Device and method for the in situ calibration of a thermometer

An in-situ calibration and temperature measurement technology, applied in the field of temperature devices, can solve problems such as errors and inaccuracies, and achieve the effect of compact structure, high precision and high precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

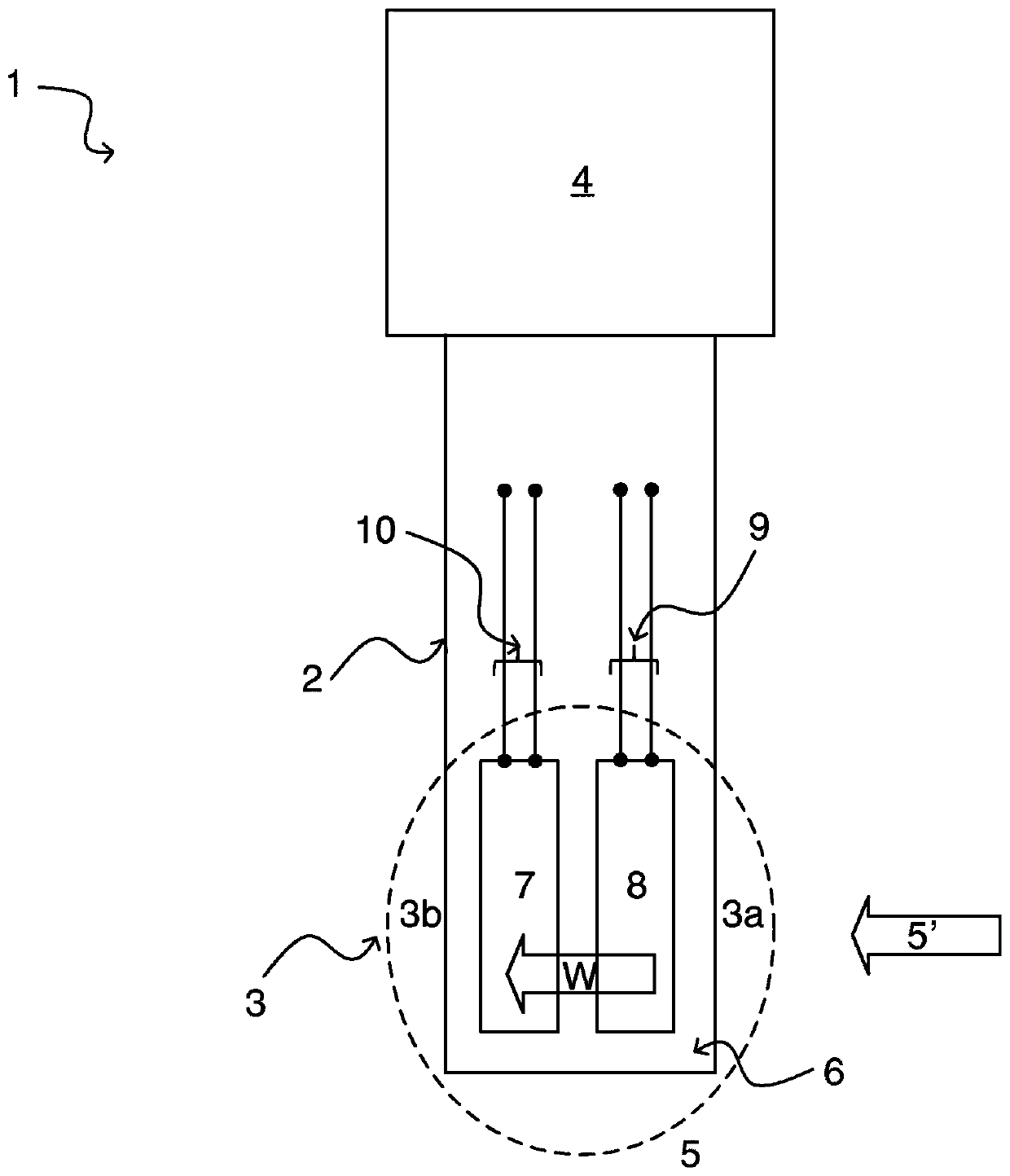

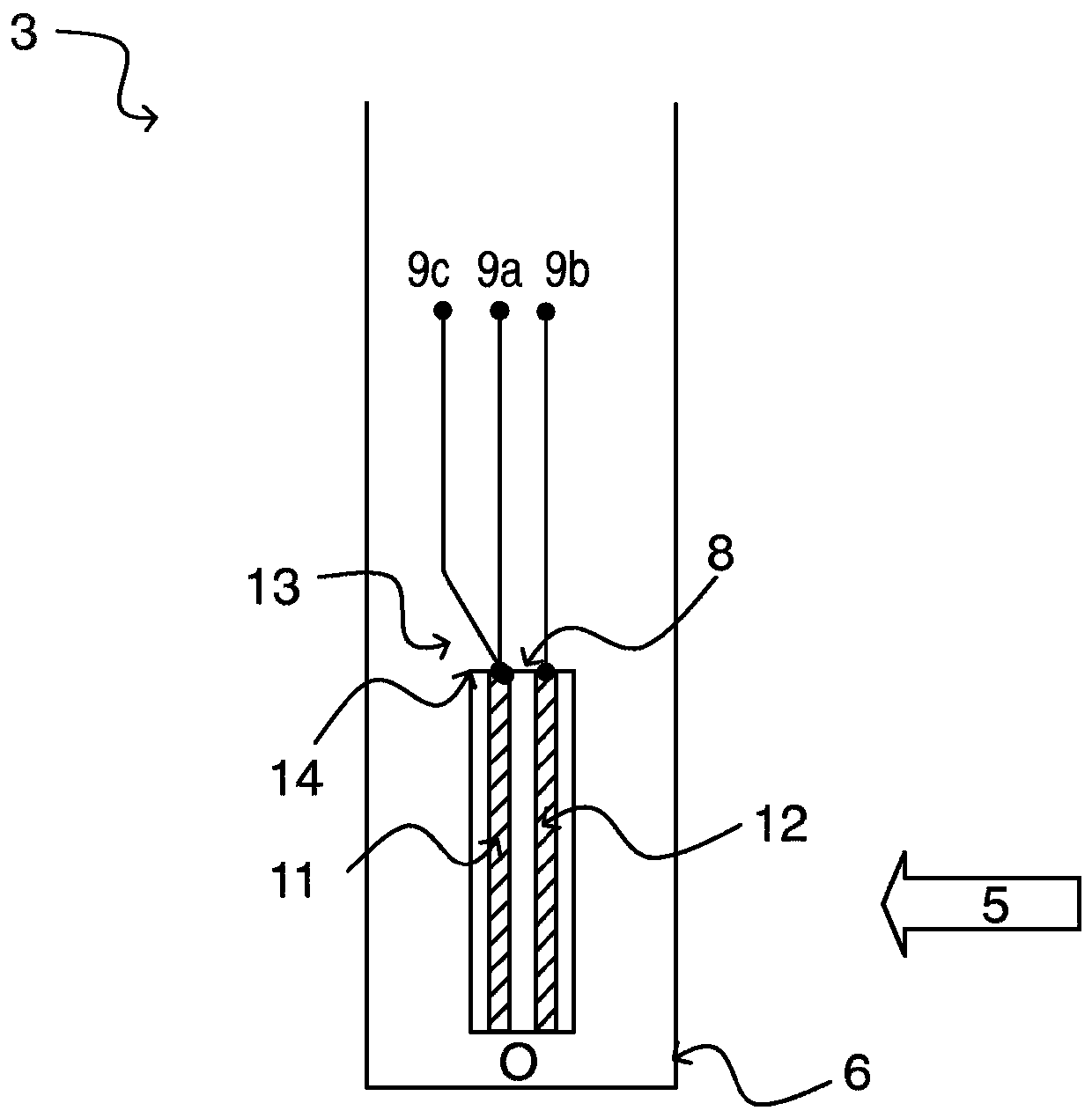

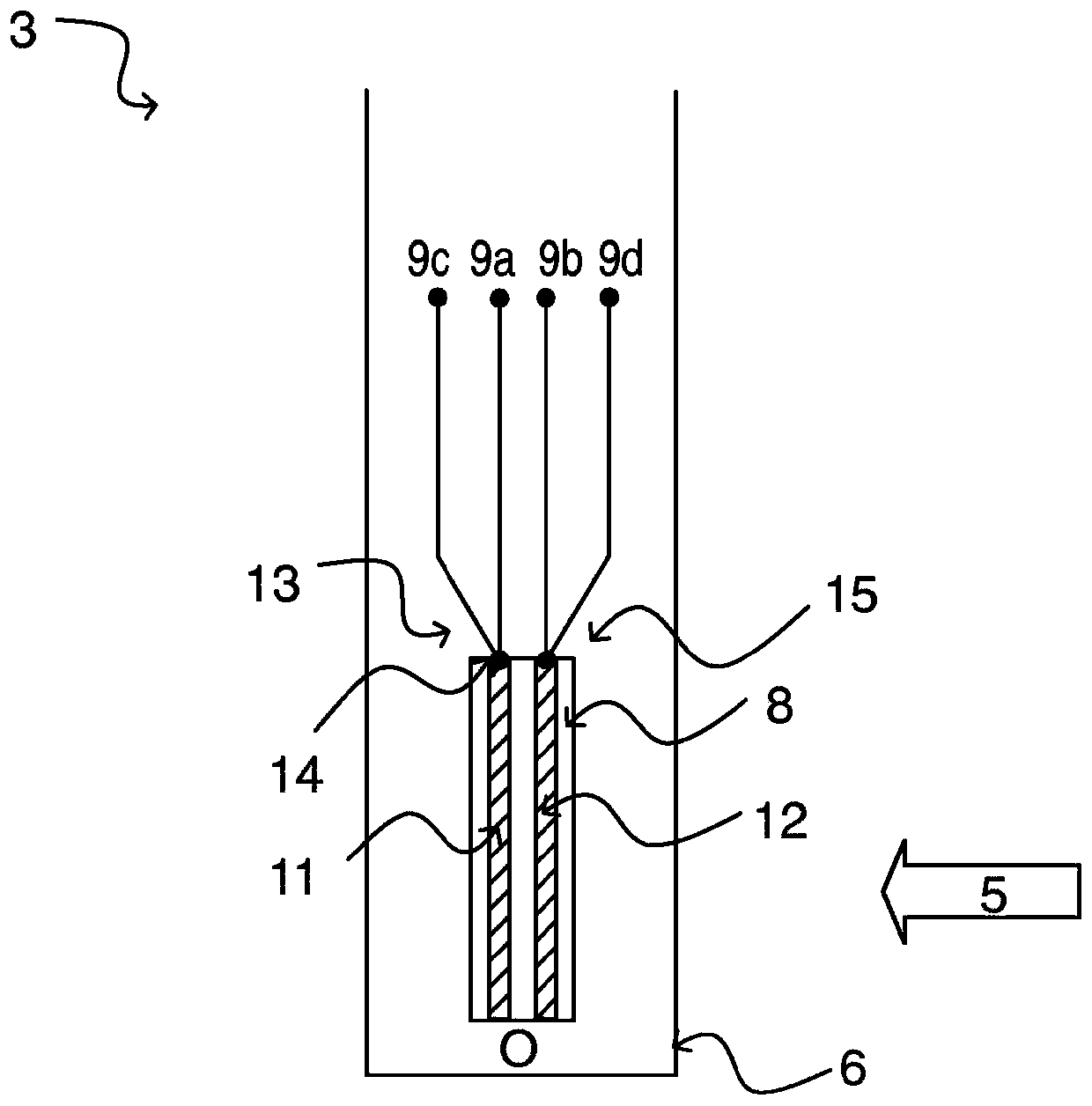

[0050] figure 1 is a schematic diagram of a thermometer 1 with a protective tube 2 and an electronic unit 4 according to the prior art. The part of the protective tube 2 facing the liquid 5 is also referred to as the sensor head 3 . The inner volume of the sensor head 3 is filled with a filler 6 , especially an electrically insulating filler 6 , especially cement. Furthermore, a temperature sensor 7 and a reference element 8 are arranged inside the sensor head 3 , each of which is in contact, in particular electrically, with electronic Unit 4 is connected. The temperature sensor 7 is, for example, a resistance element or a thermocouple. The reference element 8 instead consists at least partially of a material, in which case at least one phase transition of at least second order occurs at at least one predetermined phase transition temperature in the temperature range relevant to the operating device. The number of connecting wires 9 , 10 required for contacting the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com