Full-automatic hub bearing unit torque detector

A technology for wheel hub bearing and torque detection, which is used in mechanical bearing testing, force/torque/work measuring instruments, bearing-related force sensors, etc. Uniform force, accurate numerical value, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

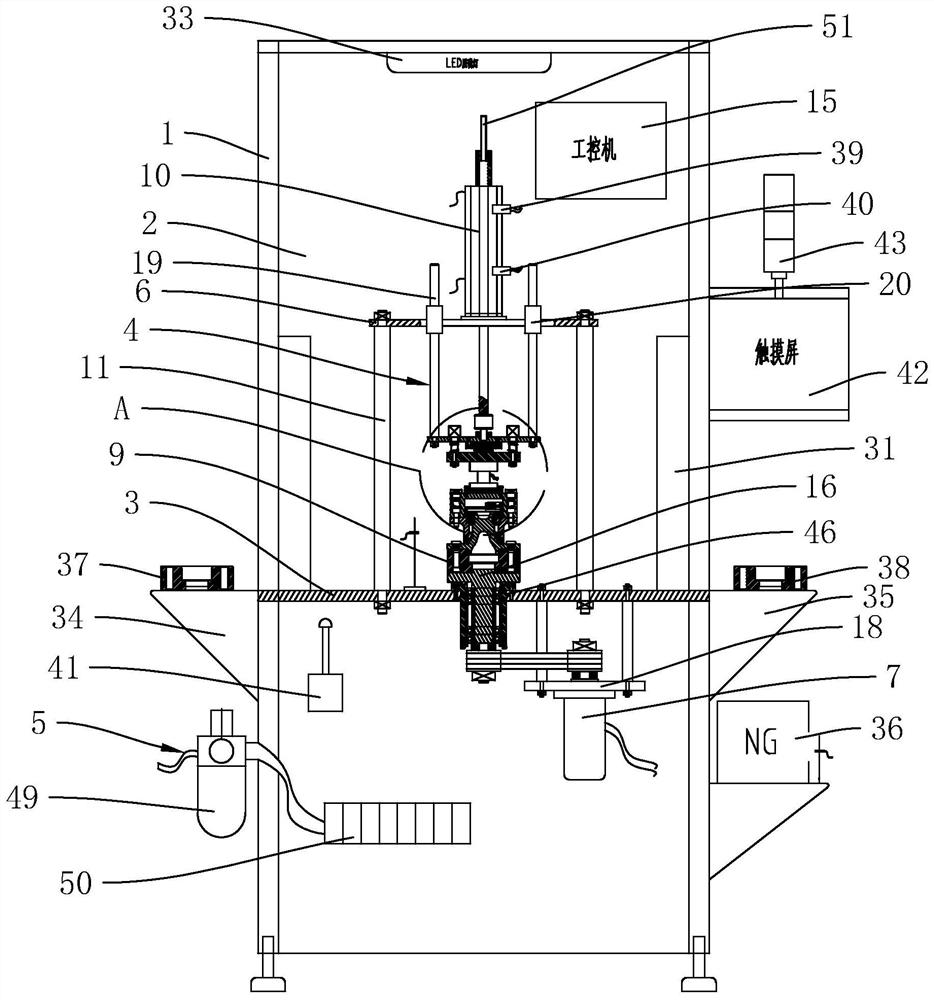

[0031] refer to figure 1 , the outer wall of the left side of the support cabinet 1 is fixedly provided with a storage level 34 to be inspected for placing the wheel hub bearing unit to be inspected. 1. The outer wall on the right side is fixedly provided with a discharge storage position 35 for placing qualified wheel hub bearing units and a discharge tool 38 for limiting the position of qualified wheel hub bearing units. The right outer wall of the support cabinet 1 is also fixedly provided with Unqualified product storage level 36 to be processed, the storage level 36 to be processed is connected with a photoelectric switch bracket, the photoelectric switch bracket is connected with a counting photoelectric switch, the outer wall of the support cabinet 1 is connected with a touch screen 42, and the top of the touch screen 42 is connected with a three-color indicator light 43.

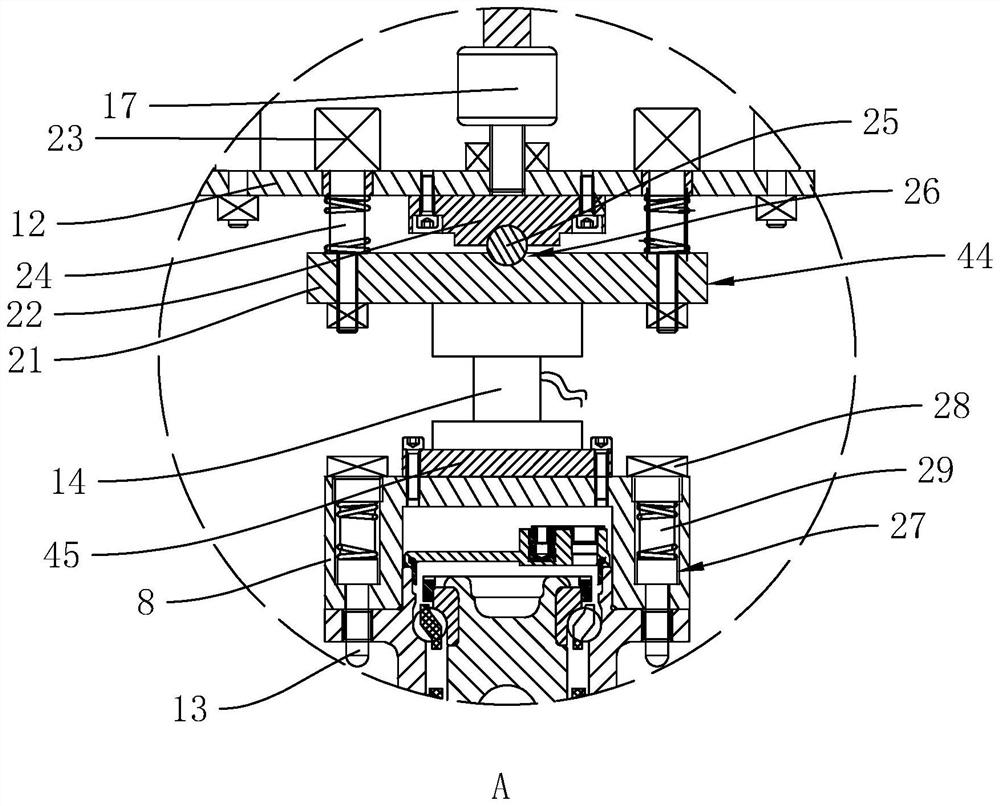

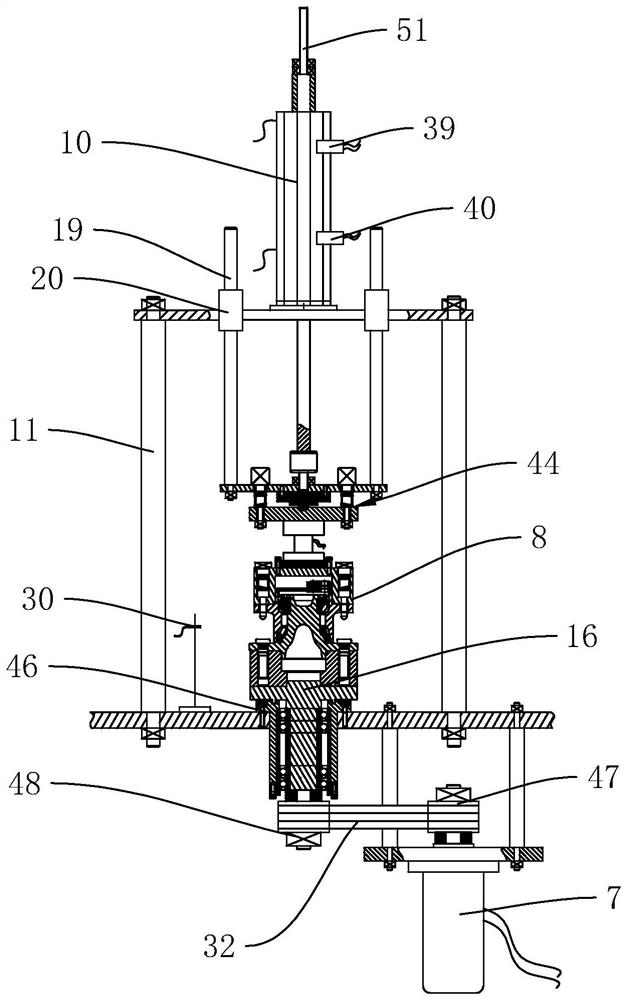

[0032] refer to figure 1 and figure 2 , the detection mechanism 4 includes a first auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com