Ultra-high admixture amount flyash grinding concrete material damming method and structure thereof

A technology for roller compacted concrete and fly ash, which is applied in construction, sustainable waste treatment, solid waste management, etc. and environmental benefits, the effect of reducing the cost of temperature control and crack prevention

Pending Publication Date: 2019-05-28

CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the 1980s, my country started to study exploration, experimental research, and engineering practice. It has made breakthroughs in the research of RCC dam construction technology, and has rich practical experience. Many RCC specification documents have been formed within the industry. Constrained by mixing fly ash in compacted concrete, the maximum content cannot exceed 60%. None of the dams currently designed break through this regulation, which greatly limits the development of roller compacted concrete dam construction technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

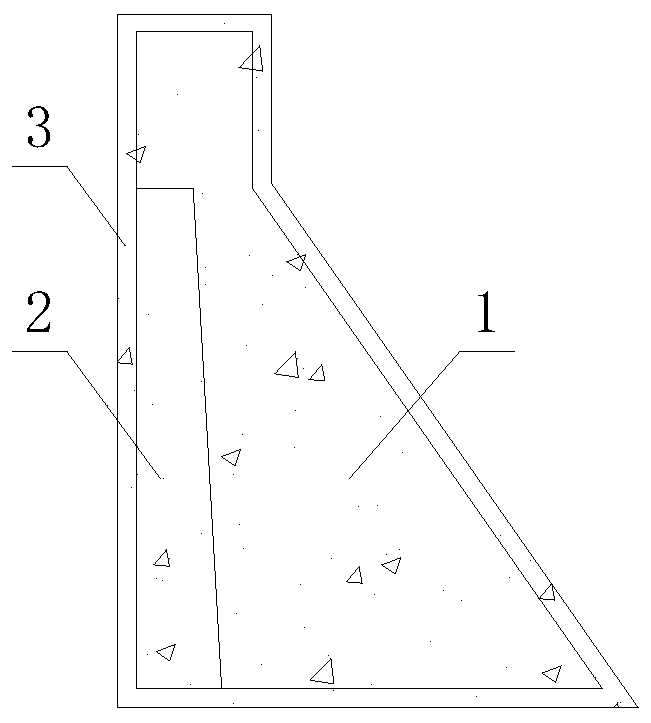

[0021] Such as figure 1 As shown, in this embodiment, the strength grade of RCC 1 is C15, and the amount of fly ash is as high as 70% to 80%, and the strength grade of anti-seepage RCC 2 is C20, and the amount of fly ash is as high as 60% to 70%, the part that is inconvenient to be rolled uses modified concrete 3, and its fly ash content is 60% to 80%, which is the same as that of the adjacent rolled concrete.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an ultra-high admixture amount flyash grinding concrete material damming method and a structure thereof. The admixture amount of flyash in grinding concrete is increased, the admixture amount of flyash in upstream-face C9020 three-graded anti-seepage grinding concrete is expected to be increased to 60%, the admixture amount of flyash in in-dam C9015 three-graded grinding concrete is expected to be increased to 70% to 80%, and a high-performance additive is adopted to lower water amount and cement amount of concrete. According to the ultra-high admixture amount flyash grinding concrete material damming method and the structure thereof disclosed by the invention, hydrated high temperature increase of concrete is effectively reduced, air shrinkage and self-shrinkage ofconcrete are reduced, temperature control and anti-cracking measures are simplified, temperature control and anti-cracking cost is reduced, and a certain economic benefit is achieved. Simplified temperature control and anti-cracking measures bring possibility to seam parting and chunk parting of a dam concrete structure, construction speed is increased, conditions are created for bringing forwardtime limit of the construction, and the economic benefits are remarkable; at the same time, flyash solid waste is greatly utilized, generated energy-conserving and emission-reducing ecological and environmental benefits are obvious.

Description

technical field [0001] The invention relates to a roller compacted concrete dam material structure, which belongs to the technical field of roller compacted concrete dams. Background technique [0002] The development of roller compacted concrete dams has gone through nearly 30 years. In the past 30 years, the world's roller compacted concrete dam technology has made great progress and developed by leaps and bounds. Since the 1980s, my country started to study exploration, experimental research, and engineering practice. It has made breakthroughs in the research of RCC dam construction technology, and has rich practical experience. Many RCC specification documents have been formed within the industry. Constrained by mixing fly ash in compacted concrete, the maximum content cannot exceed 60%. None of the dams currently designed break through this regulation, which greatly limits the development of roller compacted concrete dam construction technology. RCC dam construction te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/00E02B7/02C04B18/08C04B111/27

CPCY02W30/91

Inventor 宁华晚谭建军张斌曹小转王晓峰单承康曾树元李峻

Owner CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com