Tea leaf enzyme deactivation device

A greening device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of easy accumulation of tea leaves, and achieve the effect of uniform heating, large contact area, and avoid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

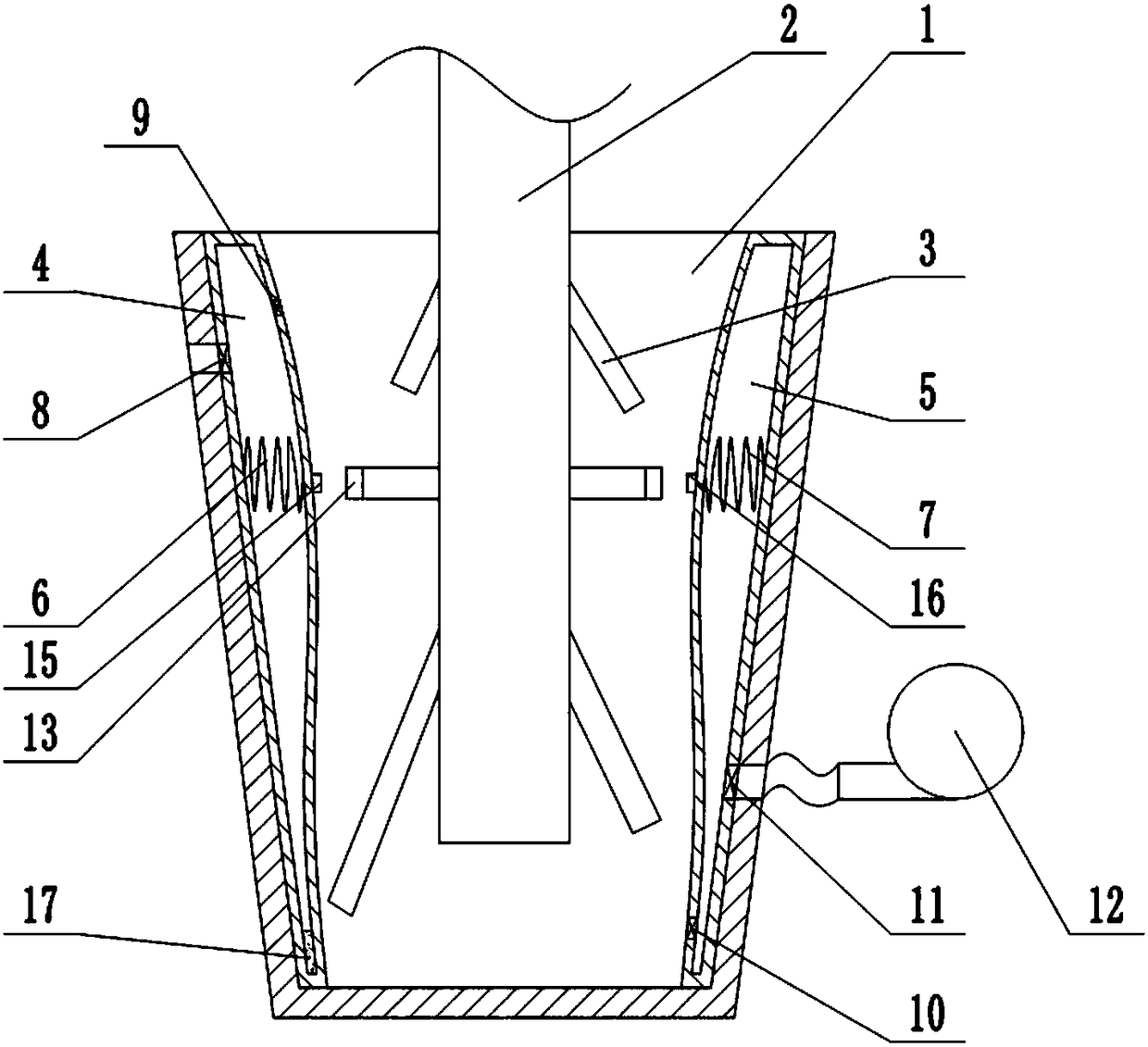

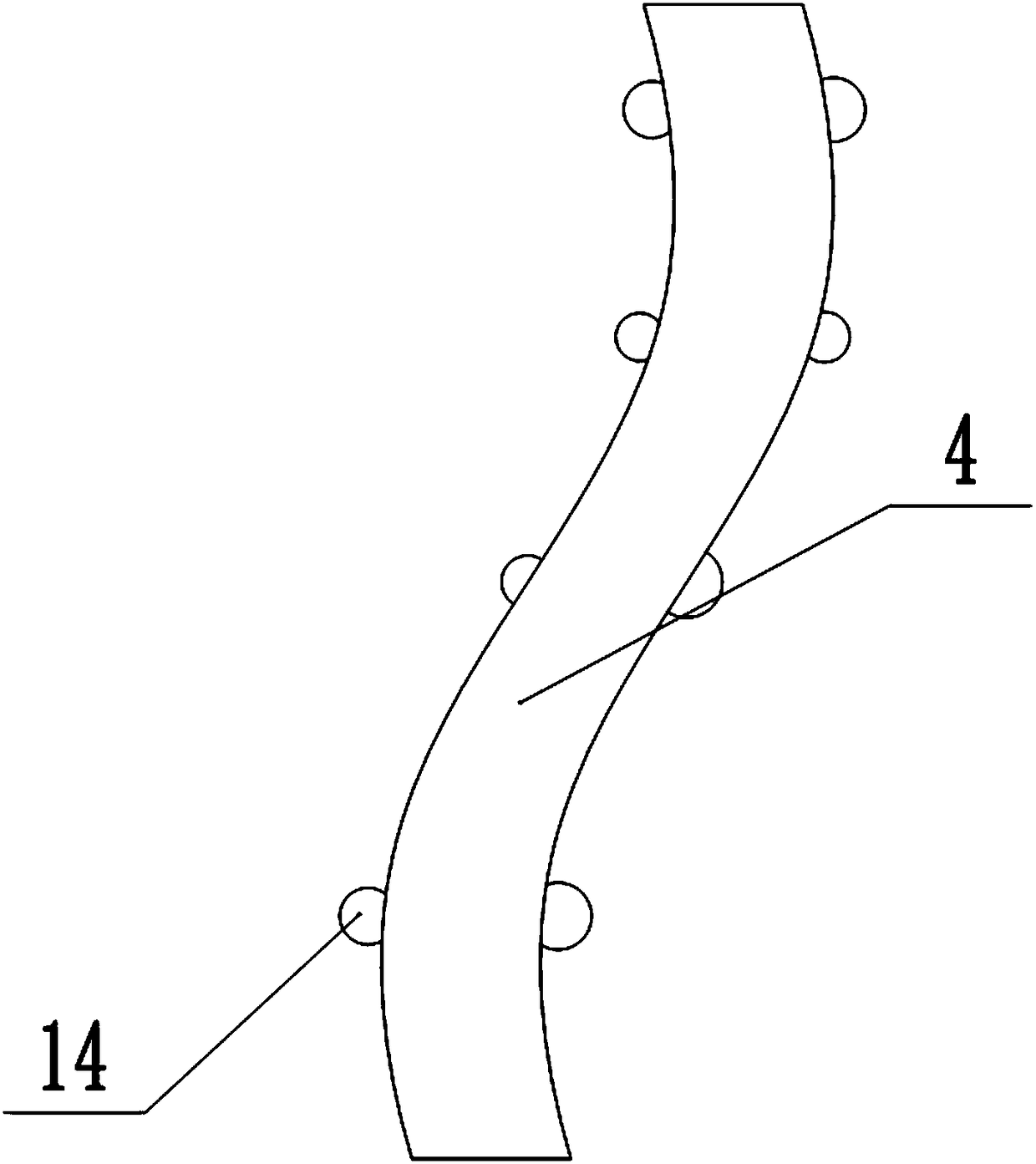

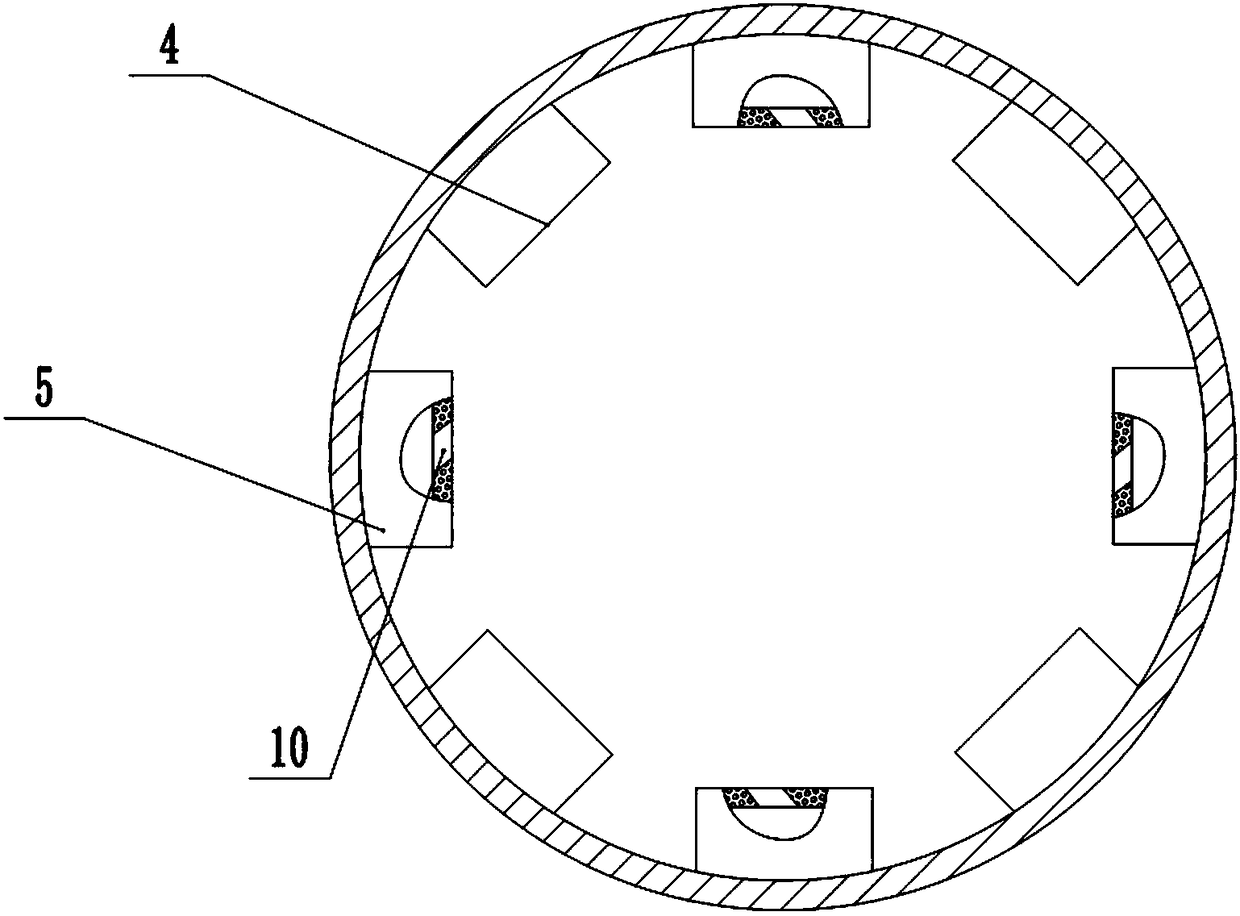

[0026] The reference signs in the accompanying drawings of the description include: the greening barrel 1, the stirring shaft 2, the stirring rod 3, the first air bag 4, the second air bag 5, the first spring 6, the second spring 7, the first air outlet 8, the first Air intake hole 9, second air outlet hole 10, second air intake hole 11, hot air blower 12, electromagnet 13, synapse 14, first magnetic block 15, second magnetic block 16, sponge layer 17.

[0027] Such as figure 1 Shown, the tea green fixing device comprises a frame, and the green fixing bucket 1 is fixed on the frame, and the green fixing bucket 1 is in the shape of a round platform, and the outer diameter of the upper end of the fixing bucket 1 is greater than that of the lower end. The frame is positioned at the top of the killing bucket 1 and is provided with a windshield. Four first airbags 4 and four second airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com