Intelligent welding method, system and device and storage medium

A welding method and intelligent technology, applied in auxiliary devices, welding equipment, program-controlled manipulators, etc., can solve problems such as difficult machine adjustment, affecting product quality and service life, and long time-consuming, so as to improve work efficiency and product quality , Reduce the workload of manual debugging and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

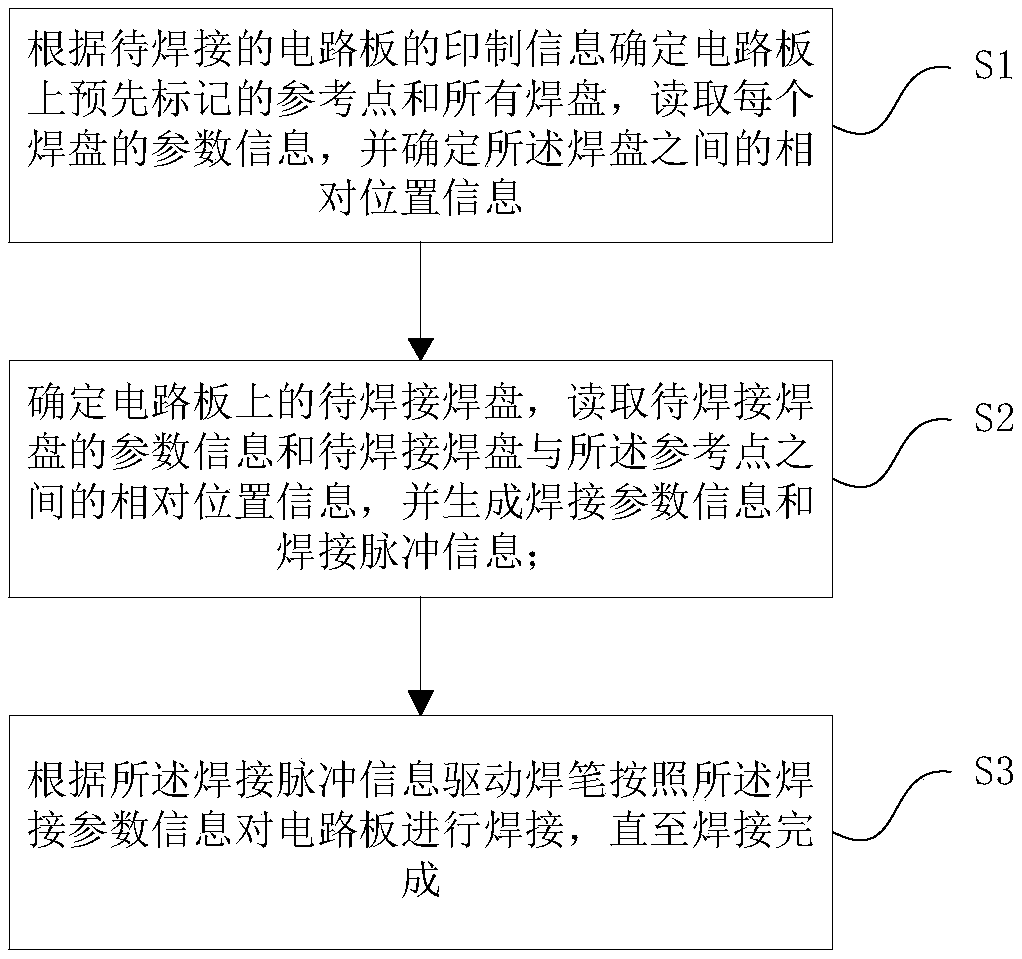

[0054] Such as figure 1 Shown, a kind of intelligent welding method comprises the following steps:

[0055] Step 1: Determine the pre-marked reference points and all pads on the circuit board according to the printed information of the circuit board to be soldered, read the parameter information of each pad, and determine the relative position information between the pads;

[0056] Step 2: Determine the pad to be welded on the circuit board, read the parameter information of the pad to be soldered and the relative position information between the pad to be soldered and the reference point, and generate welding parameter information and welding pulse information;

[0057] Step 3: Drive the soldering pen according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com