Self-leveling mortar with thick layer in unitary system and preparation method thereof

A self-leveling mortar and system technology, applied in the field of mortar, can solve the problems of material distribution, self-leveling mortar differences, influence on construction, bleeding and settlement, etc., to reduce early hydration heat release, reduce the risk of cracking, and reduce construction procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing the above-mentioned one-component thick-layer self-leveling mortar, comprising the following steps:

[0051] a) Strictly follow the feeding sequence of quartz sand→heavy calcium→→rubber powder→high belite sulfoaluminate cement→silica fume; additives include water reducing agent, water retaining agent, retarder, early strength agent, Foaming and air-entraining agents;

[0052] b) Stir for 30 minutes after feeding;

[0053] c) After the stirring is completed, the material is discharged and returned;

[0054] d) Outgoing packaging.

[0055] Among them, high belite sulfoaluminate cement, 0.45~0.9mm quartz sand, 0.22~0.45mm quartz sand, 0.105~0.22mm quartz sand, 0.045mm heavy calcium, silica fume, rubber powder, water reducing agent, water retaining agent , retarder, early strength agent, defoamer, air-entraining agent, and water are all the same as above, and will not be repeated here.

[0056] The above method ...

Embodiment 1

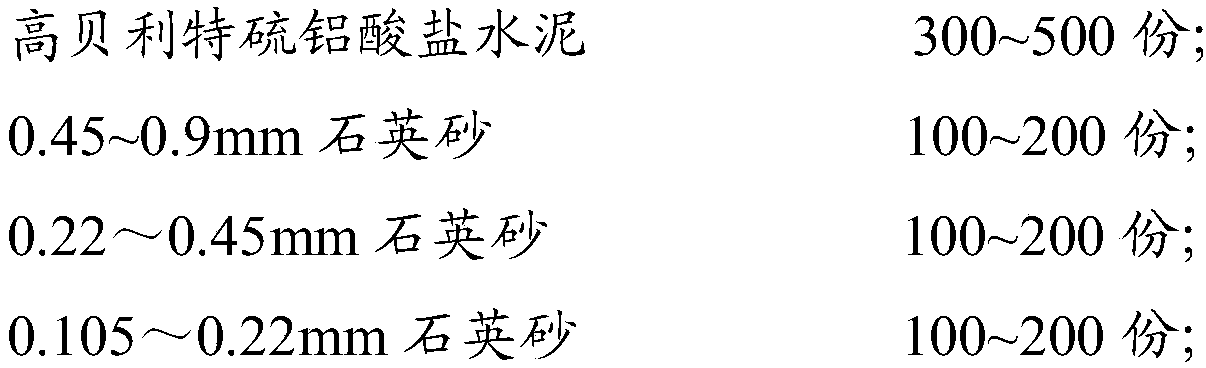

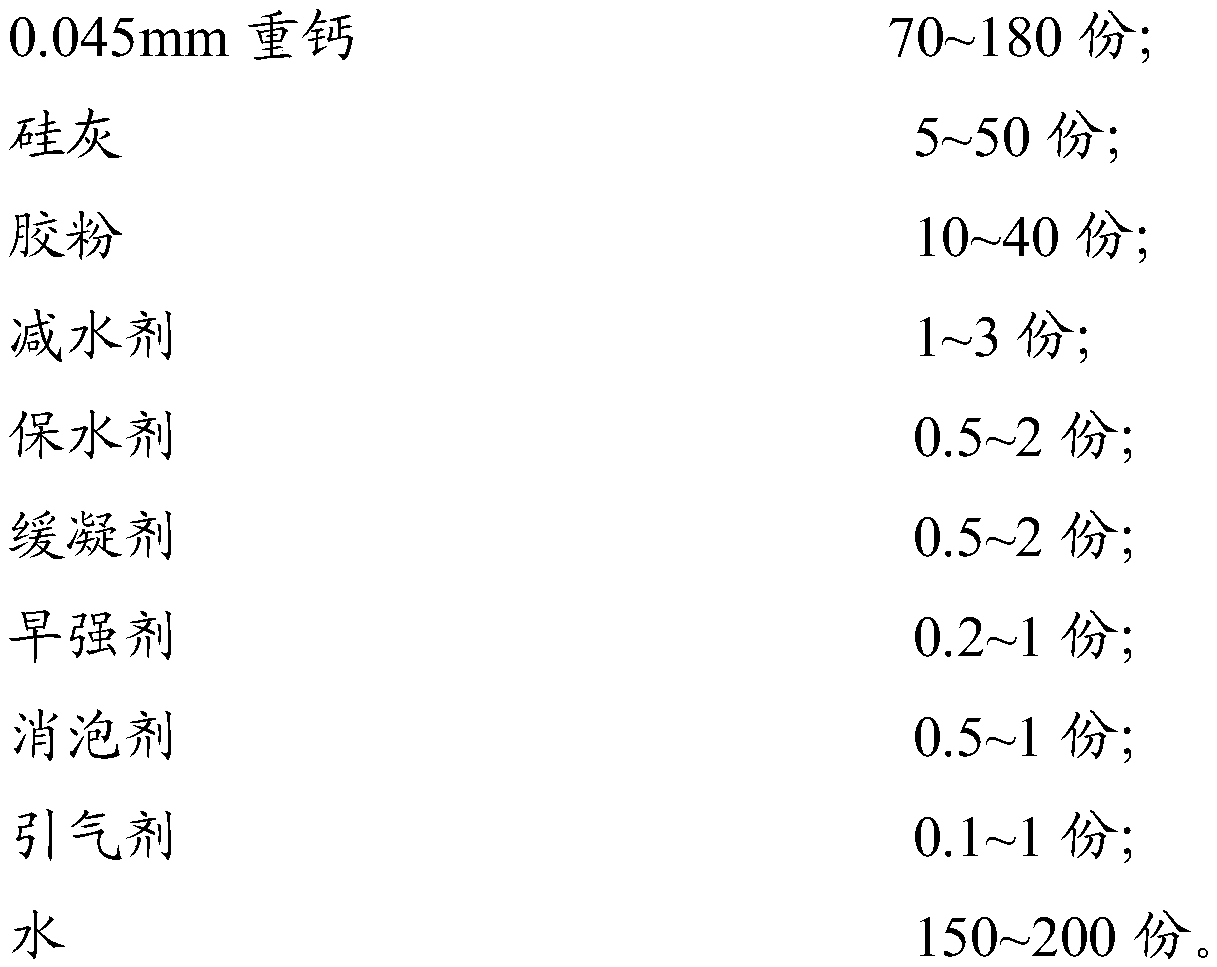

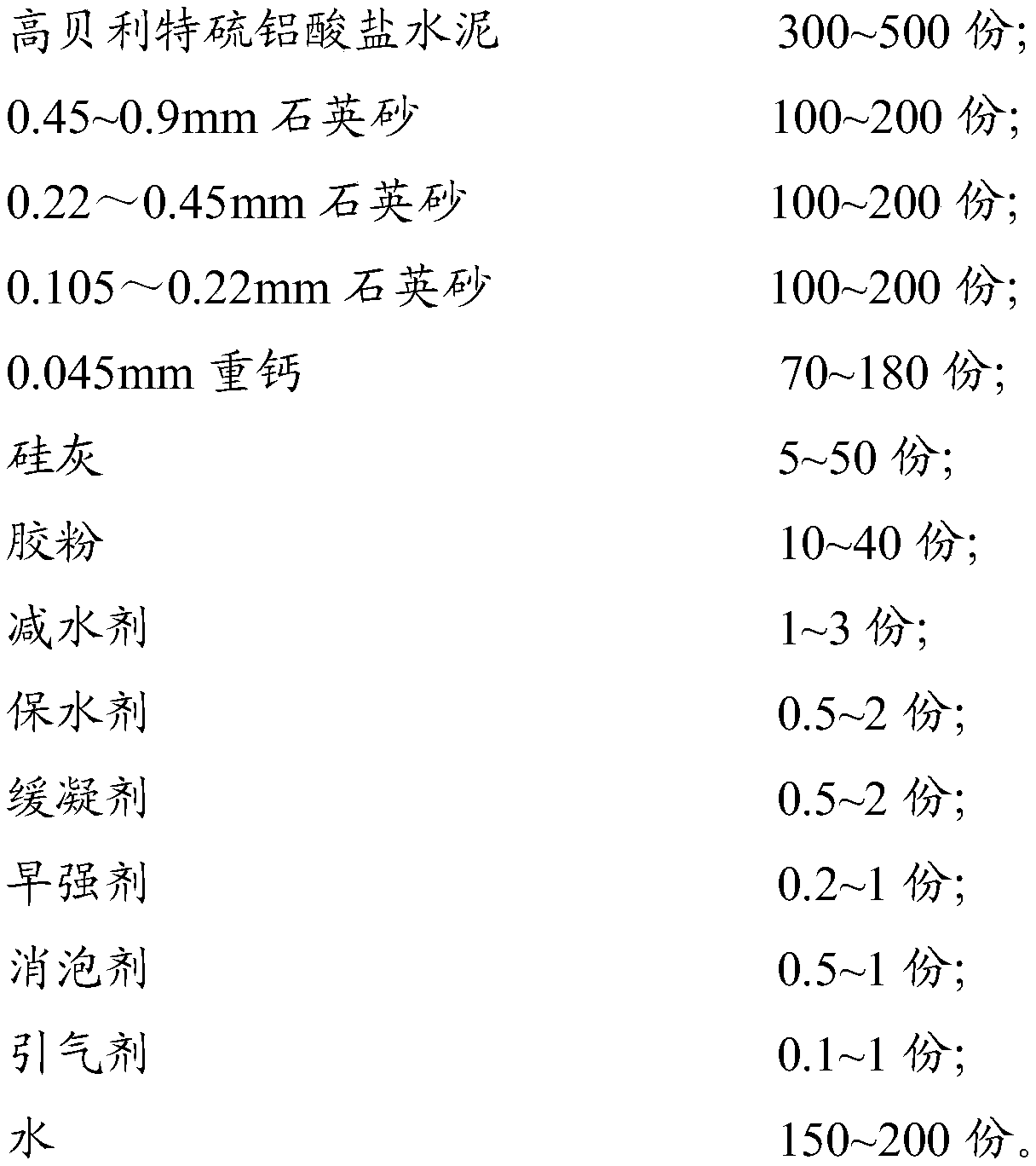

[0060] One-component system thick-layer self-leveling mortar, including the following raw materials in parts by weight:

[0061] 300 parts of high belite sulfoaluminate cement, 180 parts of 0.45-0.9mm quartz sand, 100 parts of 0.22-0.45mm quartz sand, 200 parts of 0.105-0.22mm quartz sand, 165 parts of 0.045mm heavy calcium, 30 parts of silica fume , 20 parts of rubber powder, 1.5 parts of polycarboxylate water-reducing agent, 1 part of water-retaining agent, 0.6 part of retarder, 1 part of lithium carbonate, 0.5 part of silicone defoamer, 0.4 part of fatty alcohol air-entraining agent; stir The corresponding amount of water added during use is 170 parts;

[0062] Wherein, the mass ratio of citric acid and malic acid in the retarder is 1:1.5.

[0063] The preparation method of one-component system thick-layer self-leveling mortar comprises the following steps:

[0064] a) In strict accordance with quartz sand → heavy calcium → additives (water reducer, water retaining agent,...

Embodiment 2

[0072] One-component system thick-layer self-leveling mortar, including the following raw materials in parts by weight:

[0073] 350 parts of high belite sulfoaluminate cement, 180 parts of 0.45-0.9mm quartz sand, 120 parts of 0.22-0.45mm quartz sand, 200 parts of 0.105-0.22mm quartz sand, 99 parts of 0.045mm heavy calcium, 20 parts of silica fume , 25 parts of rubber powder, 2 parts of polycarboxylate water-reducing agent, 1.2 parts of water-retaining agent, 1 part of retarder, 0.7 part of lithium carbonate, 0.6 part of silicone defoamer, 0.5 part of fatty alcohol air-entraining agent; stir The corresponding amount of water added during use is 185 parts;

[0074] Wherein, the mass ratio of citric acid and malic acid in the retarder is 1:2.

[0075] The preparation method of one-component system thick-layer self-leveling mortar comprises the following steps:

[0076] a) In strict accordance with quartz sand → heavy calcium → additives (water reducer, water retaining agent, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com