Patents

Literature

226results about How to "Avoid temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

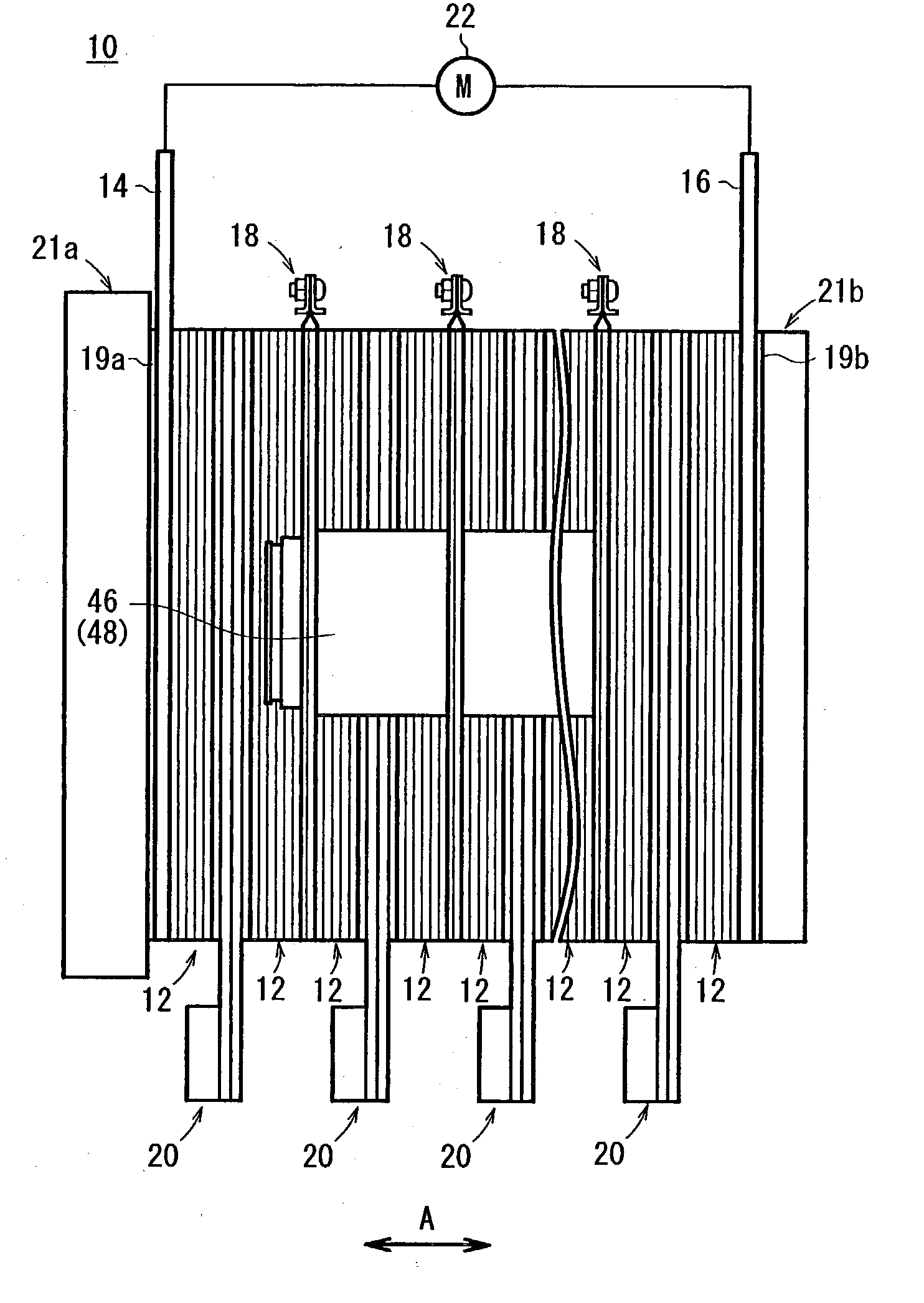

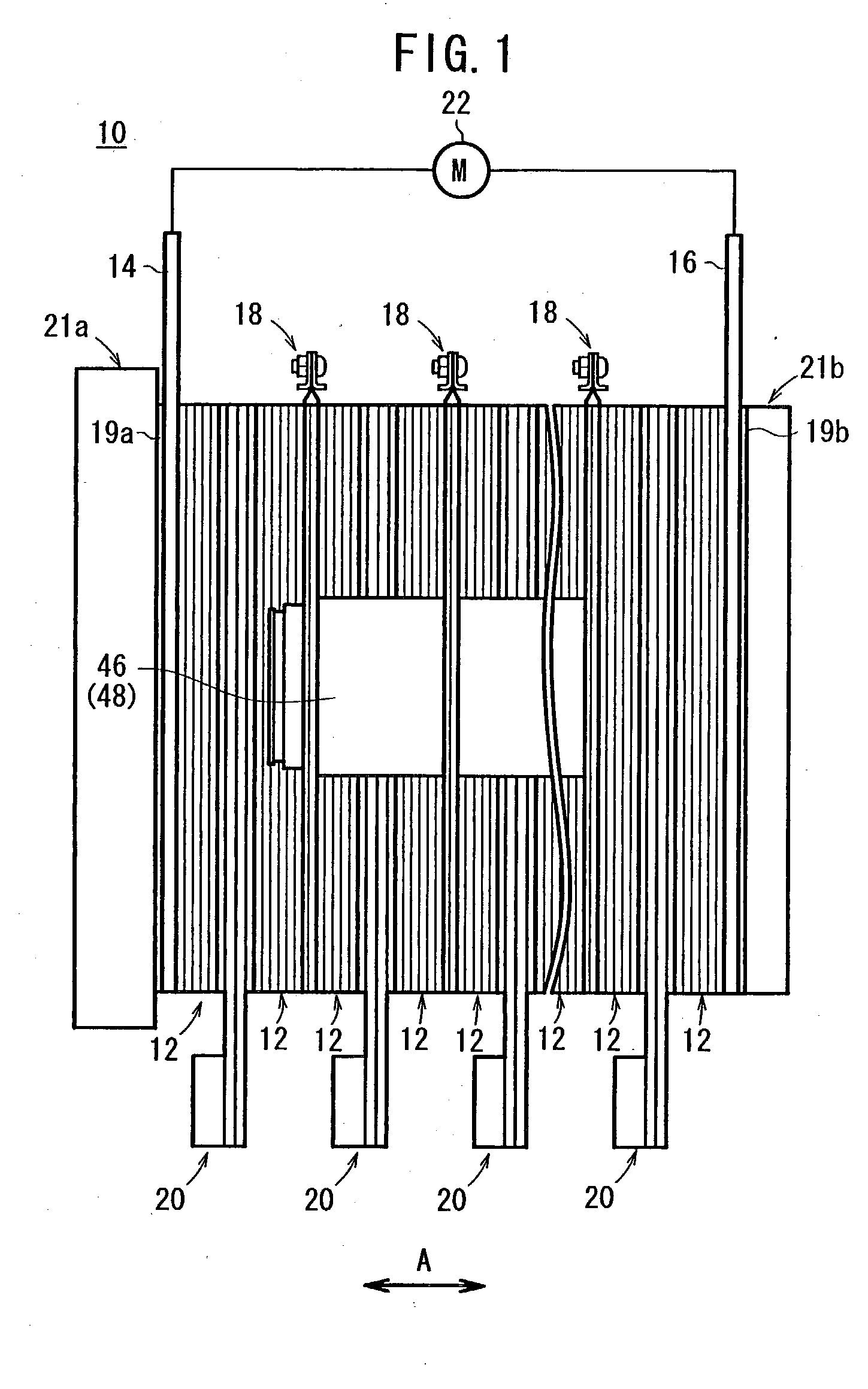

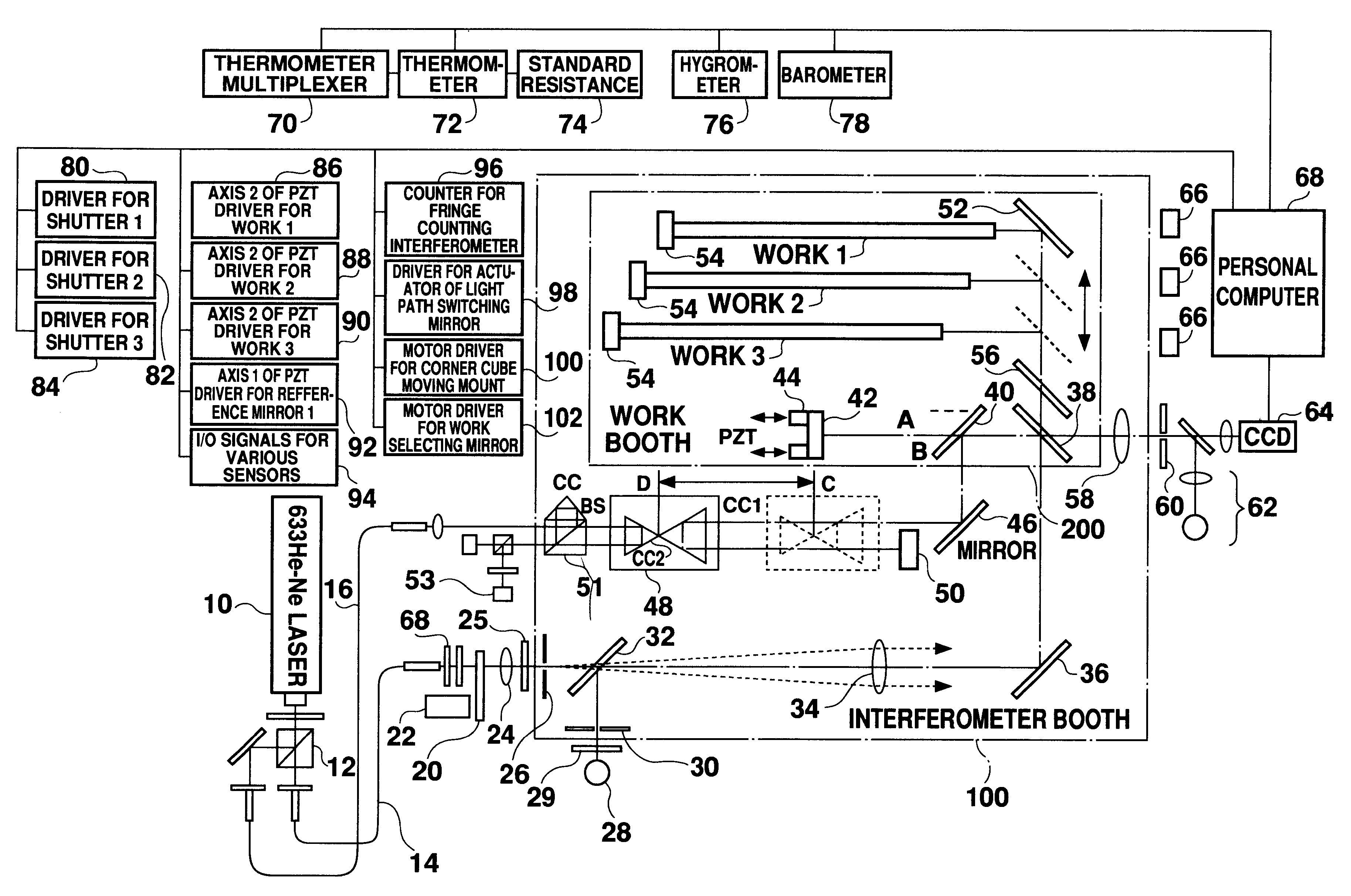

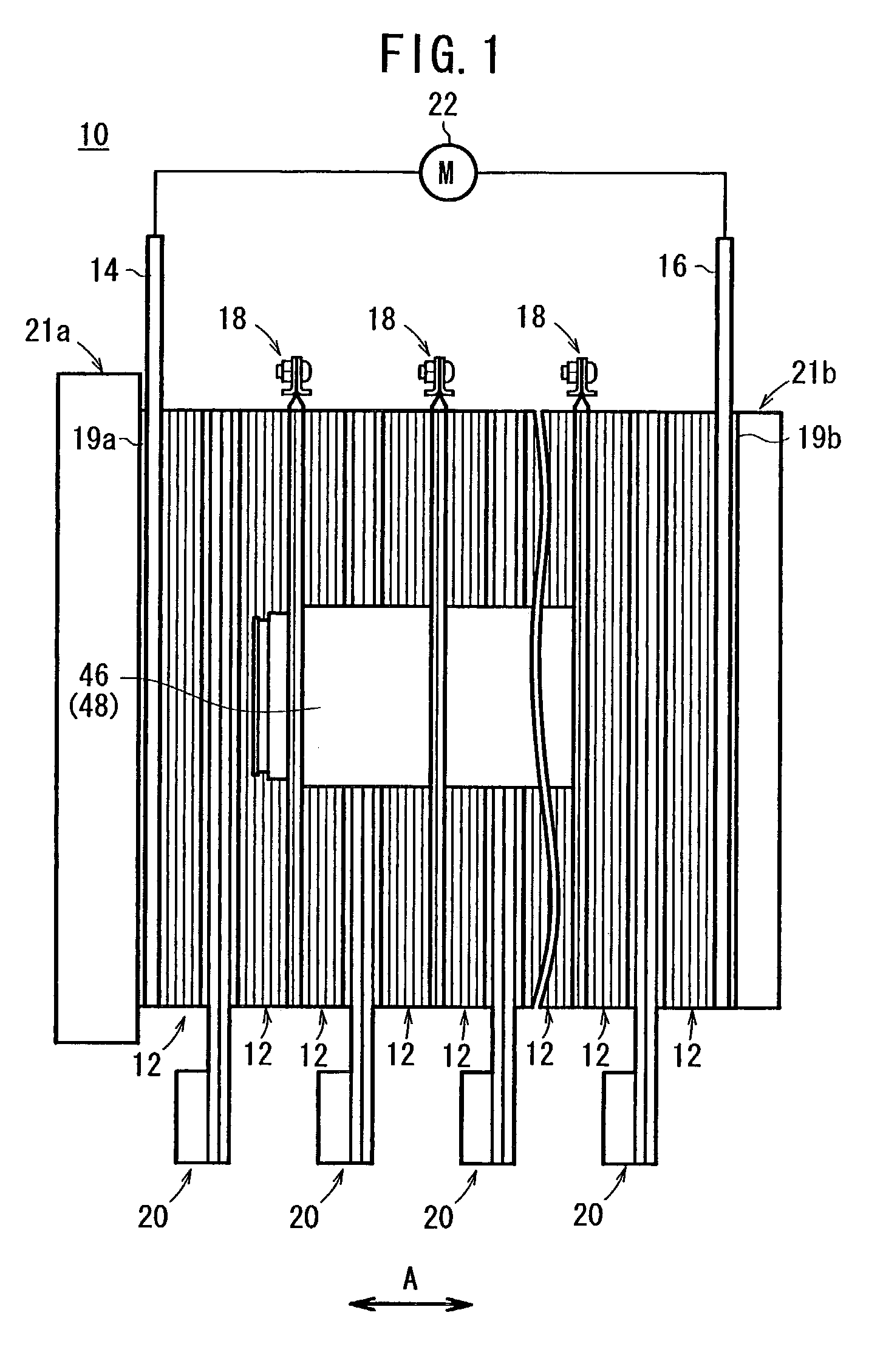

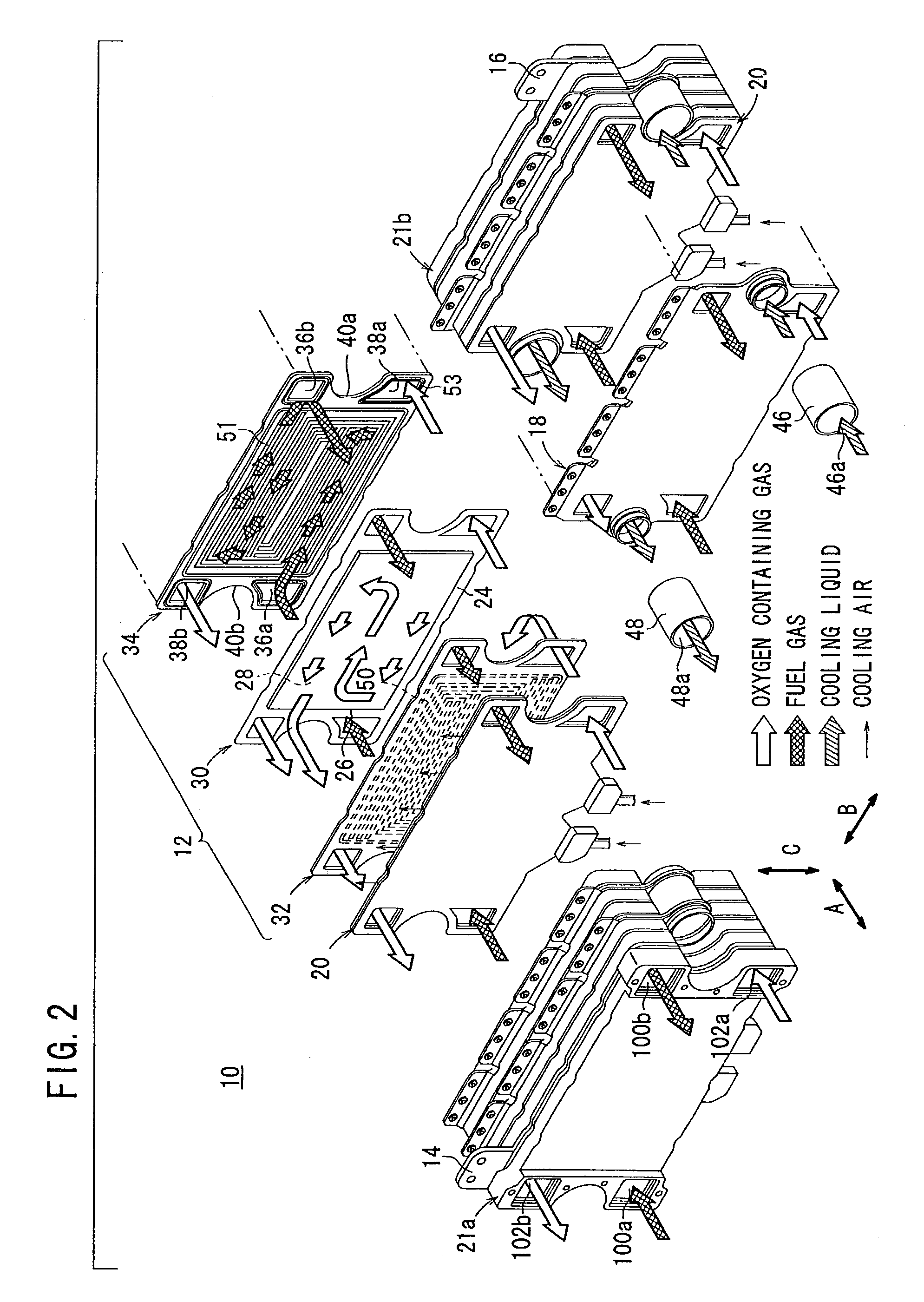

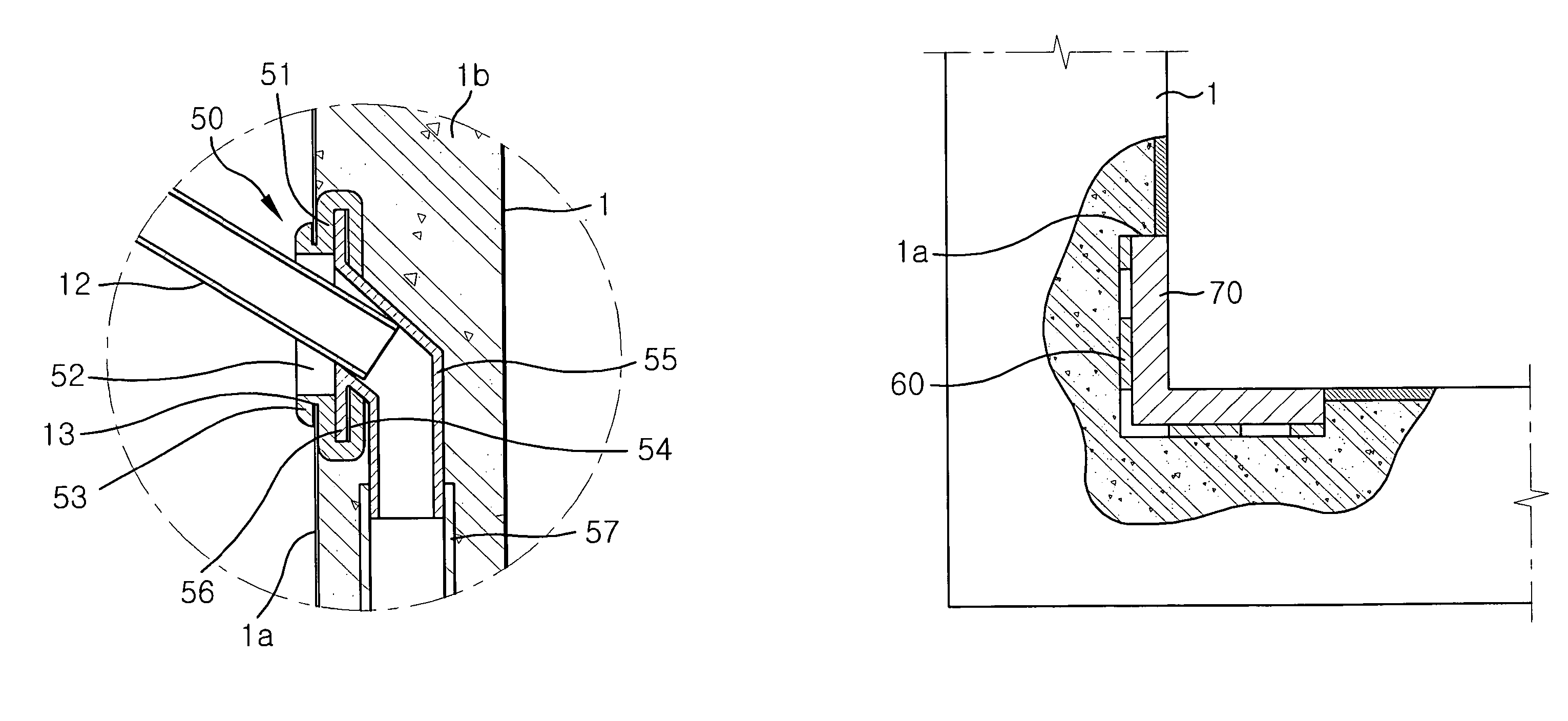

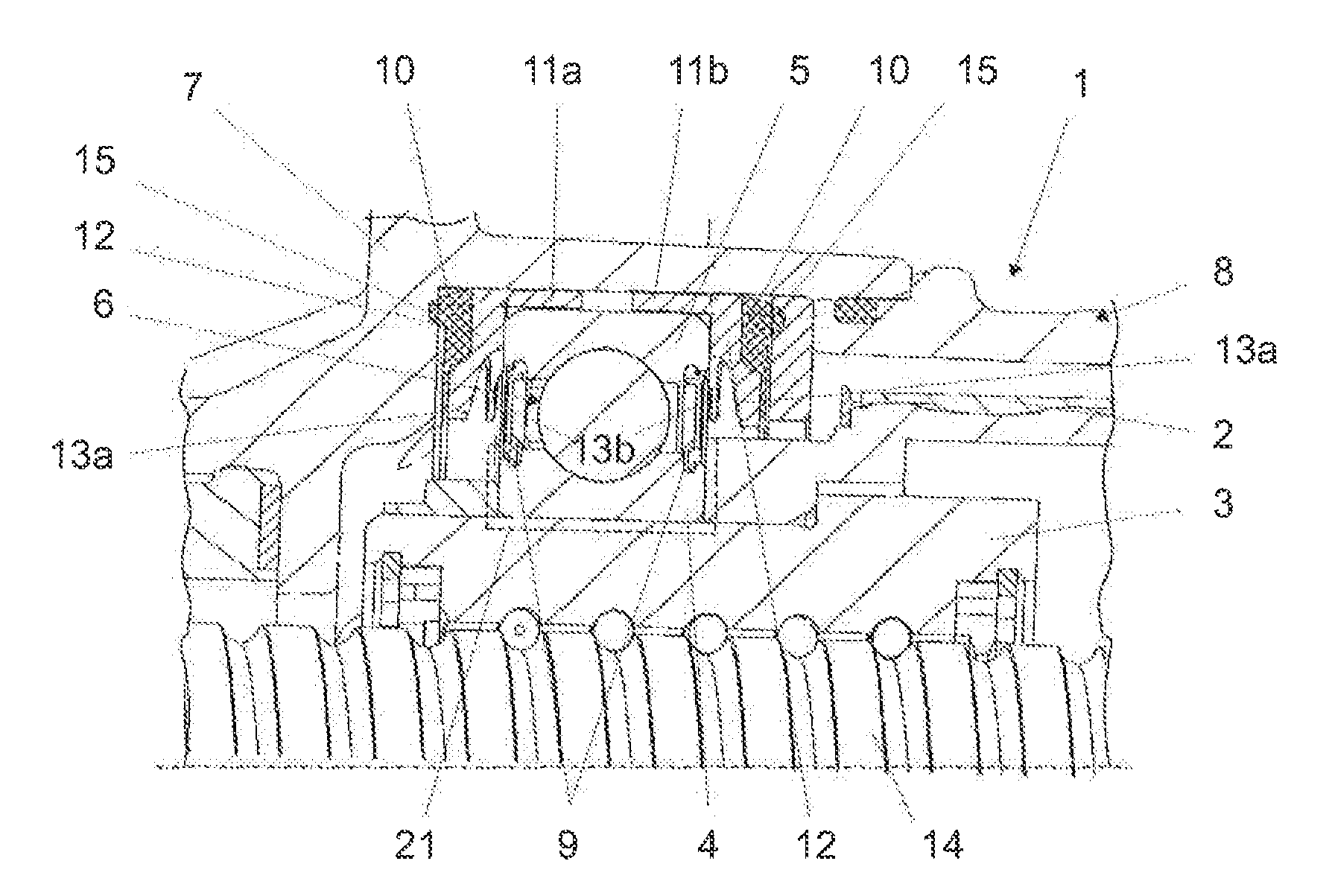

Fuel cell stack

InactiveUS20050266286A1Simple and compact structurePower generation performance is maintained desirablyFuel cell heat exchangeFuel cells groupingFuel cellsNuclear engineering

A fuel cell stack includes power generation cells, terminal plates, first cooling cells, and second cooling cells. The terminal plates are electrically connected to the power generation cells. The first cooling cells are interposed between the terminal plates, and a cooling liquid is supplied to the first cooling cells for cooling the power generation cells. The second cooling cells are interposed between the terminal plates. A predetermined number of power generation cells are interposed between the first cooling cell and the second cooling cell. A cooling air is supplied to the second cooling cell for cooing the power generation cells.

Owner:HONDA MOTOR CO LTD

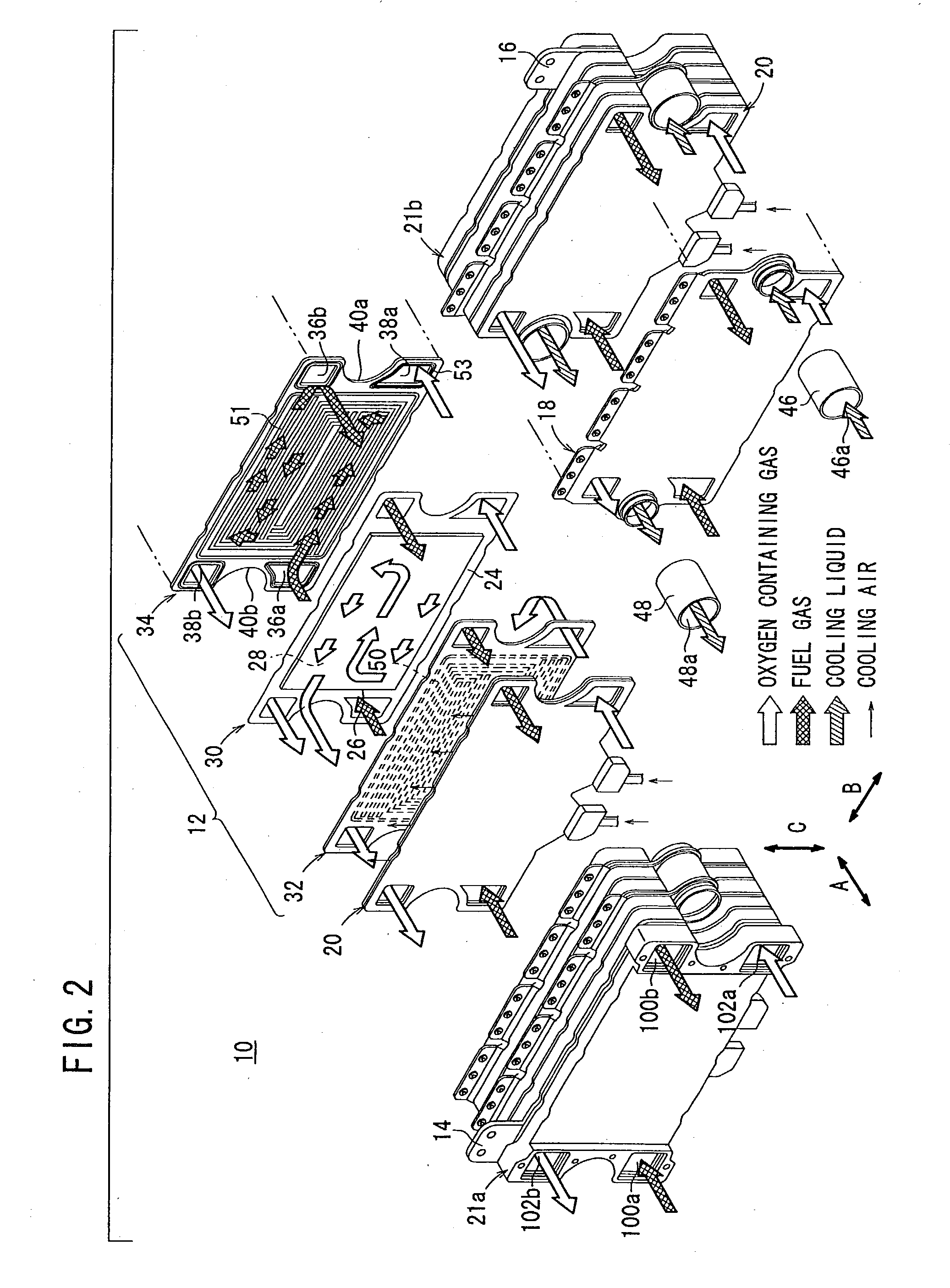

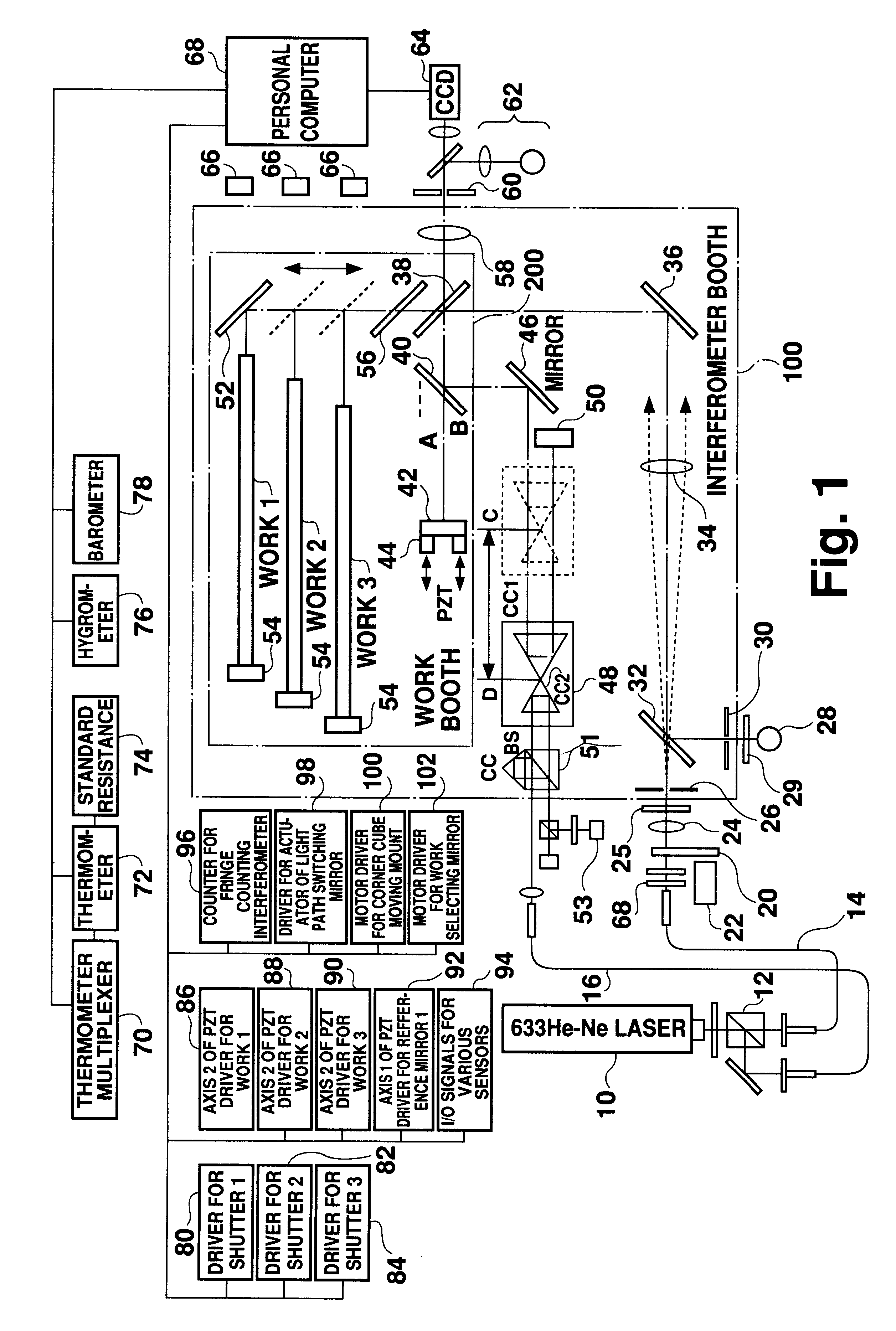

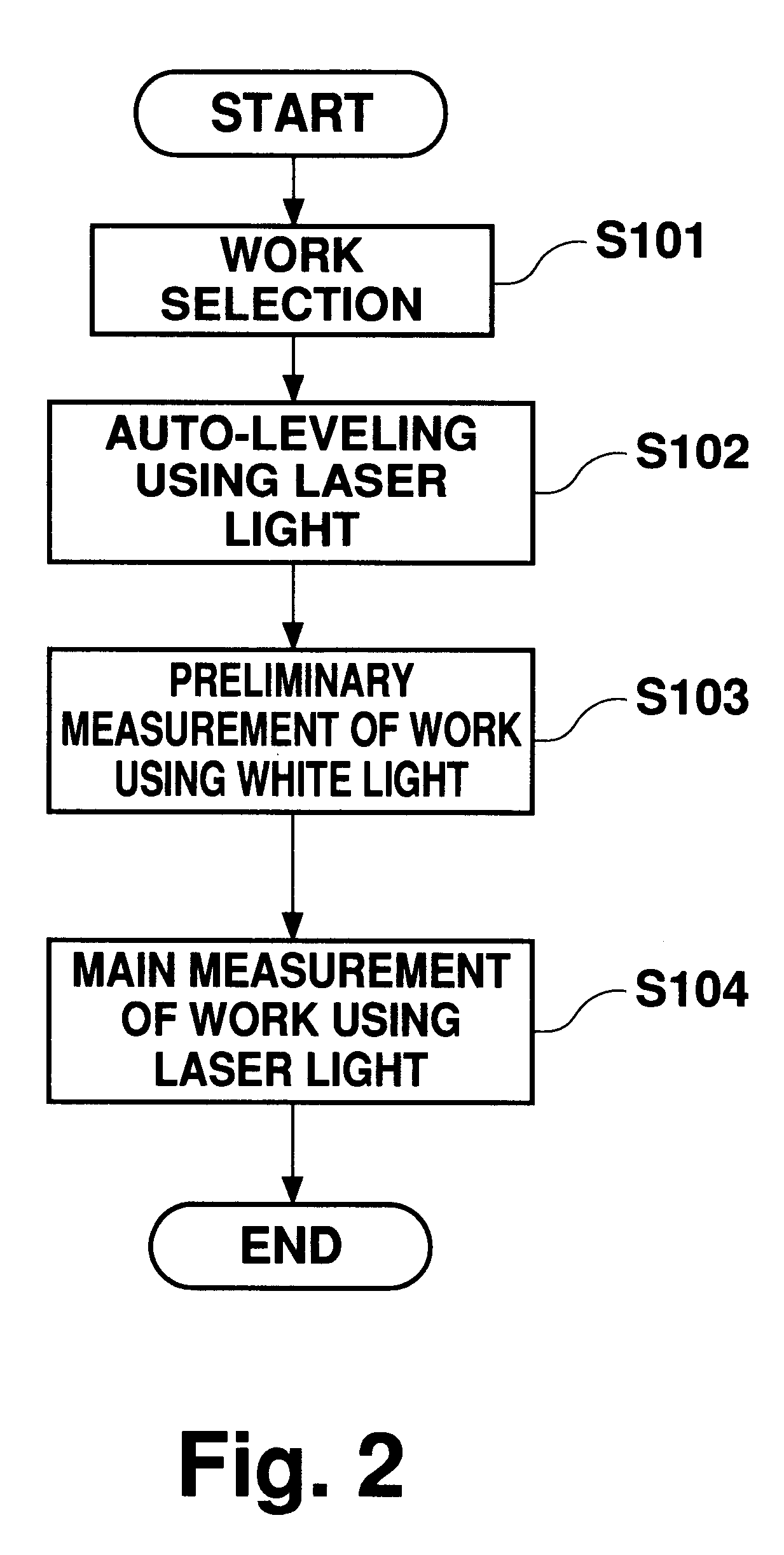

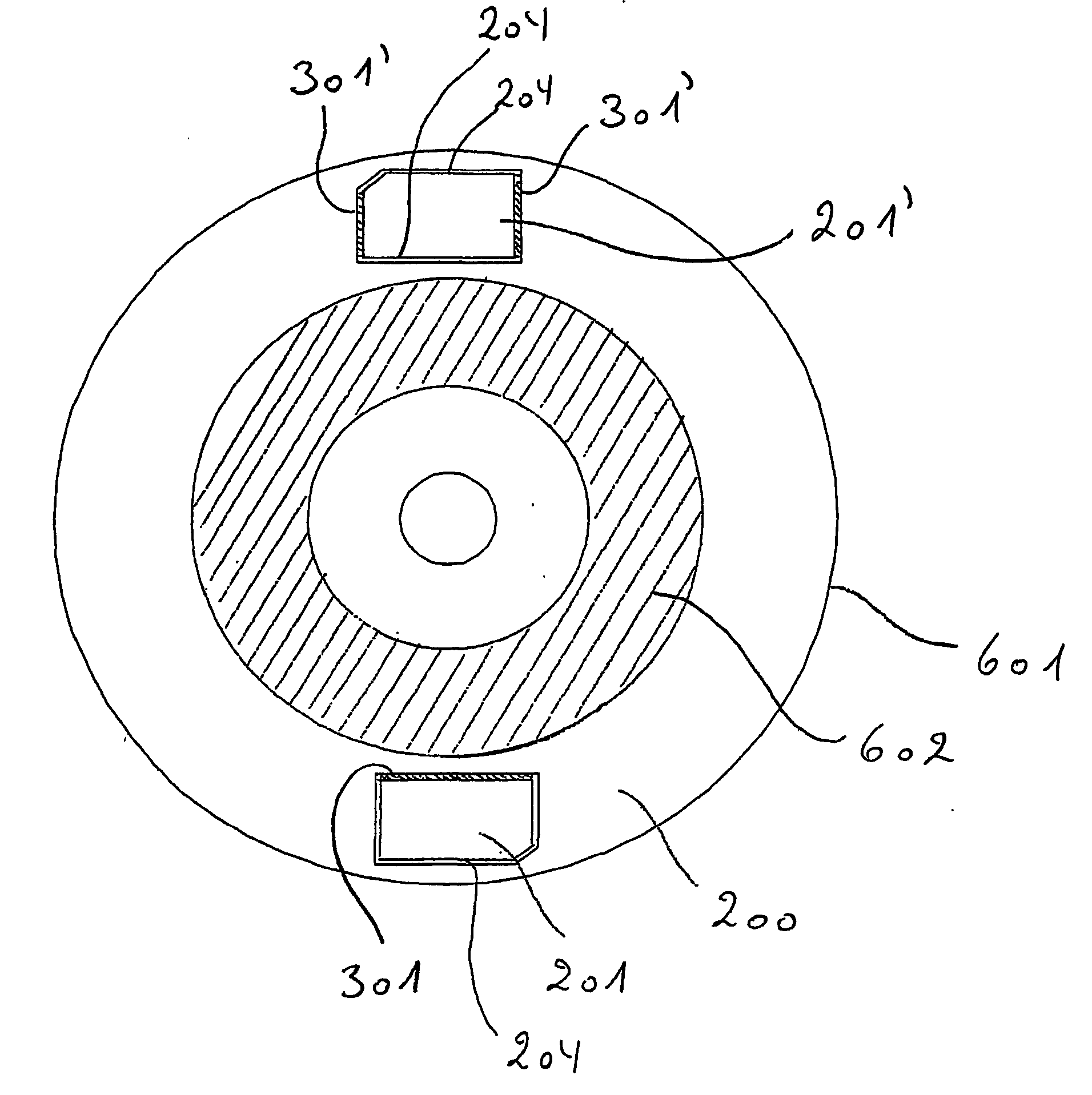

Dimension measurement using both coherent and white light interferometers

InactiveUS6285456B1Quick and highly precise measurementAvoid temperature differenceUsing optical meansLaser lightPhase coherence

An interferometer and method for performing preliminary and main measurements quickly and with high precision are provided. Laser light and white light are successively introduced to the same interferometer booth. Laser light is introduced from a laser light source, and the interference fringe with a reference mirror as a reference is detected using a CCD and a personal computer. By setting the interference fringe to a preset value, the position of a work is adjusted. White light from a halogen lamp is then introduced, a corner cube moving mount is moved, interference fringe with a reference mirror as a reference is detected, and preliminary measurement of the work is performed. Next, laser light is introduced, interference fringe with a reference mirror as a reference is detected, and the main measurement of the work is performed. Because the preliminary and main measurements are performed within the same interferometer booth, the number of steps is reduced and high precision preliminary measurement can be performed.

Owner:MITUTOYO CORP

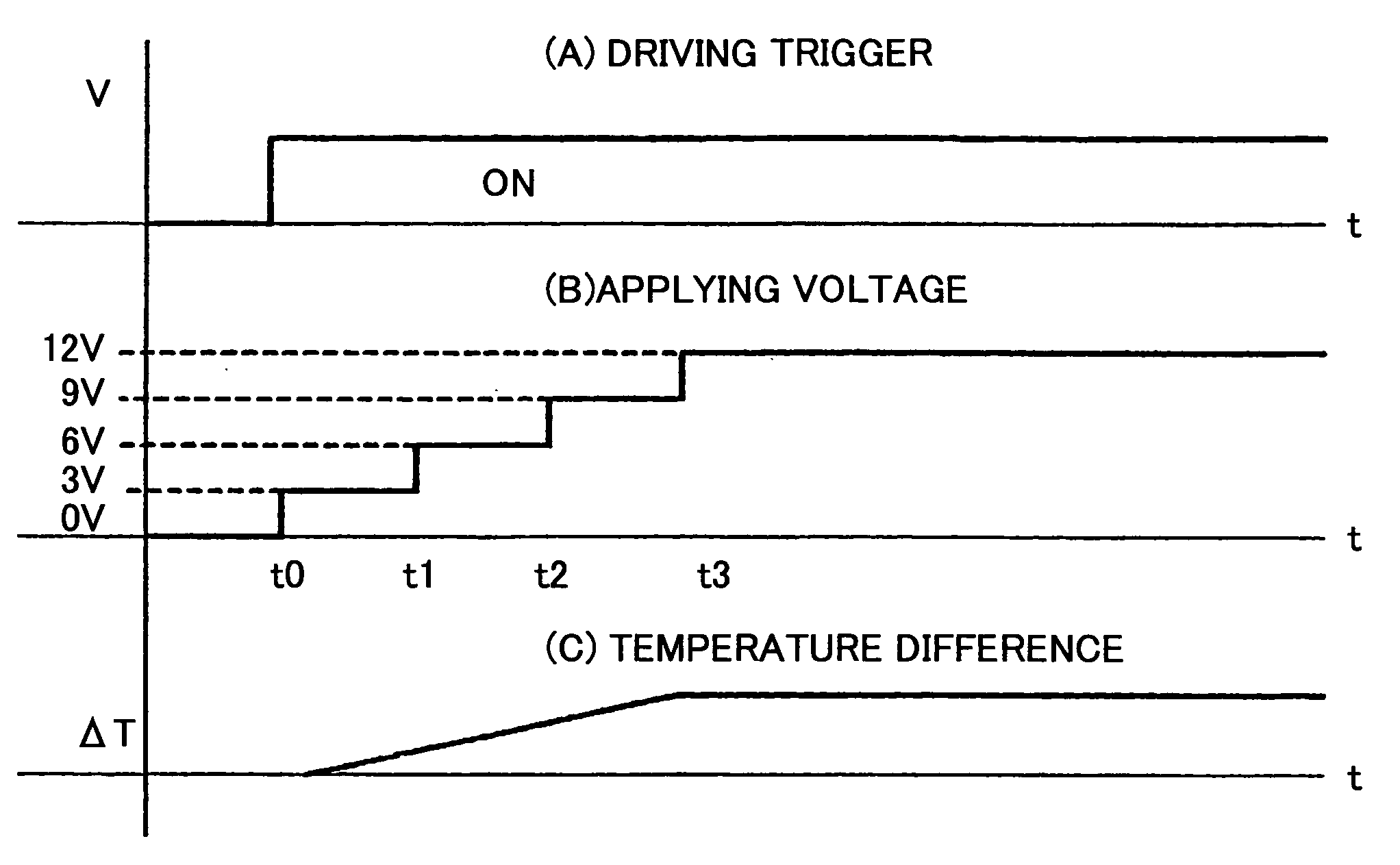

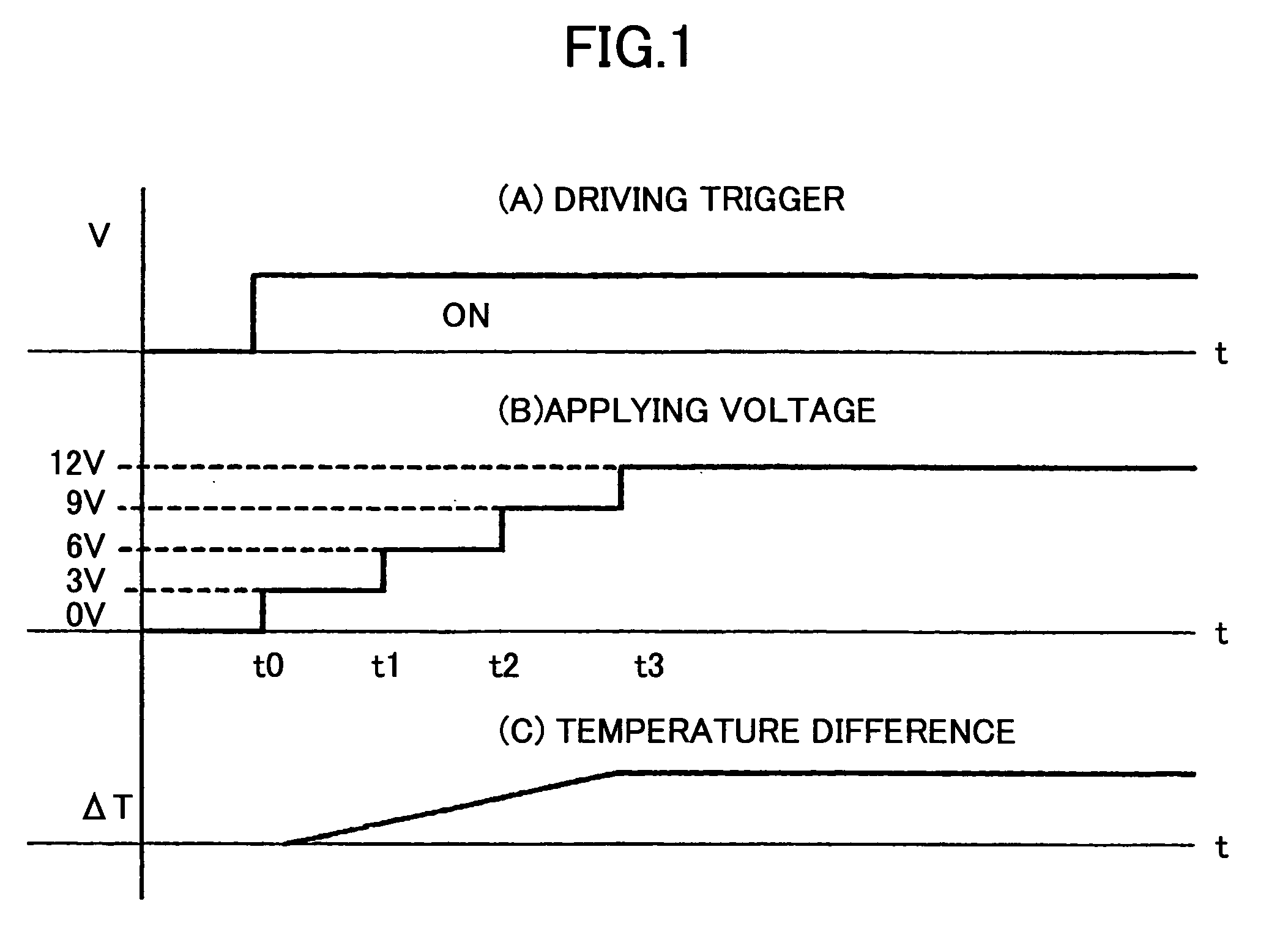

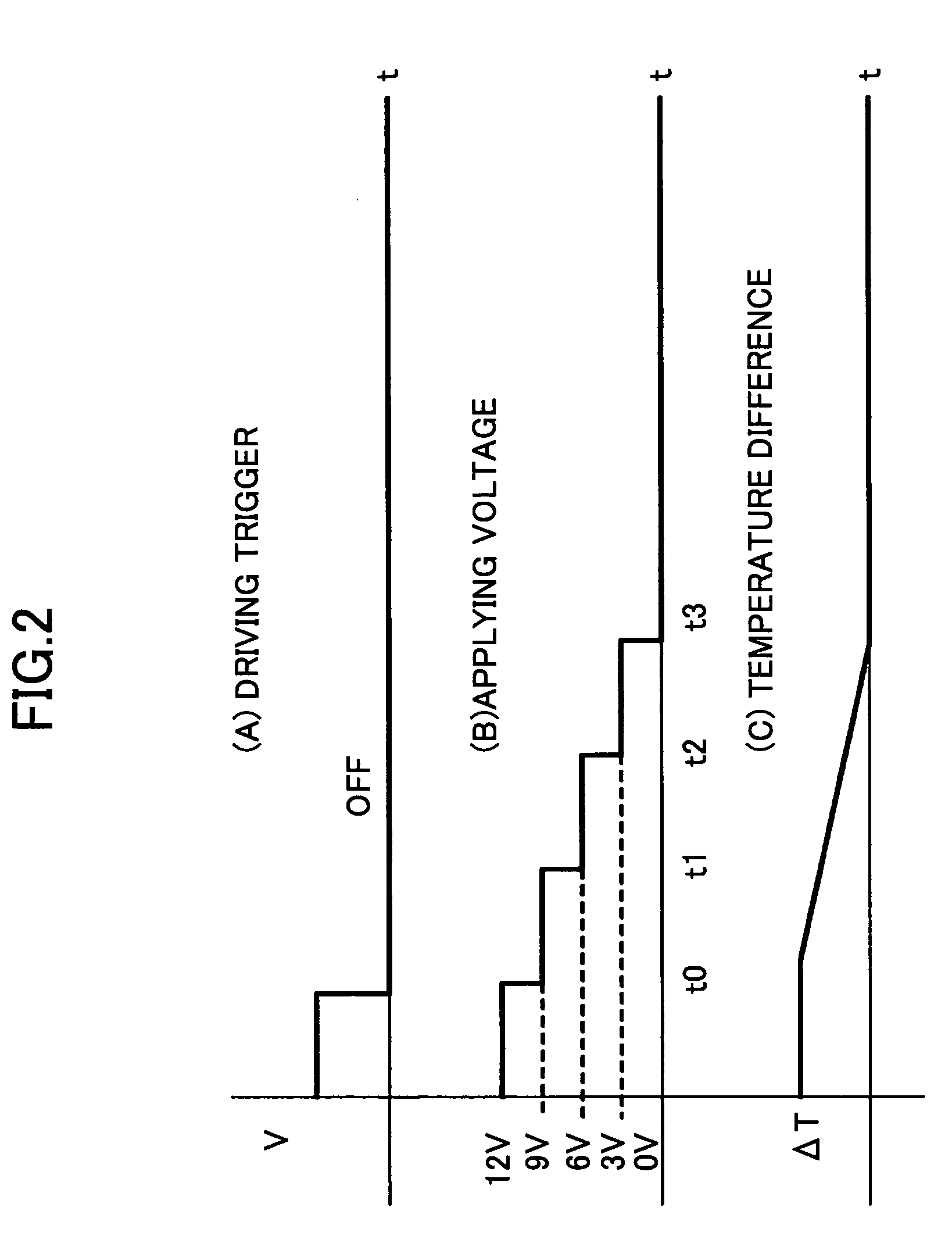

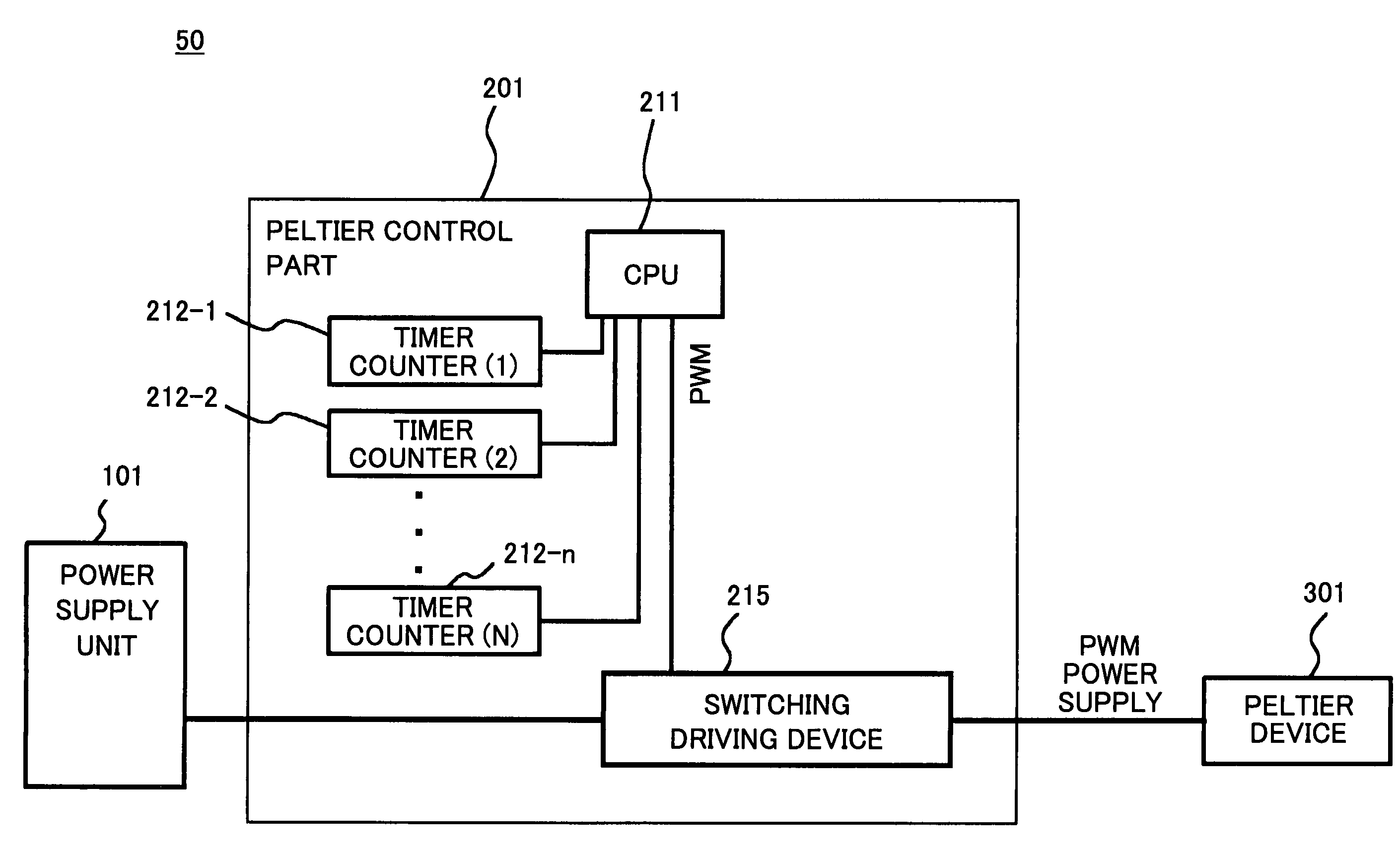

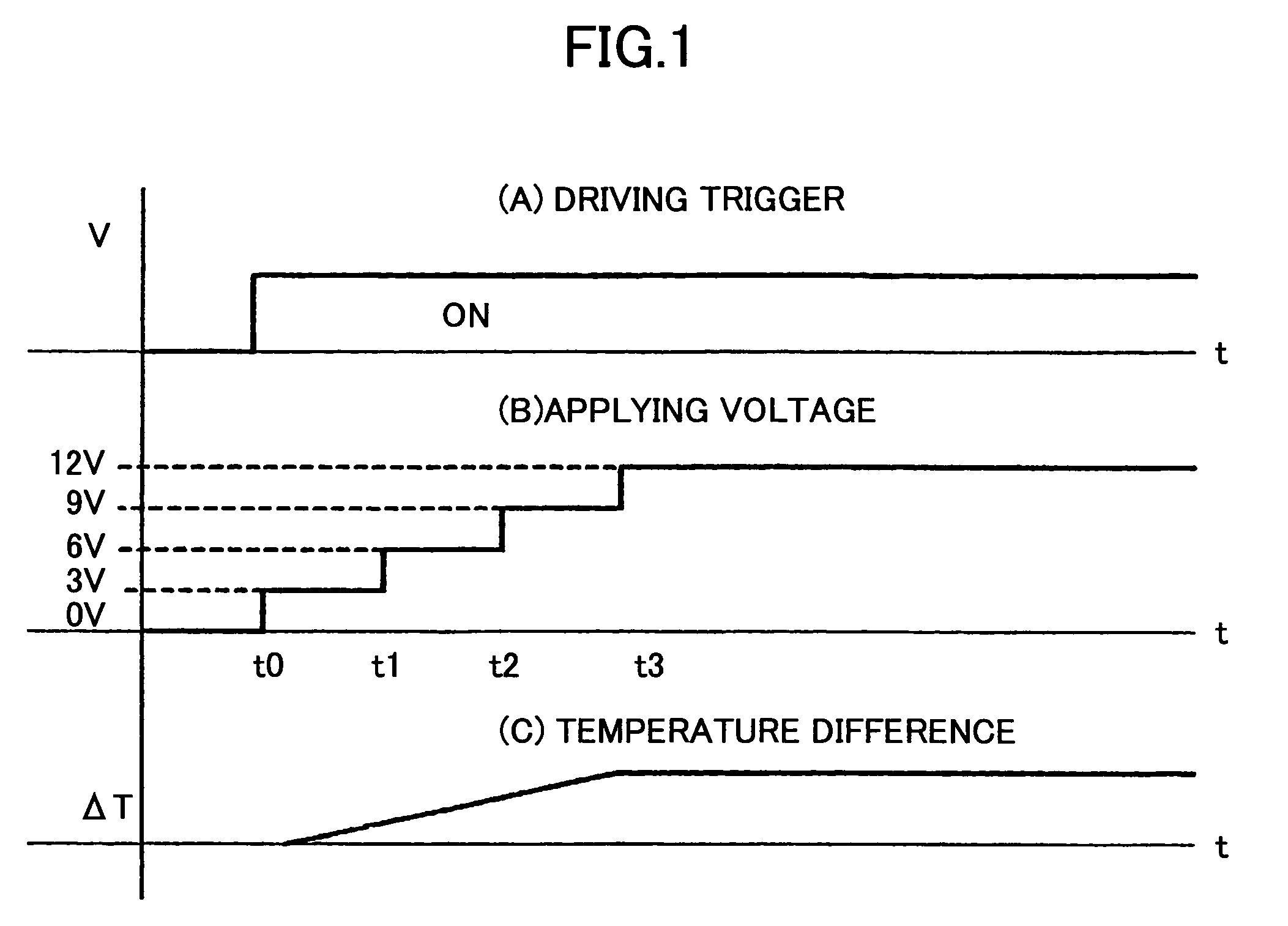

Cooling apparatus, cooling method, program, computer readable information recording medium and electronic apparatus

InactiveUS20050235652A1Amount of change be reduceAvoid degradationCompression machines with non-reversible cycleMachines using electric/magnetic effectsEngineeringCooling methods

A cooling apparatus of supplying driving power to a cooling element from a power supply unit, to drive it, includes a driving power changing part changing a power value of the driving power supplied to said cooling element from the power supply unit, by a predetermined power value at each predetermined time interval.

Owner:RICOH KK

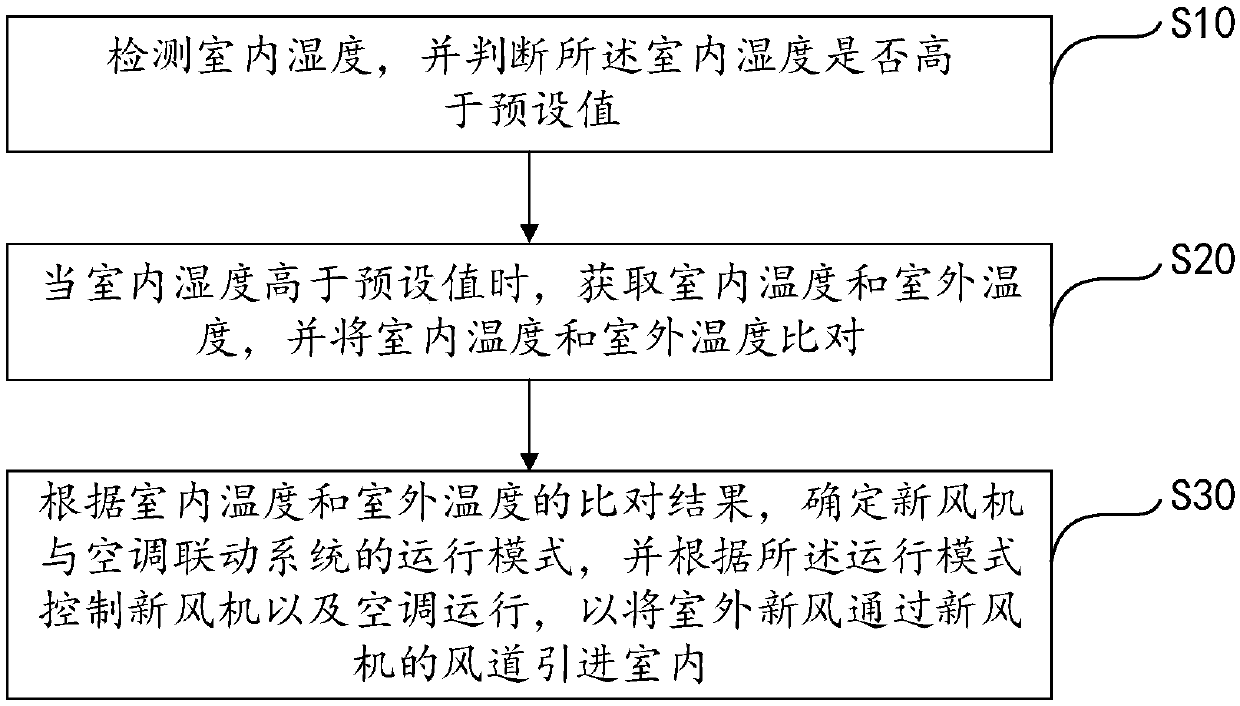

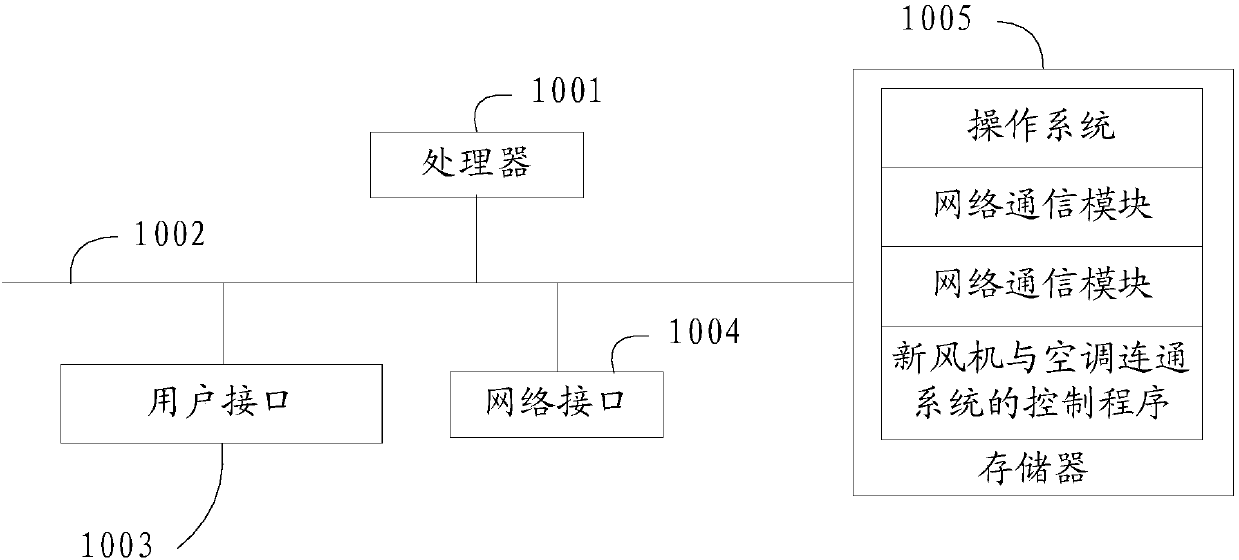

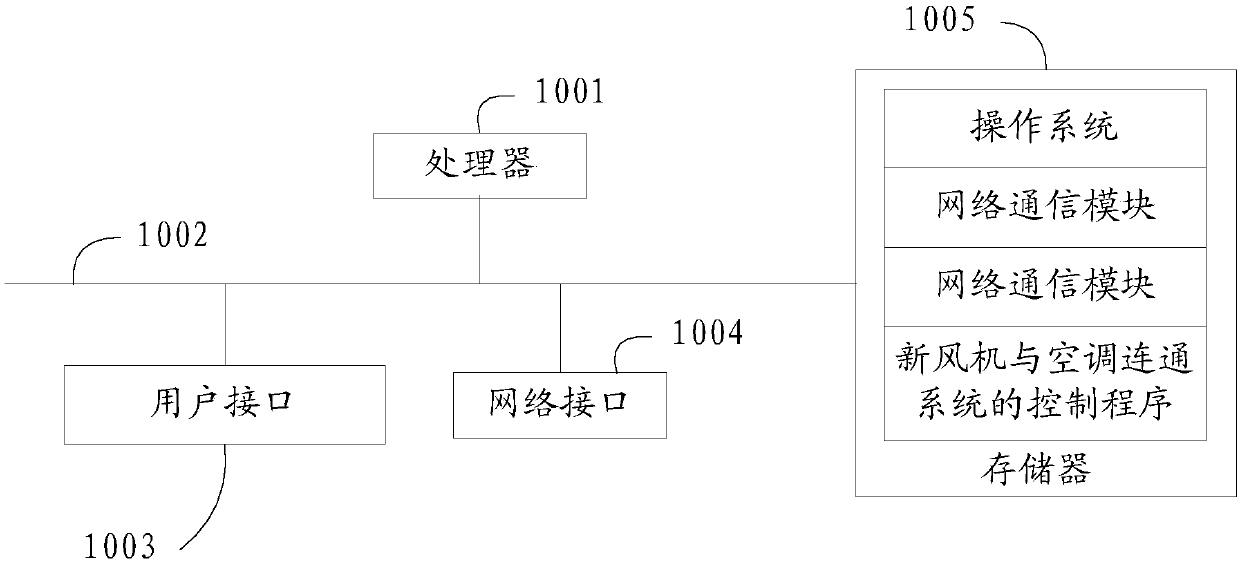

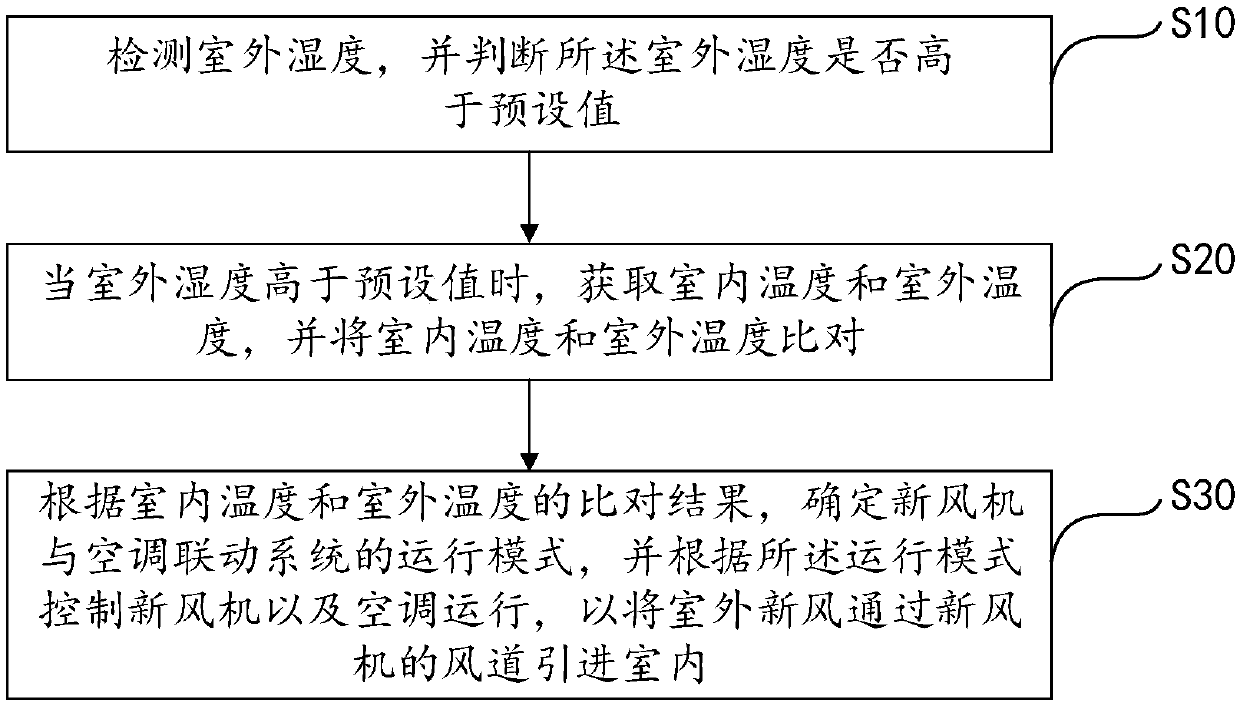

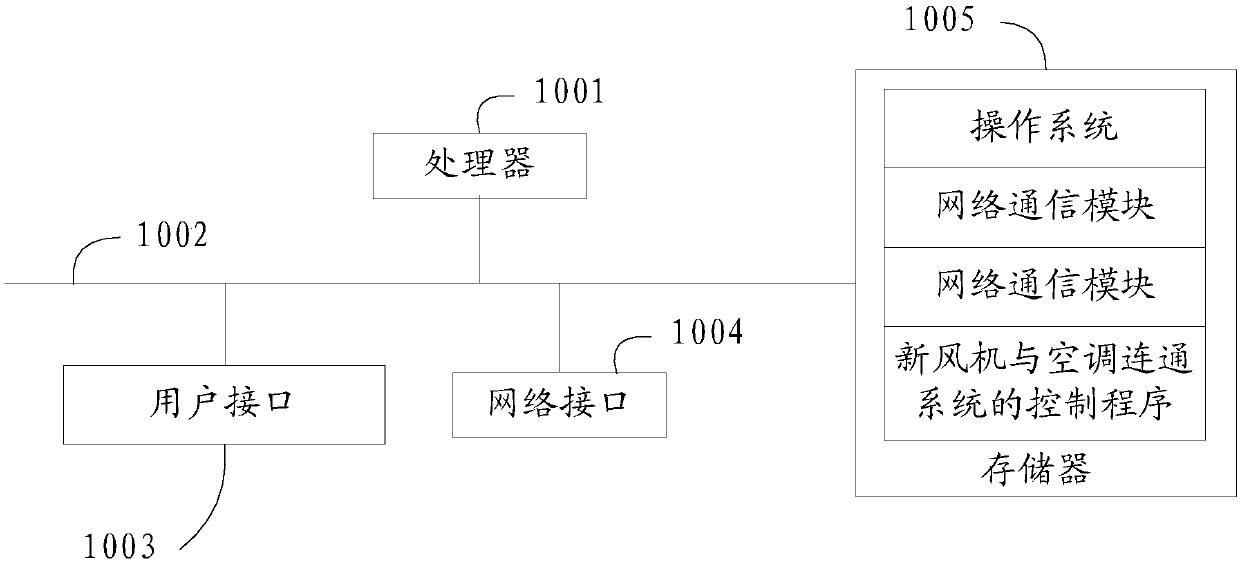

Fresh air ventilator and air conditioner linkage system, and control method, control device and storage medium of fresh air ventilator and air conditioner linkage system

ActiveCN107894073AAvoid temperature differenceImprove freshnessMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature difference

The invention discloses a control method, a control device and a storage medium of a fresh air ventilator and air conditioner linkage system. The control method comprises the following steps: measuring the indoor temperature and judging whether the indoor humidity is higher than a preset value; when the indoor humidity is higher than the preset value, acquiring the indoor temperature and the outdoor temperature, and comparing the indoor temperature with the outdoor temperature; determining the running mode of the fresh air ventilator and air conditioner linkage system according to the comparison result of the indoor temperature and the outdoor temperature, and controlling a fresh air ventilator and an air conditioner to run according to the running mode. According to the control method, the fresh air ventilator and the air conditioner are controlled to run according to the indoor humidity, the indoor temperature and the outdoor temperature. Under a heating mode of the air conditioner,outdoor fresh air is introduced into a room via an air channel of the fresh air ventilator and is exchanged with the indoor air so that the freshness of the indoor air is increased. Meanwhile, the running modes of the fresh air ventilator and the air conditioner are controlled and regulated according to the detected indoor temperature and outdoor temperature so as to prevent relatively large temperature difference between the outdoor fresh air and the indoor air, so a human body can feel more comfortable.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

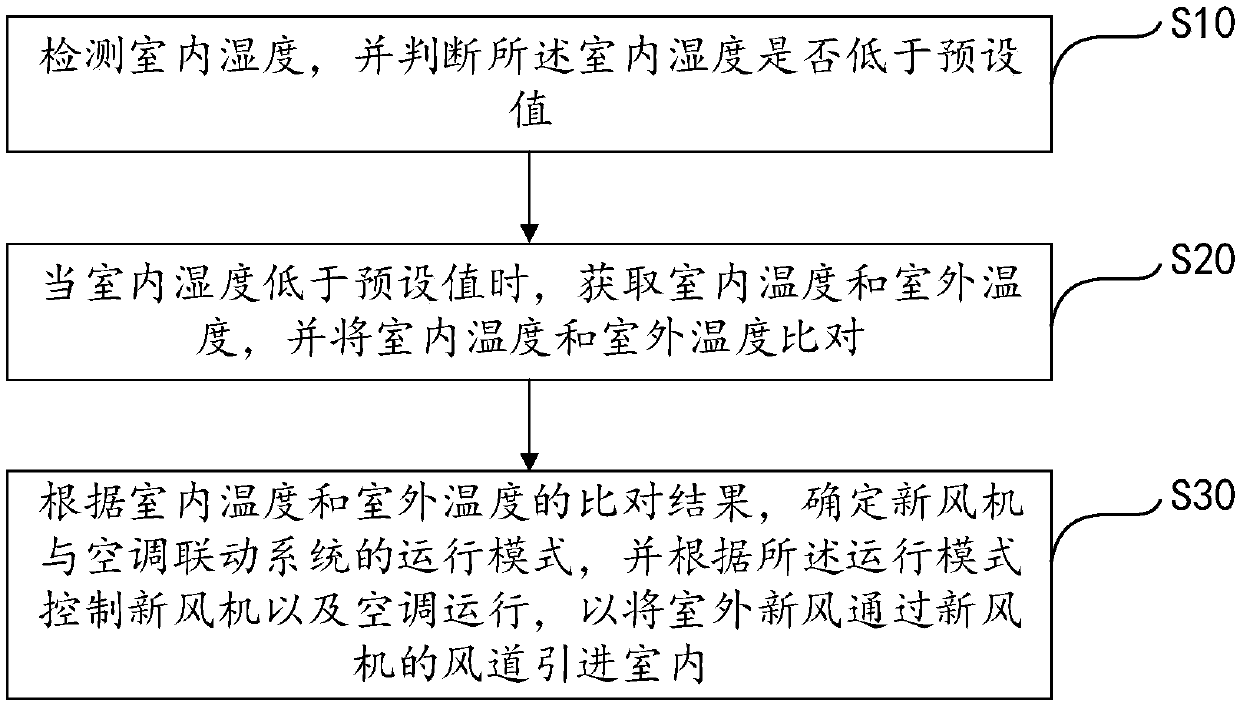

Fresh air ventilator and air conditioner linkage system, control method and device of fresh air ventilator and air conditioner linkage system and storage medium

ActiveCN107631435AImprove freshnessAvoid temperature differenceMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature difference

The invention discloses a control method and device of a fresh air ventilator and air conditioner linkage system and a storage medium. The control method comprises the steps that the indoor humidity is detected, and whether the indoor humidity is lower than the preset value or not is judged; when the indoor humidity is lower than the preset value, the indoor temperature and the outdoor temperatureare obtained and are compared; and according to the comparison result of the indoor temperature and the outdoor temperature, the operating mode of the fresh air ventilator and air conditioner linkagesystem is determined, and operation of a fresh air ventilator and an air conditioner is controlled according to the operating mode. According to the scheme, the operation of the fresh air ventilatorand the air conditioner is controlled according to the indoor humidity, the indoor temperature and the outdoor temperature; in the heating mode of the air conditioner, outdoor fresh air is introducedinto a room through an air duct of the fresh air ventilator and exchanges air with indoor air, and the freshness of the indoor air is increased; and the operating mode of the fresh air ventilator andthe air conditioner is controlled according to the detected indoor temperature and the outdoor temperature, meanwhile the large temperature difference between the introduced outdoor temperature and the indoor air is avoided, and the comfort of the human body is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

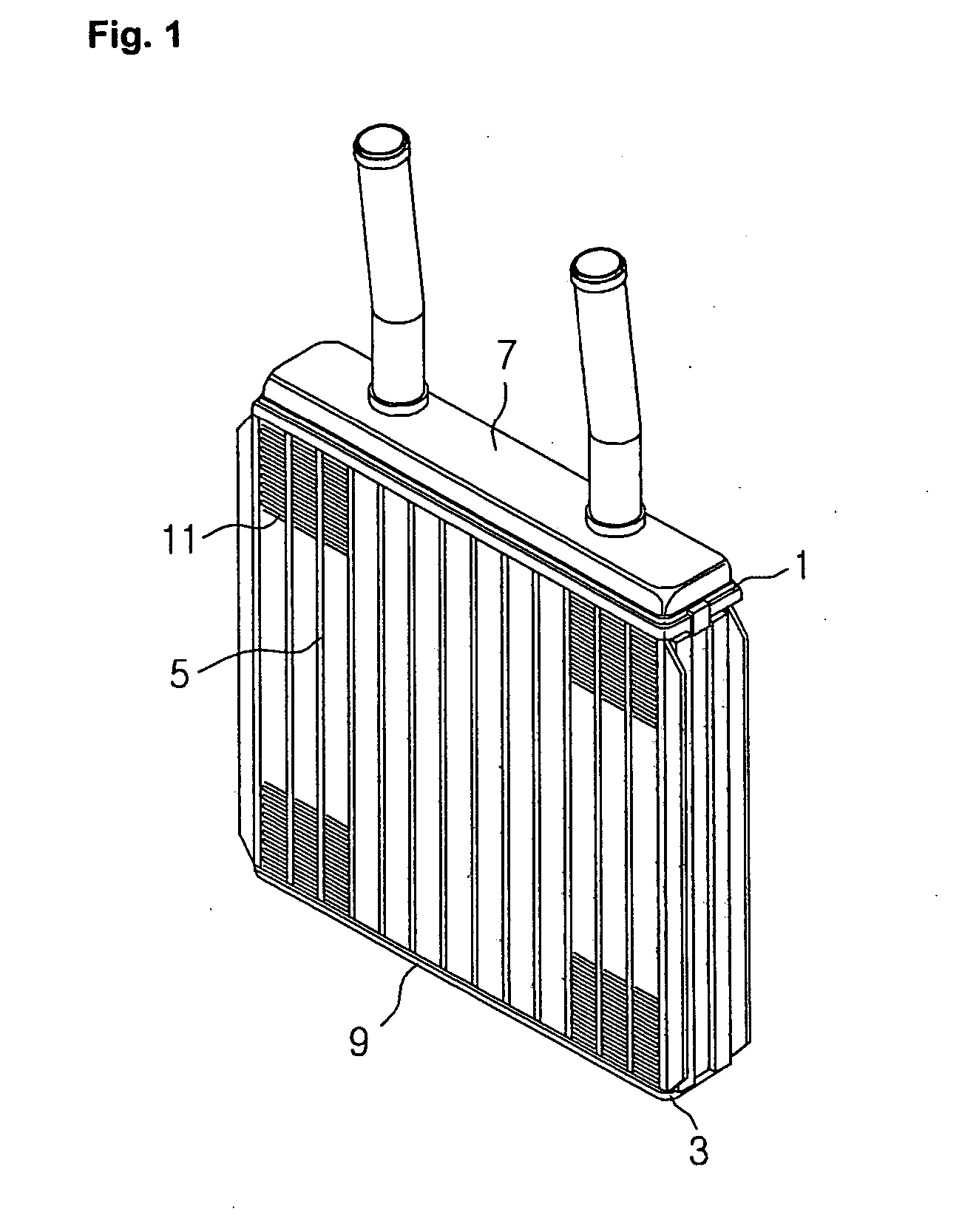

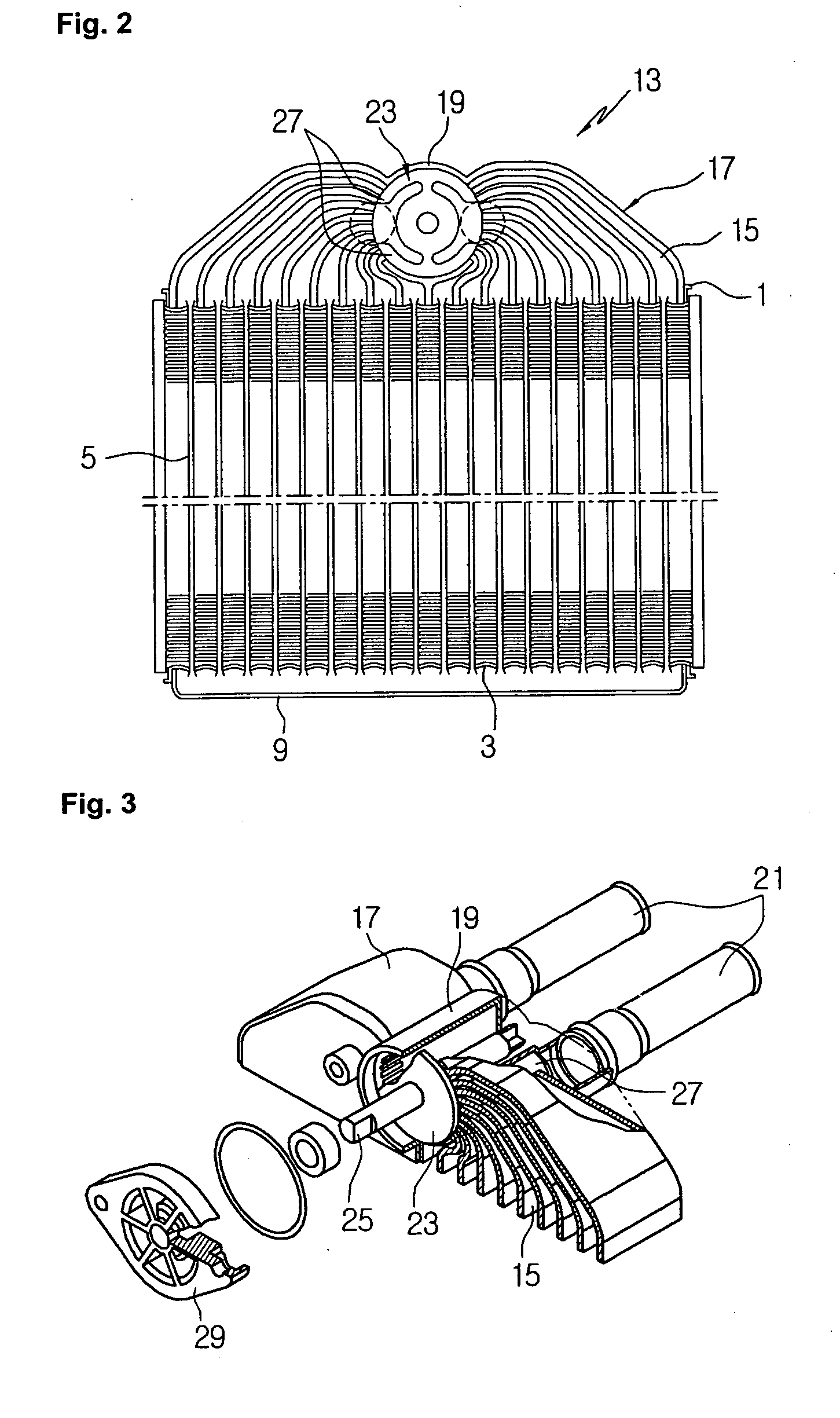

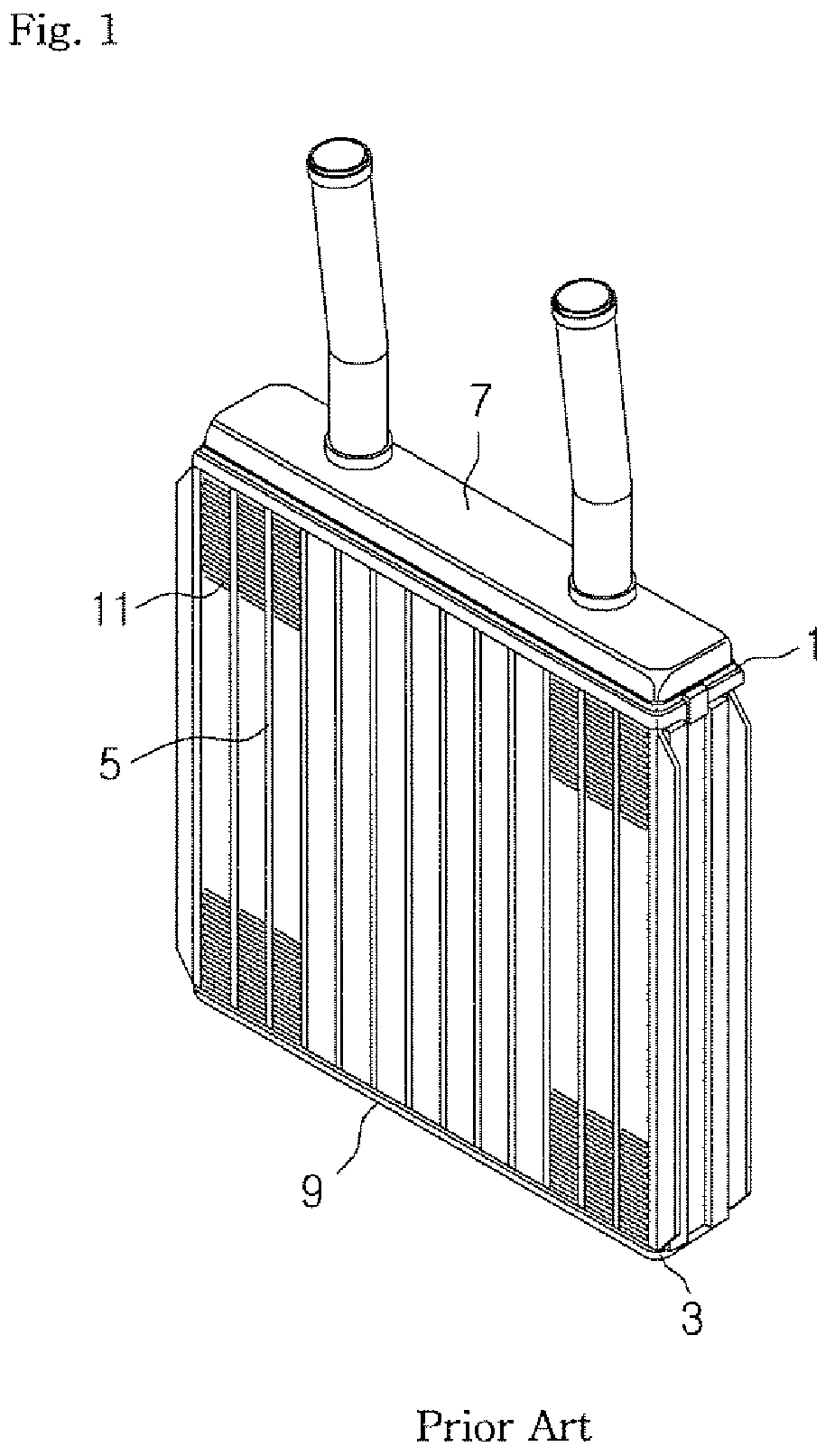

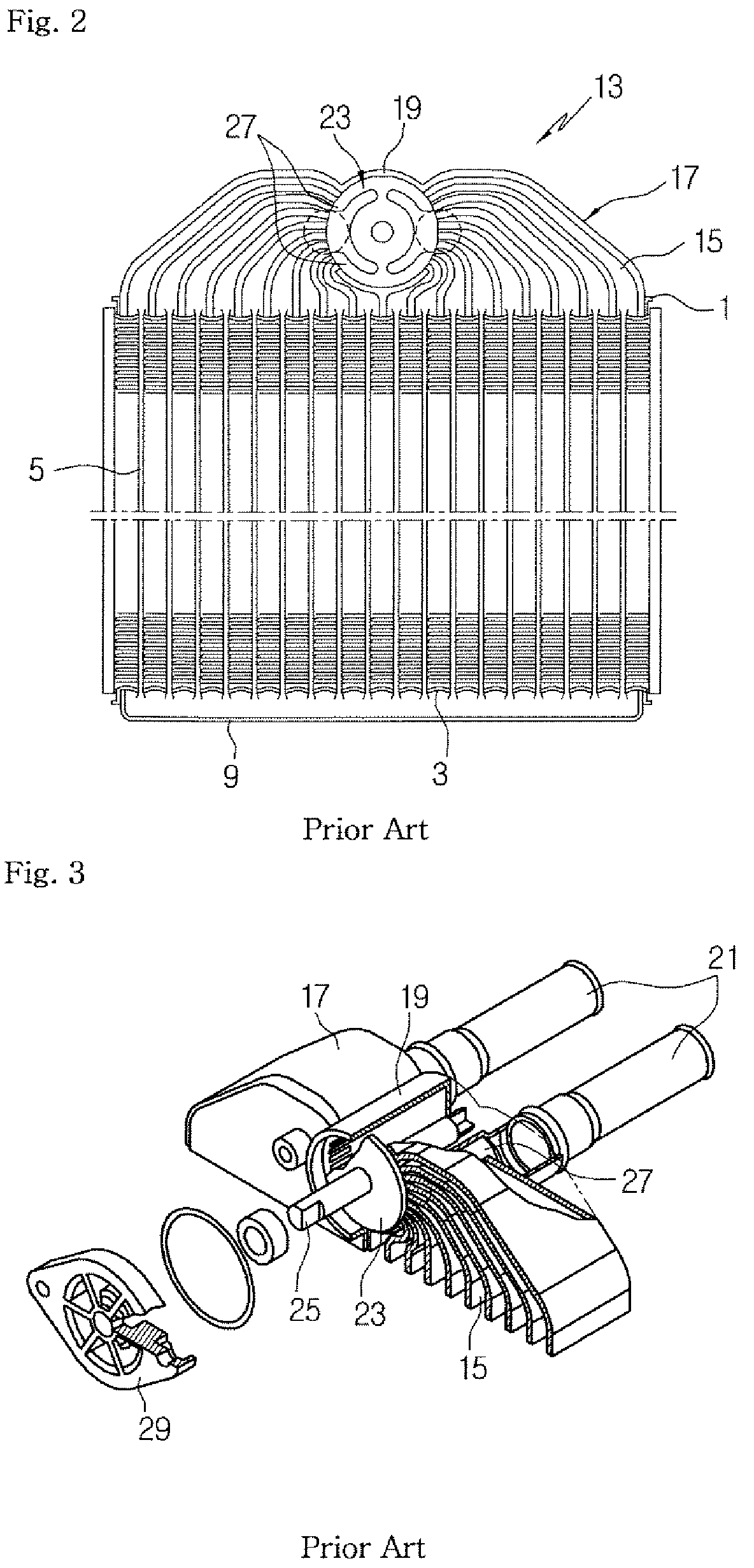

Heat exchanger

InactiveUS20050056402A1Minimizing temperature variationEvenly distributedTemperatue controlStationary conduit assembliesControl signalEngineering

The present invention relates to a heat exchanger which can suitably regulate the quantity, the feeding position or the feeding order of heat exchange medium fed into tubes to adjust heat exchange performance according to cooling and heating load. The heat exchanger comprises a plurality of tubes placed at least one header, each tube having both ends fixed to the header, medium-distributing means installed at the header for feeding heat exchange medium to the specific tubes, a tank placed over the medium-distributing means, the tank having a medium-inlet pipe, a medium-outlet pipe and distribution passages for feeding heat exchange medium to specific regions of the medium-distributing means, and medium-regulating means installed at the tank and operated in response to a control signal for adjusting the feed of the heat exchange medium.

Owner:HANON SYST

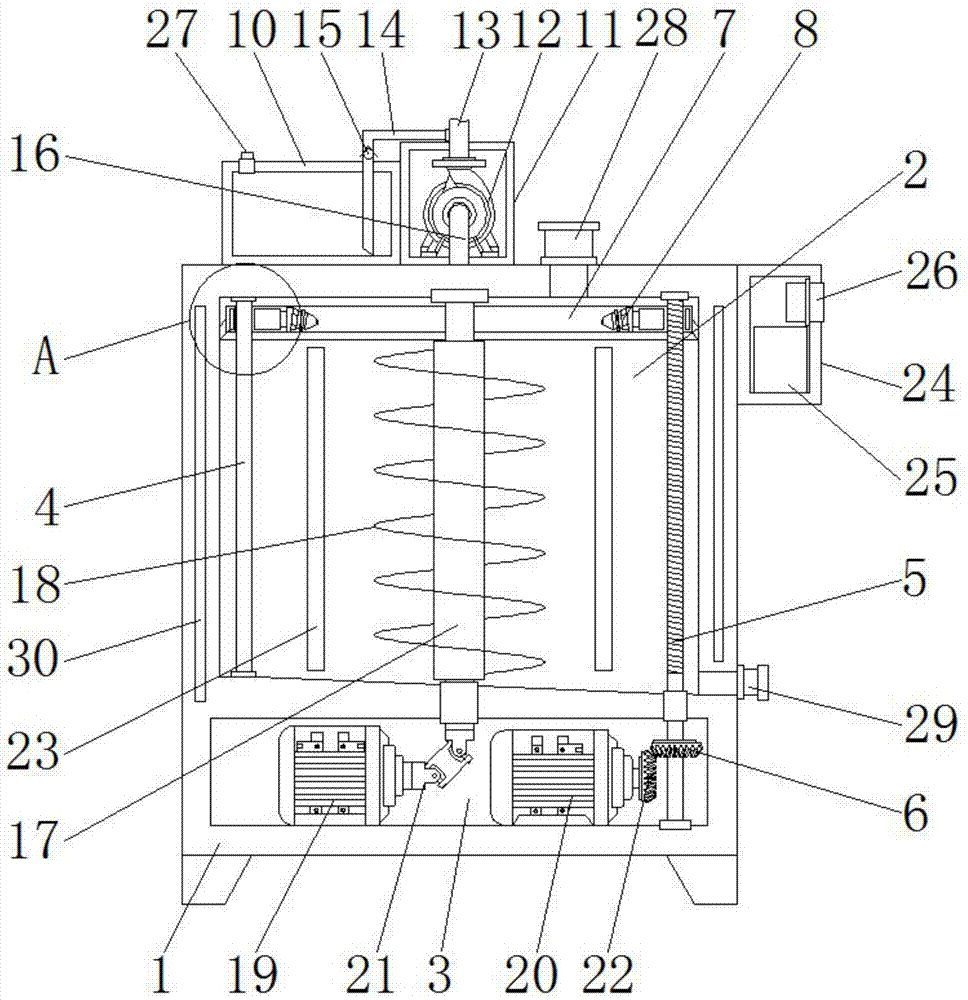

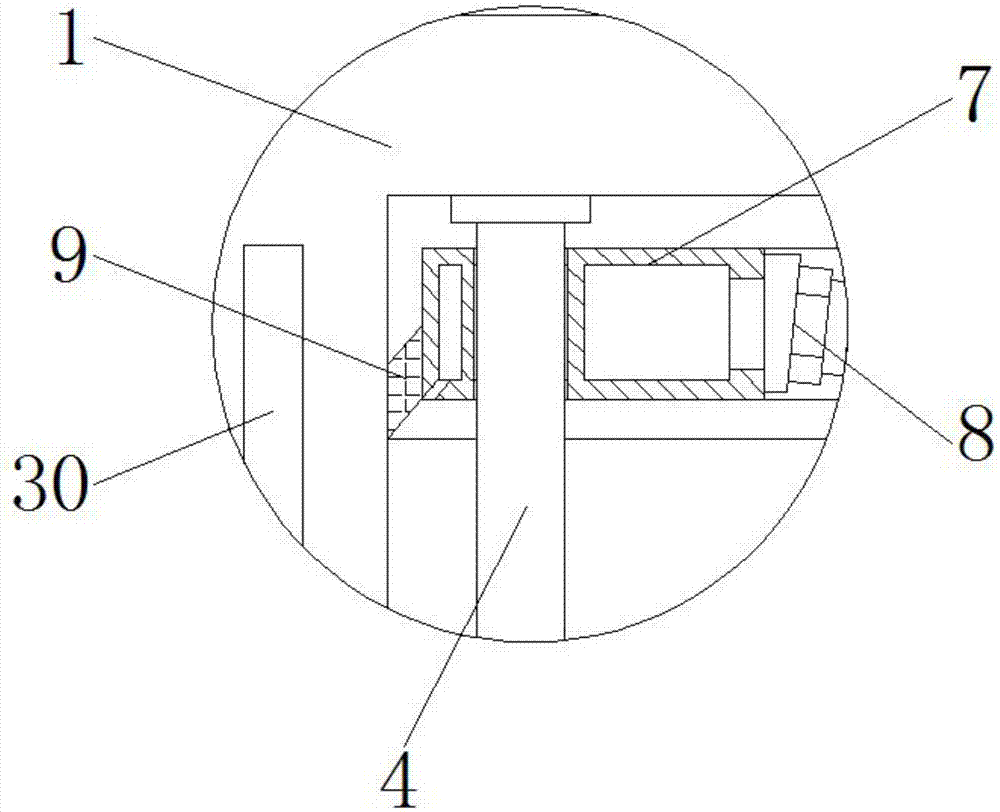

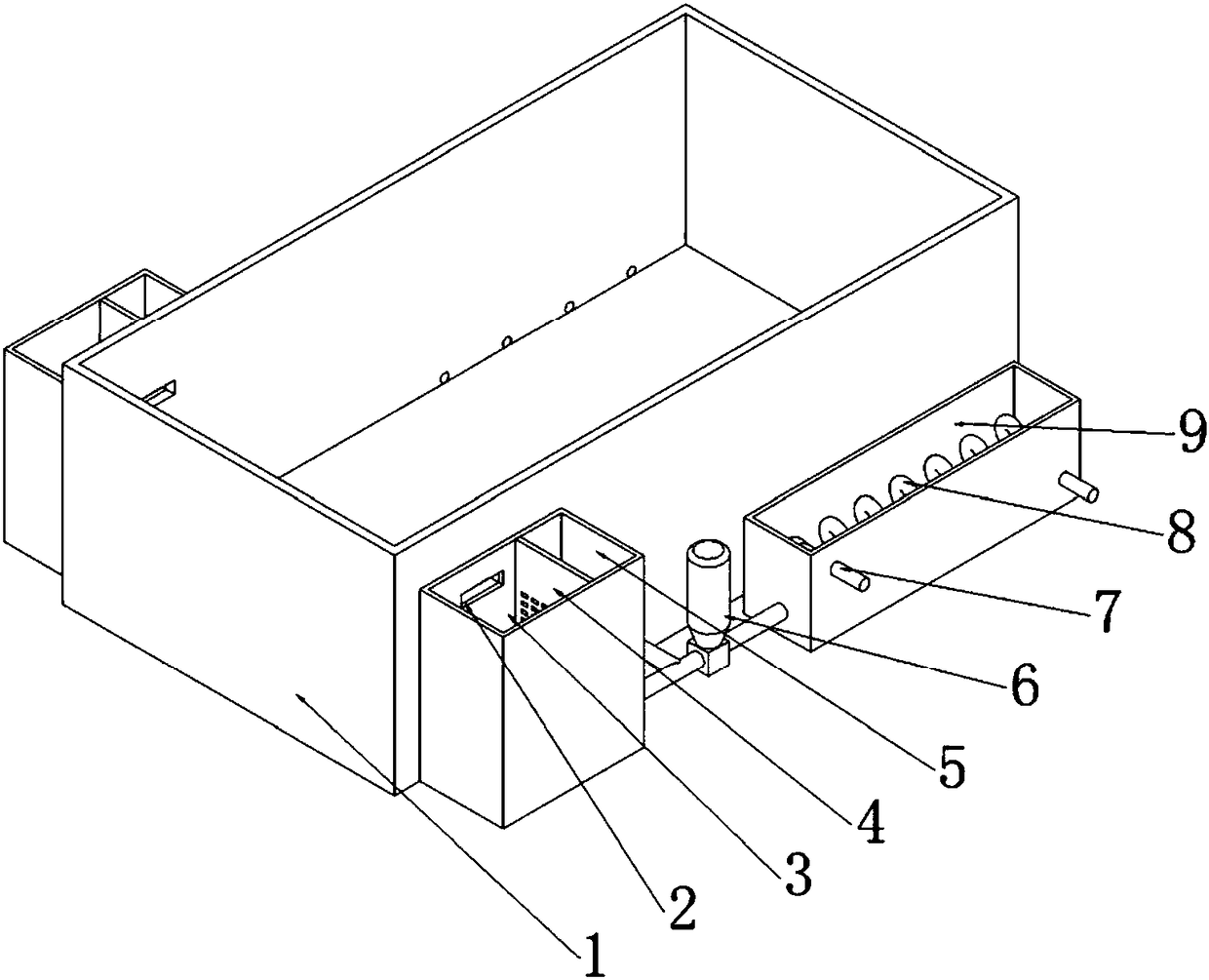

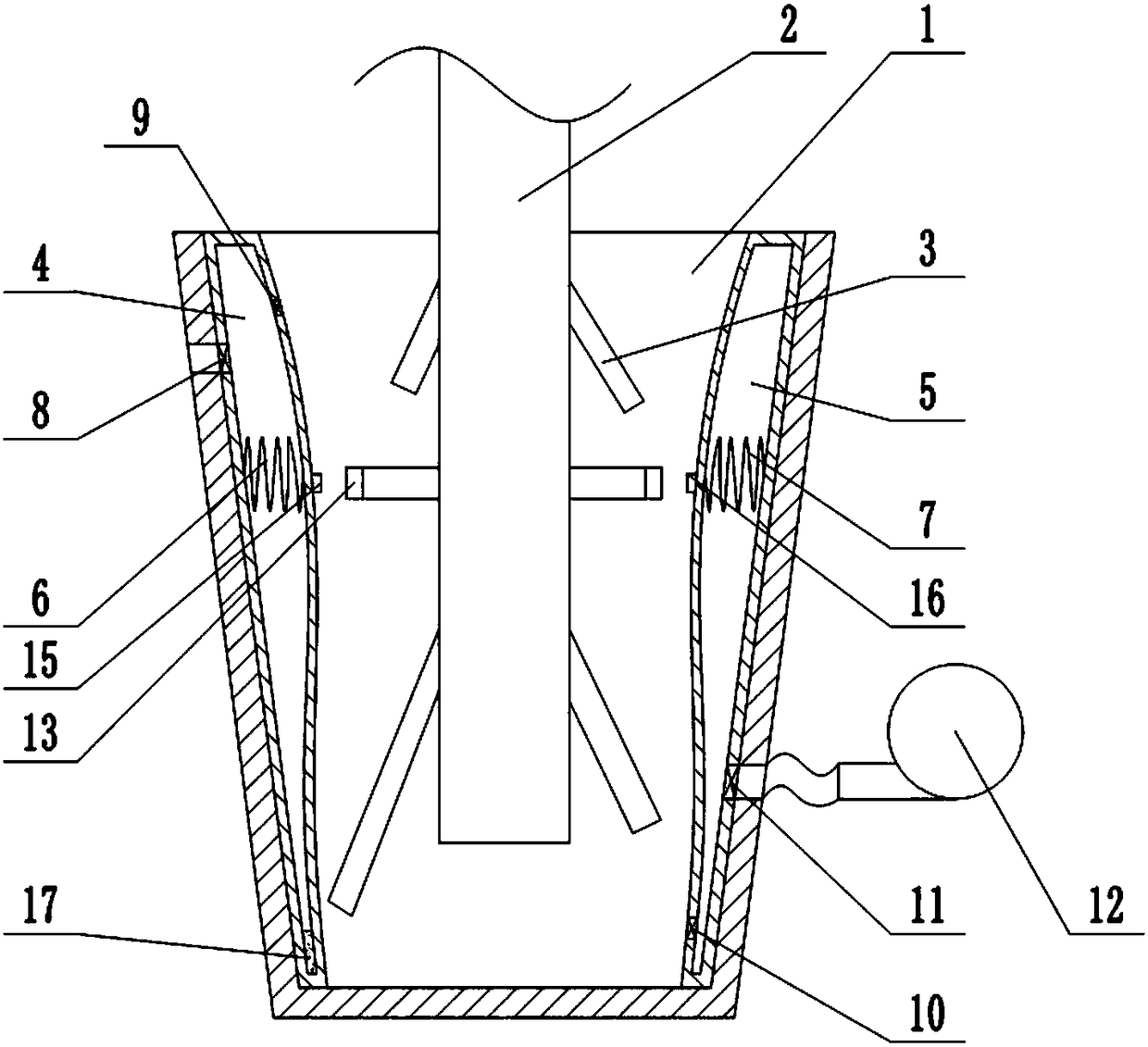

Lubricating oil heating and stirring device capable of being automatically cleaned on basis of large equipment

InactiveCN107998945AAvoid affecting productionEasy to operateTransportation and packagingRotary stirring mixersSprayerPulp and paper industry

The invention discloses a lubricating oil heating and stirring device capable of being automatically cleaned on the basis of large equipment, and relates to the technical field of automobile accessoryproduction. The device comprises a box, and a stirring bin and a machine bin are sequentially arranged in the box from top to bottom; a guide column is fixedly arranged on the left side of the stirring bin, and a screw rod is rotationally connected to the top of the right side of the stirring bin; the bottom of the screw rod penetrates through the bottom of the stirring bin and extends into the machine bin, and the bottom of the screw rod is rotationally connected with the bottom of the machine bin; a first bevel gear is fixedly arranged on the surface of the screw rod and located in the machine bin. According to the lubricating oil heating and stirring device capable of being automatically cleaned on the basis of the large equipment, a high-pressure pipe can be moved up and down throughthe screw rod, a high-pressure sprayer can spray out chemicals at a high speed, and the inner wall of the stirring bin and spiral stirring blades can be flushed; oil stains on the inner wall can be scraped by a scraping plate, the inner wall can be kept clean, and the situation that residual lubricating oil in the box is not cleaned up for a long time and goes bad and accordingly product next timeis affected is avoided; the device is easy to operate and saves time and labor..

Owner:张文凯

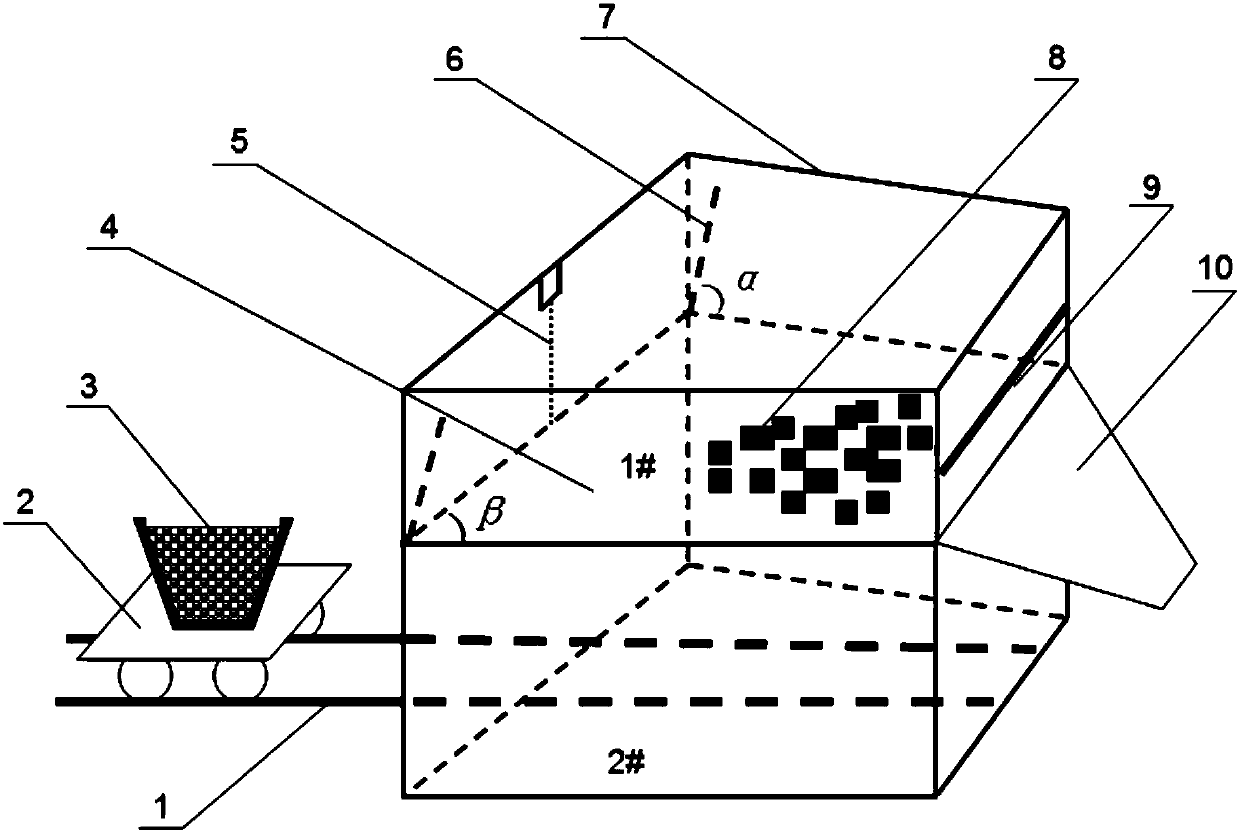

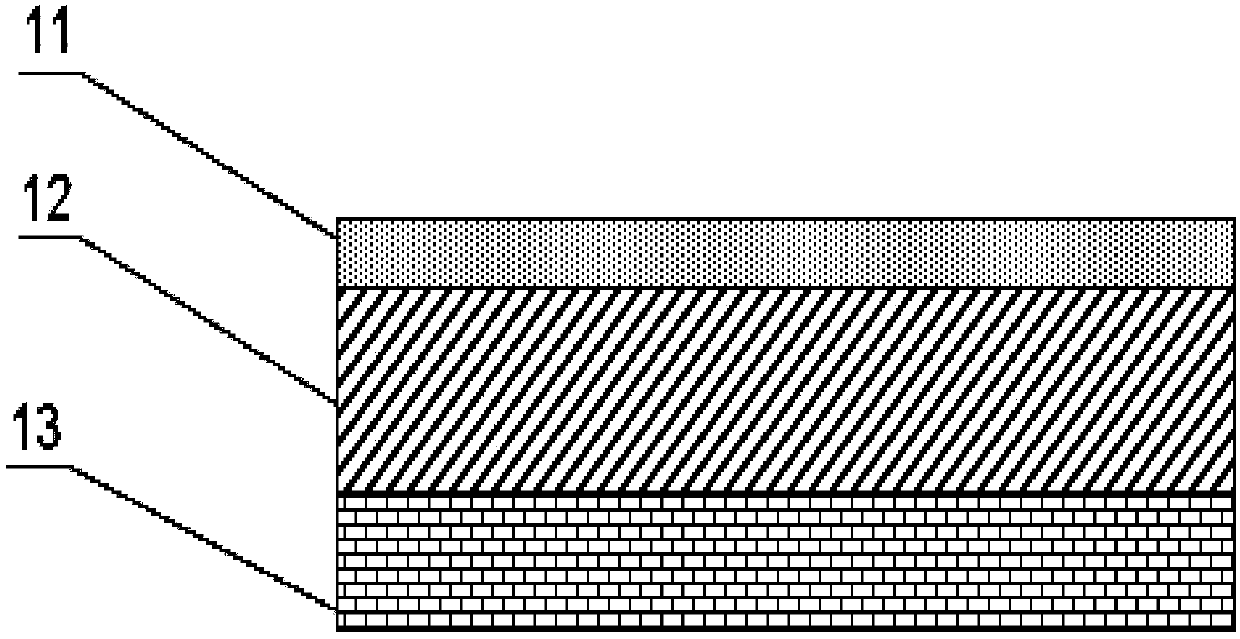

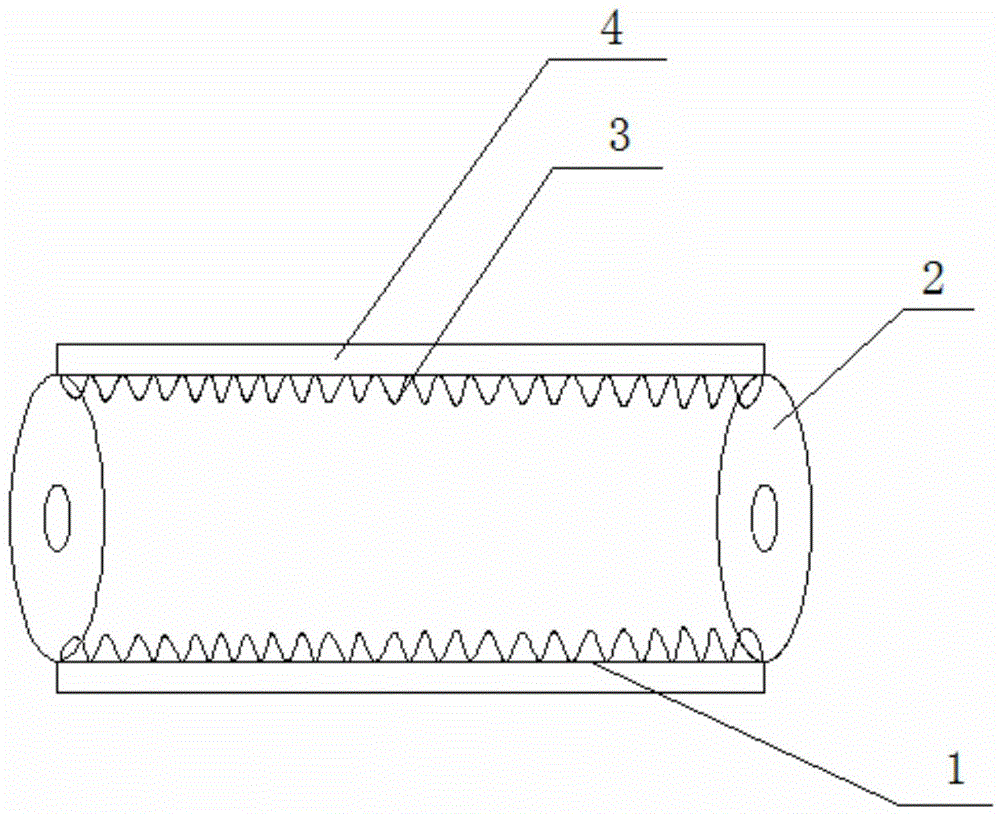

Device for preheating waste steel and alloys by using converter steel slag afterheat and application method

ActiveCN107779543ATo achieve the effect of recyclingIncreased hydrogen and nitrogen contentCharge treatment typeIncreasing energy efficiencySlagAlloy

The invention discloses a device for preheating waste steel and alloys by using converter steel slag afterheat and an application method. The device mainly consists of a waste steel and alloy adding chamber 1# chamber and a high-temperature furnace slag storage chamber 2# chamber. An insulation cover plate covers the top of the 1# chamber; the lower part of the 1# chamber is a baking chamber baseplate with a double-layer structure; a baseplate overturning driving hydraulic lifting chain is arranged above the top edge of the baseplate; overturning guide rails forming included angles alpha withthe baseplate are arranged on two side walls; and a discharge door is arranged on the back side wall. A slag tank car rail is arranged in the 2# chamber; and the top is the baseplate of the 1# chamber. In the use process, the cover plate at the top of the 1# chamber is opened to put the waste steel or the alloys on the baseplate; the insulation cover plate is covered; and then, a high-temperatureslag tank is conveyed to the 2# chamber through a slag tank car to finish baking heating of the waste steel or the alloys. Through use of the device, the converter high-temperature furnace slag afterheat can be recycled, and meanwhile, the effects of increasing the converter waste steel ratio, reducing the cost and improving the efficiency are achieved.

Owner:ANGANG STEEL CO LTD

Heat exchanger

InactiveUS7461687B2Minimizing temperature variationUniformlyTemperatue controlStationary conduit assembliesPlate heat exchangerControl signal

The present invention relates to a heat exchanger which can suitably regulate the quantity, the feeding position or the feeding order of heat exchange medium fed into tubes to adjust heat exchange performance according to cooling and heating load. The heat exchanger comprises a plurality of tubes placed at least one header, each tube having both ends fixed to the header, medium-distributing means installed at the header for feeding heat exchange medium to the specific tubes, a tank placed over the medium-distributing means, the tank having a medium-inlet pipe, a medium-outlet pipe and distribution passages for feeding heat exchange medium to specific regions of the medium-distributing means, and medium-regulating means installed at the tank and operated in response to a control signal for adjusting the feed of the heat exchange medium.

Owner:HANON SYST

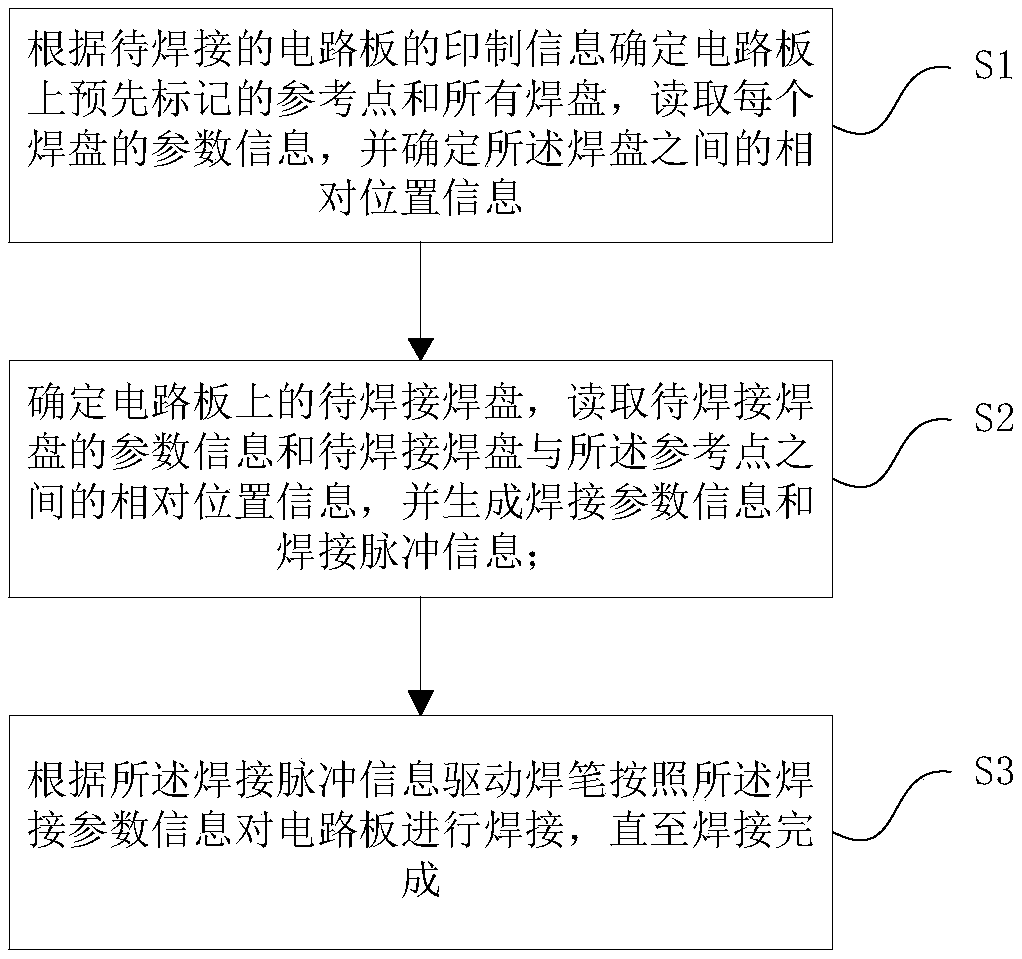

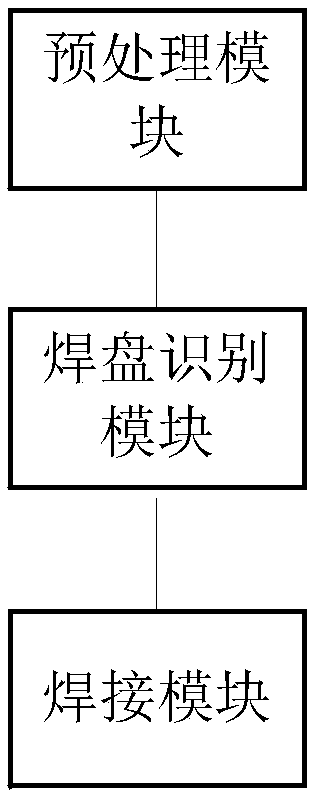

Intelligent welding method, system and device and storage medium

ActiveCN109396584AAccurate identificationRealize relative positional relationship recognitionProgramme-controlled manipulatorMetal working apparatusEngineeringWorkload

The invention relates to an intelligent welding method, system and device and a storage medium. The method comprises the steps of determining pre-marked reference points and all welding discs on a circuit board according to printing information of the circuit board to be welded, reading parameter information of each welding disc and determining relative position information between the welding discs; determining the welding discs to be welded on the circuit board, reading parameter information of the welding discs to be welded and the information about the relative positions between the welding discs to be welded and the reference points, generating welding parameter information and welding pulse information, and according to the welding parameter information and the welding pulse information, welding the circuit board; the parameter information of the welding discs to be welded on the circuit board and the information about the relative positions between the welding discs to be weldedand the reference points are obtained, the welding parameter information and the welding pulse information are generated, the circuit board is precisely welded, different soldering tin amounts are applied according to different welding discs, the manual debugging workloads at the early period are greatly reduced, work efficiency and product quality are improved, and the automation degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

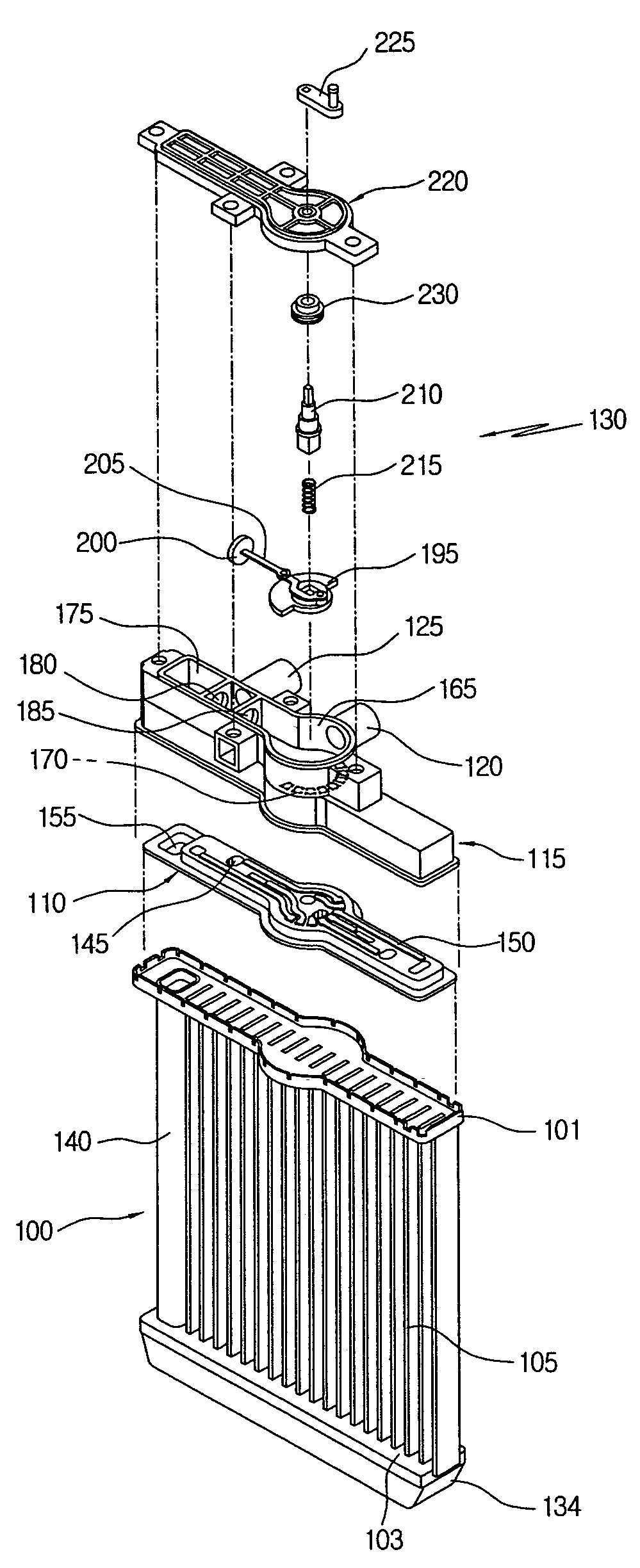

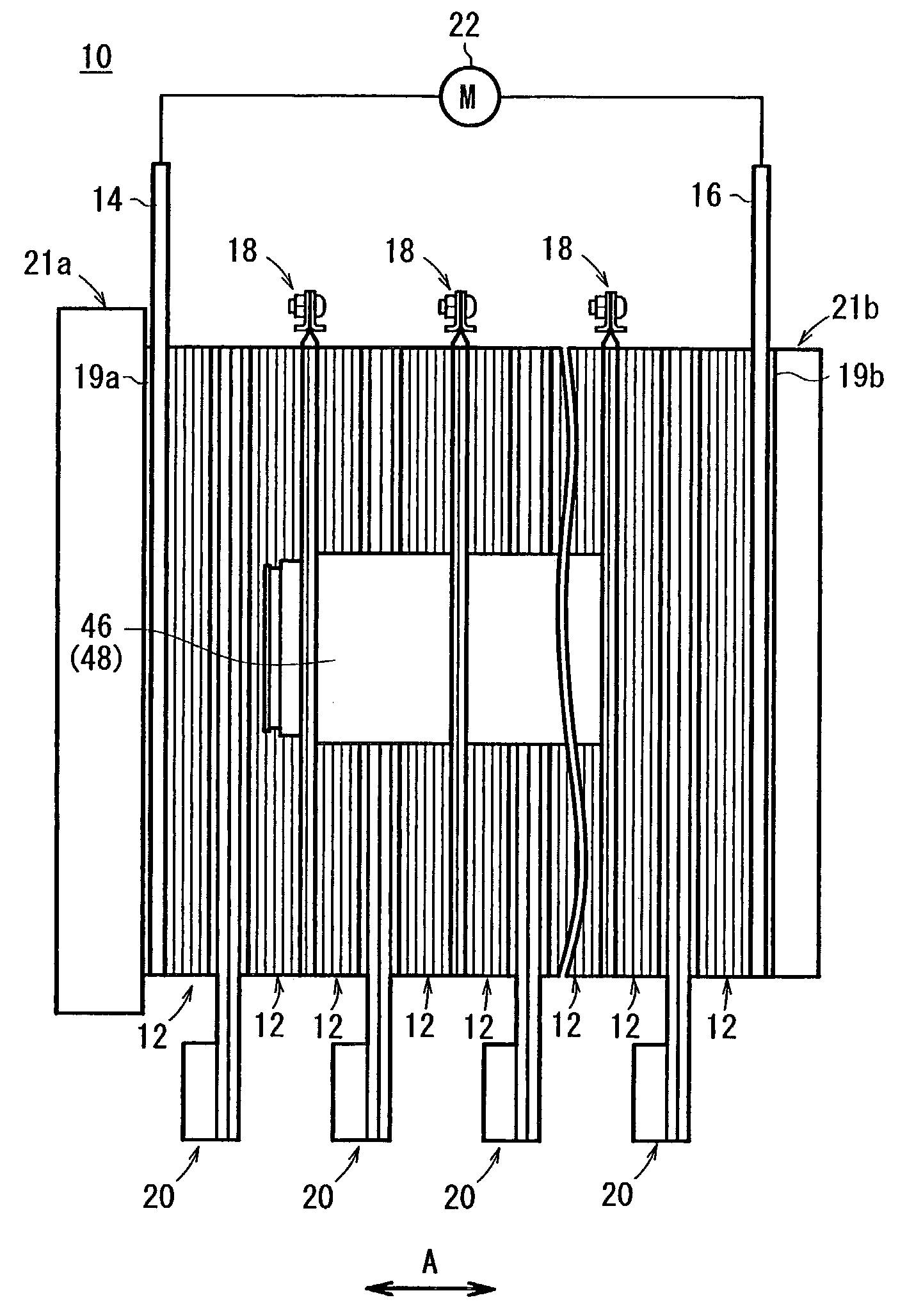

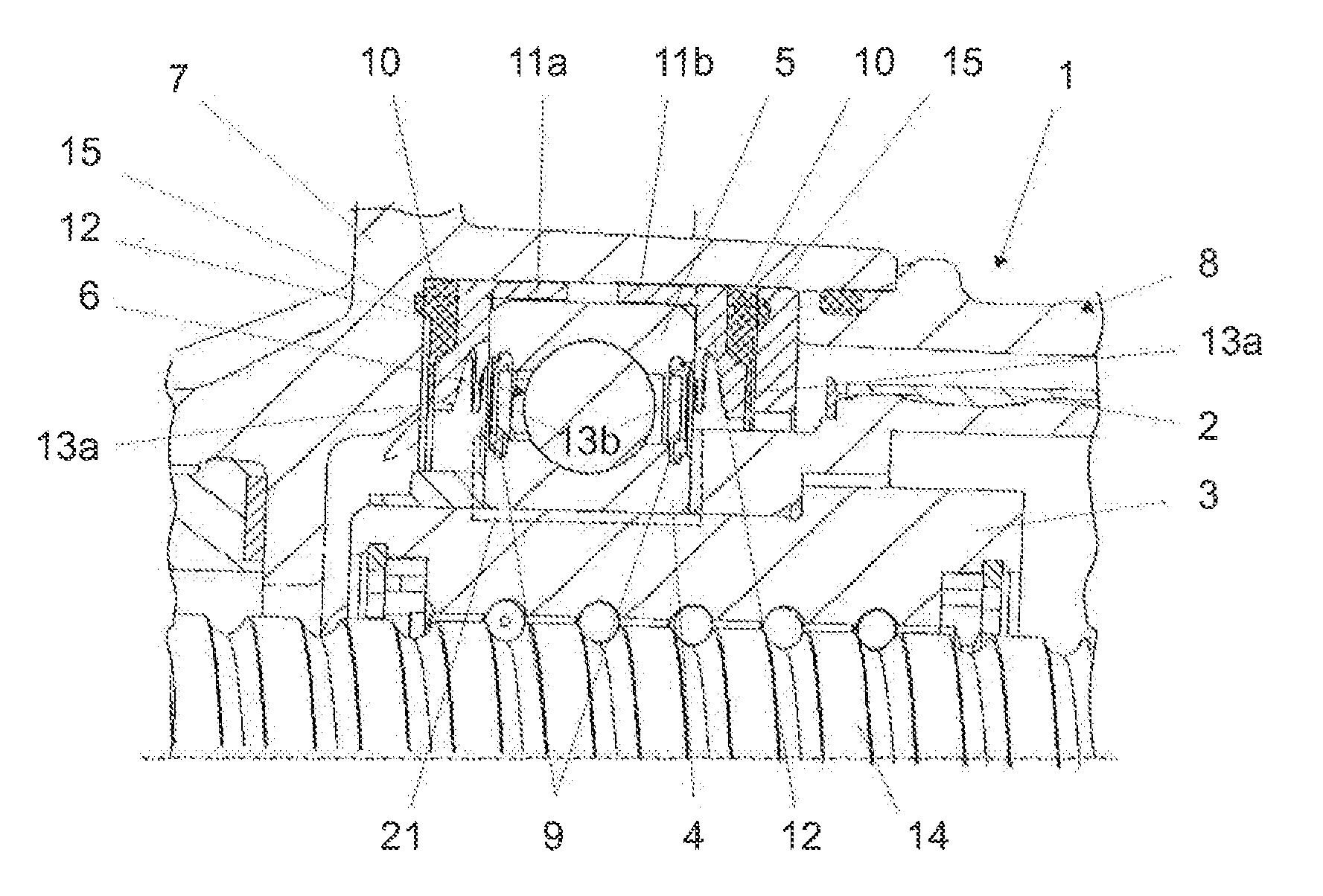

Fuel cell stack

InactiveUS6998186B2Simple and compact structurePower generation performance is maintained desirablyFuel cell heat exchangeFuel cells groupingFuel cellsNuclear engineering

A fuel cell stack includes power generation cells, terminal plates, first cooling cells, and second cooling cells. The terminal plates are electrically connected to the power generation cells. The first cooling cells are interposed between the terminal plates, and a cooling liquid is supplied to the first cooling cells for cooling the power generation cells. The second cooling cells are interposed between the terminal plates. A predetermined number of power generation cells are interposed between the first cooling cell and the second cooling cell. A cooling air is supplied to the second cooling cell for cooing the power generation cells.

Owner:HONDA MOTOR CO LTD

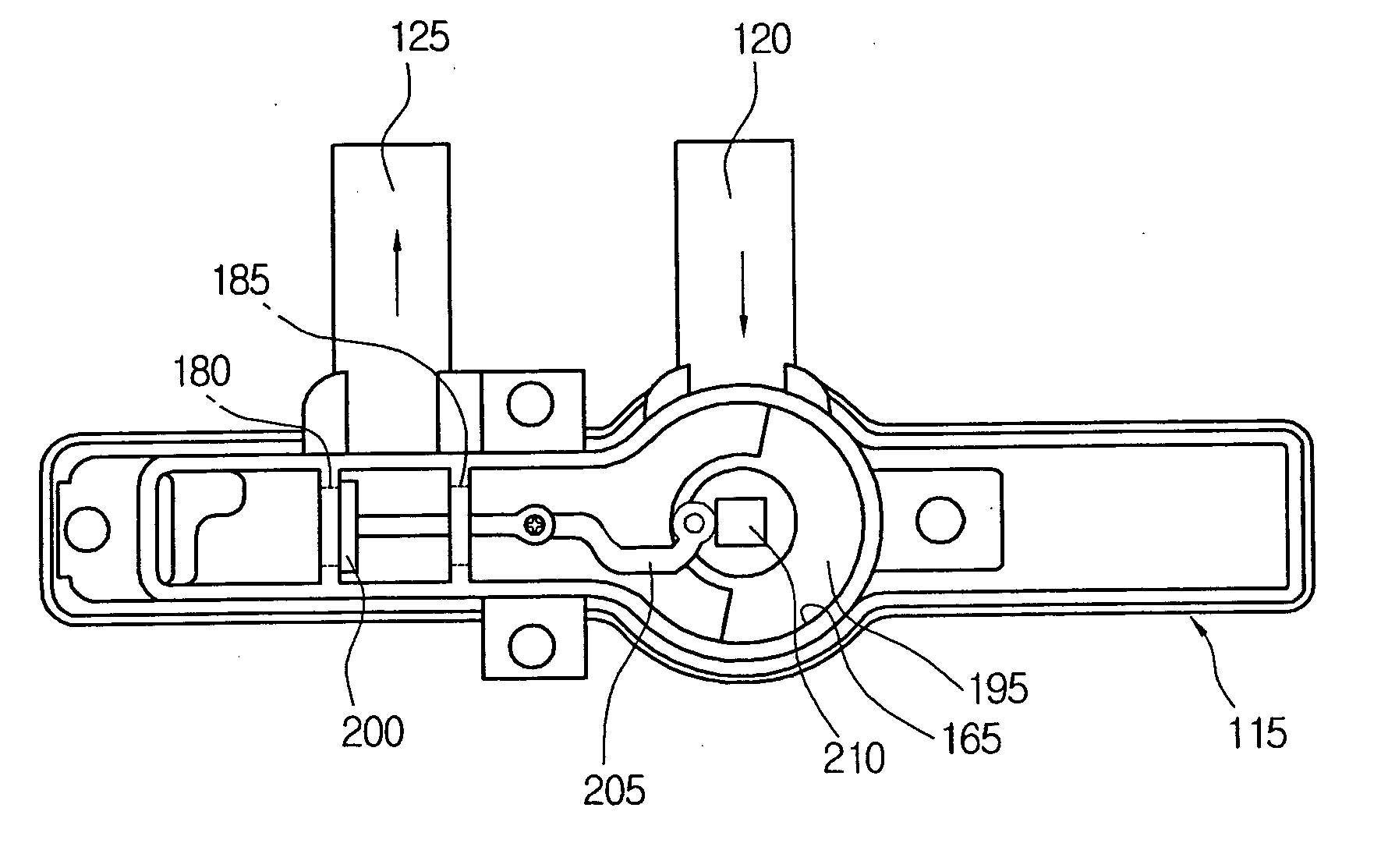

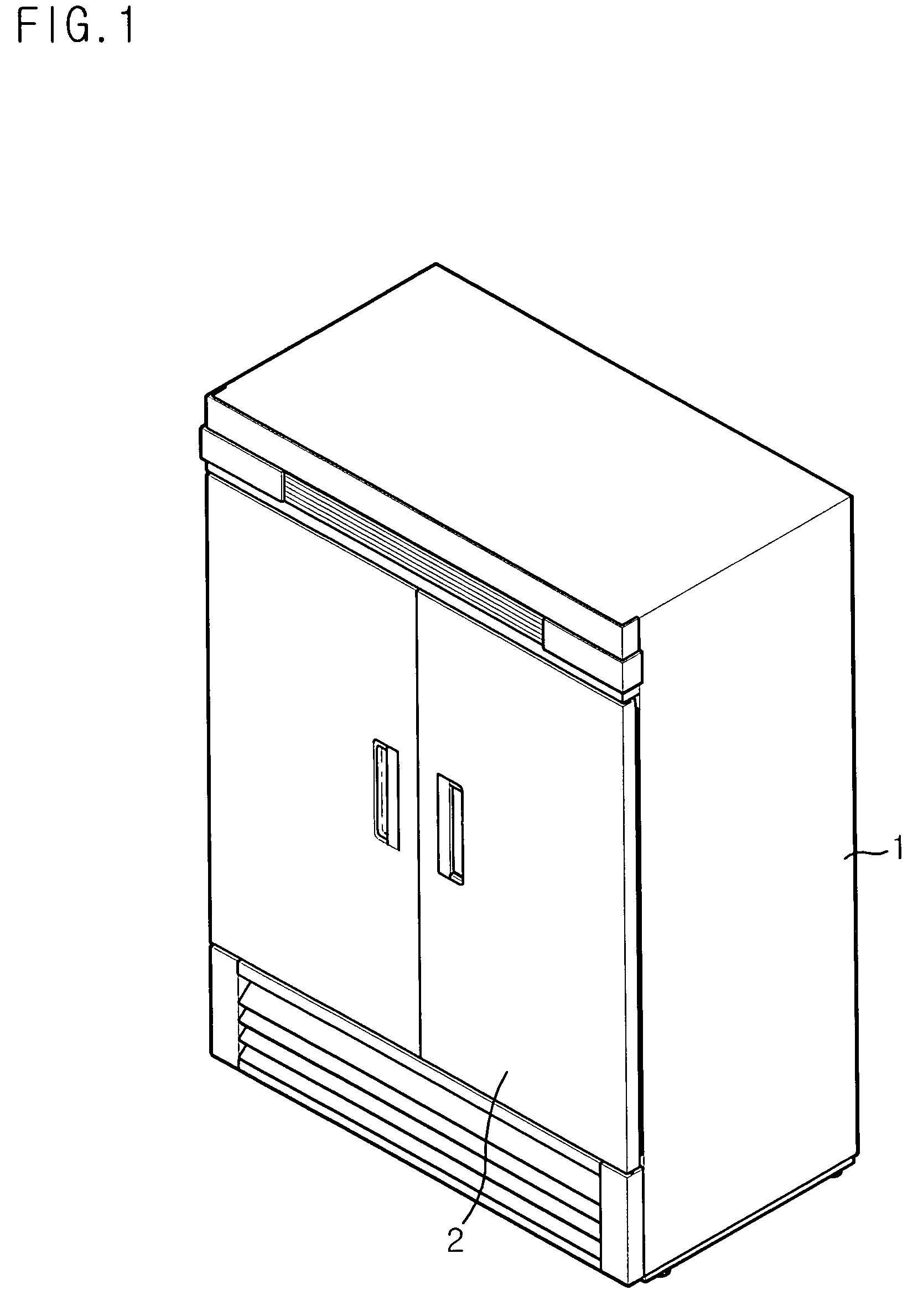

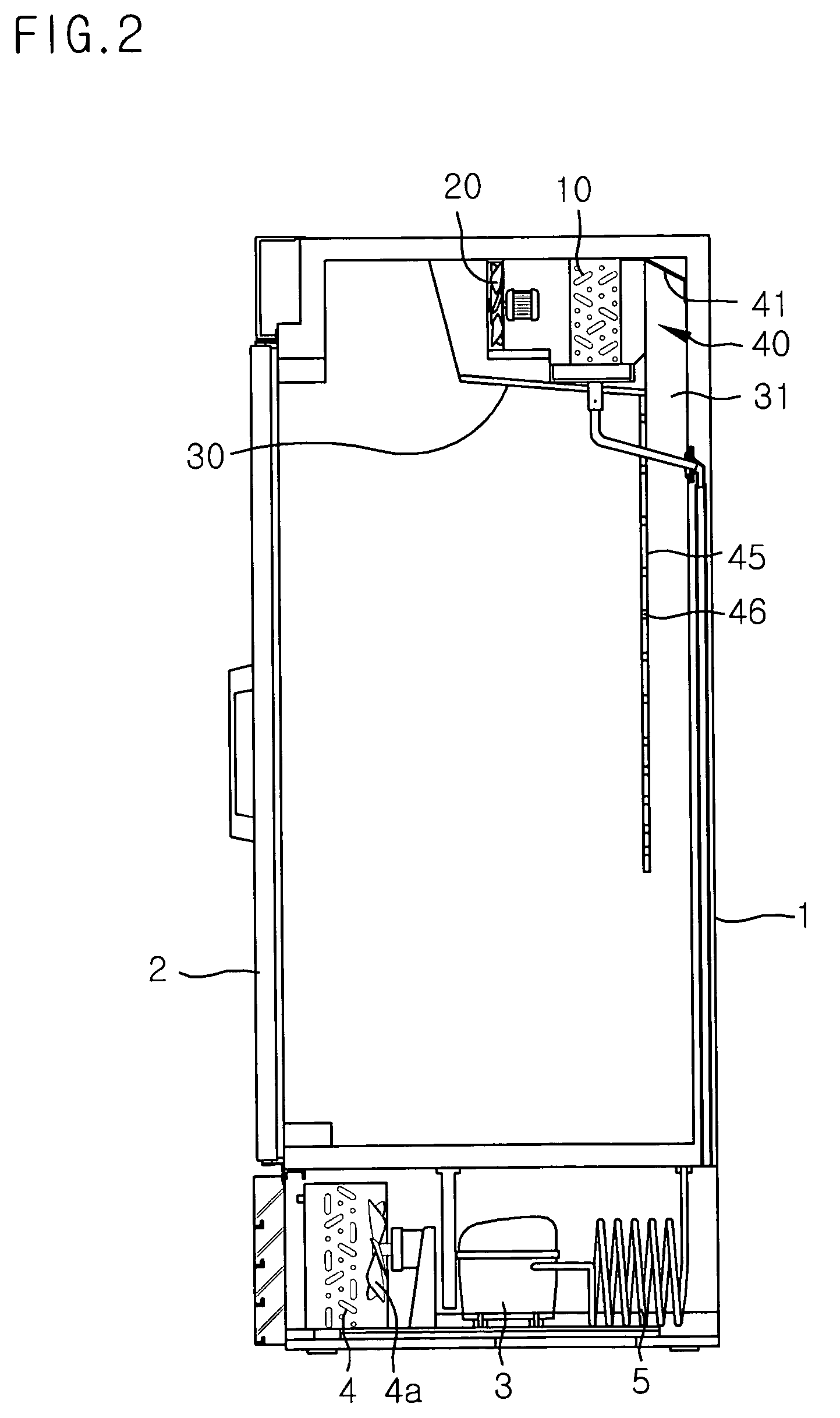

Internal temperature difference preventing structure for refrigerator

InactiveUS7007496B2Uniform temperatureAvoid temperature differenceLighting and heating apparatusFurniture partsEngineeringInternal temperature

Owner:LOTTE ENG & MACHINERY MFG

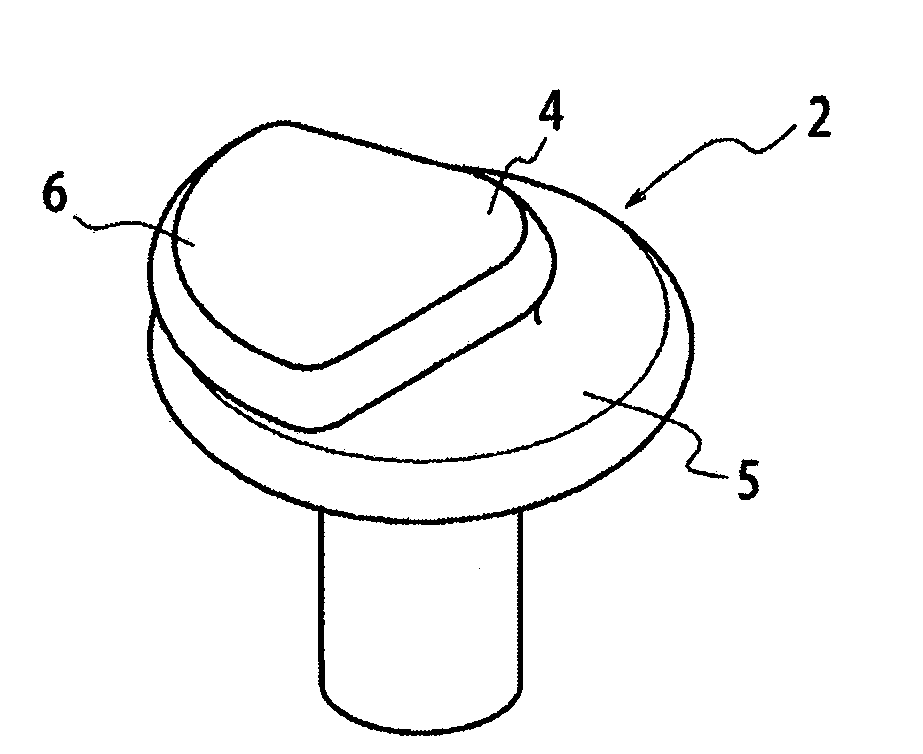

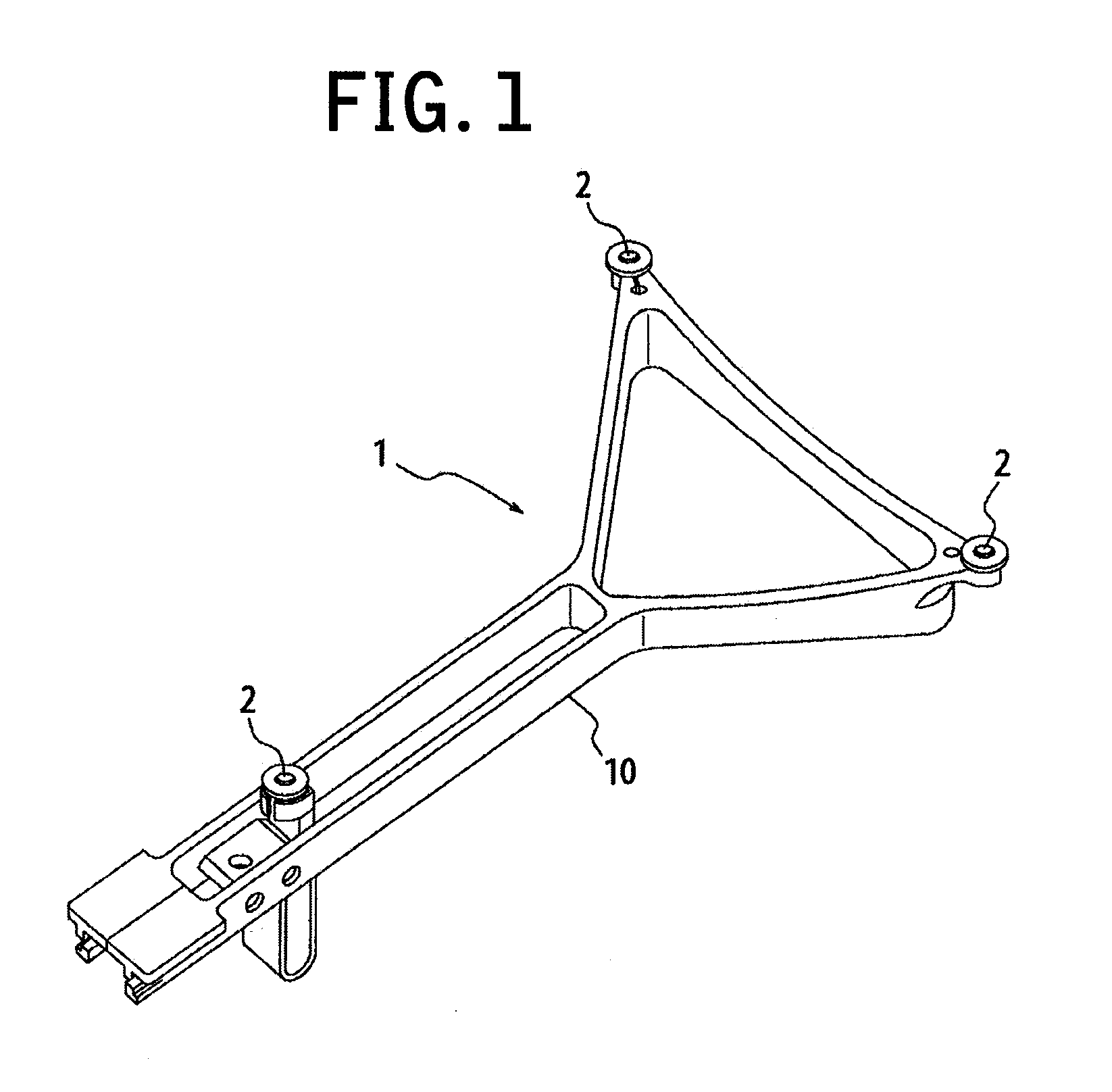

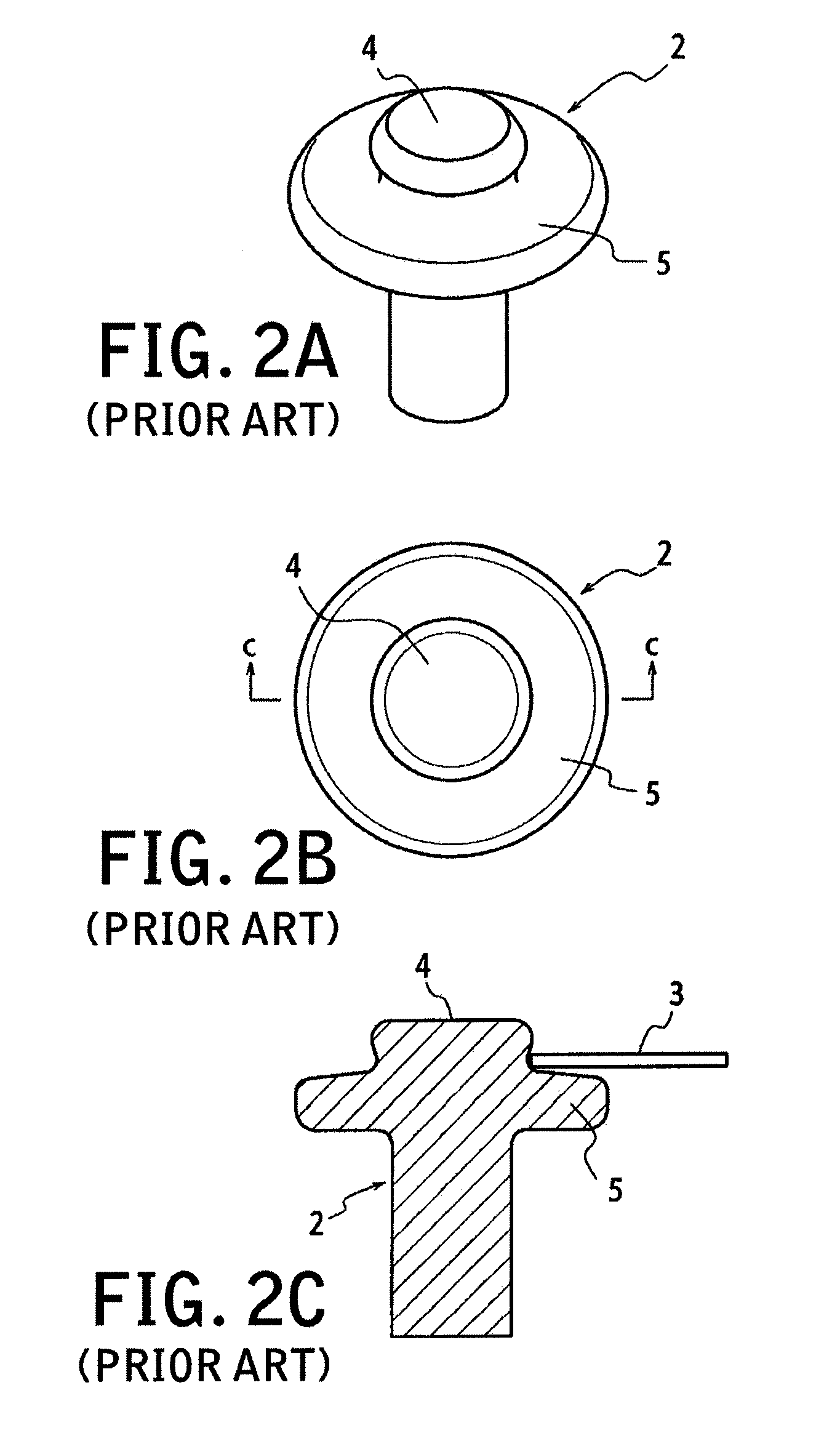

Wafer holding tool for ion implanting apparatus

ActiveUS20100012856A1Avoid temperature differenceControl temperature differenceSleeve/socket jointsMaterial analysis using wave/particle radiationTemperature differenceIrradiation

A wafer holding assembly is provided that is capable of preventing the temperature difference generated between a wafer and a holding pin through beam irradiation.In one embodiment, the wafer holding assembly has a plurality of holding pins for holding a wafer in the ion implanting apparatus, the holding pin comprises a head contacting with an end face of the wafer to control motion of the wafer and a flange projecting from the head to place the wafer, and the head is provided with a canopy portion extending in a direction different from a side placing the wafer.

Owner:SUMCO CORP

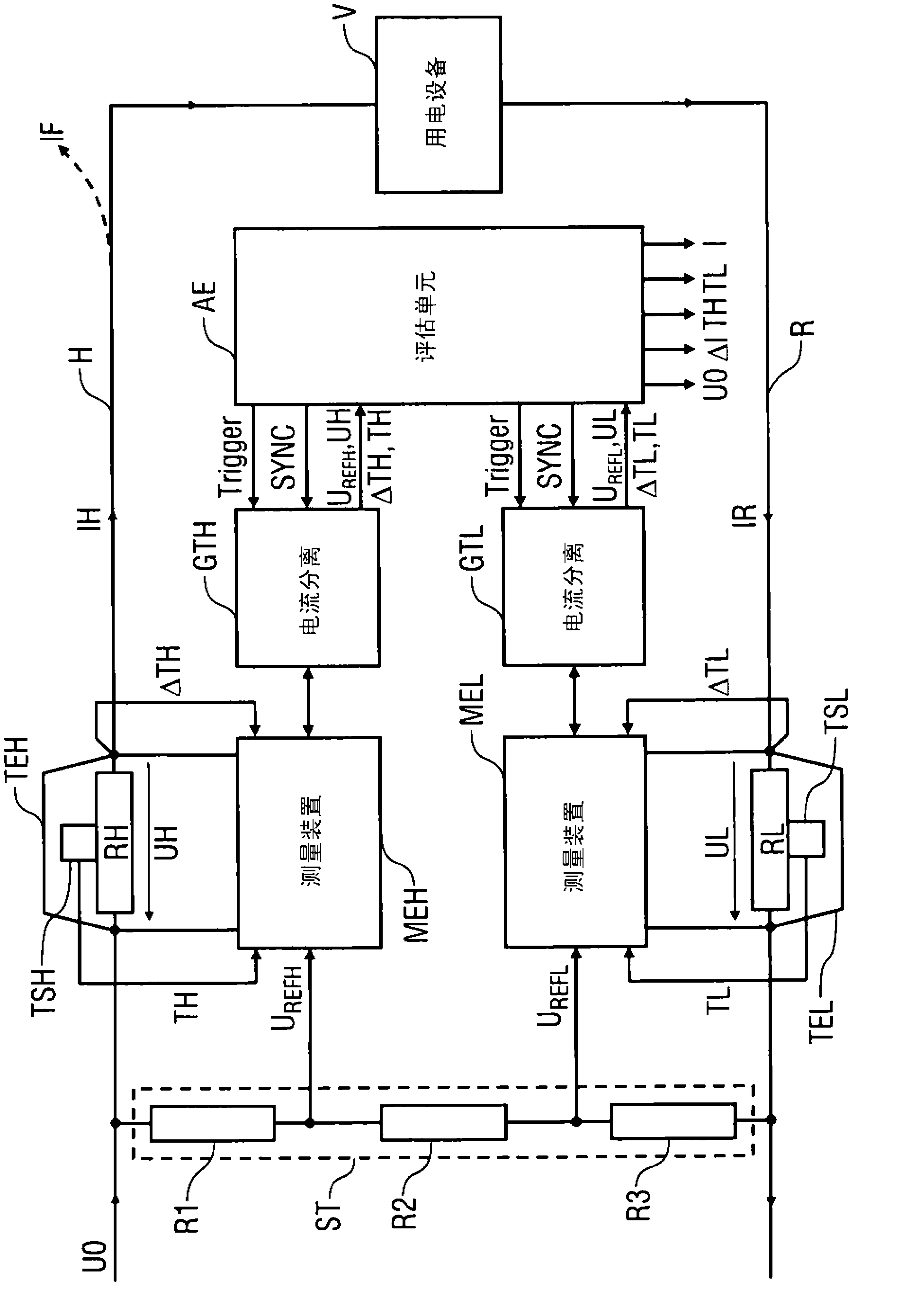

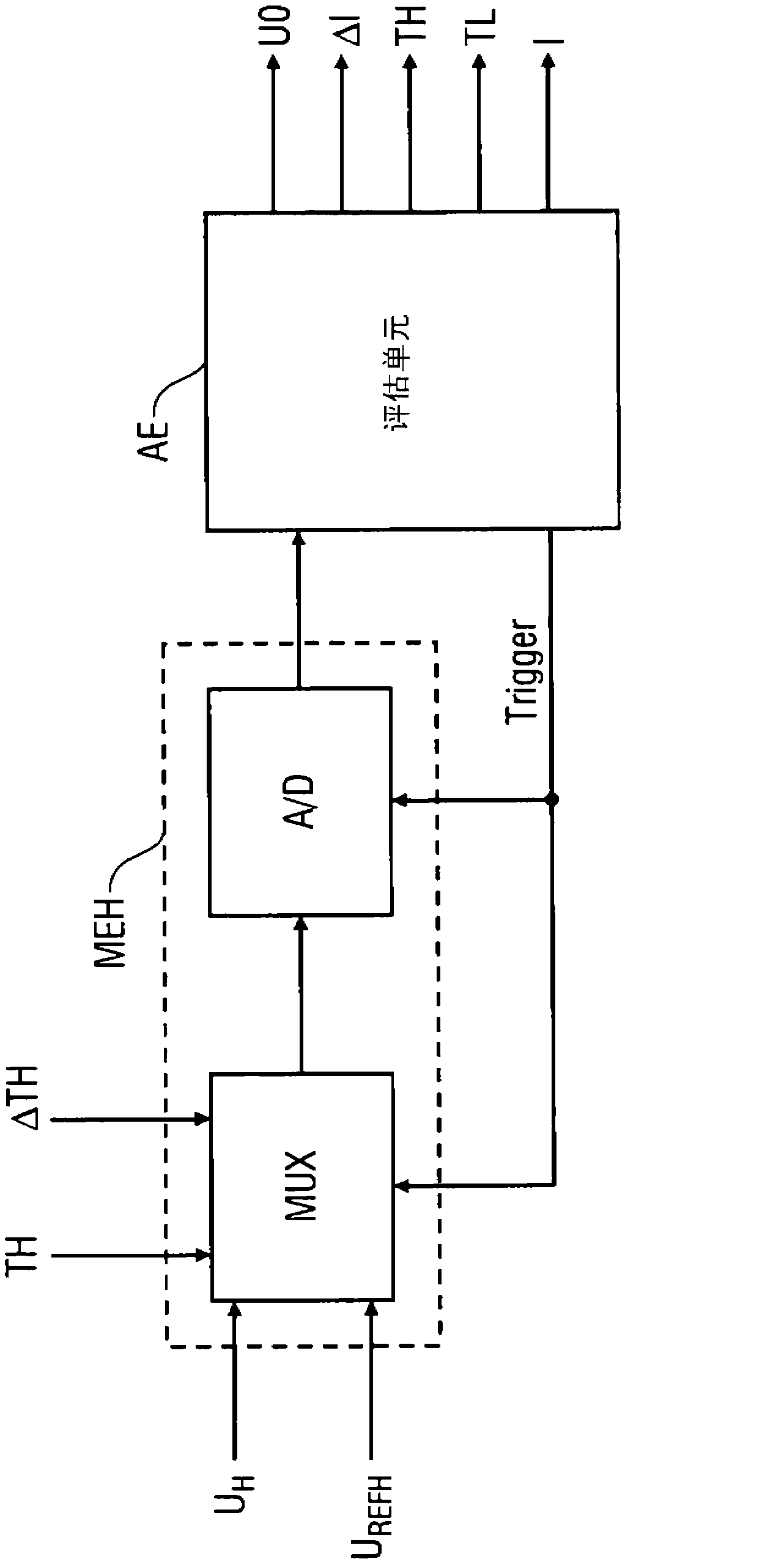

Differential current sensor

InactiveCN103229060AAvoid temperature differenceHigh precisionBase element modificationsMeasurement using digital techniquesCurrent sensorTransducer

The invention relates to a differential current sensor for measuring the differential current ([delta] I) between an electric current (IH) flowing through a feed conductor (H) and an electric current (IR) flowing through a return conductor (R), said sensor comprising: two low-resistance current measuring resistors (RH, RL) for measuring the currents (IH, IR) in the feed conductor (H) and the return conductor (R); two measuring devices (MEH, MEL), each of which has a transducer for measuring the current drops (UH, UL) across the two current measuring resistors (RH, RL); and two voltage references (UREFH, UREFL) for calibrating the measuring devices (MEH, MEL). According to the invention, the two transducers measure in succession both the voltage drop (UH) across their respective current measuring resistor (RH) and the associated voltage references (UREFH, UREFL).

Owner:ISABELLENHUTTE HEUSLER

Method and device for reducing metal dust in electric wire and cable drawing process

The invention relates to a method and a device for reducing metal dust in the electric wire and cable drawing process. A heating tube is mounted in front of a wire inlet of drawing equipment, two ends of the heating tube are sealed with sealing pads made of high-temperature-resistant materials, in-out ports matched with the diameter of a metal pole required to be drawn in size are reserved in the sealing pads at two ends, and the metal pole required to be drawn directly enters a first die of the drawing equipment after heated in the heating tube. The temperature in the heating tube is set to range from 300 DEG C to 350 DEG C if the metal pole is made of copper and set to range from 300 DEG C to 320 DEG C if the metal pole is made of an aluminum and aluminum alloy. With the adoption of the method and device, production of the metal dust is avoided essentially, the safety performance is improved, harm of the metal dust to the body health of a worker and serious accidents are avoided, the work efficiency is improved, the production cost is saved, the product quality is guaranteed, and the method and the device have great usage value.

Owner:SINOSTAR CABLE CO LTD

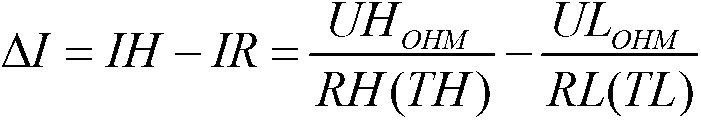

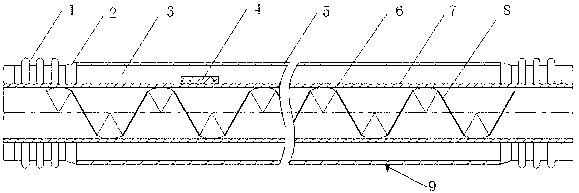

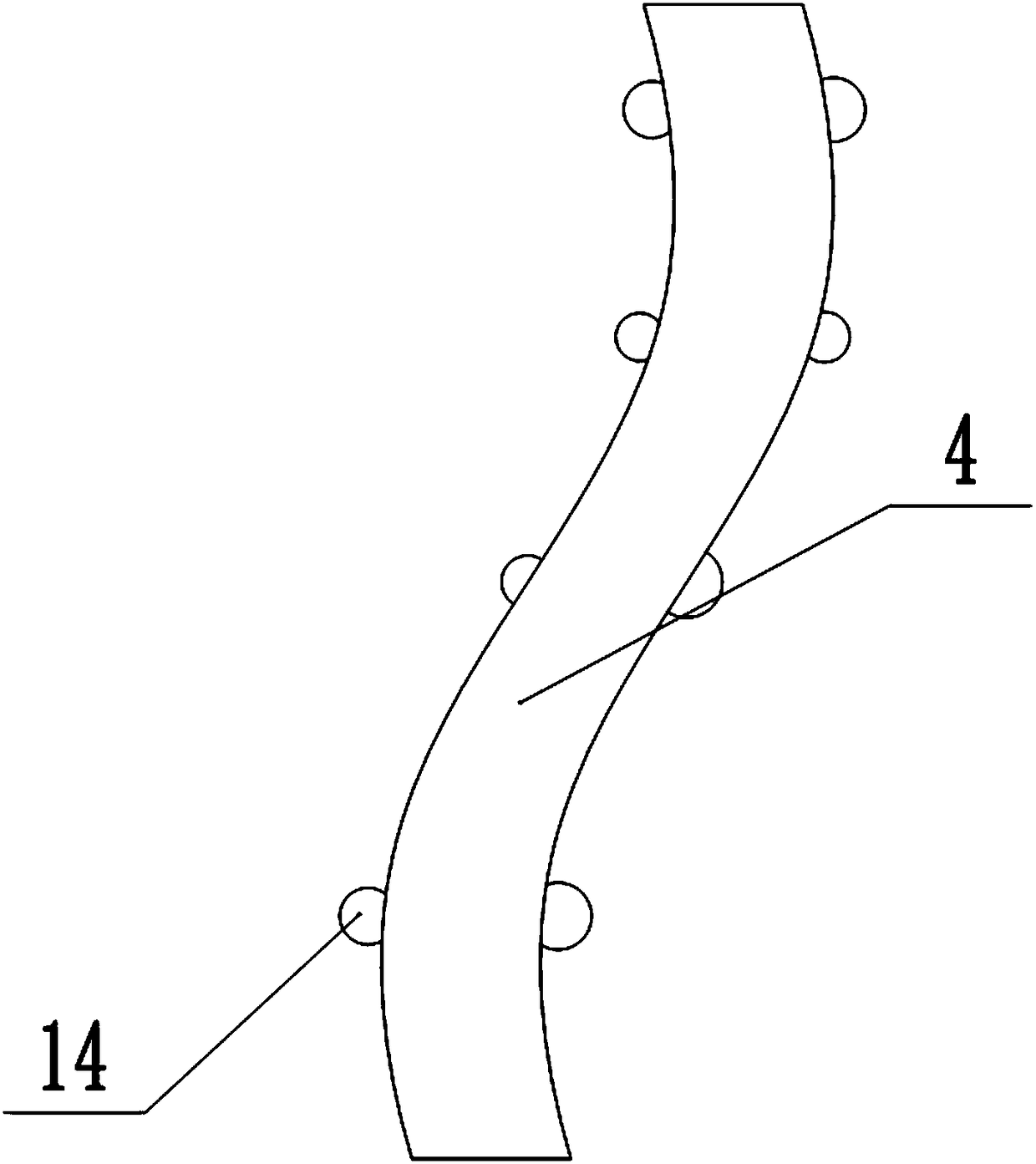

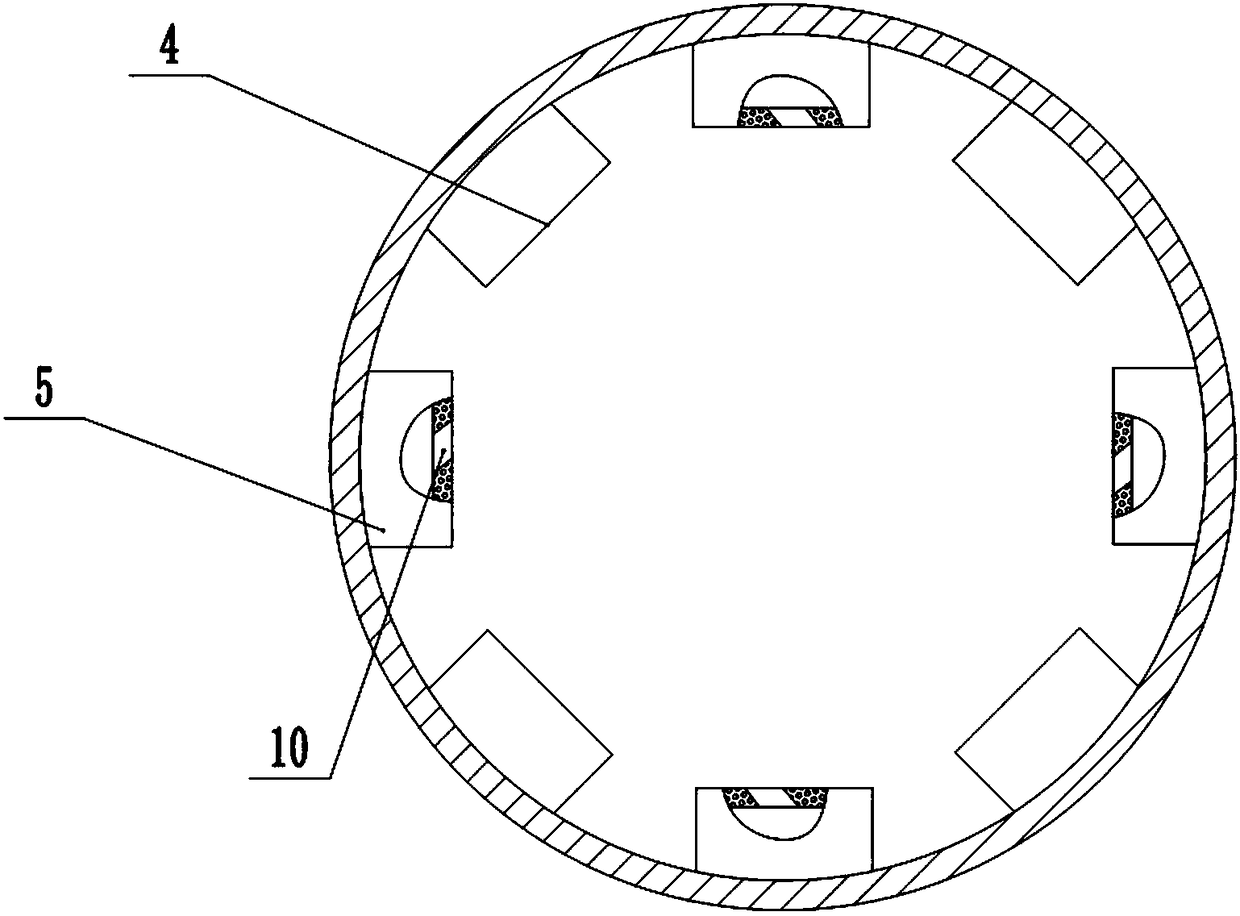

Film cooling roller

The invention relates to the field of cooling mechanisms, and discloses a film cooling roller. The film cooling roller comprises a roller and a cooling pipe, wherein discharge holes are formed in both ends of the roller, the roller is rotatably connected to the cooling pipe, a helical blade is arranged on the inner wall of the roller, and a helical flow channel is formed by the helical blade between the cooling pipe and the roller; a plurality of through holes are formed in the cooling pipe, a sliding rod is connected to the interior of the cooling pipe in a sliding mode, a diversion hole is formed in the sliding rod, an outlet of the diversion hole is located in the cooling pipe and faces towards one side, in which the through hole is formed, of the cooling pipe, an inlet of the diversion hole is located outside the cooling pipe, and the sliding rod is driven by a crank-connecting rod mechanism to do a reciprocal rectilinear motion in the cooling pipe, so that the diversion hole in the sliding rod is aligned with different through holes, and cooling water is led to different positions of the helical flow channel in the roller so as to uniformly cool the roller and eliminate the temperature difference of the roller. The invention aims to provide the film cooling roller so as to guarantee the cooling efficiency of the roller and eliminate the temperature difference of the surface of the roller.

Owner:遵义鸿达纸箱制品有限公司

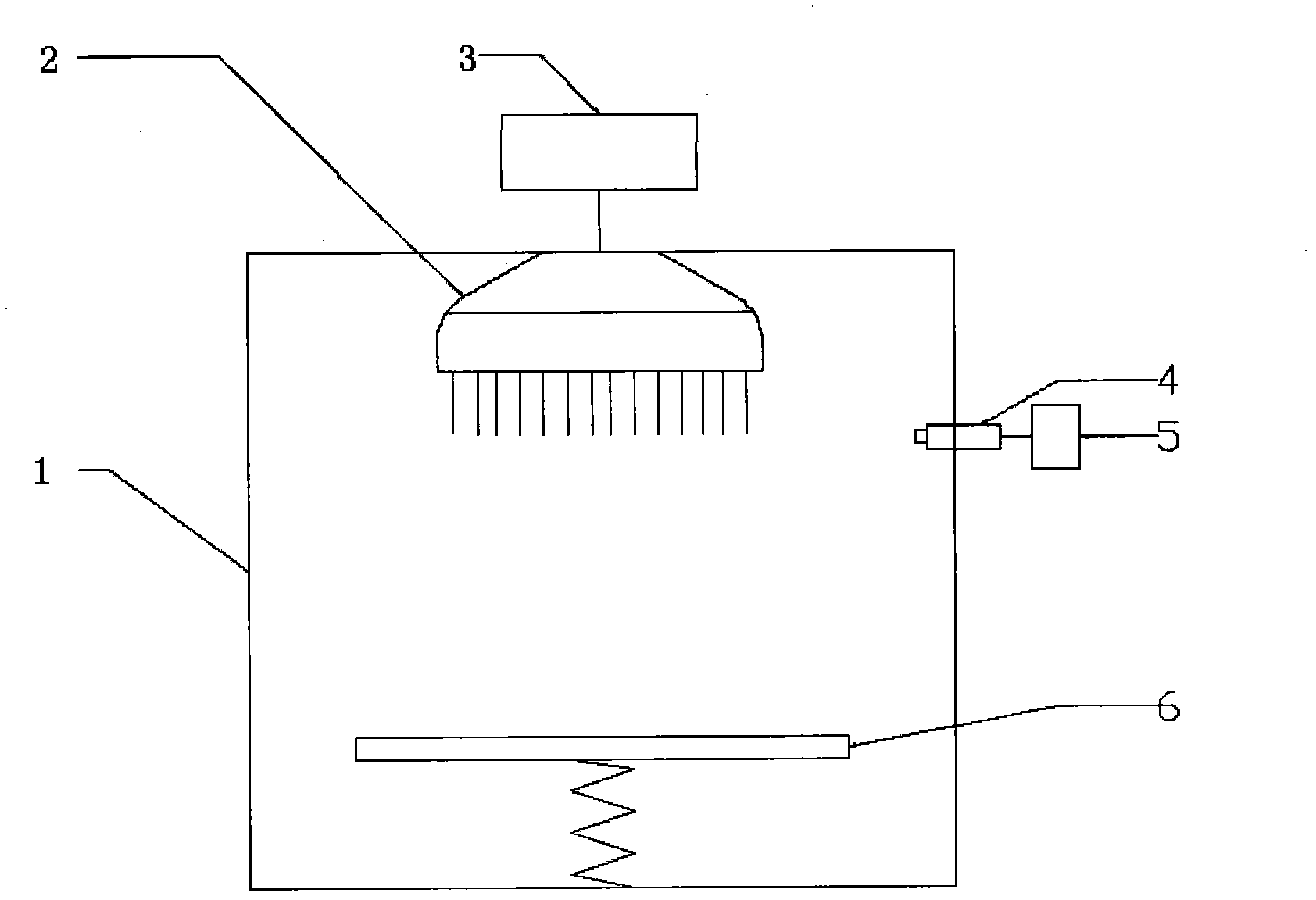

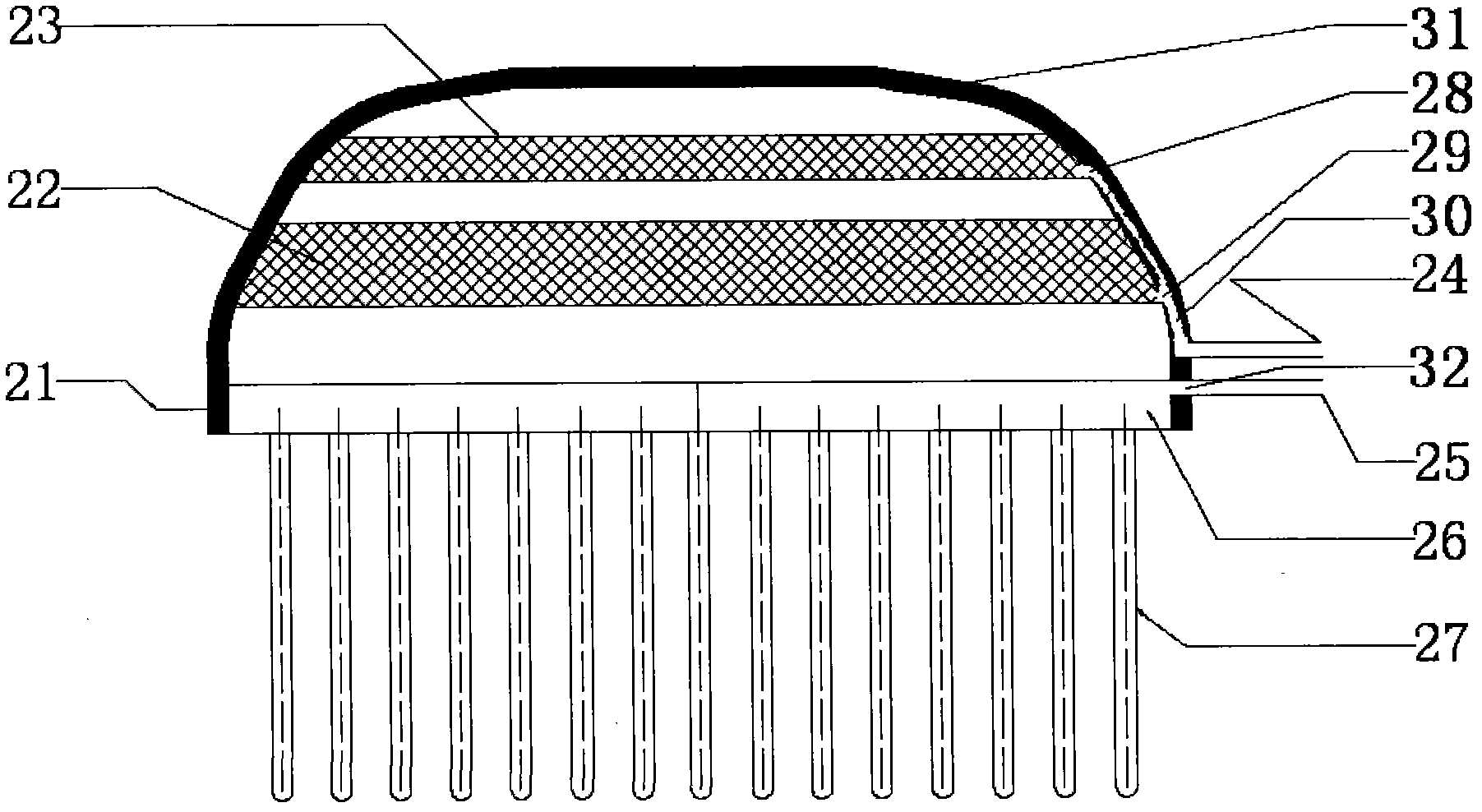

Cooling and heating device for cooked food

The invention discloses a cooling and heating device for cooked food, which comprises a processing chamber, a vacuum pump, a heat transfer device, a thermoelectric couple, a temperature controller and a lifting table, wherein the heat transfer device consists of a heat transfer pipe installation plate, a heat transfer cover connected above the periphery of the heat transfer pipe installation plate and a plurality of heat transfer pipes which are fixed to the lower surface of the heat transfer pipe installation plate and are distributed uniformly. By the cooling and heating device, the temperature difference of each part inside cooked food in the cooling or heating process can be prevented effectively, the cooling and heating time of the cooked food can be shorten greatly, and the moistureof the food is not lost in the cooling process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Cooling apparatus, cooling method, program, computer readable information recording medium and electronic apparatus

InactiveUS7712318B2Reduce degradationEasy to set upCompression machines with non-reversible cycleMachines using electric/magnetic effectsEngineeringElectric power

A cooling apparatus of supplying driving power to a cooling element from a power supply unit, to drive it, includes a driving power changing part changing a power value of the driving power supplied to said cooling element from the power supply unit, by a predetermined power value at each predetermined time interval.

Owner:RICOH KK

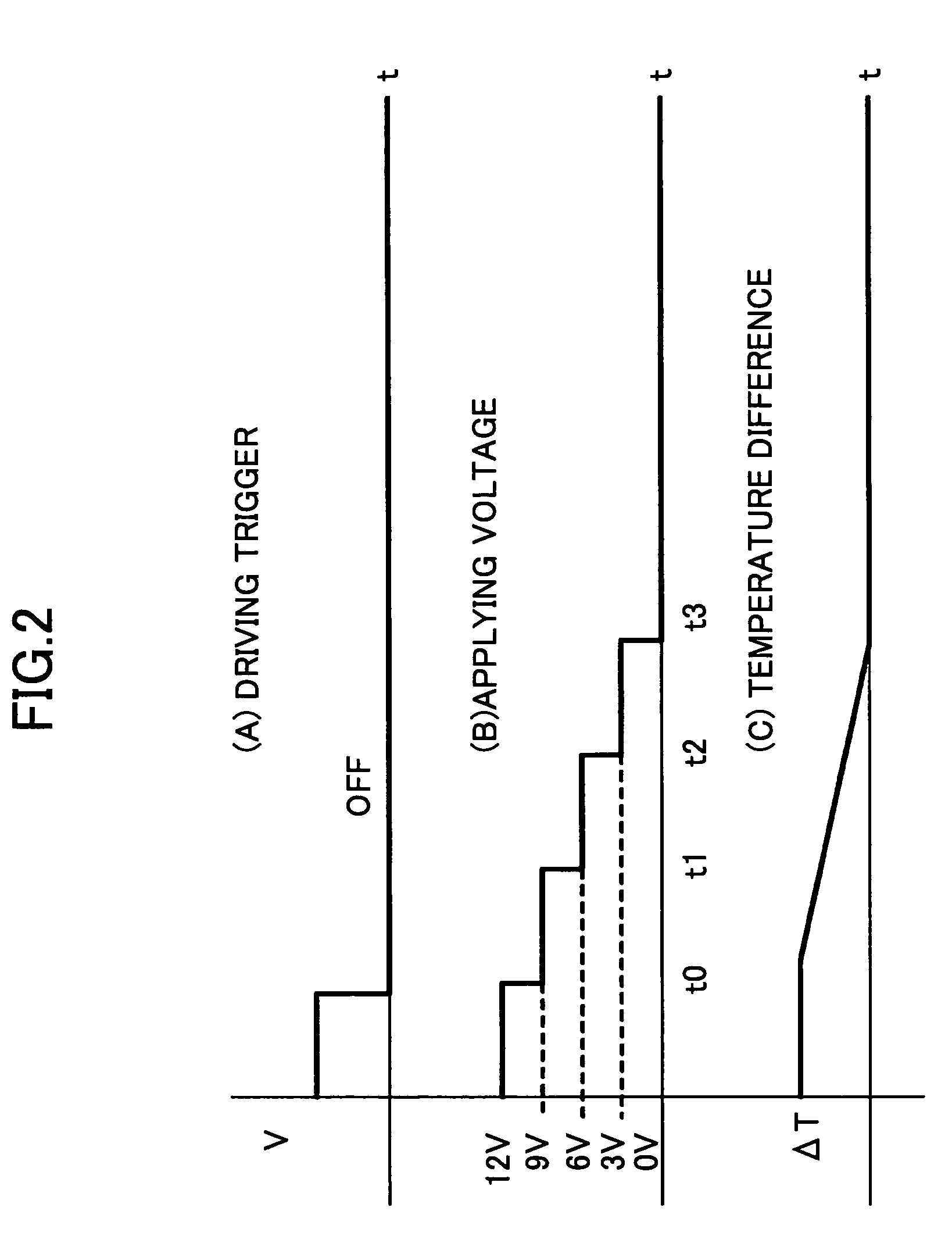

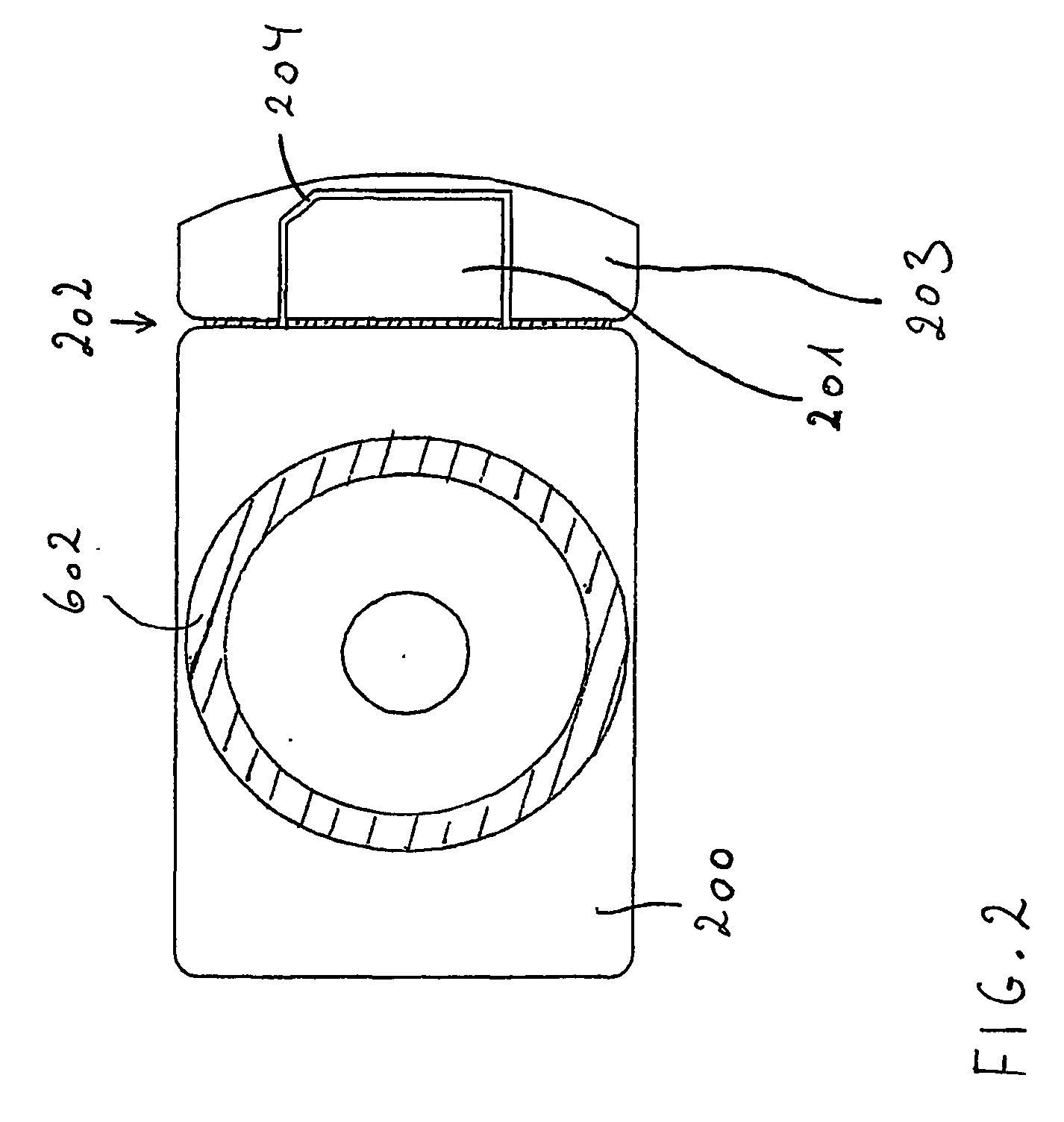

Method for production of an optical disc with a detachable module

InactiveUS20060187805A1Easy to produceEasy to processRecord carriersMechanical record carriersEngineeringInternal dimension

Method for production of an optical disc with a detachable module, where a standard mould is provided with an insert insertable into said standard mould. The insert restricting the internal dimensions of the mould cavity for shaping the optical disc into dimensions different from a standard optical disc. The insert comprises a line restrictor for providing a groove along at least one breaking line between the optical disc and the detachable module.

Owner:TELE CD CO AS

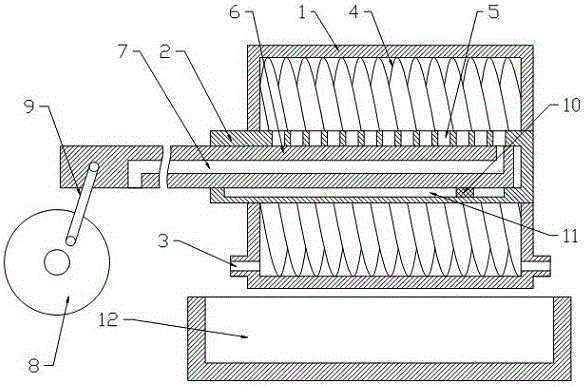

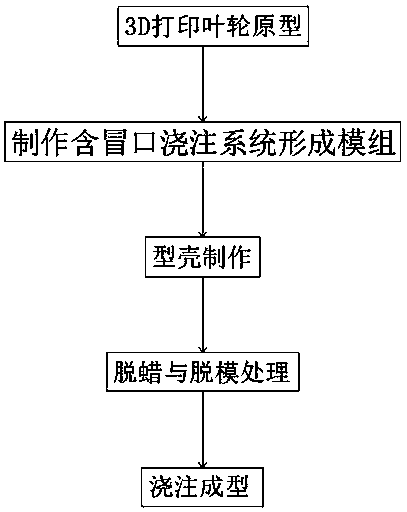

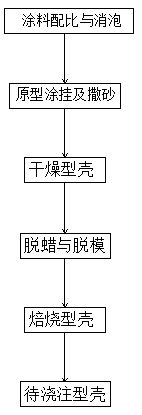

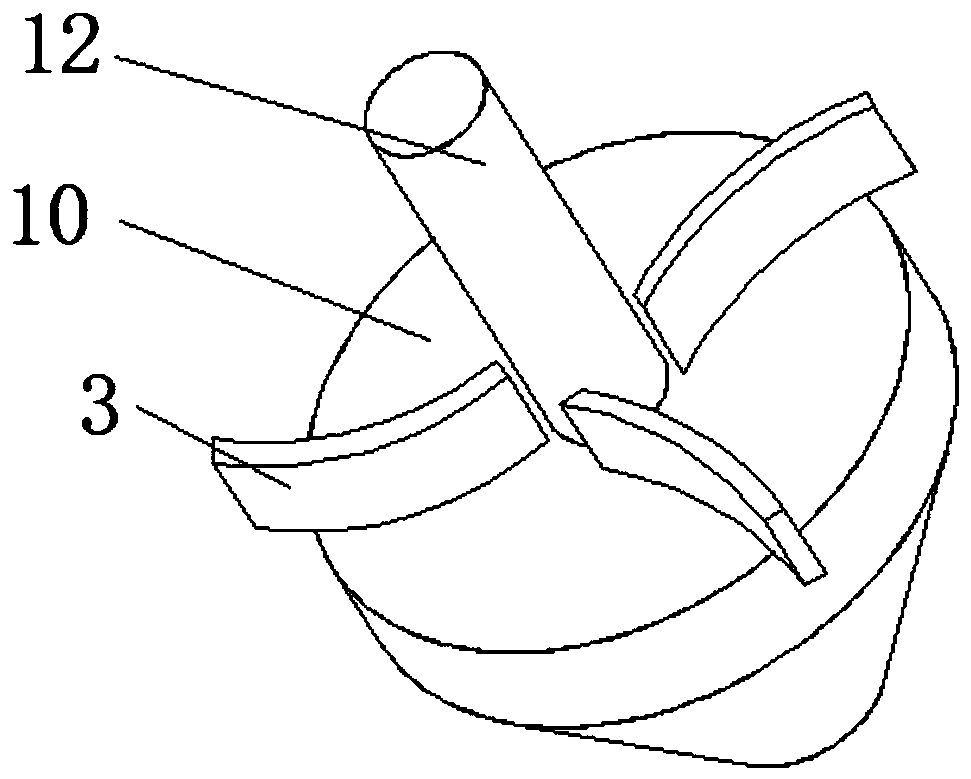

Novel manufacturing process of impeller

InactiveCN111558689AReduce lossImprove shock absorptionAdditive manufacturing apparatusFoundry moulds3d printManufacturing technology

The invention relates to a novel manufacturing process of an impeller. The novel manufacturing process is characterized by comprising the following specific process steps of S1, carrying out 3D printing on an impeller prototype; S2, manufacturing a casting system with a riser to form a module; S3, manufacturing a shell; S4, dewaxing and demolding treatment; and S5, carrying out casting molding. According to the novel manufacturing process of the impeller, compared with a traditional casting or forging method, the method has great advantages that a corresponding mold is needed when the castingor forging method is used, raw materials and time are wasted, the tedious procedures are omitted through the 3D printing technology, computer related software can be helped to directly generate the impeller, and any complex impeller can be quickly printed, so that the generation period is shortened, the cost is reduced, the advantage of greatly reducing the raw material loss in the research and development process is achieved, meanwhile, the impeller produced by using the process can greatly improve the overall shock absorption and noise reduction capabilities of a pumping set, actual production reference is provided for the rapid low-pressure investment casting production process of castings, and the feasibility of the process is verified.

Owner:JIANGSU UNIV OF SCI & TECH +1

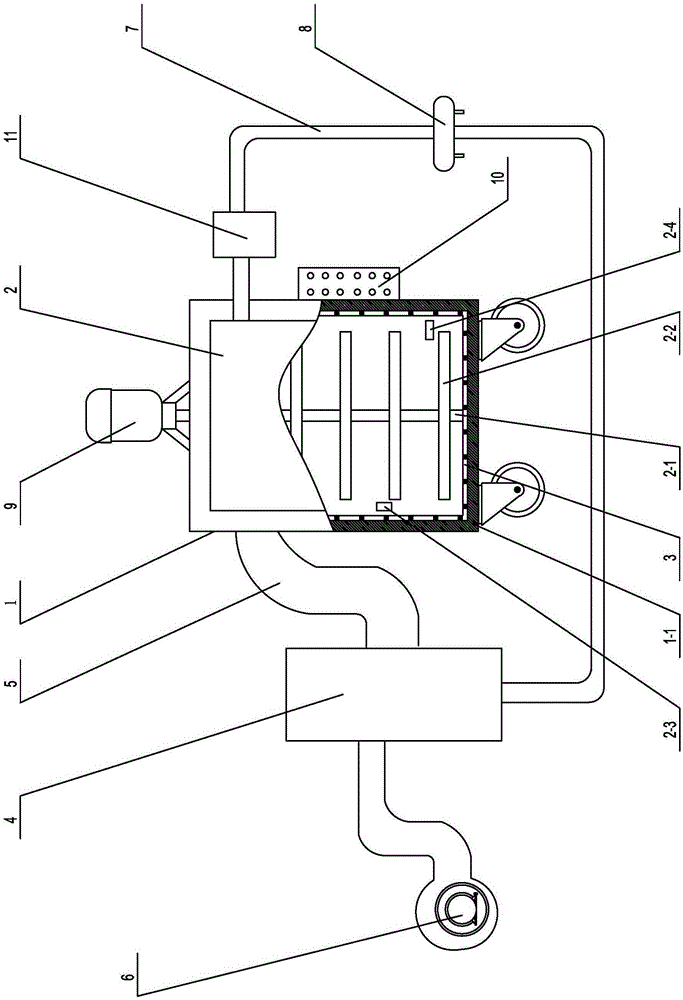

Fresh air machine and air conditioner linkage system, method and device for controlling fresh air machine and air conditioner linkage system and storage medium

ActiveCN107642885AAvoid temperature differenceImprove freshnessMechanical apparatusEfficient regulation technologiesOutdoor temperatureIndoor air

The invention discloses a fresh air machine and air conditioner linkage system, a method and a device for controlling the fresh air machine and air conditioner linkage system and a storage medium. Thefresh air machine and air conditioner linkage system comprises a fresh air machine, an air conditioner, a drying device, a detection device, a first temperature sensor, a second temperature sensor and a control device. High-humidity fresh air can be dried by the drying device, the outdoor humidity can be detected by the detection device, the indoor temperatures can be detected by the first temperature sensor, the outdoor temperatures can be detected by the second temperature sensor, and the detection device, the first temperature sensor and the second temperature sensor are electrically connected with the control device; the fresh air machine comprises an air outlet, an air inlet and an air channel, the air outlet is formed in an indoor environment, and the air inlet is formed in an outdoor environment and is communicated with the air outlet via the air channel. The fresh air machine and air conditioner linkage system, the method, the device and the storage medium have the advantagesthat the fresh air machine and the air conditioner can run under the control of the control device according to detection data of the detection device, the first temperature sensor and the second temperature sensor, so that outdoor fresh air can be led into the indoor environment by the fresh air machine after being dried and heated under the condition of refrigeration modes of the air conditioner, air exchange can be carried out between the outdoor fresh air and indoor air, the freshness of the indoor air can be improved, and the comfort can be enhanced for human bodies.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Drying device for lucid ganoderma

InactiveCN105387700AUniform temperatureImprove drying qualityDrying gas arrangementsDrying machines with non-progressive movementsGanoderma pseudoferreumProcess engineering

The invention discloses a drying device for lucid ganoderma. The drying device for lucid ganoderma comprises a drying box, a drying cavity formed in the drying box and a ventilating channel formed between the drying box and the drying cavity; the drying box is provided with a moisture removing device communicated with the drying cavity, a central rotation shaft which is vertically arranged is arranged in the drying cavity, and multiple layers of storage racks which are transversely arranged are arranged in the drying cavity along the central rotation shaft; one side of the drying box is provided with a heating system connected with a control box arranged on the drying box, one side of the heating system is provided with an air pipe which is vertically connected with the ventilating channel, and the other side of the heating system is connected with a draught fan. According to the drying device for lucid ganoderma, due to the fact that the heating system is arranged outside the drying box, it is guaranteed that lucid ganoderma is evenly heated; the advantages that the drying efficiency is high, the temperature and the humidity can be automatically adjusted in time, and the drying effect is good are achieved; meanwhile, the heat energy utilization is high, heat energy is recycled, energy conservation and practicability are achieved, and the device is worthy of wide popularization.

Owner:GUILIN DA YE LING YVU BIOTECH CO LTD

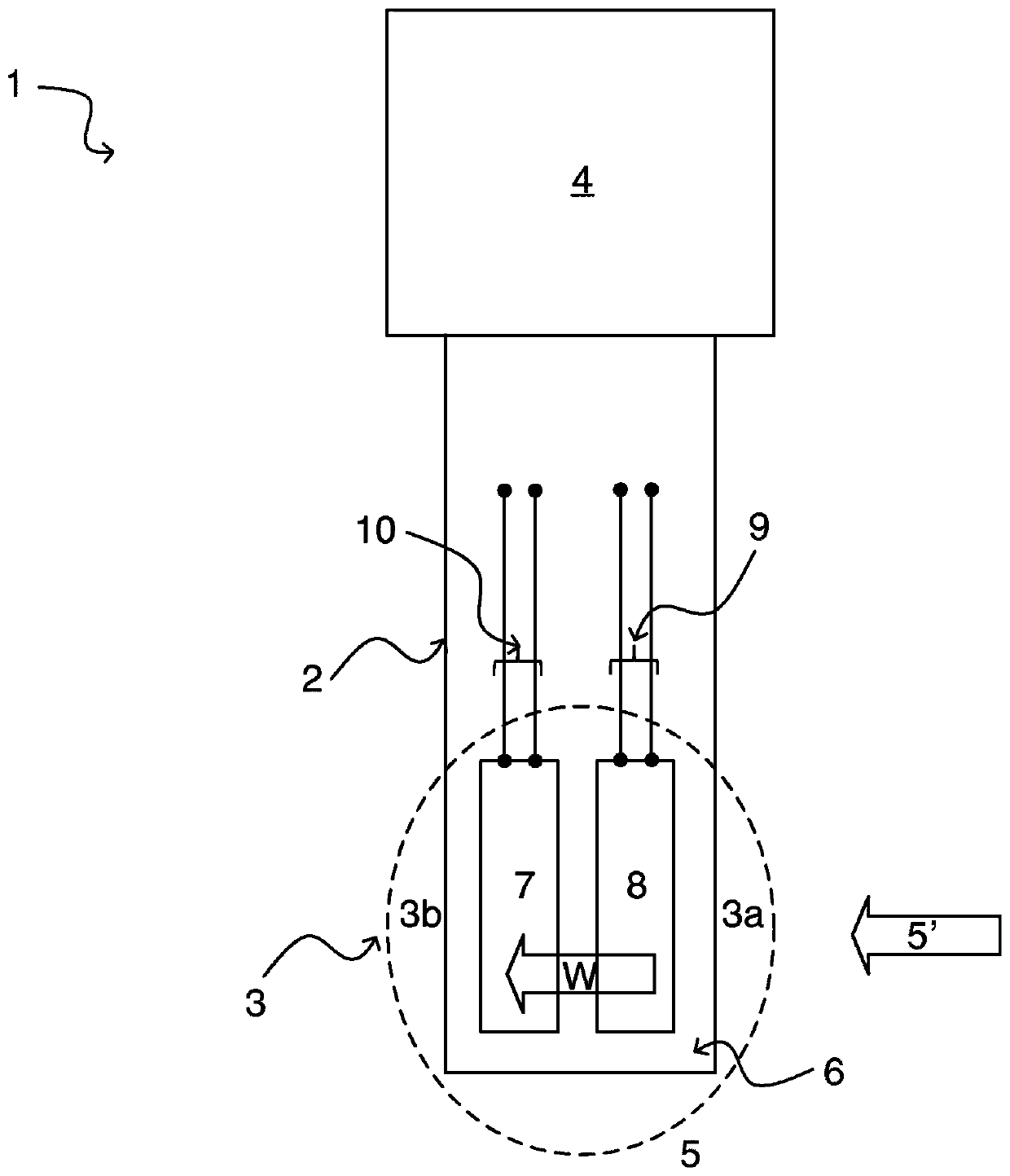

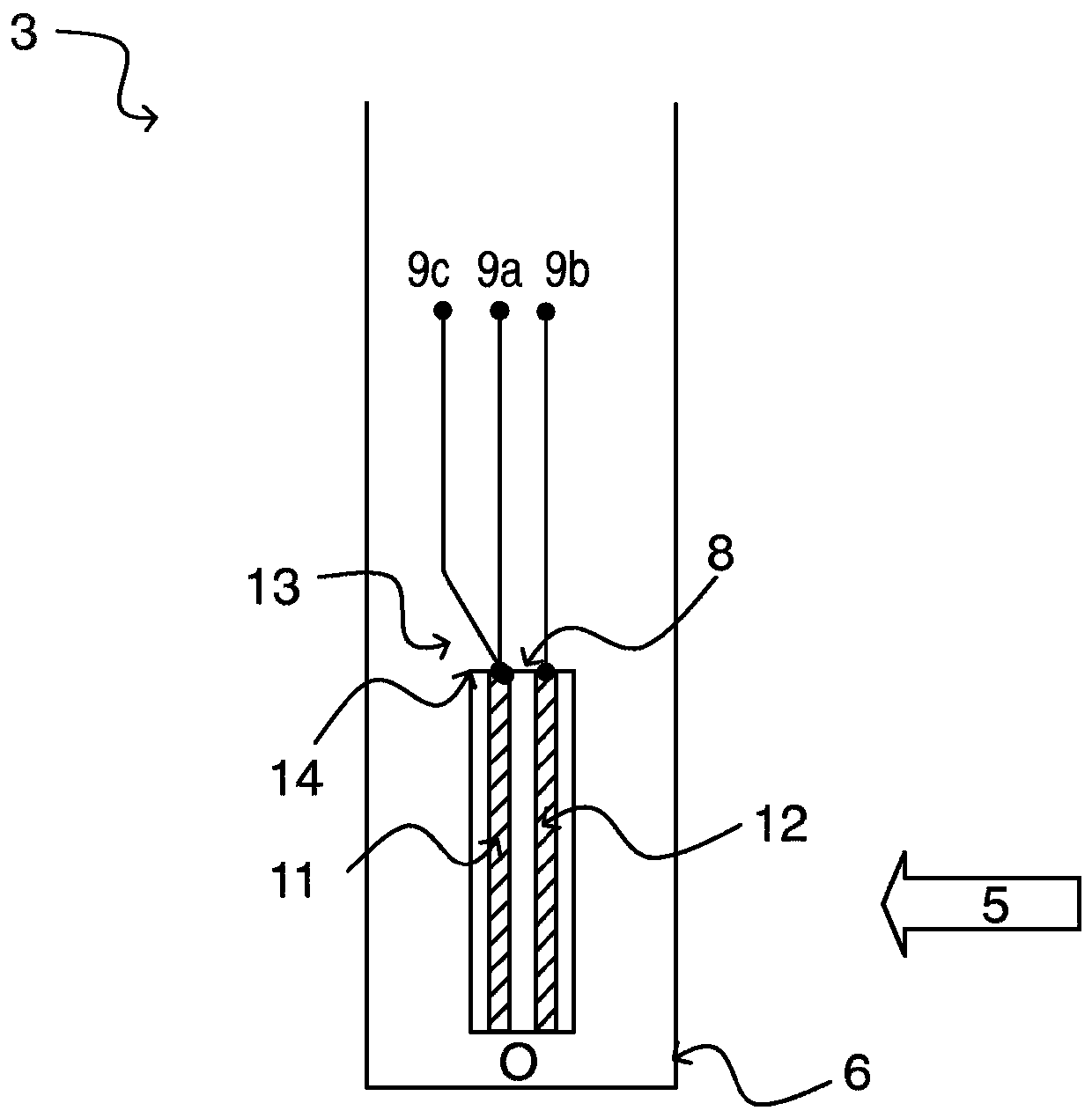

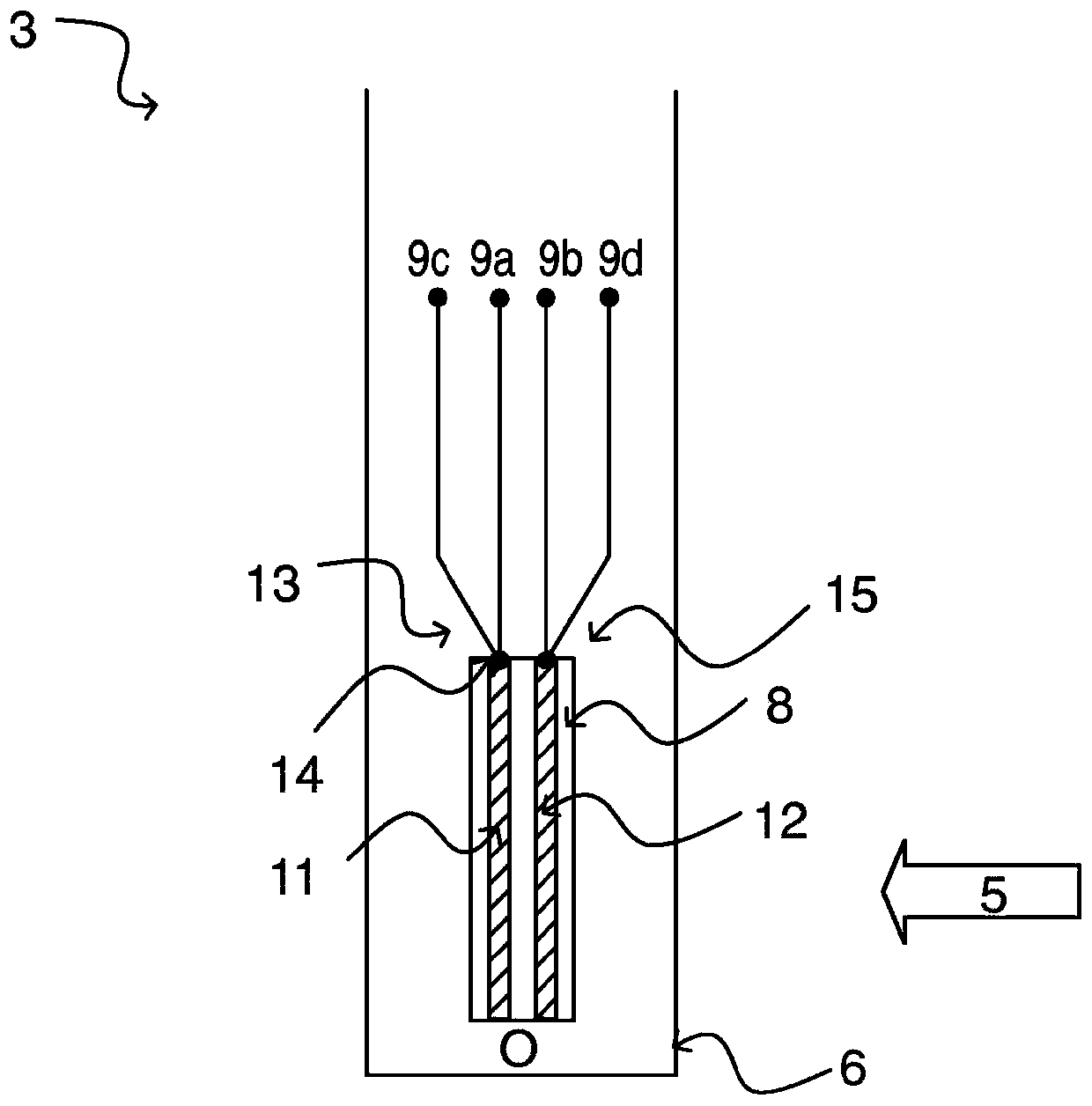

Device and method for the in situ calibration of a thermometer

PendingCN110168329AAvoid temperature differenceAvoid time-limited temperature differencesThermometers using electric/magnetic elementsUsing electrical meansEngineeringIn situ calibration

The invention relates to a device (1) for determining and / or monitoring the temperature (T) of a medium (5). The device (1) includes at least one first temperature sensor (13) for determining the temperature (T) of the medium (5); a reference element (8) for the in situ calibration and / or validation of the device (1), said reference element (8) at least partly consisting of a material which undergoes at least one phase transition at at least one specified phase transition temperature (Tph) within a temperature range which is relevant to the operation of the device (1), said material remainingin the solid phase during the phase transition, wherein at least one first (11) and a second (12) electrically conductive electrode is arranged on the reference element (8), said first (11) and secondelectrode (12) being electrically insulated from each other; a first connection line (9a) for contacting the first electrode (11), in particular in an electric manner, and a second connection line (9b) for contacting the second electrode (12), in particular in an electric manner. According to the invention, a third connection line (9c) is provided which consists of a material that differs at least from the material of the first (9a) or second connection line (9b). The third connection line (9c) is arranged such that the third connection line together with the first (9a) or the second (9b) connection line forms the first temperature sensor (13) in the form of a first thermoelement. The invention additionally relates to a method for the in situ calibration and / or validation of a device according to the invention.

Owner:EHNDRESS KHAUZER GMBKH KO KG

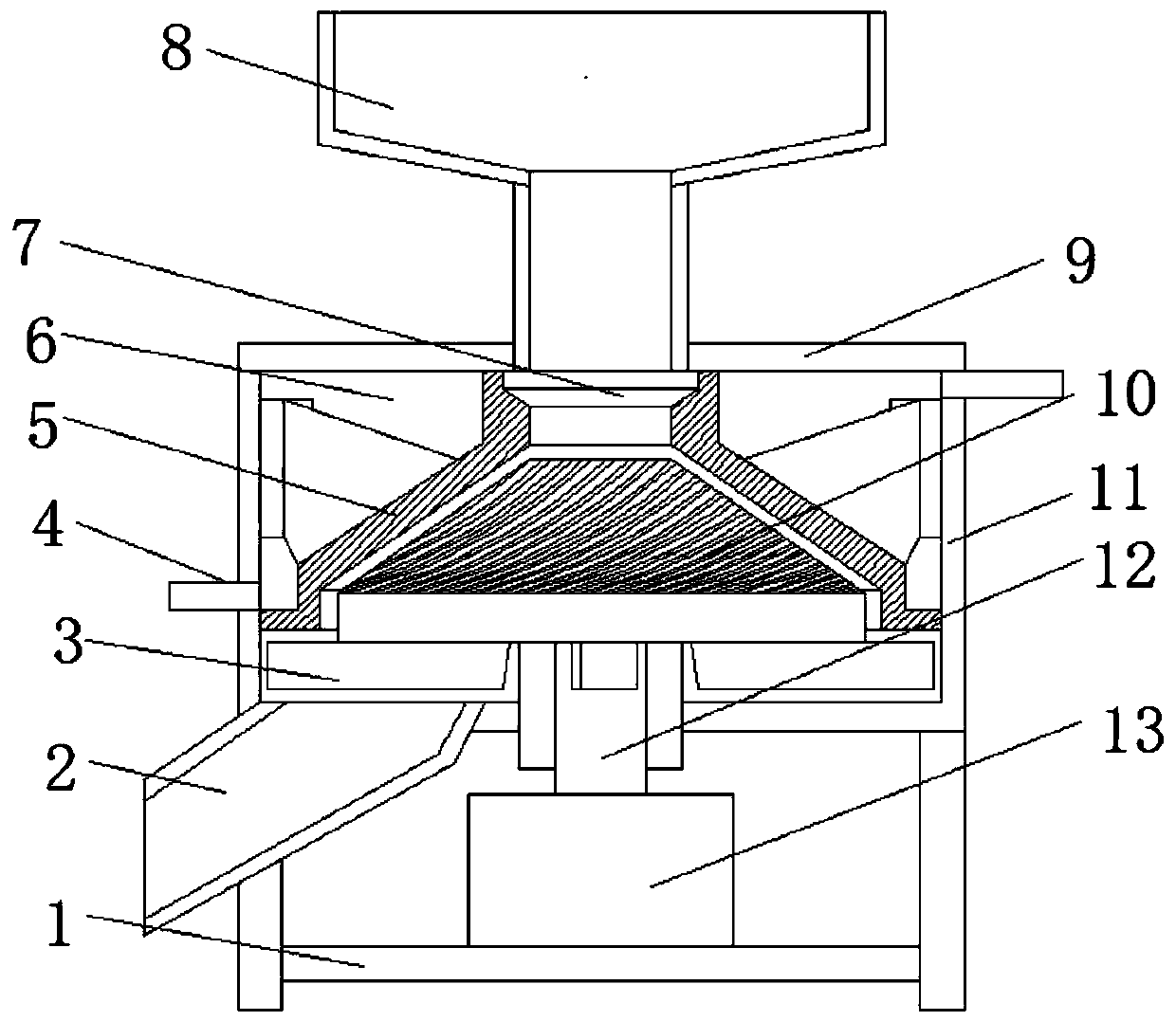

Constant-temperature motherwort powdering processing device

PendingCN110479423AMaintain a constant temperatureMaintain a constant humidity environmentCocoaGrain treatmentsWater bathsMotherwort

The invention discloses a constant-temperature motherwort powdering processing device which comprises a base. A powdering tank is connected to the top part of the base through a bolt; a cover plate isconnected to the top end of the powdering tank through a bolt; a feed hopper is connected to the top end of the cover plate through a bolt; an upper grinding ring is connected to the top end of the inner part of the powdering tank through a bolt; a feed chute port is formed in the top end of the upper grinding ring; a grinding chamber with a tapered structure is arranged at the bottom end of theupper grinding ring; a grinding pattern groove is formed in the inner wall of the grinding chamber; and a water bath chamber is formed among the upper grinding ring, the powdering tank and the cover plate. According to the constant-temperature motherwort powdering processing device provided by the invention, in the powdering process, heat-preservation hot water is fed into the inner part of the water bath chamber through a water bath pipe, so that a constant-temperature constant-humidity environment in the grinding chamber is kept. According to the constant-temperature motherwort powdering processing device provided by the invention, the temperature environment of the inner part of the grinding chamber is kept by directly utilizing a water bath manner, so that the temperature variation existed in the grinding and powdering process is avoided, and the motherwort processing quality is improved.

Owner:湖南志辉知识产权有限公司

Electroplating groove

PendingCN108103561AAvoid temperature differenceAnti-splashCellsTanksTemperature differenceEngineering

The invention discloses an electroplating groove including a main groove body, an overflow groove, a varying temperature groove and a varying temperature pump. An overflow outlet is formed in the outer wall of the main groove body, the overflow outlet is in communication with the overflow groove, and the varying temperature groove includes an inlet, an outlet and a varying temperature pipe. The overflow groove and the main groove are both in communication with a liquid inlet of the varying temperature pump, and a liquid outlet of the varying temperature pump is in communication with the inlet.The varying temperature pipe is arranged in the varying temperature groove, the outlet is in communication with the main groove body, and the inlet and the outlet of the varying temperature pipe arecorrespondingly in communication with a varying temperature liquid pipe. The liquid is prevented from splashing out by arranging the overflow outlet and the overflow groove. In order to avoid the temperature difference between the electroplating liquid due to the deep groove, the varying temperature groove is arranged. The electroplating liquid in the overflow groove and the main groove body is sent into the varying temperature groove for heat exchange by the varying temperature pump, so that firstly, the temperature of the electroplating liquid can be adjusted, and secondly it is ensured thatthe temperature of the electroplating liquid in the main groove body is all equal through continuous circulation so as to avoid the temperature difference.

Owner:遵义市汇川区吉美电镀有限责任公司

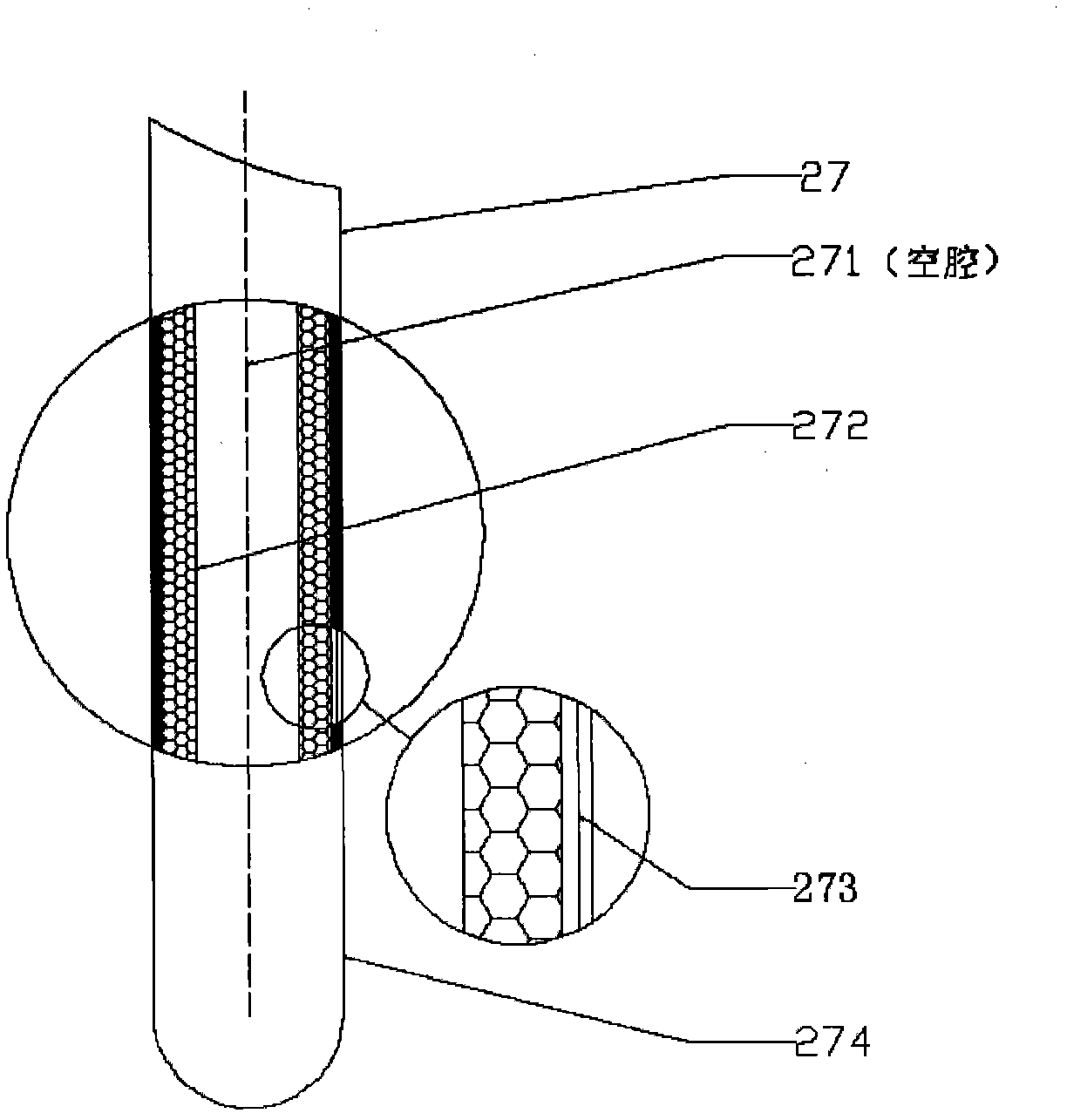

Solar vacuum heat-collecting tube with fluid mixer

InactiveCN103267377AImprove heat collection effectAvoid temperature differenceSolar heat devicesSolar thermal energy generationCollector deviceTemperature difference

The invention discloses a solar vacuum heat-collecting tube with a fluid mixer. The solar vacuum heat-collecting tube comprises an external glass tube, a metal tube packaged in the external glass tube and a packaging device. The packaging device further comprises metal corrugated tubes and kovar alloy tubes. Vacuum cavities are formed by the external glass tube and the metal tube. A sunlight selective-absorption coating is coated on the surface of the metal tube. The fluid mixer is arranged on the metal tube. The fluid mixer plays a role in disturbing and mixing of fluid in the solar vacuum heat-collecting tube to facilitate temperature of the fluid in the solar vacuum heat-collecting tube to be uniform, so that pipeline bending damages to the heat-collecting tube caused by an overlarge temperature difference between a condensation side and a non-condensation side are prevented, and bending and cracking of the insulating glass tube are avoided. With the technology of the fluid mixer, service life of the heat-collecting tube can be prolonged, and heat-collecting efficiency of a heat collector can be improved.

Owner:LIMA RENEWABLES

Power steering system, in particular for a motor vehicle

In a power steering system, in particular for a motor vehicle, comprising a servo-motor, which drives an axially displaceable component by way of a steering nut that is mounted rotatably, but axially non-displaceably in a gear housing, the steering nut is mounted in the gear housing in a radial bearing comprising an inner ring and an outer ring. A heat-insulating intermediate element is disposed between the outer ring of the radial bearing and the gear housing, or a cover of the gear housing, and / or between the inner ring of the radial bearing and the steering nut for the purpose of thermal decoupling.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

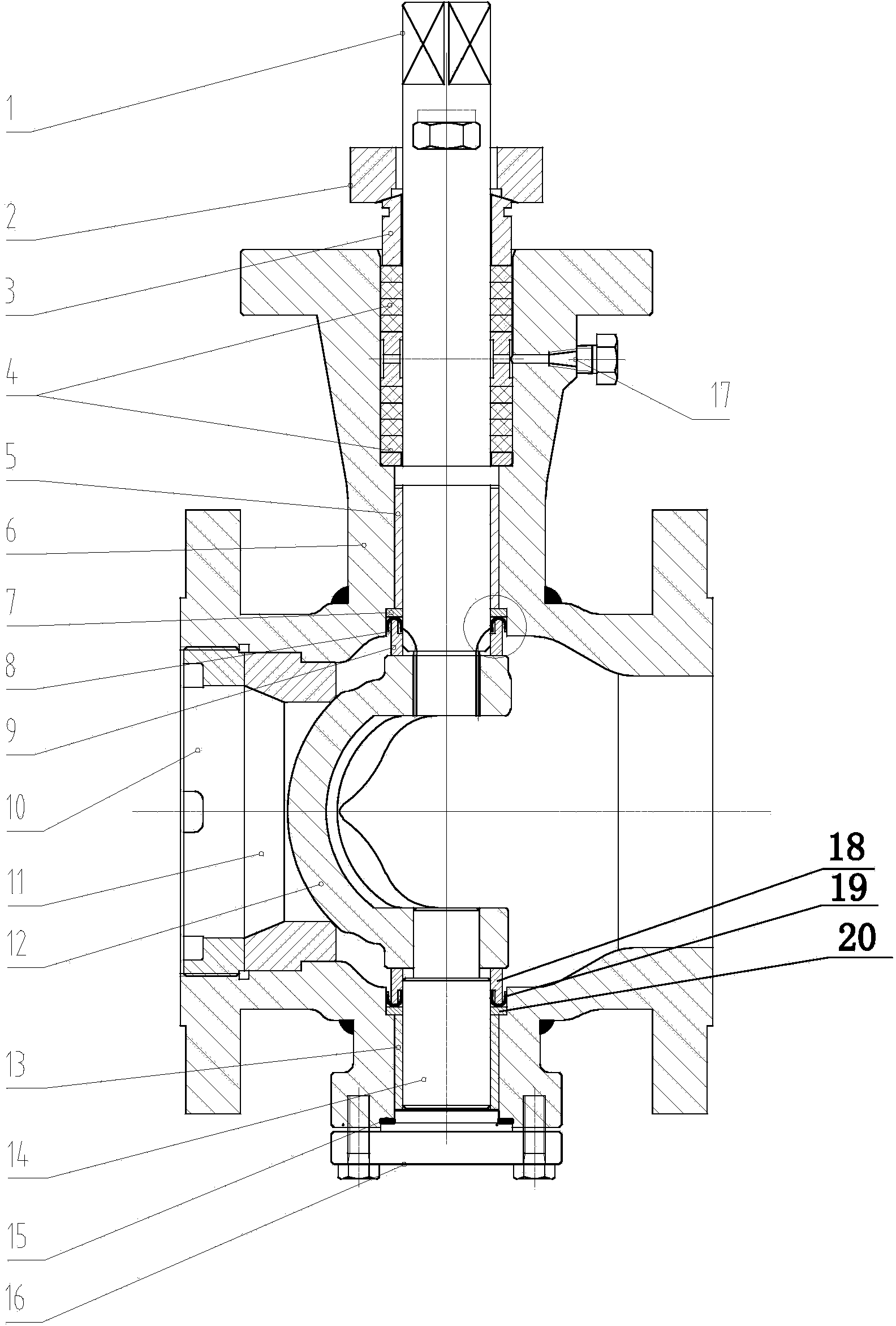

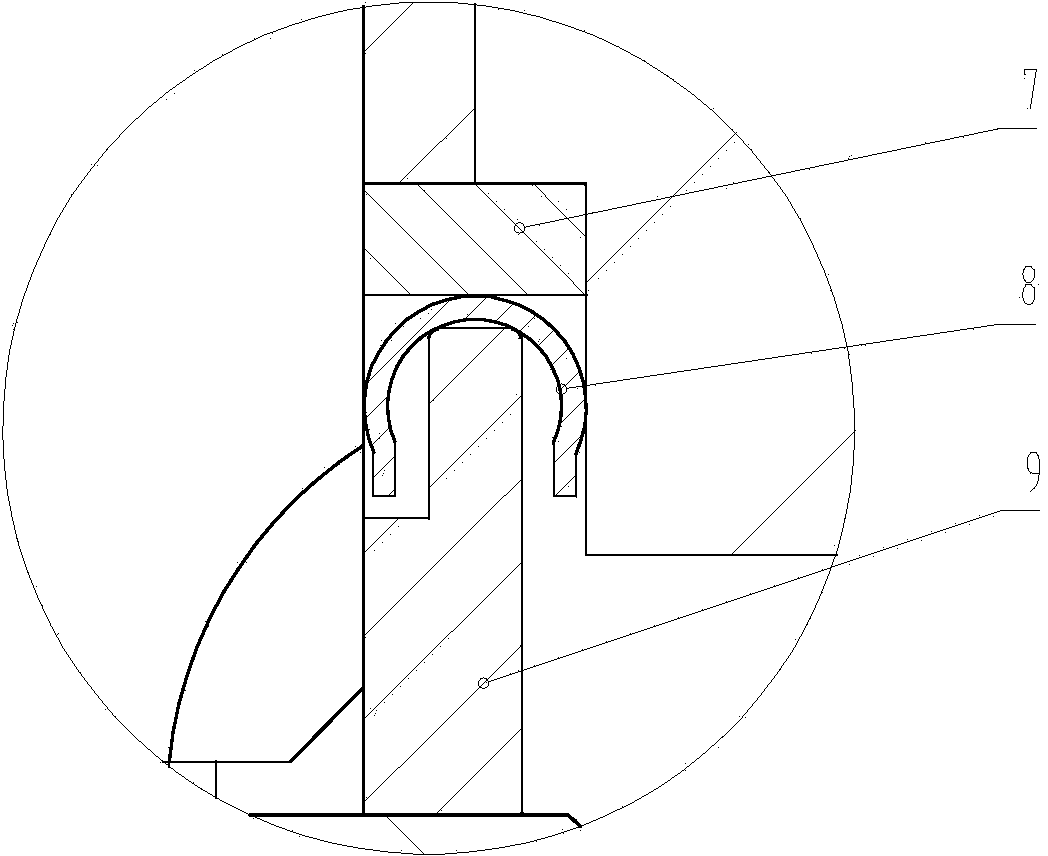

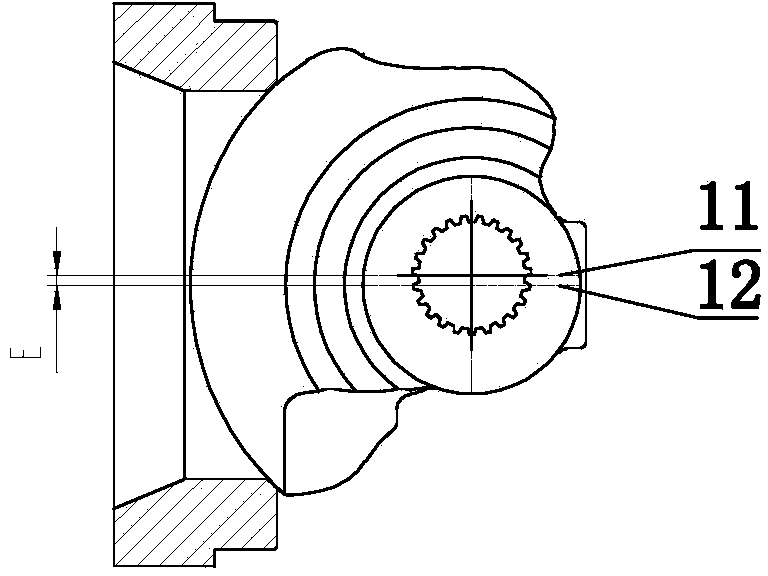

Wear-resisting small eccentric V-ball regulating valve special for salt chemical engineering

ActiveCN103591330AAvoid corrosionPrevent crystallizationPlug valvesValve housingsDrive shaftStructural engineering

The invention relates to a wear-resisting small eccentric V-ball regulating valve special for salt chemical engineering. The wear-resisting small eccentric V-ball regulating valve comprises a valve body, a packing box is machined on the valve body, a packing seal assembly, a packing gland and a packing pressing plate are sequentially arranged in the packing box and connected with the valve body in a fastening mode; a small eccentric valve ball is concentric with a transmission shaft and a driven shaft, the small eccentric valve ball is connected with the transmission shaft and the driven shaft and arranged in the valve body, an upper bush and the transmission shaft are arranged in the valve body from the top, a lower bush and the driven shaft are arranged in the valve body from the bottom, and a valve seat and a pressing ring are arranged in the valve body from the side face; a first distance adjustment pad and a second distance adjustment pad are arranged on the upper end face and the lower end face of the small eccentric valve ball; a first C-shaped seal ring is arranged in a clamping groove between the valve body and the first distance adjustment pad; a first supporting ring is arranged between the upper bush and the lower bush, and a second supporting ring is arranged between the first C-shaped seal ring and a second C-shaped seal ring. According to the wear-resisting small eccentric V-ball regulating valve, blocking of a flow channel of the valve body can be effectively prevented, corrosion of a cavity by crystals can be effectively prevented; the adjustment accuracy of the valve can be improved; scouring and corrosion of media on the valve body and components in the valve can be reduced; particle media can be prevented from entering valve shaft gaps, the adjustment accuracy of the valve can be greatly improved, and the service life of the valve can be greatly prolonged.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Tea leaf enzyme deactivation device

The invention belongs to the field of tea processing, and particularly discloses a tea leaf enzyme deactivation device. The device comprises a frame; an enzyme deactivation barrel is fixed on the frame; first air bags and second air bags are staggered on the inner wall of the enzyme deactivation barrel; the upper part of each first air bag is provided with a first projection; a first spring is fixedly arranged between the two inner side walls at each first projection and in each first air bag; each first projection is provided with a first magnetic block; the inner wall of the upper end of each first air bag is provided with a first air inlet hole; the outer wall of the upper end of each first air bag is provided with a first air outlet hole; the outer wall of the lower end of each secondair bag is provided with a second air inlet hole; the outer wall of the lower end of each second air bag is provided with a second air outlet hole; a stirring shaft is rotatably connected onto the frame; the stirring shaft is provided with some supporting rods which are close to the first projections and the second projections and are uniformly distributed in circumferential direction; and one ends, far from the stirring shaft, of the supporting rods are fixedly connected to an electromagnet for repelling first magnetic blocks and second magnetic blocks. The adopted scheme of the invention solves the problem that the tea leaves are easy to heap up during the enzyme deactivation process.

Owner:湖北小稀藤生物科技有限公司

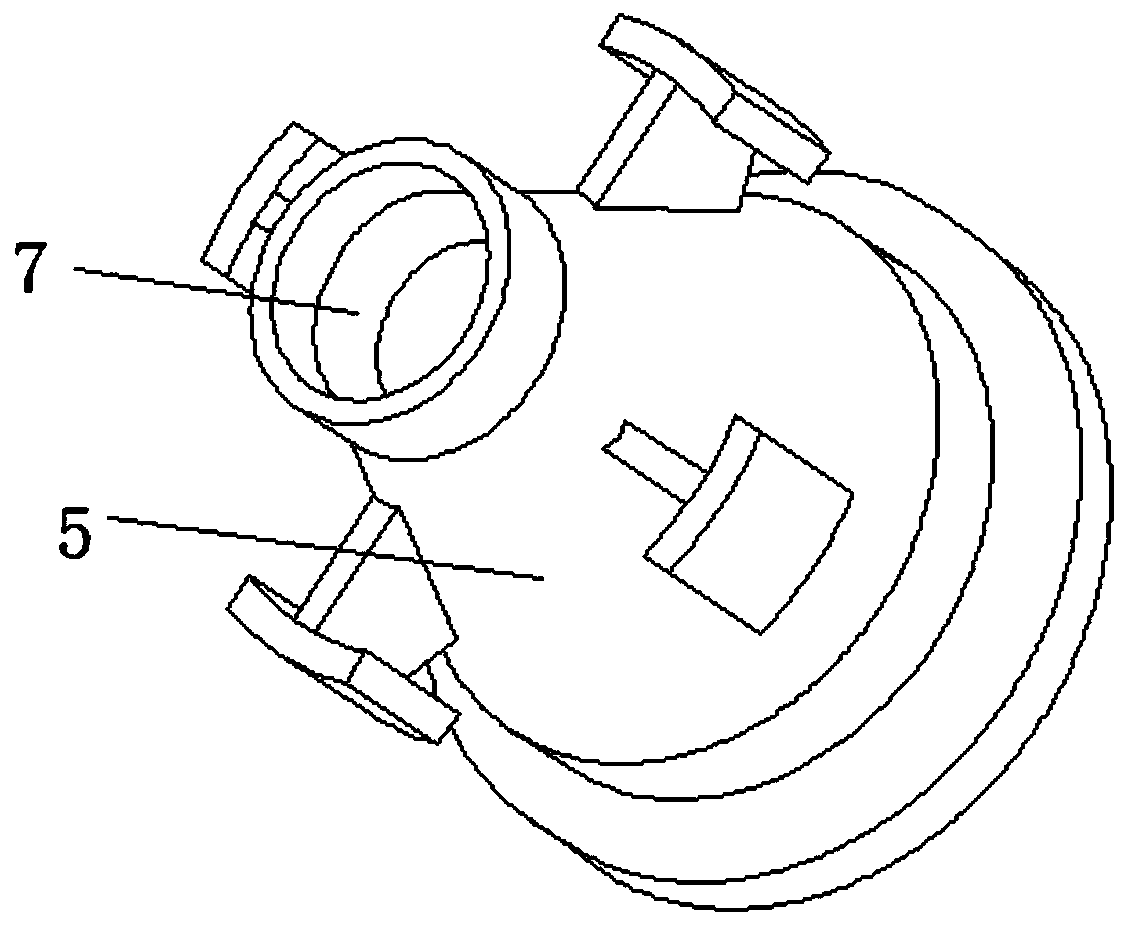

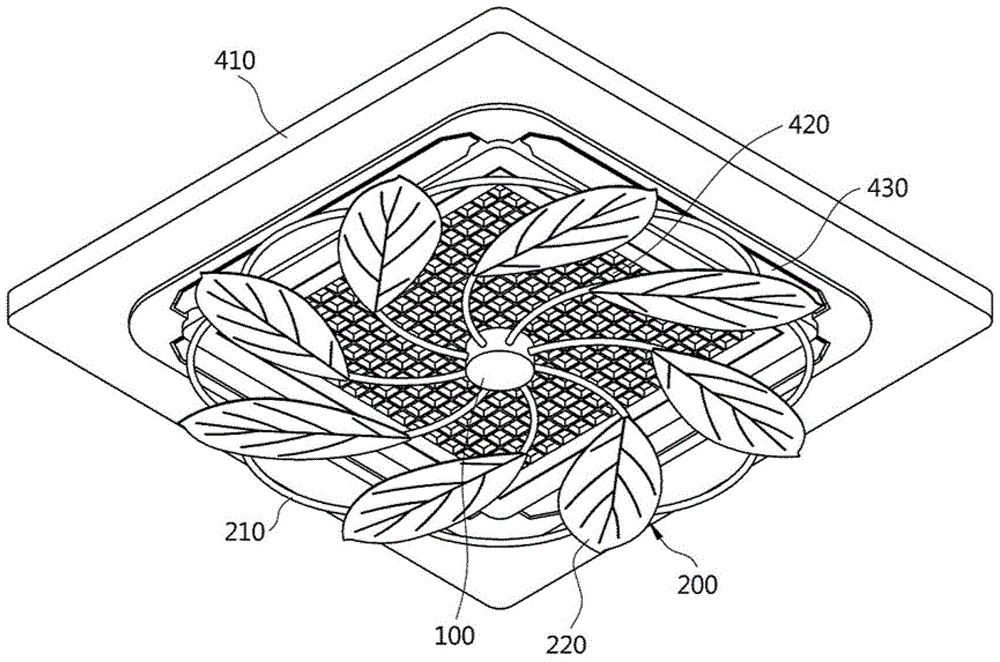

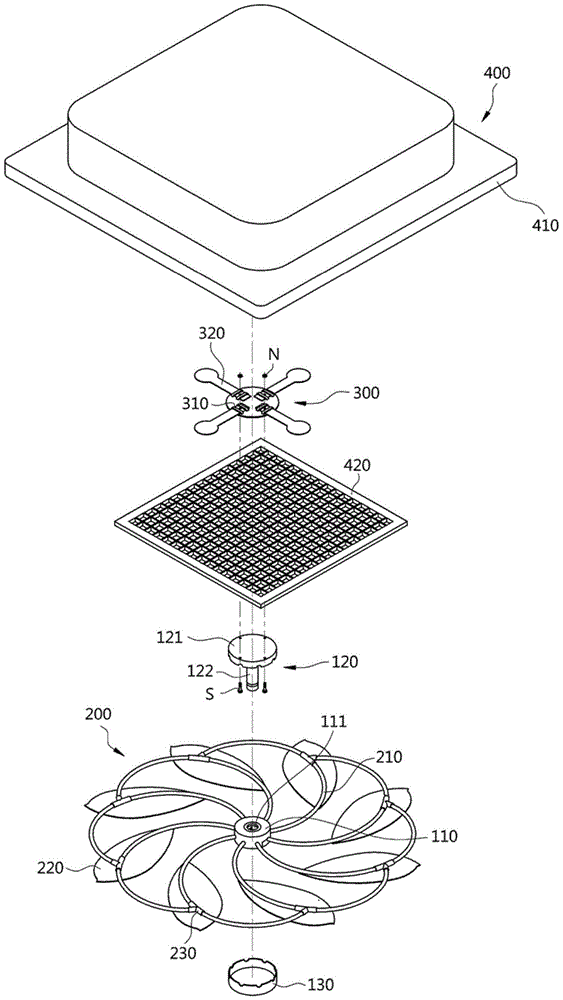

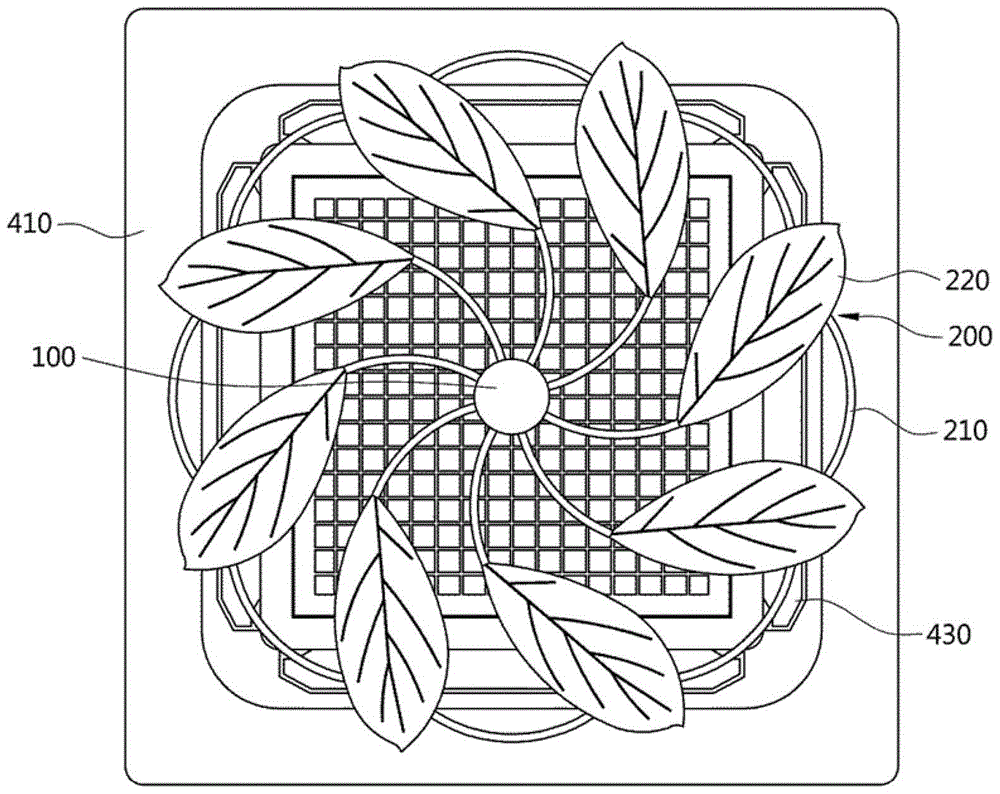

Multiblade diffusion fan assembly for attachment to ceiling cassette air conditioner

InactiveCN105605670AReduce consumptionAdd natural decoration side effectDucting arrangementsLighting and heating apparatusEngineeringElectrical and Electronics engineering

The present invention relates to a multiblade diffusion fan assembly for attachment to a ceiling cassette air conditioner, which is to be attached to an indoor unit of the ceiling cassette air conditioner, the multiblade diffusion fan assembly being driven without power by receiving a discharge air current, generating an air current in an outwardly radial direction by introducing discharged air in the direction of a hub shaft, and inducing the discharge air current to be diffused widely in an indoor space. The purpose of the present invention is to overcome a limitation of the air current discharge structure of an indoor unit of a conventional ceiling cassette air conditioner. The present invention forms a multiblade diffusion fan for attachment to an indoor unit of a ceiling cassette air conditioner, which can be attached without changing the structure of the indoor unit of the ceiling cassette air conditioner, is driven without power by receiving a discharge air current, discharged from a discharge port of the indoor unit of the air conditioner, and generates an air current in an outwardly radial direction by introducing discharged air in the direction of a hub shaft and induces the discharge air current to be diffused widely in an indoor space.

Owner:丘冀升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com