Method for controlling head and tail temperature difference of semi-endless rolled overlong casting blank

A control method and semi-headless technology, applied in the field of iron and steel metallurgy, can solve the problems of unresolved temperature uniformity of ultra-long slabs and industrial mass production, and achieve energy saving, convenient on-site operation, and simple process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

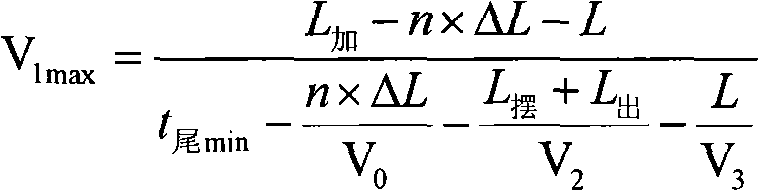

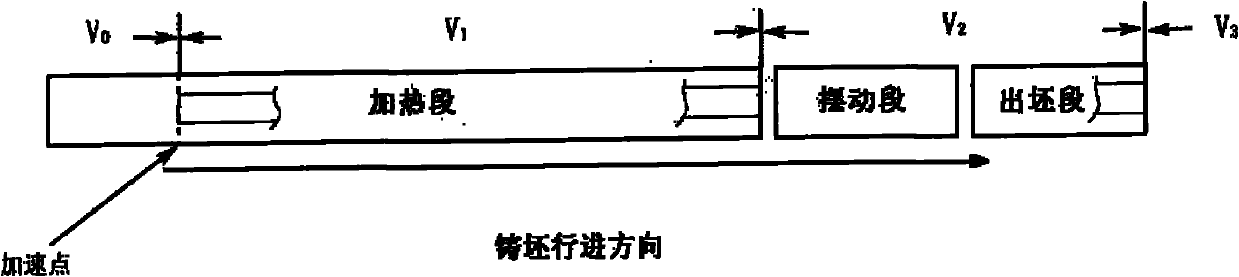

[0047] Using all two rolling, the length of the billet is about 70m, the length of the soaking furnace is 291m, and the length of the heating section is 159m. Among them, the acceleration point is set at a distance of 36m from the head of the soaking furnace, and the length of the swing section and the billet section is 96m. ; After the head of the slab leaves the continuous casting machine, it enters the soaking furnace directly at a casting speed of 4.0m / min, and continues to move forward at a speed of 25m / min after the tail of the slab passes the acceleration point until the head of the slab Reach the end of the heating section, then move quickly to the end of the billet exit section at a speed of 40m / min, and finally enter the F1 rolling mill at a speed of 30m / min until the tail of the slab leaves the soaking furnace.

[0048] The measurement results of the on-site infrared thermometer show that the temperature difference between the head and the tail of the slab is 20°C. ...

Embodiment 2

[0050] Using all three rolling, the length of the billet is about 100m, the length of the soaking furnace is 291m, and the length of the heating section is 159m. Among them, the acceleration point is set at a distance of 36m from the head of the soaking furnace, and the length of the swing section and billet discharge section is 96m. ; After the head of the slab leaves the continuous casting machine, it enters the soaking furnace directly at a casting speed of 4.2m / min, and continues to move forward at a speed of 25m / min after the tail of the slab passes the acceleration point until the head of the slab Reach the end of the heating section, then move quickly to the end of the billet exit section at a speed of 45m / min, and finally enter the F1 rolling mill at a speed of 30m / min until the tail of the slab leaves the soaking furnace.

[0051] The measurement results of the on-site infrared thermometer show that the temperature difference between the head and the tail of the slab i...

Embodiment 3

[0053] All four-rolling is adopted, the length of the billet is about 120m, the length of the soaking furnace is 291m, and the length of the heating section is 159m. Among them, the acceleration point is set at a distance of 36m from the head of the soaking furnace, and the length of the swing section and the billet section is 96m. ; After the head of the slab leaves the continuous casting machine, it enters the soaking furnace directly at a casting speed of 4.5m / min, and continues to move forward at a speed of 25m / min after the tail of the slab passes the acceleration point until the head of the slab Reach the end of the heating section, then move quickly to the end of the billet exit section at a speed of 45m / min, and finally enter the F1 rolling mill at a speed of 30m / min until the tail of the slab leaves the soaking furnace.

[0054] The measurement results of the on-site infrared thermometer show that the temperature difference between the head and the tail of the slab is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com