High-accuracy micro deformation star sensor mounting bracket

A technology of star sensor and mounting bracket, which is applied in the directions of aircraft, transportation and packaging, aerospace aircraft, etc., can solve the problems of high-orbit spacecraft high-precision attitude determination and image navigation registration requirements, etc., and achieves light weight. , the effect of reducing the tension and torsion effect and releasing the thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

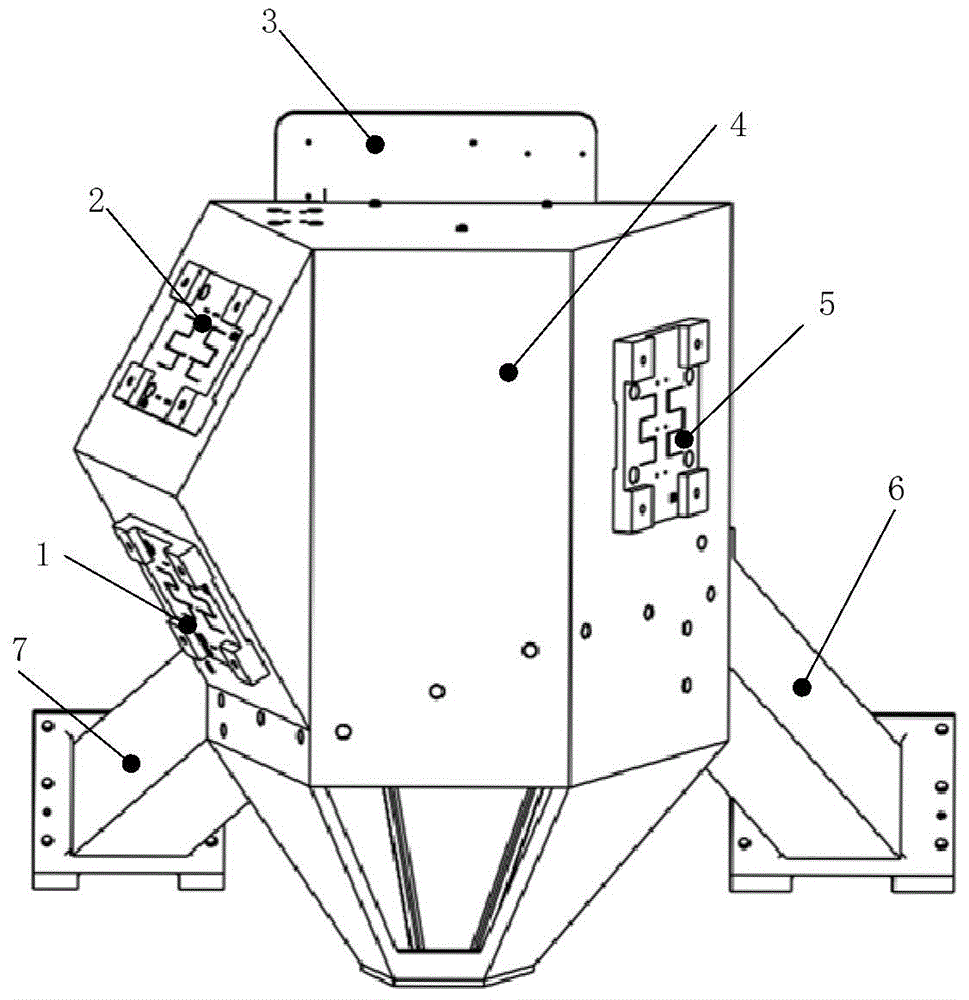

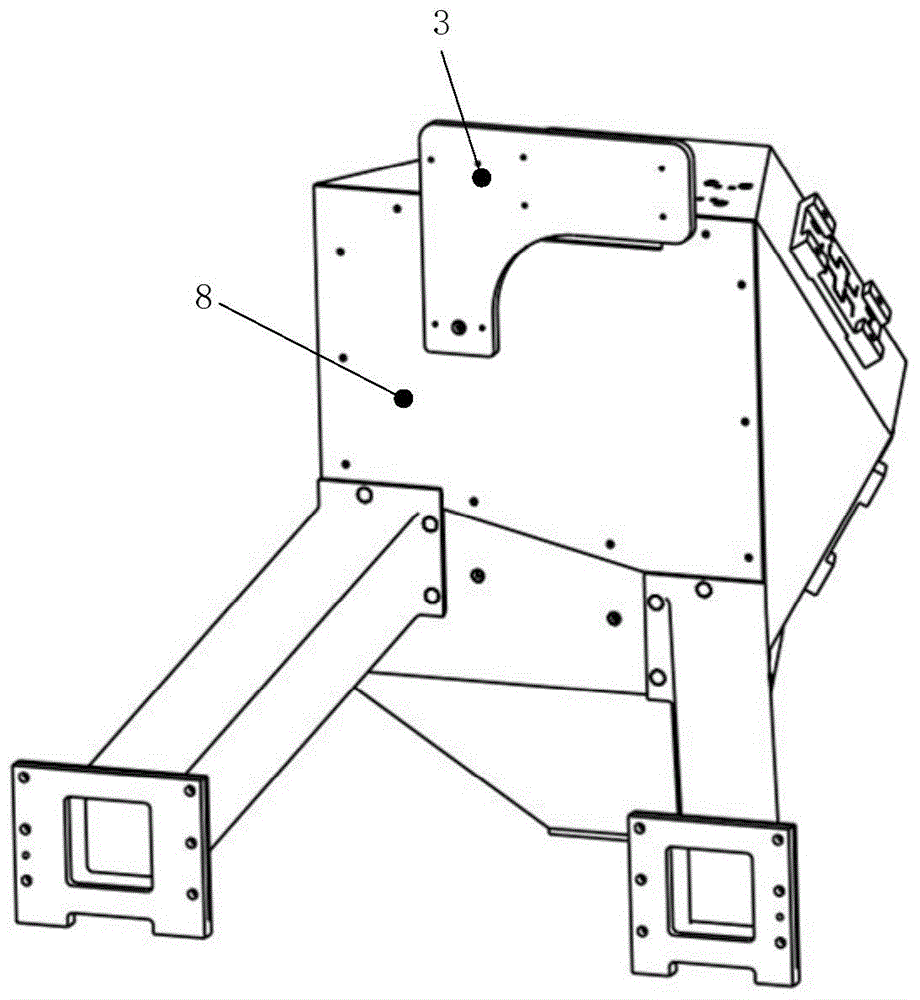

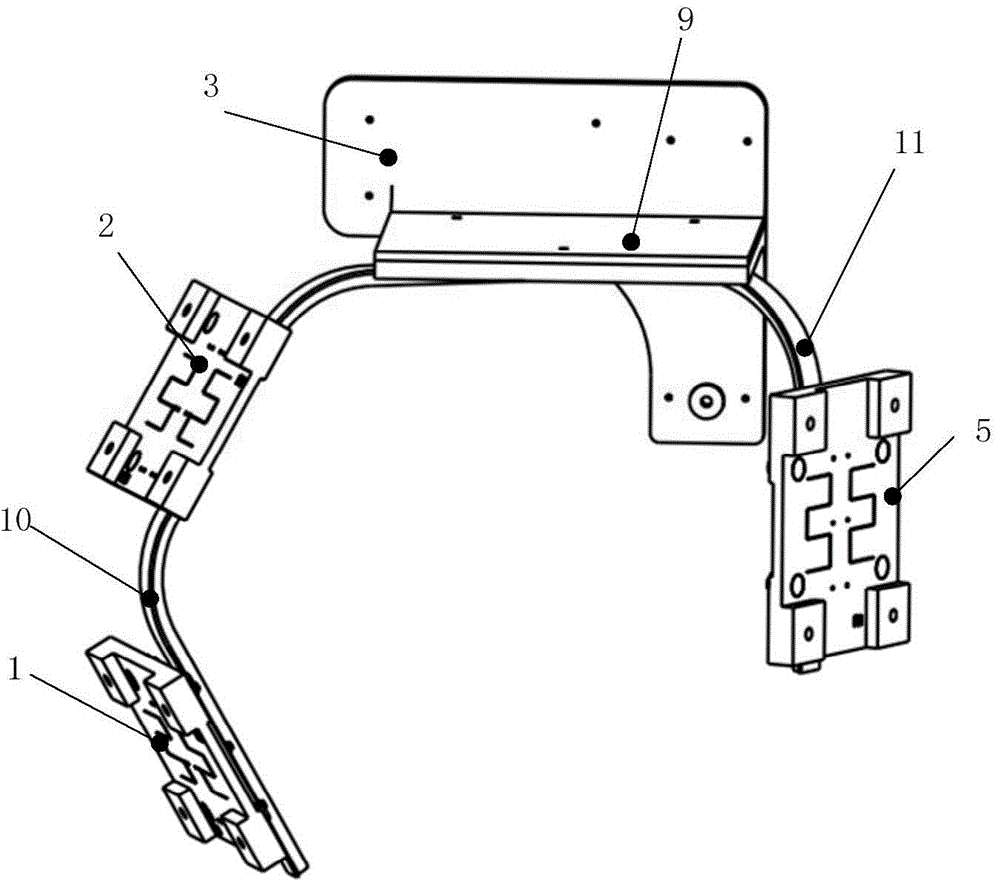

[0036] Please also see Figure 1 to Figure 7 .

[0037] This embodiment provides a high-precision micro-deformation star sensor mounting bracket, including: a thin-walled shell structure, a rear cover plate, a star sensor mounting plate, a heat collection plate, a heat insulation pad, a heat pipe and a support rod assembly, wherein, The star-sensitive mounting plate is connected to the outside of the thin-walled shell structure for installing the star sensor; the heat pipe is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com