Electrically controlled opening apparatus for kiln door

An opening device and electric control technology, which is applied in the direction of furnace control devices, furnaces, lighting and heating equipment, etc., can solve the problems of difficult control of the temperature difference between the inside and outside of the kiln, and achieve the effects of saving labor, reducing production costs and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

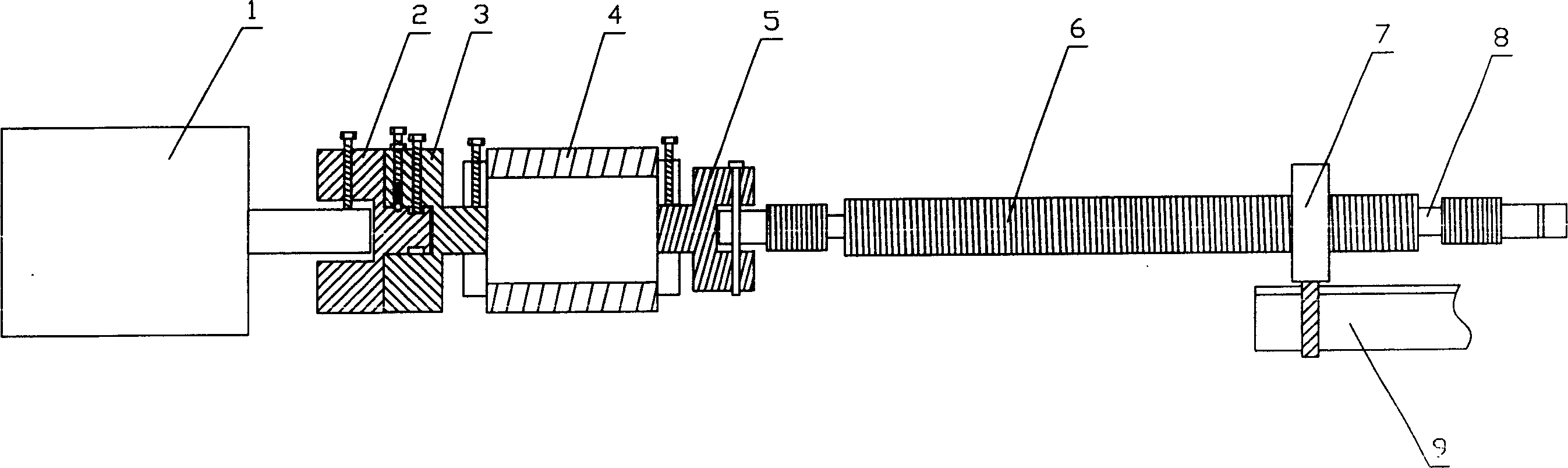

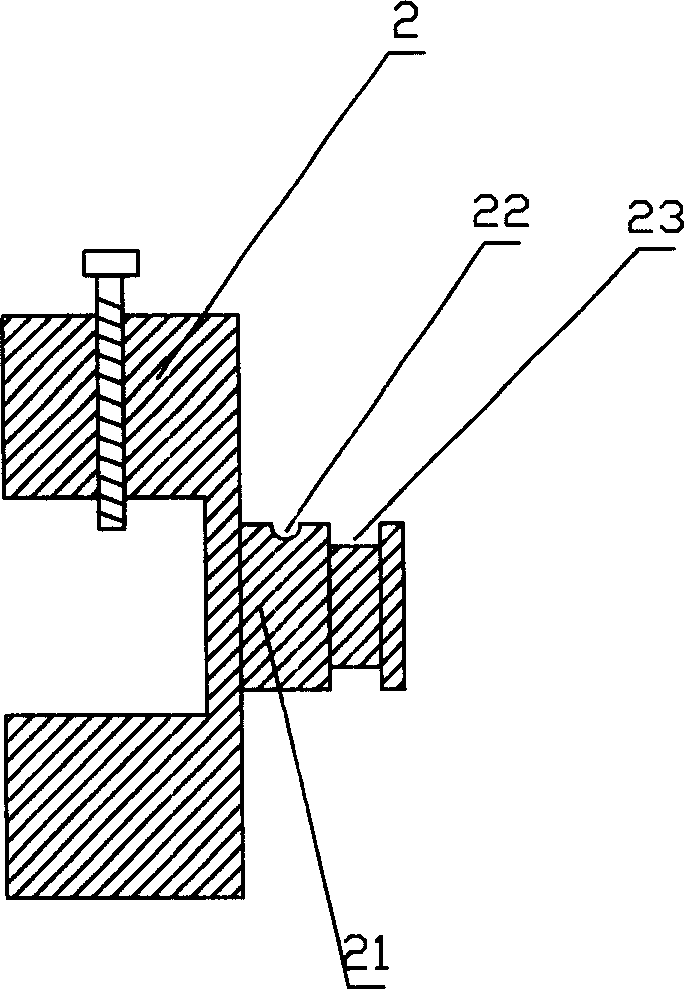

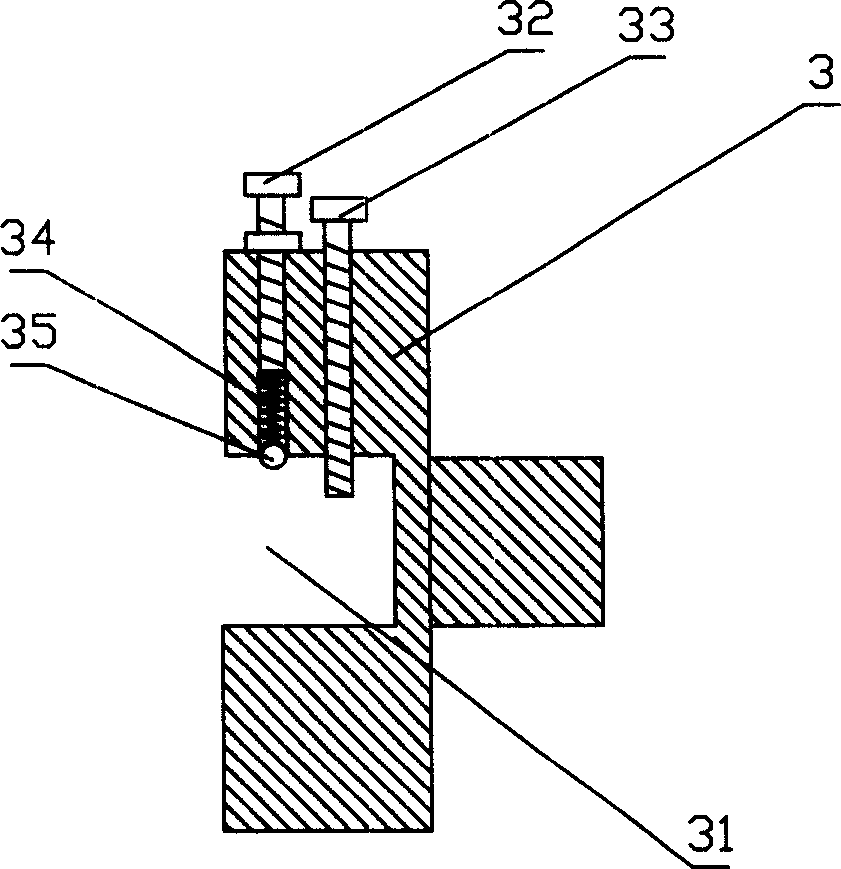

[0015] The kiln door electric control opening device provided by the present invention is shown in the figure. figure 1 It is a schematic diagram of the structure of the electric transmission device. The motor 1 is a geared motor, which is installed on the iron frame on the side of the oil furnace. Connected to the motor 1 are a connector 2, a pressure controller 3, a universal angler 4, a connector 5 and a transmission screw 6 in sequence. The specific structure is that the motor 1 and the pressure controller 3 are connected through the connector 2; as figure 2 As shown, the large end of the connector is fixed to the output shaft of the motor, and the other end is a boss 21, and the boss is provided with a pressure control hole 22 and an anti-loosening groove 23; image 3 It is a structural diagram of the pressure controller 3. One end of the pressure controller 3 has a concave hole 31 matched with the connector boss 21, and its outer wall is respectively equipped with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com