Temperature-control cooling system for large-size concrete structure and cooling control method of temperature-control cooling system

A large-volume concrete and cooling system technology, applied in building construction, building material processing, construction, etc., can solve the problems of reducing the unevenness of the temperature gradient temperature field, the blindness of the cooling water pipe layout, and the large amount of calculation. Achieve the effect of changing the asymmetry of the vertical cooling temperature field, avoiding uneven vertical cooling, and reducing the horizontal temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

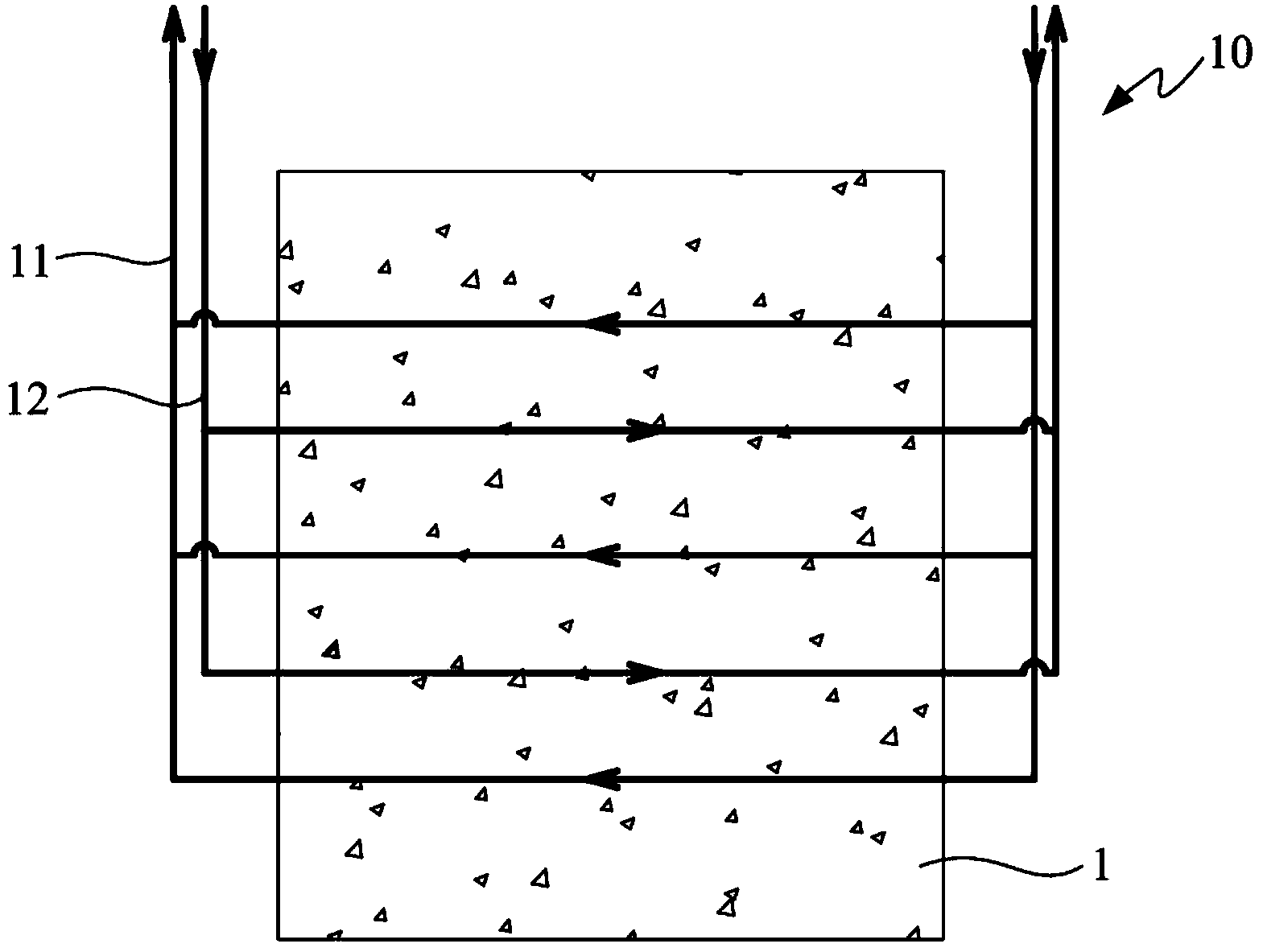

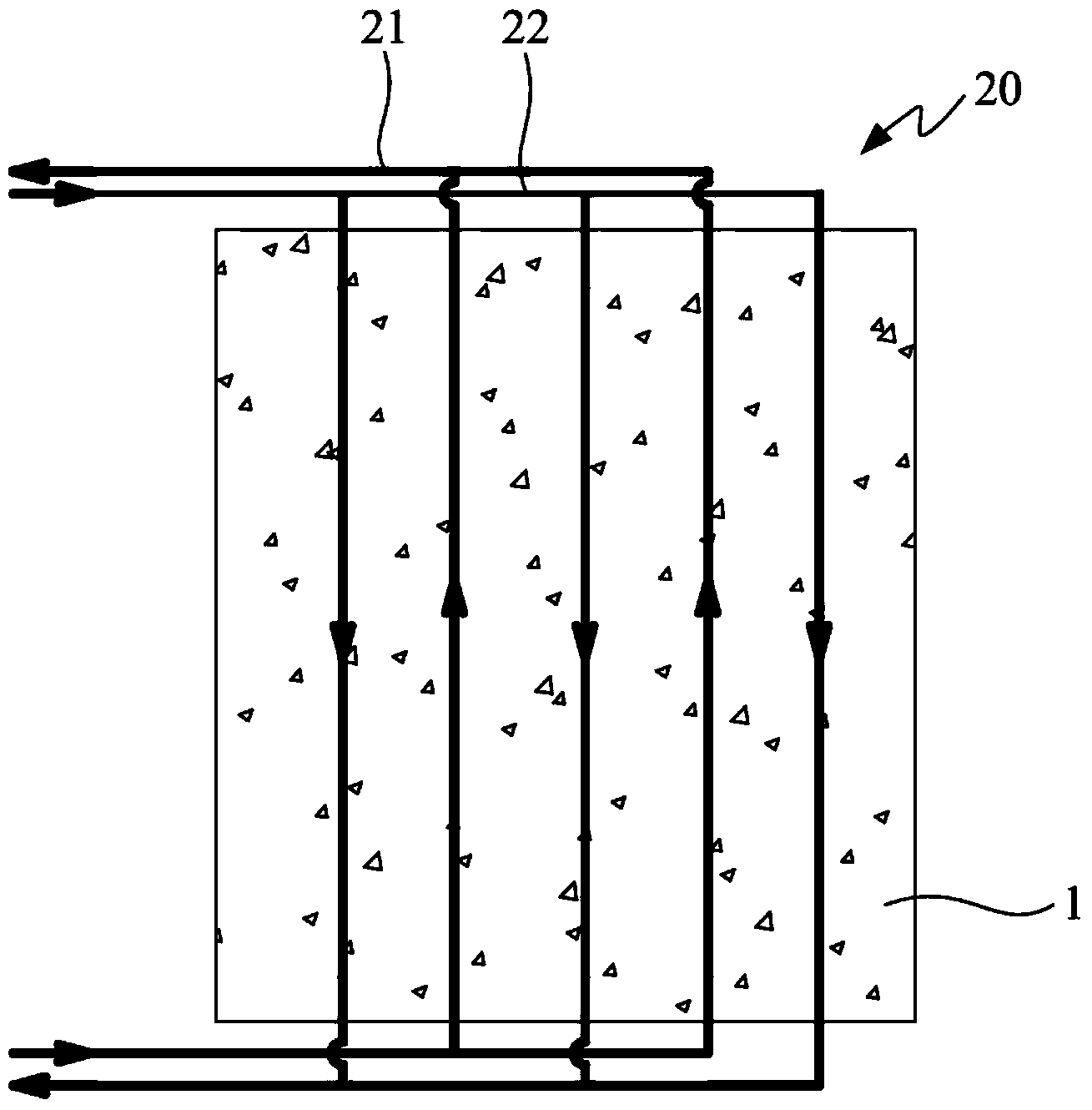

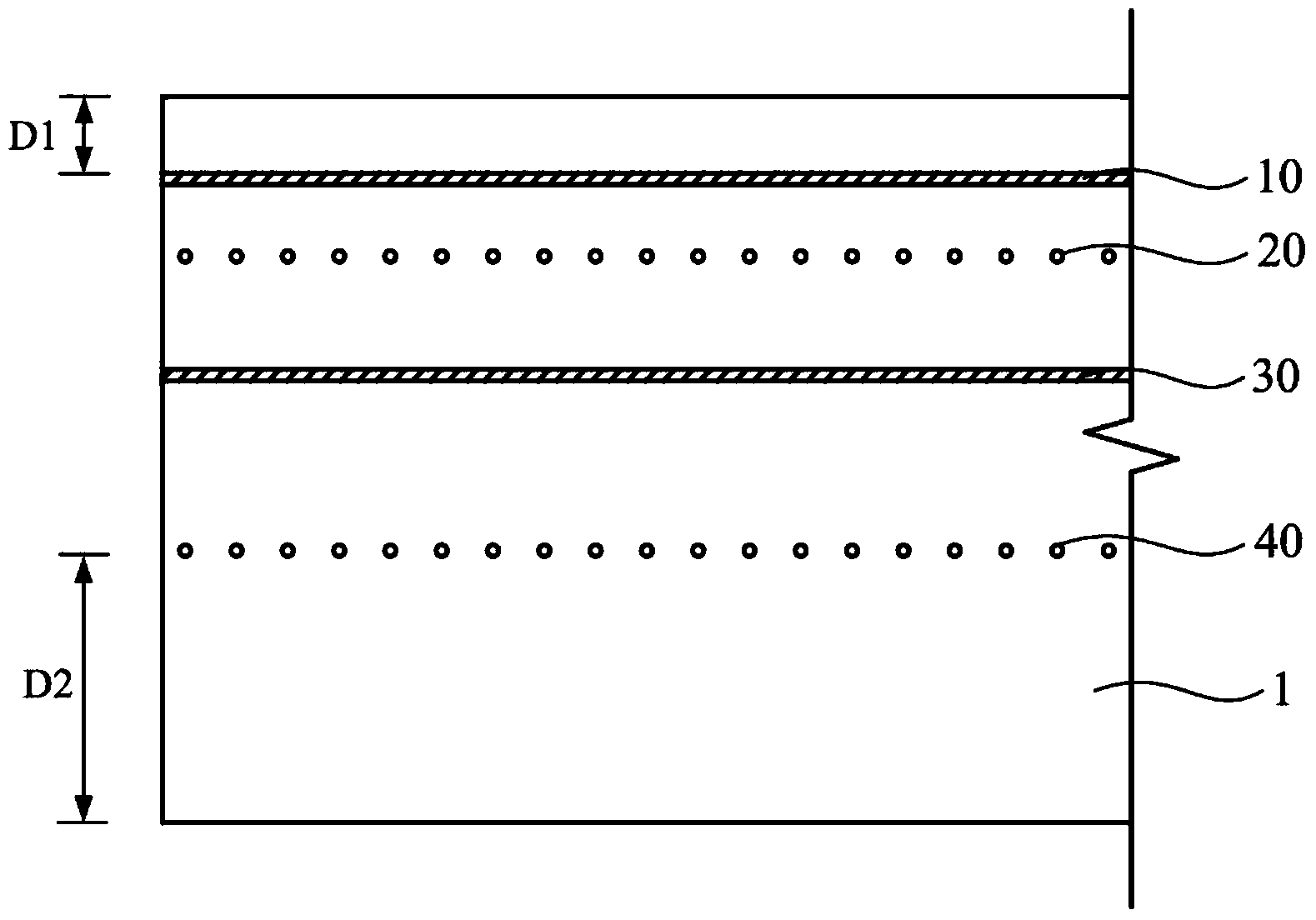

[0028] Example 1: Combining Figure 1 to Figure 3 Illustrate the temperature-controlled cooling system of the large-volume concrete structure of the present invention (the direction of the arrow in the figure is the flow direction of circulating cooling water), which includes a circulating cooling water system, a frequency converter, a central controller, a computer and a plurality of temperature sensors. Among them, multiple temperature sensors are arranged inside the formwork of the mass concrete structure and are connected to the central controller for signals. The central controller is connected to the computer through a communication cable, and the central controller is also connected to the circulating cooling water system through a frequency converter. The circulating cooling water system includes a frequency conversion water pump, a cooling water pipe and a water tank which are connected in sequence to form a loop, and the frequency conversion water pump is connected wit...

Embodiment 2

[0036] Embodiment 2: Combination Figure 1 to Figure 4 Illustrate the cooling control method of mass concrete structure of the present invention, step is as follows:

[0037] S101: Establish a finite element model of the mass concrete structure in the computer, perform grid division, and conduct hydrothermal analysis to obtain the maximum temperature and temperature distribution, and then determine the maximum temperature difference and temperature gradient.

[0038] S102: According to the principle of heat energy exchange, for the purpose of effectively controlling the temperature gradient, initially determine the arrangement proportions of the cooling water pipe units in different temperature regions, and obtain the arrangement plan of the cooling water pipe units. And select the cooling water pipe diameter, flow and other parameters;

[0039] S103: Substituting the information of the above cooling water pipe unit layout plan into the finite element model for simulation, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com