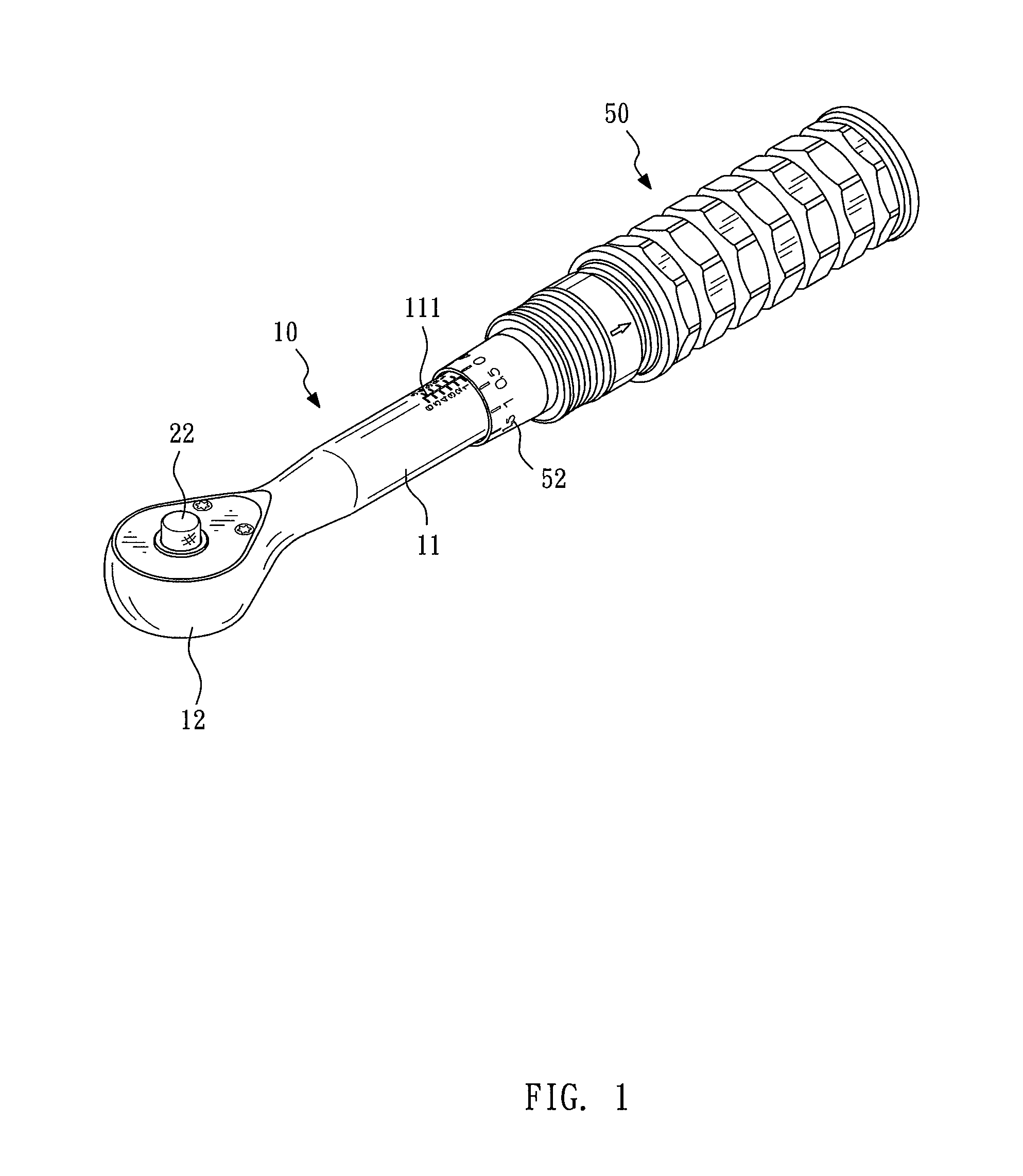

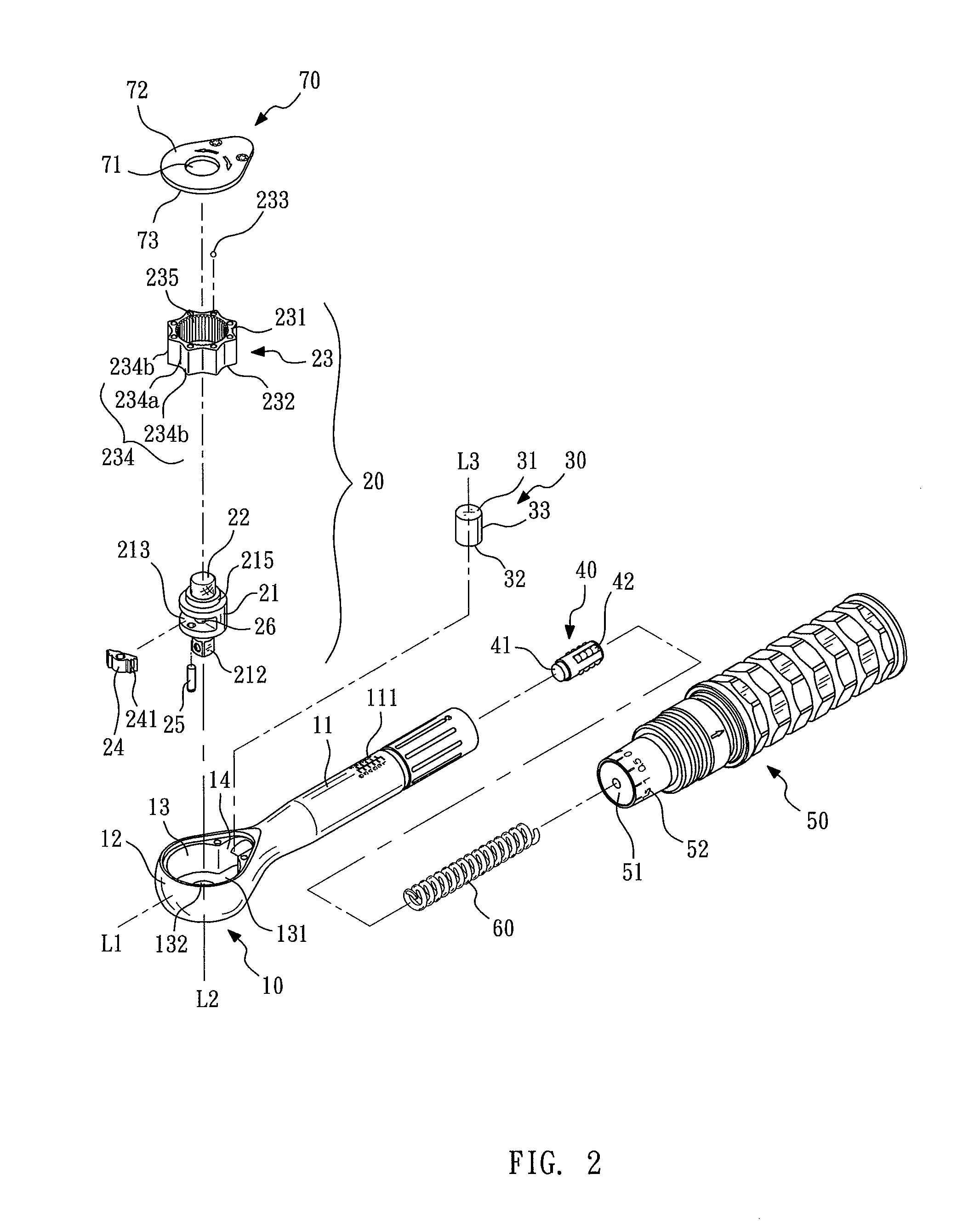

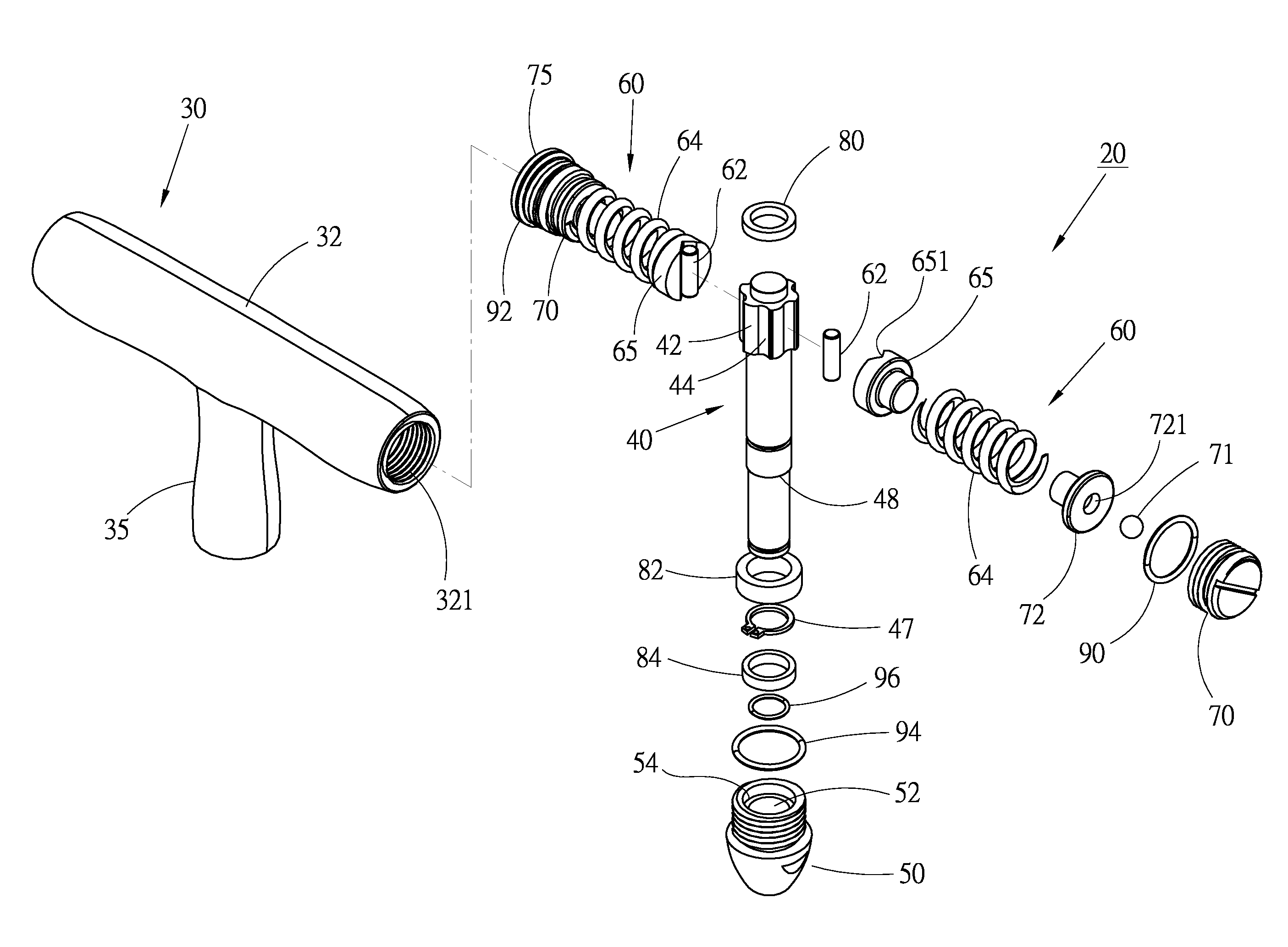

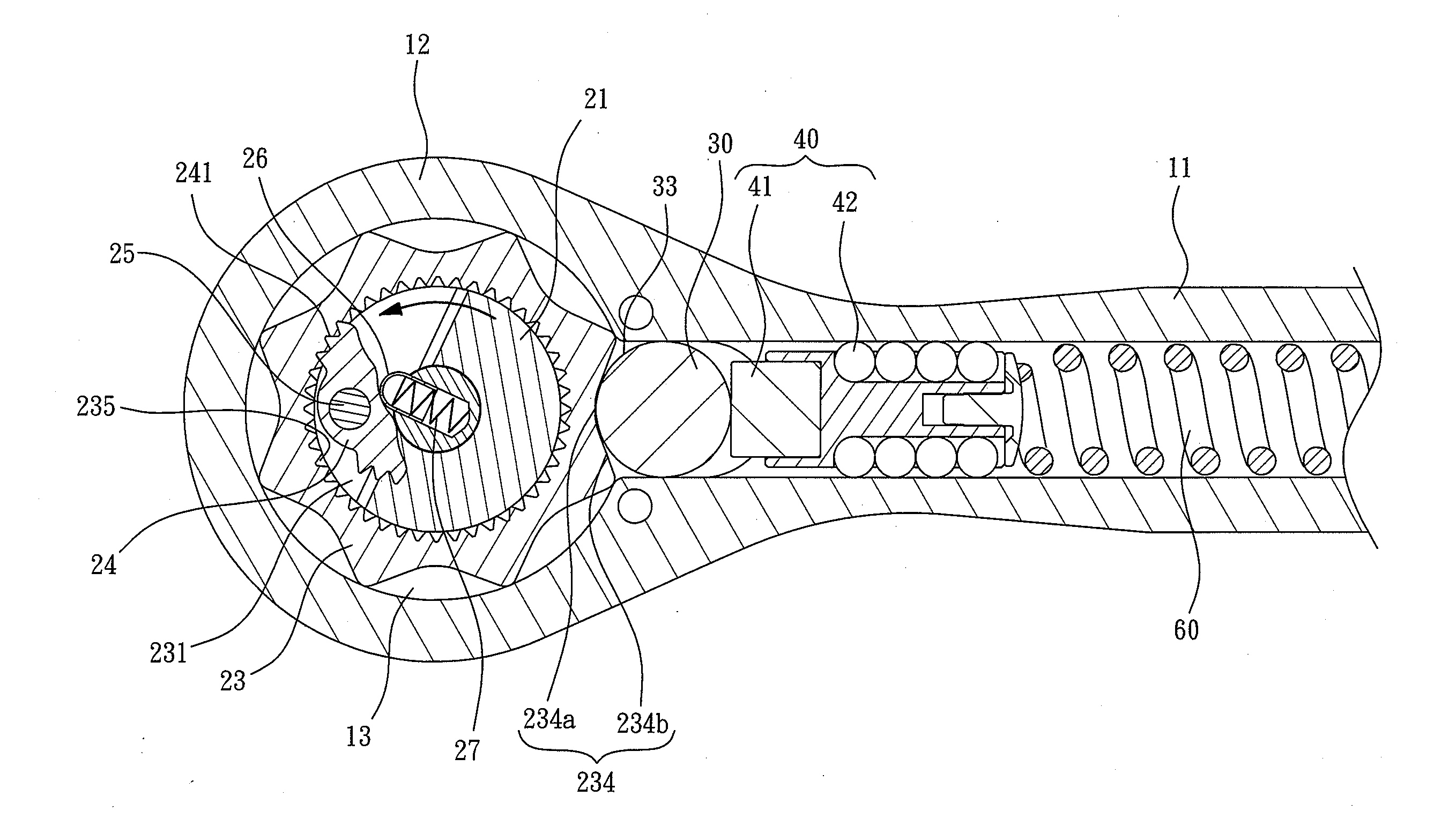

Wrench Equipped with a Precise Torque-Measuring Device

A wrench includes a shank including a slot defined therein longitudinally, a handle attached to an end of the shank, a head, a torque assembly for connecting the head to another end of the shank, a torque-setting device and a torque-measuring device. The torque-setting device includes a knob inserted in the handle and a pin movable in and along the slot as the knob is spun. The torque-measuring device includes a measurement sleeve and a collar. The measurement sleeve is rotationally located around the shank and includes a helical groove defined in an internal side and a scale provided on an external side. A portion of the pin is movably inserted in the helical groove so that the measurement sleeve is spun as the pin is moved in and along the slot. The collar is located around the shank and includes a window through which the scale is observable.

Owner:MATATAKITOYO TOOL

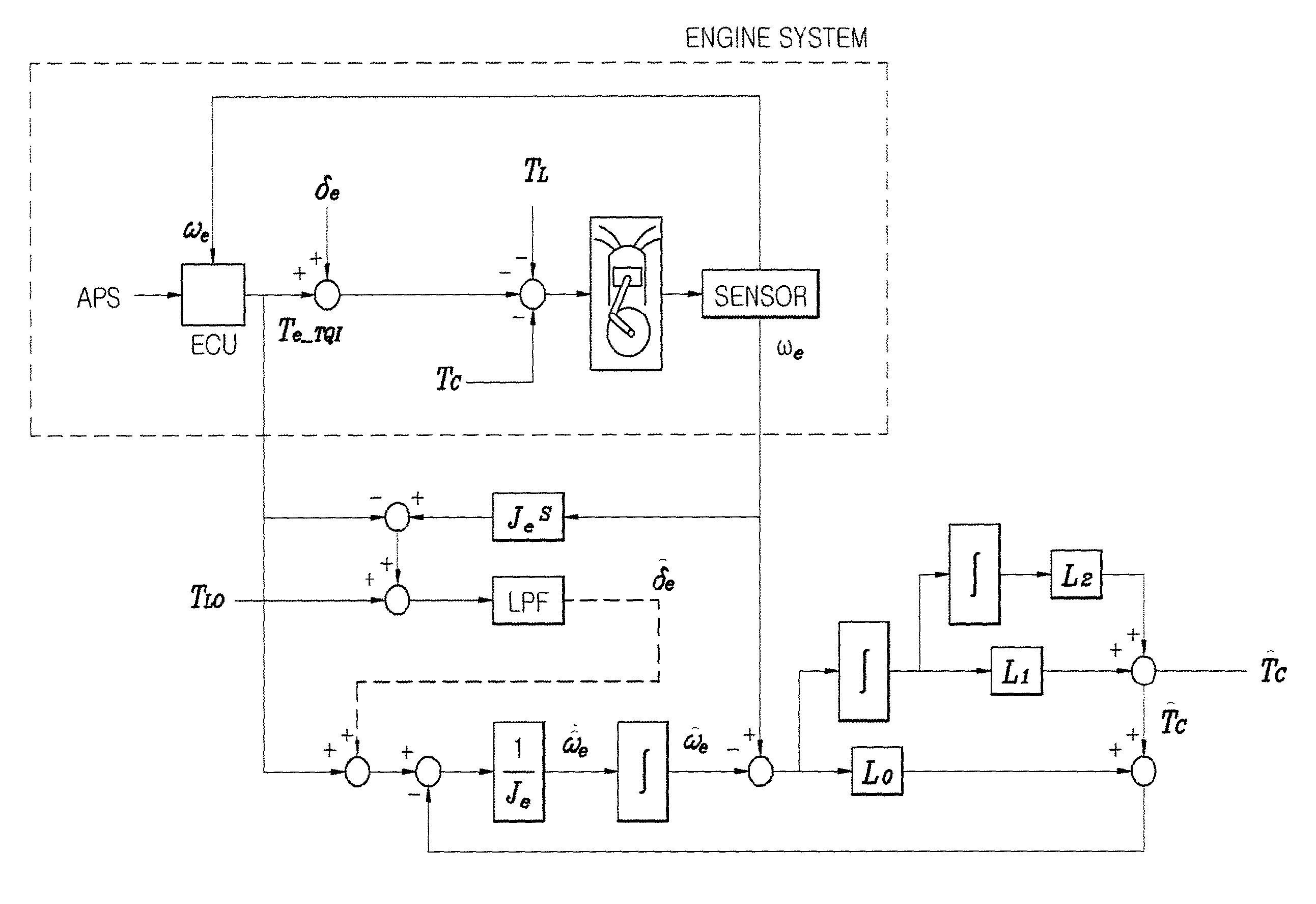

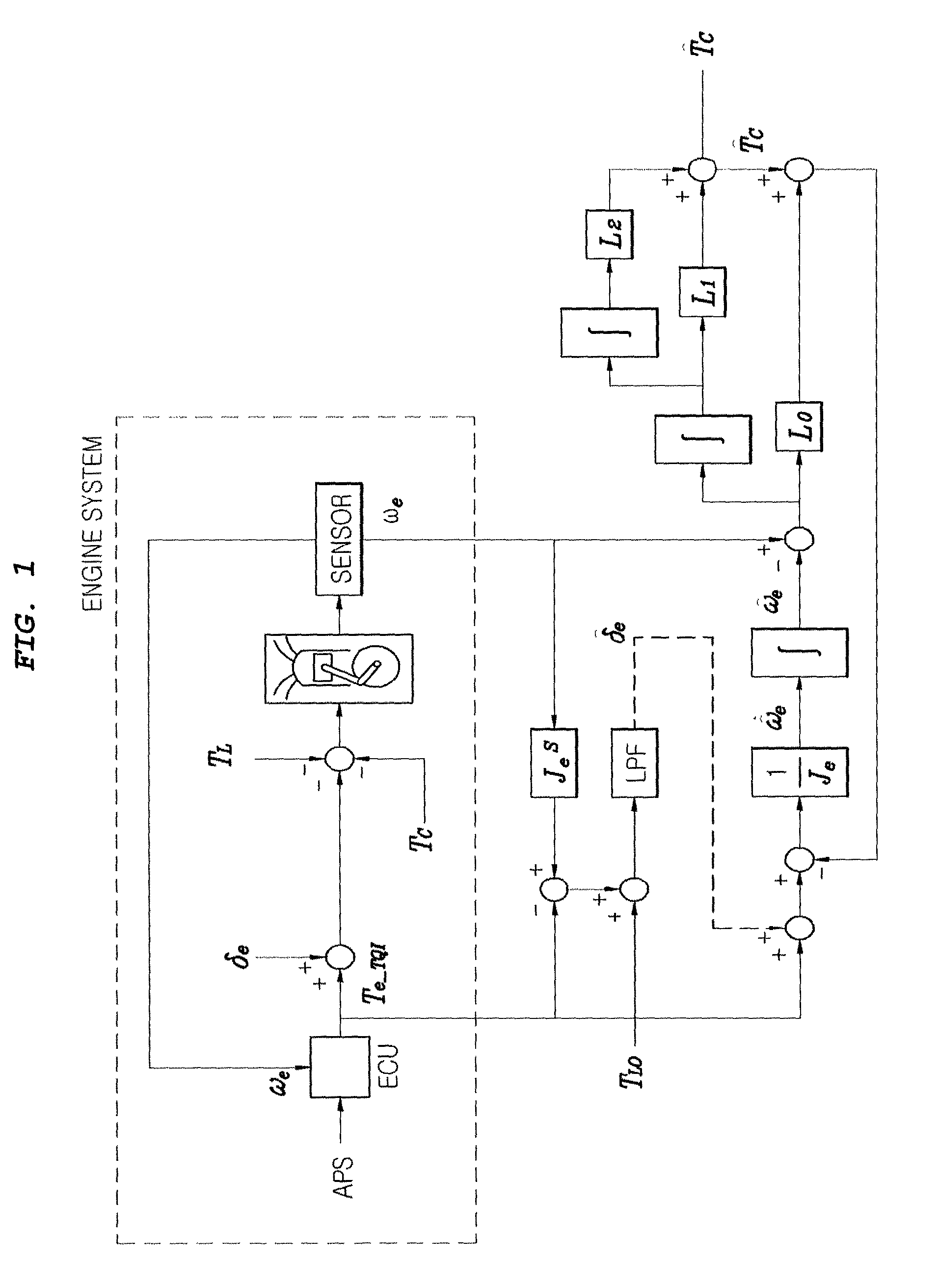

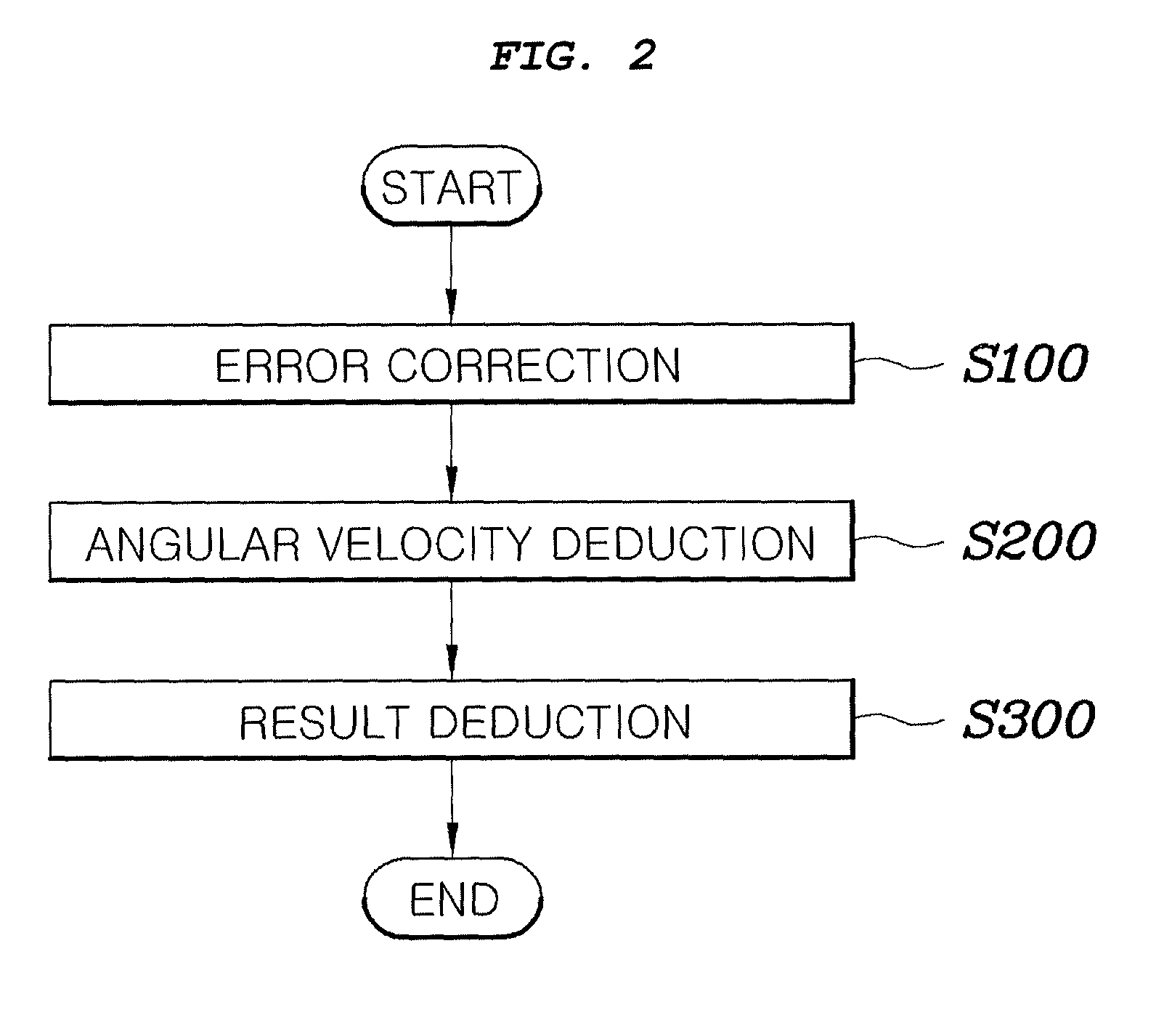

Torque estimation method for transmission clutch

A method of estimating a torque of a transmission clutch may include correcting an error by deducing an engine transient torque based on an engine angular velocity measured using a sensor, an engine static torque deduced using a data map, and a load torque depending on a driving load, deducing an engine angular velocity estimation value based on the engine static torque and the engine transient torque, and deducing a clutch torque estimation value depending on a slip in the transmission clutch from a difference between the engine angular velocity estimation value and the measured engine angular velocity.

Owner:HYUNDAI MOTOR CO LTD +1

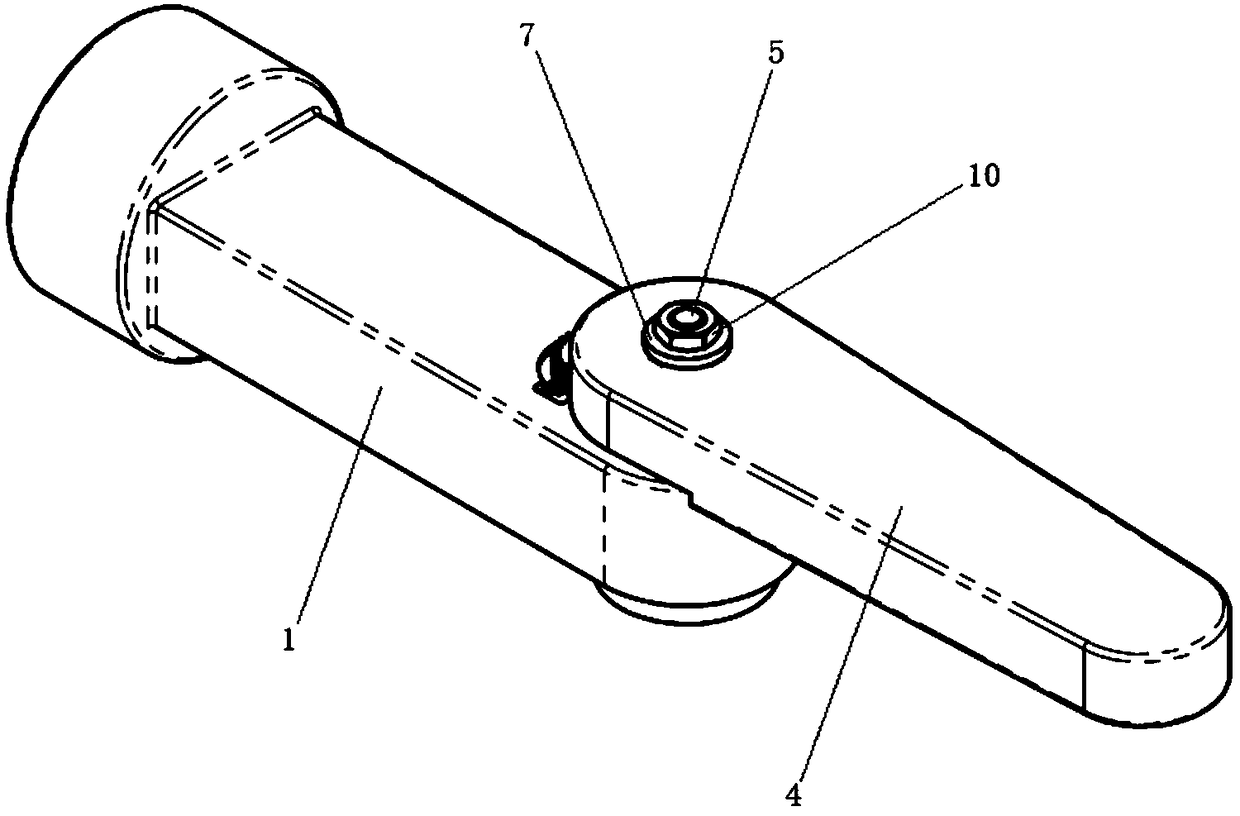

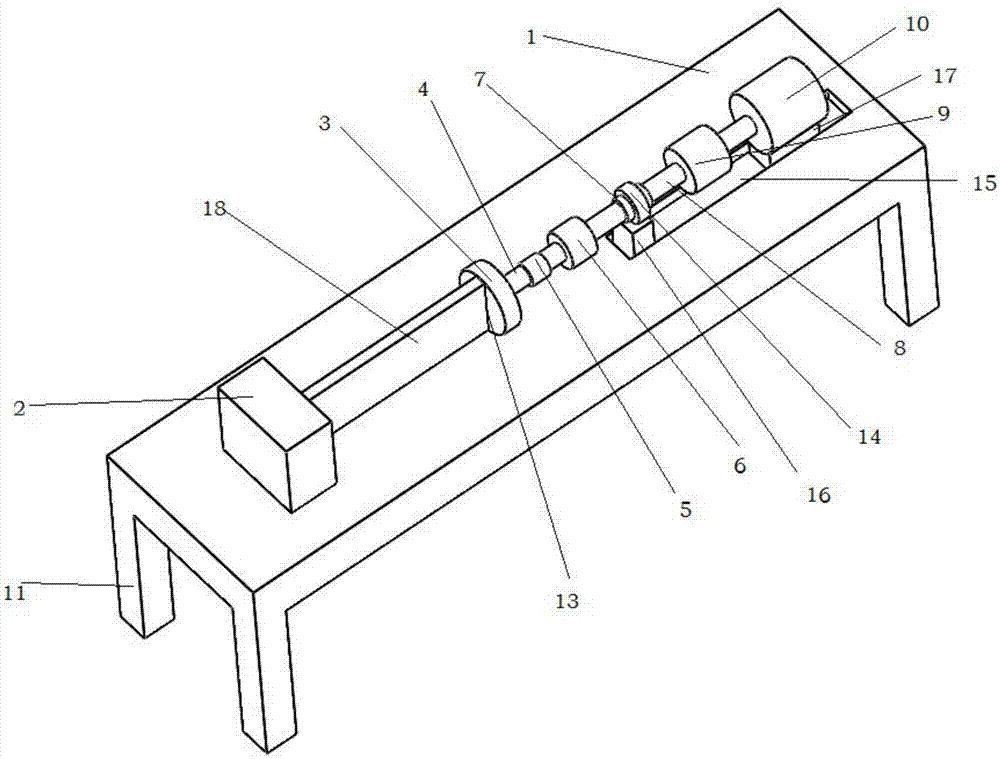

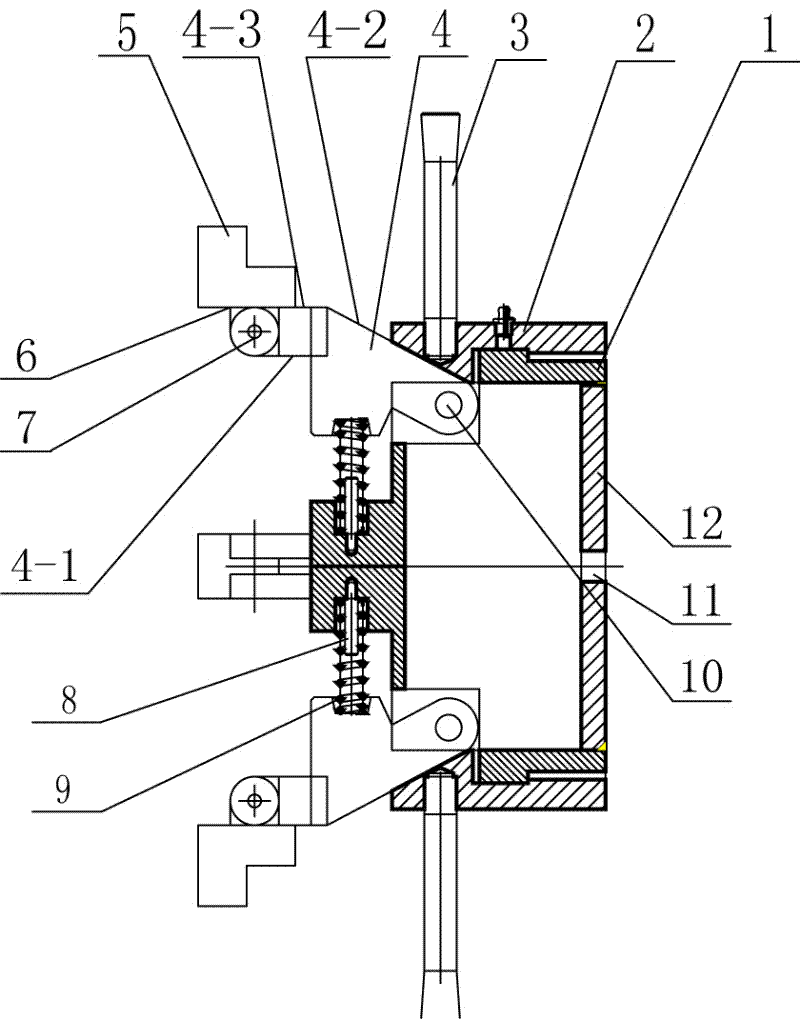

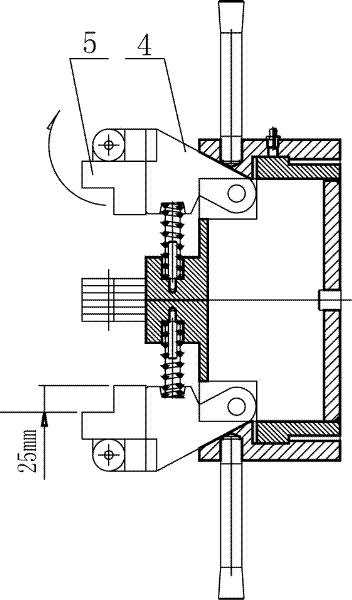

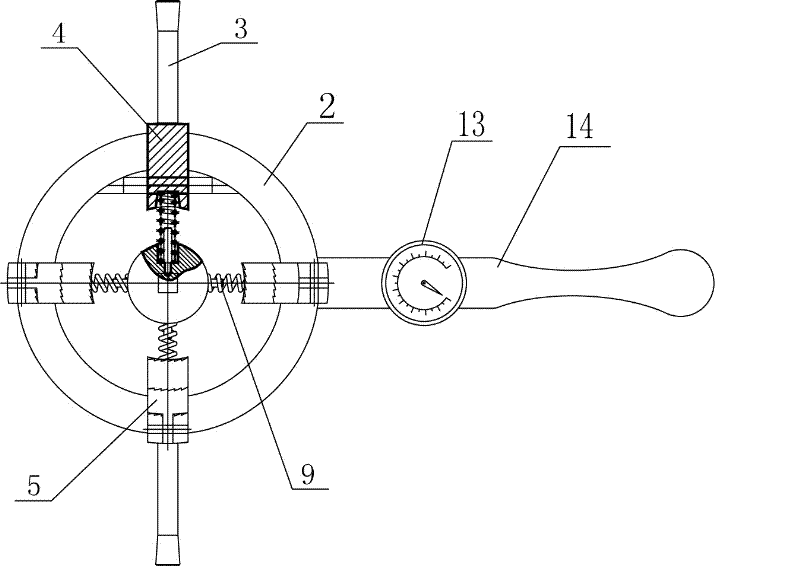

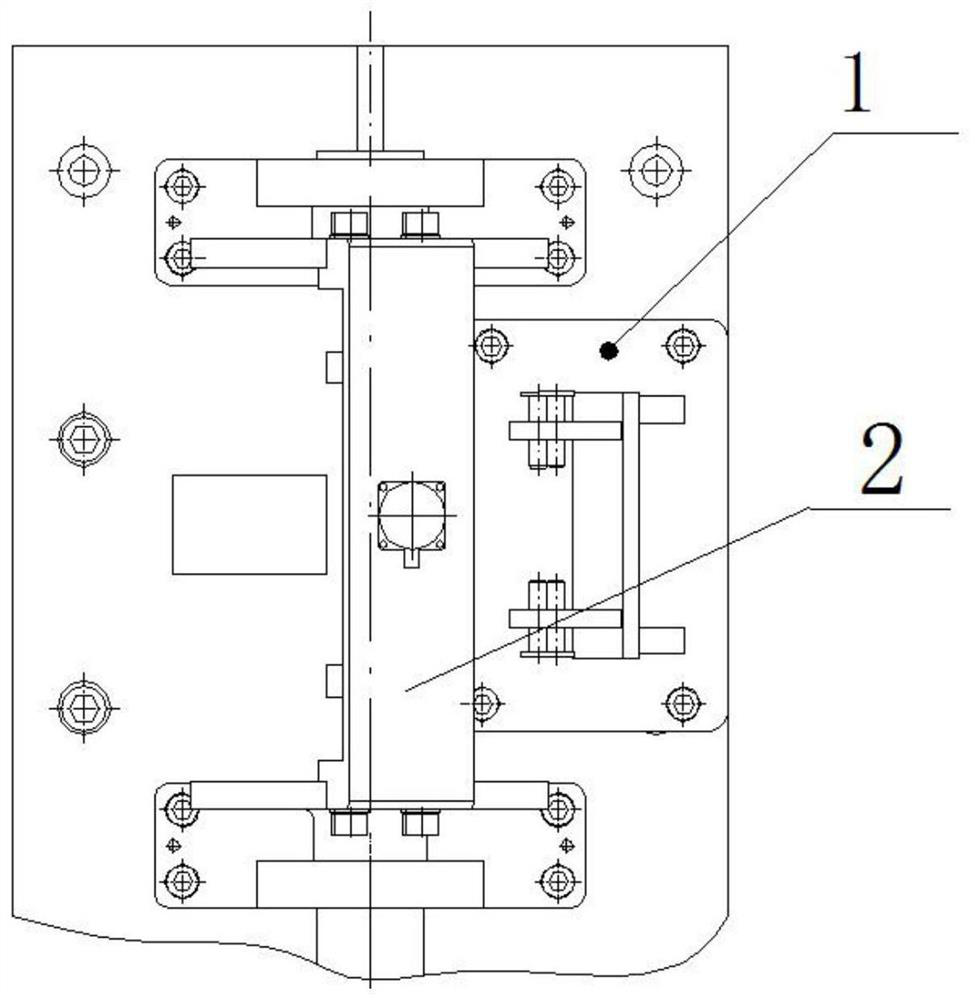

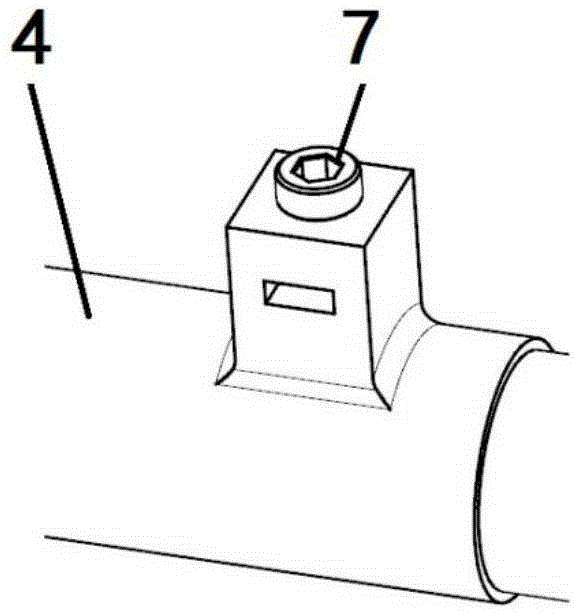

Reducing clamping connector for torsion detection of drive shaft

ActiveCN102445292AImprove working efficiency of torque detectionEasy to operateApparatus for force/torque/work measurementDrive shaftClassical mechanics

The invention relates to a reducing clamping connector for torsion detection of a drive shaft. The reducing clamping connector comprises a clamping jaw fixing sleeve (1) and a clamping jaw jacking and pressing sleeve (2), wherein the clamping jaw jacking and pressing sleeve (2) is in threaded connection with the clamping jaw fixing sleeve (1); the front end of the clamping jaw fixing sleeve (1) is connected with a plurality of clamping jaws through a hinged shaft (10); the outer lateral face of the clamping jaws is provided with an inclined face (4-2); the inclined face (4-2) is matched with the front end of the clamping jaw jacking and pressing sleeve (2); support springs (9) are arranged at the inner sides of the clamping jaws (4); a connecting plate (6) is hinged in an installation groove (4-4) of each clamping jaw (4), can rotate in the installation groove and is fixedly connected with a reducing cushion block (5); and each reducing cushion block (5) is provided with two clamping faces which are parallel to each other and different in clamping sizes. By adopting the reducing clamping connector, the purpose that drive shafts of different specifications can be clamped by one connector is achieved, the reducing operation is convenient, and the working efficiency in the torsion detection of the drive shaft is improved.

Owner:JINAN JINNIU BRICKMAKING MACHINERY

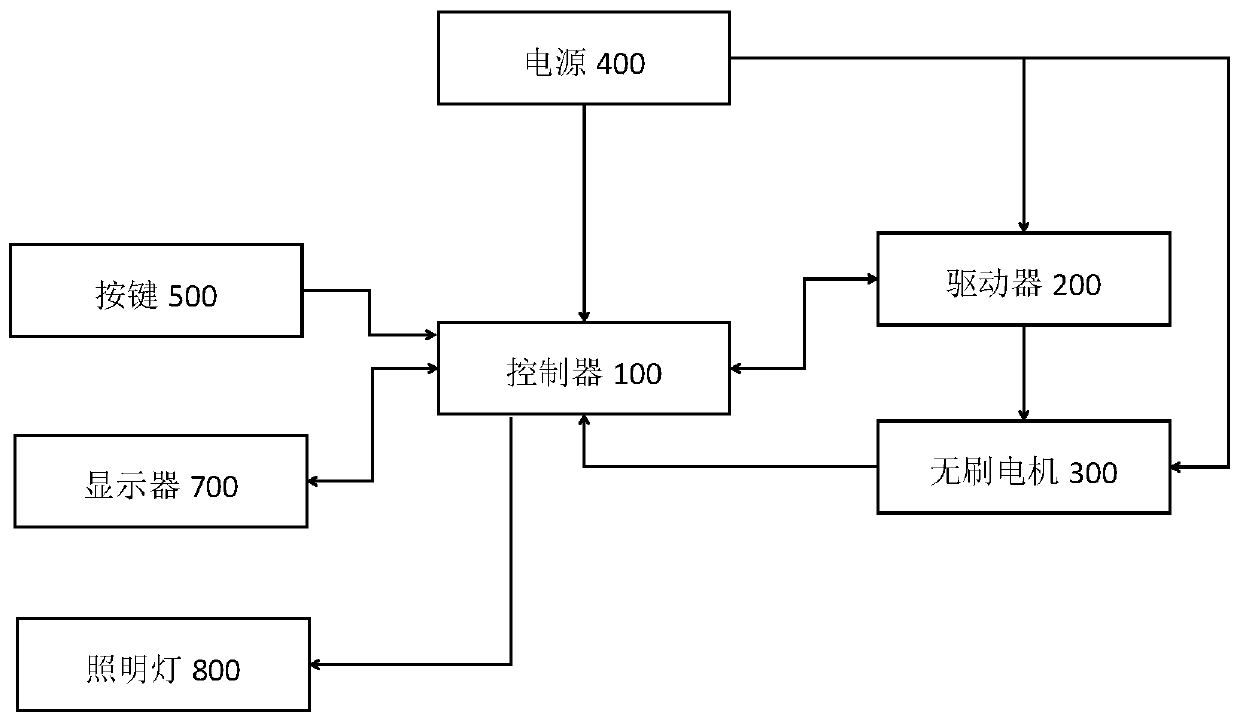

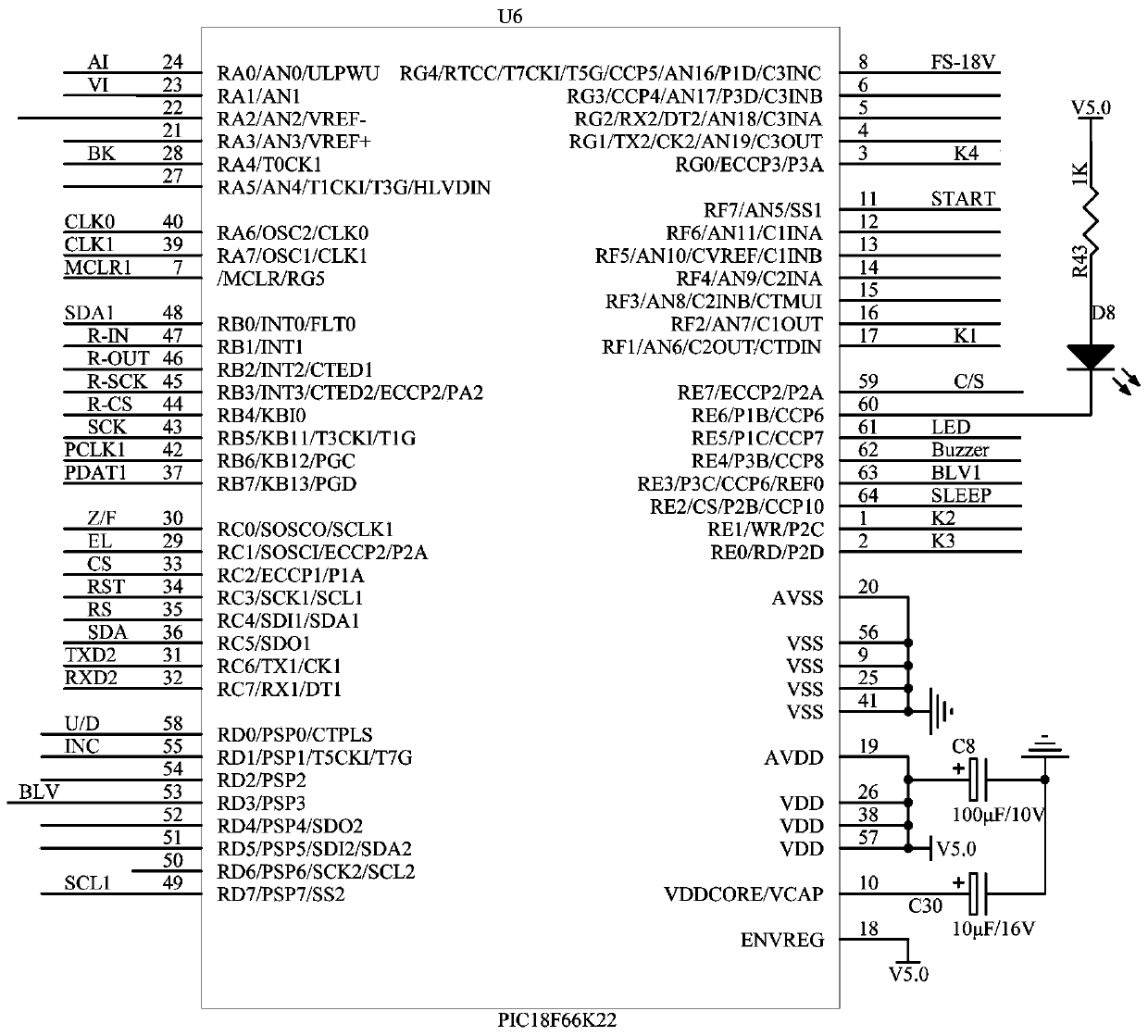

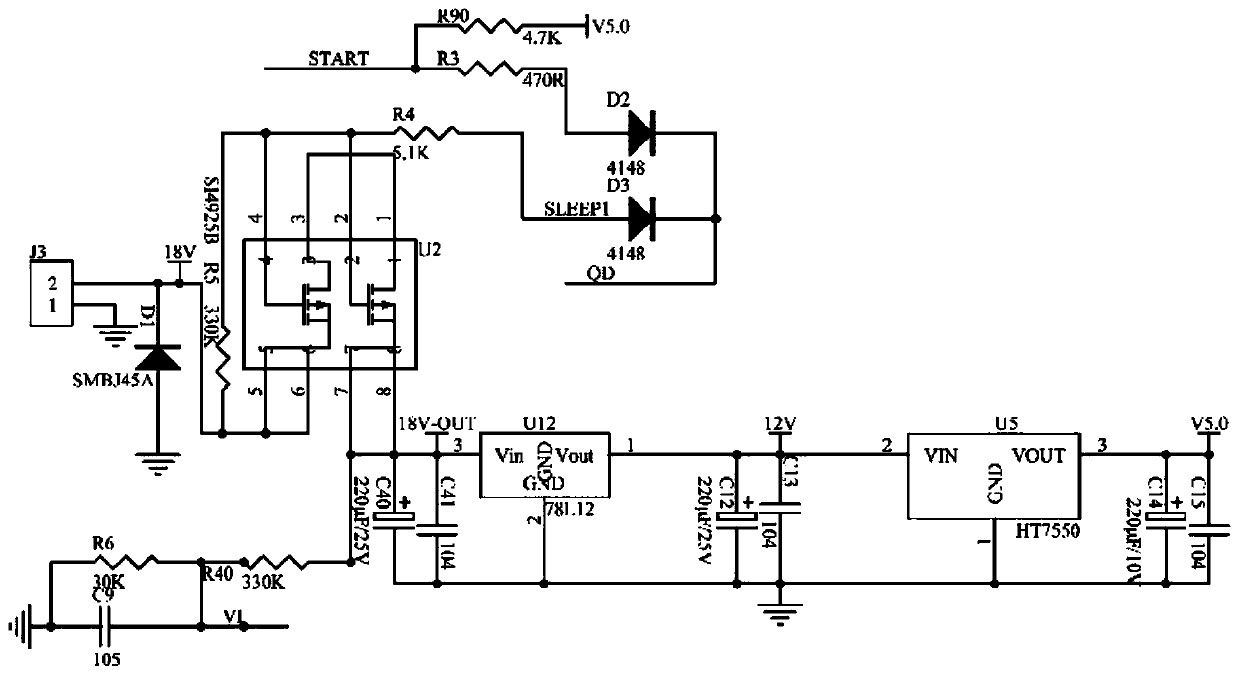

Control system of rechargeable torque wrench

InactiveCN111168616AEasy to controlAccurate torque valueMechanical power/torque controlSpannersControl systemBrushless motors

The embodiment of the invention discloses a control system of a rechargeable torque wrench. The control system comprises a controller, a driver, a brushless electric machine and a power source. The controller is used for controlling the driver to drive the brushless electric machine to rotate to drive the wrench to work. The driver is further used for acquiring current change information of the brushless electric machine during rotation, and feeding back the current change information to the controller, so that the controller acquires the output torque of the brushless electric machine according to the current change information and adjusts the output torque. According to the control system, modular unit control is adopted, a precise torque value can be output, and precise control over thework of the wrench can be achieved.

Owner:BEIJING TIANZE ELECTRIC POWER GRP CO LTD

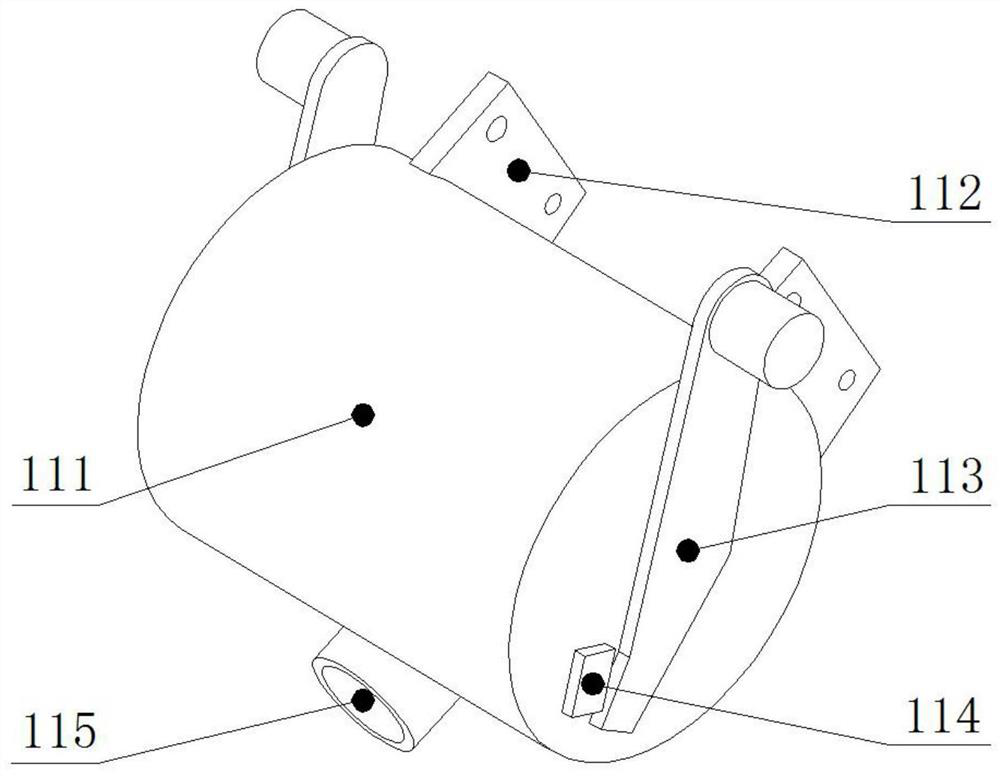

Actuator cylinder intelligent test system

PendingCN112834196AAvoid adding additional torqueEasy to installMachine part testingFriction torqueReduction drive

The invention discloses an actuator cylinder intelligent test system, which comprises an actuator cylinder fixing seat, a dial-turn mechanism, a torque sensor, a coupling, a jaw clutch, a harmonic gear reducer, a motor, a support and a table board. According to the actuator cylinder intelligent test system, the test bench is vertically arranged to test a product, the additional torque of the connecting plate in the turning mechanism to the actuating cylinder of the product due to the dead weight can be avoided; as the mounting surface of the table surface of the test table is independently processed and is provided with the key slots, and the supports mounted on the table surface are also provided with the key slots, the requirements of mounting flatness and coaxiality are ensured, and the mounting is convenient for workers; and the torque sensor is installed close to one side of the product, and the measured torque value of the actuator cylinder of the product is accurate due to the fact that the additional friction torque value generated in the middle transmission link is reduced. Whether the movable end and the fixed end of the jaw clutch are meshed or not is judged by installing the distance sensor, and it can be guaranteed that the tooth sliding phenomenon cannot be generated in the torque transmission process.

Owner:SHAANXI SCI TECH UNIV

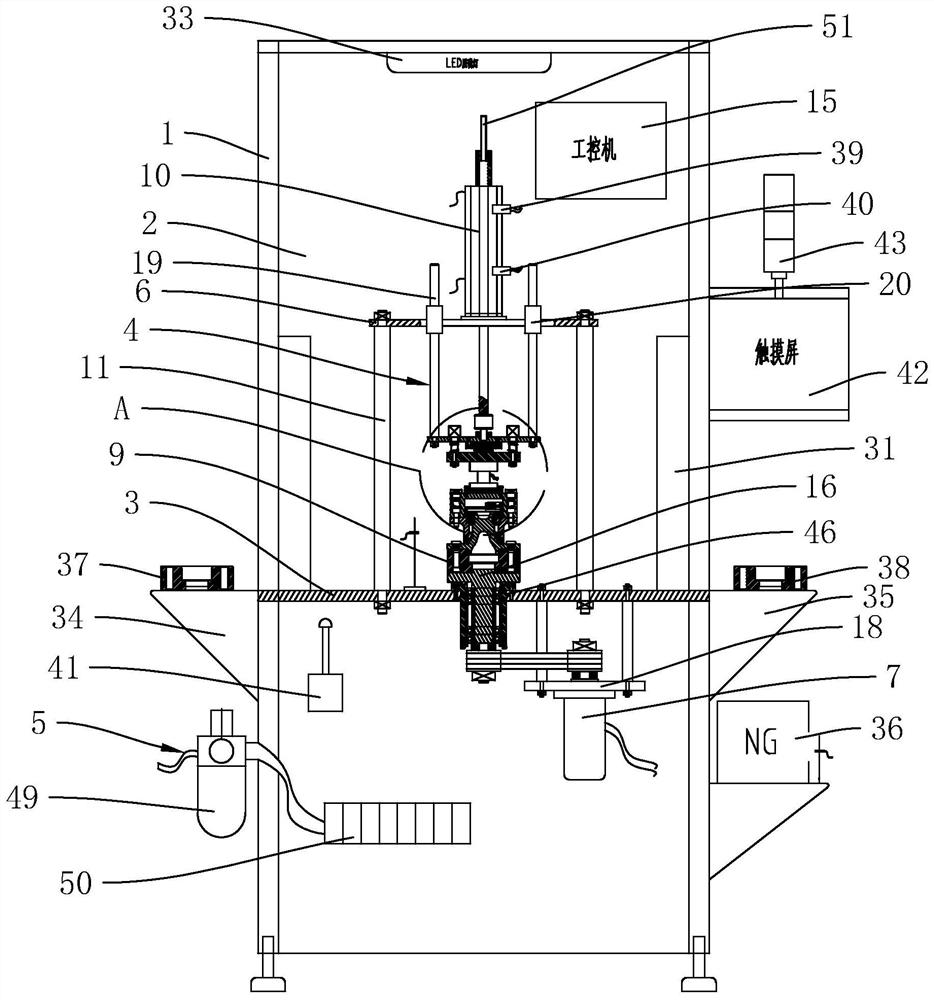

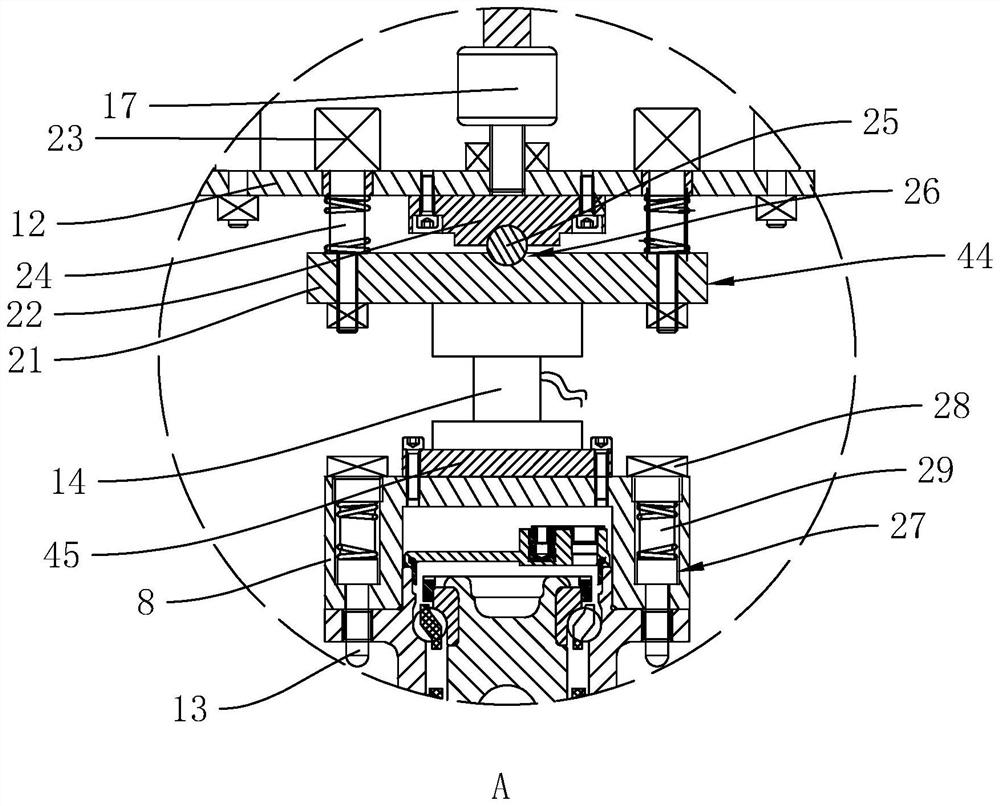

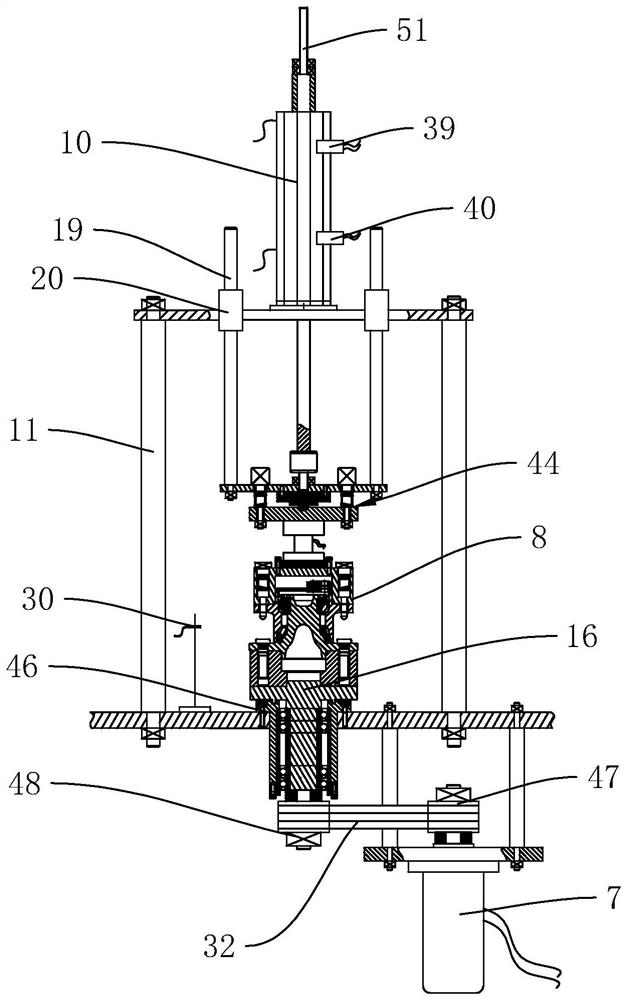

Full-automatic hub bearing unit torque detector

PendingCN114646416AAccurate torque valueImprove fitMachine bearings testingForce sensorsRotational axisBalancing machine

The invention discloses a full-automatic hub bearing unit torque detection machine which comprises a supporting cabinet, a cavity is formed in the supporting cabinet, a main workbench is arranged on the inner wall, provided with the cavity, of the supporting cabinet, and a detection mechanism used for detecting the starting torque and the rotating torque of a hub bearing unit is arranged on the main workbench. The supporting cabinet is provided with a driving mechanism used for driving the detection mechanism to work, the supporting cabinet is connected with a touch screen used for displaying numerical values of the static torque sensor, a rotating shaft is rotationally arranged on the upper surface of the main workbench, the servo motor is fixedly connected with the main workbench and used for driving the rotating shaft to rotate, and the lower tool is fixedly connected with the upper end face of the rotating shaft. Through the arrangement of the detection mechanism, the automatic balance adjustment mechanism and the like, the device can automatically detect the torque of the hub bearing unit, and the torque detection precision is improved.

Owner:海宁奥通汽车零件有限公司

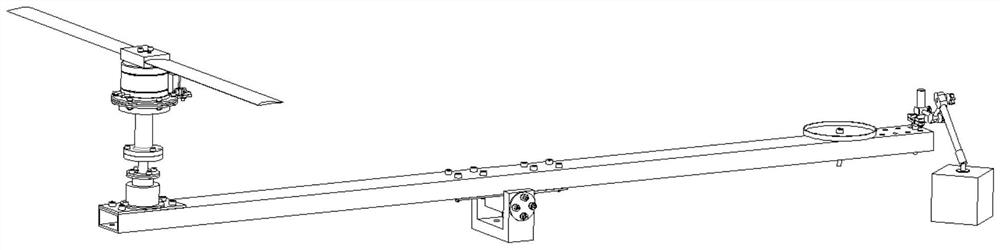

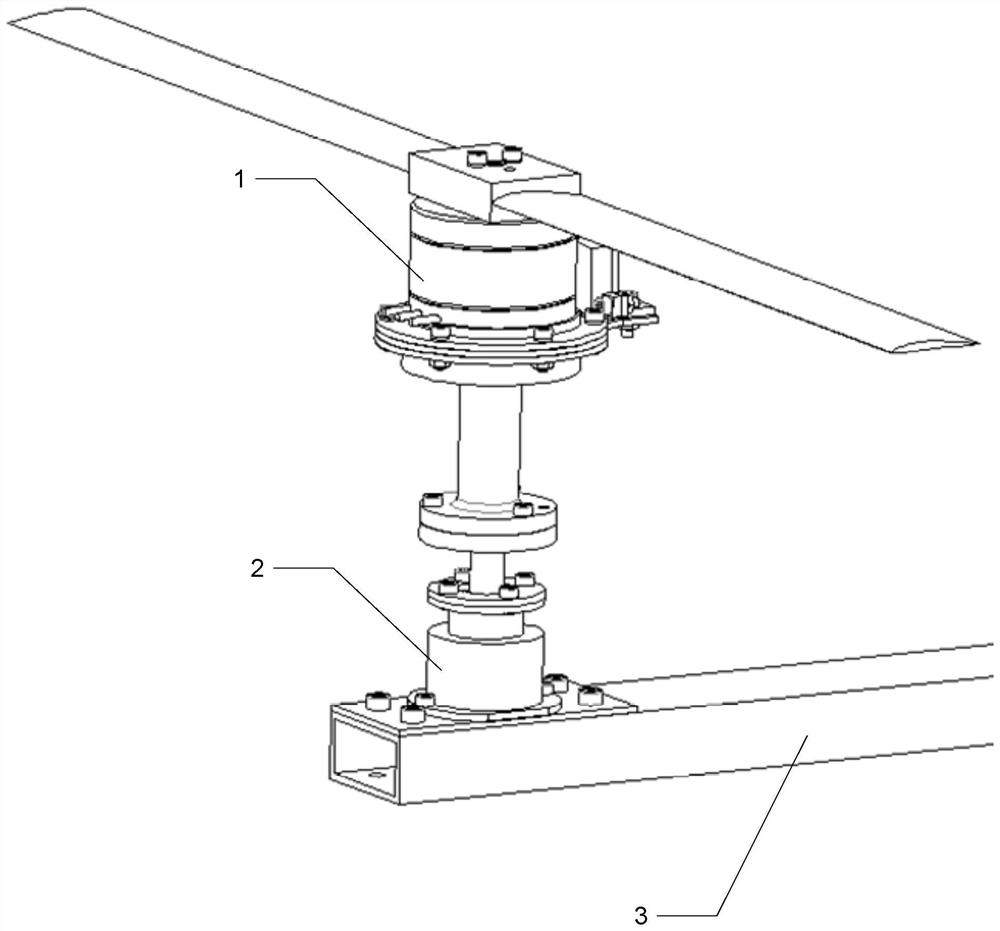

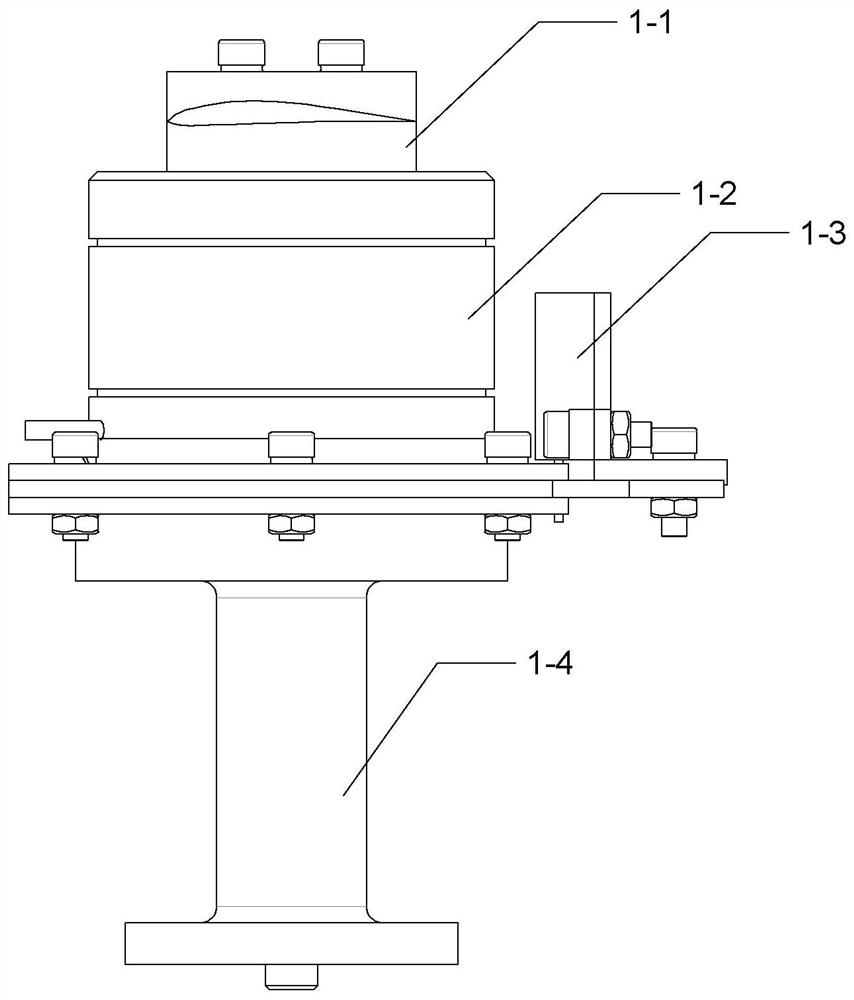

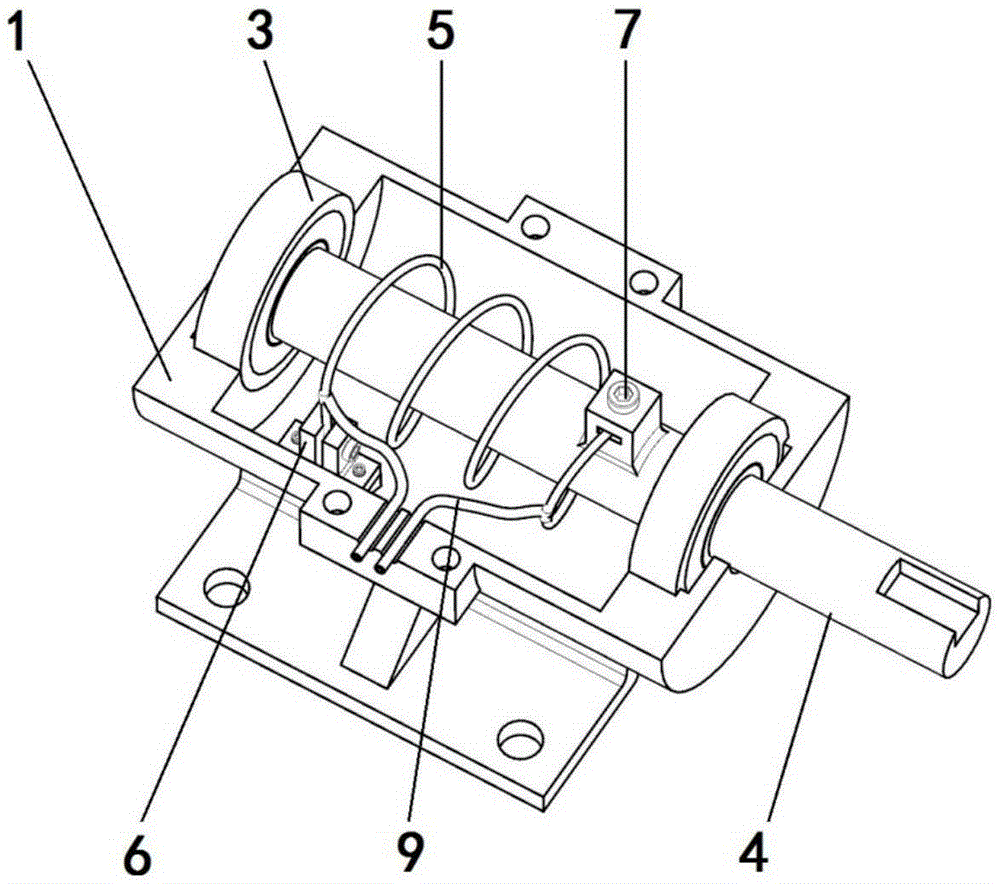

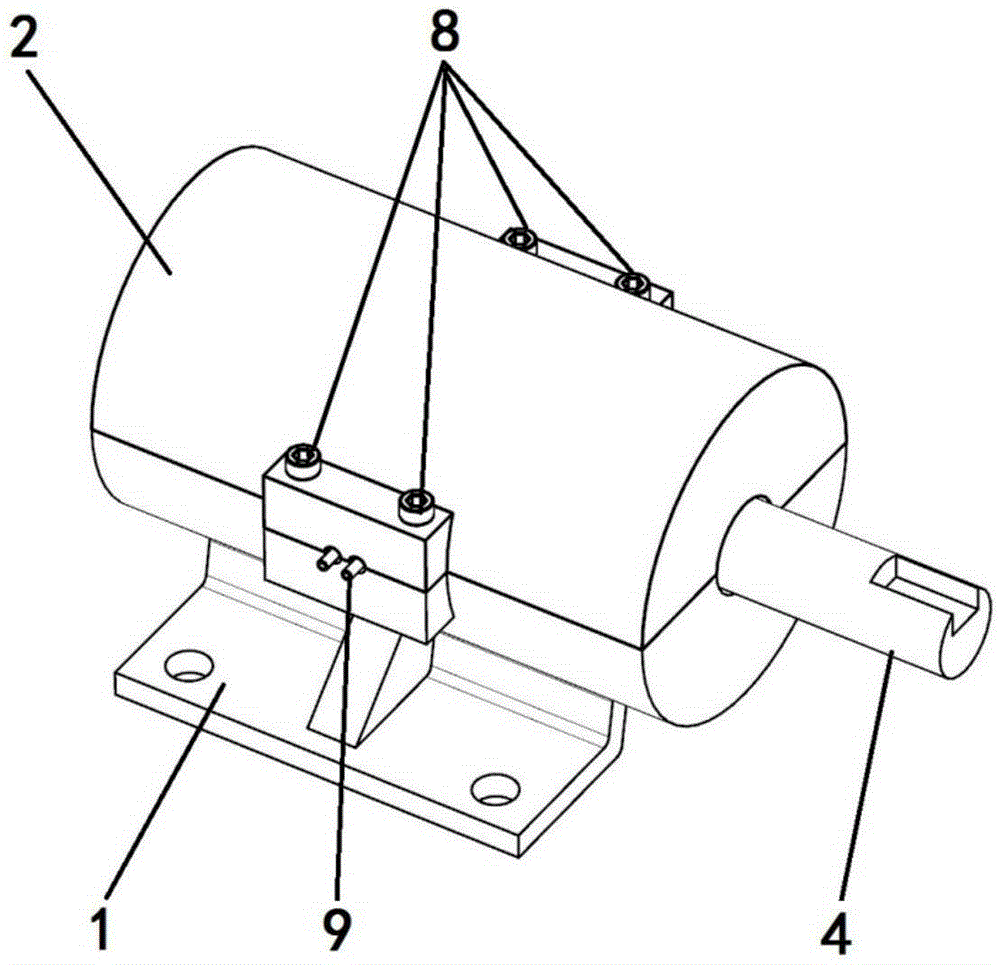

Rotary-wing Mars UAV single-rotor system aerodynamic characteristics test device and torque test method and lift test method

ActiveCN108593169BAccurate torque valueMeet the requirements of measurement accuracyMachine part testingApparatus for force/torque/work measurementClassical mechanicsUncrewed vehicle

The aerodynamic characteristic test device, torque test method and lift test method of the single-rotor system of the rotor-type Mars unmanned aerial vehicle belong to the technical field of the single-rotor unmanned aerial vehicle. The small lift and low torque index requirements of the rotor system, poor applicability, and large measurement errors. The present invention comprises a movement module, a torque measurement module and a lift measurement module; the lower end surface of the movement module is connected to the upper end of the torque measurement module, and the movement module and the torque measurement module are placed on the upper end surface of one end of the balance bar of the lift measurement module; the movement module is used to generate rotational movement , and then generate torque and lift; the torque measurement module is used to measure the torque generated by the motion module; the lift measurement module is used to measure the lift generated by the motion module. The invention is an unmanned aerial vehicle single-rotor system used for Mars exploration.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com