Patents

Literature

87results about How to "Control temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

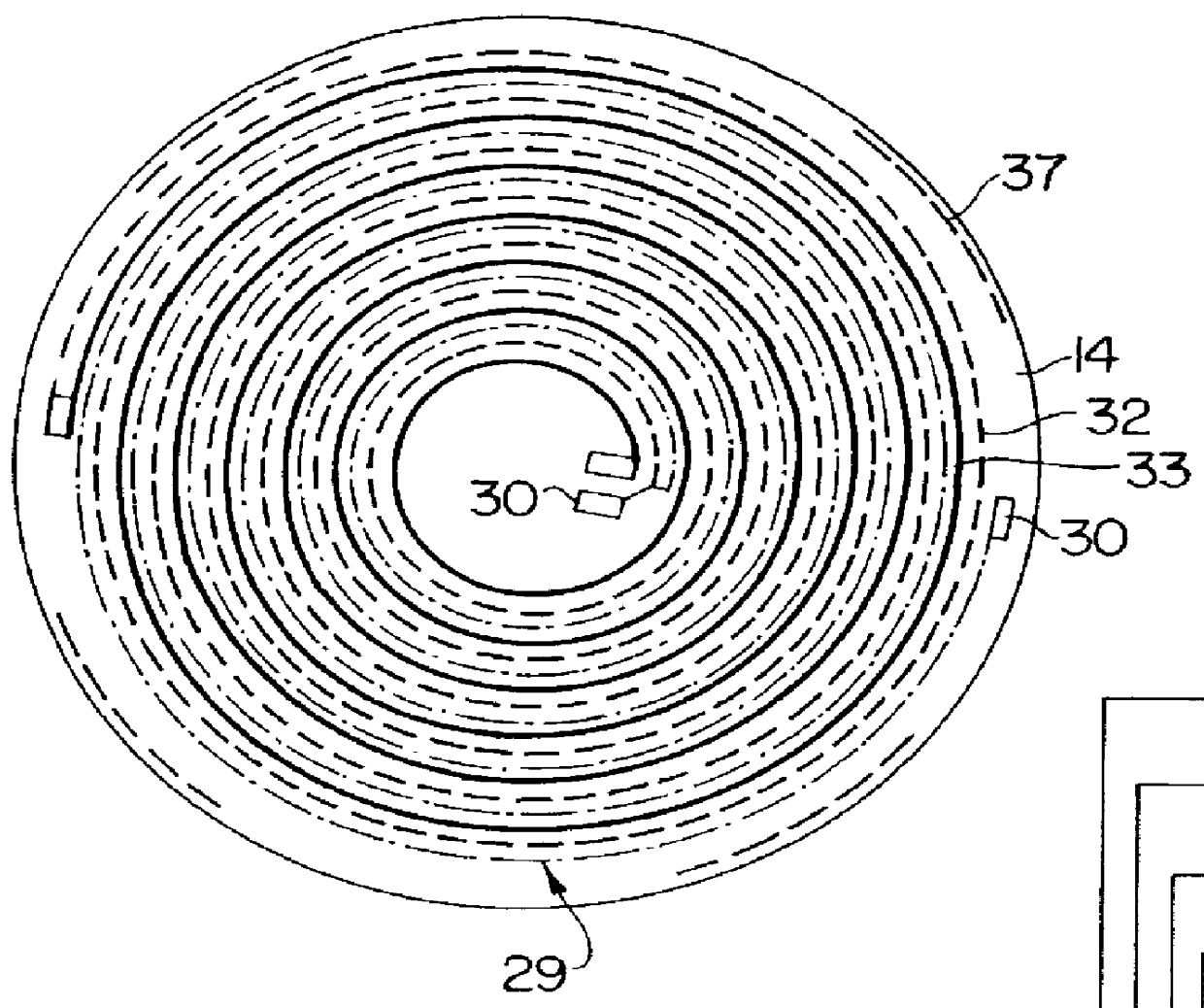

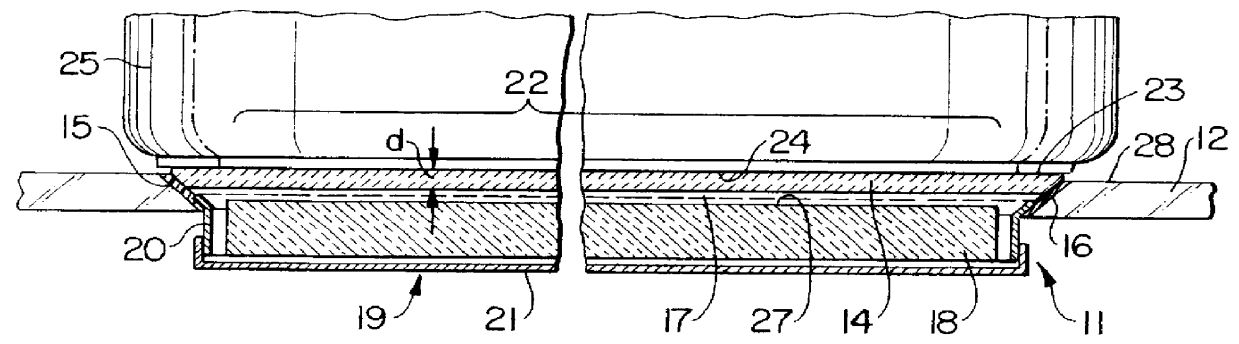

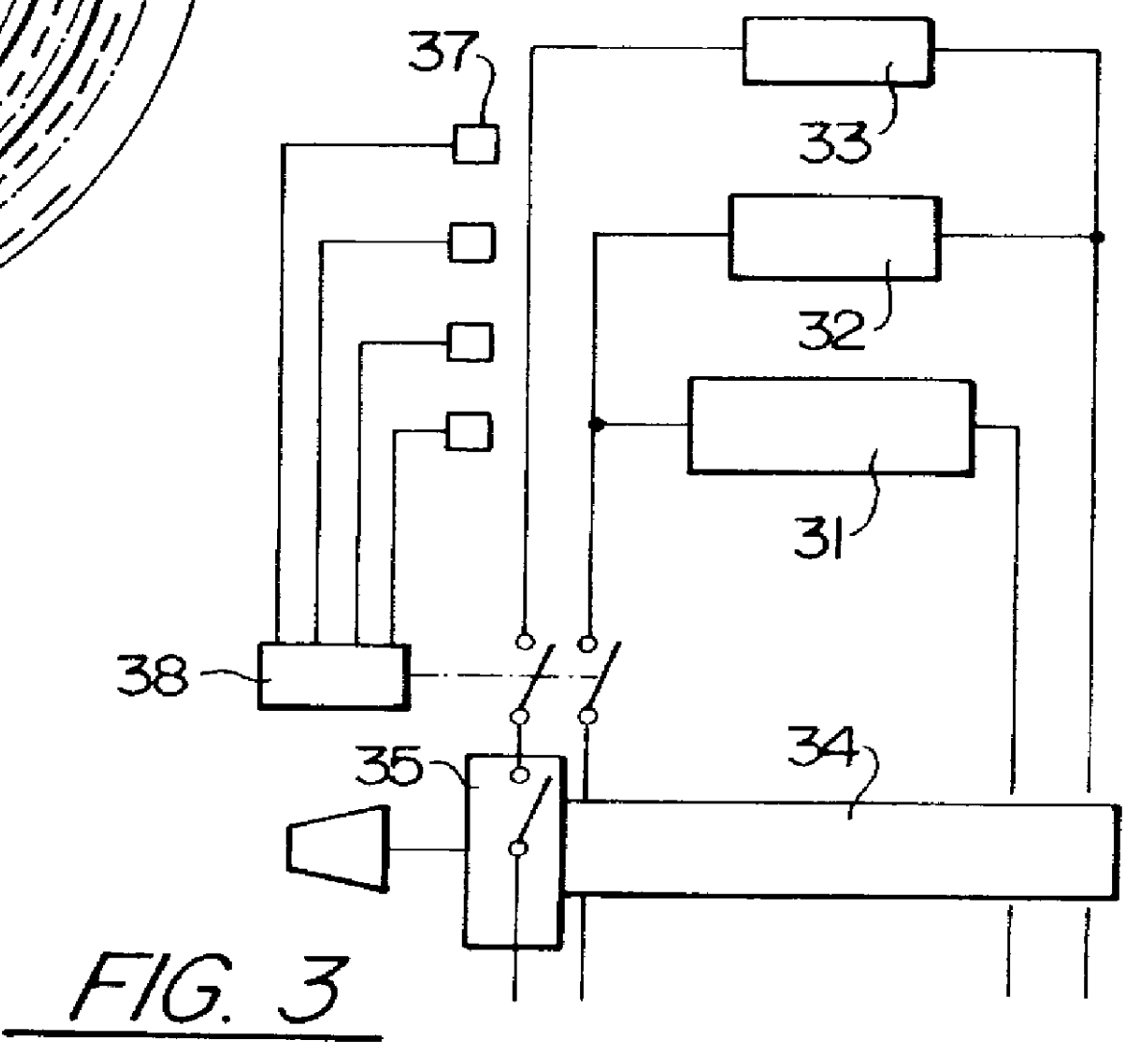

Contact heat-transferring cooking system with an electric hotplate

InactiveUS6150636AImprove heat transfer performanceIncrease temperature differenceCooking-vessel materialsDomestic stoves or rangesCouplingVolumetric Mass Density

A contact heat-transferring electric hotplate (11) is provided, which is made from nonoxidic ceramic, particularly silicon nitride. Its very thin hotplate body (14) in the form of a disk is installed in self-supporting manner in a hob plate, e.g. by bonding, and has an extremely flat surface or which is adapted to the cooking vessel shape, which creates such a small gap with respect to said vessel that a coupling is possible even with higher power densities with only a temperature difference of a few degrees. The heating means (17) is also in contact with or directly connected to the underside of the hotplate body (14).

Owner:E G O ELEKTRO GERAETEBAU GMBH

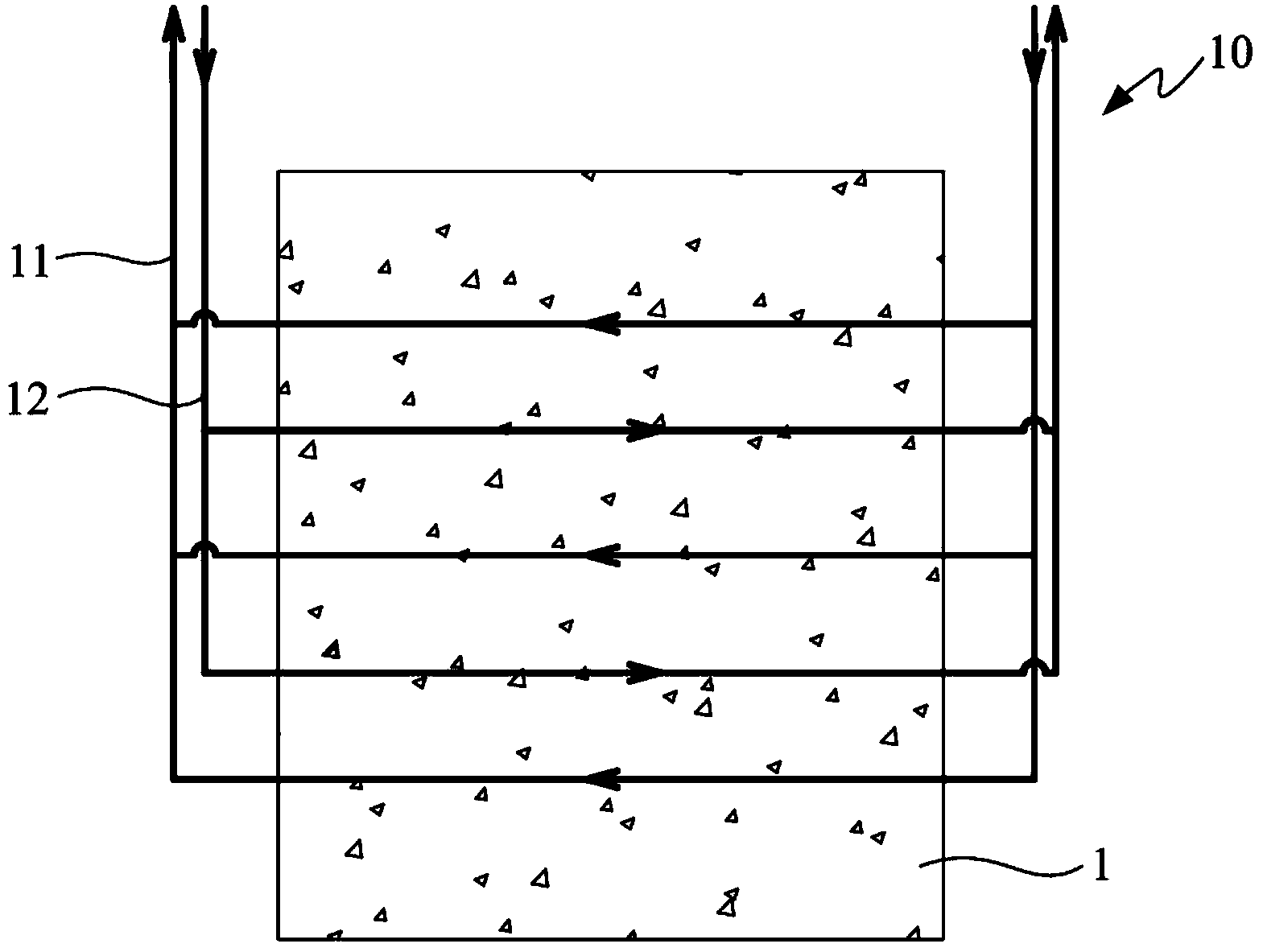

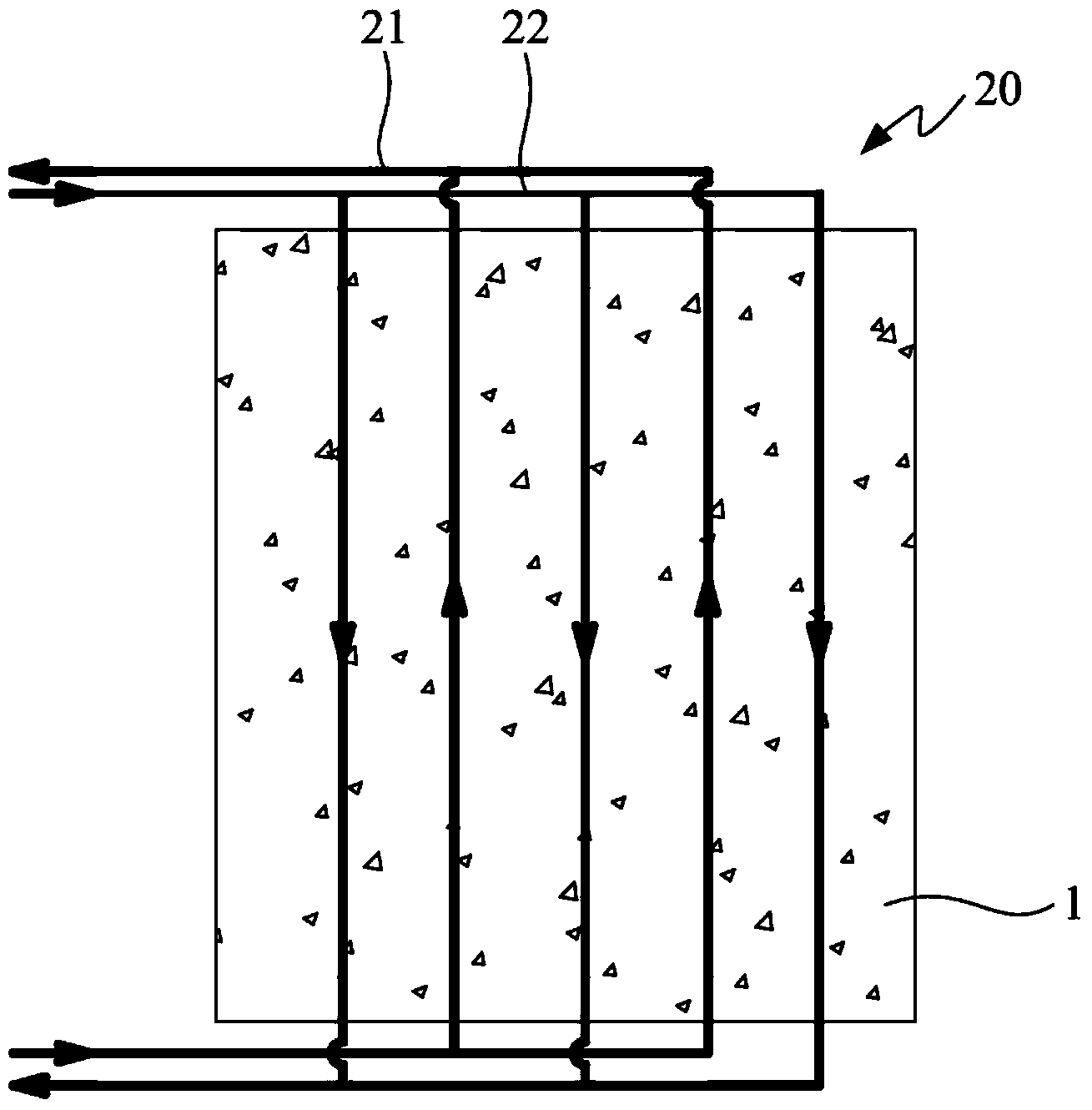

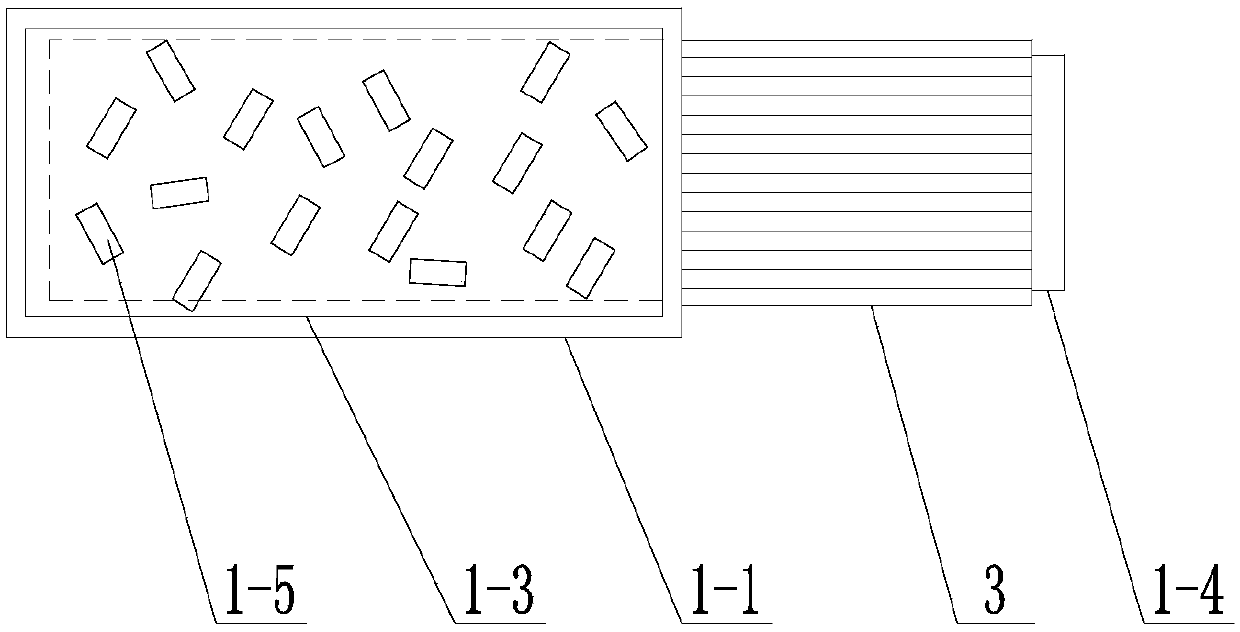

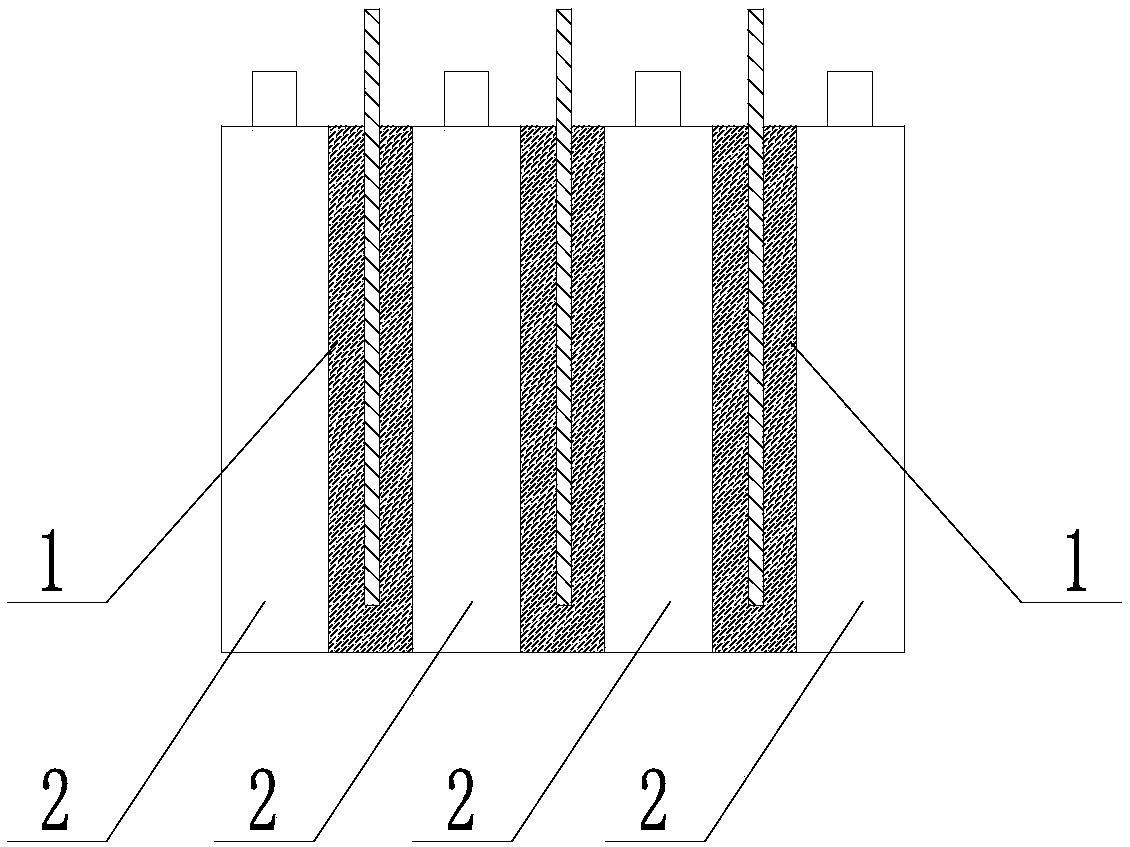

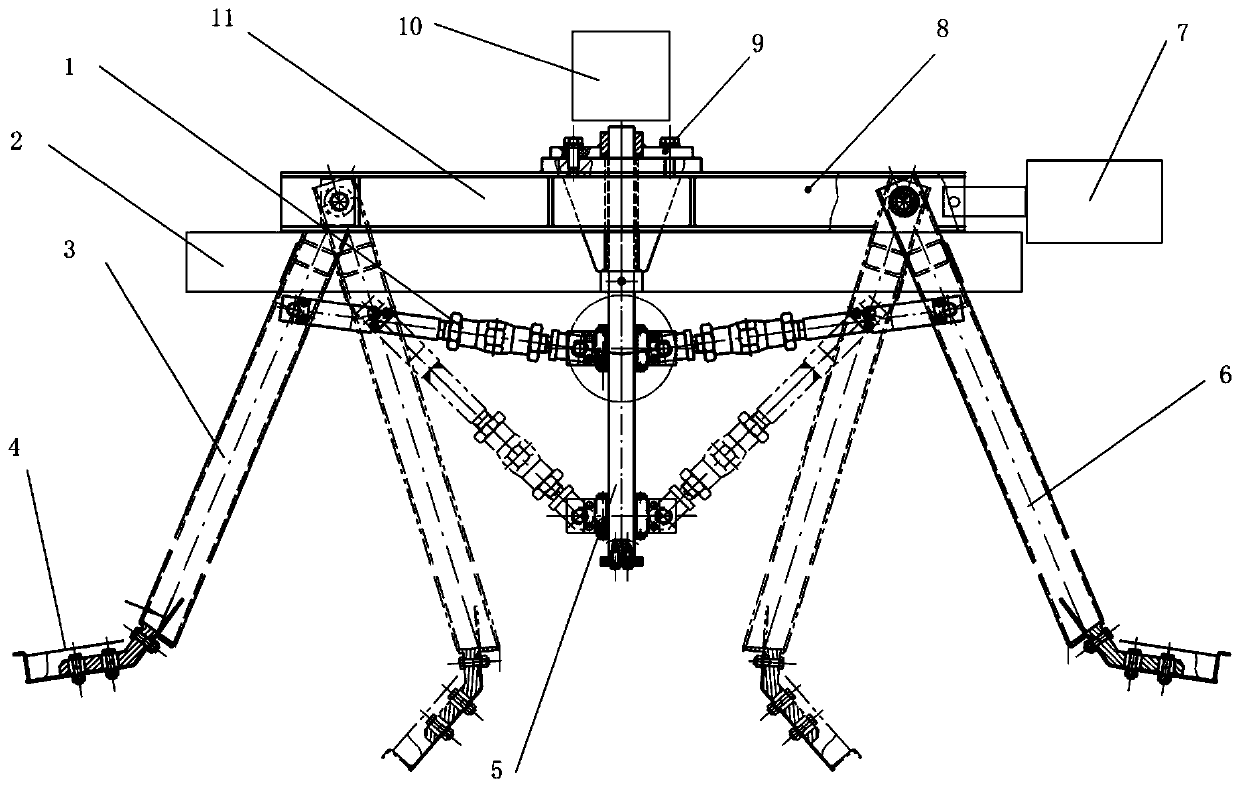

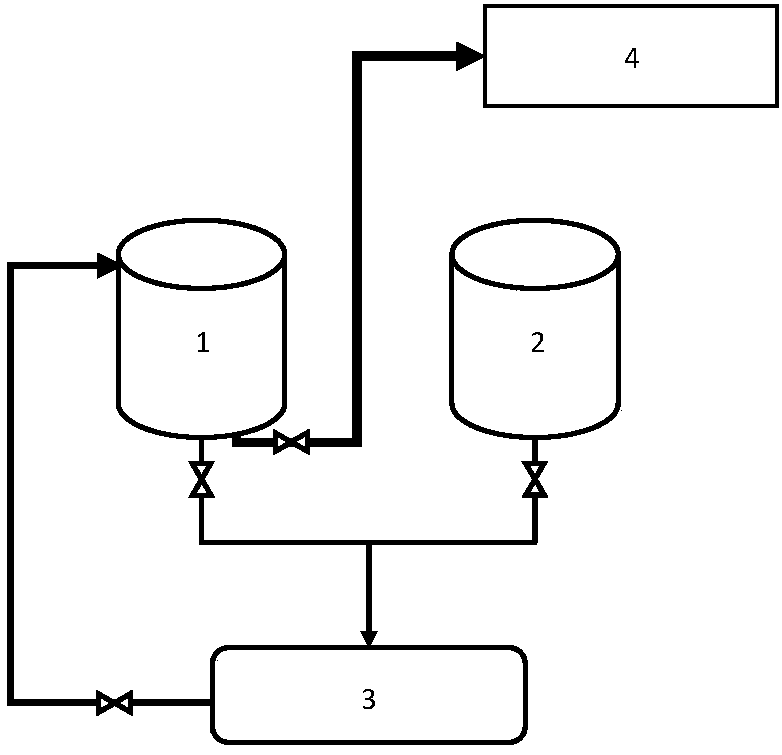

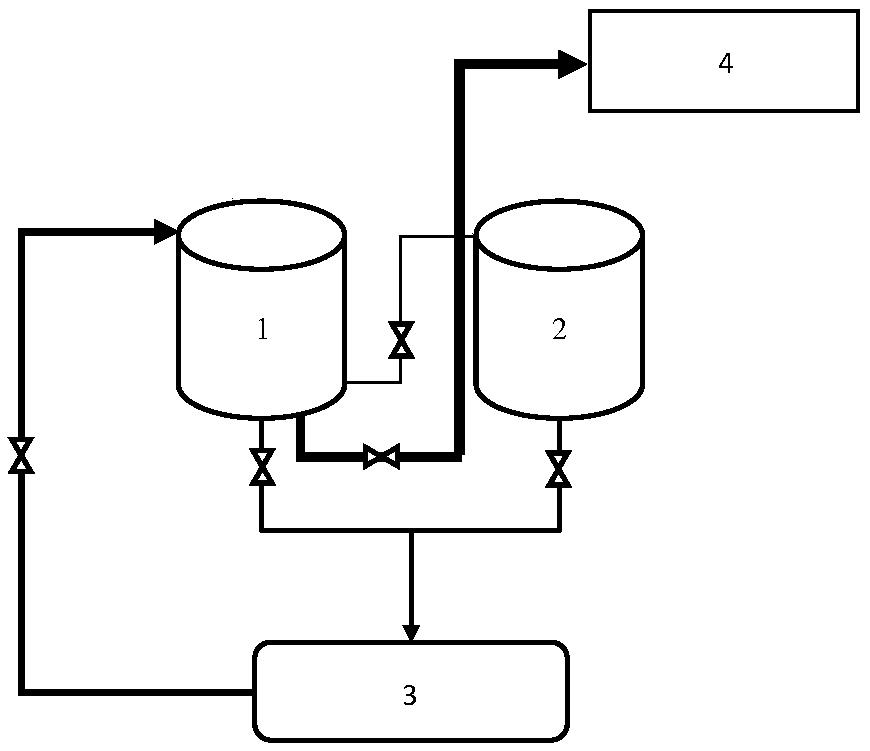

Temperature-control cooling system for large-size concrete structure and cooling control method of temperature-control cooling system

InactiveCN104234431AControl the phenomenon of uneven coolingChange asymmetryBuilding material handlingElement modelEngineering

The invention provides a temperature-control cooling system for a large-size concrete structure and a cooling control method of the temperature-control cooling system, and relates to the technical field of large-size concrete construction by aiming at the problems that in the existing method, the arrangement blindness of cooling pipes is great, the inside temperature distribution rule of the concrete cannot be well combined, and the inside temperature reduction uniformity of the cooling pipes cannot be effectively controlled. Cooling water pipe units are horizontally arranged in a template, and comprise two cooling water pipe groups, the two cooling water pipe groups are staggered and overlapped, the cooling water pipes of the two cooling water pipe groups are parallel and are separately arranged, and the flowing directions of cooling circulation water in the adjacent cooling water pipes are opposite. The method comprises the following steps that 1, a finite element model is created, and in addition, the water thermalization analysis is carried out for judging the highest temperature difference and the temperature gradient; 2, the arrangement scheme of the cooling water pipe units is primarily determined; 3, the information of the arrangement scheme is substituted into the finite element model for analogue simulation, when the judging result is assertive, the construction is carried out according to the arrangement scheme, and when the judging result is negative, the arrangement and the flow rate of the cooling water pipe units are regulated until the requirements are met.

Owner:SHANGHAI CONSTRUCTION GROUP

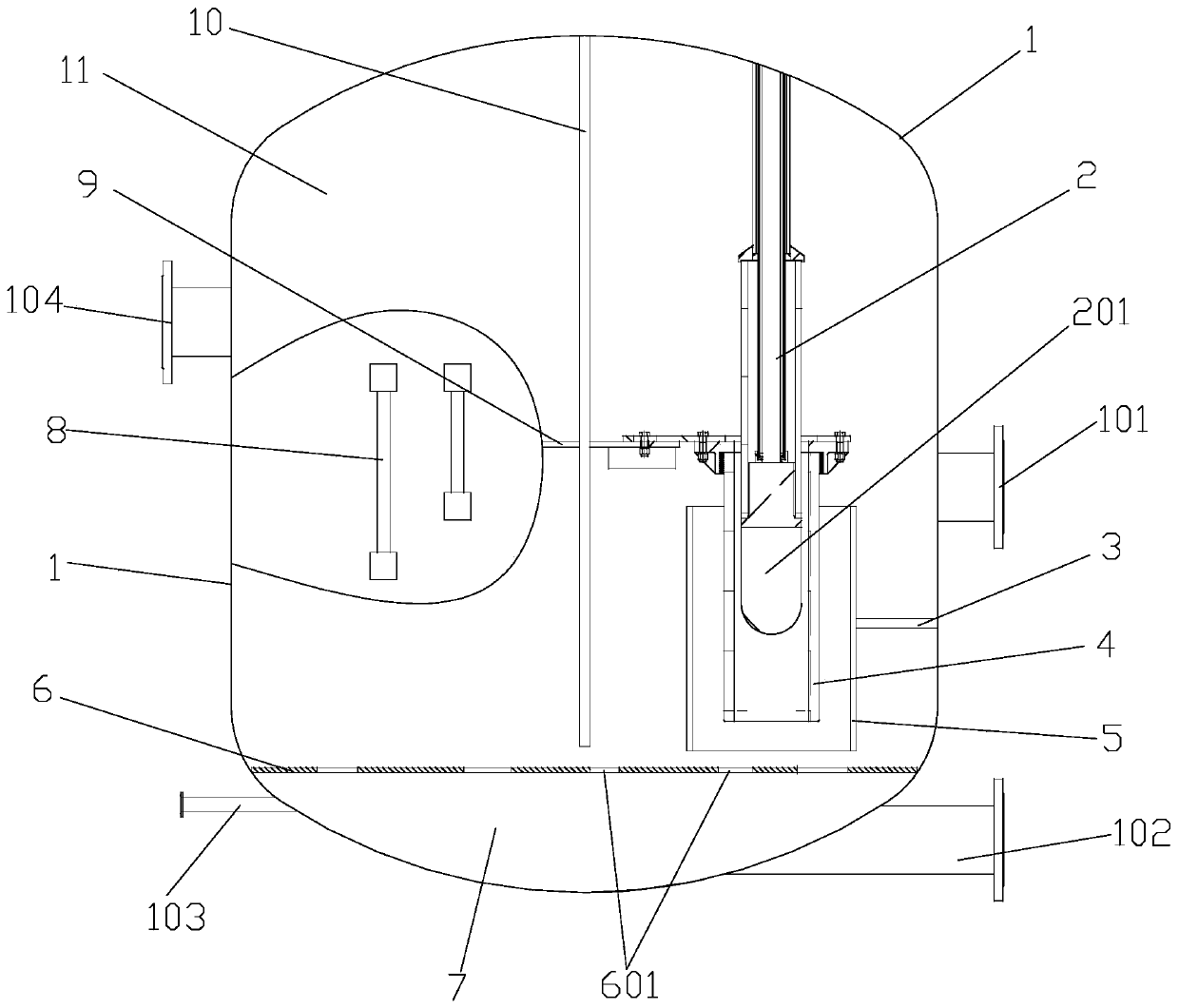

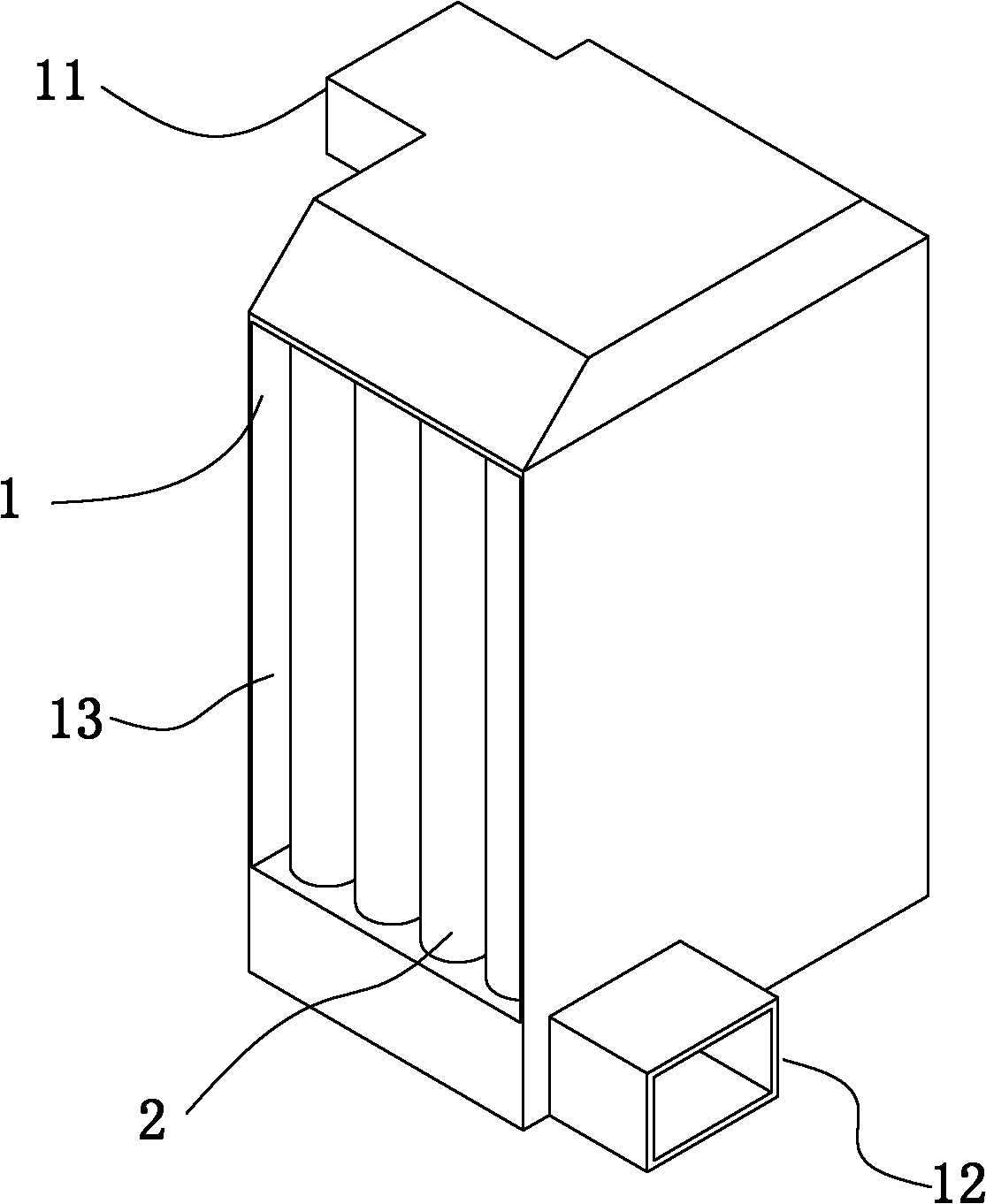

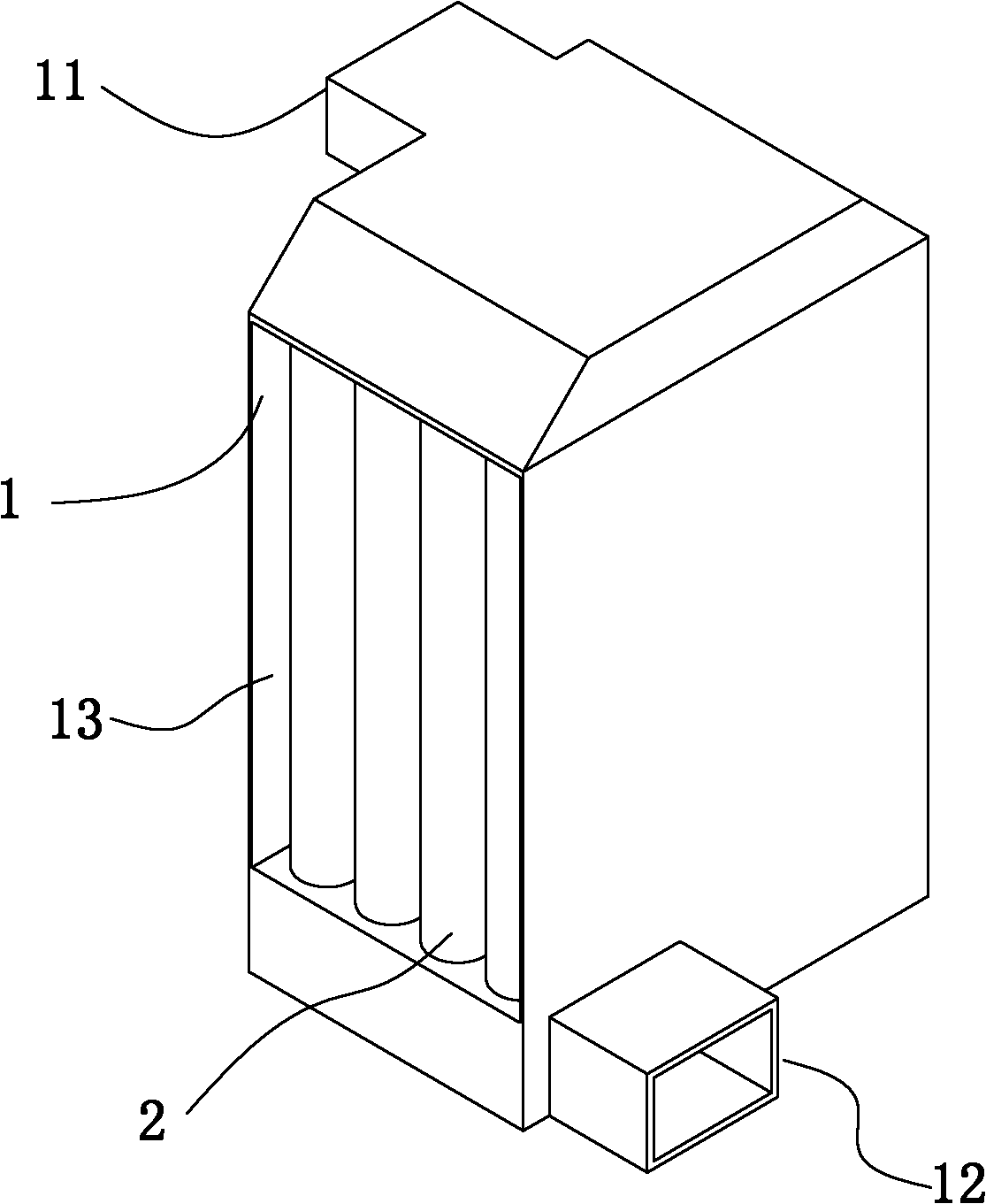

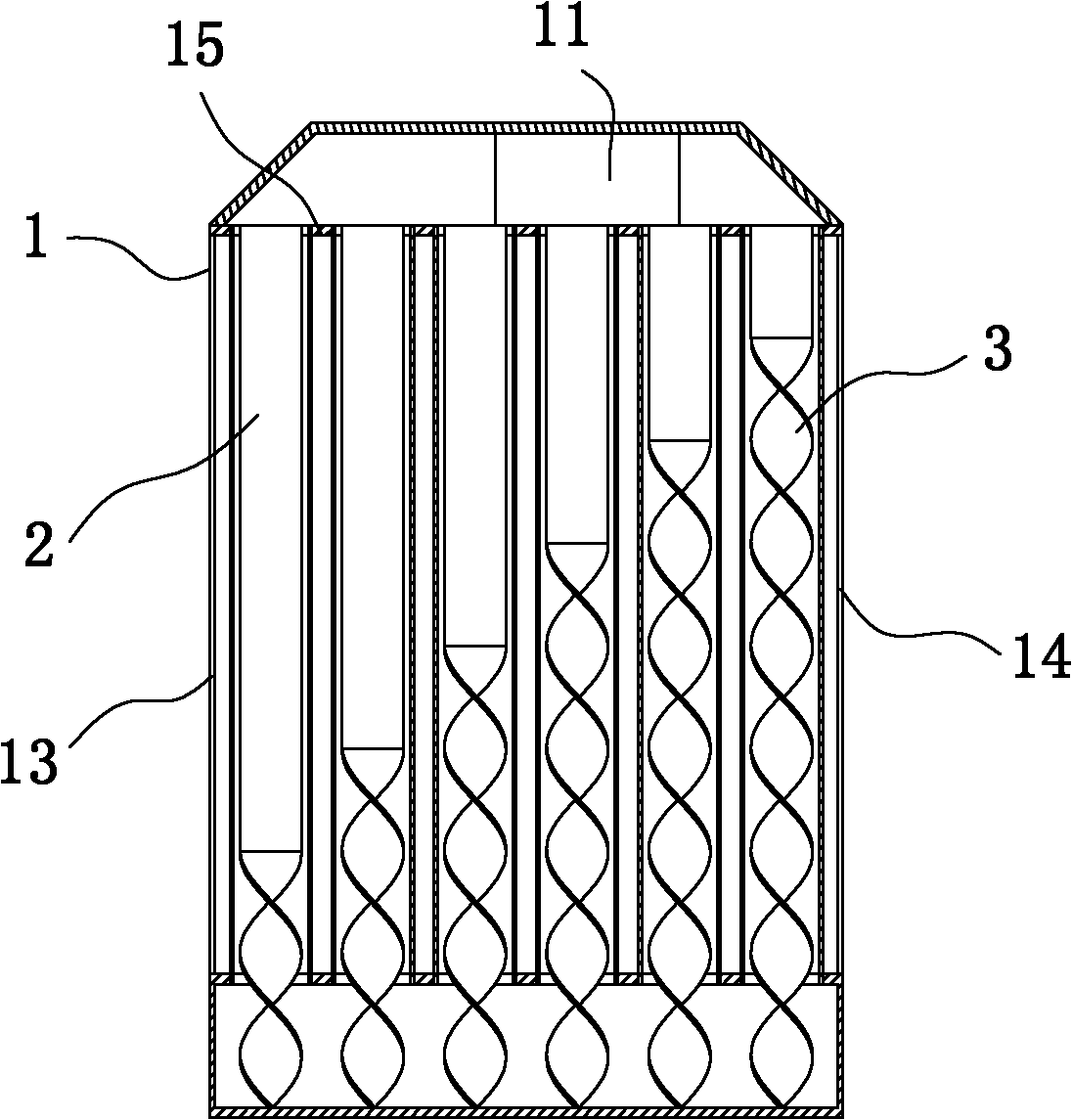

Fully submerged electrode steam boiler with circulating device

PendingCN110375286AMonitor water levelControl temperature differenceElectrode boilersSteam boilers componentsEngineeringLower half

The application discloses a fully submerged electrode steam boiler with a circulating device. The steam boiler comprises a boiler shell, a partition plate and a heating device; the partition plate isarranged in the boiler shell and divides the boiler shell into a lower half cavity and an upper half cavity which are independent and communicates with each other; the heating device is arranged in the upper half cavity; the lower half cavity is provided with a water replenishing port, and the upper half cavity is provided with a first outlet. The steam boiler also comprises a circulating water inlet, a circulating water outlet and a circulating power device; the circulating water inlet is arranged on the lower half cavity; the circulating water outlet is arranged on the upper half cavity; thecirculating power device is respectively connected with the circulating water inlet and the circulating water outlet; and the circulating power device is used for conveying the water in the upper half cavity to the lower half cavity.

Owner:ZHEJIANG SHANGNENG BOILER

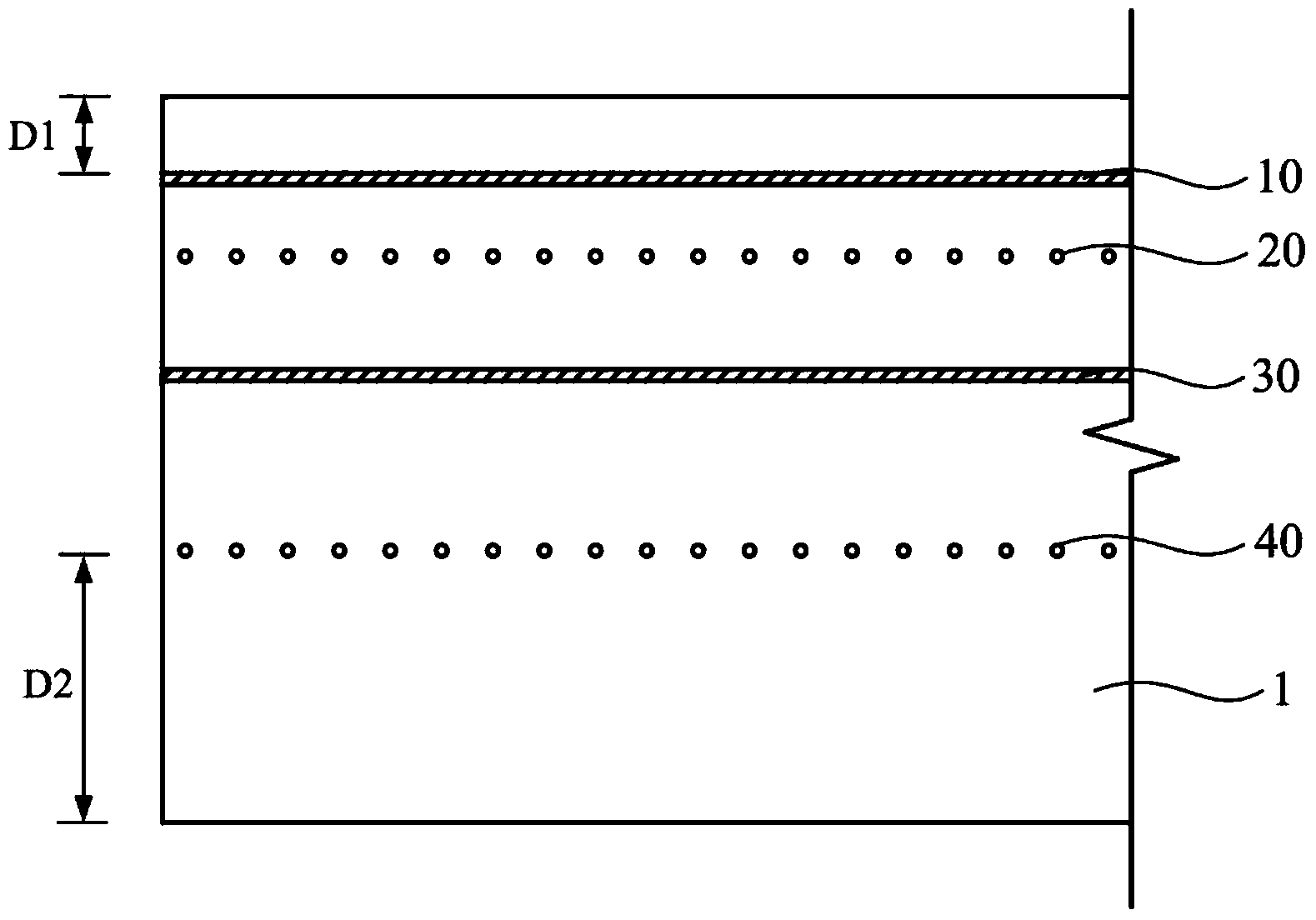

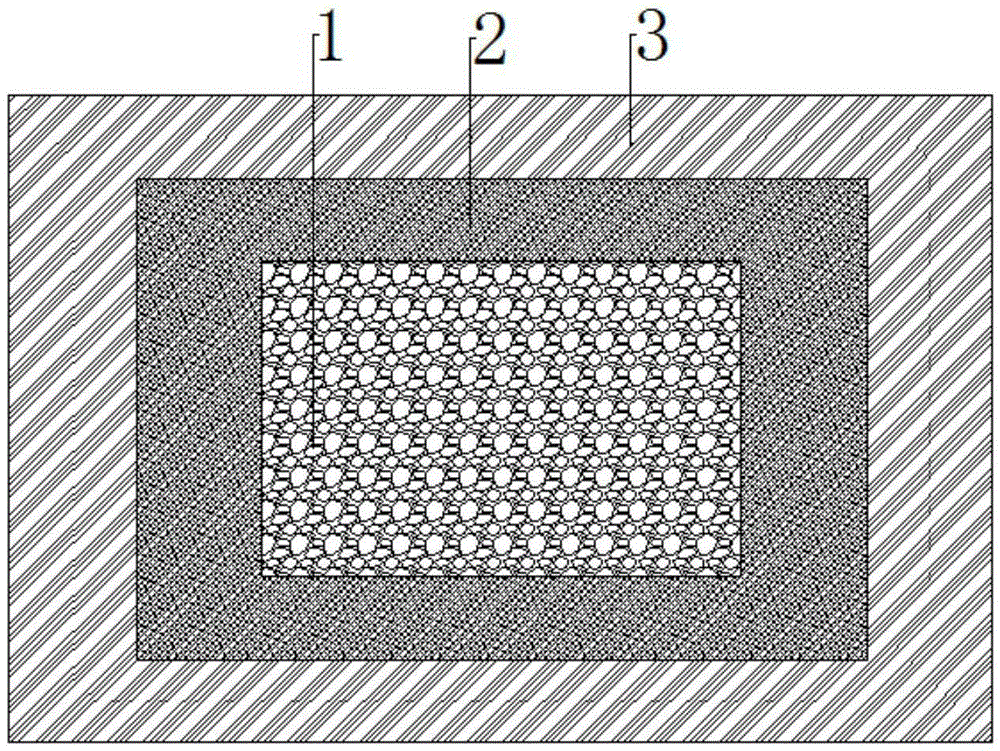

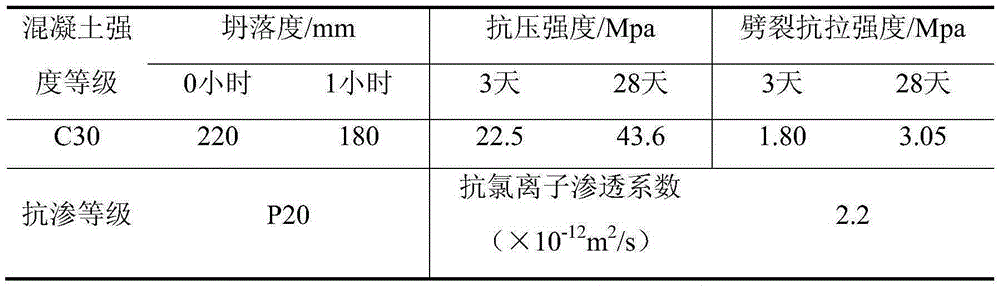

Temperature gradient controlled mass concrete for bridges

ActiveCN105418006AImprove densification performanceLimit crackingBridge engineeringMaterials science

The invention discloses a temperature gradient controlled mass concrete for bridges. The mass concrete comprises an inner layer of low-temperature rise anti-crack concrete I, a middle layer of low-temperature rise anti-crack concrete II and an outer layer of high-tenacity high-crack resistance concrete from the inside to the outside. According to the mass concrete disclosed by the invention, under combination of the low-temperature rise anti-crack concrete (the inner layer of low-temperature rise anti-crack concrete I and the middle layer of low-temperature rise anti-crack concrete II) and the high-tenacity high-crack resistance concrete structure, hydration heat of cementing materials on various layers is respectively absorbed through the characteristics of a high phase-transition temperature of a composite temperature control material in the inner layer of low-temperature rise anti-crack concrete and a low phase-transition temperature of a composite temperature control material in the middle layer of low-temperature rise anti-crack concrete; the inside and the middle temperatures of the concrete are lowered; meanwhile, different thicknesses and layout forms of two concrete materials are optimized and designed; reduction of the temperature difference between the layers is achieved; the overall temperature stress level is reduced; the technical problem of crack of the mass concrete widely existing in bridge engineering can be effectively solved; and the temperature gradient controlled mass concrete for the bridges is applicable to popularization and application.

Owner:HUBEI UNIV +1

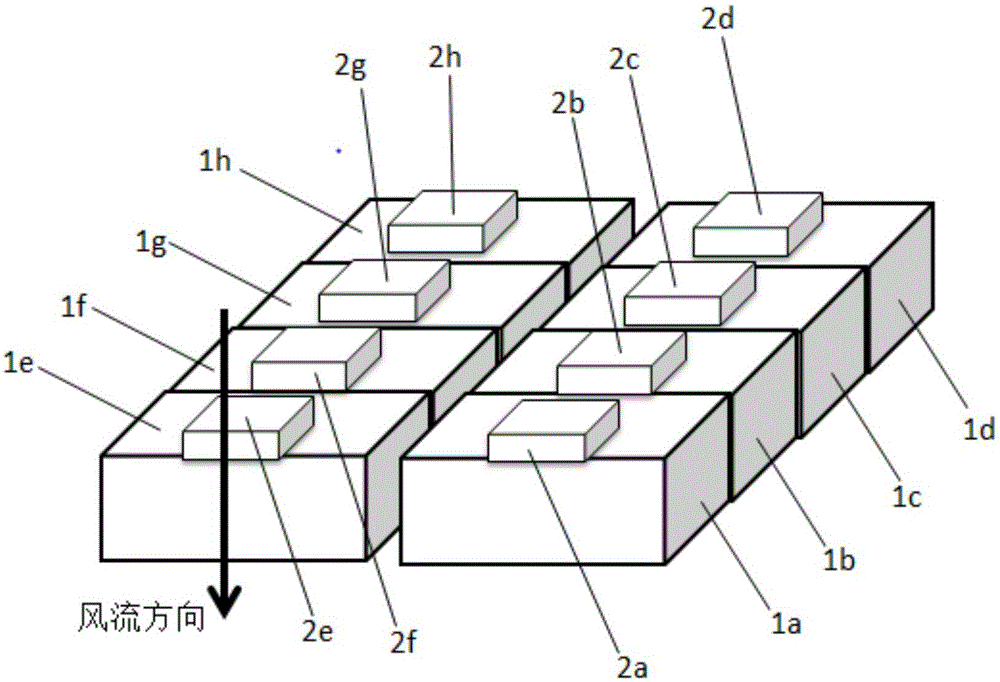

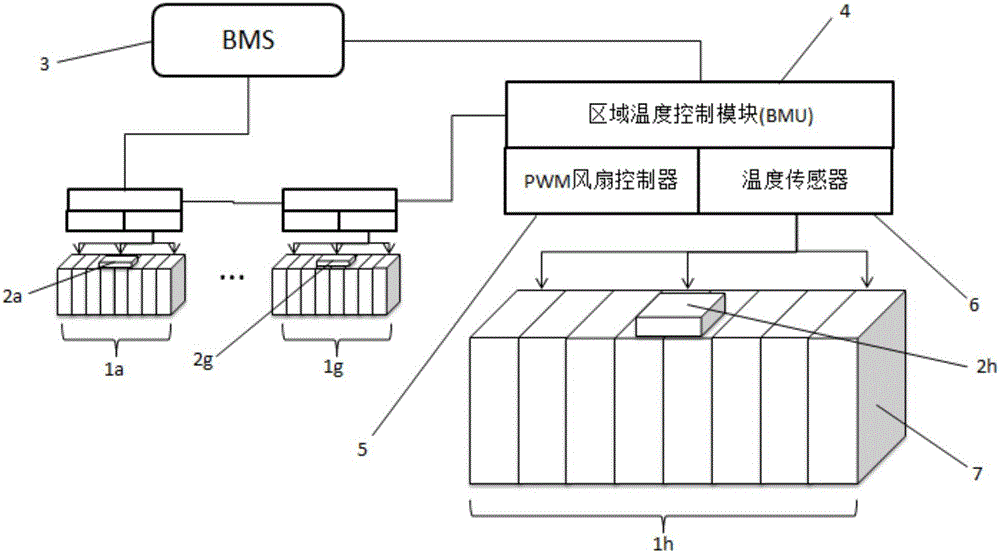

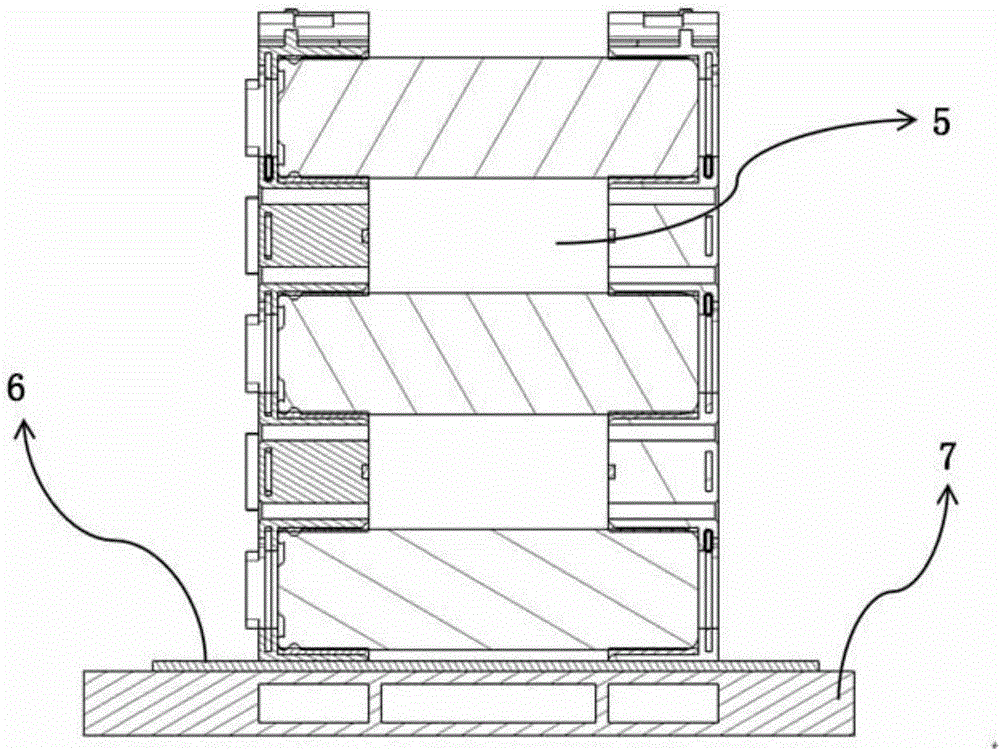

Heat dissipation device and method for power battery pack

InactiveCN105070975AThe problem of lifespan is effectively maintainedControl temperature differenceSecondary cellsBatteriesPower batteryElectrical battery

The invention discloses a heat dissipation device and method for a power battery pack. The battery pack comprises multiple battery modules (1) which are mutually connected and a main control unit BMS (3). The heat dissipation device for the power battery pack is characterized in that each battery module (1) is provided with a heat dissipation fan (2), and meanwhile each battery module (1) is further provided with a temperature controller correspondingly; each temperature controller comprises a battery module control unit (BMU) (4), a PMW fan controller (5) and a temperature sensor (6); each battery module control unit (BMU) (4) collects a battery module (1) temperature signal detected by the corresponding temperature sensor (6), the corresponding heat dissipation fan (2) is controlled to work through the corresponding PMW fan controller (5) according to the temperature signal, and therefore the temperature of the corresponding battery module (1) is controlled. The method can control temperature differences among the battery modules in the battery pack and conduct self temperature protection. The problem that the service life of batteries is affected by the temperature differences among the battery modules caused by uneven battery pack temperature fields and flow fields is solved.

Owner:BEIJING SHANXIN DINGZHONG TECH

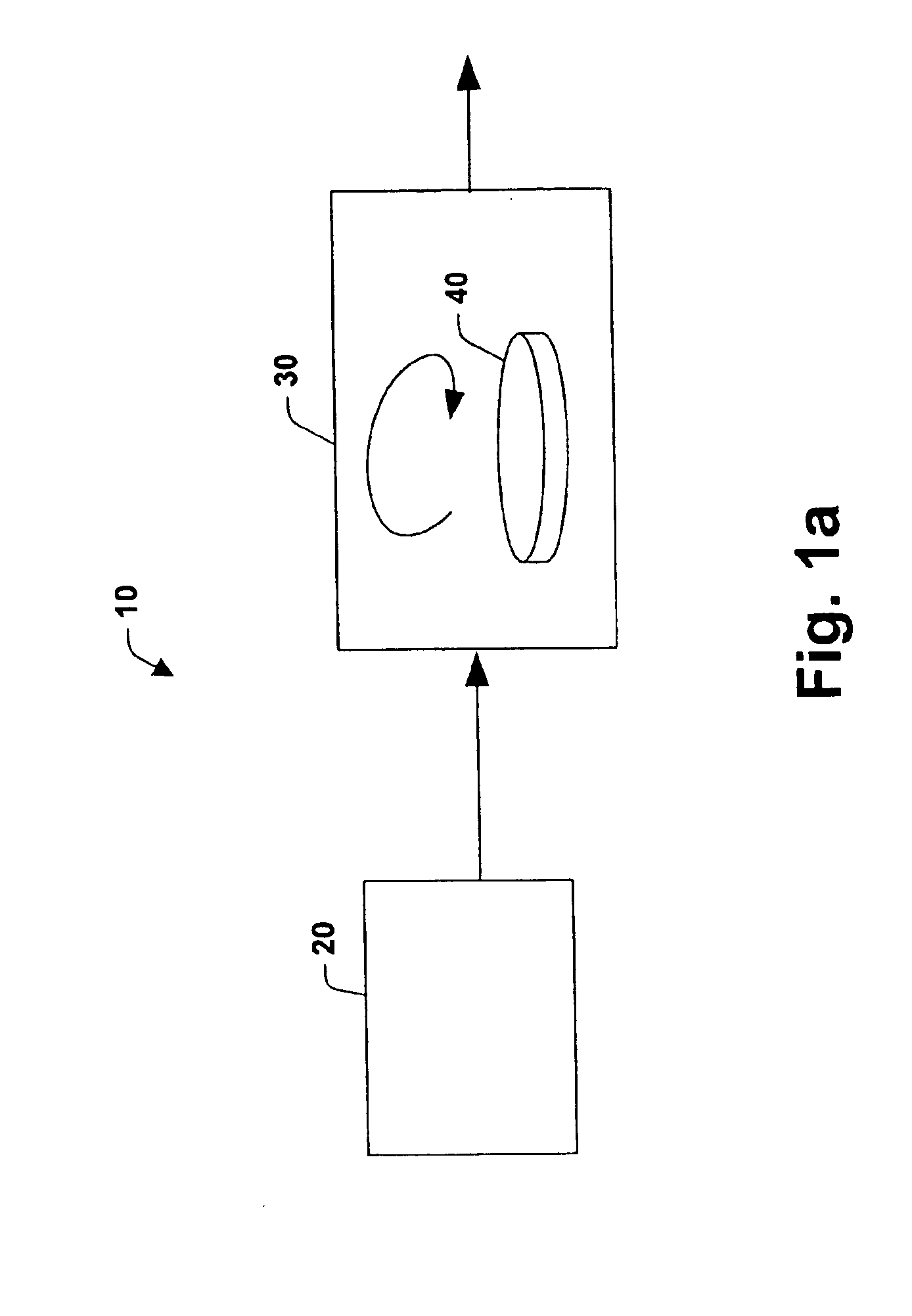

System for rapidly and uniformly cooling resist

InactiveUS6889763B1Temperature differenceCool evenlySpace heating and ventilation safety systemsSpace heating and ventilation control systemsResistAtmospheric air

Resist coated wafers are rapidly and uniformly cooled by a fluid that has been cooled through the Joule-Thompson effect. Fluid from a high pressure reservoir is vented into a chamber that contains the substrates. By varying the pressure difference between the reservoir and the chamber, the temperature of the cooling fluid entering the chamber can be controlled. By also controlling the flow rate through the chamber, the average temperature difference between the fluid in the chamber and the substrates may be limited, whereby more uniform cooling is obtained. While the chamber pressure is lower than that in the high pressure reservoir, the chamber pressure may still be substantially greater than atmospheric. An elevated chamber pressure raises the specific heat and residence time of the fluid in the chamber, which also promotes uniform cooling.

Owner:ADVANCED MICRO DEVICES INC

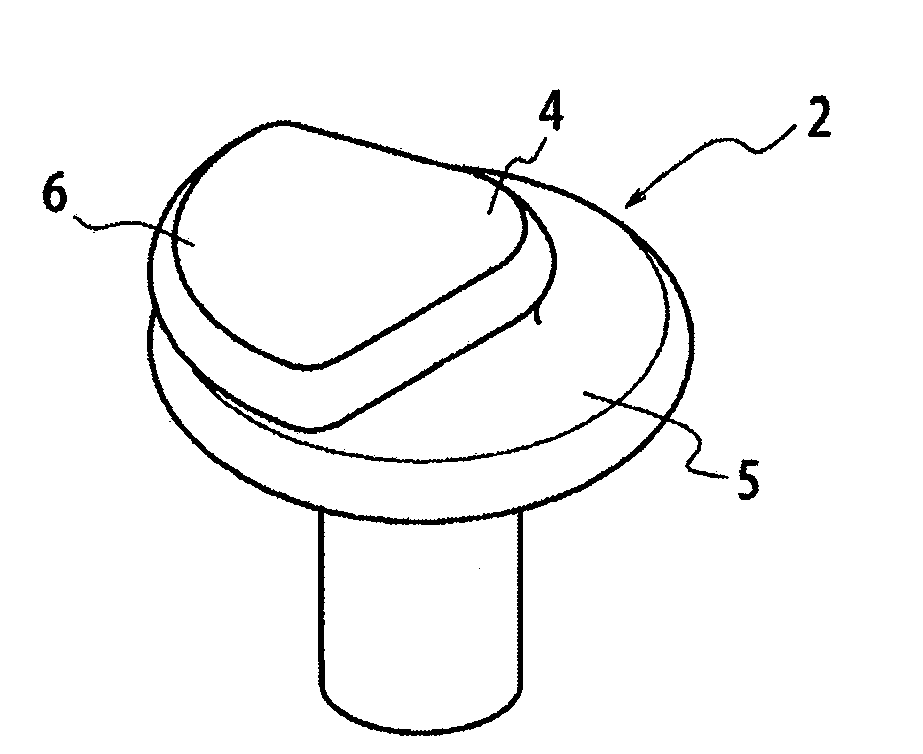

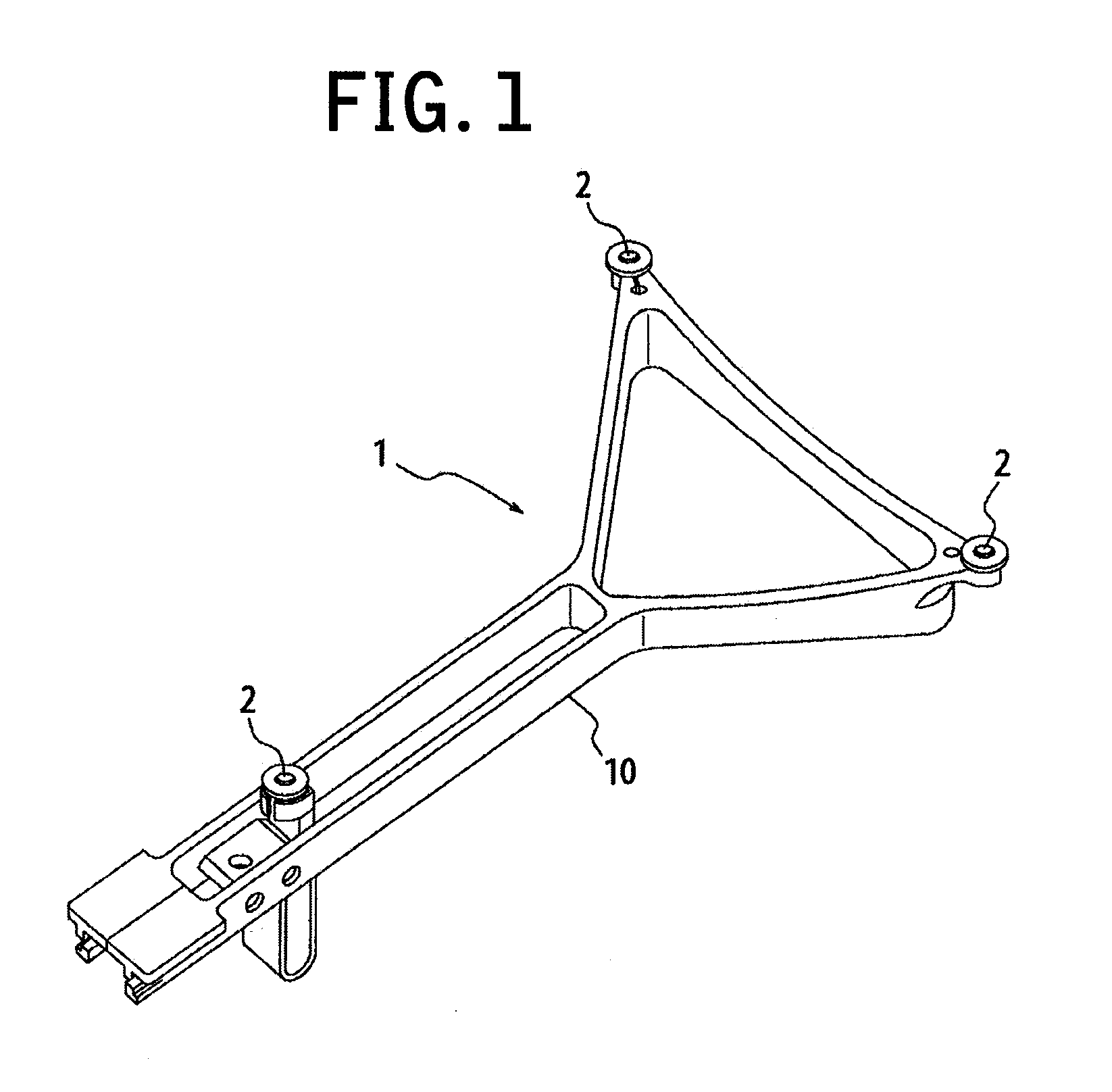

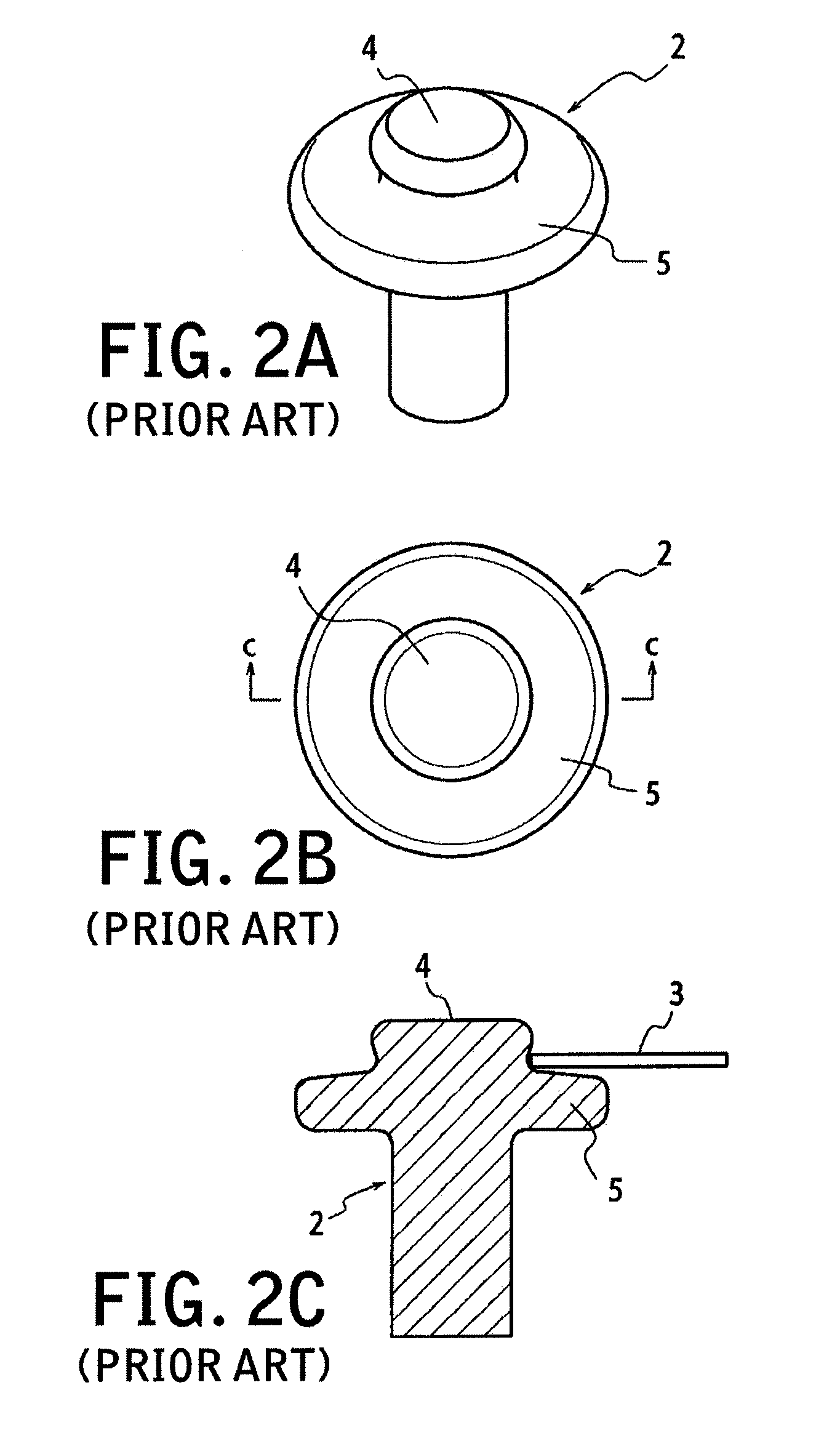

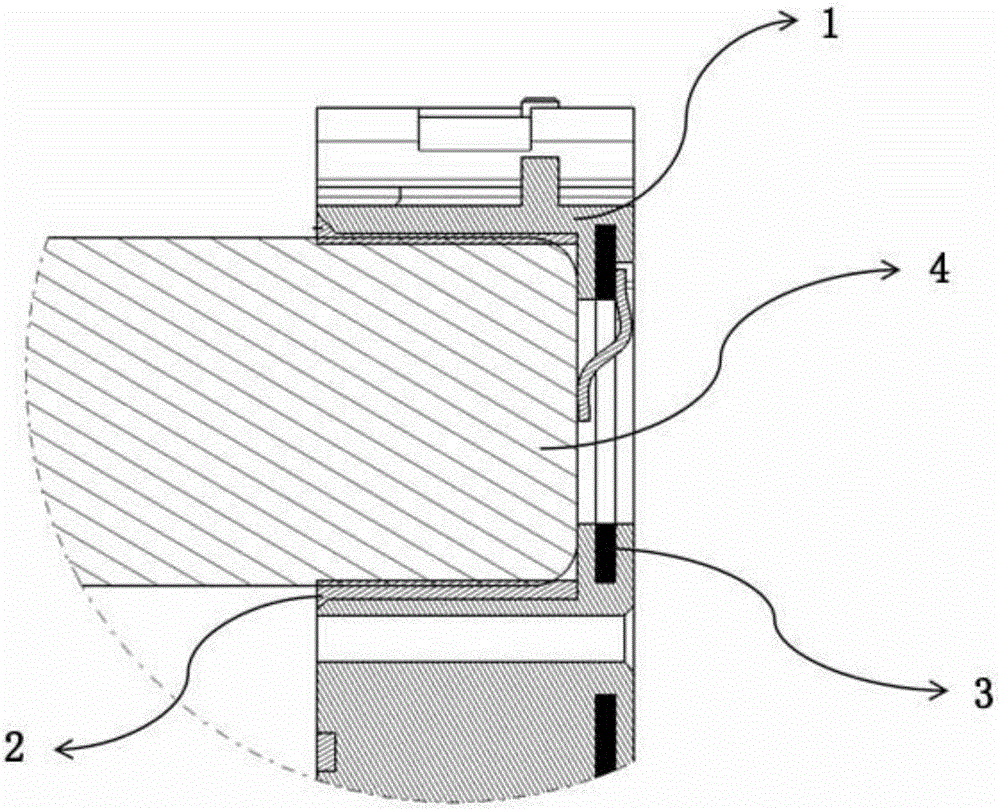

Wafer holding tool for ion implanting apparatus

ActiveUS20100012856A1Avoid temperature differenceControl temperature differenceSleeve/socket jointsMaterial analysis using wave/particle radiationTemperature differenceIrradiation

A wafer holding assembly is provided that is capable of preventing the temperature difference generated between a wafer and a holding pin through beam irradiation.In one embodiment, the wafer holding assembly has a plurality of holding pins for holding a wafer in the ion implanting apparatus, the holding pin comprises a head contacting with an end face of the wafer to control motion of the wafer and a flange projecting from the head to place the wafer, and the head is provided with a canopy portion extending in a direction different from a side placing the wafer.

Owner:SUMCO CORP

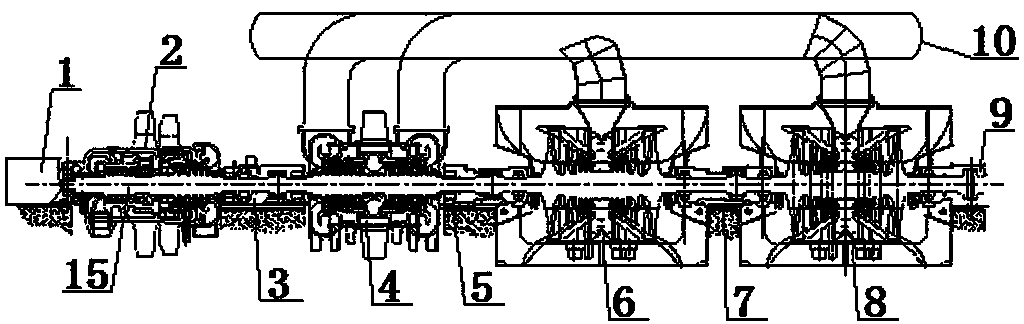

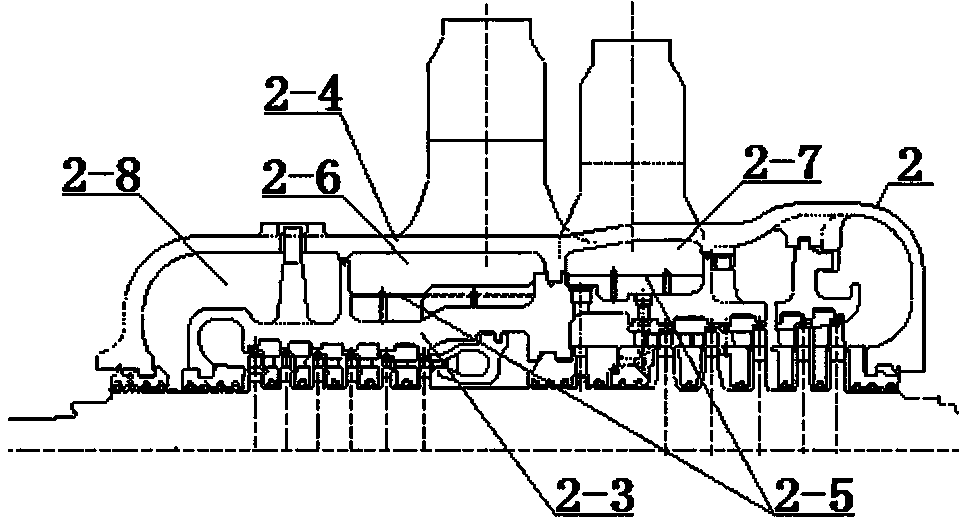

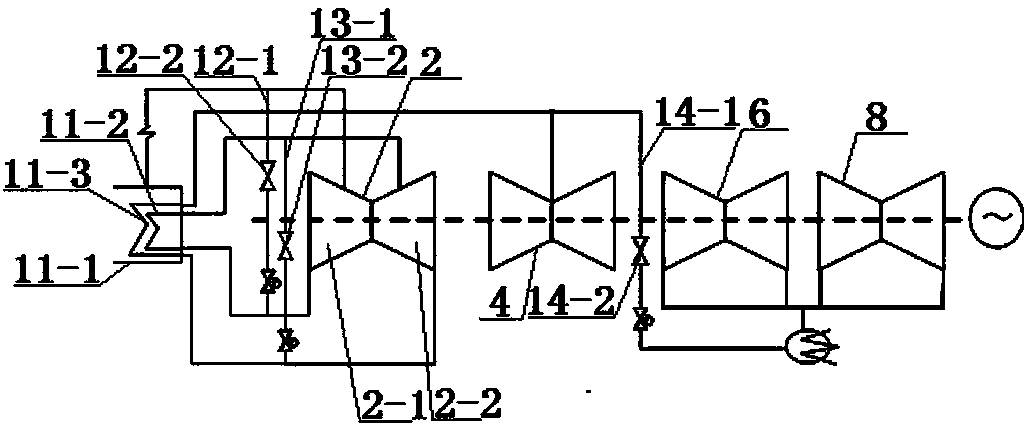

Ultra-supercritical secondary re-heating steam turbine set

InactiveCN103670550ADoes not affect safety and reliabilityDoes not affect runnabilityEngine componentsSteam engine plantsUltra high pressureEngineering

The invention discloses an ultra-supercritical secondary re-heating steam turbine set. The ultra-supercritical secondary re-heating steam turbine set comprises a first bearing box, an ultra high pressure-high pressure cylinder, a second bearing box, a medium-pressure cylinder, a third bearing box, a first low-pressure cylinder, a fourth bearing box, a second low-pressure cylinder and a turning gear box which are assembled on a rotor in sequence. The capacity of the steam turbine set is 1000-1300MW, the ultra high pressure-high pressure cylinder is of a cylinder combined structure, the pressure of a steam inlet of an ultra high pressure part is 30-35MPa, the temperature is 600 DEG C, the pressure of a primary re-heating steam inlet of a high pressure part is 10MPa, the temperature is 610-630 DEG C, the medium-pressure cylinder, the first low-pressure cylinder and the second low-pressure cylinder are respectively of a double-flow-division structure, the medium-pressure cylinder provides steam for the first low-pressure cylinder and the second low-pressure cylinder respectively through communication pipes, the pressure of a secondary re-heating steam inlet of the medium-pressure cylinder is 2.8MPa, and the temperature is 610-630 DEG C. The ultra-supercritical secondary re-heating steam turbine set has the advantages of being large in capacity, high in parameter, small in occupied space, low in investment cost, stable and reliable in operation and obvious in economical benefit, saving energy, reducing consumption and the like.

Owner:DONGFANG TURBINE CO LTD

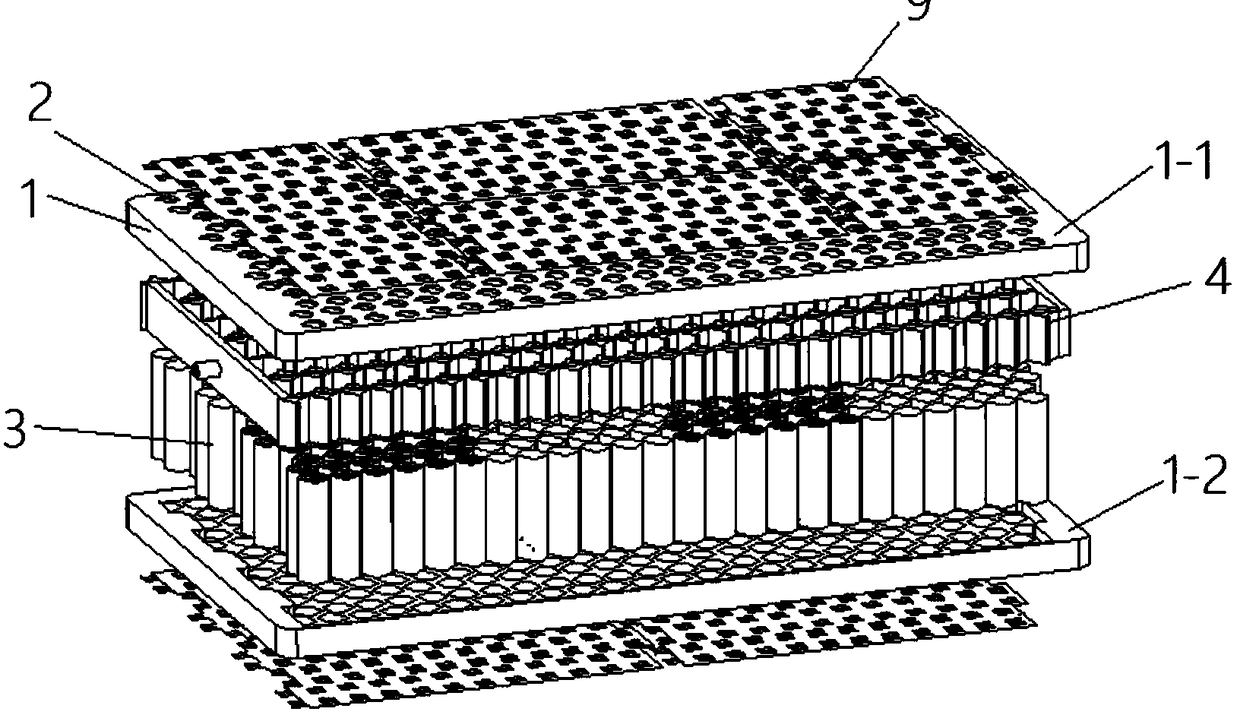

Heat dissipating structure of cylindrical battery module

InactiveCN105977423AEnough cooling areaImprove cooling efficiencySecondary cellsCell component detailsHeat conductingBusbar

The invention relates to a heat dissipating structure of a cylindrical battery module. The heat dissipating structure comprises a fixing bracket, batteries and a busbar, wherein the batteries are mounted on the fixing bracket and are distributed in parallel, and the busbar is integrated into the fixing bracket; the fixing bracket is made from heat-conducting plastics, and a heat conducting block structure is formed, so that two poles of each battery are fixedly arranged in a heat conducting block separately; the busbar is of a heat conductor, and the heat conductor is embedded in the heat conducting block. According to the heat dissipating structure, a battery mounting bracket is made from a heat conducting material, so that the batteries have a sufficient heat dissipating area, and the heat dissipating efficiency is relatively high; the metallic busbar inside the battery bracket is also used for conducting heat, and the overall temperature difference of the battery bracket can be controlled while heat is transferred rapidly due to the high heat conductivity of the battery bracket, so that the concentration of heat cannot be caused; a liquid cooling plate is additionally arranged outside the battery module, so that the heat dissipating effect is improved.

Owner:上海星历新能源科技有限公司

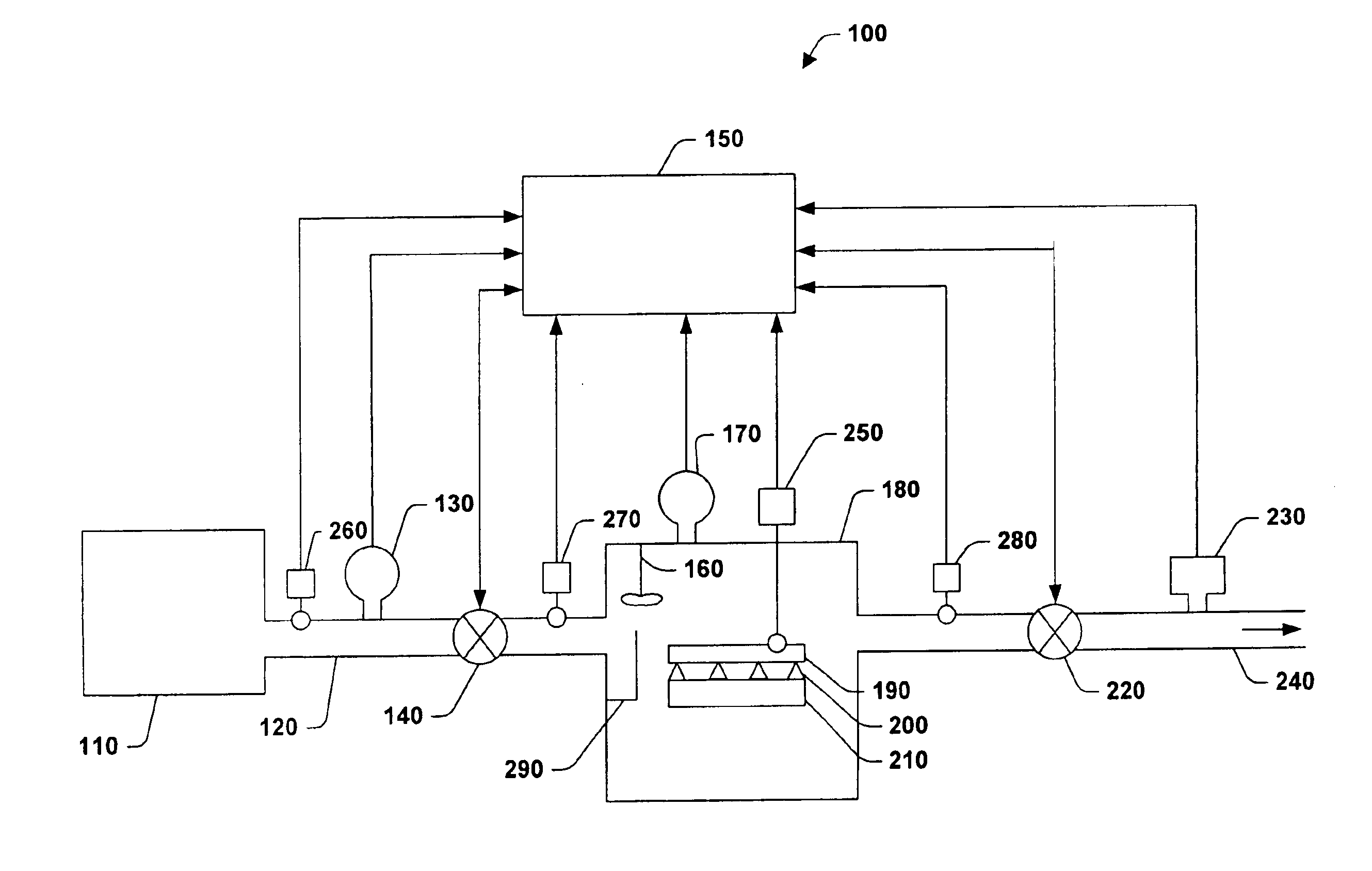

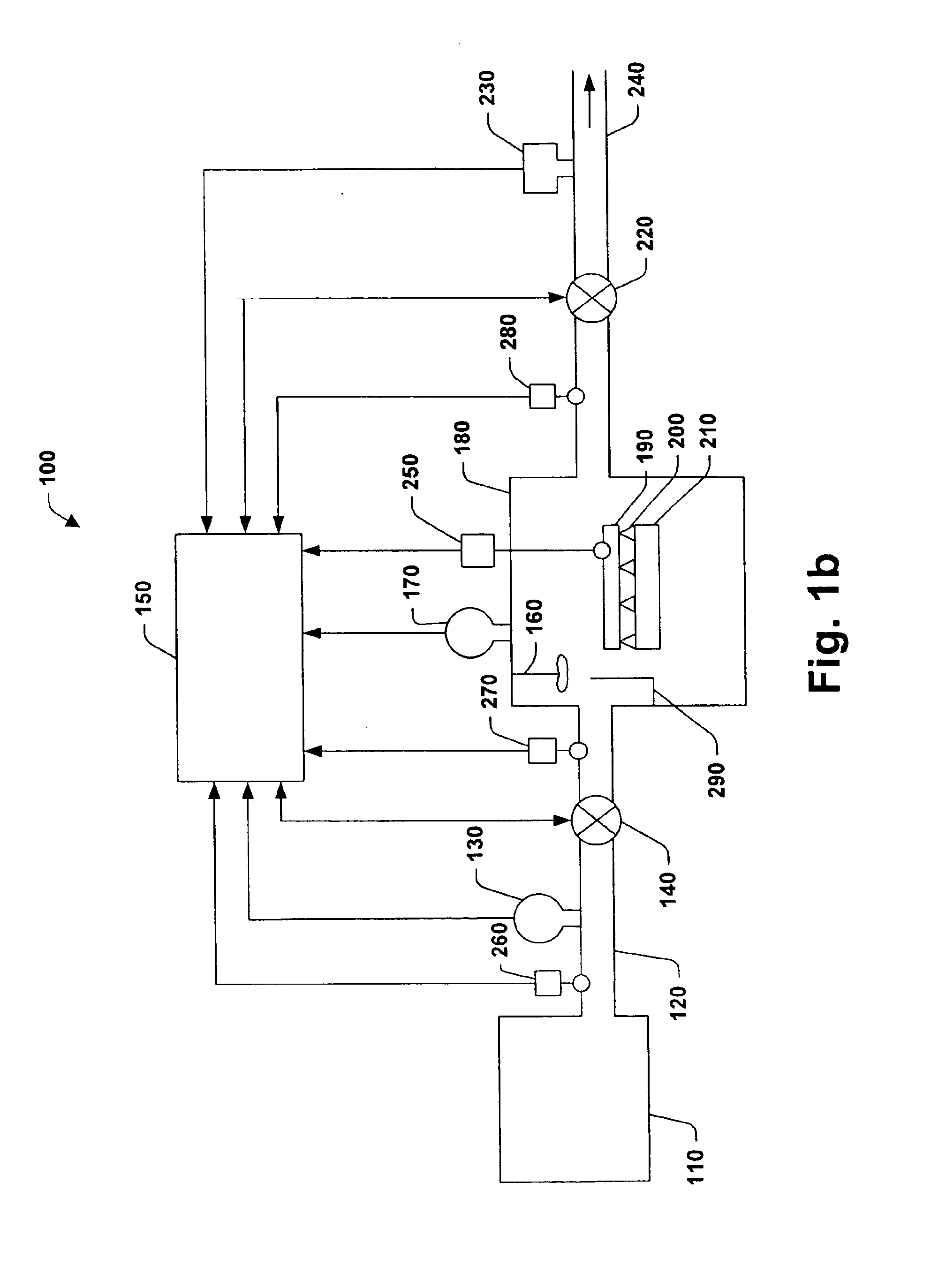

Electric vehicle battery heat dissipation and temperature control system and method based on liquid-gas phase change heat storage

InactiveCN108777338AEnsure equal pressure and constant temperature to absorb heatControl working temperatureCell temperature controlBatteriesHeat fluxAutomotive battery

The invention discloses an electric vehicle battery heat dissipation and temperature control system and method based on liquid-gas phase change heat storage. The system comprises: a phase change evaporative cooling circulation system, a heating system and a control system. The phase change evaporative cooling circulation system includes a liquid reservoir, an adsorption phase change evaporative cooling device, a communicating pipe, a gas supply pipeline, a one-way valve, a steam drum, a condensing pipeline, an electromagnetic valve, an electric throttle valve, a condenser, a reflux pipeline, and a cooling fan. The heating system includes an adsorption phase change evaporative cooling device and a heater. The control system includes: a controller, a temperature sensor, a heat flux density sensor and a pressure sensor. The system and method provided by the invention have the beneficial effects that: through real-time monitoring of the temperature of the adsorption phase change evaporative cooling device, the heat flux density and the steam drum pressure by the control system, the working temperature and temperature difference of the power battery are effectively controlled, and the thermal reliability and working life of the power battery are improved.

Owner:XINGTAI POLYTECHNIC COLLEGE

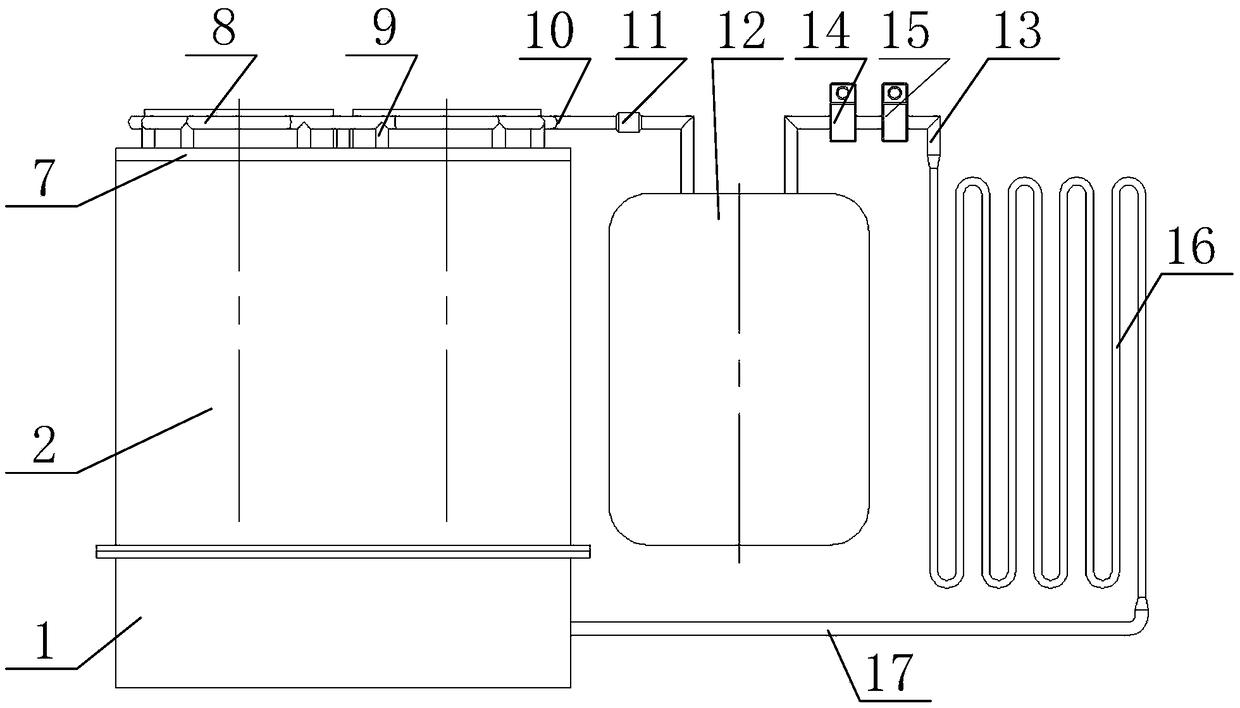

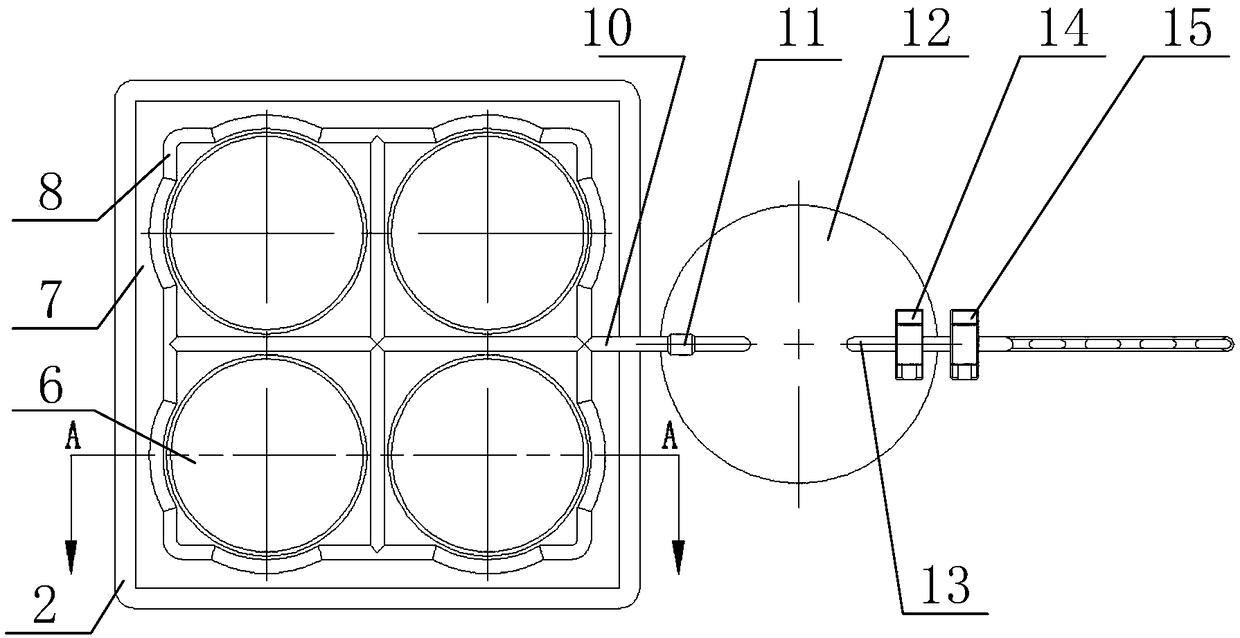

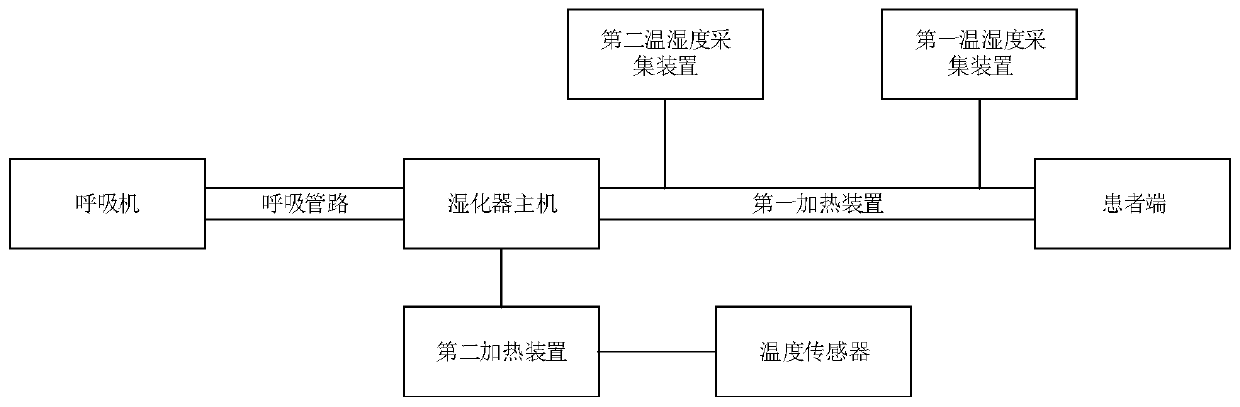

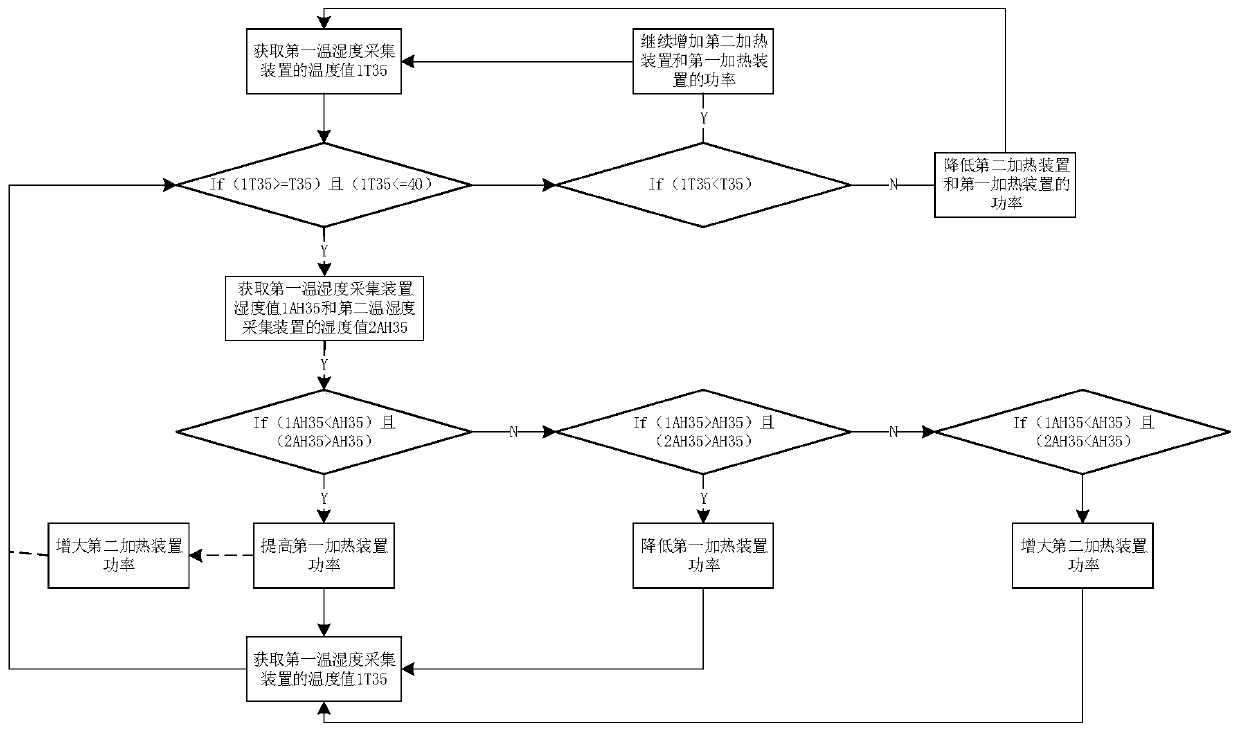

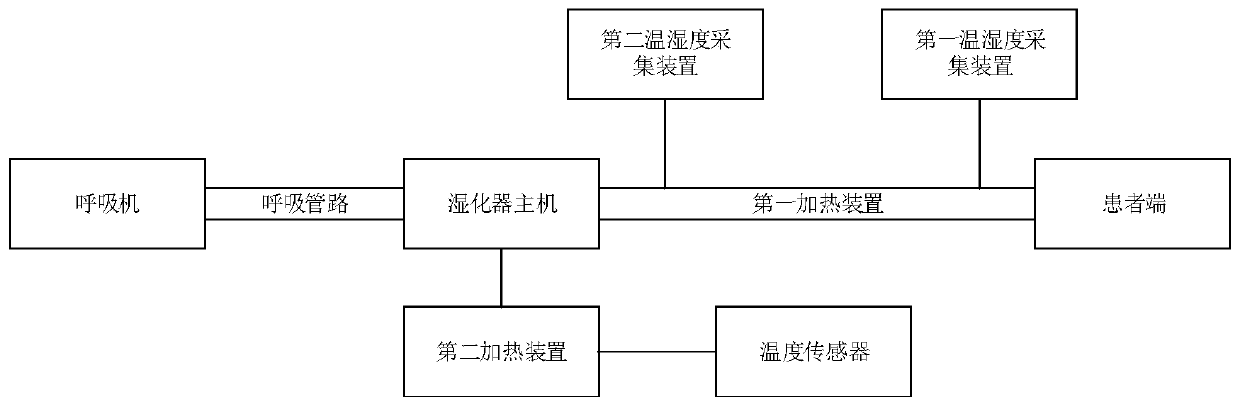

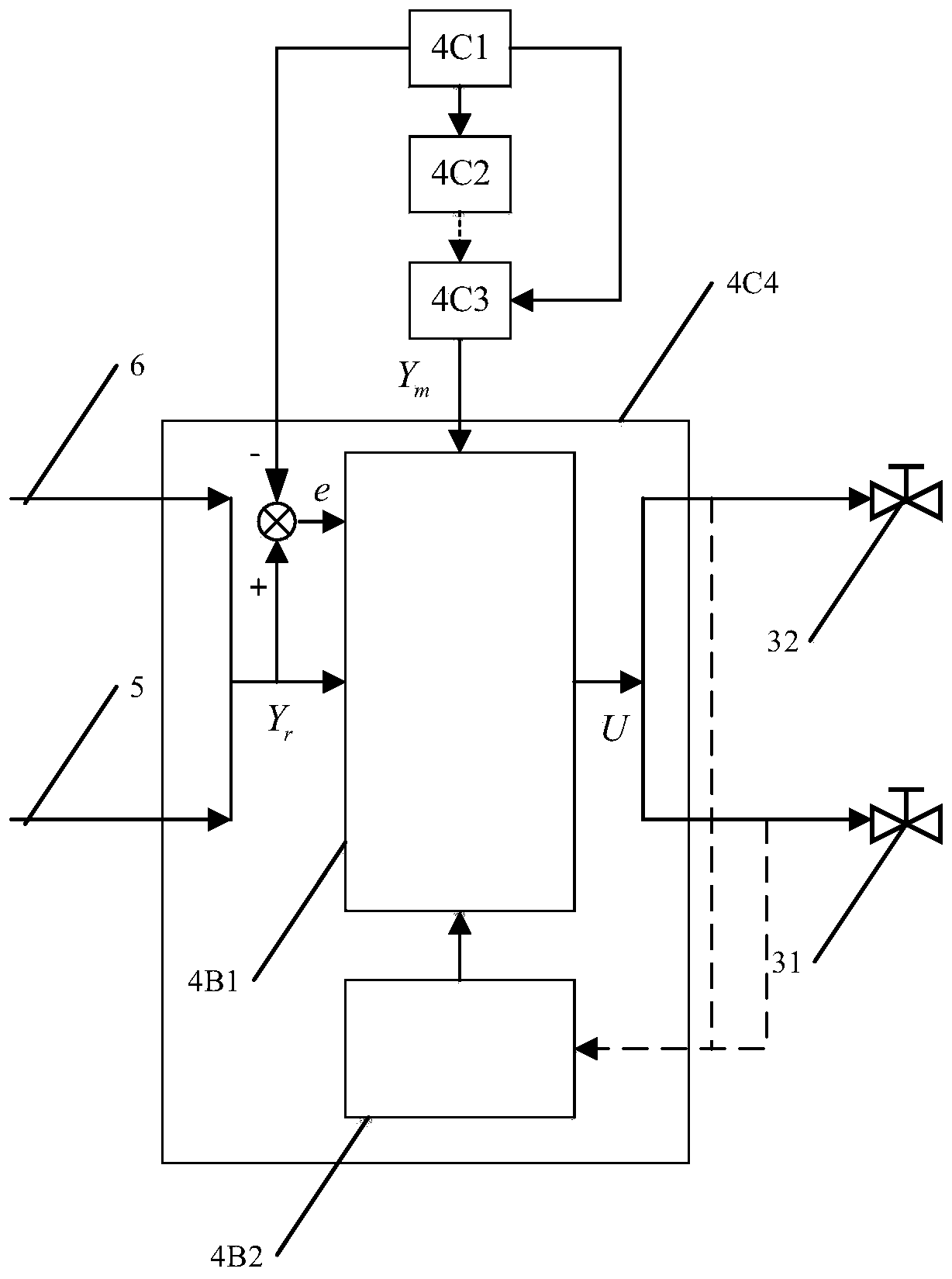

Temperature and humidity control system for humidifier of respiratory support equipment and control method thereof

ActiveCN111110975AImprove Humidity LevelsReduced comfortRespiratorsMedical devicesTemperature controlMedicine

The invention provides a temperature and humidity control system for a humidifier of respiratory support equipment and a control method thereof, wherein the temperature and humidity control system forthe humidifier of the respiratory support equipment comprises: a humidifier main body, a first temperature and humidity acquisition device, a second temperature and humidity acquisition device, a first heating device, a second heating device, a temperature acquisition device and a humidifying controller. A water box is arranged inside the humidifier main body, the first heating device is used forheating gas in a pipeline of the respiratory support equipment, the second heating device is used for heating water in the water box, the temperature acquisition device is used for acquiring a temperature value of the second heating device, and the humidifying controller is used for receiving the temperature and humidity values acquired by the first temperature and humidity acquisition device andthe second temperature and humidity acquisition device, comparing the received temperature and humidity values with the target temperature and humidity values, and outputting a control signal to thefirst heating device or the second heating device. The invention aims to change the existing temperature control method into a humidity control method in order to control humidity, and partial temperature adjustment is only for humidity control, so that the humidity output to a patient end is constant, and the degree of comfort and the treatment effect of the patient are improved.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

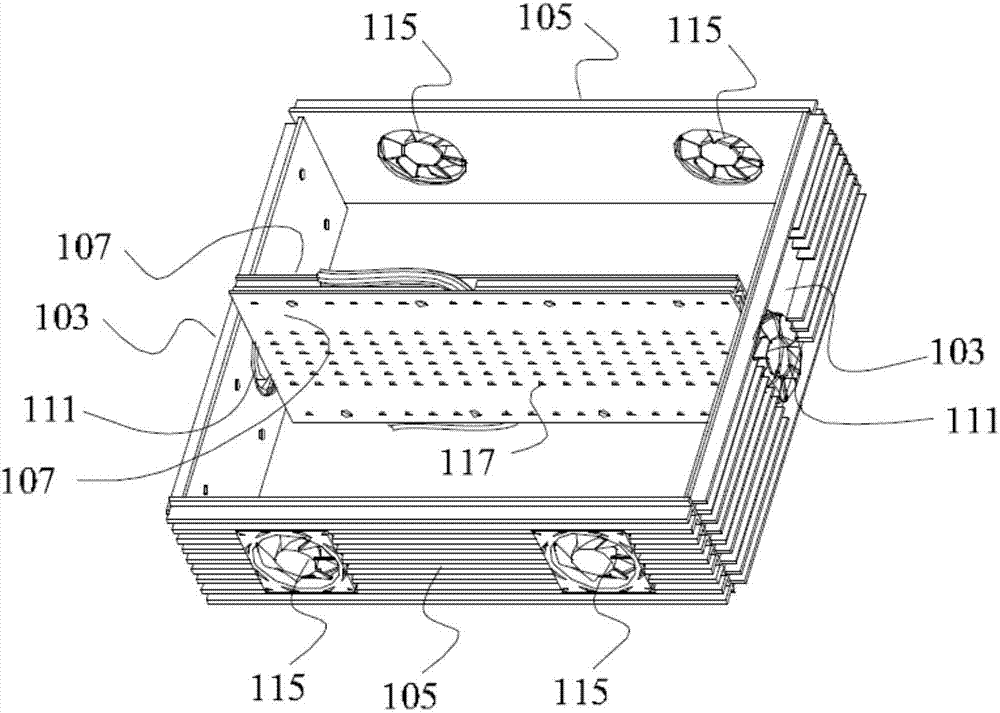

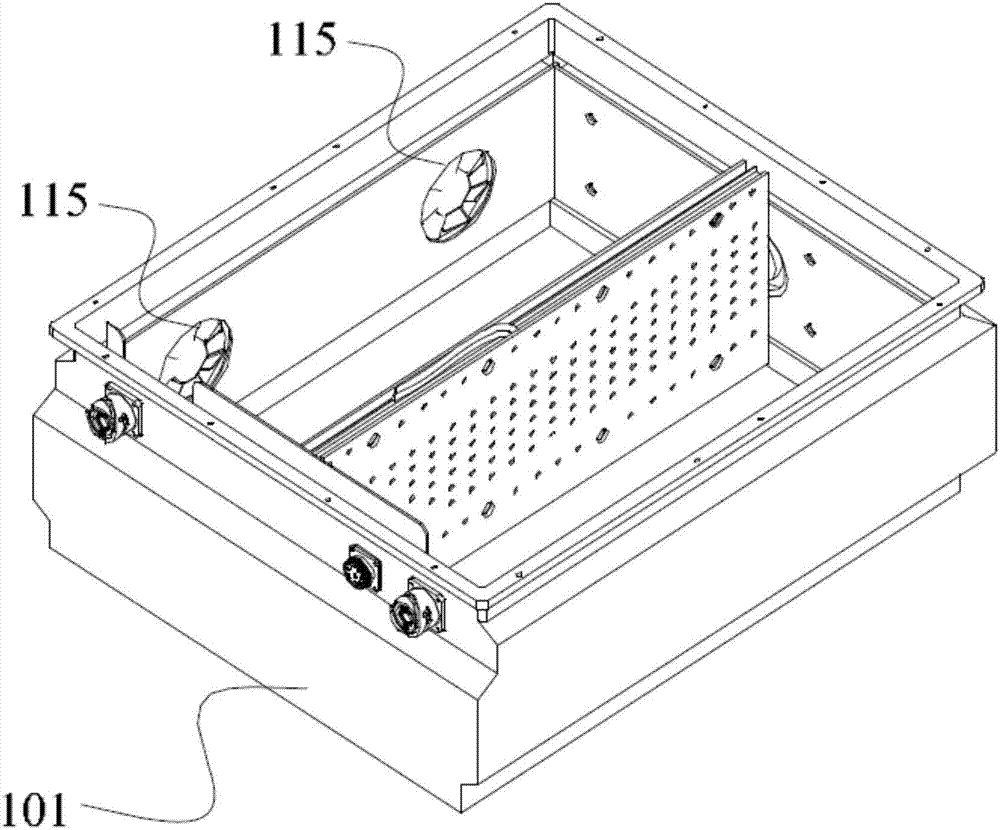

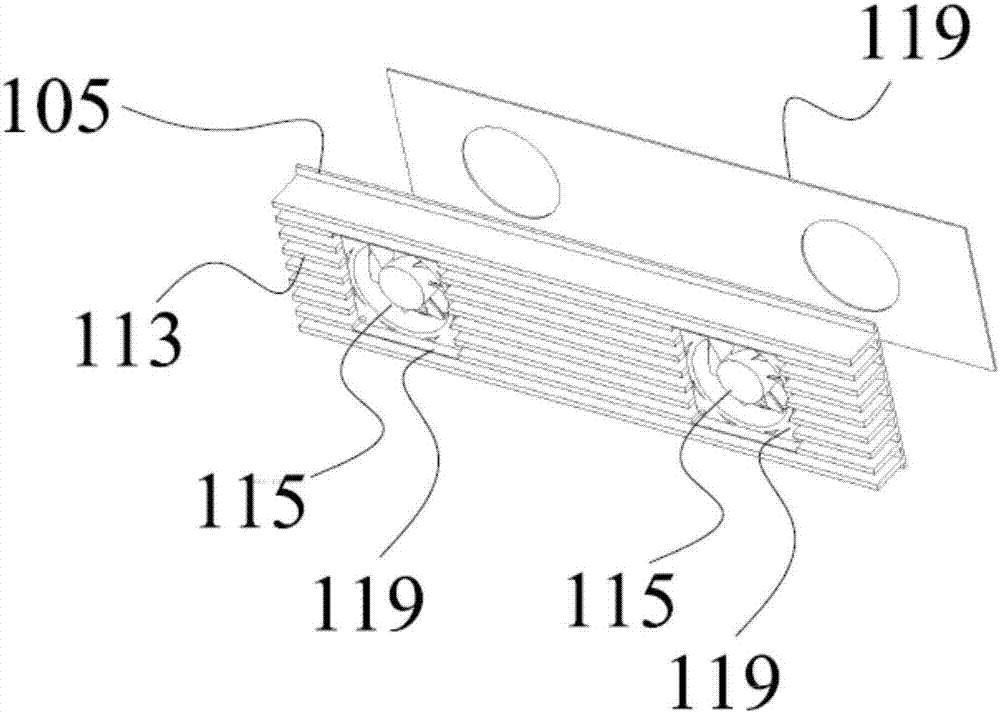

Thermal management device for battery pack

InactiveCN107112608ASmall temperature differenceGuaranteed charging and discharging workSecondary cellsCell component detailsThermodynamicsHeat management

Disclosed in the present application is a thermal management device for a battery pack. The thermal management device comprises: a battery box, the circumference of the inner wall of which outwards protrudes; two first heat-dissipation plates, provided with bidirectional fans; a second heat-dissipation plate, provided with a plurality of heat-dissipation fans; two heating and heat-dissipation plates, provided with a plurality of ventilation holes; and a heater; and a battery management circuit. The thermal management device for a battery pack in the present application creatively resolves the contradictive demands of a battery box body between the demand for a good heat-dissipation structure and the demand for a good heating and heat preservation structure in the prior art, thereby ensuring that a batty packet in a battery system carries out charging and discharging work in a proper environment, controlling the temperature increase and the temperature difference in the battery box, improving the cycle life of the battery pack, and reducing a variety of safety risks caused by a high temperature and a low temperature.

Owner:SHENZHEN PUYI BATTERY TECH

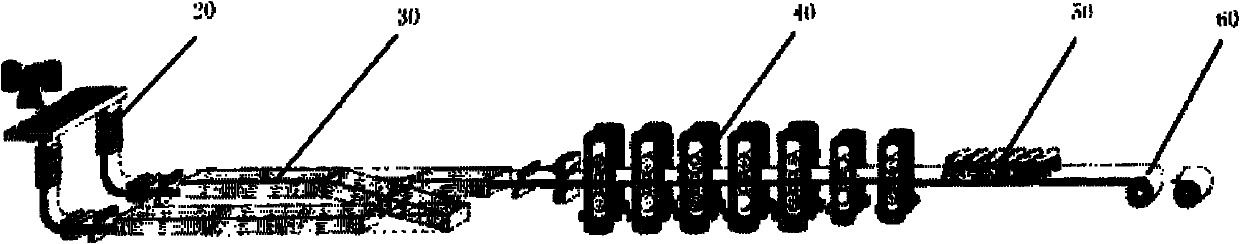

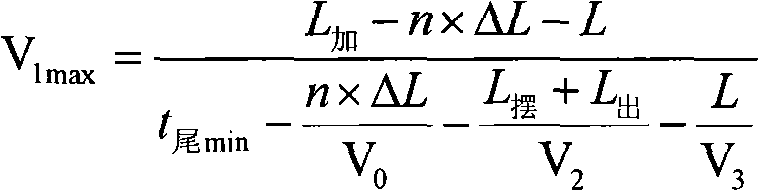

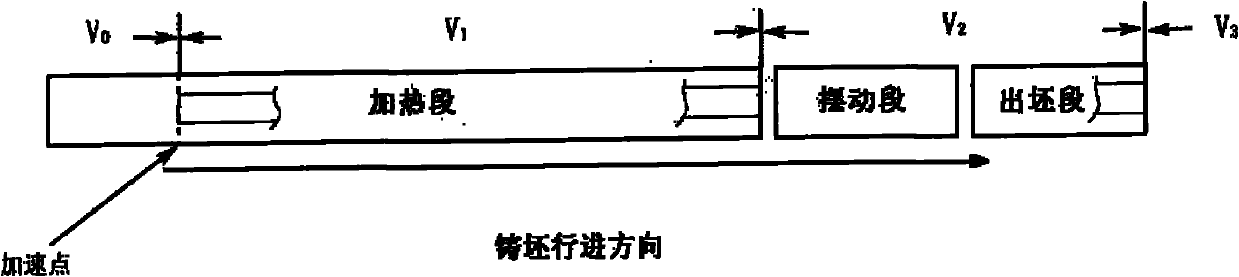

Method for controlling head and tail temperature difference of semi-endless rolled overlong casting blank

InactiveCN101905247AGuaranteed temperature uniformityReduce head-to-tail temperature differenceTemperature control deviceTemperature differenceEnergy source

The invention discloses a method for controlling the head and tail temperature difference of a semi-endless rolled overlong casting blank, which is used for solving the problem of poor longitudinal temperature uniformity of an overlong casting blank in a semi-endless rolling process. The invention has the technical scheme that the method comprises the following steps of: making the overlong casting blank enter a soaking pit at a fixed blank pulling speed V0 and making the overlong casting blank advance at a speed V1 not higher than V1max after the tail of the overlong casting blank passes through an accelerated point until the head of the casting blank arrives at the tail end of a heating section, wherein V1 is not less than V0 and not greater than V1max; then making the overlong casting blank advance to the tail end of a blank discharging section at a speed V2; and finally making the overlong casting blank enter a rolling mill at a speed V3 matched with a rolling mill F1 until that the tail of the casting blank leaves the soaking pit. The method has no influence to production rhythms, can also ensure the temperature uniformity of the semi-endless rolled overlong casting blank, greatly reduces the head and tail temperature difference of the overlong casting blank, has the advantages of simple process control and convenient field operation and can further save energy sources.

Owner:UNIV OF SCI & TECH BEIJING +1

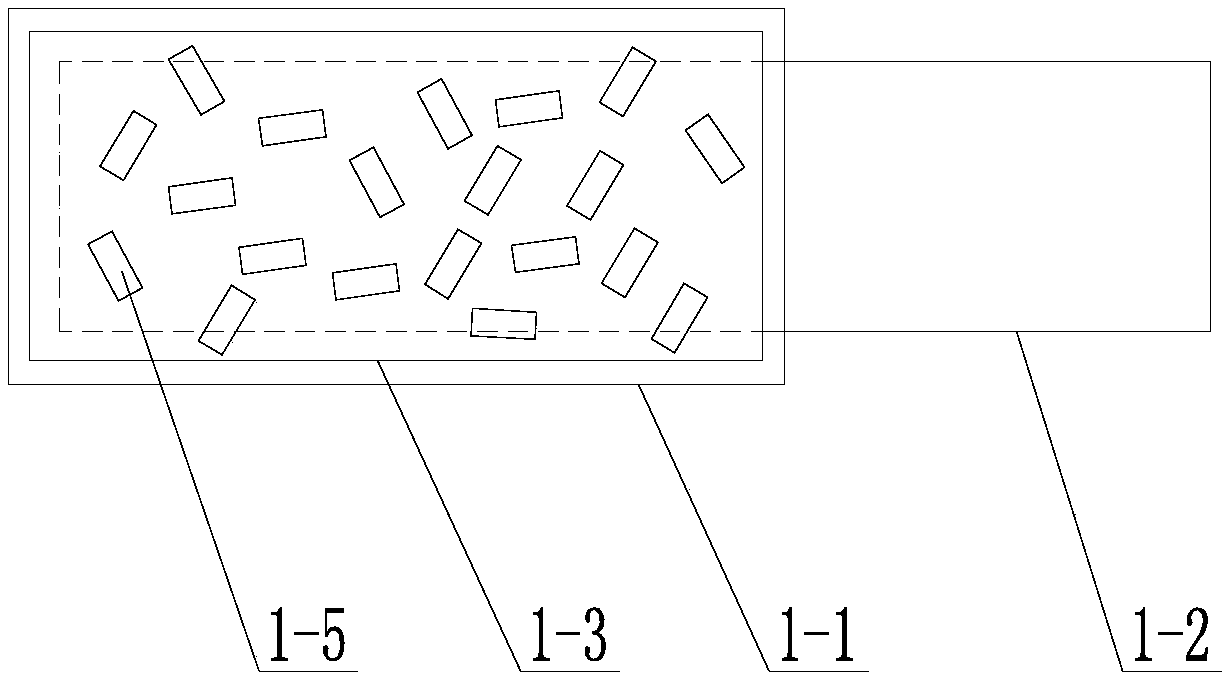

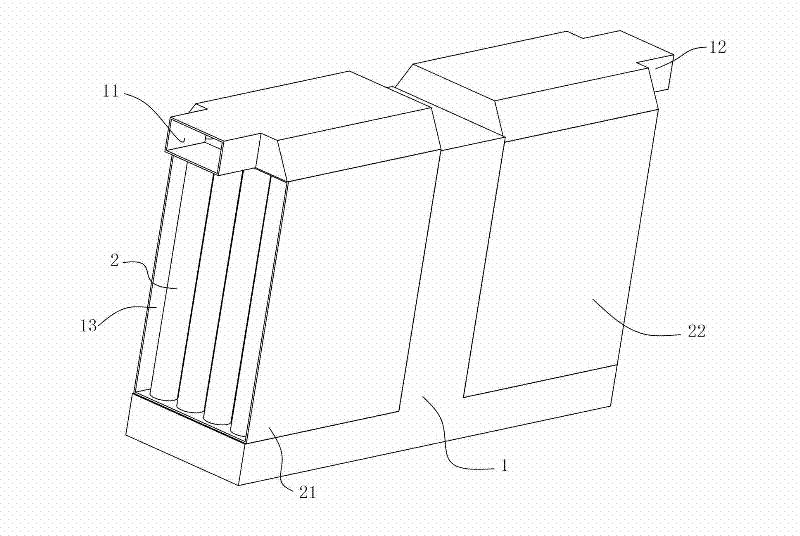

Self-cooled emergency battery pack composed of phase change energy storage individuals

The invention discloses a self-cooled emergency battery pack composed of phase change energy storage individuals. An existing passive server emergency battery pack has a compact structure and a high heat dissipation requirement, but lacks a matching heat dissipation structure so as to have a poor heat dissipation effect which affects the performance of the existing passive server emergency batterypack. The phase change energy storage individual in the invention comprises an outer capsule body and a heat conducting plate, wherein the outer capsule body is provided therein with a phase change heat conductor; one end of a heat conducting plate is inserted into the phase change heat conductor through the outer capsule body; and the other end of the heat conducting plate is disposed outside the outer capsule body. A plurality of battery individuals of the battery pack are vertically arranged side by side. A gap is formed between the outer sidewalls of every two adjacent battery individuals. Each phase change energy storage individual is disposed in the corresponding gap. Each phase change energy storage individual comprises the outer capsule body and the heat conducting plate. The outer capsule body is provided therein with the phase change heat conductor. One end of the heat conducting plate passes through the outer capsule body and is disposed inside the phase change heat conductor. The other end of the heat conducting plate is placed outside the outer capsule body.

Owner:广东硅岳能源科技有限公司

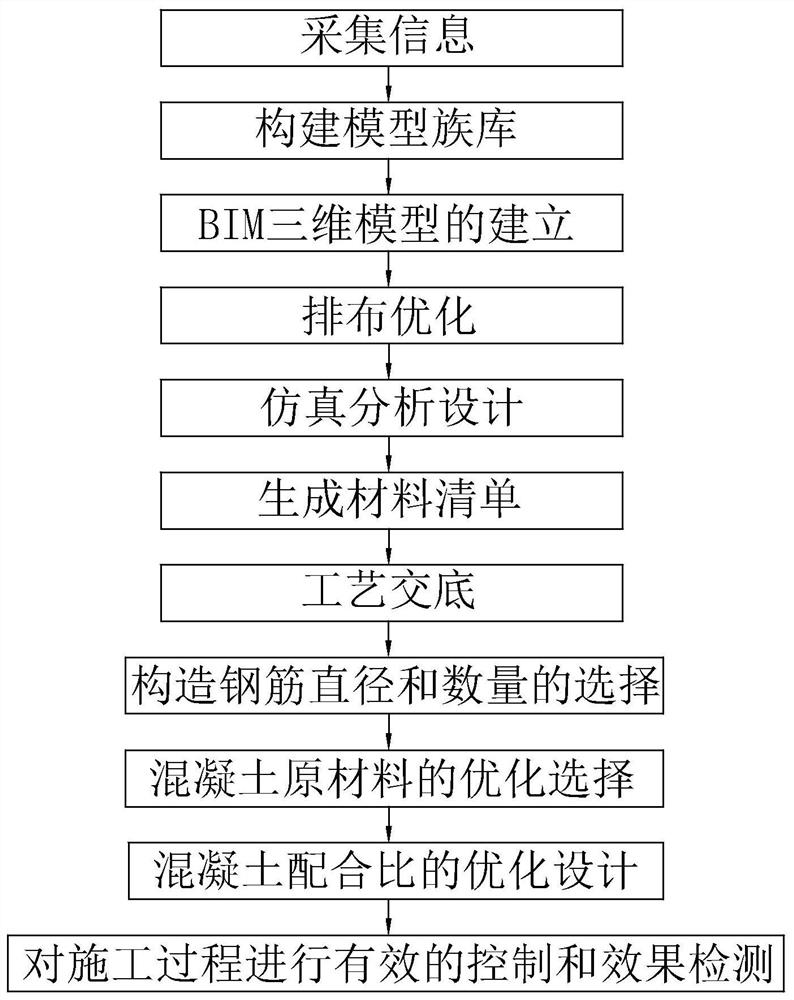

Method for controlling wall body crevices

The invention relates to a method for controlling wall body crevices. The method for controlling the wall body crevices comprises the following steps that firstly, information is collected; secondly,a model family library is constructed, and by utilizing a Revit software, a building information modeling (BIM) wall body standard parameterized model family library of a wall body is established; thirdly, a BIM wall body three-dimensional model is established, wherein the BIM wall body three-dimensional model comprises manufacturing constructional steel bars, casting molding plates, split bolts,concrete structure layers and structural steel bar nets; fourthly, configuration and optimization are conducted, wherein the configuration condition of the structural steel bar nets is inspected layerby layer through BIM model simulated view; fifthly, simulated analysis design is conducted, wherein a BIM building information model established by the Revit software is imported into Navisworks software, and real-time roaming is conducted; sixthly, a material list is generated, wherein the quantity of materials needed by each layer of the wall body structure is counted by applying the BIM software detailed list function, the material list is generated, and the site construction scheme is determined; and seventhly, technology disclosure is conducted, wherein through an animated short film manufactured with a 3Dmax software or Navisworks software, visualized construction technology disclosure is conducted on site construction staff, and all-round instruction of construction is conducted. The method for controlling the wall body crevices has the effect that the possibility that the crevices are generated by the wall body is reduced.

Owner:北京住总第一开发建设有限公司

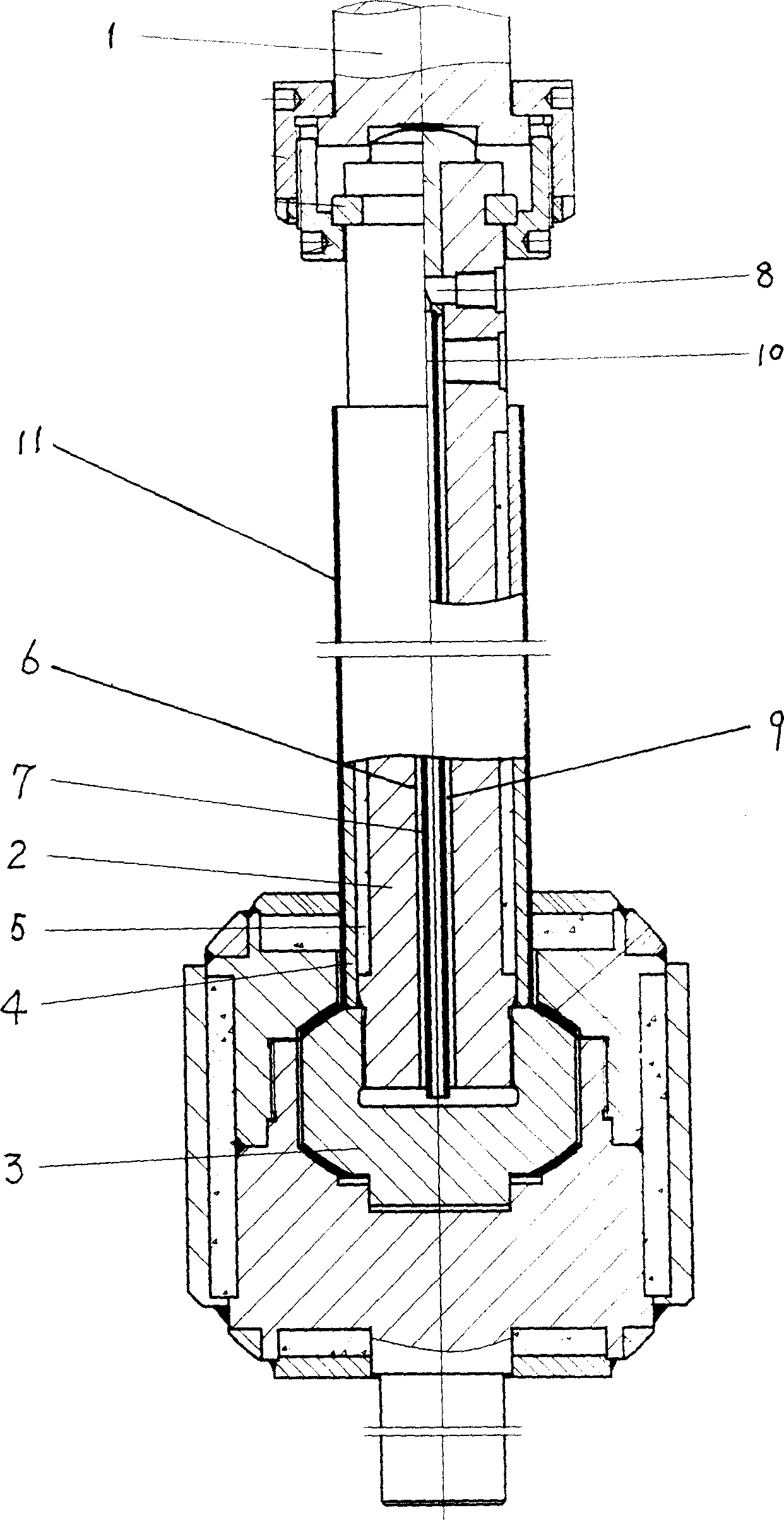

Valve rod mechanism for superhigh temperature high pressure valve

InactiveCN1673586AHigh strengthCompact structureValve members for heating/coolingLift valveEngineeringHigh pressure

The valve rod mechanism for super high temperature and super high pressure valve includes upper valve rod, lower valve rod connected to the upper valve rod, valve rod head fixed to the end of the lower valve rod, protecting jacket around the lower valve rod and with lower end fixed to the valve rod head and upper end matched with the slide sleeve around the upper part of the lower valve rod, heat isolating layer between the protecting jacket and the lower valve rod, and cooling gas pipe inside the lower valve rod communicated with the gas inlet. The present invention has effectively controlled inner and outer temperature difference of valve rod body, raised valve rod strength, compact structure, high reliability and long service life.

Owner:杨荣水

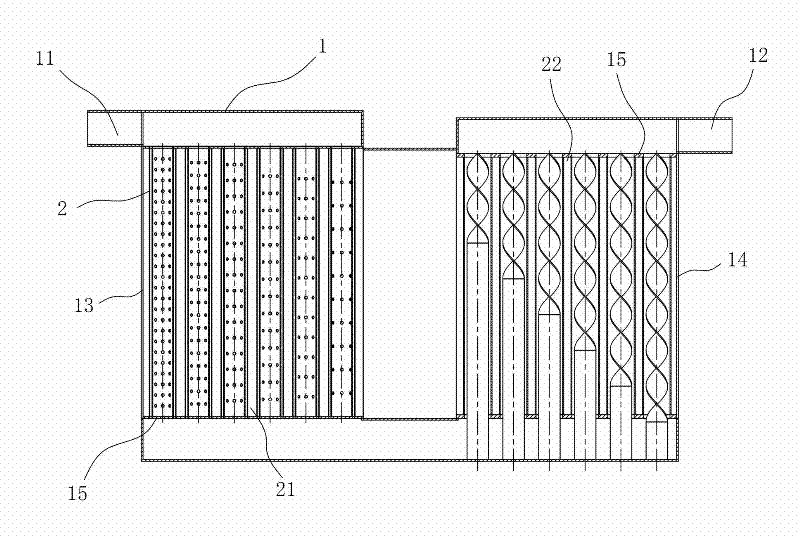

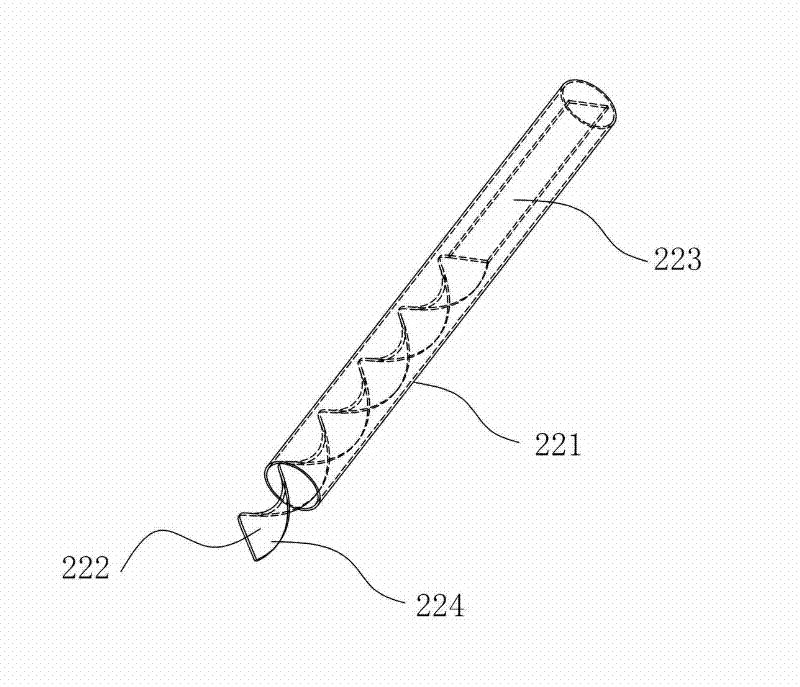

Insert type air preheater with same inlet-outlet temperature difference of heat exchange tubes

InactiveCN101813323AHydraulic diameter reductionLow costCombustion processIndirect carbon-dioxide mitigationCold airAir preheater

The invention discloses an insert type air preheater with the same inlet-outlet temperature difference of heat exchange tubes, comprising an air bellow and a plurality of rows of heat exchange tubes, wherein the upper end of the air bellow is provided with a cold air inlet, the lower end of the air bellow is provided with a hot air outlet, one side of the air bellow is provided with a smoke inlet, the other side of the air bellow is provided with a smoke outlet, the heat exchange tubes are evenly arranged in the air bellow and communicated with the cold air inlet and the hot air outlet, the heat exchange tubes are internally provided with inserters comprising straight sections and spiral sections, the straight sections are arranged at the inlet sections of the heat exchange tubes, and the spiral sections are arranged at the outlet sections of the heat exchange tubes. The percentage of the lengths of the straight sections of the inserters in each row of the heat exchange tubes in total length is gradually decreased from the smoke inlet to the smoke outlet. The insert type air preheater with the same inlet-outlet temperature difference of heat exchange tubes can reduce tube wall temperature differences among the heat exchange tubes to enable air to be heated in the heat exchange tubes to have the same inlet-outlet temperature difference, thereby achieving the optimal comprehensive heat exchange effect.

Owner:杭州美宝炉窑工程有限公司

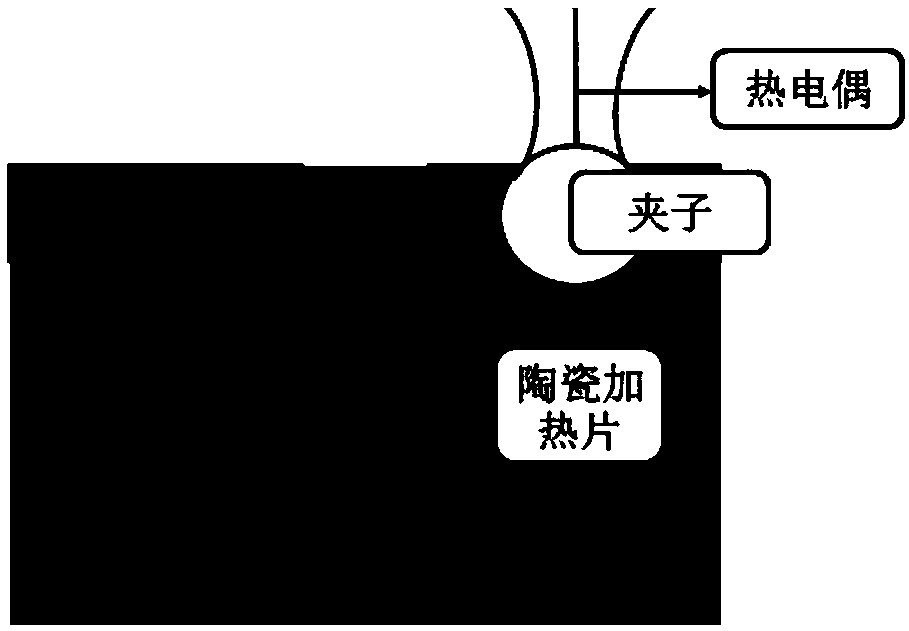

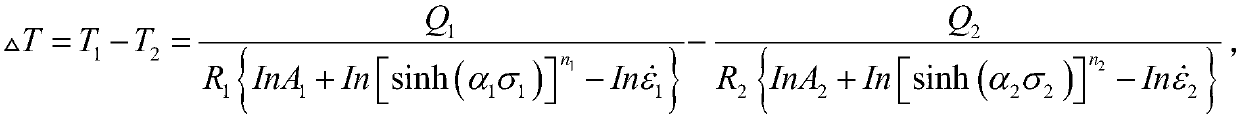

Micro solder joint thermal migration test method

InactiveCN108663402AControl temperature differenceStable temperature differenceMaterial heat developmentSolder pasteTest structure

The invention discloses a micro solder joint thermal migration test structure and a production method thereof, and belongs to the field of production and connection of materials. A solder pad for thermal migration test has a raised shape, is adhered to a base plate through a double-faced adhesive tape, a solder paste is filled between two solder pads, the two solder pads are welded to form a solder joint, and the solder joint is polished to form a solder joint for thermal migration test. One ends of the solder pads of the solder joint are heated by ceramic heating pieces, a thermocouple monitors the ceramic heating pieces, a controller is used to control the temperature, and the other ends of the solder pads keep a room temperature state, so two ends of the solder joint have a temperaturedifference, and stable temperature gradient is realized. The temperature controller is arranged to control the temperature of one ends of the solder point solder pads and realize the accurate controlof the temperature difference between two ends of the solder point, so two sides of the solder joint have the controllable temperature gradient, the problem of difficult realization and control of thetemperature gradient in the thermal migration test process of the micro-size solder joint is solved, reliable solder joint thermal migration data is obtained on the premise of the controllable solderjoint temperature gradient, and is evaluated.

Owner:BEIJING UNIV OF TECH

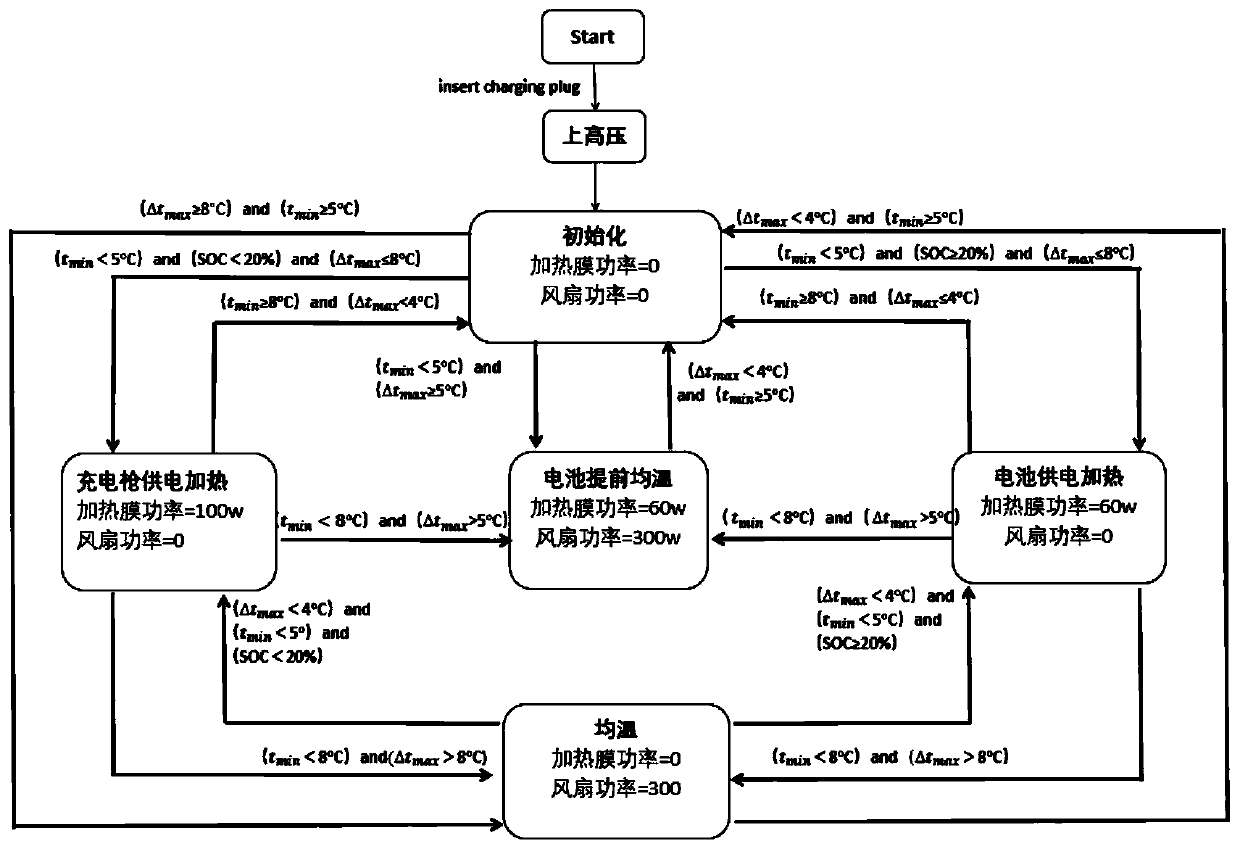

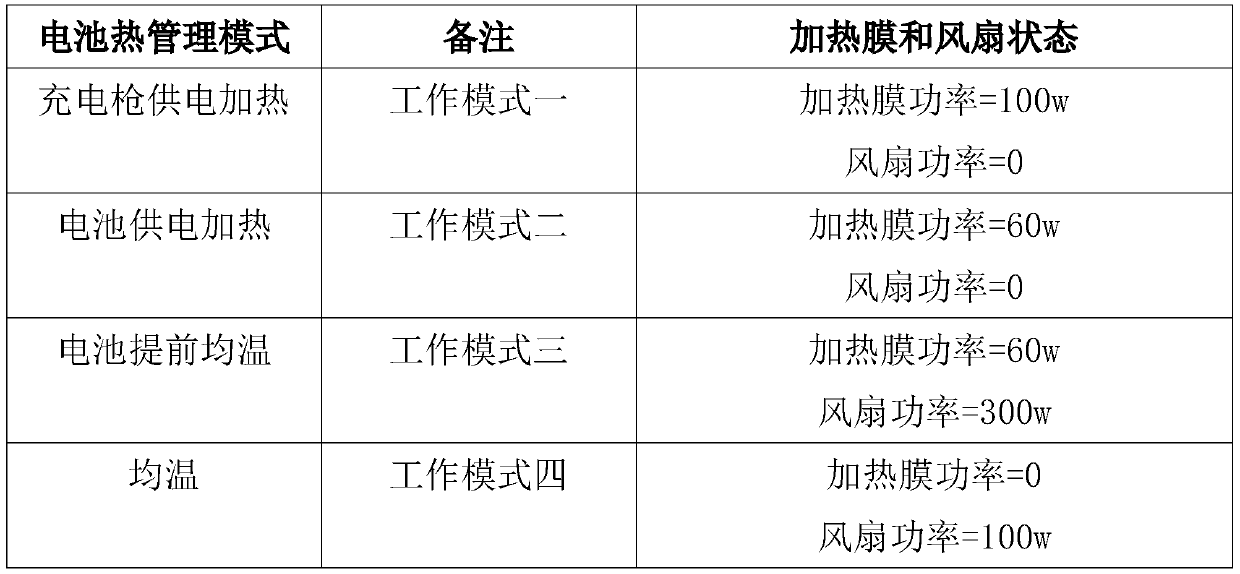

High-energy battery pack heating temperature control system and method

InactiveCN110154835ATemperature controlControl temperature differenceVehicular energy storageBattery/fuel cell control arrangementTemperature controlControl system

The invention discloses a high-energy battery pack heating temperature control system. The high-energy battery pack heating temperature control system comprises a battery pack residual electric quantity detection system, a battery pack temperature detection system, a battery pack heating system, a battery pack temperature equalizing system and a controller, wherein the battery pack residual electric quantity detection system is used for detecting battery residual electric quantity, the battery pack temperature detection system is used for detecting the battery temperature, the battery pack heating system is used for heating batteries, the battery pack temperature equalizing system is used for equalizing the temperature of a battery pack, the controller is connected with and controls the battery pack residual electric quantity detection system, and a battery thermal management mode can be judged through the battery pack temperature detection system and the battery pack heating system. According to the high-energy battery pack heating temperature control system, the good charge and discharge performance of the batteries is ensured through the synergistic effect. The invention provides a high-energy battery pack heating temperature control method, through synergistic effect control of the temperature control system, the batteries can be rapidly heated to the target temperature, moreover, the consistency of the temperature of the battery individuals and the module temperature can be ensured, and then all the parts are all in a reasonable temperature range when the battery packworks.

Owner:JILIN UNIV

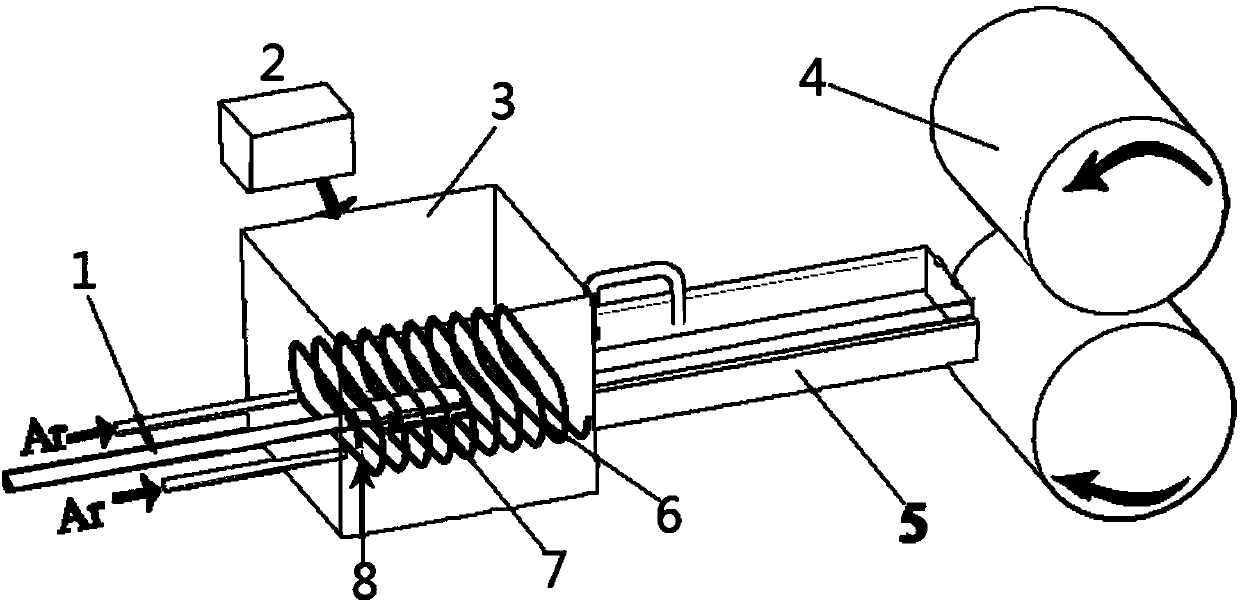

Method for preparing steel-aluminum composite board through electromagnetic induction heating and rolling process

ActiveCN108421825AHigh bonding strengthReduce the difference in deformation resistanceWork heating devicesMetal rolling arrangementsSheet steelTemperature difference

The invention discloses a method for preparing a steel-aluminum composite board through an electromagnetic induction heating and rolling process. The method for preparing the steel-aluminum compositeboard through the electromagnetic induction heating and rolling process comprises the steps of S1, surface pre-treatment of a board; S2, blank assembling and fixing, specifically, after a steel plateand an aluminum plate are stacked, a gasket is placed between the steel plate and the aluminum plate to reserve a gap, and the steel plate and the aluminum plate are fixed with rivets; S3, induction heating of an assembled blank, specifically, the temperature of the steel plate can be rapidly increased to 750-1000 DEG C under the effect of vortex heating of a ferromagnetic material, the temperature of the aluminum plate is increased to 100-300 DEG C, and thus, a temperature difference over 500 DEG C is generated between the steel plate and the aluminum plate; S4, rolling, specifically, the heated blank is conveyed into a rolling machine; and S5, annealing and straightening. According to the method for preparing the steel-aluminum composite board through an electromagnetic induction heatingand rolling process, the requirement for the capacity of the rolling machine is greatly lowered, the deformation rate of a steel-aluminum rolling composite critical surface is greatly decreased, andcooperative deformation of steel and aluminum is achieved; and the obtained steel-aluminum composite board has good bending resistance and high bonding performance, the work hardening of the steel-aluminum composite board is greatly reduced, and the subsequent machinability is improved.

Owner:YANSHAN UNIV

Jet and insert combined air pre-heater capable of realizing same inlet/outlet temperature difference of gas in heat exchange pipes

InactiveCN102252340AImprove heat transfer efficiencyImprove the overall heat transfer coefficientCombustion processHeat transfer modificationAir preheaterCold air

The invention discloses a jet and insert combined air pre-heater capable of realizing same inlet / outlet equal temperature difference of gas in heat exchange pipes. The combined air pre-heater comprises a bellows and a plurality of rows of heat exchange pipes, wherein the bellows is provided with a cold air inlet and a hot air outlet, one side of the bellows is provided with a flue gas inlet, and the other side of the bellows is provided with a flue gas outlet; the plurality of rows of heat exchange pipes are arranged in the bellows and divided into a jet area and an insert area, the jet area is arranged at one side close to the flue gas inlet, and the insert area is arranged at one side close to the flue gas outlet; and the cold air inlet sequentially passes through the jet area and the insert area and then is communicated with the hot air outlet. Through the jet and insert combined air pre-heater capable of realizing the same inlet / outlet equal temperature difference of gas in the heat exchange pipes, the pipe wall temperature difference among the heat exchange pipes can be reduced, and the air heated in the heat exchange pipes has the same inlet / outlet temperature difference andthe optimal comprehensive heat exchange effect.

Owner:杭州美宝炉窑工程有限公司 +1

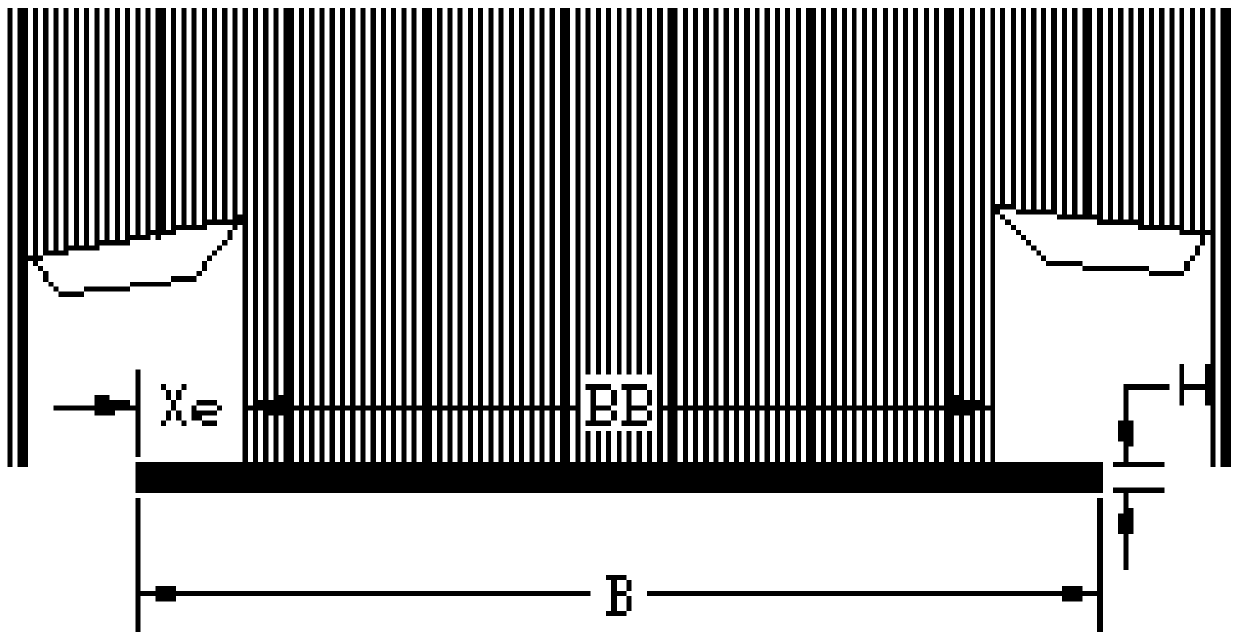

Method for accurately realizing symmetric shielding of strip steel edge parts

ActiveCN110860565AQuality improvementEasy to analyzeTemperature control deviceTemperature controlStructural engineering

The invention relates to a method for accurately realizing symmetric shielding of strip steel edge parts, and belongs to the technical field of hot rolling equipment modification and hot rolling process control in the metallurgical industry. According to the technical scheme, edge shielding parameters corresponding to different varieties and specifications are preset in a model data table, deviation of an actual shielding width are further identified and fed back by detecting the transverse temperature distribution of strip steel, flexible control of the edge shielding width adjustment is achieved, edge shielding requirements of different varieties of strip steel are guaranteed, and then temperature control of different varieties of strip steel is ensured. According to the method, by adjusting a transverse position of an edge shielding mechanism, symmetrical side part shielding of misalignment strip steel is achieved; and coordination and control are realized through two methods, so that the quality problems of the performance, the plate type and the like due to the influence of the edge temperature gradient of hot rolled products with different varieties, different specificationsand different alignment degrees are reduced.

Owner:HEBEI IRON AND STEEL

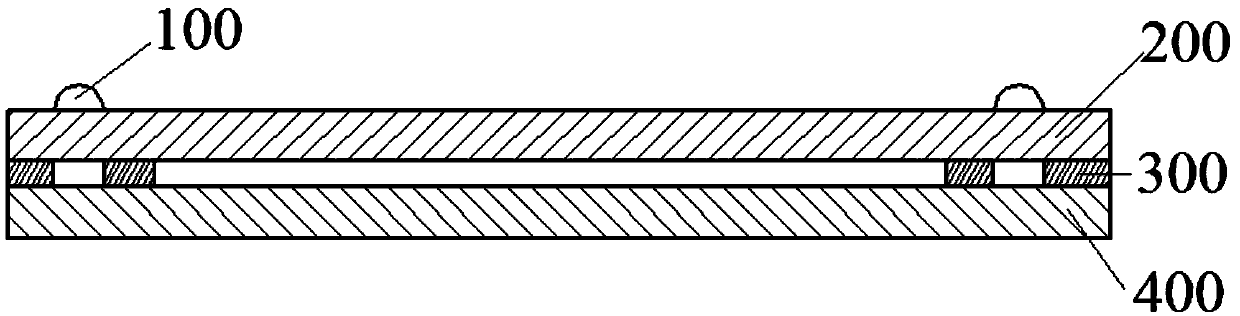

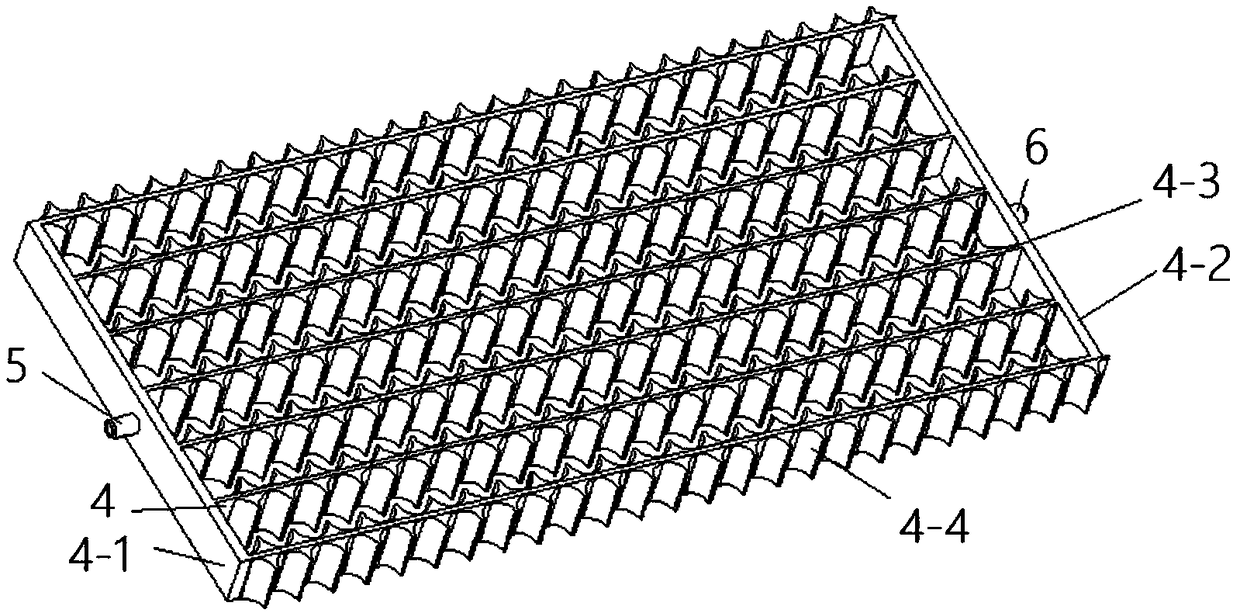

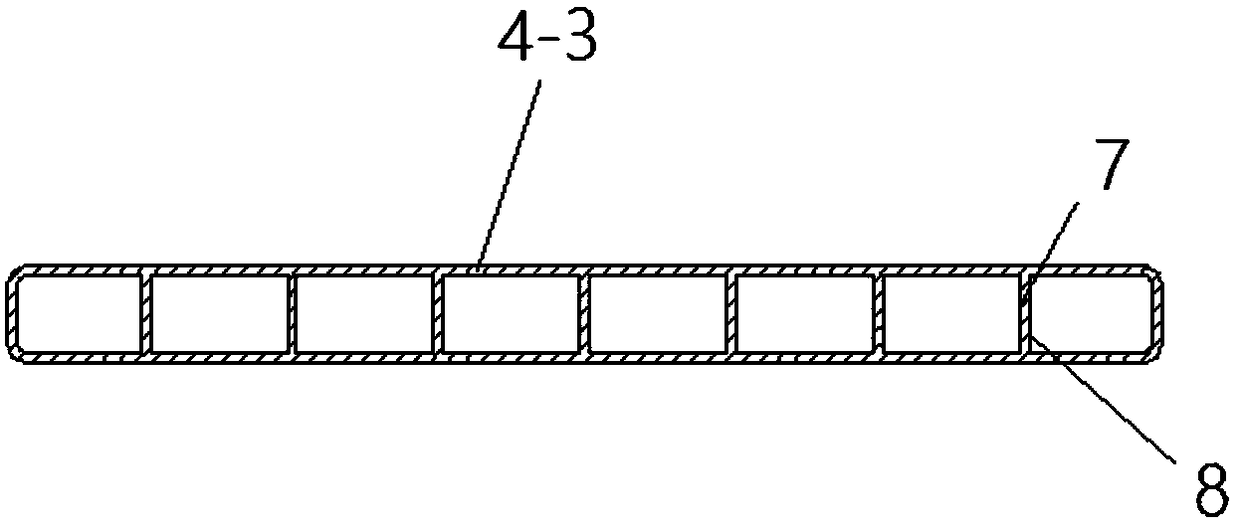

Novel liquid cooling module with multi-channel thin-wall straight pipe structure

InactiveCN108281732AControl temperature riseImprove fitCell temperature controlTemperature differenceEngineering

The invention relates to a novel liquid cooling module with a multi-channel thin-wall straight pipe structure. The novel liquid cooling module comprises a battery cell bracket, wherein the battery cell bracket comprises an upper bracket plate and a lower bracket plate; the upper bracket plate and the lower bracket plate are symmetrically provided with a plurality of battery cell fixing grooves; abattery cell is fixedly arranged in each battery cell fixing groove; a liquid cooling module is sheathed under the connecting end of the upper bracket plate and each battery cell, and consists of a left harmonica vertical pipe, a right harmonica vertical pipe and a plurality of harmonica transverse pipes; the harmonica transverse pipes are welded between the left harmonica vertical pipe and the right harmonica vertical pipe; a plurality of triangular aluminum blocks are respectively welded at the two sides of each harmonica transverse pipe; the outer end surface of the left harmonica verticalpipe is provided with a liquid inlet, and the outer end surface of the right harmonica vertical pipe is provided with a liquid outlet. The novel liquid cooling module has the beneficial effects that by adopting the multi-channel straight pipe parallel type liquid cooling module, the structure is simple, the installation is convenient, the liquid cooling module can be well attached with the batterycell, and the temperature rise of the battery cell and the temperature difference between the battery cell can be effectively controlled; by designing the light-weight structure, the energy density of the module is high, and the pressure drop is little.

Owner:天臣新能源研究南京有限公司

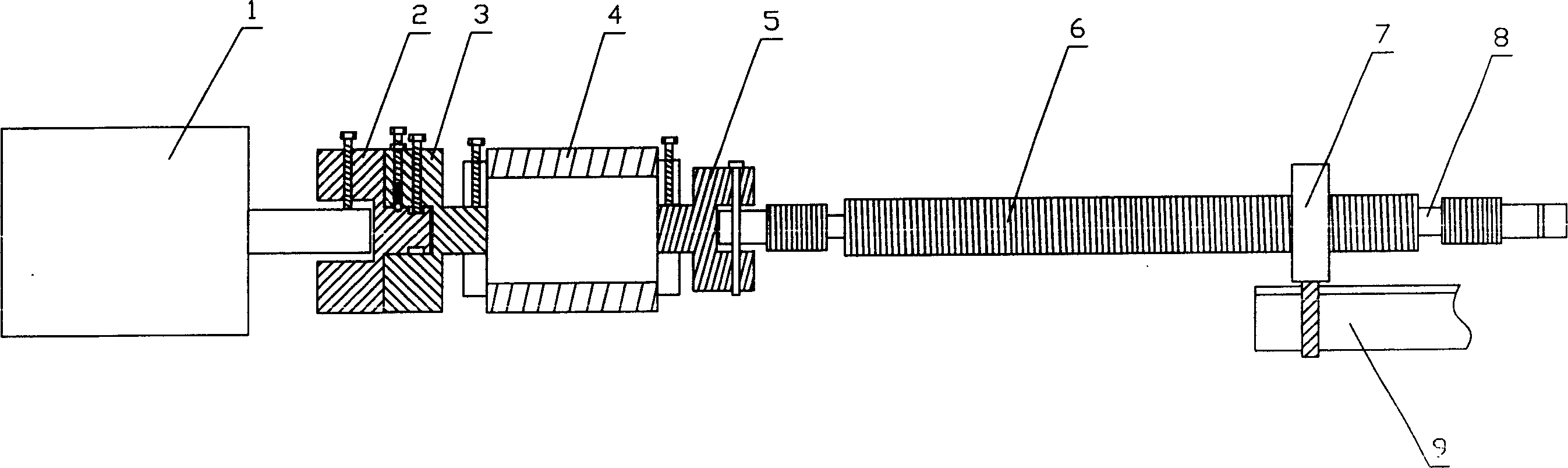

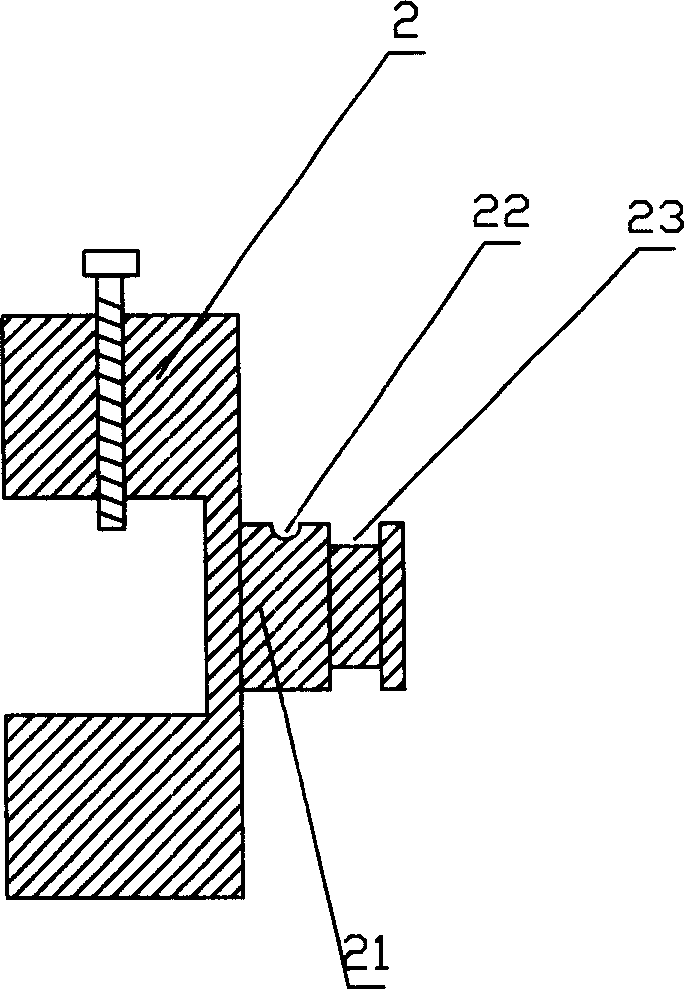

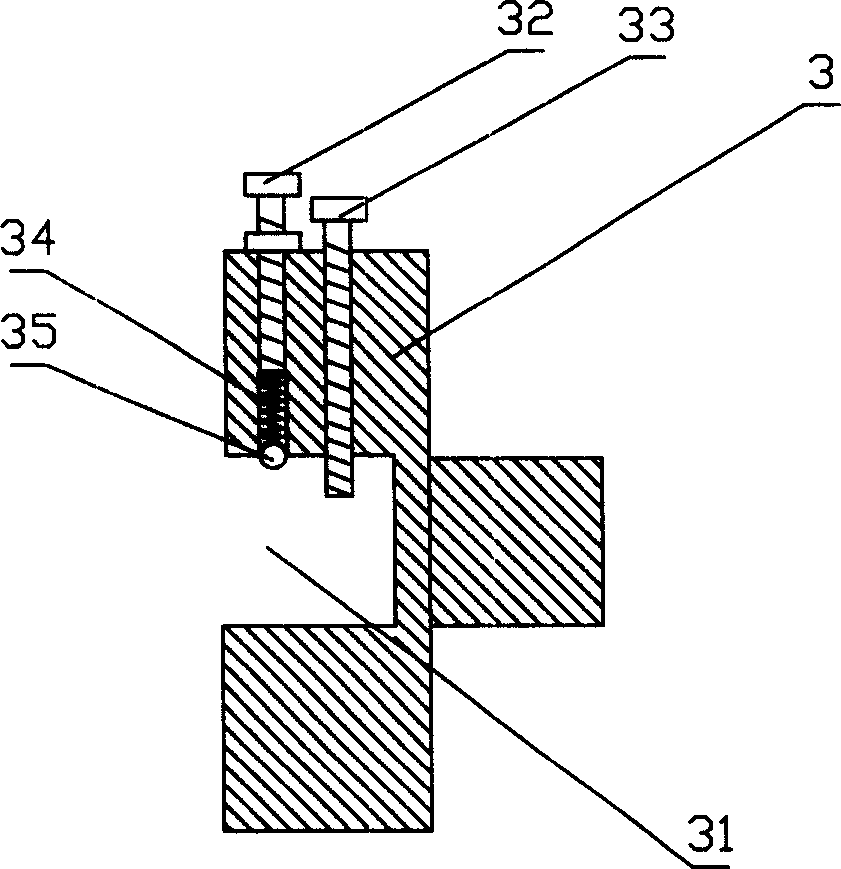

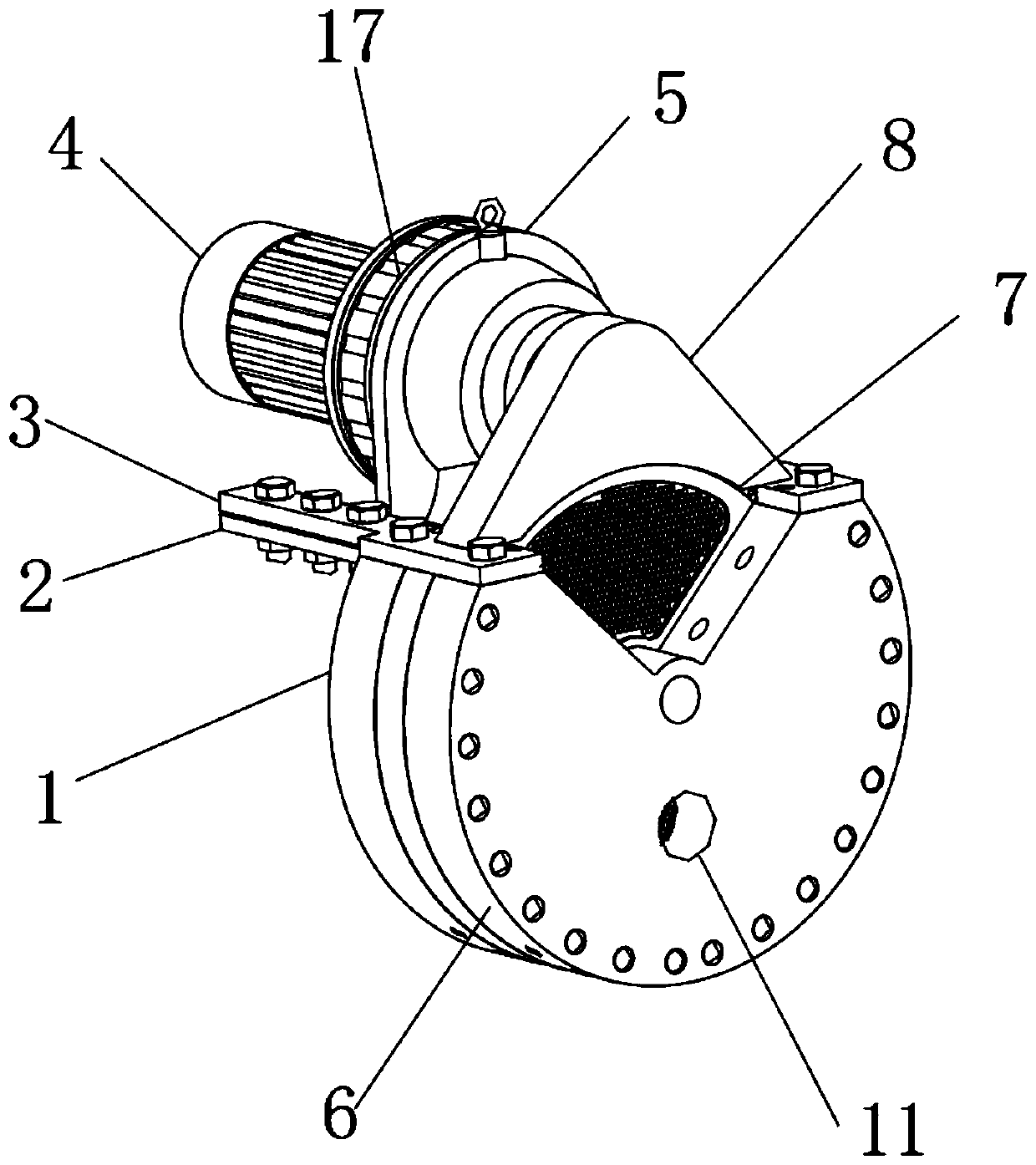

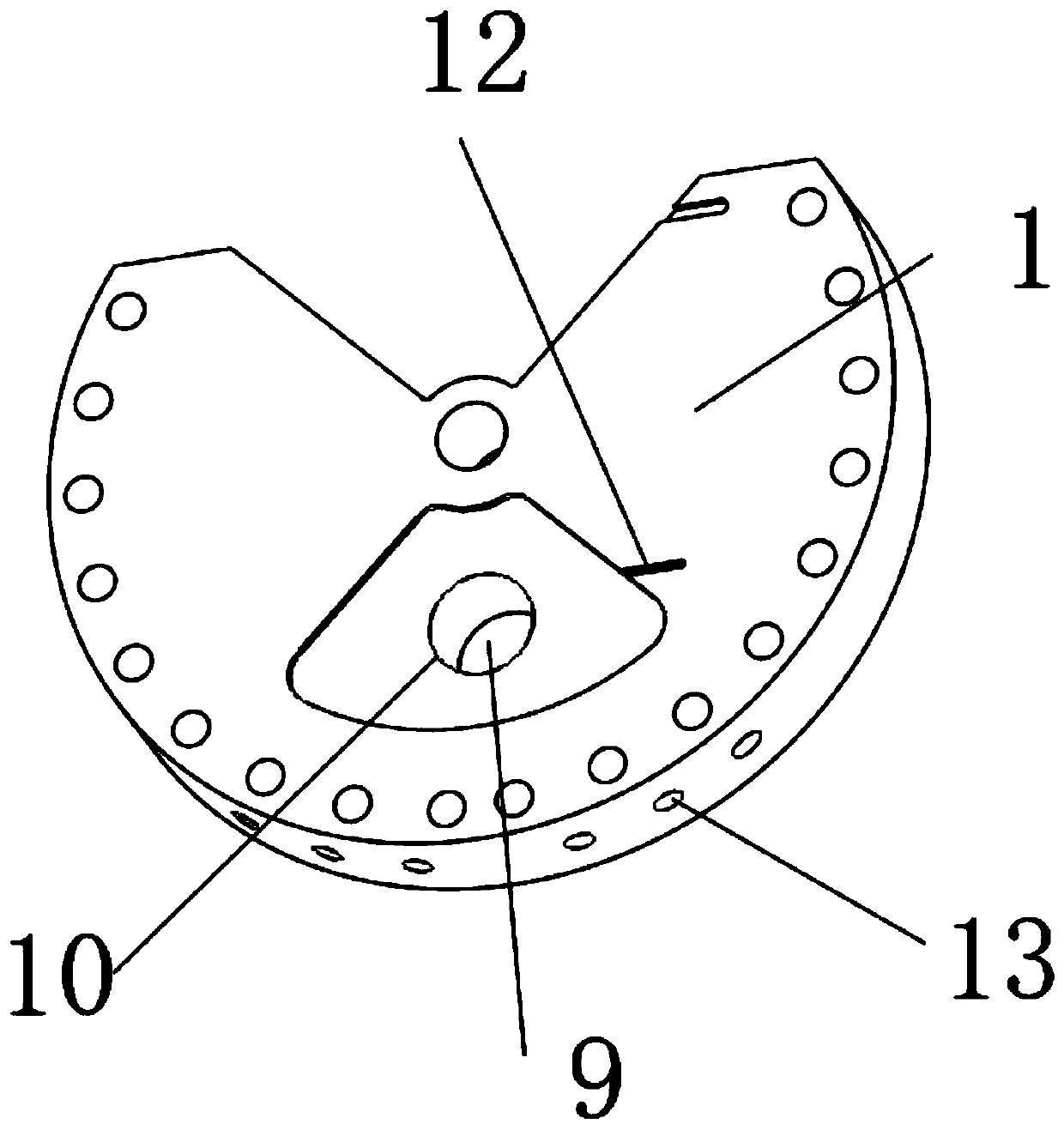

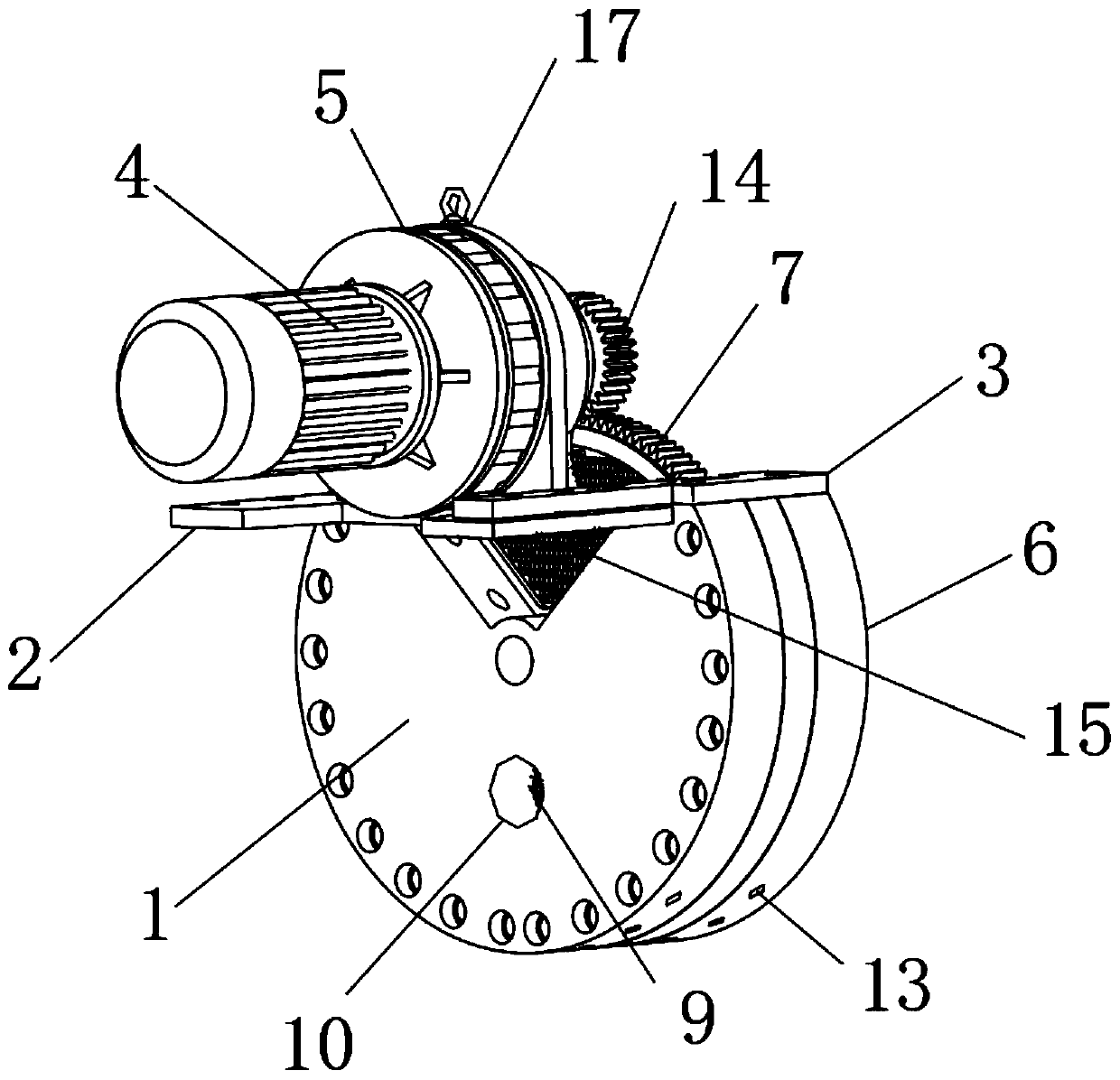

Electrically controlled opening apparatus for kiln door

InactiveCN1880906ATo achieve the purpose of opening the kiln doorControl temperature differenceControl devices for furnacesPressure controllerTemperature difference

The invention relates to a furnace door electric control switch of ceramic furnace, which is formed by electric transmission device and temperature controller, wherein the electric transmission device comprises a motor, a pressure controller, an universal angle device, a jointer and a transmission screw, while the motor and the pressure controller are connected via connector; the connector is arranged with pressurize control hole and anti-drop groove; the pressure controller is mounted with pressure control bolt and anti-drop bolt; the universal angle device is one flexible muffle, whose one end is connected to the pressure controller and another end is connected to the jointer; the transmission screw is connected to the jointer, while it is arranged with limit groove and positioning actor. The invention can full-automatically switch on the furnace door at special temperature and time, to effectively control the temperature difference between inside and outside space when the ceramic product has been sintered, to confirm the quality and reduce the producing cost.

Owner:陈岳忠

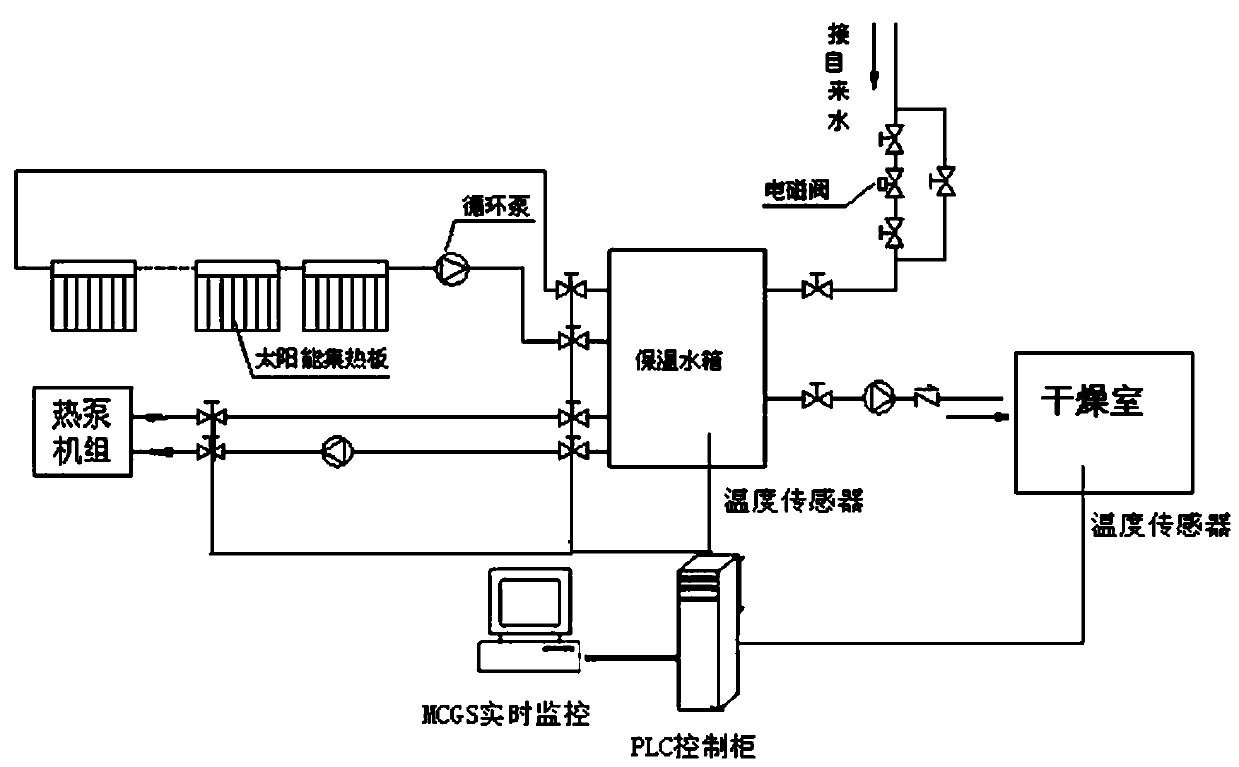

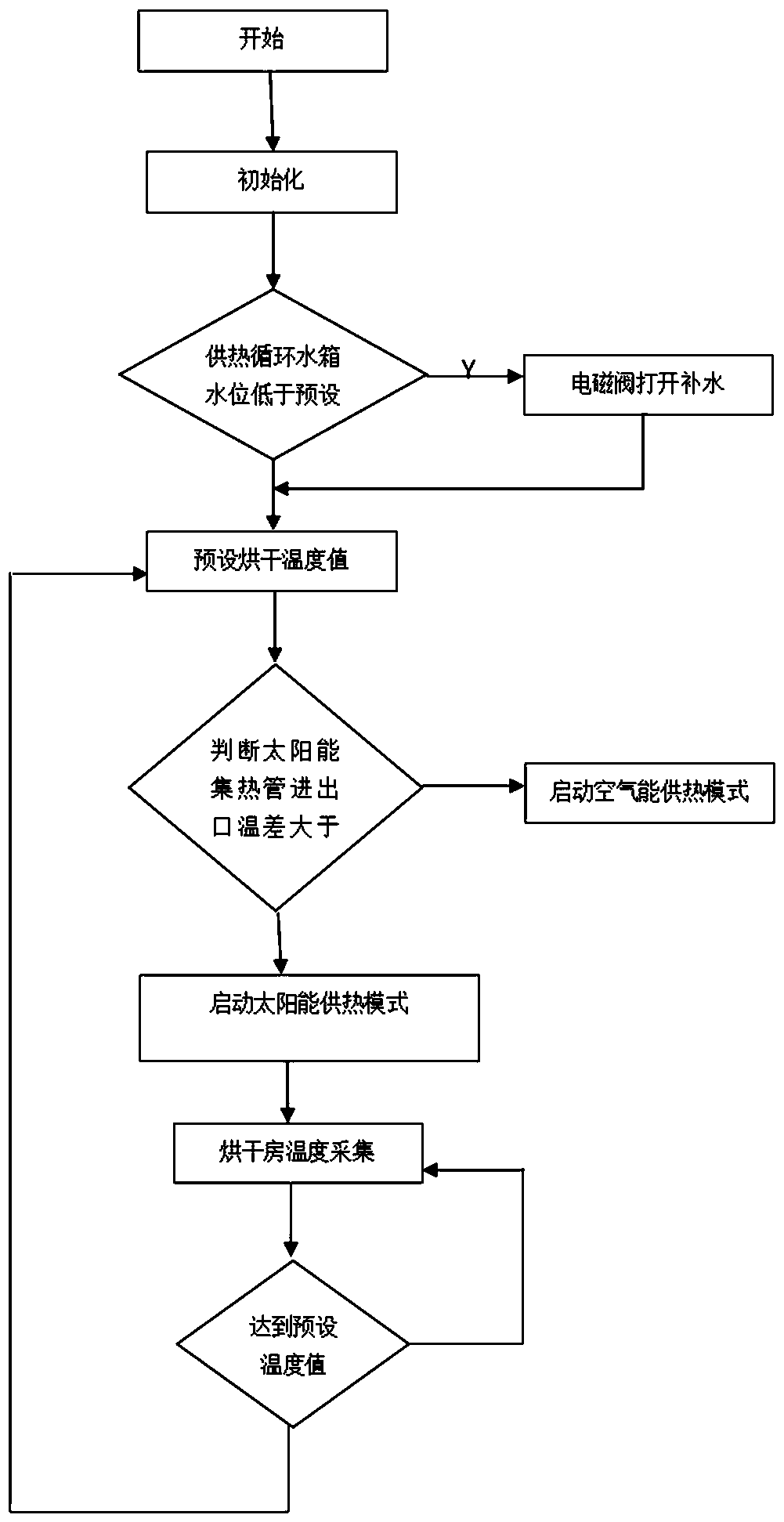

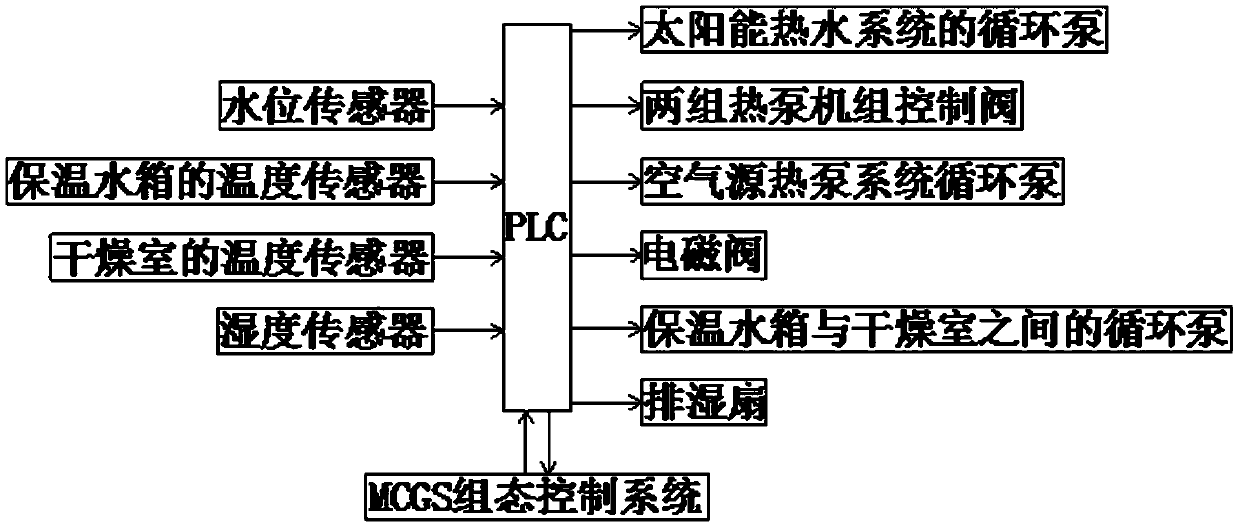

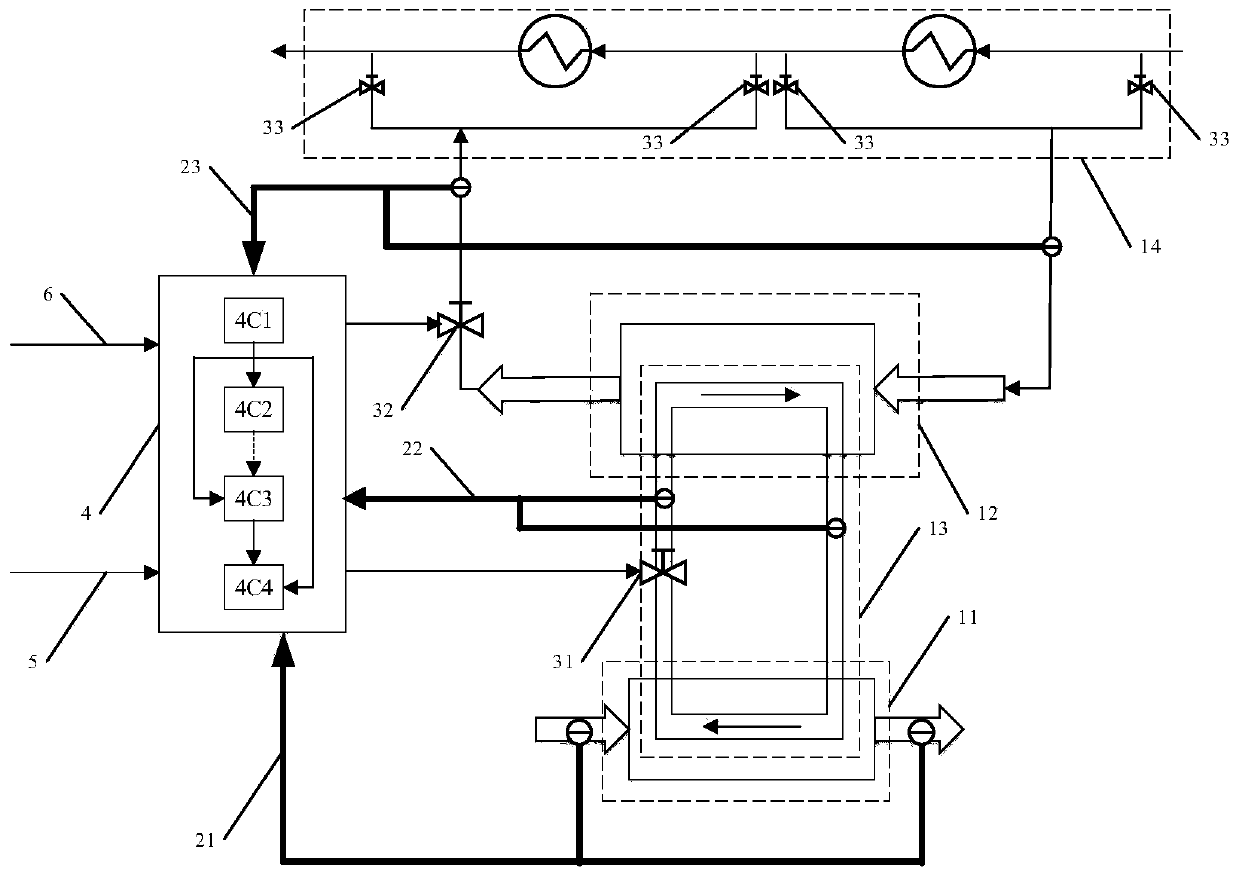

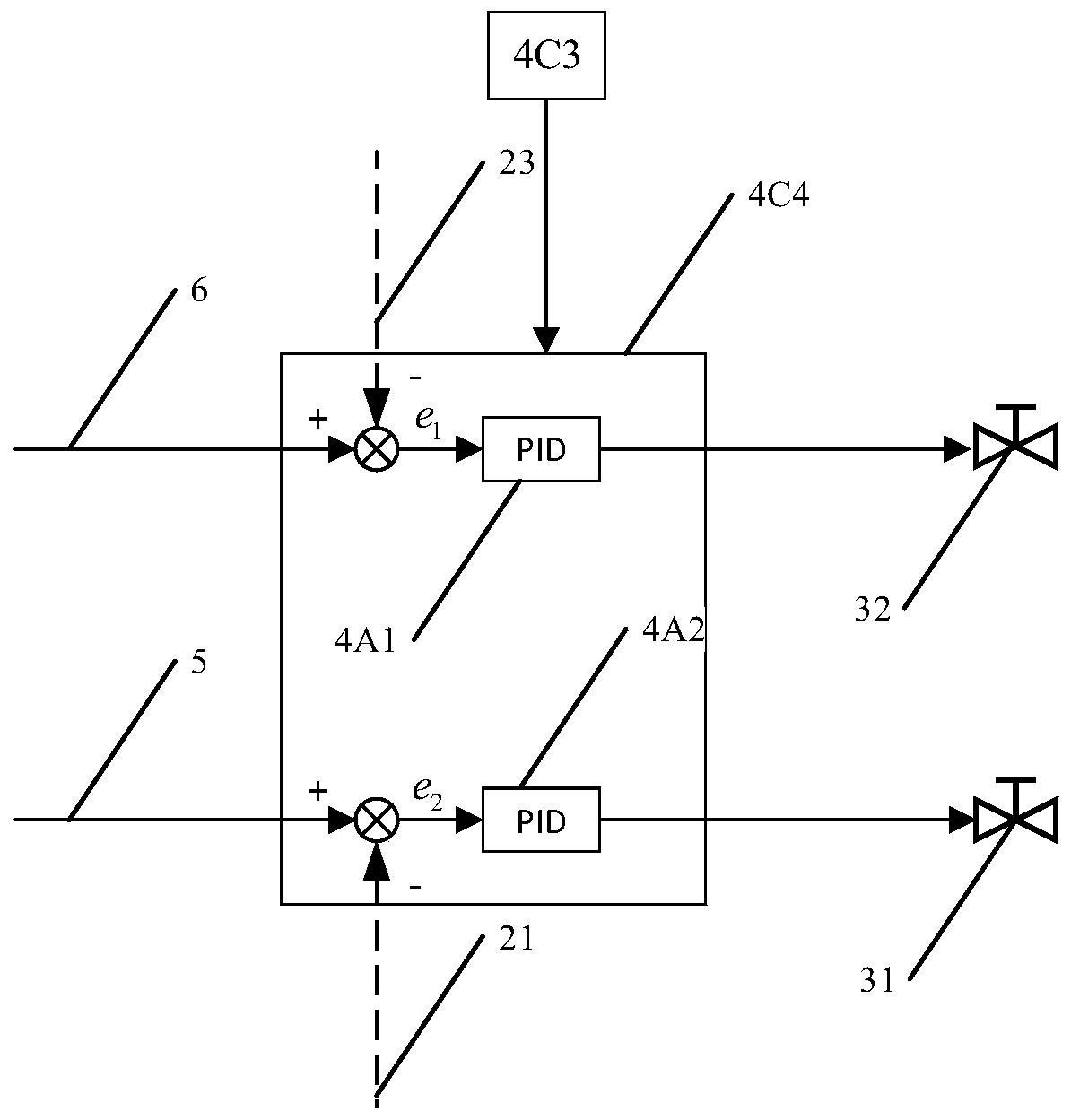

Solar energy-heat pump combined Bozhou chrysanthemum drying system based on orthogonal optimization

InactiveCN110836573AControl temperature differenceEasy to control temperatureSolar heating energySolar heat collector controllersThermodynamicsControl system

The invention discloses a solar energy-heat pump combined Bozhou chrysanthemum drying system based on orthogonal optimization. The Bozhou chrysanthemum drying system involves a heat supply system, a heat storage system, a drying system body and a monitoring system, wherein the monitoring system is composed of an MCGS configuration control system and a PLC, one side of the heat storage system is connected with the heat supply system, and the other side of the heat storage system is connected with the drying system body. According to the solar energy-heat pump combined Bozhou chrysanthemum drying system based on the orthogonal optimization analysis, the heat storage system is arranged, and heat generated by the whole system is stored in a heat preservation water tank, so that the situation that heat generated by solar energy and a heat pump directly acts on a drying chamber is avoided, the temperature difference between the heat generated by the solar energy and the heat generated by theheat pump is effectively controlled, the drying efficiency is improved, and the drying temperature can be accurately controlled; and the MCGS configuration control system is adopted to connect the PLC, so that programming and control are facilitated, accurate control over the temperature is realized, and accurate exchange between the solar energy heat supply and the heat pump heat supply is met.

Owner:BOZHOU VOCATIONAL & TECHNICAL COLLEGE

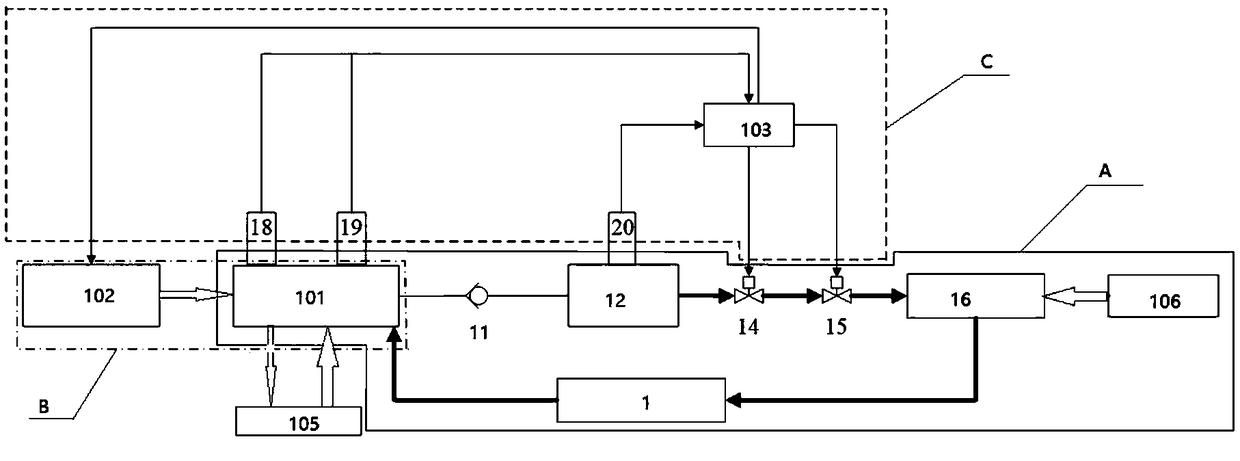

Intelligent control system for flue gas waste heat utilization of thermal power generation unit

ActiveCN110486706AControl temperature differenceIncrease profitMeasurement devicesBoiler controlIntelligent control systemFlue gas

The invention relates to an intelligent control system for flue gas waste heat utilization of a thermal generator unit. The system is provided with a heat exchange structure, a measurement sensing structure, a heat exchange optimization structure and an optimization control structure. The heat exchange structure can recover the waste heat of high-temperature flue gas at the tail of a boiler, and sends the waste heat to a condensation water heat exchange system through the intermediate heat exchange of a circulating water system. Based on parameters such as temperature and flow of flue gas, circulating water and condensate water, real-time feedback and calculation analysis are carried out on the waste heat utilization scheme. With maximum utilization of flue gas waste heat as a target, thecondensate water inlet / outlet position, circulating water flow and condensate water flow are adjusted to realize intelligent control of a waste heat utilization system, so that flue gas waste heat isrecycled and is fully used for assisting a steam turbine heater of the thermal power generating unit.

Owner:GUODIAN NEW ENERGY TECH INST

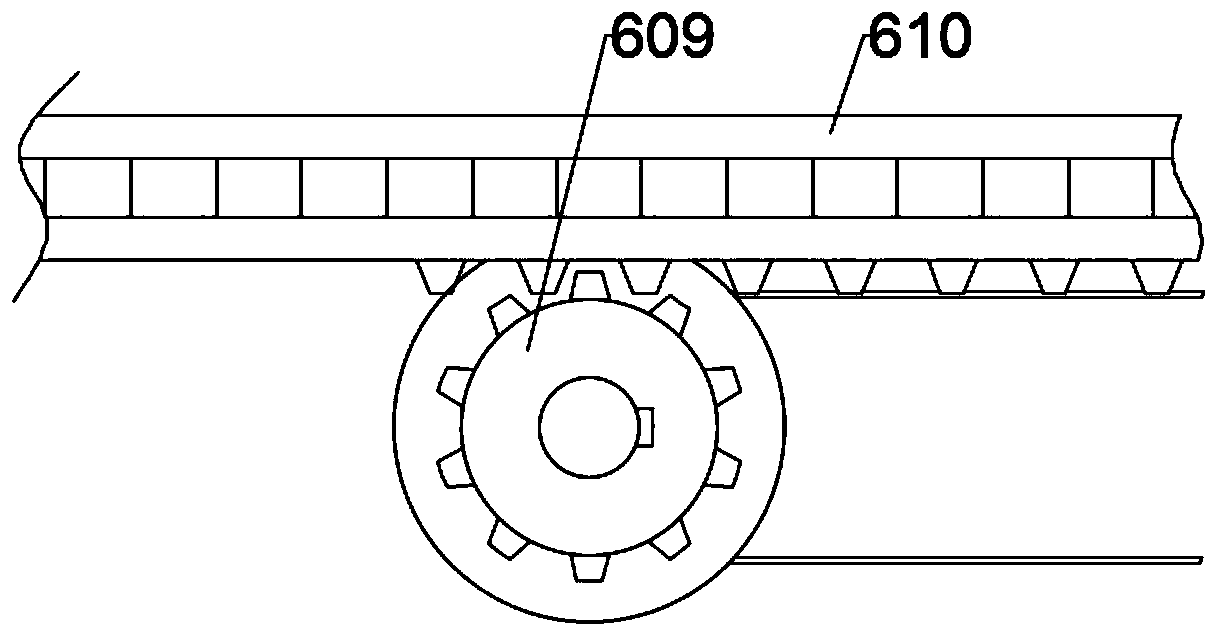

Non-stop automatic screen changer

The invention discloses a non-stop automatic screen changer comprising a front shell, a support plate, a motor bracket, a rotating motor, a speed reducer, a rear shell, a gear disk, a gear housing, adriving gear, a filter plate and filter screen clamping slots. Fixing plates are fixedly welded on the top of one side of the front shell symmetrically, and the top of each fixing plate is fixedly connected with the motor bracket by bolts; one side of the motor bracket is fixedly provided with the rotating motor, and an output shaft of the rotating motor is fixedly provided with the speed reducer;an output shaft of the speed reducer is fixedly provided with the driving gear, and the side, far away from the fixing plates, of the front shell is provided with the rear shell; and the top end of the rear shell is fixedly connected with the motor bracket by bolts, and the gear disk is arranged between the front shell and the rear shell. According to the non-stop automatic screen changer, filterscreens can be replaced under the non-stop condition of a plastic extruding machine, not only is the machining speed of the plastic extruding machine increased, but also the efficiency of the plasticextruding machine is improved.

Owner:李增现 +1

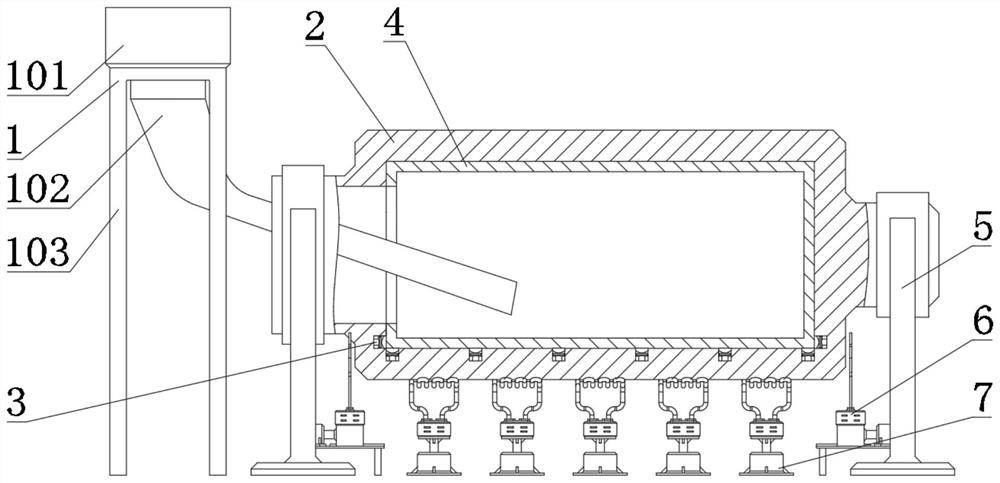

Temperature control device and method for centrifugal casting

ActiveCN113751685AControl temperature differenceImprove casting qualityTemperature controlEngineering

The invention relates to a temperature control device and a method for centrifugal casting, and the temperature control device detects the temperature of a working layer of a roller during casting through a plurality of groups of temperature detection devices, and carries out temperature compensation on the working layer through a side heating device and a cylindrical surface heating device. According to the method for centrifugal casting, the casting temperature of the cylindrical surface, the casting temperature of the side surface and the casting temperature of the center are compared and calculated, the distance between a heating coil and the outer wall of a mold is adjusted and controlled through the temperature difference, and centrifugal casting temperature control is achieved; the problem that the temperature difference between different casting metals and a formed working layer part and the temperature difference between working layers are too large during casting of a composite roller is effectively solved. According to the temperature control device and the method for centrifugal casting, the temperature difference regulation and control of different casting metals, formed working layer parts and working layers during casting of the composite roller are realized, and the cylindrical surface temperature difference and the edge temperature difference of the working layers of the composite roller can be effectively regulated and controlled; and meanwhile, the temperature difference of the working layers of the composite roller in the casting process is precisely regulated and controlled, and the casting quality of the working layers of the composite roller is improved.

Owner:LINYI TIANKUO CASTING CO LTD

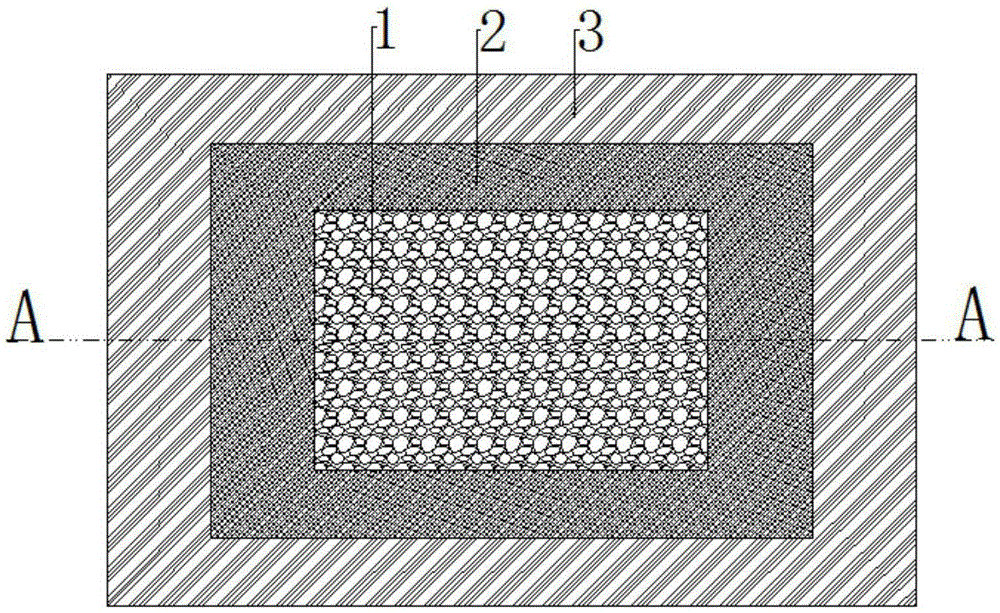

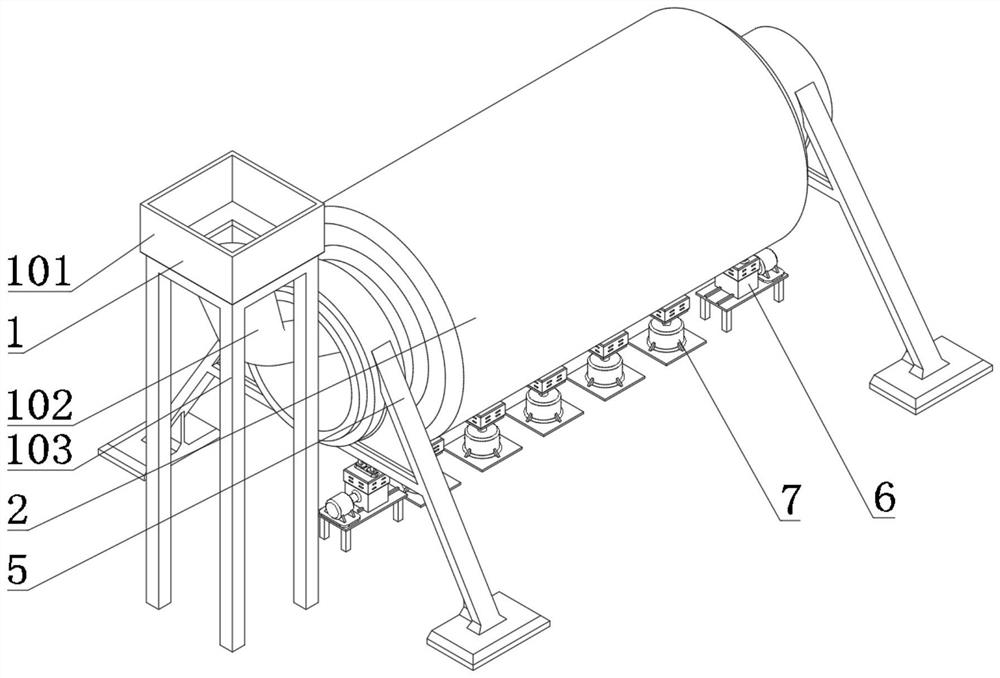

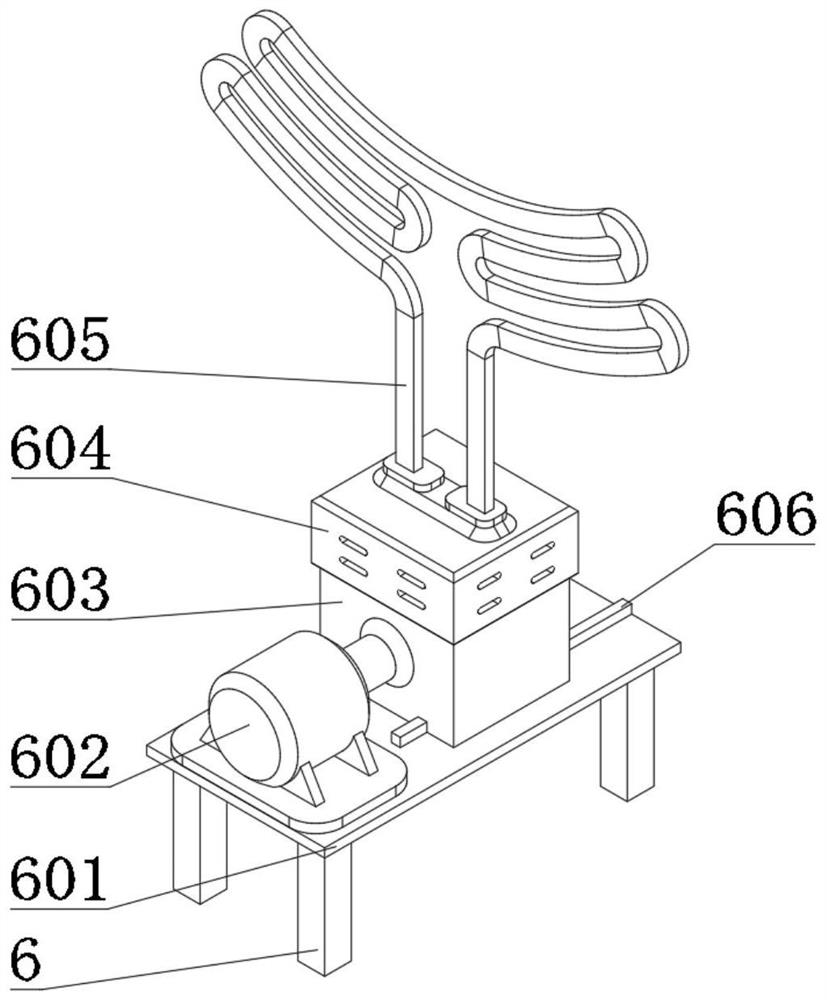

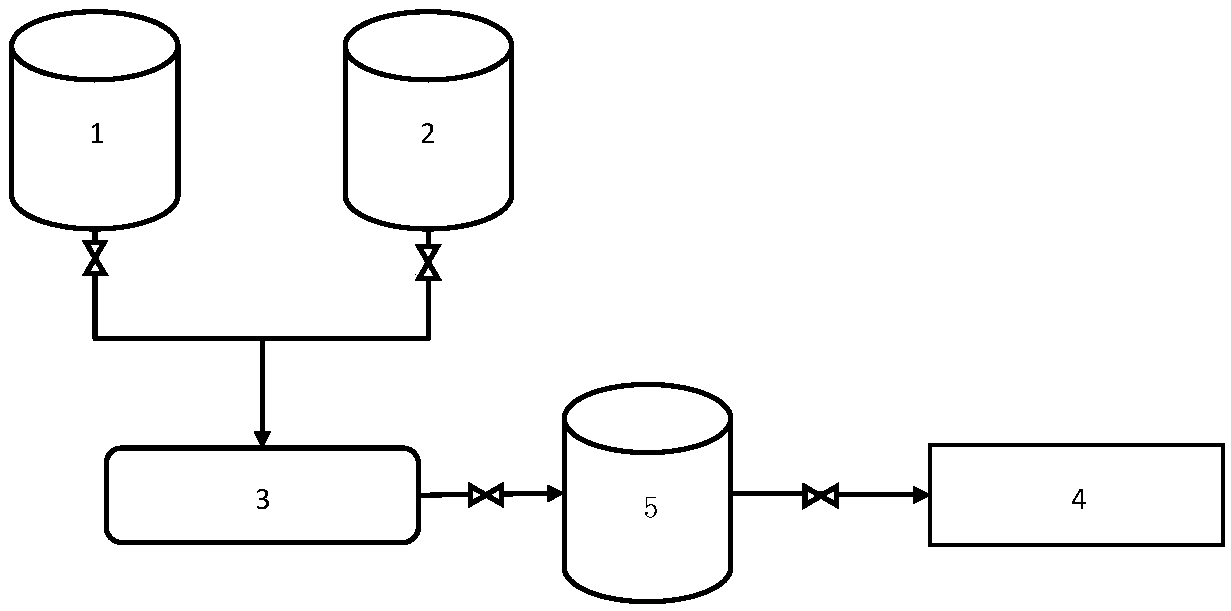

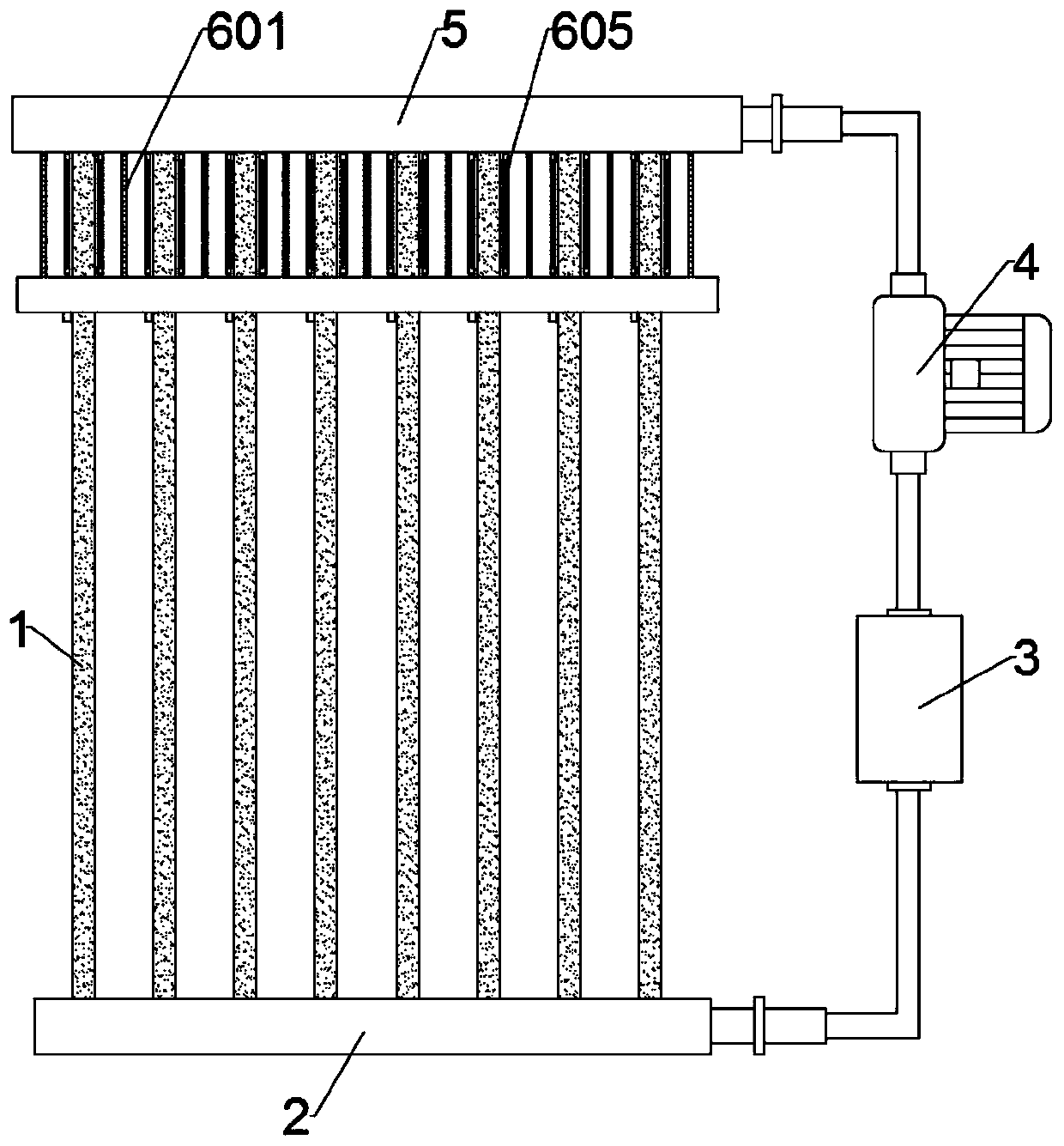

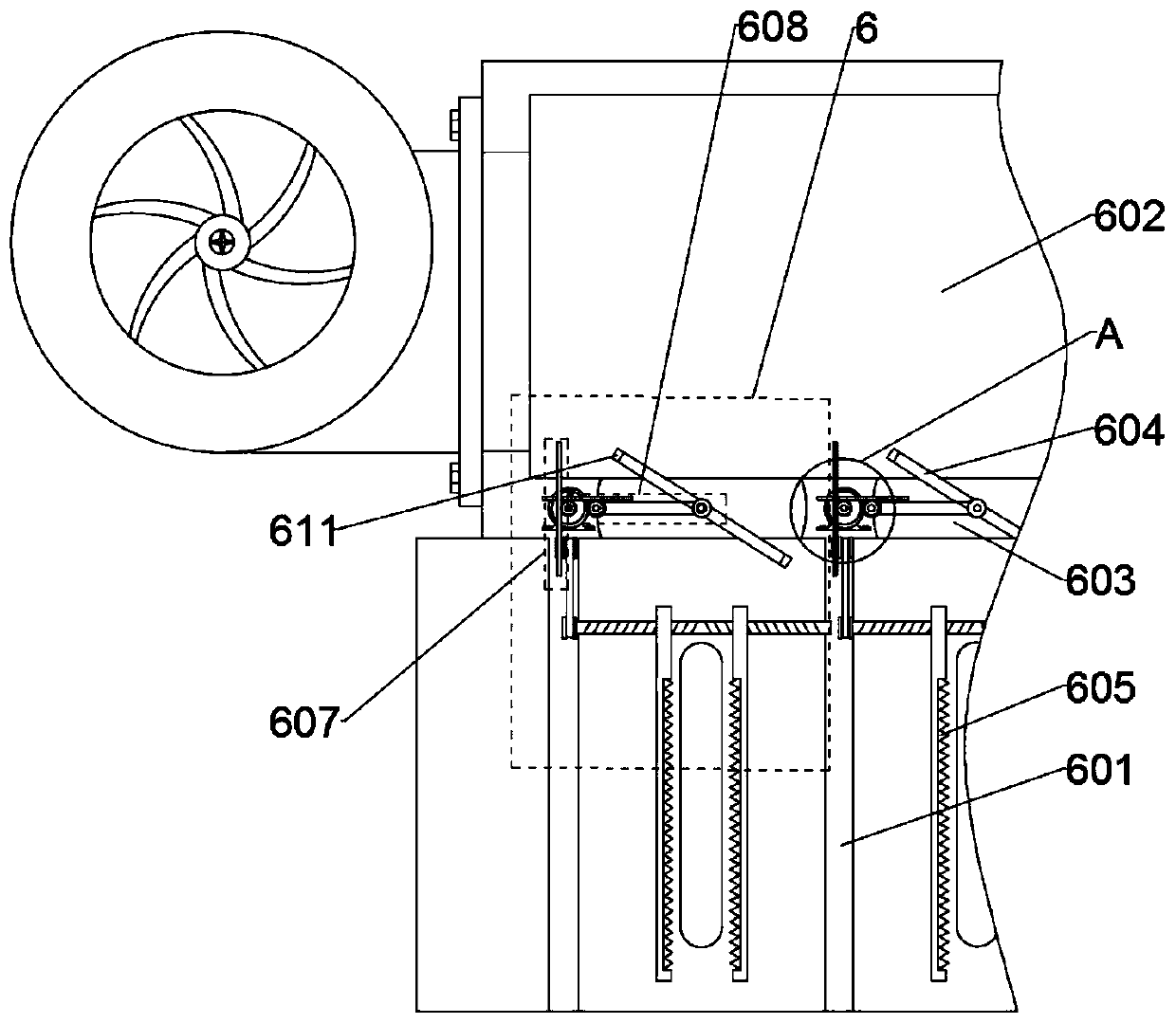

Equipment for preparing lipid nanospheres

PendingCN108927080AGood emulsifying effectReduce surface oil slicksMixing methodsTransportation and packagingLipid formationMicrosphere

The invention provides equipment for preparing lipid nanospheres. The primary emulsion preparation part comprises a water phase tank, an oil phase tank and a multi-stage online dispersion machine; anda high-speed shear emulsification head is installed in the water phase tank. According to the equipment provided by the invention, combined emulsification is performed by the multi-stage online dispersing machine and the high-speed shear emulsification head in the equipment, so that stability of a primary emulsion is improved; the water phase tank in the equipment has the functions of water phasepreparation, emulsification and primary-emulsion final product temporary storage, and connection of the water phase tank and the top of the oil phase tank can realize cyclic shearing of a mixed phasein the multi-stage online dispersion machine while the oil phase tank is washed; and the equipment is simplified, reduces adhesion loss of the primary emulsion in the transfer process, and is suitable for industrialized production of the lipid nanospheres.

Owner:本溪恒康制药有限公司 +1

Cooling verification method and device of power transformer cooling equipment

ActiveCN111487077AAvoid defectsEffective cooling simulationStructural/machines measurementHeat sinkProcess engineering

The embodiment of the invention discloses a cooling verification method of power transformer cooling equipment. The method comprises the following steps: establishing a temperature database of each part of a transformer without cooling equipment; then manufacturing a cooling fin model which is scaled down in an equal proportion; connecting to an oil cooling cycle; carrying out preheating through aheating device; finely adjusting the temperature of an oil cooling liquid by using a temperature fine adjustment device according to the temperature database; installing the heat dissipation equipment which is scaled down in the equal proportion; starting the heat dissipation equipment to detect the temperature change of a cooling fin; comparing acquired temperature change data with cooling simulation data; and completing cooling verification, wherein the cooling equipment includes a heat dissipation pipe, an oil outlet pipe, a heating box used for heating the oil cooling liquid, a pressure pump used for enabling the oil cooling liquid to flow circularly and an oil inlet pipe which are connected together in sequence. During usage, a fine adjustment assembly is utilized to control a temperature difference among the plurality of cooling fins in actual use so that simulation is more vivid.

Owner:GUANGDONG POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com