Autoclaved light sand aerated concrete blocks, and preparation method thereof

A technology of aerated concrete and production process, which is applied in the directions of climate sustainability, other household appliances, sustainable waste treatment, etc., can solve the problem that sawing mud is not easy to deal with and pollute the environment, and achieves good sound insulation effect, healthy use and investment saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

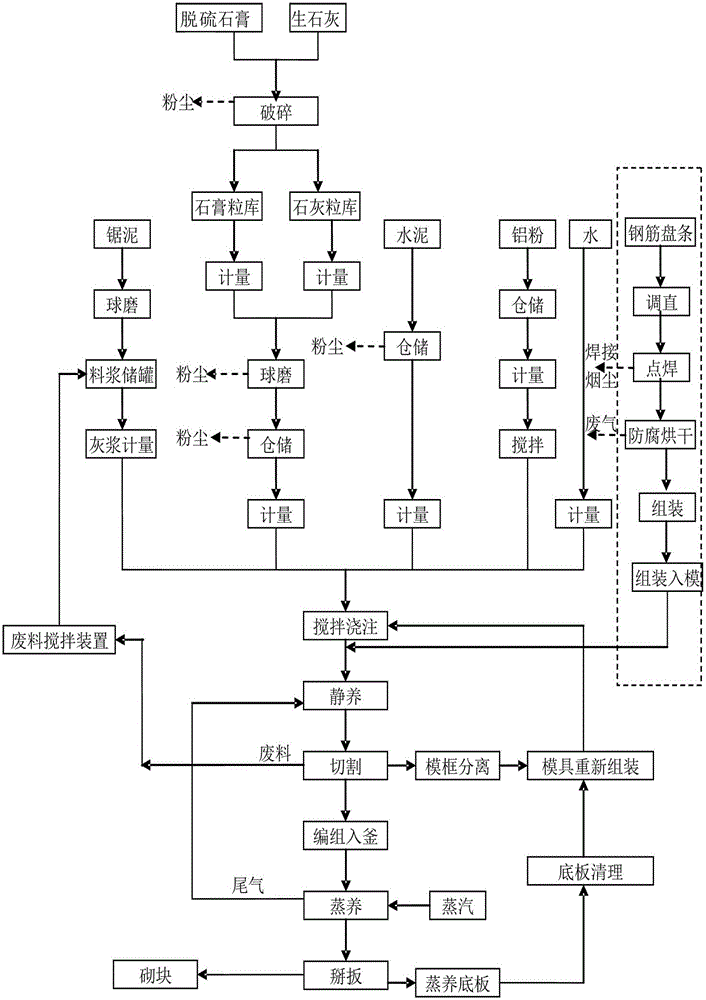

[0031] refer to figure 1 , an autoclaved lightweight sand aerated concrete block described in this specific embodiment, which is made of the following main materials by weight percentage and water, the main materials include saw mud: 69%; desulfurized gypsum: 3 %; quicklime: 13%; cement: 10%; aluminum powder: 0.5%.

[0032] The ratio of the water material to the main material is: 0.6.

[0033] A production process of an autoclaved lightweight sand aerated concrete block, comprising the following steps:

[0034] a. Quicklime and desulfurized gypsum are crushed and ball milled after entering the factory, and broken into particles with a particle size of ≤25mm, which are sent to the lime bin and desulfurized gypsum bin by the bucket elevator through the three-way slide for storage for use; quicklime and desulfurized gypsum particles The materials are fed through the respective speed-regulating belt scales, and enter the ball mill through the respective feeding sliders for mixin...

Embodiment 2

[0048] refer to figure 1 , an autoclaved lightweight sand aerated concrete block described in this specific embodiment, which is made of the following main materials by weight percentage and water, the main materials include saw mud: 71%; desulfurized gypsum: 4 %; quicklime: 14%; cement: 11%; aluminum powder: 0.5%.

[0049] 2. An autoclaved lightweight sand aerated concrete block as claimed in claim 1, wherein the ratio of the water material to the main material is 0.7.

[0050] 3. A production process of autoclaved lightweight sand aerated concrete block, characterized in that it comprises the following steps:

[0051] a. Quicklime and desulfurized gypsum are crushed and ball milled after entering the factory, and broken into particles with a particle size of ≤25mm, which are sent to the lime bin and desulfurized gypsum bin by the bucket elevator through the three-way slide for storage for use; quicklime and desulfurized gypsum particles The materials are fed through the re...

Embodiment 3

[0065] refer to figure 1 , an autoclaved lightweight sand aerated concrete block described in this specific embodiment, which is made by adding water to the main material in the following weight percentages, the main material includes saw mud: 74%; desulfurized gypsum: 4 %; quicklime: 16%; cement: 12%; aluminum powder: 0.6%.

[0066] The ratio of the water material to the main material is: 0.8.

[0067] A production process of an autoclaved lightweight sand aerated concrete block, comprising the following steps:

[0068] a. Quicklime and desulfurized gypsum are crushed and ball milled after entering the factory, and broken into particles with a particle size of ≤25mm, which are sent to the lime bin and desulfurized gypsum bin by the bucket elevator through the three-way slide for storage for use; quicklime and desulfurized gypsum particles The materials are fed through the respective speed-regulating belt scales, and enter the ball mill through the respective feeding sliders...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com