Patents

Literature

67results about How to "Small shrinkage value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

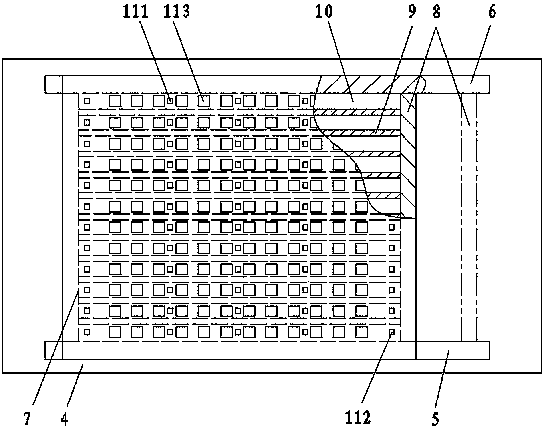

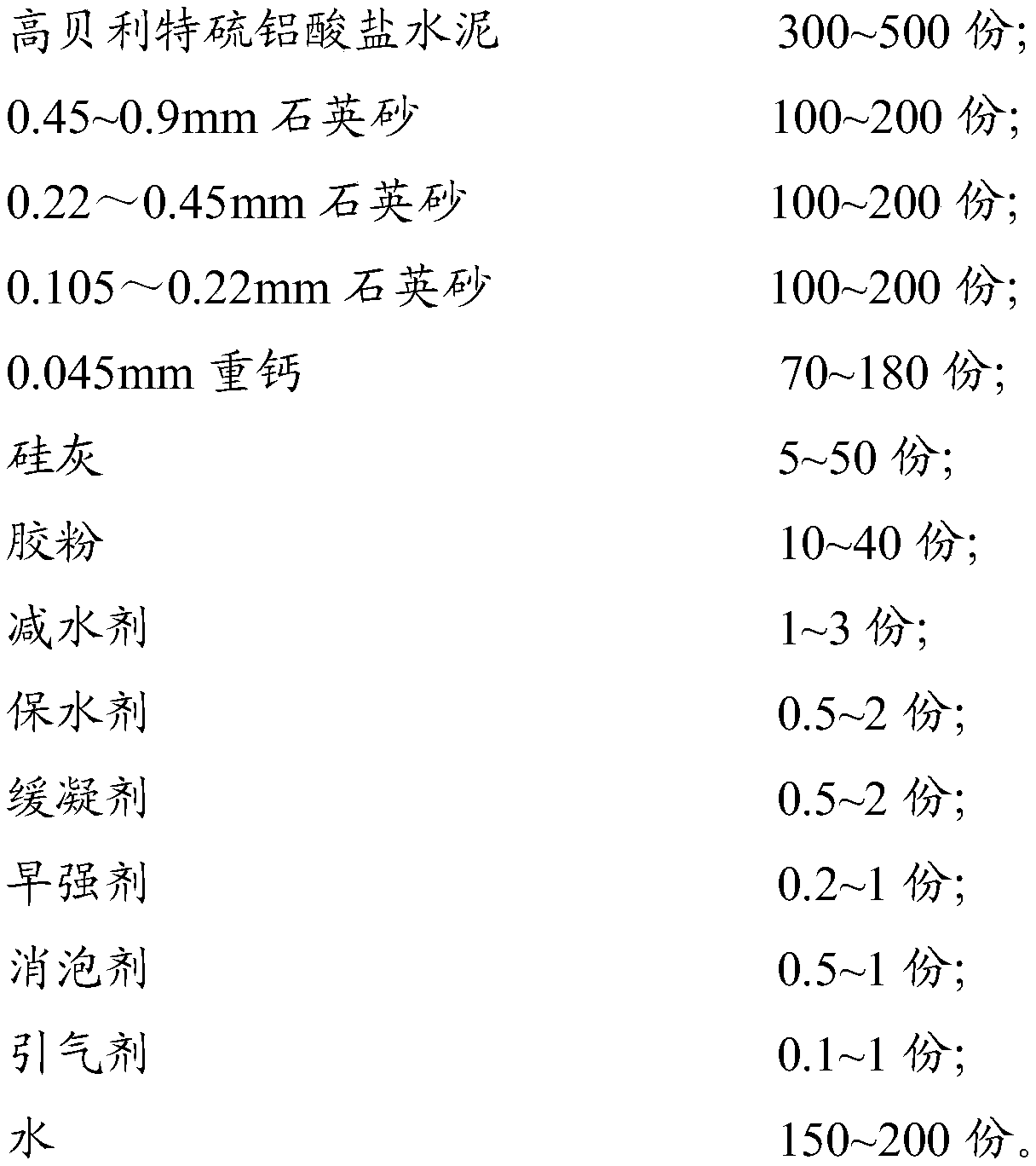

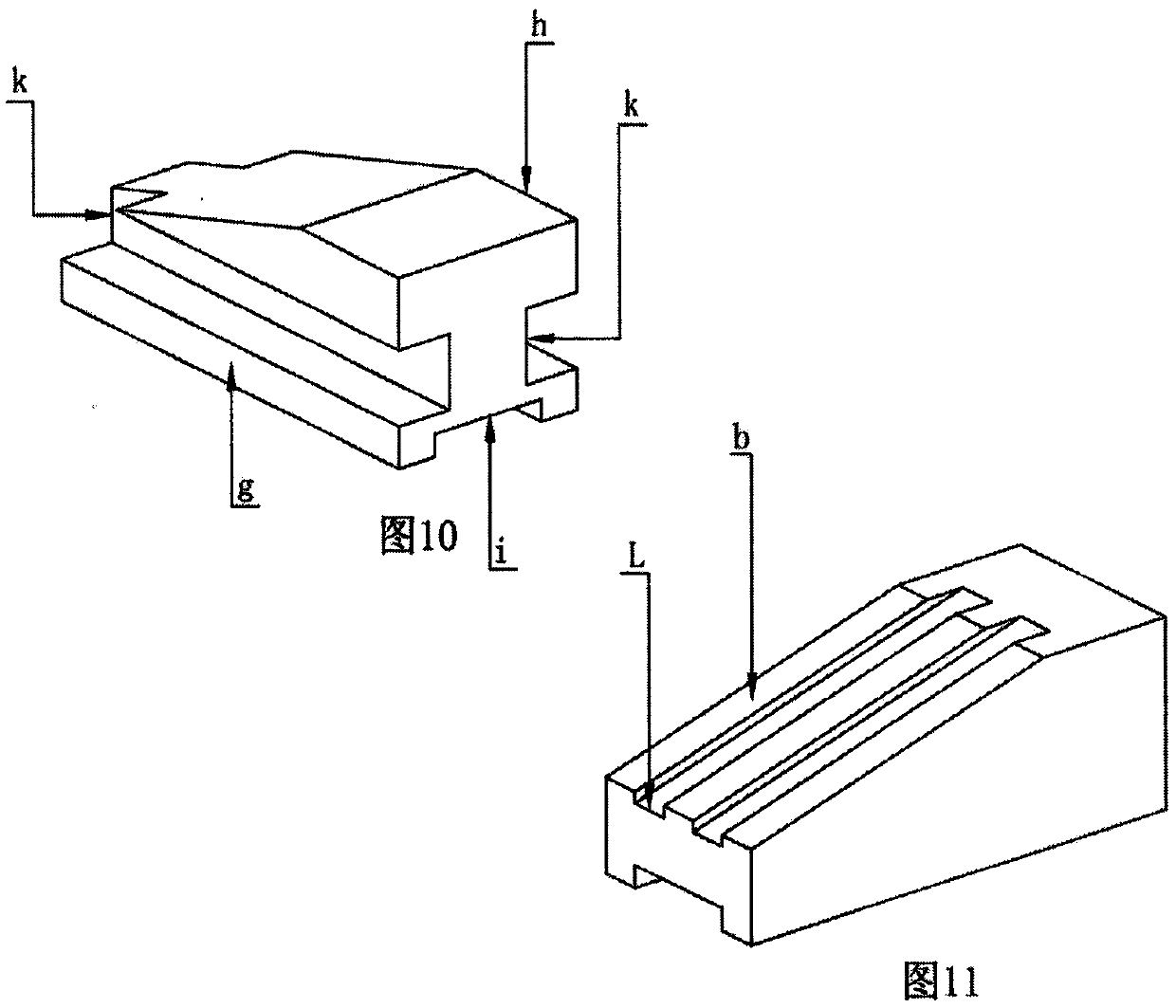

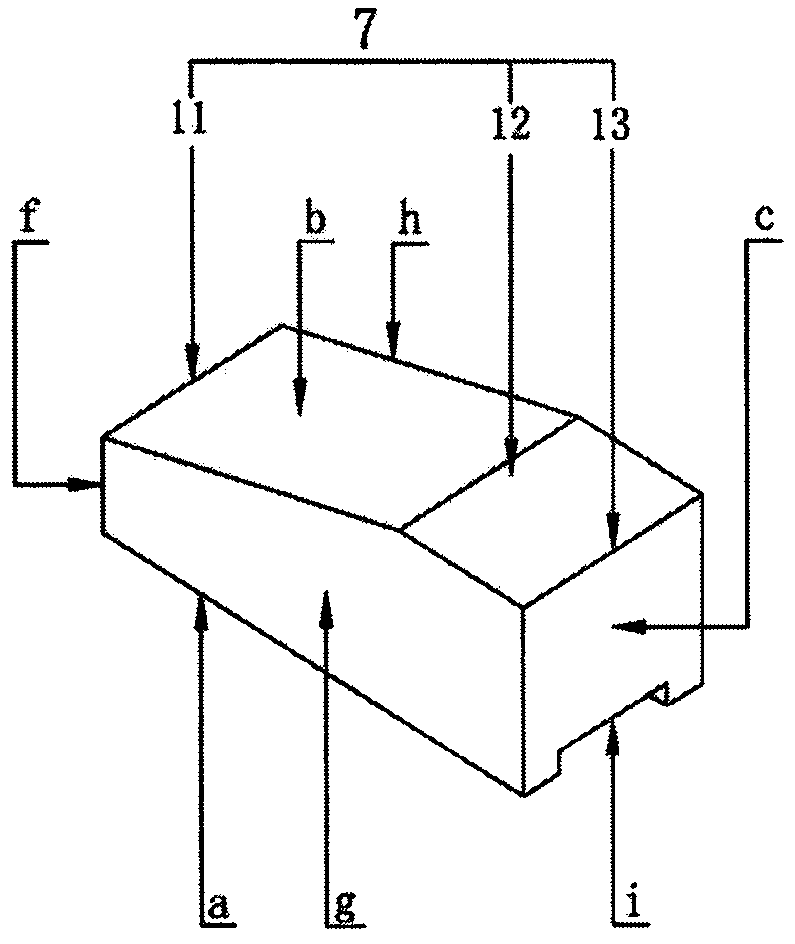

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

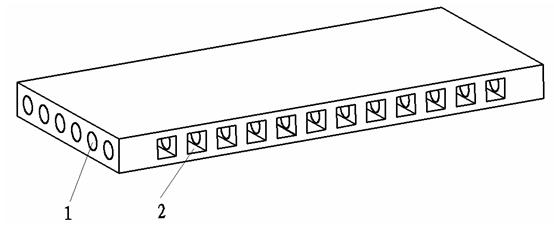

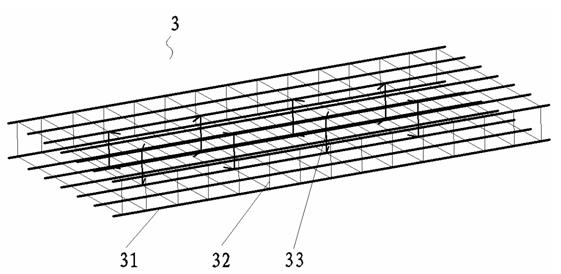

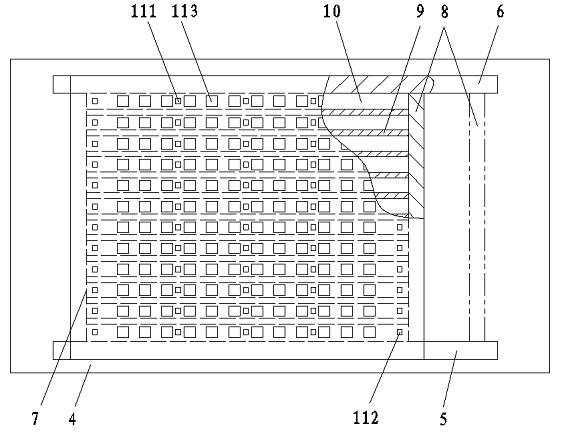

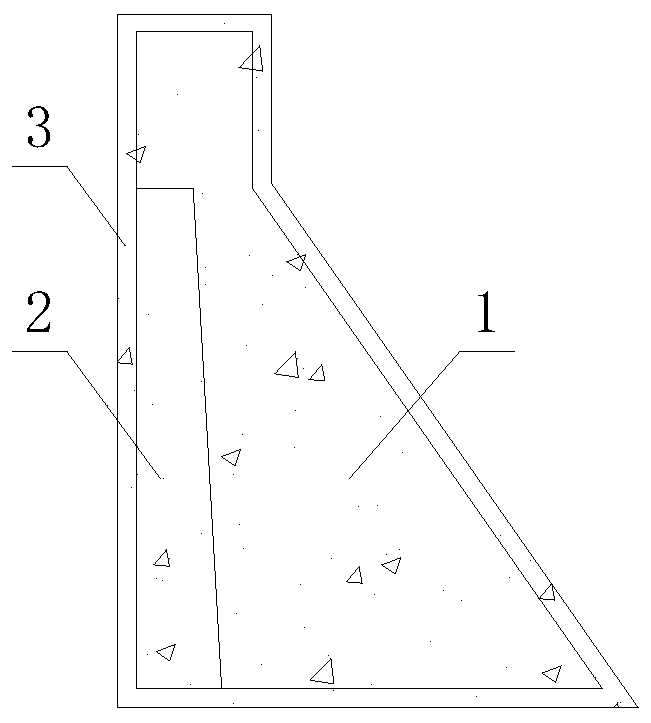

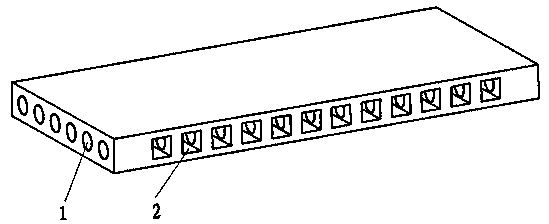

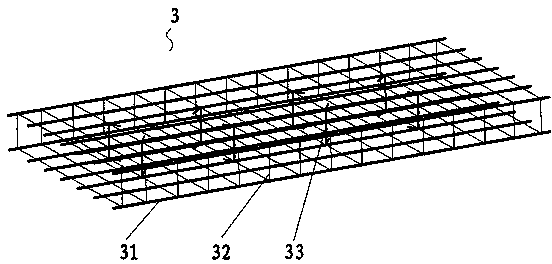

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

Aerated concrete building block and preparation technology thereof

ActiveCN102206095AHigh tensile strengthHigh impact strengthCeramicwarePhosphogypsumUltimate tensile strength

The invention discloses an aerated concrete building block. The aerated concrete building block comprises, by weight, 65-72 parts of fly ash, 15-20 parts of quick lime, 5-10 parts of cement, 2.83-3.83 parts of phosphogypsum, 0.1 parts of aluminum powers, 0.05 parts of a foam stabilizer and 0.02 parts of a polypropylene fibre. The modified polypropylene fiber is added to the concrete structure material, such that tensile strength and anti-impact strength of the concrete structure material are improved, a drying shrinkage value of the concrete structure material is reduced, and cracks are prevented from formation and extension during cement solidification. During a green body structural strength formation, a plurality of microcracks are generated due to a plastic shrinkage of the green body, such that during a later autoclaved process, larger cracks are easily generated from the microcracks when the aerated concrete structure extends; meanwhile, because a gradient variation of humidity of the aerated concrete material is large, cracks in the aerated concrete material are easily generated during humidity changing. Therefore, the internal structure of the aerated concrete provided by the present invention can enable improving the disadvantages of generation of aerated concrete wall cracks through an enhancement of the polypropylene fibre.

Owner:俞华贵

Epoxy cement based road antiskid coating and preparation thereof

InactiveCN101328379AGood alkali resistanceStrong cohesionIn situ pavingsPolyamide coatingsEpoxyTetramine

Epoxy cement group road nonskid paint consists of three components, namely epoxy latex, a curing agent and powder materials. The curing agent is prepared from triethylene triamine or triethylene tetramine and versamid resin which are mixed. The powder materials consist of silicate cement, quartz sand and a water reducing agent. The invention also discloses a preparation method for the epoxy cement group road nonskid paint. The epoxy cement group road nonskid paint saves resources with healthfulness, environmental friendliness, safety and convenience during use.

Owner:上海宝元化学建材有限公司

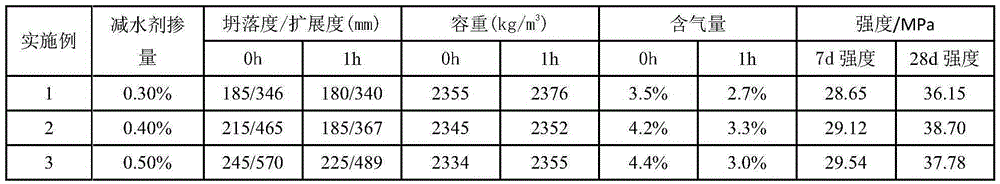

Polycarboxylate water reducer for ultra-compact concrete for nuclear power and preparation method of polycarboxylate water reducer

The invention relates to a polycarboxylate water reducer for ultra-compact concrete for nuclear power and a preparation method of the polycarboxylate water reducer. Every 100 parts of the water reducer comprises components in parts by weight as follows: 50-55 parts of a dispersing ether type polycarboxylate water reducer, 20-25 parts of a slump retaining ether type polycarboxylate water reducer, 3-5 parts of a retarder, 0.01-0.05 parts of a defoaming agent, 1-3 parts of a water retaining agent, 1-2 parts of a shrinkage reducing agent, 0.1-0.3 parts of a preservative and the balance of water. The components are uniformly mixed in parts by weight during preparation. Compared with the prior art, the water reducer has the advantages as follows: concrete workability and liquidity are improved, a temperature peak value and a shrinkage value of the concrete are reduced, the internal porosity of the concrete is reduced, the self-compacting performance and the durability of the concrete are improved and the like; besides, the preparation method is simple, raw material sources are wide, the cost is low, and the water reducer is environment-friendly and has the good application prospect.

Owner:TONGJI UNIV

High-flexibility and low-shrinkage fiber reinforced cement-based composite material

The invention belongs to the technical field of building materials, and in particular relates to a high-flexibility and low-shrinkage fiber reinforced cement-based composite material. The composite material is prepared by mixing cement, coal ash, silicon powder, gypsum, an expanding agent, a water reducing agent, a shrinkage reducing agent, a defoaming agent, a thickening agent, fine sand, fibers and water, wherein the total mass percentage of the cement, the coal ash, the silicon powder, the gypsum, the expanding agent, the water reducing agent, the shrinkage reducing agent, the defoaming agent, the thickening agent, the fine sand and the fibers is 77-85 percent, and the mass percentage of the water is 15-23 percent. The fiber reinforced cement-based composite material has the performance characteristics of low shrinkage, high flexibility, small crack width, quickness in condensation and early strength and is high in compressive strength and good in synergism with other materials.

Owner:TSINGHUA UNIV

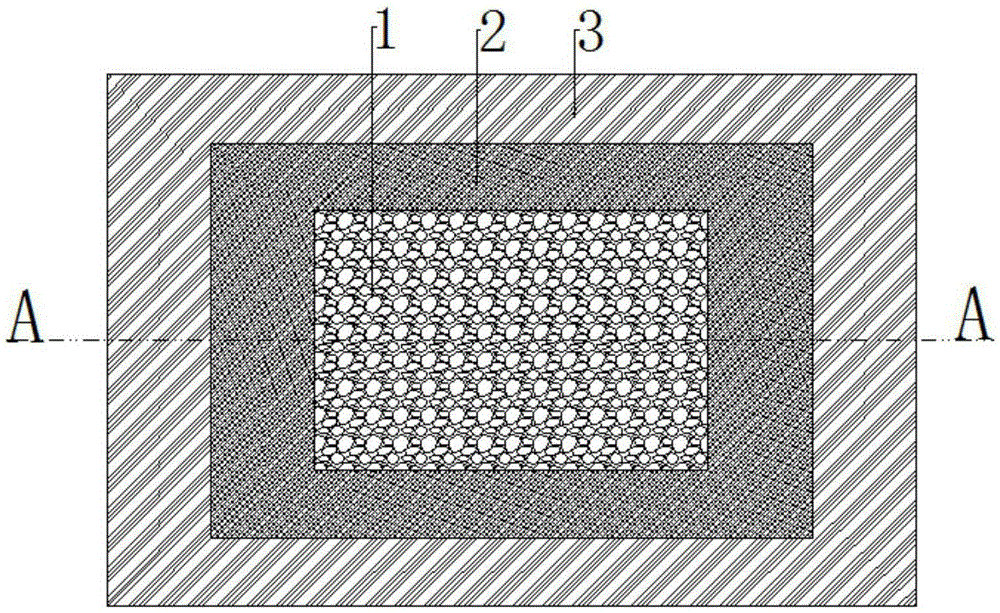

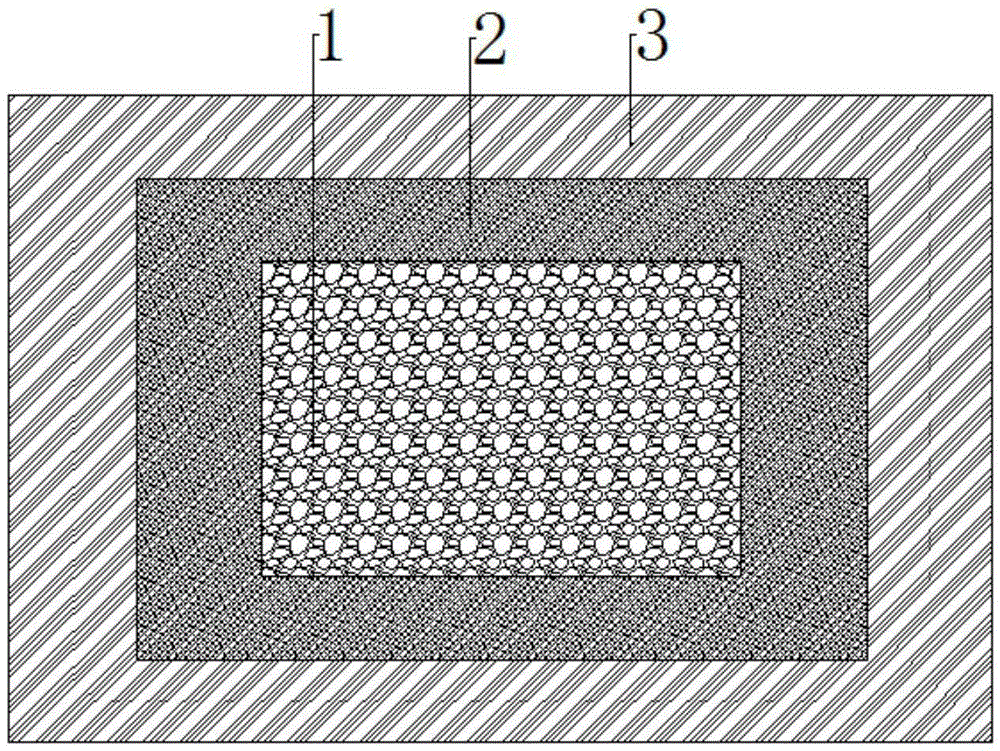

Temperature gradient controlled mass concrete for bridges

ActiveCN105418006AImprove densification performanceLimit crackingBridge engineeringMaterials science

The invention discloses a temperature gradient controlled mass concrete for bridges. The mass concrete comprises an inner layer of low-temperature rise anti-crack concrete I, a middle layer of low-temperature rise anti-crack concrete II and an outer layer of high-tenacity high-crack resistance concrete from the inside to the outside. According to the mass concrete disclosed by the invention, under combination of the low-temperature rise anti-crack concrete (the inner layer of low-temperature rise anti-crack concrete I and the middle layer of low-temperature rise anti-crack concrete II) and the high-tenacity high-crack resistance concrete structure, hydration heat of cementing materials on various layers is respectively absorbed through the characteristics of a high phase-transition temperature of a composite temperature control material in the inner layer of low-temperature rise anti-crack concrete and a low phase-transition temperature of a composite temperature control material in the middle layer of low-temperature rise anti-crack concrete; the inside and the middle temperatures of the concrete are lowered; meanwhile, different thicknesses and layout forms of two concrete materials are optimized and designed; reduction of the temperature difference between the layers is achieved; the overall temperature stress level is reduced; the technical problem of crack of the mass concrete widely existing in bridge engineering can be effectively solved; and the temperature gradient controlled mass concrete for the bridges is applicable to popularization and application.

Owner:HUBEI UNIV +1

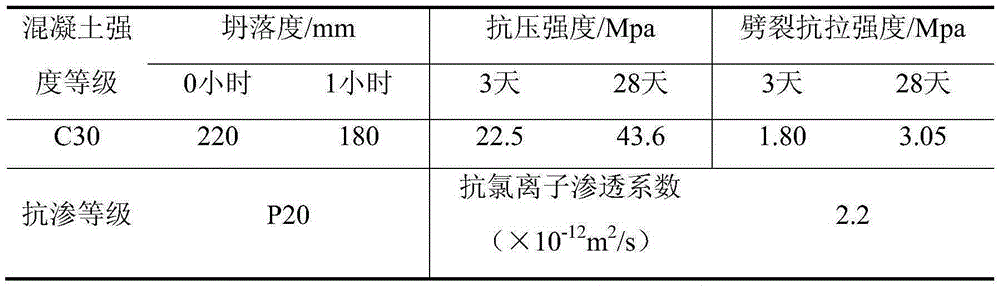

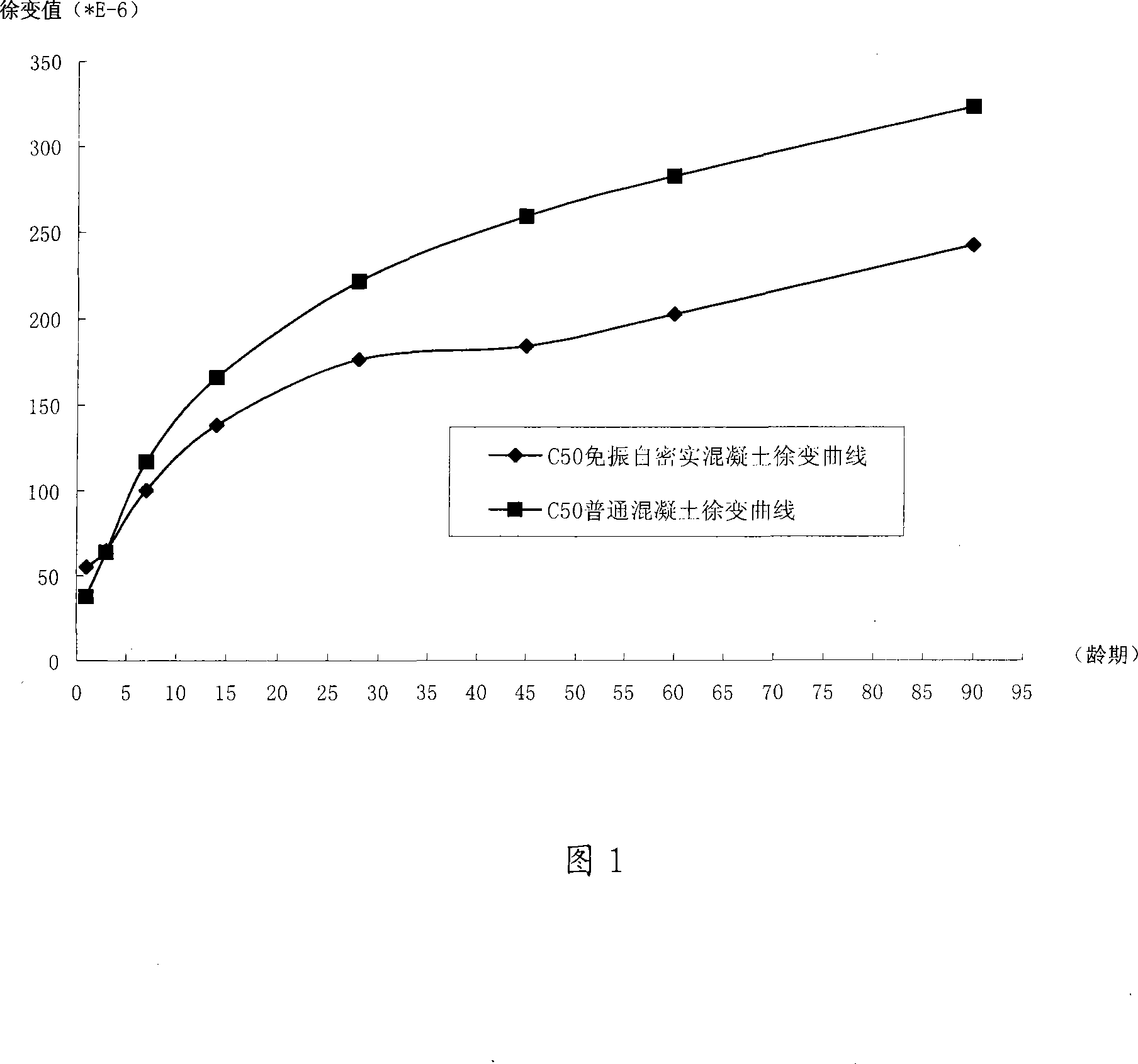

Vibration-free self-flowing dense concrete

InactiveCN101186480AExcellent working performanceWorkability is goodSolid waste managementRebarWork performance

The invention provides a C50 non-vibration self-flowing dense concrete used in the construction structures such as bridges, of which the mixing proportion by per cubic meter is that 375kg of concrete, 162kg of fly ash, 167kg of water, 767kg of sand, 901kg of gravel and 10.74kg of high efficiency water reducing agent; water-gel ratio is 0.325 and mortar-aggregate bond ratio is 0.352: 0.648; the invention can evenly and densely fill in a structure with dense concrete reinforcing bars and complicated physiques without stirring by relying on self weight of the concrete, which conquers the defect of structure quality of being not dense, etc.; the invention meets the requirements of C50 common concrete for working performance, mechanical property, impermeability, freezing resistance, Chloride ions diffusibility resistance, shrinkage and creep property, etc., and has good workability and little gradual loss in slump.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Quick-setting epoxy grouting mortar suitable for summer first-aid repair construction

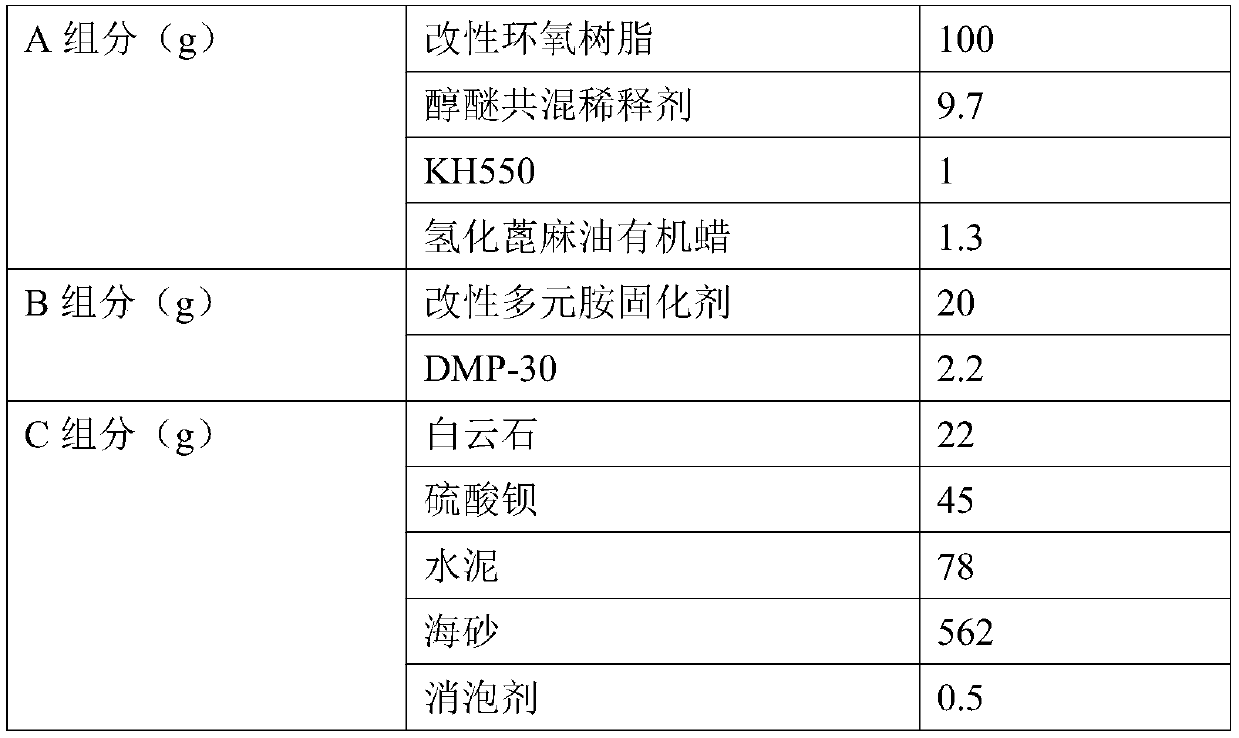

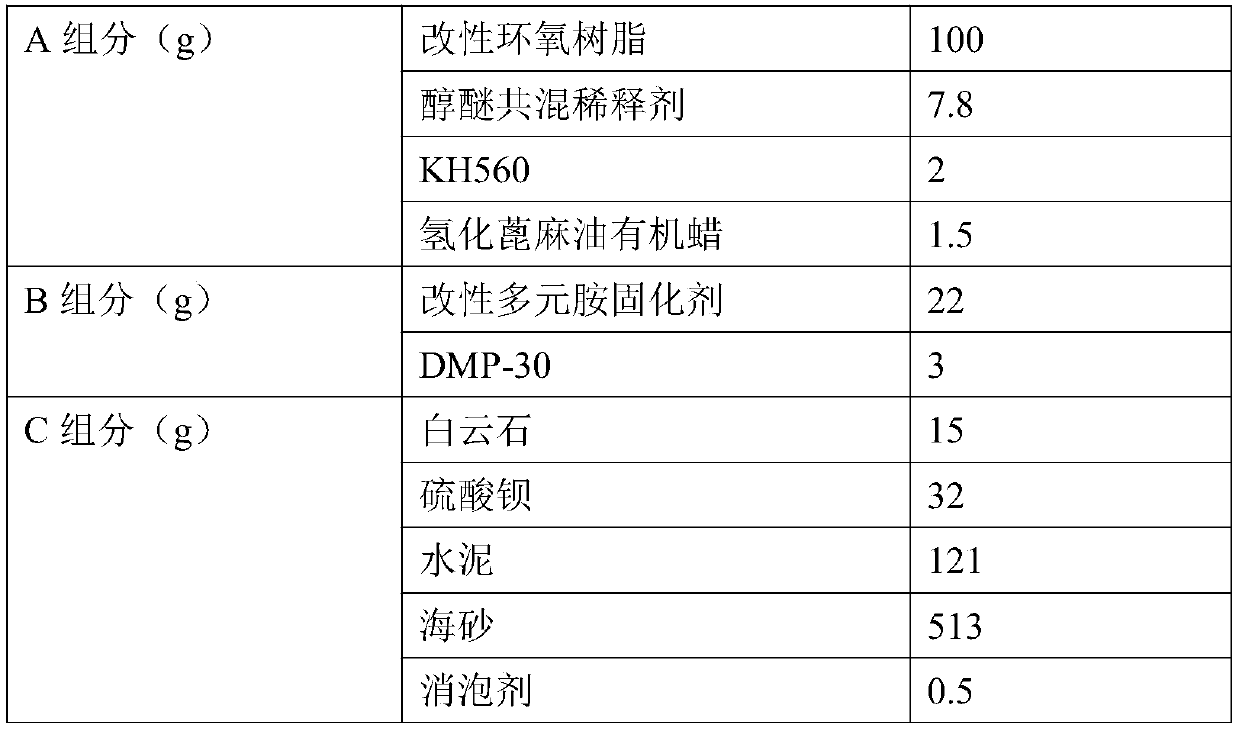

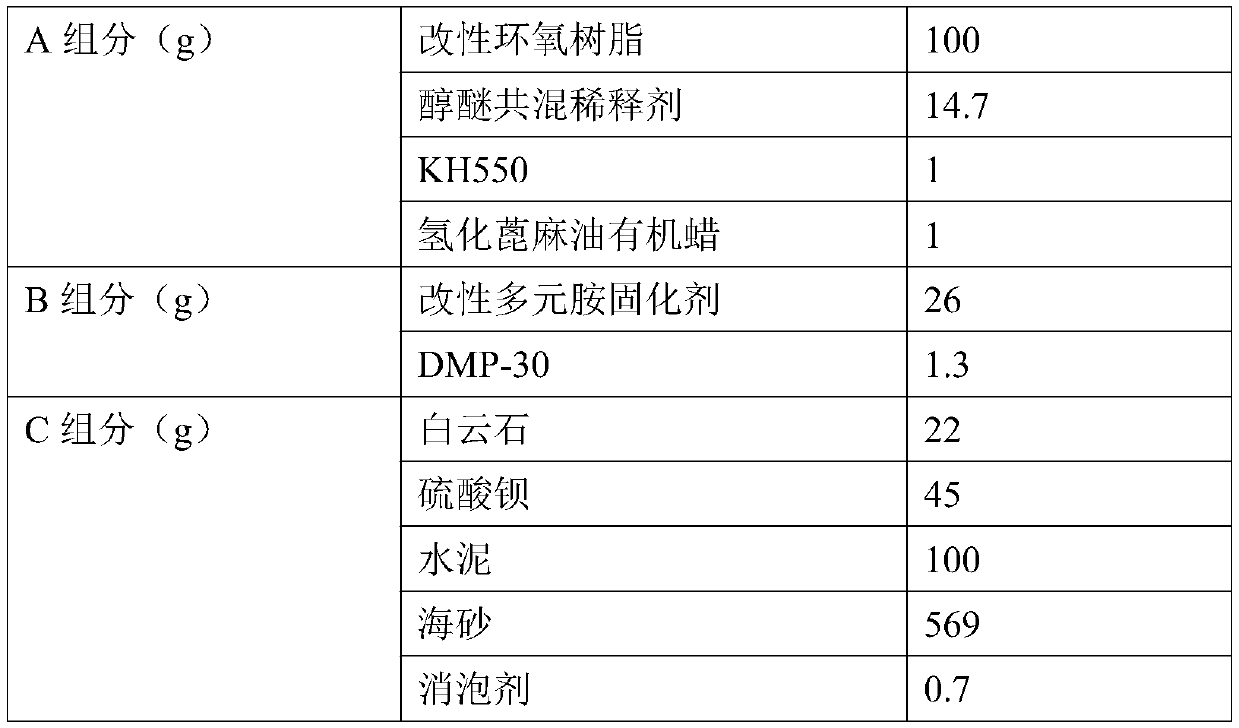

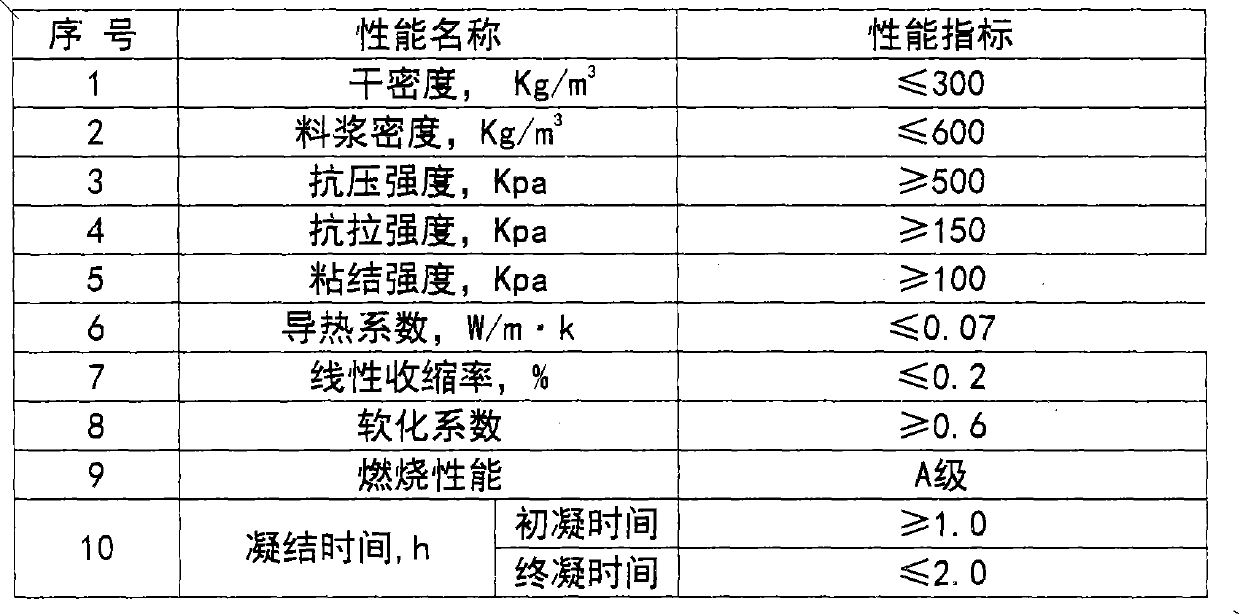

The invention discloses a quick-setting epoxy grouting mortar suitable for summer first-aid repair construction. The quick-setting epoxy grouting mortar is formed by mixing of a resin component A, a curing agent component B and a bone powder component C in a mass ratio of 1:(0.2-0.26):(5-7) during use. Specifically, the component A comprises the following components by weight: 100 parts of modified epoxy resin, 1-15 parts of an alcohol ether composite diluent, 1-3 parts of a coupling agent, and 0.5-3 parts of a rheological agent; the component B comprises the following components by weight: 16-23 parts of a modified polyamine curing agent, and 1-3 parts of an accelerator; and the component C comprises the following components by weight: 1-23 parts of dolomite powder, 15-46 parts of bariumsulfate powder, 10-121 parts of cement, 385-588 parts of sea sand, and 0.1-1.5 parts of a defoamer. The quick-setting epoxy grouting mortar provided by the invention has the technical characteristicsof short curing time, high hour strength, and no flash polymerization during high temperature construction, at the same time is non-toxic and harmless, and is simple to prepare, and is widely applicable to concrete structure repair with quick-setting and early strength requirements and construction of installation and anchoring projects, especially suitable for summer repair construction.

Owner:中冶武汉冶金建筑研究院有限公司

Composite silicate heat preservation mortar

The invention relates to the technical field of materials for construction industry, in particular to composite silicate heat preservation mortar. The invention adopts the following technical scheme that the mortar comprises the following raw materials in weight ratio: 45-65 percent of composite portland cement, 34-54 percent of glazed hollow bead, 0.5-2 percent of dispersible rubber powder, 0.1-0.6 percent of hydroxypropyl methyl cellulose, 0.5-1.2 percent of fiber and 0.1-0.4 percent of organic silicon waterproof powder. When in construction carried out by adopting the mortar produced by the technical scheme, an on-site construction mode can be adopted, and water is directly added to the mortar for stirring and then the mortar can be used. The stirred material can be directly constructed to a dry wall body; the construction performance is superior and the construction process is simple; and the construction efficiency can be greatly improved and the construction cost of a construction is reduced.

Owner:DONGGUAN HENGHE ENERGY SAVING TECH

Highly anti-bending and wearing-resistant lightweight concrete

The invention discloses highly anti-bending and wearing-resistant lightweight concrete, which comprises the following raw material constituents in parts by weight: 200-250 parts of cement, 100-150 parts of coal ash, 150-200 parts of river sand, 100-180 parts of manganese residue, 150-200 parts of ceramsite, 20-50 parts of silicon carbide, 15-35 parts of plant fiber, 200-250 parts of water, 0.3-1.5 parts of dipropyl ethylene glycol monobutyl ether, 3-6 parts of silicon resin polyether emulsion, 0.3-1.8 parts of sodium chloride, 2-5 parts of triethanolamine, 0.3-1 part of sodium sulfate, 1-3 parts of epoxy resin, 1-3.5 parts of waste polyurethane, 1-2.3 parts of sodium stearate, 5-16 parts of nano calcium oxide, 0.3-0.9 part of coagulant, 2-5 parts of melamine water reducer and 5-18 parts of foaming agent. The highly anti-bending and wearing-resistant lightweight concrete provided by the invention has high anti-bending strength, good wear resistance, light weight and excellent water resistance.

Owner:无为县严桥双龙建材厂

Glassfiber reinforced polypropylene material without fiber exposion and manufacturing process thereof

The invention relates to an organic high-molecular composite material, in particular to a glassfiber reinforced polypropylene material without fiber exposion and a manufacturing process thereof. The organic high-molecular composite material comprises the following components in percentage by weight: 49.5%-95% of polypropylene, 5%-50% of alkali-free glass fibers, 0.1%-3.0% of heat stabilizers, 0.1%-3.0% of glass fiber finishing agents, 0.2%-8% of coupling agents, 0.1%-2.0% of light stabilizers, 0.1%2.0% of ultraviolet absorbers and 1.3%-5.5% of other auxiliary agents. The glassfiber reinforced polypropylene material without the fiber exposion is not easily subject to embrittlement at low temperature, abrasion, aging and melt disruption, decomposition in contact with hot metal for a long time, contraction cavity, sink mark and deformation and has small constriction range and constriction value, stable dimension and high surface smoothness of generated products.

Owner:KECHUANG POLYMER SUZHOU

Industrial waste coagulating agent and goaf filling material using same

The invention provides an industrial waste coagulating agent which comprises 3-20 wt% of sodium sulfate, 10-80 wt% of gypsum, 0-20 wt% of silica fume, 0-30 wt% of quick hardening cement, 5-75 wt% of alum and 2-10 parts of quick lime. Under the synergistic effect of all components and the condition that no or few cementitious materials are added, a cementation process of industrial waste can be completed by activating the activity of industrial waste and using effective components in industrial waste, a solidification body meeting the strength requirement of the goaf filling material is formed, the cost is low, and indirect discharge of waste cannot be caused. The goaf filling material comprises industrial waste and the industrial waste coagulating agent in a mass ratio of (3:1)-(15:1), the usage amount of the industrial waste coagulating agent is small, the cost is low, indirect discharge of waste cannot be caused, industrial waste can be effectively and reasonably used, and sustainable development of industrial production and economy is guaranteed.

Owner:南京坤元材料有限公司

Thermal insulation anti-cracking foam concrete

InactiveCN104591776AAdd surface active componentsGood foaming effectCeramicwareFoam concreteThermal insulation

The invention discloses thermal insulation anti-cracking foam concrete. The thermal insulation anti-cracking foam concrete comprises the following raw materials: cement, glass beads, limestone flour, a composite foaming agent, metakaolin, basalt fiber, lignin fiber, alpha-methyl-2,4-pentanediol, vinyl acetate-ethylene copolymer, a water reducer, an early strength agent, a pumping aid and water, wherein the composite foaming agent contains the following raw materials: N-lauroyl-L-sodium glutamate, sodium dodecyl benzene sulfonate, fatty alcohol-polyoxyethylene ether, oleic acid, triethanolamine, lauryl diethanolamine, zeolite powder and water. The thermal insulation anti-cracking foam concrete has high strength, a good anti-cracking effect and excellent thermal insulation performance.

Owner:无为县严桥双龙建材厂

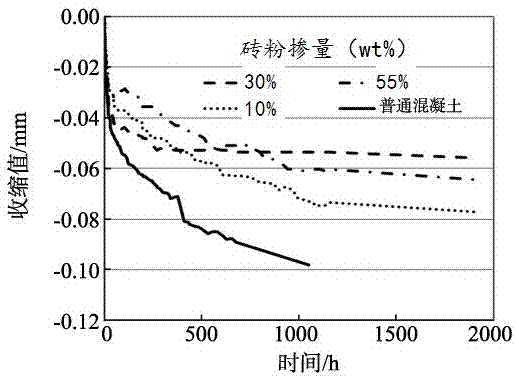

Recycled concrete mixed with waste clay brick powder and brick sand

InactiveCN107021694ASimple processReduce energy consumptionSolid waste managementFlexural strengthCompressive strength

The invention relates to recycled concrete mixed with waste clay brick powder and brick sand, the waste clay brick powder is mixed into concrete for replacing part of cement, the waste clay brick sand is mixed into the concrete for replacing part of natural sandstone aggregate without reducing the performance of the concrete, the recycled concrete is prepared from the waste clay brick powder and brick sand obtained by crushing of waste clay bricks, the dosage of the cement is reduced by 0-55% not including 0, the dosage of the natural sandstone aggregate is reduced by 0-25% not including 0 without changing of concrete strength and workability, the waste clay brick powder and brick sand are obtained by crushing of the waste clay bricks in construction waste, the cost is low, the brick powder has less influence on the compressive strength and the flexural strength of the concrete, and can improve shrinkage of the concrete. The recycled concrete adopts a multi-stage preparation and multi-time feeding method for production, first cement mortar is premixed, according to the granular composition, the brick sand, small stones and large stones are in turn fed in, mixing time and energy consumption are reduced, the strength of the concrete is improved, the homogeneity and the workability of the concrete are improved, and the recycled concrete has important significance for energy conservation and emission reduction.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

High-performance foam concrete

The invention discloses a high-performance foam concrete which comprises the following raw materials: cement, river sand, lime, a composite foaming agent, fly ash, metakaolin, expanded perlite, lignin fiber, polypropylene glycol, hydroxymethyl propyl cellulose, styrene-acrylic emulsion, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, a water-reducing agent, an early strength agent and water; the composite foaming agent comprises the following raw materials: tea saponin, lauryl sodium sulfate, sodium fatty alcohol polyoxyethylene ether sulfonate, 1,4-butanediol, triethanolamine, soybean oil, sodium hydroxide, zeolite powder, polyacrylate resin and water. The high-performance foam concrete disclosed by the invention is good in pumpability in the construction process, high in compressive strength and good in durability.

Owner:无为县严桥双龙建材厂

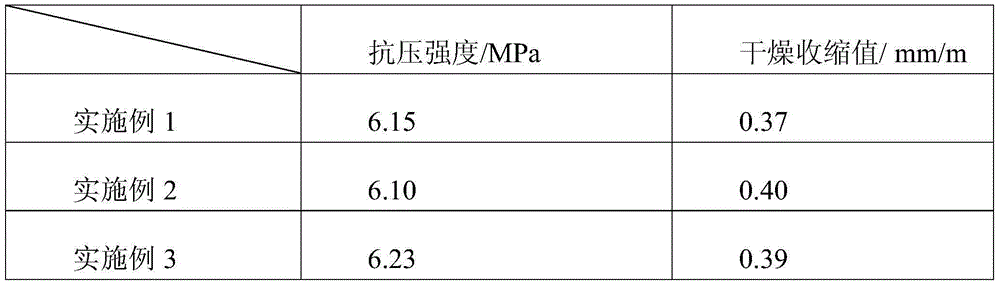

Production process for low-cost autolaved aerated concrete blocks

InactiveCN104987119AReduce manufacturing costHigh compressive strengthCeramicwareAluminium powderPulverized fuel ash

The invention discloses a production process for low-cost autolaved aerated concrete blocks. The low-cost autolaved aerated concrete blocks are prepared from the following raw materials by weight: 18-21 parts of 32.5# concrete, 29-30 parts of unslaked lime, 7-8 parts of gypsum, 19-22 parts of pulverized fuel ash, 35-37 parts of water, 126-130 parts of lake sand with 50-100 meshes, 0.135 part of aluminium powder, and 1-2 parts of water reducing agents. Lake sand is adopted to replace quartz sand, and the prepared autolaved aerated concrete blocks are low in cost, good in compressive strength which is as high as 6.2 MPa, and small in shrinkage value which is 0.40 mm / m or below.

Owner:江苏中技新型建材有限公司

Calcining-free energy-saving and heat-insulating brick of desulfurized gypsum and building waste

InactiveCN102515688ASmall shrinkage valueImprove flexural strengthSolid waste managementBrickFlexural strength

The invention discloses a calcining-free energy-saving and heat-insulating brick of desulfurized gypsum and building waste, belonging to the production field of building material. The calcining-free energy-saving and heat-insulating brick of desulfurized gypsum and building waste comprises raw materials in the following ratio: 40-55 parts of desulfurized gypsum, 35-55 parts of building waste, 10-17 parts of No. 32.5 cement, 7-14 parts of sodium hexafluorisilicate, 7-8 parts of closed cell perlite, 6-9 parts of sodium silicate, 1-2 parts of coagulation accelerator and 0.08-0.15 parts of aluminium silicate fibres. In the calcining-free energy-saving and heat-insulating brick of desulfurized gypsum and building waste disclosed by the invention, desulfurized gypsum and building waste are adequately utilized, as well as secondary energy consumption and secondary pollution are reduced. The product has the advantages of being high in compressive strength and flexural strength, low in thermal conductivity, good in water resistance, small in drying shrinkage value, good in heat-insulating performance and the like, as well as is suitable for civil houses, common residential buildings, household splitting walls, partition walls and filling walls.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aerated concrete block and preparing method thereof

The present invention relates to an air-entrained concrete block and its manufacturing method, comprising cement, lime, polypropylene fiber and other components including one of fly ash, sand, gypsum, aluminum powder and waste slurry species or several. By optimizing the ingredients and process parameters of air-entrained concrete, the obtained air-entrained concrete blocks have the advantages of high strength, low shrinkage and crack prevention. At the same time, modified polypropylene fibers can improve the tensile strength of concrete structural materials, Impact strength, reduce the drying shrinkage value of concrete structural materials and prevent the formation and expansion of cracks during cement curing.

Owner:欧士玺

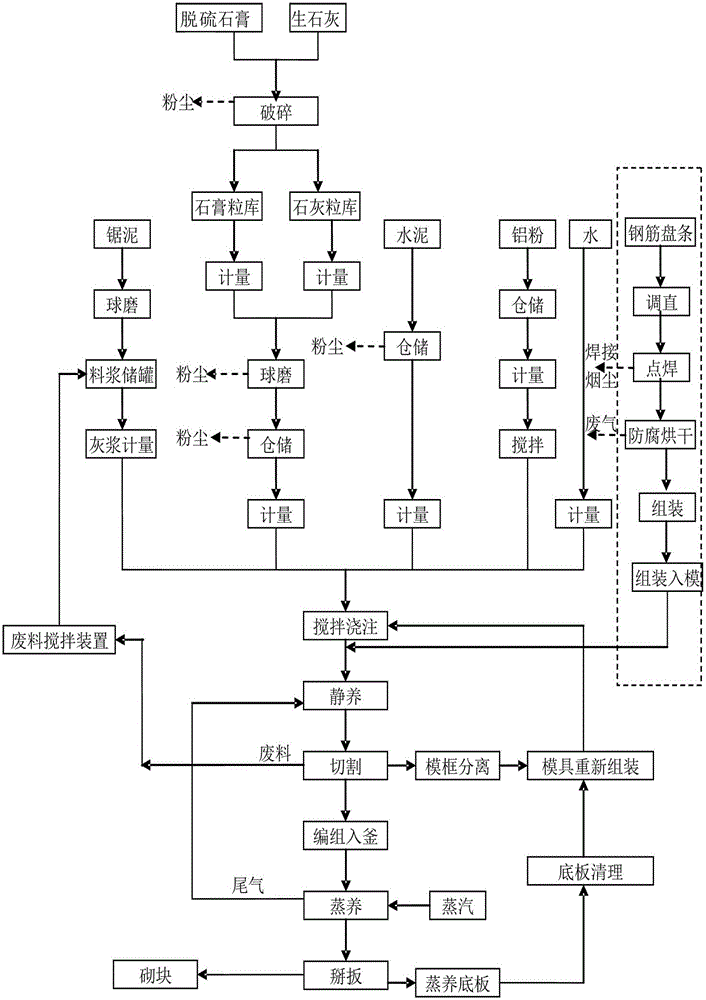

Autoclaved light sand aerated concrete blocks, and preparation method thereof

InactiveCN105000855AImprove insulation effectImprove sound insulationSolid waste managementCeramicwareThermal insulationWastewater

The invention relates to autoclaved light sand aerated concrete blocks. The autoclaved light sand aerated concrete blocks are prepared from water and a main material at a ratio of 0.6 to 0.8; the main material is prepared from, by weight, 64 to 78% of saw mud, 3 to 6% of desulfurized gypsum, 10 to 18% of quick lime, 8 to 14% of cement, and 0.4 to 0.7% of aluminium powder. A preparation method comprises following steps: quick lime and desulfurized gypsum are smashed, and are subjected to ball milling; saw mud is grinded; steel bar is subjected to treatment; an obtained material slurry, a cementing agent, and cement are stirred at a certain ratio; after pouring, moulds are delivered to a standing area for aeration and prehardening; an obtained product is subjecting to cutting; obtained green bodies are delivered into a still kettle for maintenance, and are subjected to separation, packaging, and conveying; and generated wastewater and waste materials are recycled. Beneficial effects of the autoclaved light sand aerated concrete blocks are that: thermal insulation properties are excellent; permeability resistance is excellent; shrinkage value is lower; the autoclaved light sand aerated concrete blocks are green and friendly to the environment, are safer, are excellent in sound insulation effect and machinability, and are economical.

Owner:SHANDONG TONGDE BUILDING MATERIALS CO LTD

Ultra-high admixture amount flyash grinding concrete material damming method and structure thereof

PendingCN109809745AReduce dosageIncrease dosageBarrages/weirsSolid waste managementRoller-compacted concreteTemperature control

The invention discloses an ultra-high admixture amount flyash grinding concrete material damming method and a structure thereof. The admixture amount of flyash in grinding concrete is increased, the admixture amount of flyash in upstream-face C9020 three-graded anti-seepage grinding concrete is expected to be increased to 60%, the admixture amount of flyash in in-dam C9015 three-graded grinding concrete is expected to be increased to 70% to 80%, and a high-performance additive is adopted to lower water amount and cement amount of concrete. According to the ultra-high admixture amount flyash grinding concrete material damming method and the structure thereof disclosed by the invention, hydrated high temperature increase of concrete is effectively reduced, air shrinkage and self-shrinkage ofconcrete are reduced, temperature control and anti-cracking measures are simplified, temperature control and anti-cracking cost is reduced, and a certain economic benefit is achieved. Simplified temperature control and anti-cracking measures bring possibility to seam parting and chunk parting of a dam concrete structure, construction speed is increased, conditions are created for bringing forwardtime limit of the construction, and the economic benefits are remarkable; at the same time, flyash solid waste is greatly utilized, generated energy-conserving and emission-reducing ecological and environmental benefits are obvious.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Cement foaming agent

The invention discloses a cement foaming agent which comprises the following raw materials in parts by weight: 1-1.9 parts of rosin, 0.5-1 part of bone glue, 0.2-0.5 part of sodium hydroxide, 0.2-0.5 part of lauryl sodium sulfate, 3-5 parts of glutinous rice starch and 90-95 parts of water. The rosin is first level rosin, the bone glue is high quality bone glue, and the cement foaming agent also comprises 0.5-1 part of a silicone resin polyether emulsion as a foam stabilizer. The cement foaming agent is high in foaming rate, good in cement compatibility and stable in foam, is light in weight, high in strength, small in dosage and low in cost, is good in fireproof and waterproof properties, free of radioactivity and wide in application, and has energy-saving and environmental-friendly effects; the raw materials are easily available, and the preparation process is simple and easy to implement.

Owner:舒浪平 +1

Method for manufacturing honeycomb bottom plates

The invention provides a method for manufacturing honeycomb bottom plates. The method comprises the following steps of: electronically metering prepared pulverized fuel ash, sand, cement and slag; putting the metered materials into a stirring machine, adding an appropriate amount of water, stirring to form a semi-wet mixture, putting the semi-wet mixture into a container or a mold, and distributing the materials; feeding the container with the distributed materials into a 2,100-ton pressing machine, and performing extrusion molding to obtain semi-finished bottom plates; sucking the semi-finished bottom plates, and stacking; putting into a precuring chamber at the temperature of 40 DEG C, and drying; transporting the dried semi-finished bottom plates into a steam curing kettle by using a steam curing trolley, and performing high-temperature high-pressure steam curing for 8 to 10 hours; and discharging finished honeycomb bottom plates subjected to steam curing. The method has the advantages that: the honeycomb bottom plates are manufactured by fully utilizing non-renewable resources and using the pulverized fuel ash and the like generated by a power plant as raw materials; and a honeycomb bottom plate product has the advantages of light weight, small contraction values, high intensity, low cost and the like.

Owner:欧阳忠贞

Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

The invention relates to a prefabricated reinforced concrete hollow template internally provided with cross holes and a molding and forming device of the prefabricated reinforced concrete hollow template. The hollow template is internally provided with longitudinal through holes with round cross sections along the length direction and latitudinal through holes with square cross sections along the width direction, wherein the longitudinal through holes are arrayed parallel one another, the latitudinal through holes are also arrayed parallel one another, and the diameter of each longitudinal through hole is less than the length of the side of each latitudinal through hole. Two large surfaces of the hollow template are flat surfaces formed by molding. A casting mold of the molding and forming device is of a vertical type and provided with one or more mold cavities; each mold cavity is surrounded by a front face plate, a rear face plate, a left side plate and a right side plate; a core tube frame or upper side plate capable of fixing a vertical core tube is arranged on the upper part or above each mold cavity; and the left side plate, the right side plate and the upper side plate are provided with a plurality of horizontal holes and vertical holes respectively. Each surface of the hollow template processed by using the molding and forming device is flat without being polished and subjected to similar treatment. The hollow template is high in strength and good in quality, can be directly used for the construction of a load-bearing wall with few procedures in a short time and can ensure that the load-bearing wall is not easy to shrink and crack.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

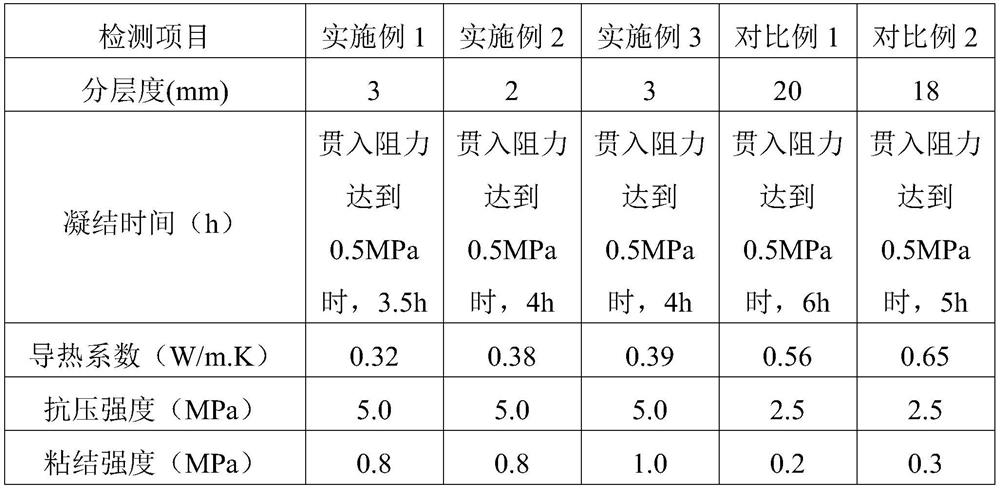

Mortar and preparation method thereof

ActiveCN112094081AImprove performanceMeet the requirementsSolid waste managementSlagUltimate tensile strength

The invention provides a mortar. The mortar takes industrial solid waste steel slag powder with different particle sizes and an aggregate forming agent composed of industrial solid wastes as main rawmaterials, and steel slag with the particle size of about 1 mm can play a skeleton role, so that the strength of the mortar is improved, the heat resistance of the mortar is improved, the mortar is ensured to have relatively high strength in a using process, various stress effects can be borne, and cracks are avoided; gaps of 1 mm steel slag can be filled with the steel slag with the particle sizeof 150 [mu]m, so that the density of the mortar is increased, and the strength of the mortar is further enhanced; and the steel slag with the particle size of 100 [mu]m improves the uniform stabilityof the mortar. The mortar provided by the invention does not contain cement, the dependence of the mortar on the cement is reduced, meanwhile, the burden of industrial solid wastes on the environmentis solved, and the obtained mortar has the characteristics of uniformity and stability, small layering degree, high bonding strength, excellent frost resistance and low shrinkage value.

Owner:唐山中陶纪元工程设计有限公司

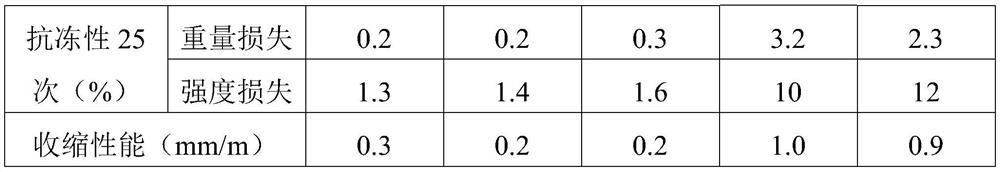

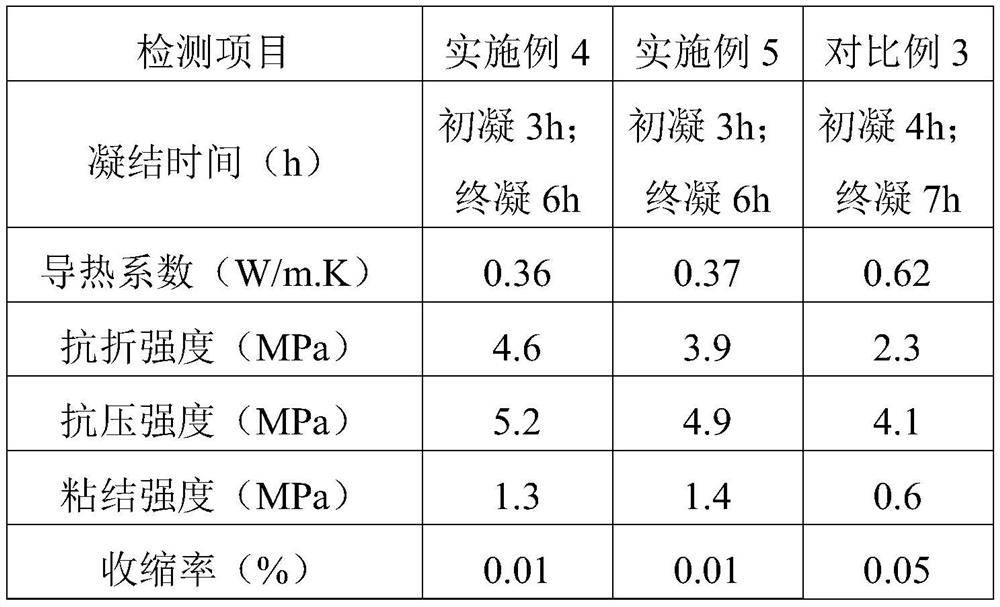

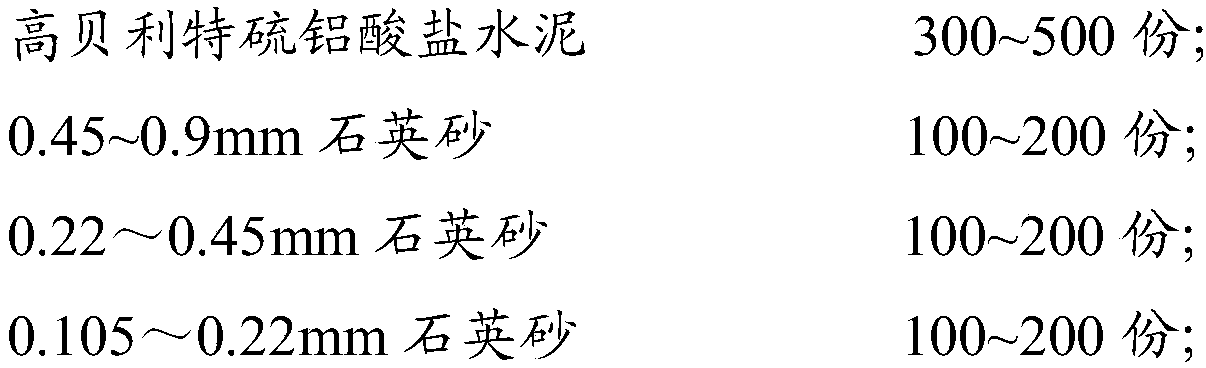

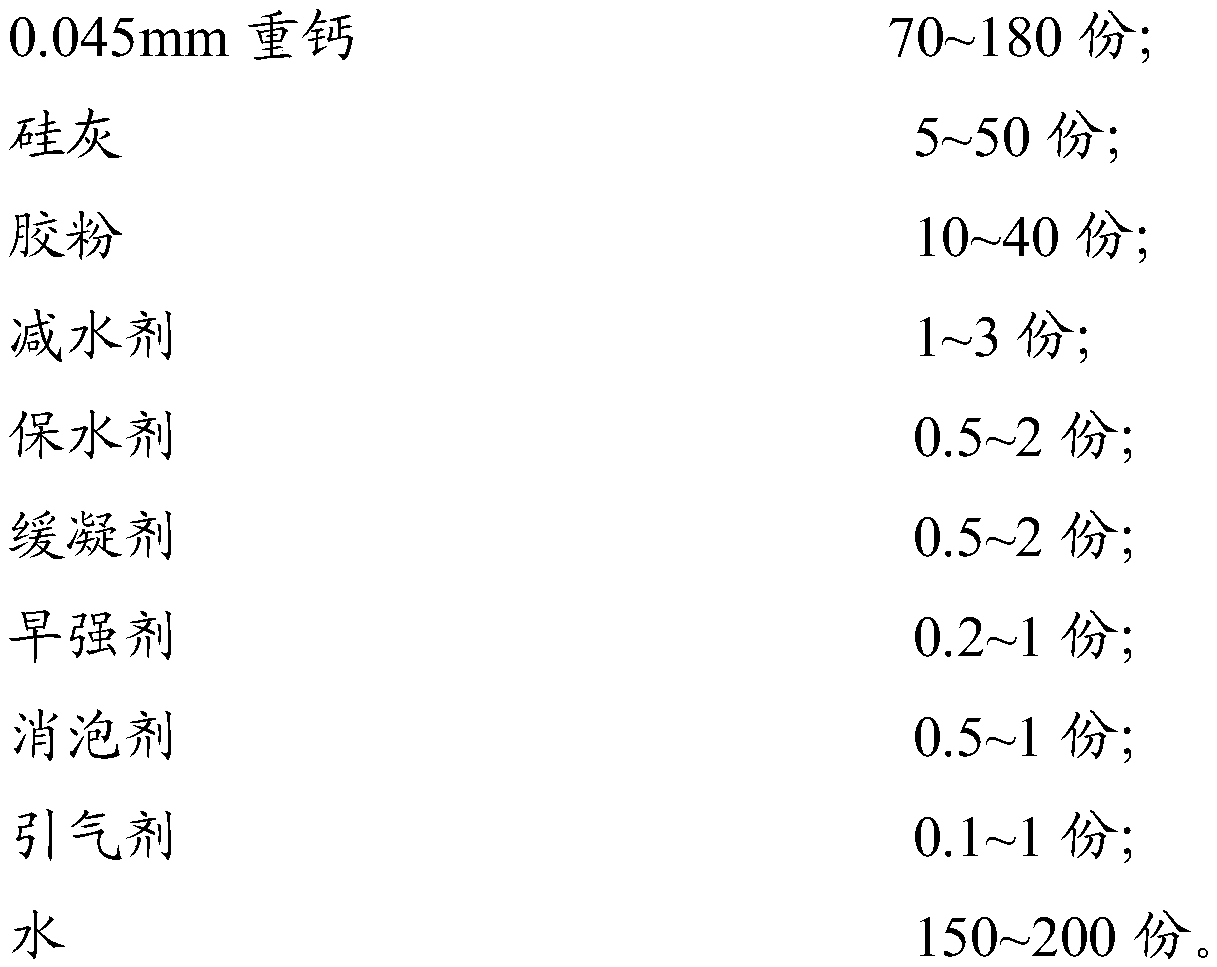

Self-leveling mortar with thick layer in unitary system and preparation method thereof

The invention discloses self-leveling mortar with a thick layer in a unitary system and a preparation method thereof. High belitesulphoaluminate cement is used as a cementing material, and the shrinkage value is low, the cracking of the mortar is effectively inhibited; an active fine filler is added, the early hydration heat release and the formula cost are reduced, the shrinkage is further reduced and the risk of cracking is reduced. The balance of early strength development and sufficient construction time can be achieved by adding an early strength agent and a retarder. By adding adefoamingagent and an air entrainment agent, the newly-mixed mortar contains some non-connected bubbles with small particle sizes, which gives the newly-mixed mortar suitable construction property, and facilitates improving the strength, impermeability and frost resistance of the hardened body of the mortar. In addition, the mortar has high early strength, the strength reaches 20Mpa after one day, and 40Mpa after 28 days, a single construction thickness is 40 millimeters, the construction process is reduced and the cost is saved, and the thick layer self-levelinghas better fluidity and no sedimentation.

Owner:君旺节能科技股份有限公司

Multi-purpose plasticizing flyash mortar powder

The present invention belongs to the field of building mortar technology, and it relates to a multipurpose plasticizing flyash mortar powder. Said invention is characterized by that it uses lots of flyash instead of cement, at the same time adds chemical additive so as to raise improve its water retentivity, early-strength and endurance. Said invention is applicable to indoor and outdoor plastering of building, brick mansory and tiling in the room, etc.

Owner:勾睿卿

Method for producing multi-functional aerated concrete block

The invention discloses a method for producing a multi-functional aerated concrete block. The method comprises 1) preparing 250 to 350 parts by weight of water, 3 to 8 parts by weight of aluminum powder, 60 to 80 parts by weight of gypsum, 80 to 90 parts by weight of lime, 150 to 200 parts by weight of tailings, 150 to 200 parts by weight of silt, 30 to 50 parts by weight of slag, 60 to 80 parts by weight of fly ash, 70 to 90 parts by weight of cement, 3 to 8 parts by weight of additives, 30 to 50 parts by weight of a foam stabilizer and 5 to 20 parts by weight of sodium carbonate, 2) carrying out mixing stirring, 3) carrying out pouring, then carrying out gas formation initial coagulation at 45-60 DEG C through an initial curing chamber, carrying out initial curing for 2h and then carrying out cutting, 4) carrying out segmented maintenance, and 5) processing a finished product, discharging the finished product out of a reactor, carrying out inspection and carrying out classification stacking.

Owner:HENGYANG HENGYU LIGHTWEIGHT INSULATION MATERIAL CO LTD

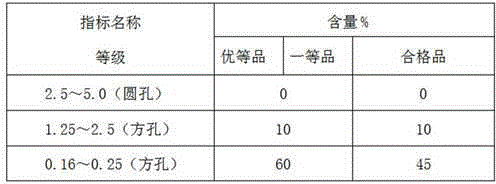

Autoclaved aerated concrete block and preparation method thereof

InactiveCN105000852AHigh strengthSmall shrinkage valueSolid waste managementCeramicwareFly ashLow shrinkage

The invention discloses an autoclaved aerated concrete block with high strength and low shrinkage value. The autoclaved aerated concrete block comprises the following components by weight: 50-68 parts of fly ash, 3-5 parts of gypsum, 18-25 parts of quicklime, 6-15 parts of cement, and 8 parts of aluminum powder. The autoclaved aerated concrete block itself is an environment-friendly novel building material with low energy consumption.

Owner:安徽恒创环保建材有限公司

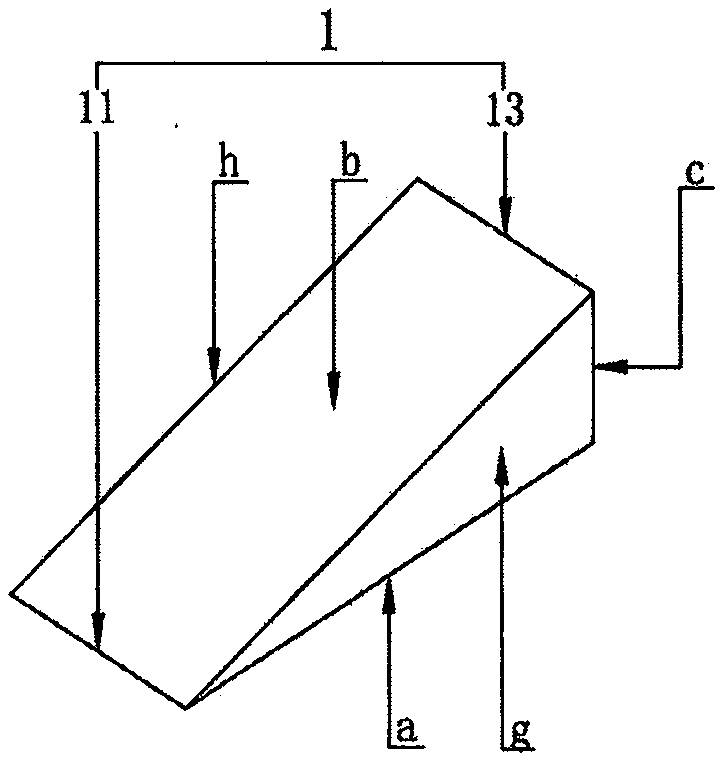

Wedge special for building, and using method and mounting protection part of wedge

The invention discloses a wedge special for a building, and a using method and mounting protection part of the wedge. The special wedge is formed by integrally pouring cementing materials for the building, and an overall base structure of the wedge can be made into a short tail wedge 1 composed of a wedge tip 11 and a wedge tail 13, or made into a long tail wedge 2 composed of the wedge tip 11, awedge body 12 and the wedge tail 13. The wedge tip 11 is composed of an acute angle formed by a wedge bottom face a and a wedge upper bevel b, and the wedge tail 13 comprises a hitting face c. Plant fiber cementing materials can be selected as the cementing materials for the building. The special wedge can be made to be in various shapes by taking the base structure of the short tail wedge 1 or the long tail wedge 2 as an example. The mounting protection part 8 is made of a metal material, is a U-shaped frame body, and comprises a left protection plate 81, a right protection plate 82 and a tail protection plate 83. An operation handle 84 is arranged on the end face of the tail protection plate 83.

Owner:姚井祥

Glass fiber enhanced polypropylene

The invention relates to a glass fiber enhanced polypropylene, comprising components by weight of 55.5-95% of polypropylene, 5-45% of alkali-free glass fiber, 0.1-3.0% of heat stabilizer, 0.1-3.0% of synthetic resin, 0.2-8% of fire retardant, 0.1-2.0% of light stabilizer, 0.1-2.0% of ultraviolet ray absorber, 1.3-5.5% of other auxiliary agent and 3-12% of active carbon. The glass fiber enhanced polypropylene of the present invention has beneficial effects of wear resistance at low temperature, ageing resistance, decomposition resistance during long-term contact with hot metal, small contraction scope and contraction value, contraction cavity resistance, indenture resistance, deformation resistance and high product surface fineness.

Owner:SUZHOU IND PARK XINFENGLIN PLASTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com