Quick-setting epoxy grouting mortar suitable for summer first-aid repair construction

A rapid-setting, mortar technology, applied in the field of emergency repair of construction projects, can solve the problems of heat accumulation, human toxicity, and high mixing and weighing accuracy requirements, reducing viscosity, increasing cross-linking density, and improving curing speed and mechanics. performance effect

Active Publication Date: 2019-11-15

中冶武汉冶金建筑研究院有限公司

View PDF10 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Chinese patent CN201210312422.3 discloses a "high-strength and fast-curing epoxy resin grouting material and its preparation method". It has the characteristics of high adhesion to the substrate, but the hourly strength of this method is not high, and the curing time of 60MPa is more than 10h. There is still a big gap in the early strength development and the requirements for emergency repairs.

At the same time, due to the relatively small size of the mortar (<2.5), for deeper pouring depths, the amount of glue used will cause heat accumulation, especially when the ambient temperature is high in summer.

[0005] Chinese patent CN201610227275.0 discloses a "high-strength quick-setting epoxy resin mortar and its preparation method". However, the curing time is still above 6 hours, and the dosage range of triethylenetetramine and tetraethylenepentamine aliphatic amine curing agents is relatively small, which requires high accuracy of mixing and weighing, and is easy to explode at high temperature, and is harmful to the human body. More poisonous

[0006] Chinese patent CN201711423774.5 discloses a "high-strength and high-fluidity epoxy resin grouting material and its preparation method". In this method, a curing agent system of aliphatic amine, alicyclic amine and polyether amine and a thixotropic agent are used. Excellent construction fluidity and mechanical strength, but long curing time, unable to meet emergency repair requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

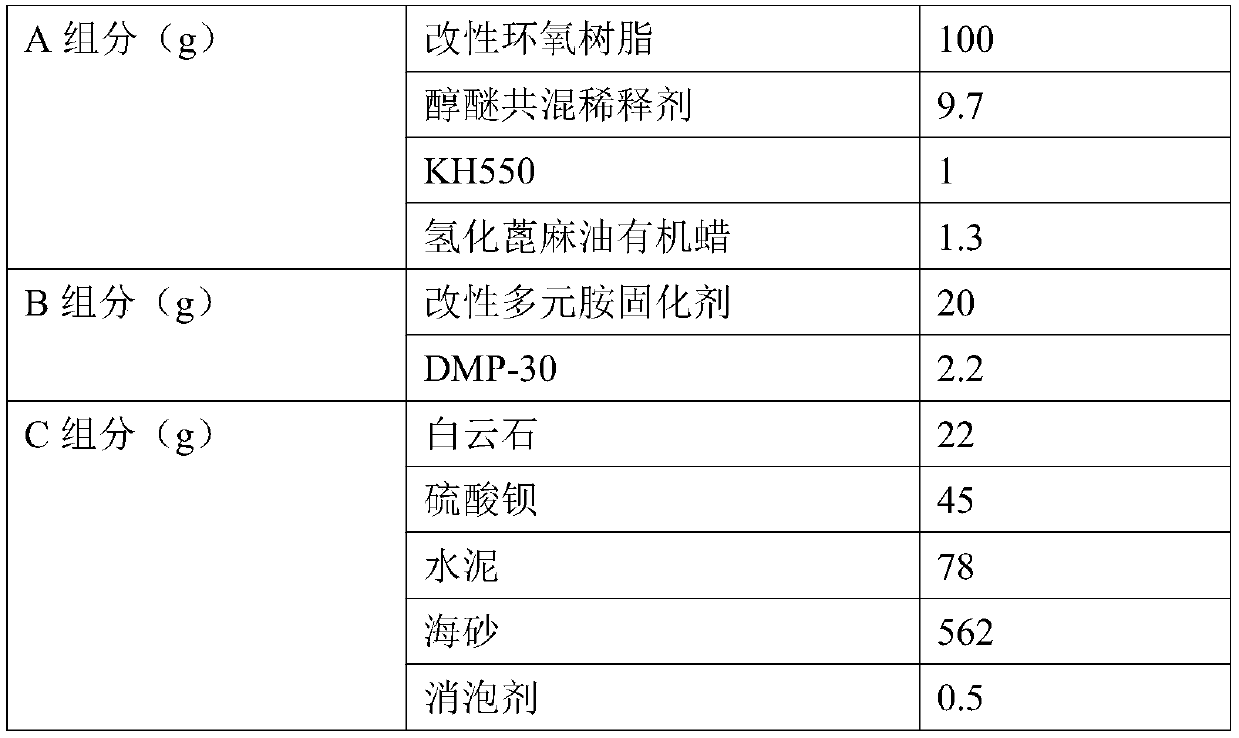

Embodiment 2

[0049] Table 2 Example 2 Epoxy perfusion mortar proportioning

[0050]

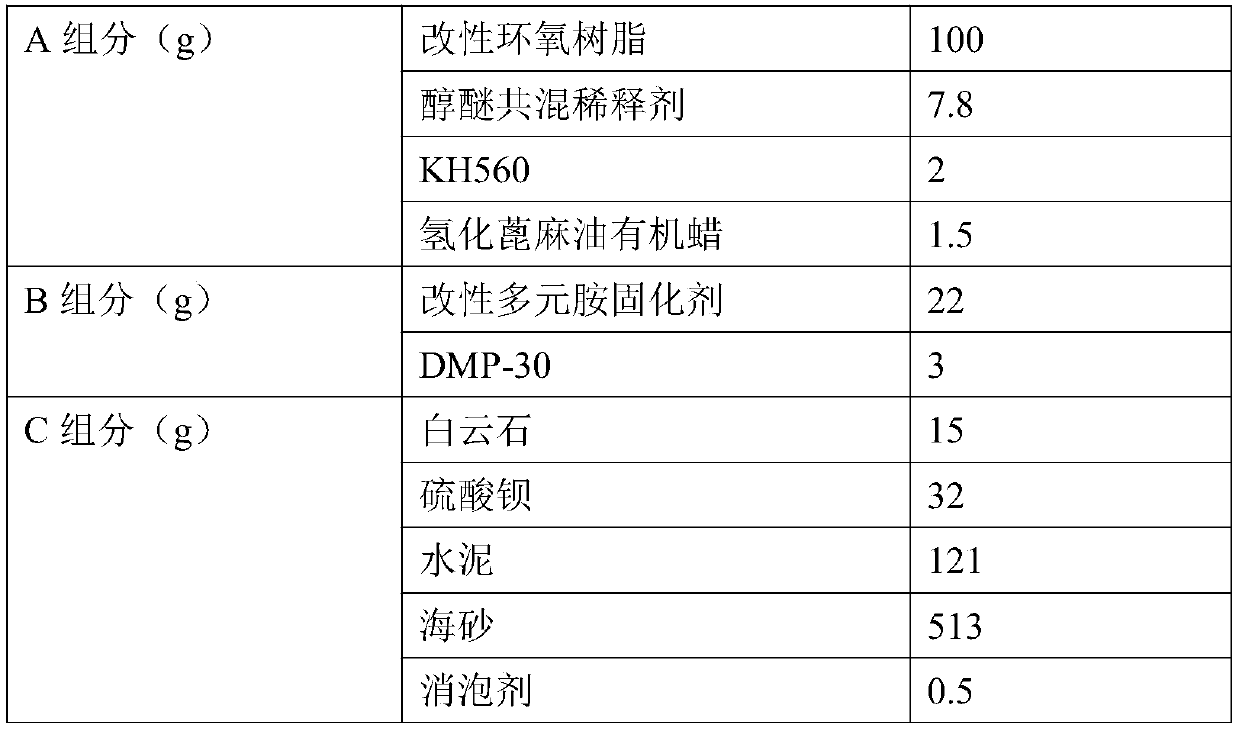

Embodiment 3

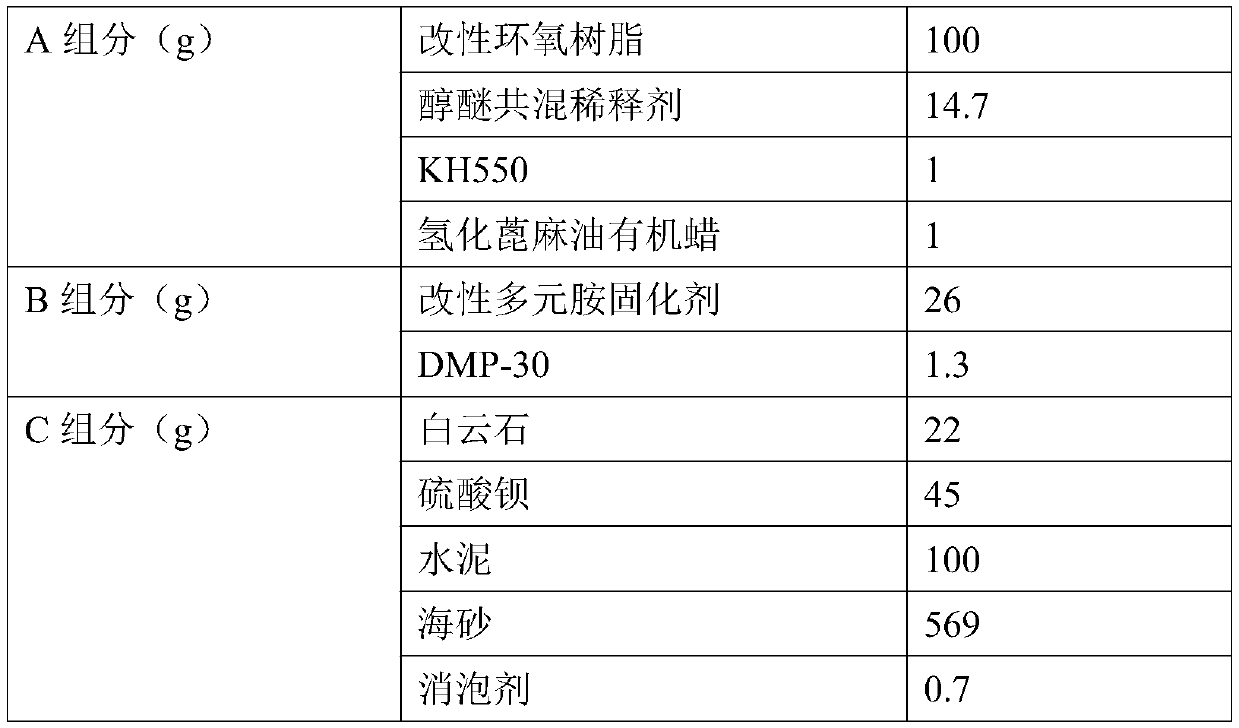

[0052] Table 3 Example 3 Epoxy perfusion mortar proportioning

[0053]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a quick-setting epoxy grouting mortar suitable for summer first-aid repair construction. The quick-setting epoxy grouting mortar is formed by mixing of a resin component A, a curing agent component B and a bone powder component C in a mass ratio of 1:(0.2-0.26):(5-7) during use. Specifically, the component A comprises the following components by weight: 100 parts of modified epoxy resin, 1-15 parts of an alcohol ether composite diluent, 1-3 parts of a coupling agent, and 0.5-3 parts of a rheological agent; the component B comprises the following components by weight: 16-23 parts of a modified polyamine curing agent, and 1-3 parts of an accelerator; and the component C comprises the following components by weight: 1-23 parts of dolomite powder, 15-46 parts of bariumsulfate powder, 10-121 parts of cement, 385-588 parts of sea sand, and 0.1-1.5 parts of a defoamer. The quick-setting epoxy grouting mortar provided by the invention has the technical characteristicsof short curing time, high hour strength, and no flash polymerization during high temperature construction, at the same time is non-toxic and harmless, and is simple to prepare, and is widely applicable to concrete structure repair with quick-setting and early strength requirements and construction of installation and anchoring projects, especially suitable for summer repair construction.

Description

technical field [0001] The invention belongs to the technical field of emergency repair construction of construction engineering, and in particular relates to a quick-setting epoxy perfusion mortar suitable for emergency repair construction in summer. Background technique [0002] Epoxy perfusion mortar is a kind of perfusion gravity mortar material mixed with epoxy resin, curing agent and bone powder in a certain proportion. Epoxy perfusion mortar has excellent mechanical properties and bonding properties, high early strength, and is widely used in defect repair and reinforcement of concrete engineering structures; epoxy mortar also has excellent flexural and fatigue resistance, and is often used in bridge supports, Anchoring of equipment foundations, grouting of supporting substrates of large equipment under dynamic load conditions such as rails and door cranes. [0003] The current repair materials mostly use finished cement-based grouting materials, which have good cons...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B24/28C04B24/30C08G14/073C08G14/08C08G59/62C04B111/70C04B111/72

CPCC04B24/28C04B24/30C04B28/04C04B2111/70C04B2111/72C04B2201/05C04B2201/52C08G14/06C08G14/08C08G59/623C04B24/281C04B24/02C04B24/023C04B24/08C04B24/42C04B24/122C04B14/26C04B14/368C04B14/068C04B2103/50

Inventor 周紫晨曾明张冰王智罗英杰

Owner 中冶武汉冶金建筑研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com