Heat dissipating structure of cylindrical battery module

A battery module and heat dissipation structure technology, applied in secondary batteries, structural parts, battery pack parts, etc., can solve the problems of complex structure, unfavorable promotion and use, manufacturing difficulties, etc. The effect of contact heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing.

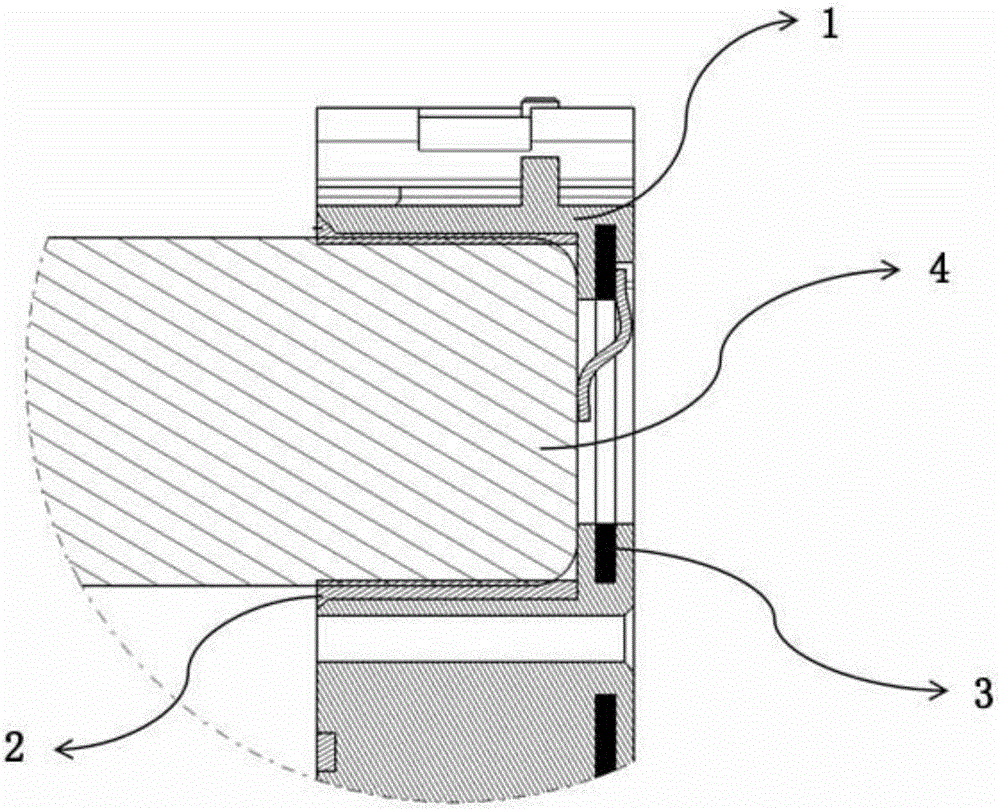

[0018] see figure 1 , figure 1 Shown is an embodiment of the present invention, which is a cylindrical battery module, including a fixed bracket 1, batteries 4 installed on the fixed bracket 1 and arranged in parallel, and a bus bar 3 integrated in the fixed bracket 1 .Wherein, the fixed bracket 1 preferably has engineering plastics such as PC / PA / PPS / PP with heat-conducting fillers, thus forming a heat-conducting block structure, so that the two stages of the battery 4 are respectively fixed in the heat-conducting block. Such a design makes the battery 4 Have enough cooling area. The bus bar 3 is a heat conductor, and the heat conductor is embedded in the heat conduction block. The busbar 3 made of metal can not only transfer heat quickly, but also control the overall temperature difference of the fixing bracket 1 due to its high thermal conductivity, thereby avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com