Production process for low-cost autolaved aerated concrete blocks

A concrete block and production process technology, applied in the field of building materials, can solve the problems of large power consumption, etc., and achieve the effects of reducing material shrinkage, low salt content, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

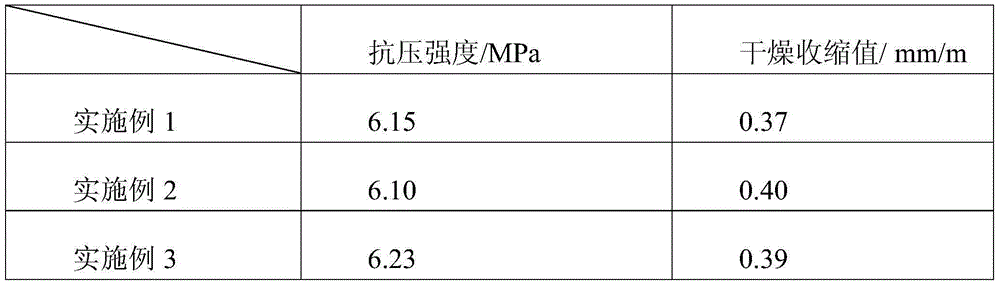

Examples

Embodiment 1

[0021] Prepare materials:

[0022] Weigh by weight: 18 parts of No. 32.5 cement, 29 parts of quicklime, 7 parts of gypsum, 19 parts of fly ash, 35 parts of water, 32 parts of 50-100 mesh lake sand, 1 part of water reducing agent, 0.135 parts of aluminum powder;

[0023] The water reducer is composed of MNC-AS amino high-efficiency water reducer and MNC-PCP polycarboxylate water reducer, wherein the weight ratio of the two is 1:1;

[0024] Sand aerated concrete block production steps:

[0025] 1) Lake sand pretreatment: wash the natural lake sand fully with water, dry it in the sun, then crush and sieve to 50-100 mesh;

[0026] 2) Take No. 32.5 cement, quicklime, aluminum powder, and treated lake sand in the weight ratio, add it to water and mix it evenly to form a slurry, then add water reducing agent and stir for 10 minutes at a speed of 100r / min, and finally add gypsum and fly ash , stir at 40°C, 200-300r / min for 0.5 hours to get the concrete slurry;

[0027] 3) pour the ...

Embodiment 2

[0030] Weigh by weight: 21 parts of No. 32.5 cement, 30 parts of quicklime, 8 parts of gypsum, 22 parts of fly ash, 37 parts of water, 38 parts of 50-100 mesh lake sand, 2 parts of water reducing agent, 0.135 parts of aluminum powder ;

[0031] The water reducer is composed of MNC-AS amino high-efficiency water reducer and MNC-PCP polycarboxylate water reducer, wherein the weight ratio of the two is 1:1;

[0032] Sand aerated concrete block production steps:

[0033] 1) Lake sand pretreatment: wash the natural lake sand fully with water, dry it in the sun, then crush and sieve to 50-100 mesh;

[0034] 2) Take No. 32.5 cement, quicklime, aluminum powder, and treated lake sand in the weight ratio and mix them into water to form a slurry, then add water reducing agent and stir at 200r / min for 10 minutes, and finally add gypsum and fly ash , stir at 40°C and 300r / min for 0.5 hour to get the concrete slurry;

[0035] 3) pour the concrete slurry into the concrete block brick mold...

Embodiment 3

[0038] Prepare materials:

[0039] Weigh 19 parts of No. 32.5 cement, 29 parts of quicklime, 8 parts of gypsum, 20 parts of fly ash, 36 parts of water, 1280 parts of 50-100 mesh lake sand, 0.135 parts of aluminum powder, and 1.5 parts of water reducing agent according to the weight ratio;

[0040] The water reducer is composed of MNC-AS amino high-efficiency water reducer and MNC-PCP polycarboxylate water reducer, wherein the weight ratio of the two is 1:1;

[0041] Sand aerated concrete block production steps:

[0042] 1) Lake sand pretreatment: wash the natural lake sand fully with water, dry it in the sun, then crush and sieve to 50-100 mesh;

[0043] 2) Take No. 32.5 cement, quicklime, aluminum powder, and treated lake sand in the weight ratio and mix them into water to form a slurry, then add water reducing agent and stir at 200r / min for 10 minutes, and finally add gypsum and fly ash , stir at 40°C and 200r / min for 0.5 hour to get the concrete slurry;

[0044] 3) pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com