Prefabricated reinforced concrete hollow template internally provided with cross holes and molding and forming device thereof

A molding equipment, reinforced concrete technology, applied in the direction of molds and other directions, can solve the problems of huge workload of on-site assembling and dismantling of templates, the templates cannot be reused many times, and the quality of products is affected, so as to save a lot of templates, easy to control the quality, improve the quality of products, etc. The effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

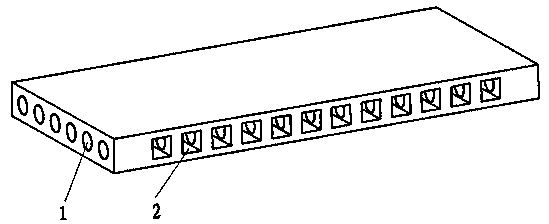

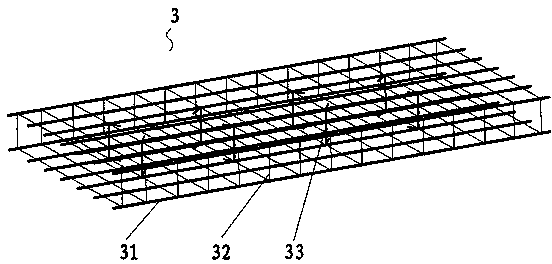

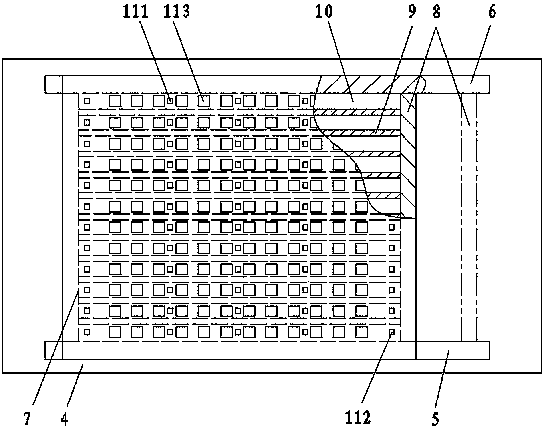

[0026] see figure 1 , the present invention provides a prefabricated reinforced concrete hollow formwork with cross holes inside. There are several horizontal through holes 2 arranged in parallel in one direction, and the through holes in one direction are used for the binding connection between the adjacent hollow templates by inserting steel bars into them. The longitudinal through holes and the transverse through holes penetrate each other. When concrete is poured into it on site, each of the hollow formworks connected together can be conveniently formed into a solid body to form a wall.

[0027] The equivalent diameter of the longitudinal through holes is preferably smaller than the equivalent diameter of the transverse through holes. The so-called equivalent diameter of the through hole means: if the through hole is circular, its equivalent diameter is equal to the diameter of the circle; if the through hole is non-circular, its equivalent diameter is equal to the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com