Temperature gradient controlled mass concrete for bridges

A large-volume concrete and temperature gradient technology, applied in the field of building materials, can solve problems such as internal and external temperature difference control, cap cracking, etc., and achieve the effects of reducing shrinkage, increasing corrosion resistance, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

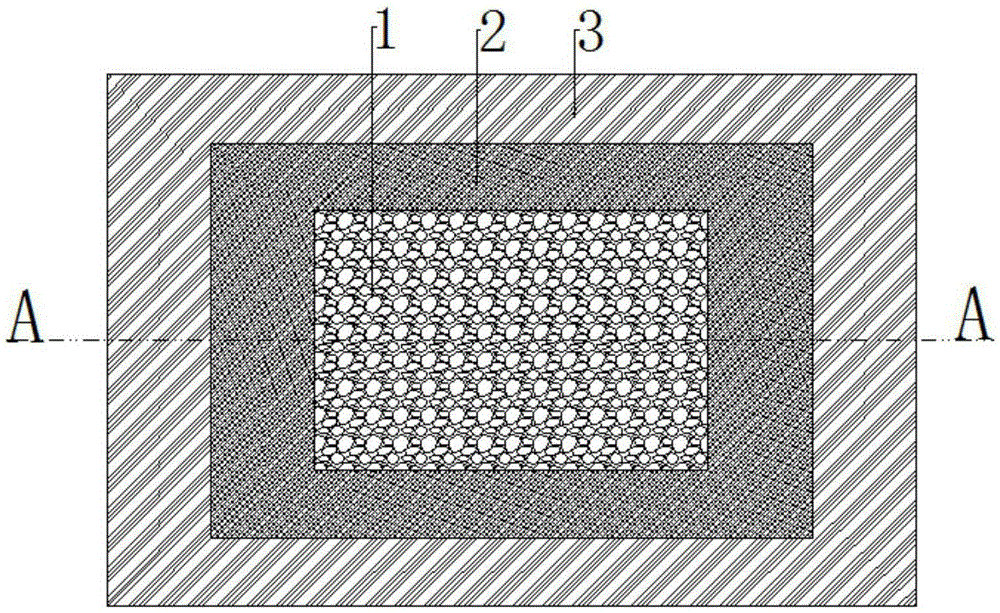

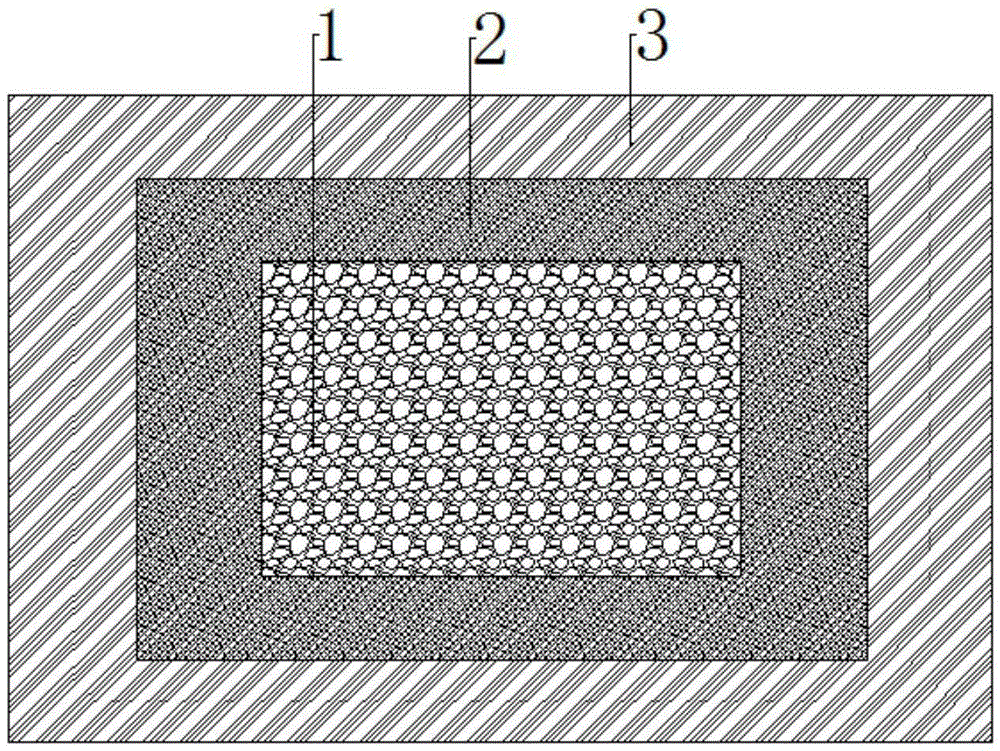

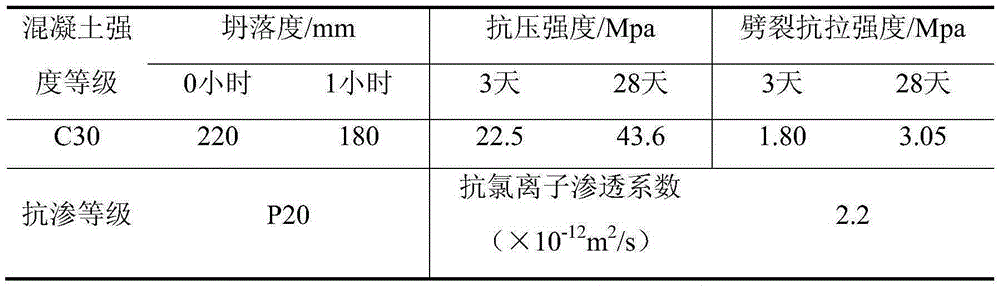

[0039] A temperature gradient controlled bridge mass concrete is used to prepare the mass concrete of a certain river-sea bridge cap, and its structure is as follows figure 1 and 2 As shown, the cap size is 20m (length) * 15m (width) * 4m (height), the design strength grade of concrete is C30, and the outer layer of high toughness and high crack resistance with a thickness of 0.8m is set outside the mass concrete Concrete 3, the middle layer is poured with 2m-thick middle-layer low-temperature-rising crack-resistant concrete II2, and the inner layer is poured with low-temperature-rising crack-resistant concrete I1, so that the overall structure forms a large-volume temperature gradient control with high crack resistance at the periphery and low temperature rise in the middle and inside Structure, among them, the mix ratio of each layer of concrete is shown in Table 1 and Table 2 respectively.

[0040] The mixing ratio (kg / m3) of the inner layer and the middle layer low temper...

Embodiment 2

[0052] A temperature gradient controlled bridge mass concrete, which is used to prepare the mass concrete of a certain river-sea bridge cap. An outer layer of high toughness and high crack resistance concrete with a thickness of 0.6m is arranged on the outside of the mass concrete, and the middle layer is poured with a middle layer of low temperature rising cracking resistant concrete II with a thickness of 2m, and the inner layer is poured with an inner layer of low temperature rising cracking resistant concrete I, Make the structure as a whole form a large-volume temperature gradient control structure with high crack resistance in the periphery and low temperature rise in the middle and interior. Among them, the mix ratio of concrete in each layer is shown in Table 5 and Table 6 respectively.

[0053] Table 5 Example 2 Inner layer, middle layer low-temperature rise crack-resistant concrete I and II mix ratio (kg / m 3 )

[0054]

[0055] Among them, the inner composite tem...

Embodiment 3

[0065] A temperature gradient controlled bridge mass concrete is used to prepare the mass concrete of a certain river-sea bridge. The cap size is 33m (length) * 16.5m (width) * 5m (height). Set a ring of high-toughness and high-crack-resistant concrete with a thickness of 0.5m outside the large-volume concrete, pour the middle layer of low-temperature rise crack-resistant concrete II with a thickness of 2.5m in the middle, and pour the inner layer of low-temperature rise crack-resistant concrete I, Make the structure as a whole form a large-volume temperature gradient control structure with high crack resistance in the periphery and low temperature rise in the middle and interior. Among them, the mix ratio of each layer of concrete is shown in Table 9 and Table 10 respectively.

[0066] The mixing ratio (kg / m3) of the inner layer and the middle layer low-temperature rising crack-resistant concrete I and II in the embodiment 3 of table 9 3 )

[0067]

[0068] Among them, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com