Novel liquid cooling module with multi-channel thin-wall straight pipe structure

A multi-channel, thin-walled technology, applied in the direction of circuits, electrochemical generators, electrical components, etc., can solve the problems of poor process operability, many system structural components, and large temperature difference of batteries, and achieve simple structure, high energy density, The effect of small pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

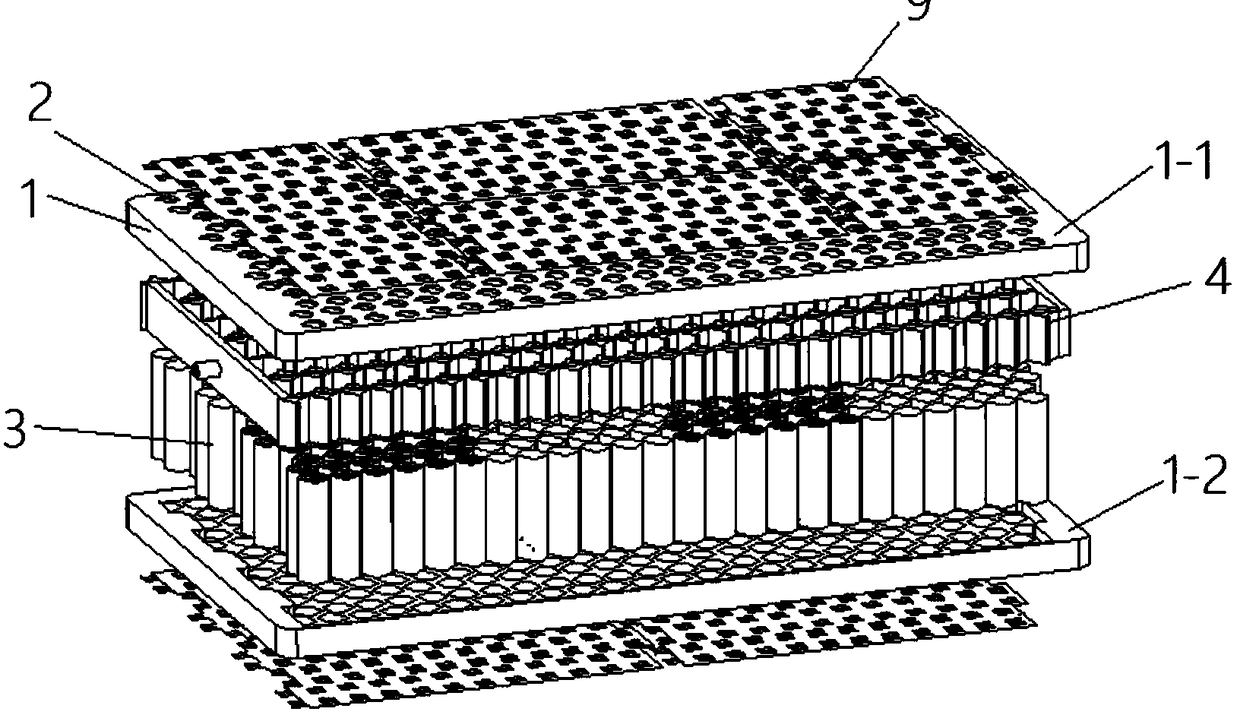

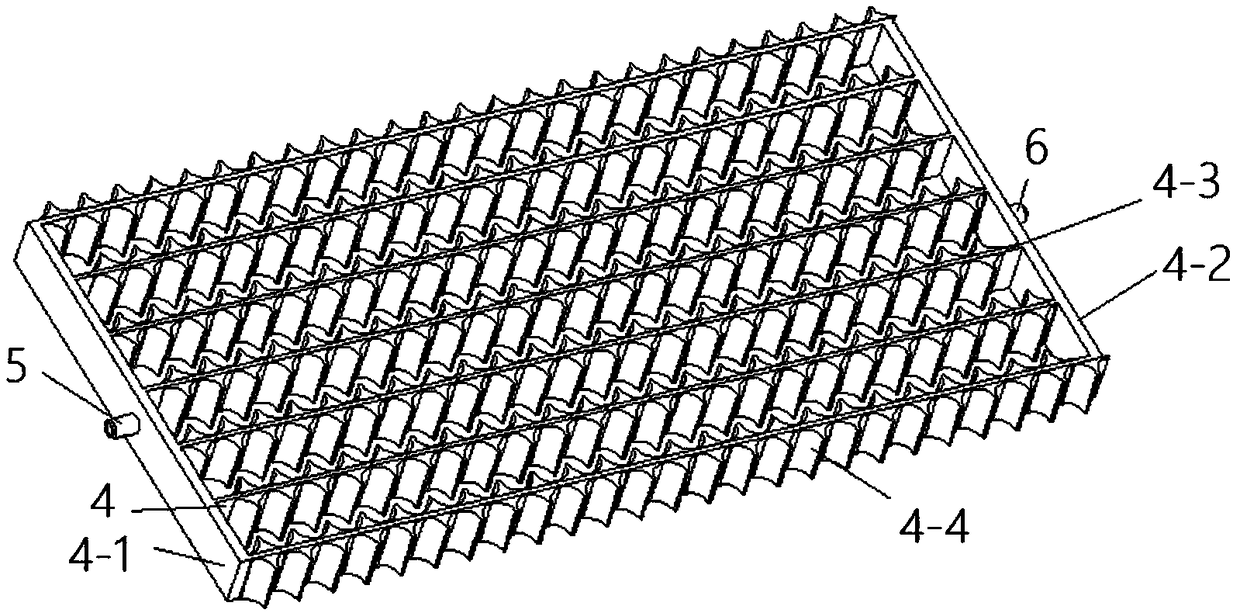

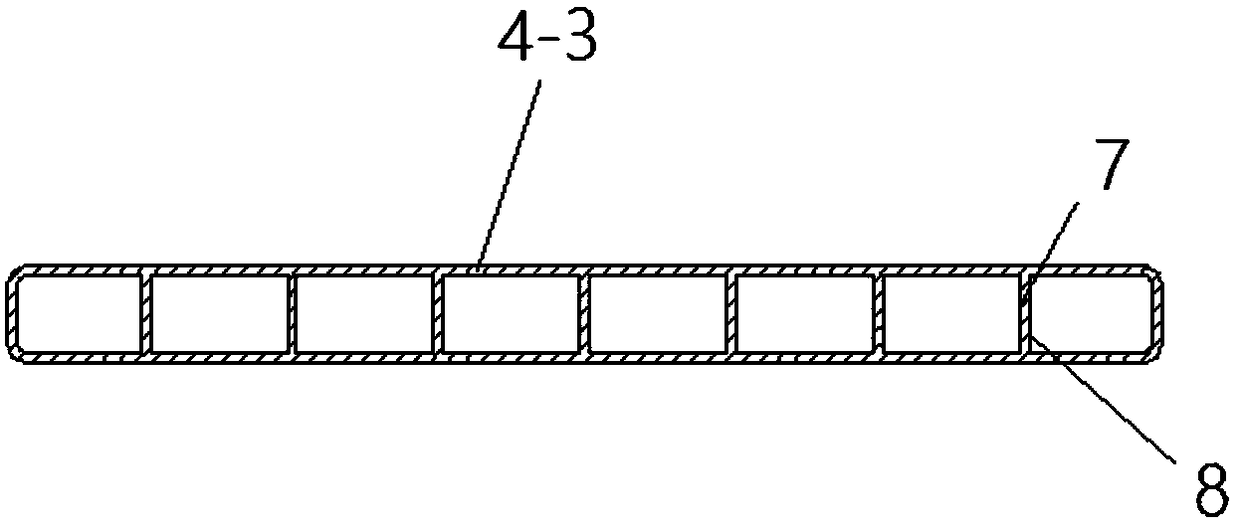

[0019] Such as Figure 1~4 As shown, a new multi-channel thin-wall straight tube structure liquid cooling module includes a cell support 1, and the cell support 1 includes an upper shelf plate 1-1 and a lower shelf plate 1-2, an upper shelf plate 1-1 and a lower shelf There are several cell fixing slots 2 symmetrically arranged on the plate 1-2, and the cell 3 is fixed in the cell fixing slot 2, and the liquid cooling module 4 is set under the connection end between the upper shelf plate 1-1 and the cell 3, and the liquid cooling The module 4 is composed of a left harmonica vertical pipe 4-1, a right harmonica vertical pipe 4-2 and a plurality of harmonica horizontal pipes 4-3 welded between the left harmonica vertical pipe 4-1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com