Patents

Literature

49results about How to "Determine the length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

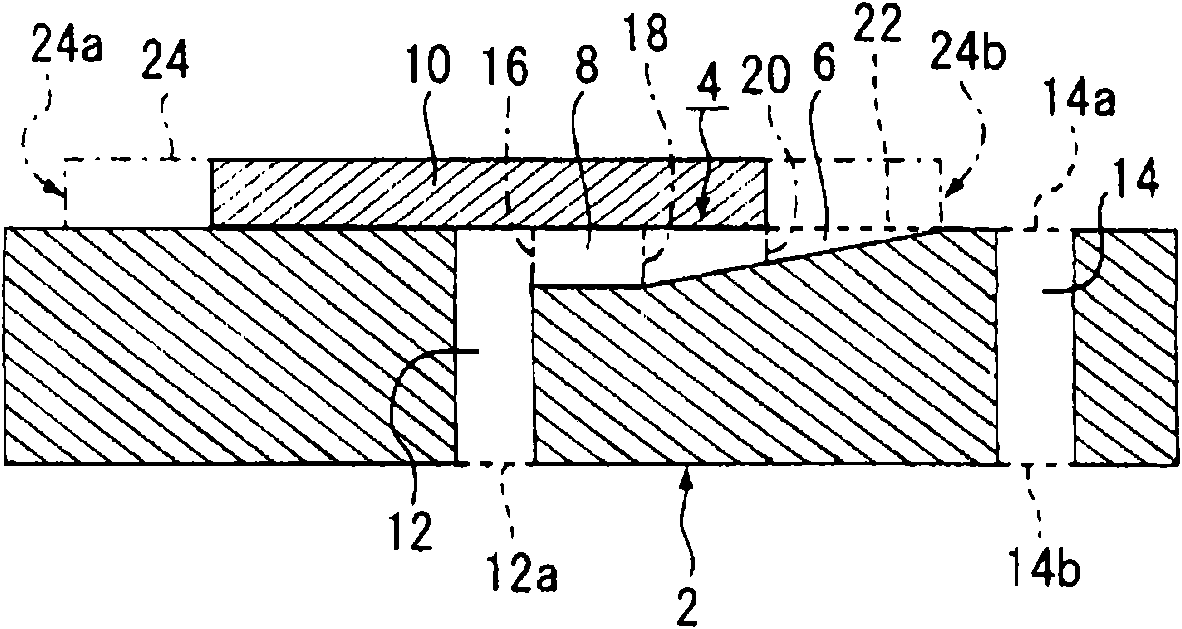

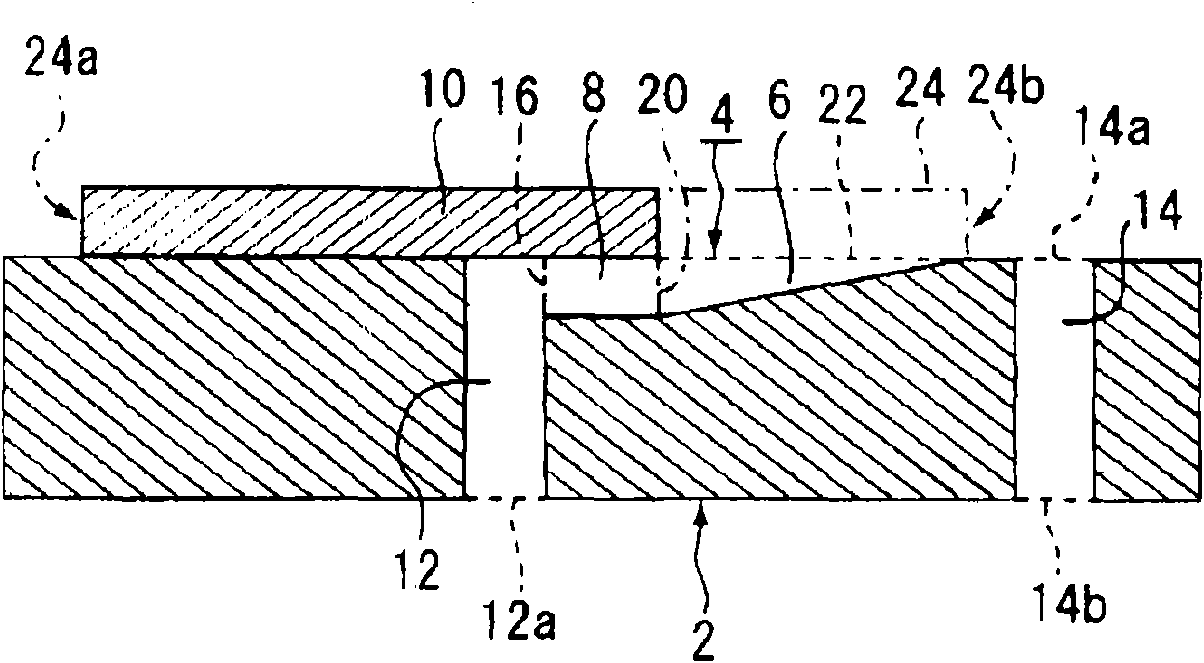

Semiconductor detector for measuring radiation and imaging device

ActiveCN101577284AOvercoming the difficulty of being thin and not suitable for preparationOvercome too thinTelevision system detailsColor television detailsSignal processing circuitsSemiconductor detector

The invention discloses a semiconductor detector for measuring radiation and an imaging device, wherein the semiconductor detector comprises a semiconductor medium capable of absorbing radiation to be measured of at least one energy section, an anode electrode arranged on one surface of the semiconductor medium, a cathode electrode arranged on another surface of the semiconductor medium opposite to the first surface, and a signal processing circuit which is connected with the anode electrode and the cathode electrode and processes a detected signal as a numerical value representing energy deposition rate of the radiation, wherein the semiconductor medium receives the incident radiation along the direction parallel with the electrode surfaces, and the anode electrode and the cathode electrode are divided into a plurality of sub-electrode couples at intervals along the incident direction of the radiation for detecting the energy deposition rate of the radiation of corresponding energy sections respectively.

Owner:NUCTECH CO LTD +1

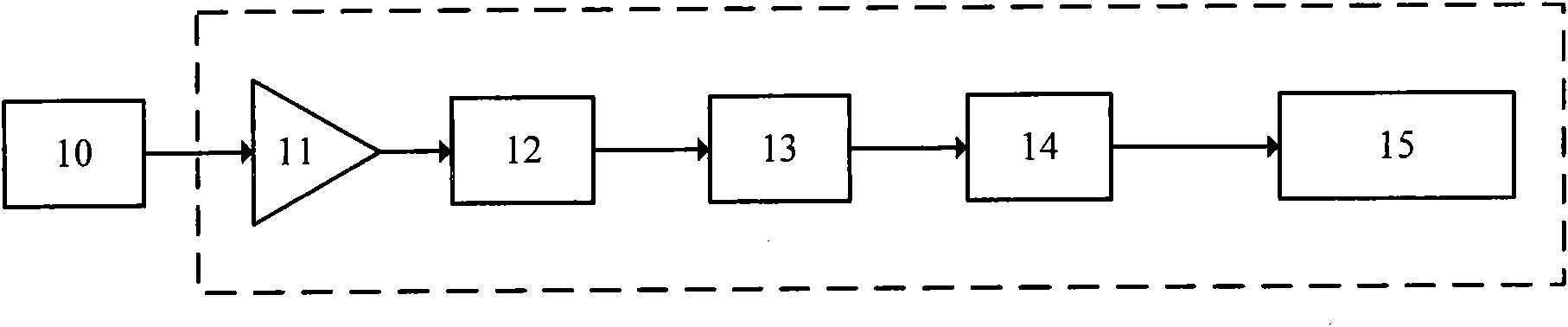

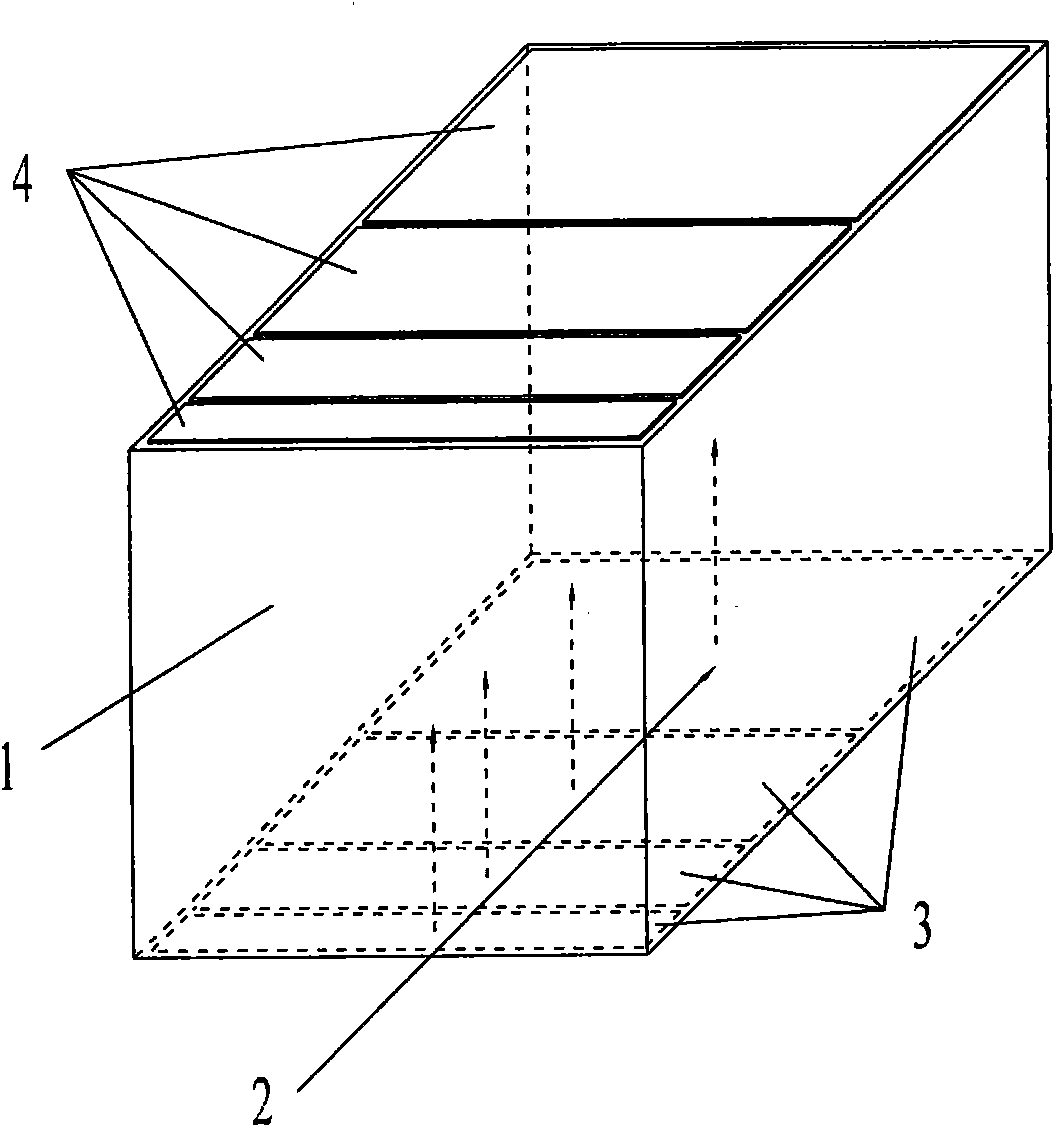

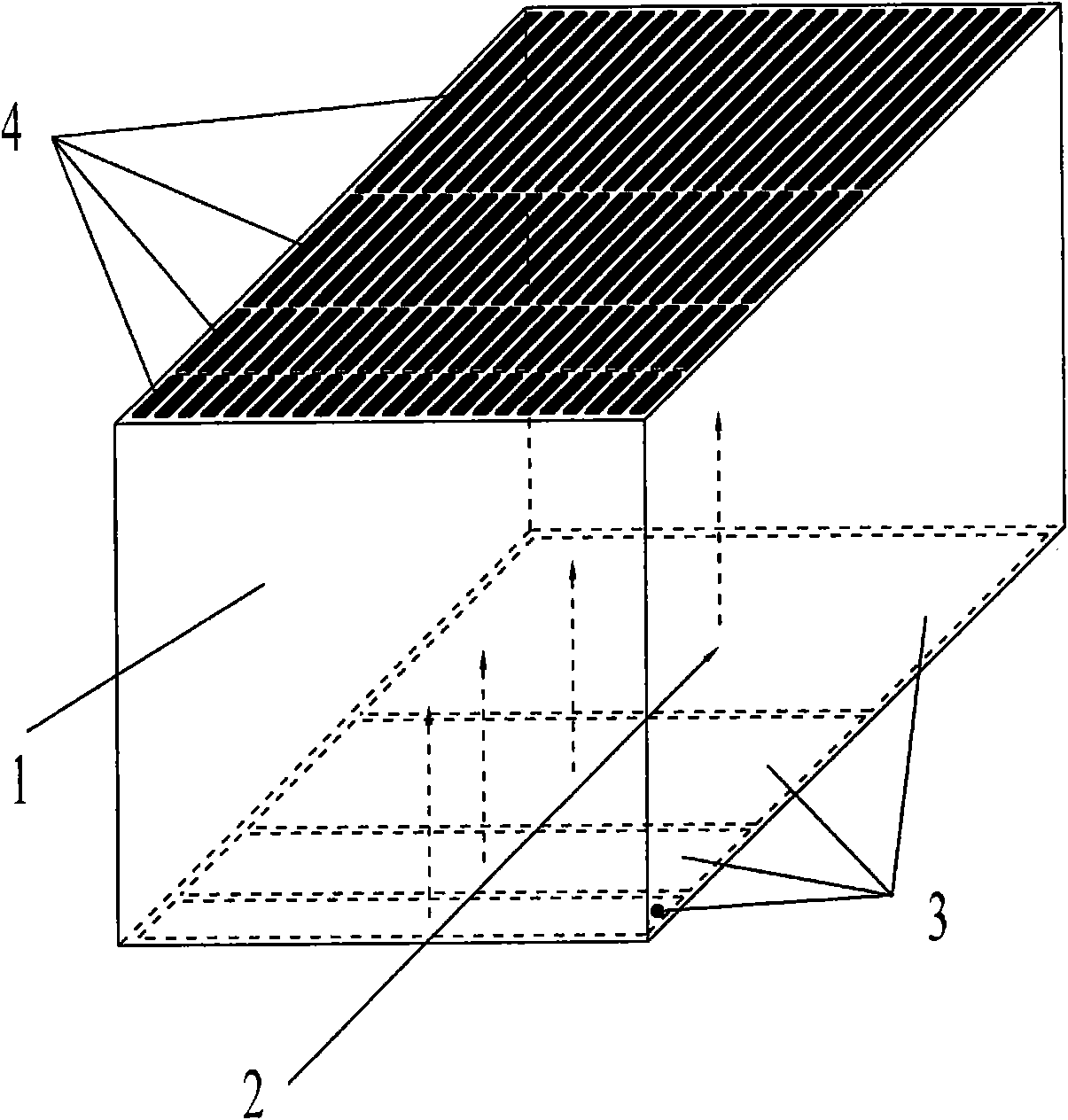

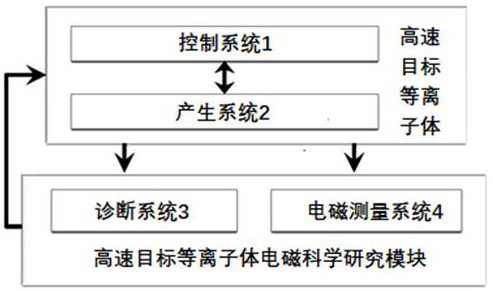

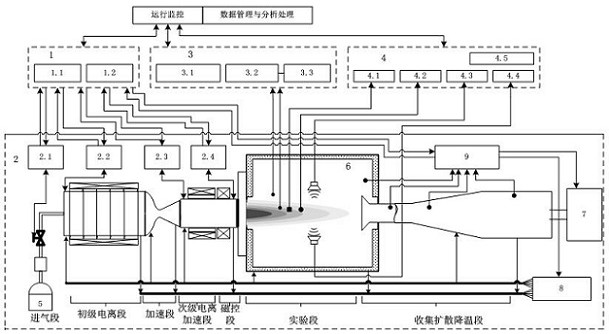

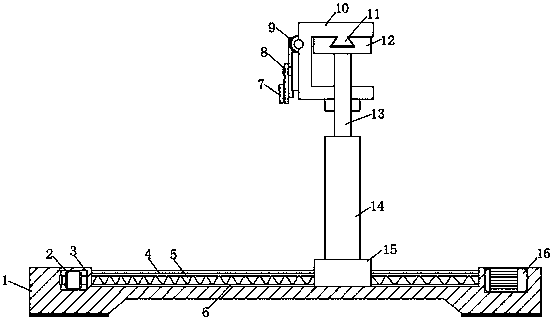

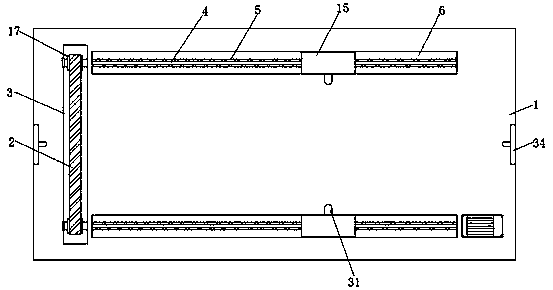

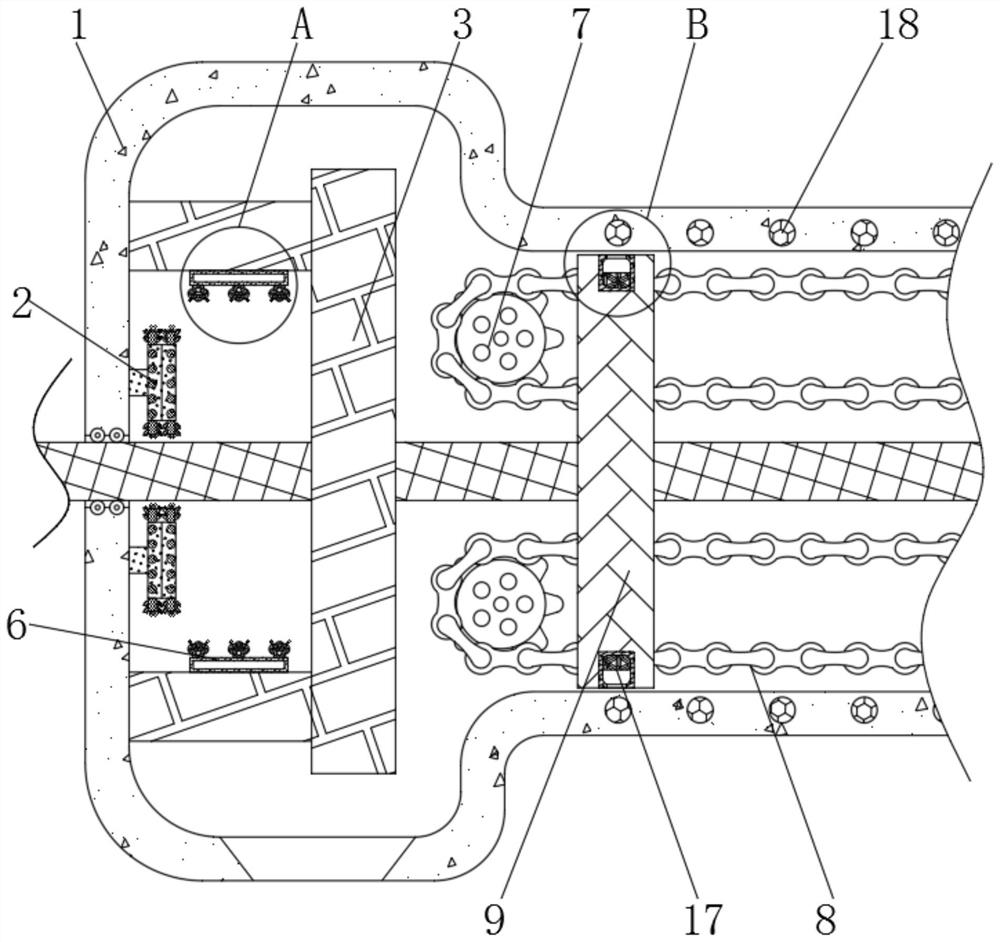

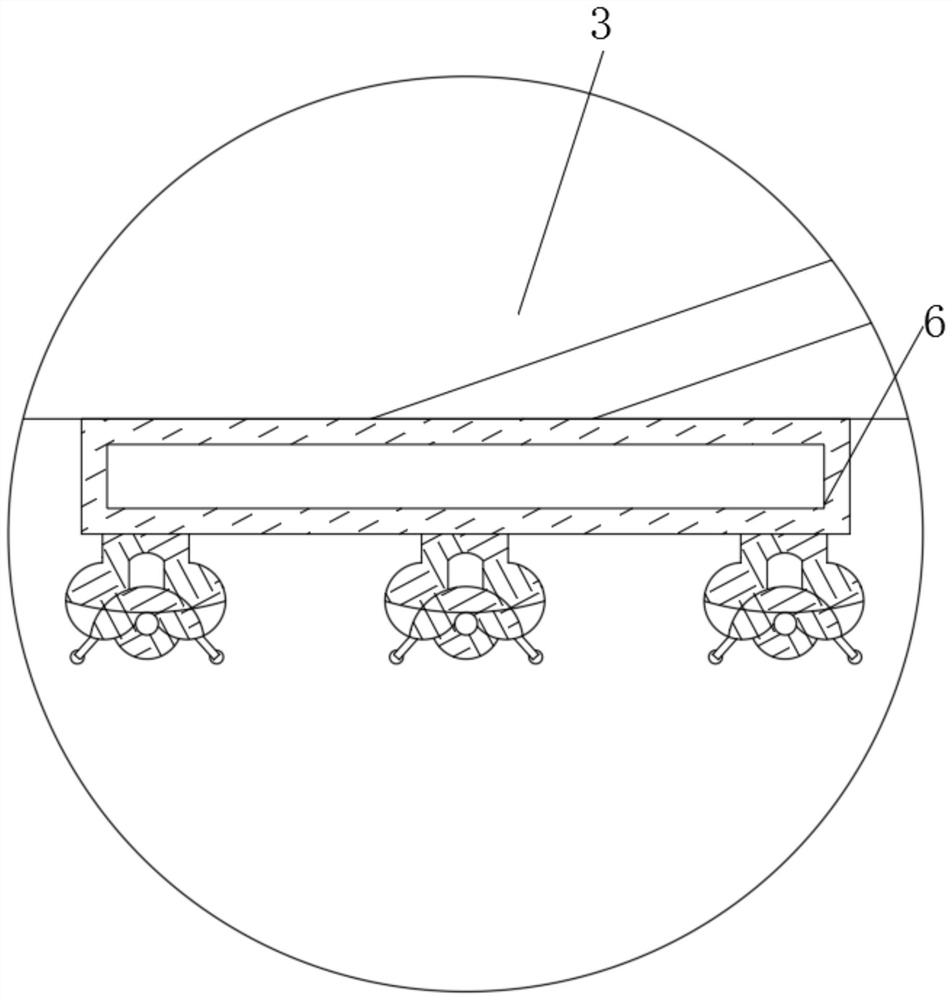

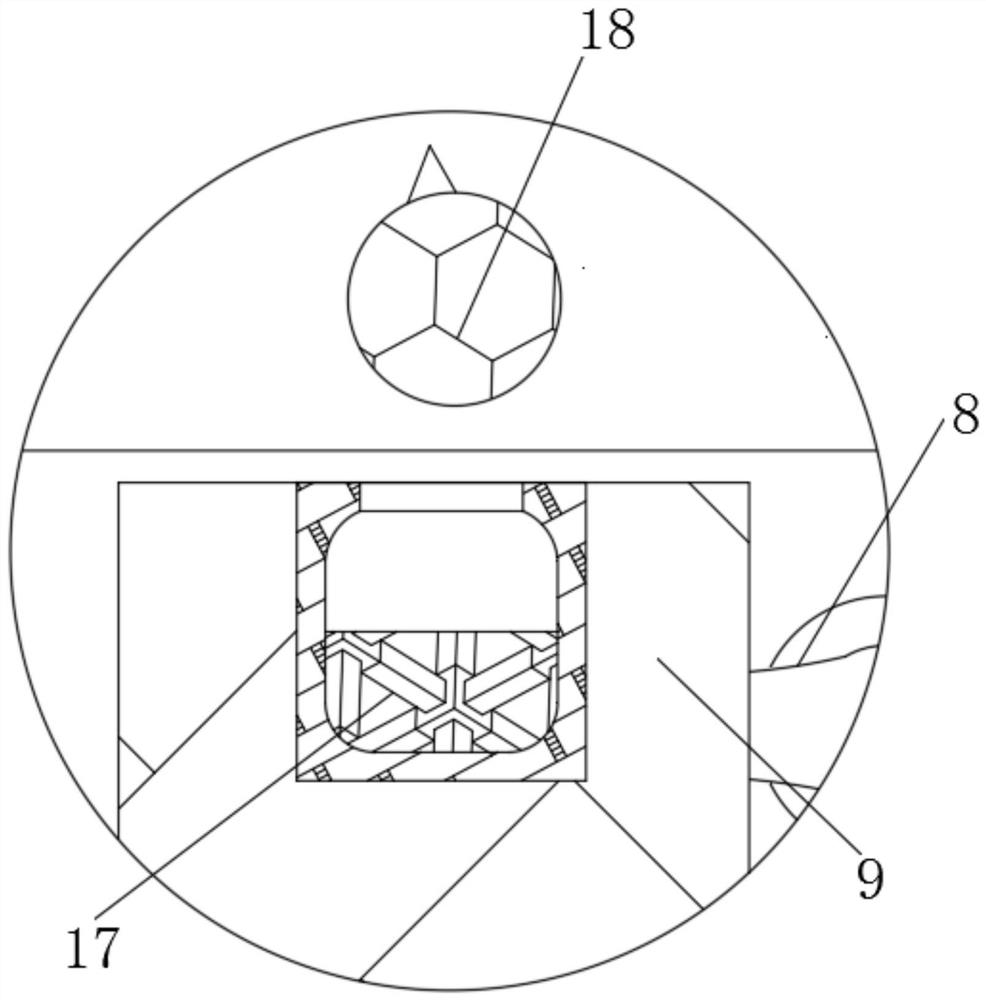

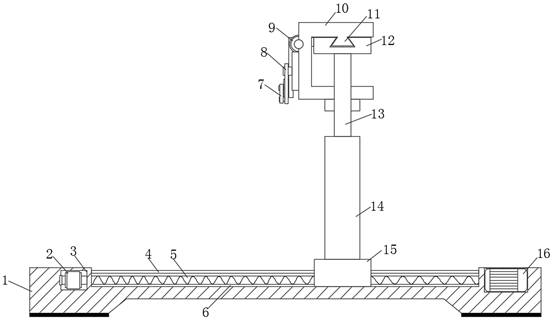

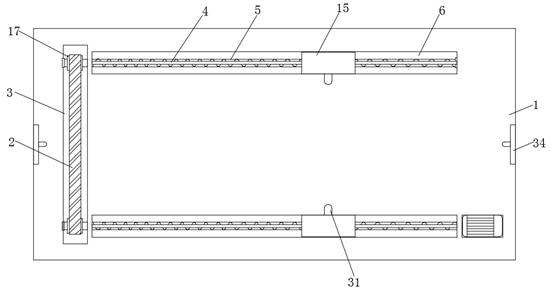

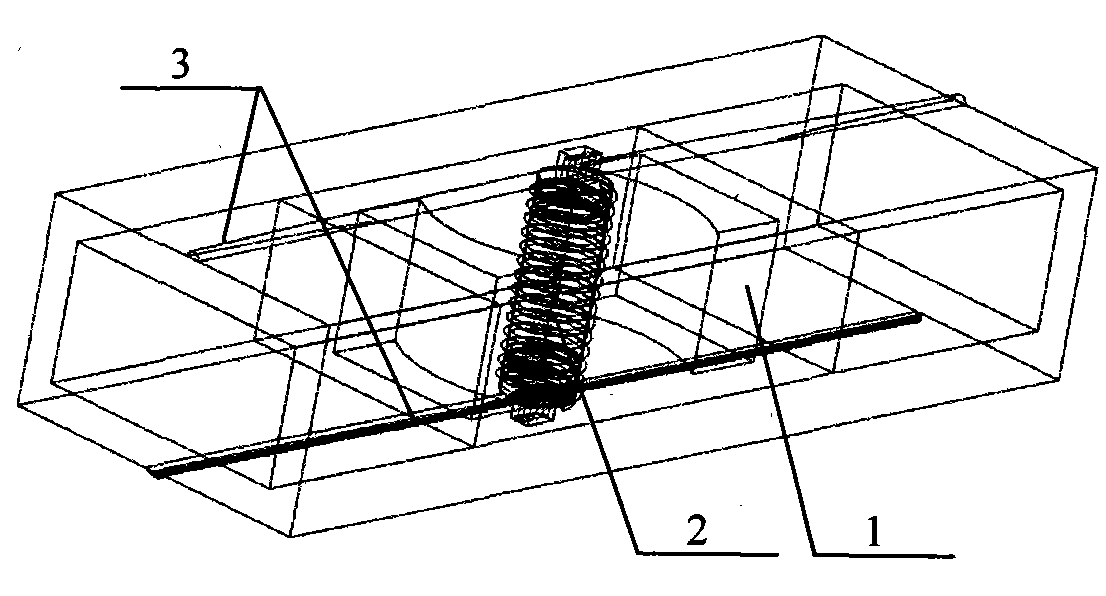

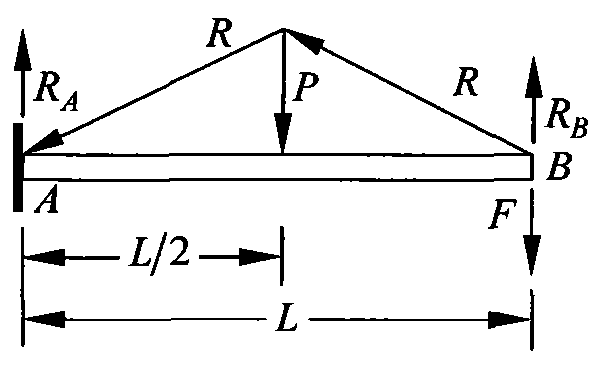

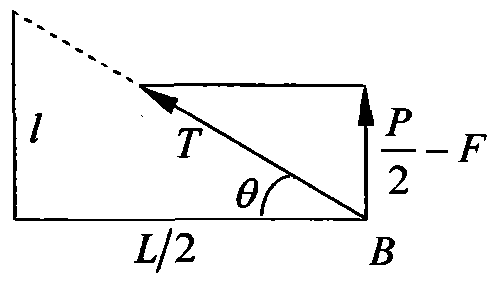

Near space high-speed target plasma electromagnetic measurement system

ActiveCN112816795ADetermine the lengthAccurately calculate the radiusElectromagentic field characteristicsMagnetic measurementsEngineering

The invention discloses a near space high-speed target plasma electromagnetic measurement system which comprises a cylindrical horizontal vacuum cavity, wherein a nozzle plane of plasma entering the vacuum cavity cannot be coplanar with the end face of the vacuum cavity; transmitting and receiving antennas of a transmission measurement system are respectively erected on the lower guide rails on the two sides, the transmitting and receiving antennas of the transmission measurement system are symmetrically erected and can perform two-dimensional movement along the axis direction and the radial direction of the plasma, a to-be-measured target of a scattering measurement system is erected on the lower guide rail in the middle, and transmitting and receiving antennas of the scattering measurement system are all erected on the upper guide rail; and a transmitting antenna of an internal electromagnetic field measurement system is erected on any group of lower guide rails on the two side edges, and an electric field / magnetic field probe for receiving an electromagnetic field is erected on the lower guide rail in the middle. According to the invention, three measurement systems, namely, the transmission measurement system, the scattering measurement system and the internal electromagnetic field measurement system, in plasma electromagnetic measurement are considered at the same time, so that an electromagnetic scattering experiment and a transmission experiment can be configured at the same time and do not influence each other.

Owner:XIDIAN UNIV

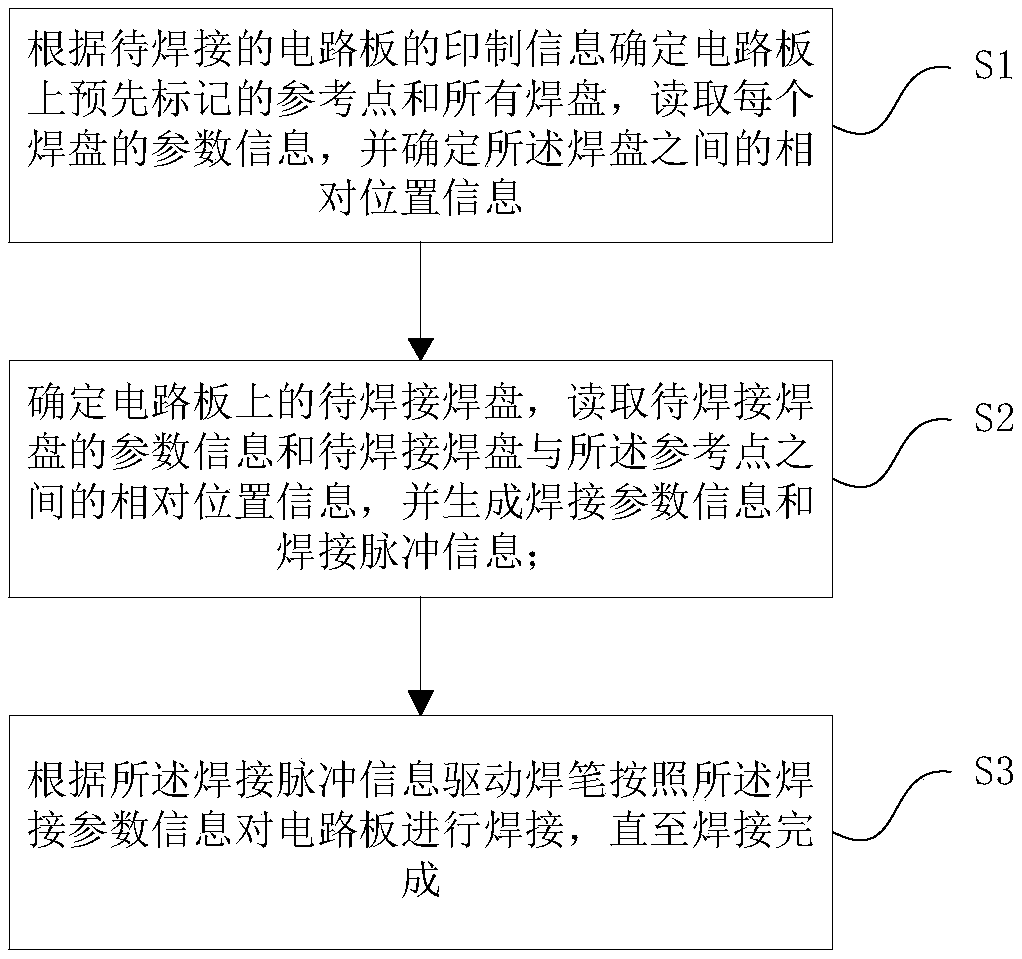

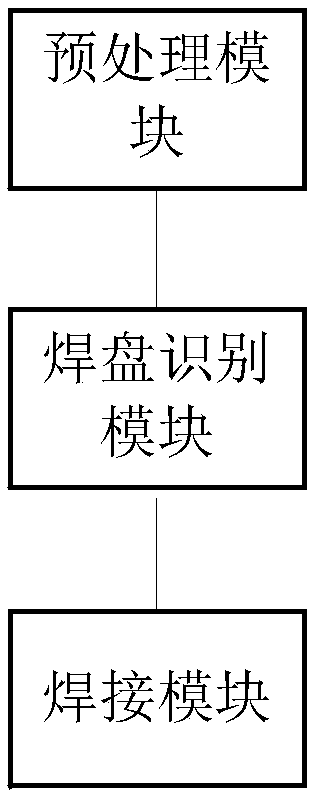

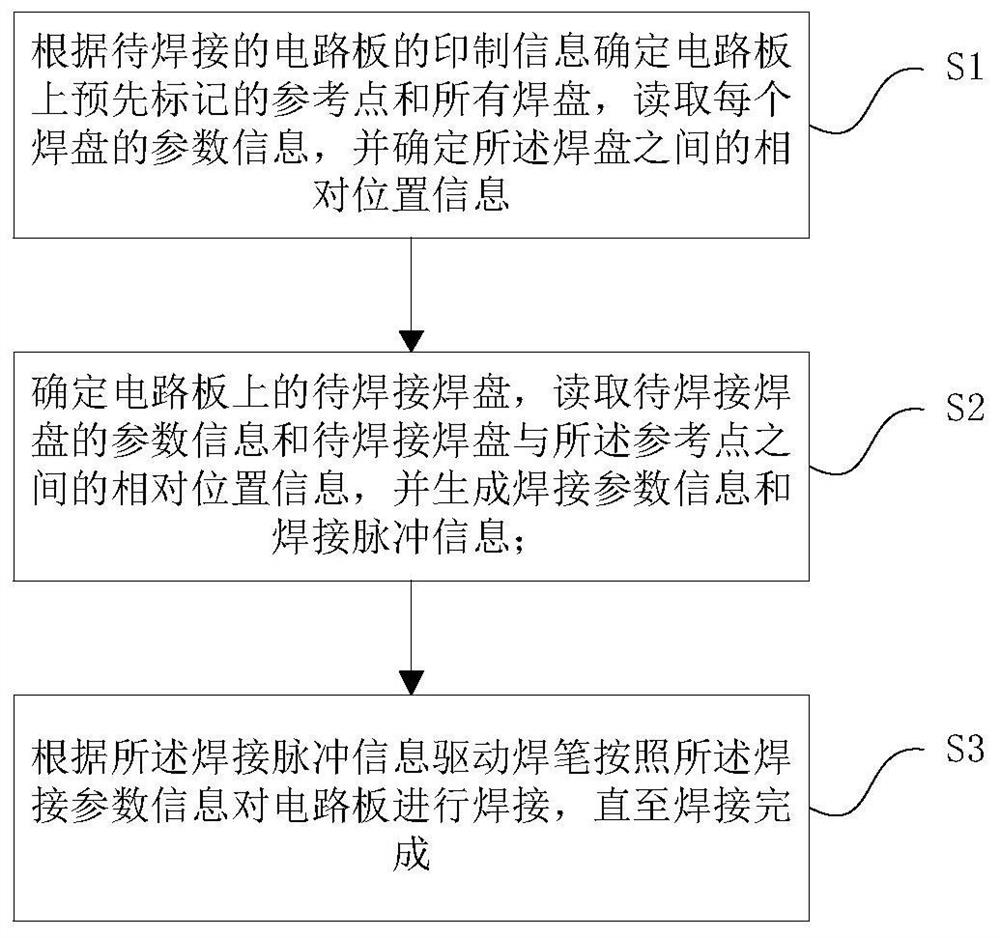

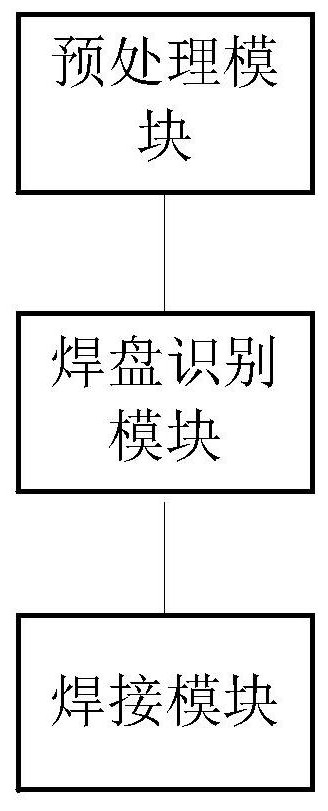

Intelligent welding method, system and device and storage medium

ActiveCN109396584AAccurate identificationRealize relative positional relationship recognitionProgramme-controlled manipulatorMetal working apparatusEngineeringWorkload

The invention relates to an intelligent welding method, system and device and a storage medium. The method comprises the steps of determining pre-marked reference points and all welding discs on a circuit board according to printing information of the circuit board to be welded, reading parameter information of each welding disc and determining relative position information between the welding discs; determining the welding discs to be welded on the circuit board, reading parameter information of the welding discs to be welded and the information about the relative positions between the welding discs to be welded and the reference points, generating welding parameter information and welding pulse information, and according to the welding parameter information and the welding pulse information, welding the circuit board; the parameter information of the welding discs to be welded on the circuit board and the information about the relative positions between the welding discs to be weldedand the reference points are obtained, the welding parameter information and the welding pulse information are generated, the circuit board is precisely welded, different soldering tin amounts are applied according to different welding discs, the manual debugging workloads at the early period are greatly reduced, work efficiency and product quality are improved, and the automation degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

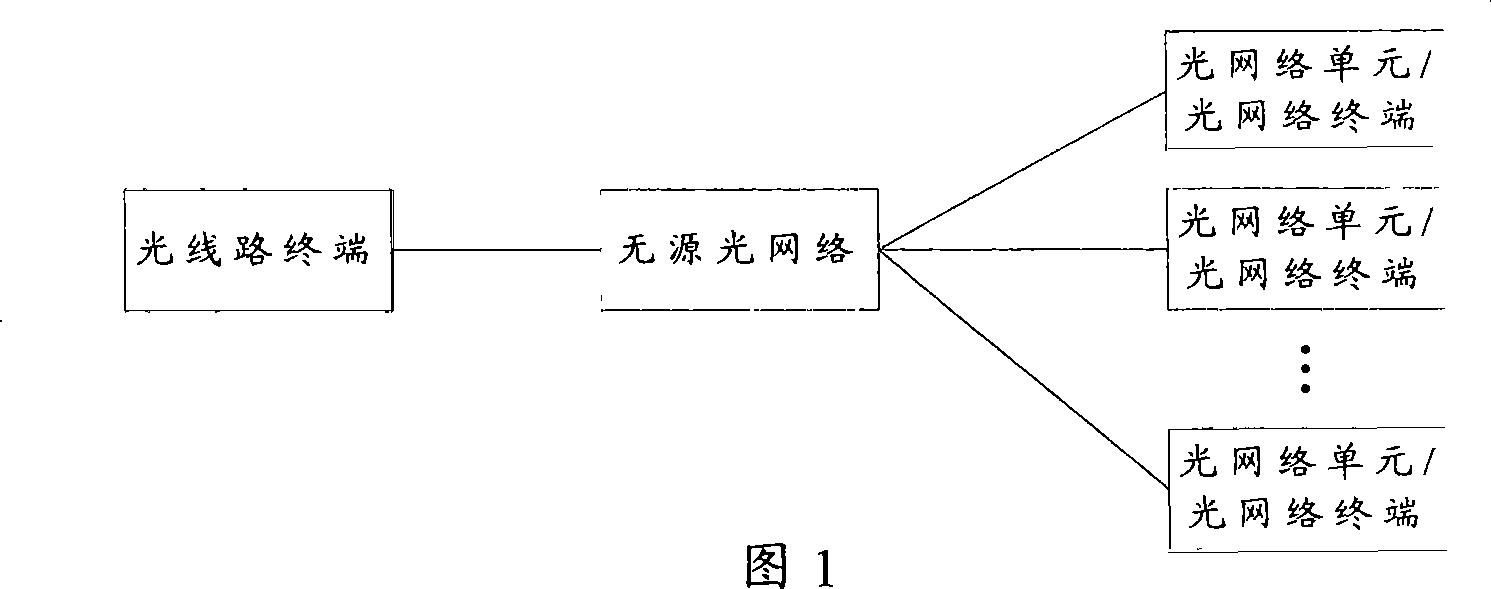

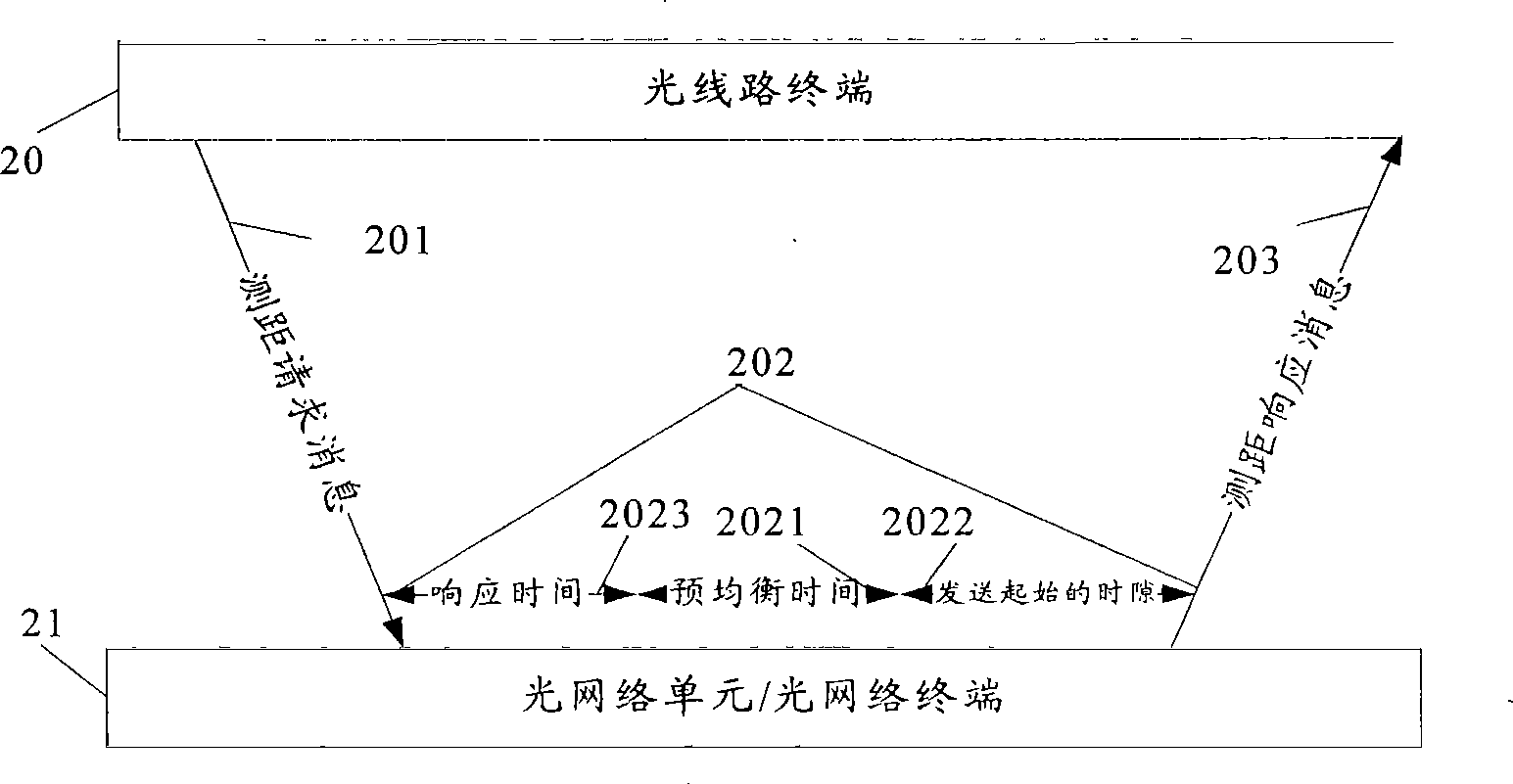

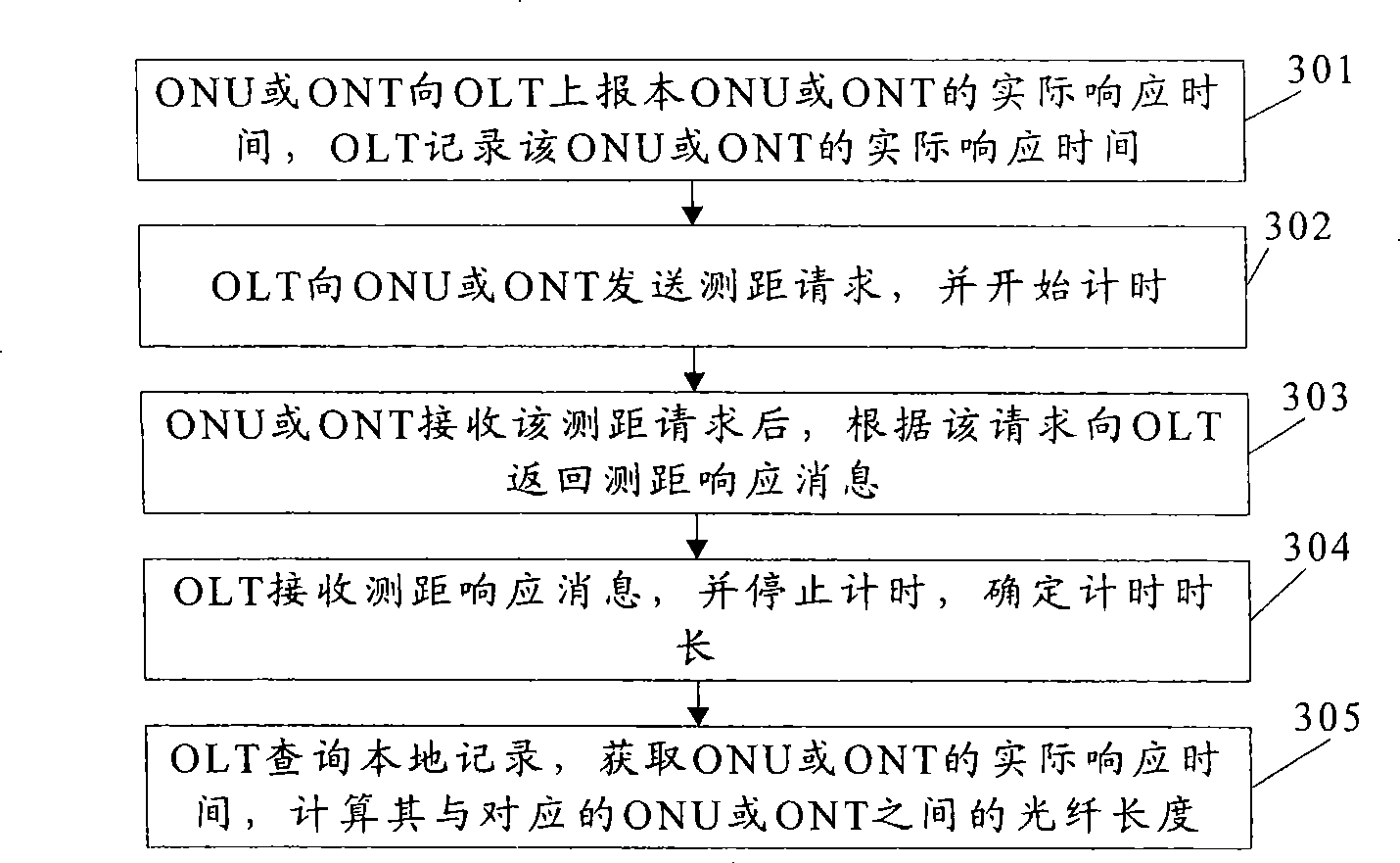

Optical fiber length measuring, communication apparatus and communication system

ActiveCN101441070AHigh precisionDetermine the lengthMeasurement devicesTransmission monitoring/testing/fault-measurement systemsCommunications systemTime delays

The embodiment of the present invention discloses an optical fiber length measuring method, a communication equipment and a communication system. The method includes that: an optical line terminal carries message interaction with an optical network unit or an optical network terminal and determines time scale of the message interaction; and the optical line terminal determines length of optical fiber between the optical line terminal and the optical network unit or the optical network terminal on the basis of the time scales, real response time of the optical network unit or the optical network terminal, pre-equalization time delay of the optical network unit or the optical network terminal designated by the optical line terminal, and time slot of initial transmission. Length of the optical fiber between OLT and ONU or ONT can be measured accurately by applying technical solution of the embodiment of the present invention.

Owner:HUAWEI TECH CO LTD

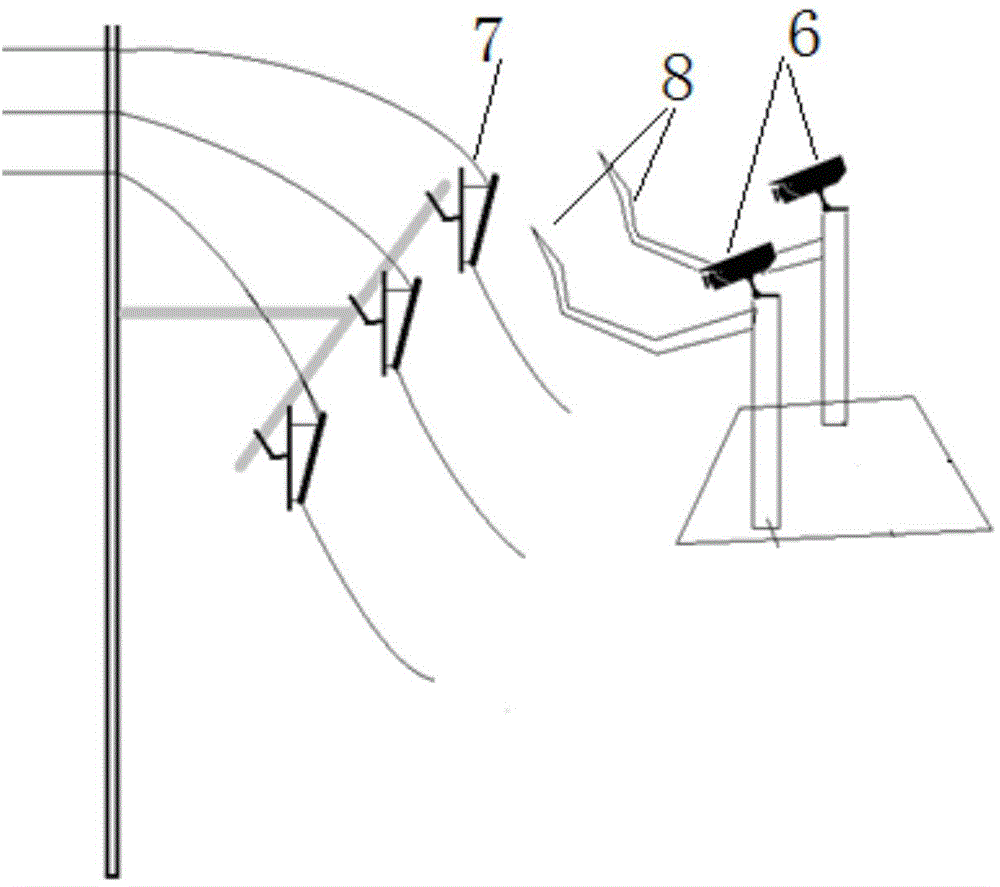

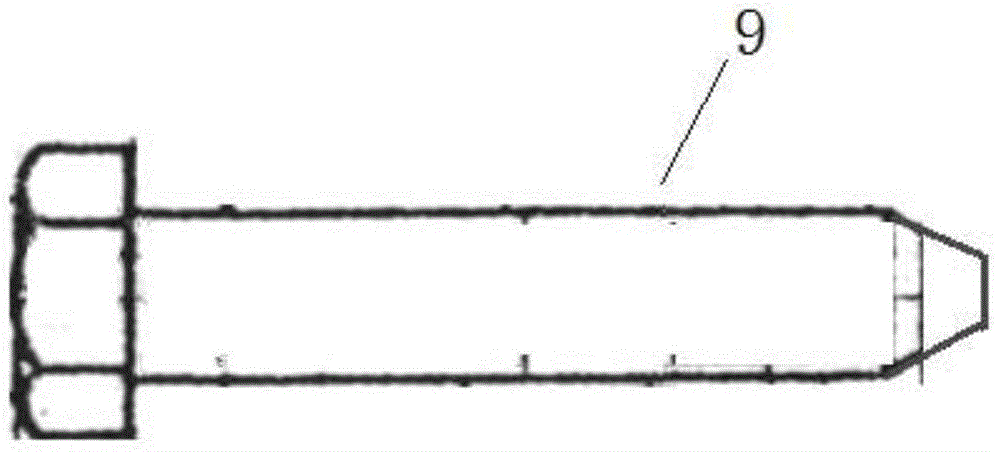

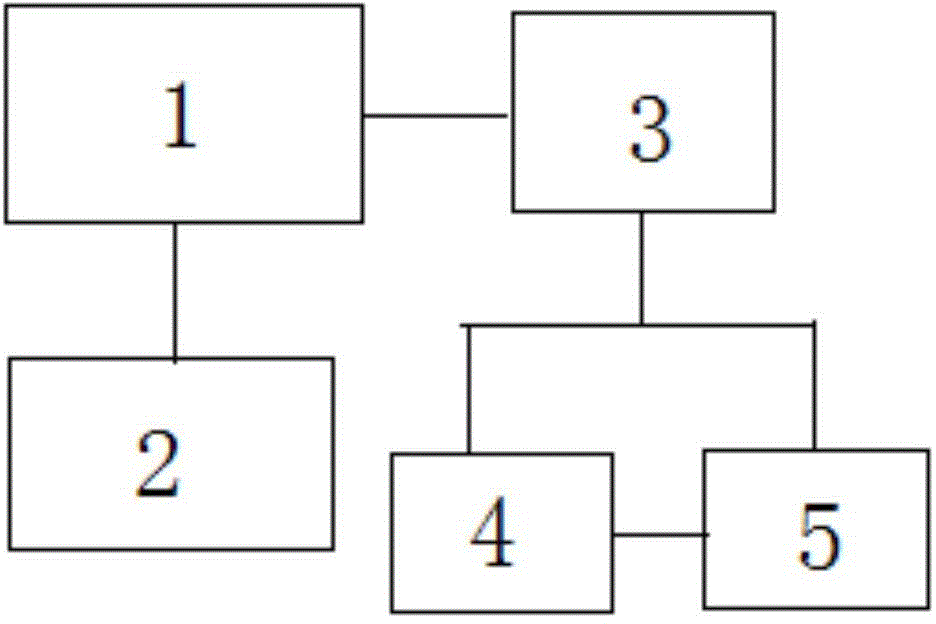

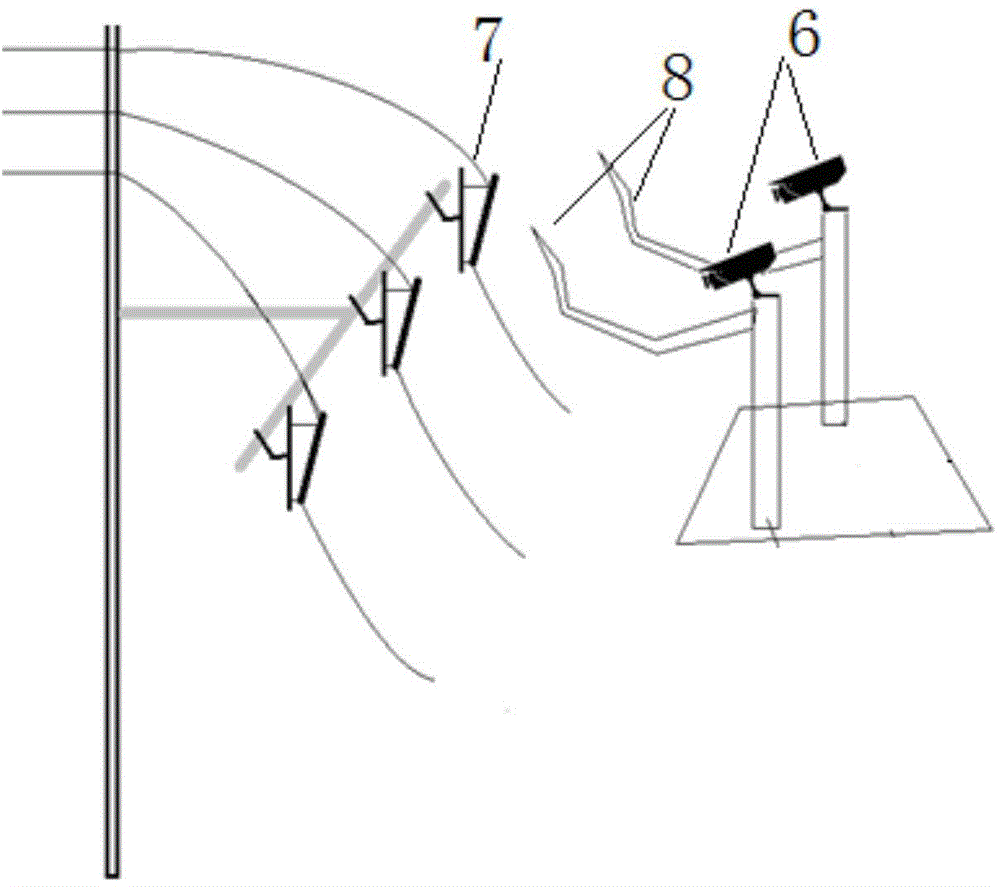

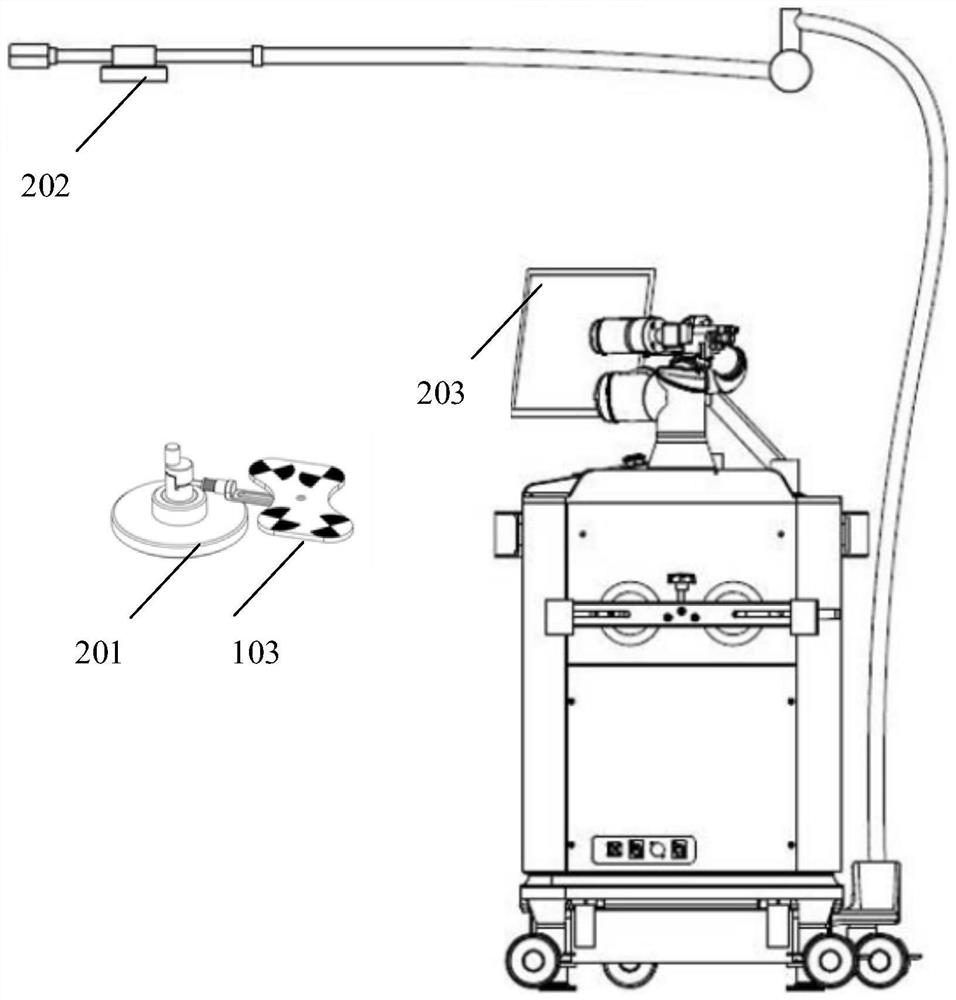

Drop type switch replacing control system and method based on high-voltage live working robot

ActiveCN104786227AAutomatic and precise replacementAutomatic precise automatic replacementMetal working apparatusManipulatorControl systemComputer module

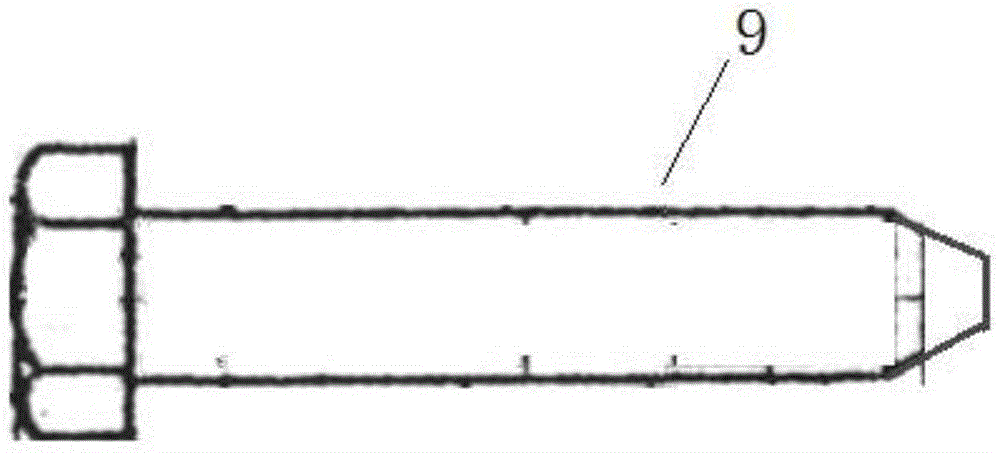

The invention discloses a drop type switch replacing control system and method based on a high-voltage electric power live working robot. The system is characterized in that a control unit of the high-voltage electric power live working robot is connected with an image data processing center and a mechanical arm control unit, and the image data processing center is connected with a vision module and a target tracking module; the vision module is connected with the target tracking module. The system and method have the advantages that the top end of a bolt is conical so as to go deep into a bolt hole conveniently, even if the locating of the bolt has an error of several millimeters, the bolt still can go deep into the bolt fixing hole, and the difficulty of making the bolt go deep into the bolt hole is reduced. By additionally setting color marks at the two ends of the bolt, the bolt can be highlighted in the background, the position of the bolt can be tracked out according to the color information, and the length of the bolt can be determined according to the color information of the marks at the two ends.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Automatic replacement control system for high-voltage line drop switch and control method

ActiveCN104858877AAutomatic and precise replacementAutomatic precise automatic replacementMetal working apparatusManipulatorAutomatic train controlComputer module

The invention discloses an automatic replacement control system for a high-voltage line drop switch and a control method. The automatic replacement control system comprises a robot control unit, a mechanical arm control unit, a vision module, a target tracking module and an image data treatment center, wherein the robot control unit is respectively connected with the image data treatment center and the mechanical arm control unit; the image data treatment center is connected with the vision module and the target tracking module respectively; the vision module is connected with the target tracking module. The automatic replacement control system has the benefits as follows: by arranging the top end of a bolt to be conical, the top end of the bolt can stretch into a bolt hole conveniently, and even if the difference of a few millimeters exists in positioning of the bolt, the bolt can still stretch into the bolt fixing hole, so that difficulty of stretching the bolt into the bolt hole is reduced. By additionally arranging color marks at the two ends of the bolt, the bolt can be highlighted in the background, so that the bolt can be tracked conveniently through color information, and meanwhile, the length of the bolt can be determined through the color information of the marks at the two ends.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

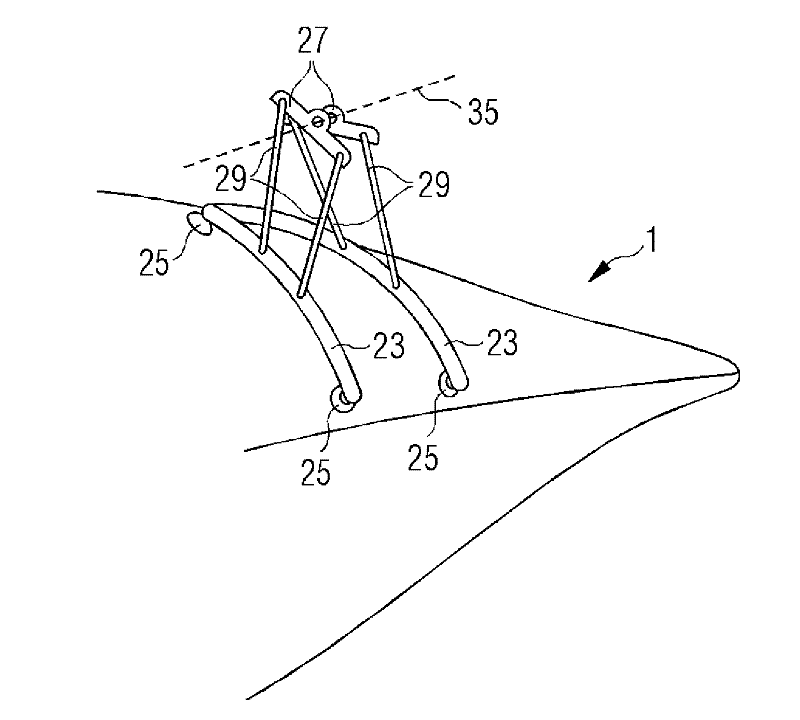

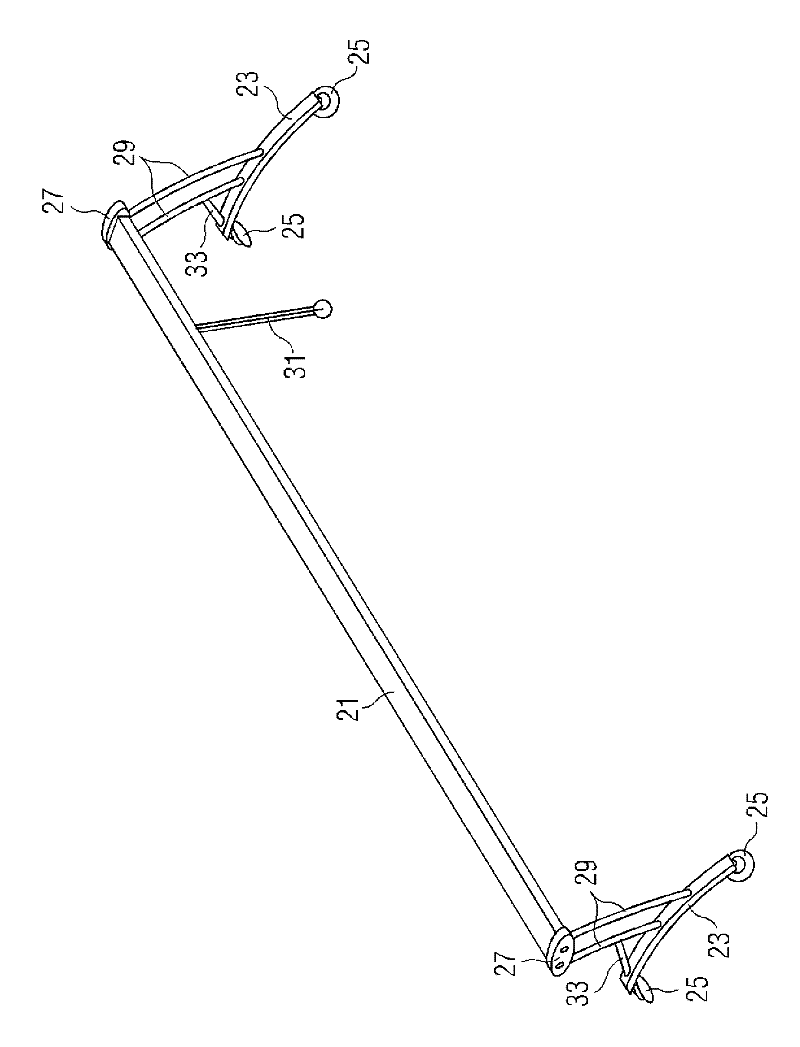

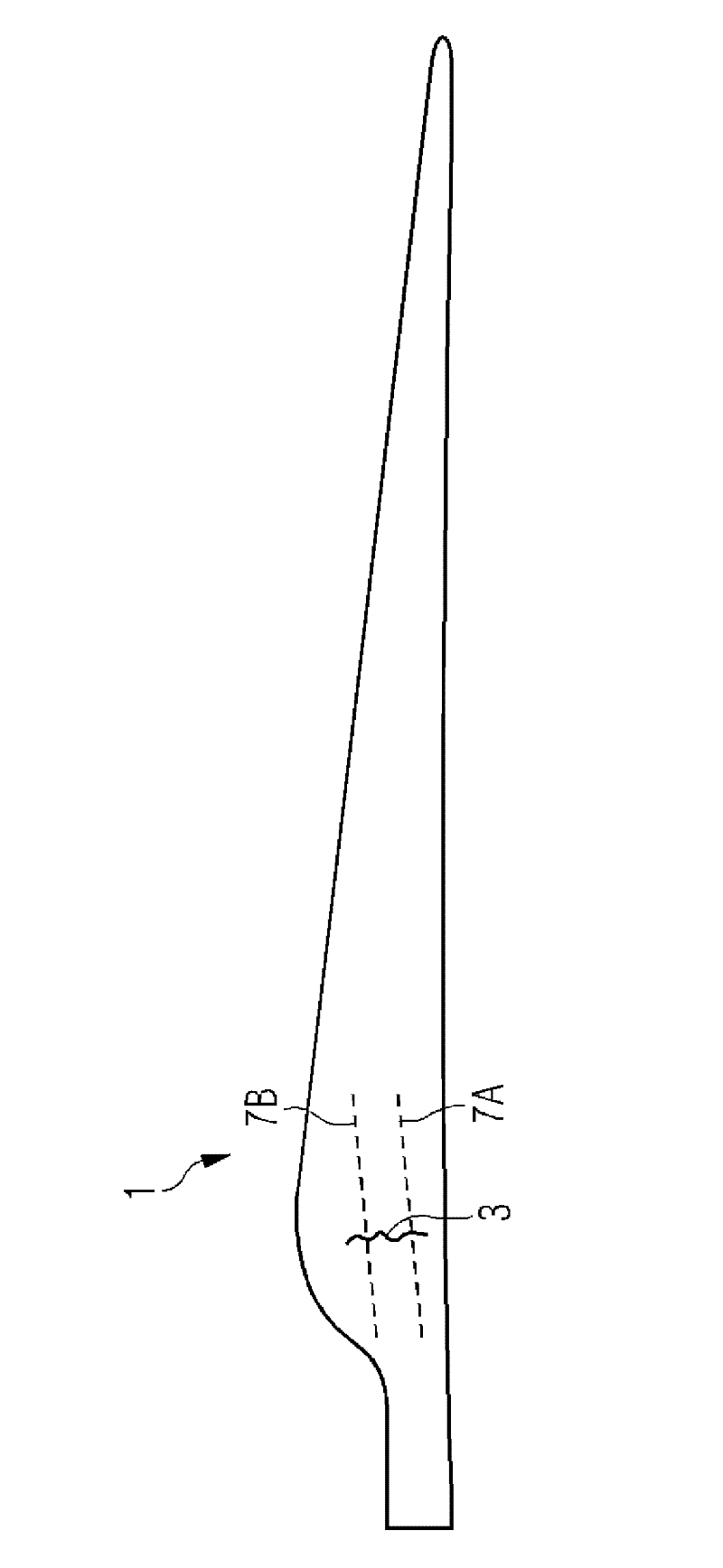

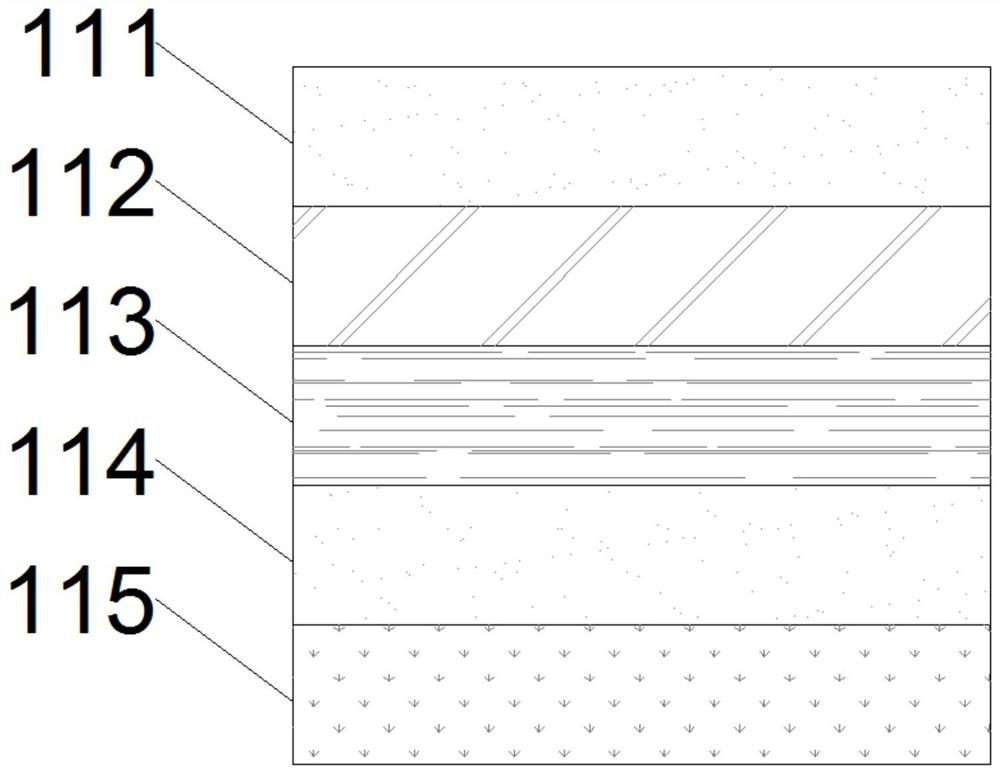

Method of detecting wrinkles in a fiber reinforced laminated structure and auxiliary device for performing thermal scans

InactiveCN102650605AScan accuratelyImprove thermal efficiencyMaterial heat developmentMaterial flaws investigationWrinkle skinEngineering

A method of detecting wrinkles (3) in a fiber reinforced laminated structure (1) is provided. In this method, - the structure (1) is locally heated or cooled, the location of the heating or cooling being moved along a defined path (7), - the temperature of the structure (1) is measured at a measuring location being different from the location of the heating or cooling, the measuring location being moved along the same path (7) as the location of the heating or cooling, and - wrinkles (3) are detected from temperature anomalies found along the defined path (7).

Owner:SIEMENS AG

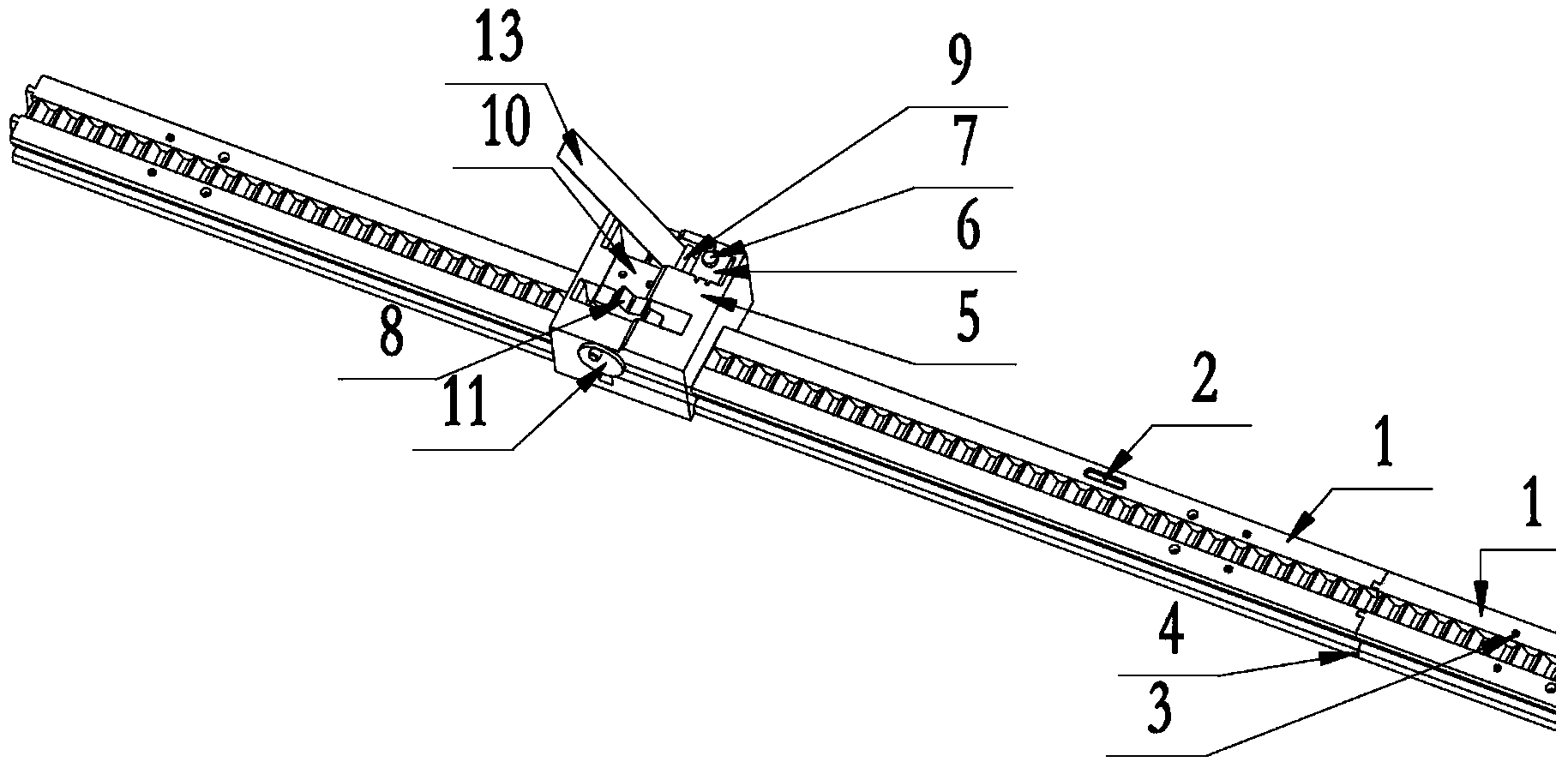

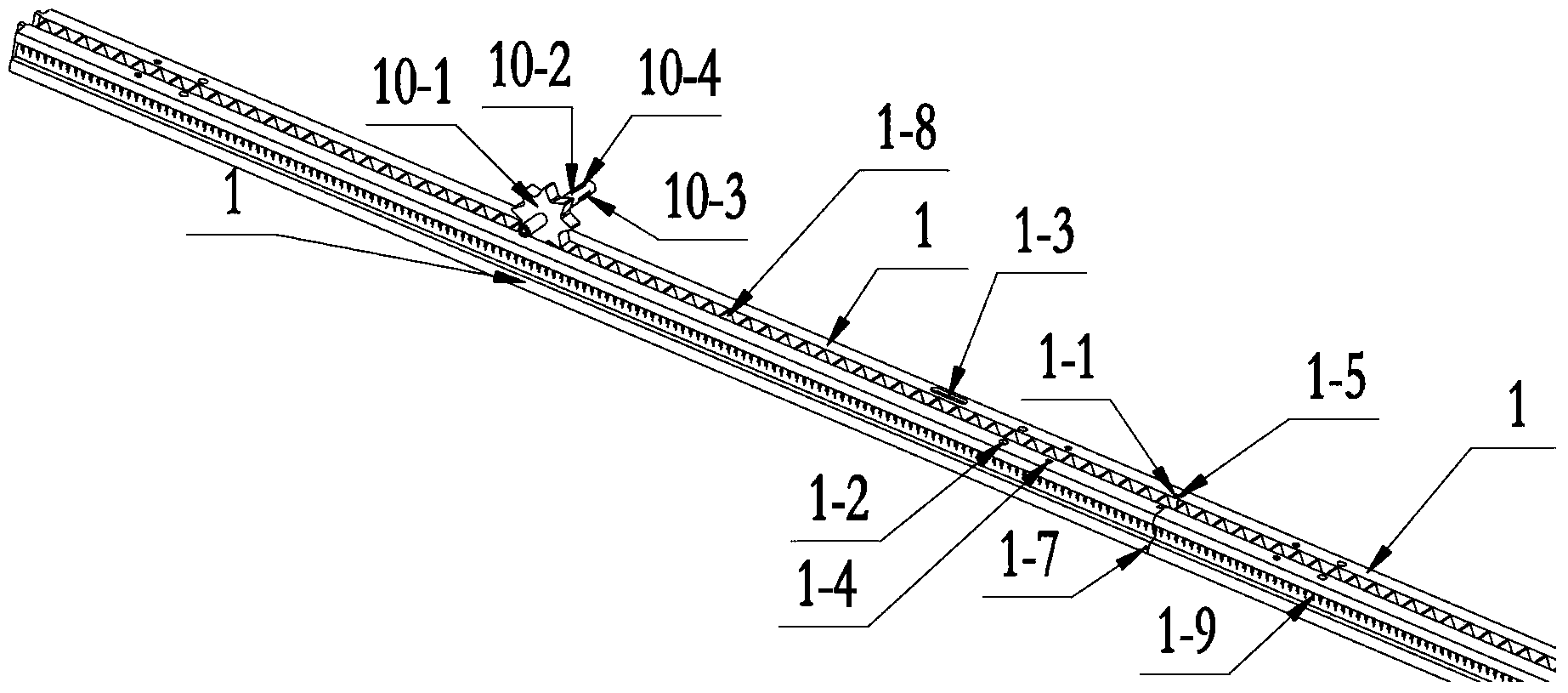

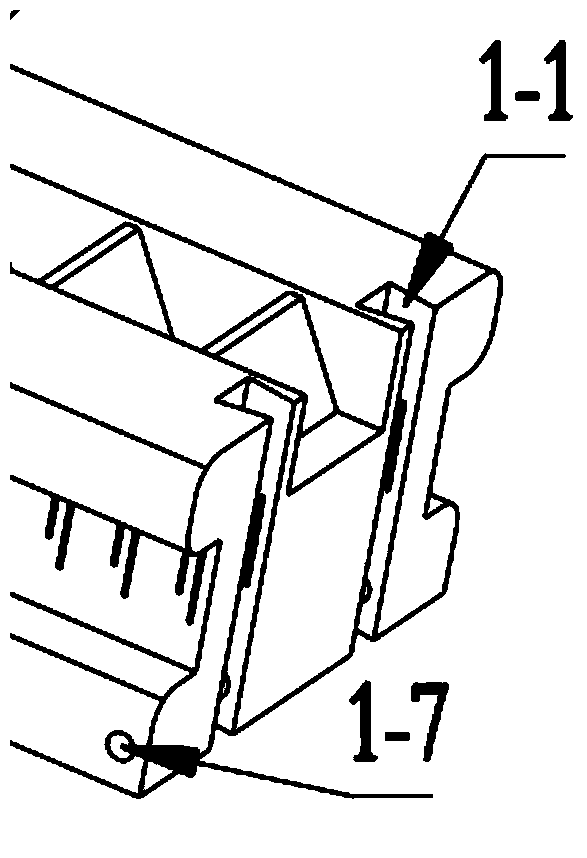

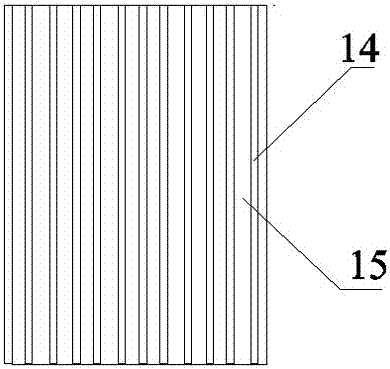

Grating ruler mounting tool capable being elongated

ActiveCN104295578AQuickly press and pasteQuick and automatic separation and windingFastening meansGratingEngineering

The invention provides a grating ruler mounting tool capable of being elongated. The tool is characterized by comprising more than one guide rail, sliding block devices and grating rulers. A plurality of guide rails are connected to achieve mounting of the grating rulers in length, only the sliding block devices need to be dragged to slide along the guide rails, pressing and pasting of the grating rulers and automatic separation and winding of grating cover paper can be finished quickly, and the extensible grating ruler mounting tool is convenient to use, reliable and stable in whole structure and capable of being widely applied.

Owner:杭州光学精密机械研究所

An intelligent welding method, system, device and storage medium

ActiveCN109396584BAccurate identificationRealize relative positional relationship recognitionProgramme-controlled manipulatorMetal working apparatusEngineeringSoldering

The invention relates to an intelligent welding method, system and device and a storage medium. The method comprises the steps of determining pre-marked reference points and all welding discs on a circuit board according to printing information of the circuit board to be welded, reading parameter information of each welding disc and determining relative position information between the welding discs; determining the welding discs to be welded on the circuit board, reading parameter information of the welding discs to be welded and the information about the relative positions between the welding discs to be welded and the reference points, generating welding parameter information and welding pulse information, and according to the welding parameter information and the welding pulse information, welding the circuit board; the parameter information of the welding discs to be welded on the circuit board and the information about the relative positions between the welding discs to be weldedand the reference points are obtained, the welding parameter information and the welding pulse information are generated, the circuit board is precisely welded, different soldering tin amounts are applied according to different welding discs, the manual debugging workloads at the early period are greatly reduced, work efficiency and product quality are improved, and the automation degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

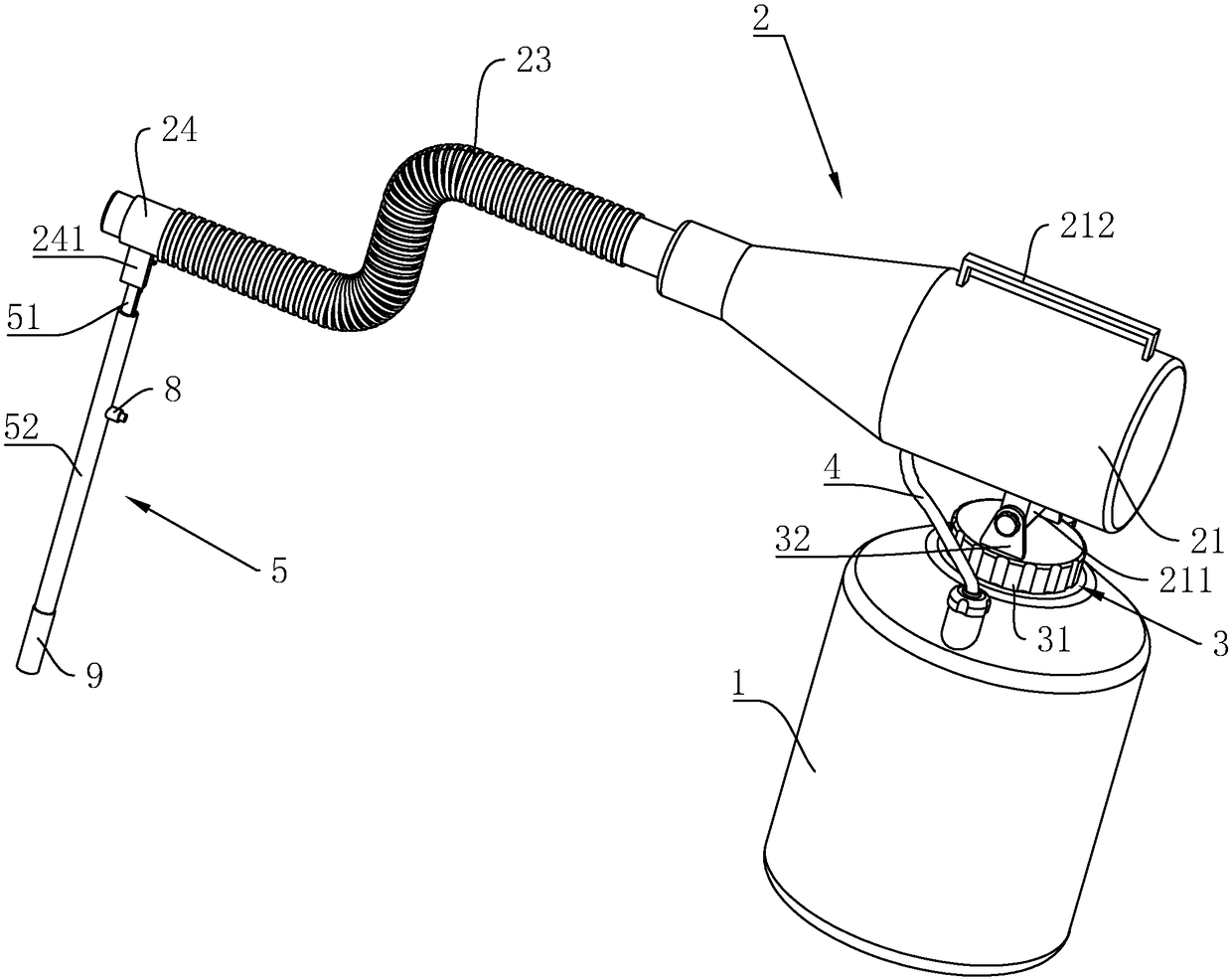

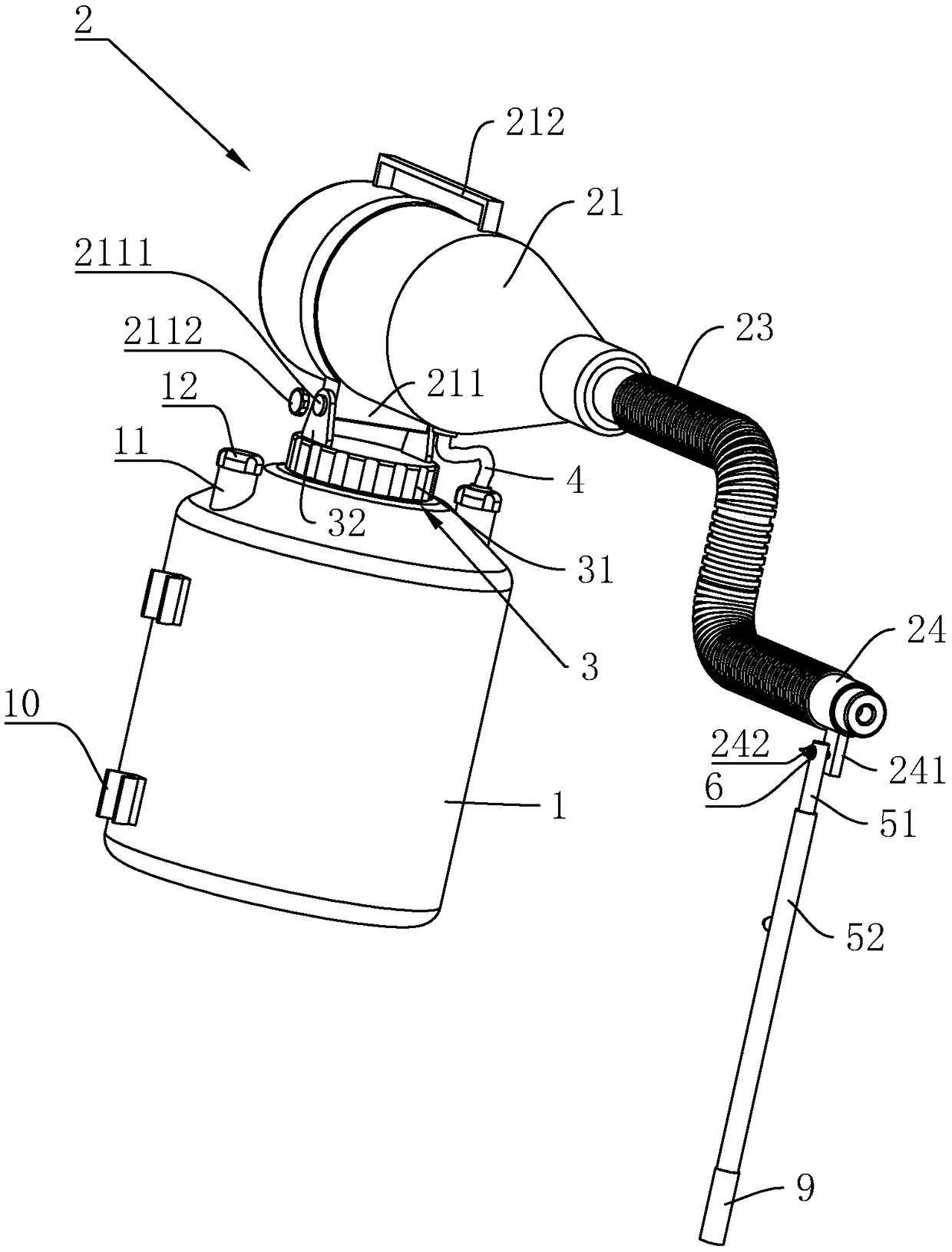

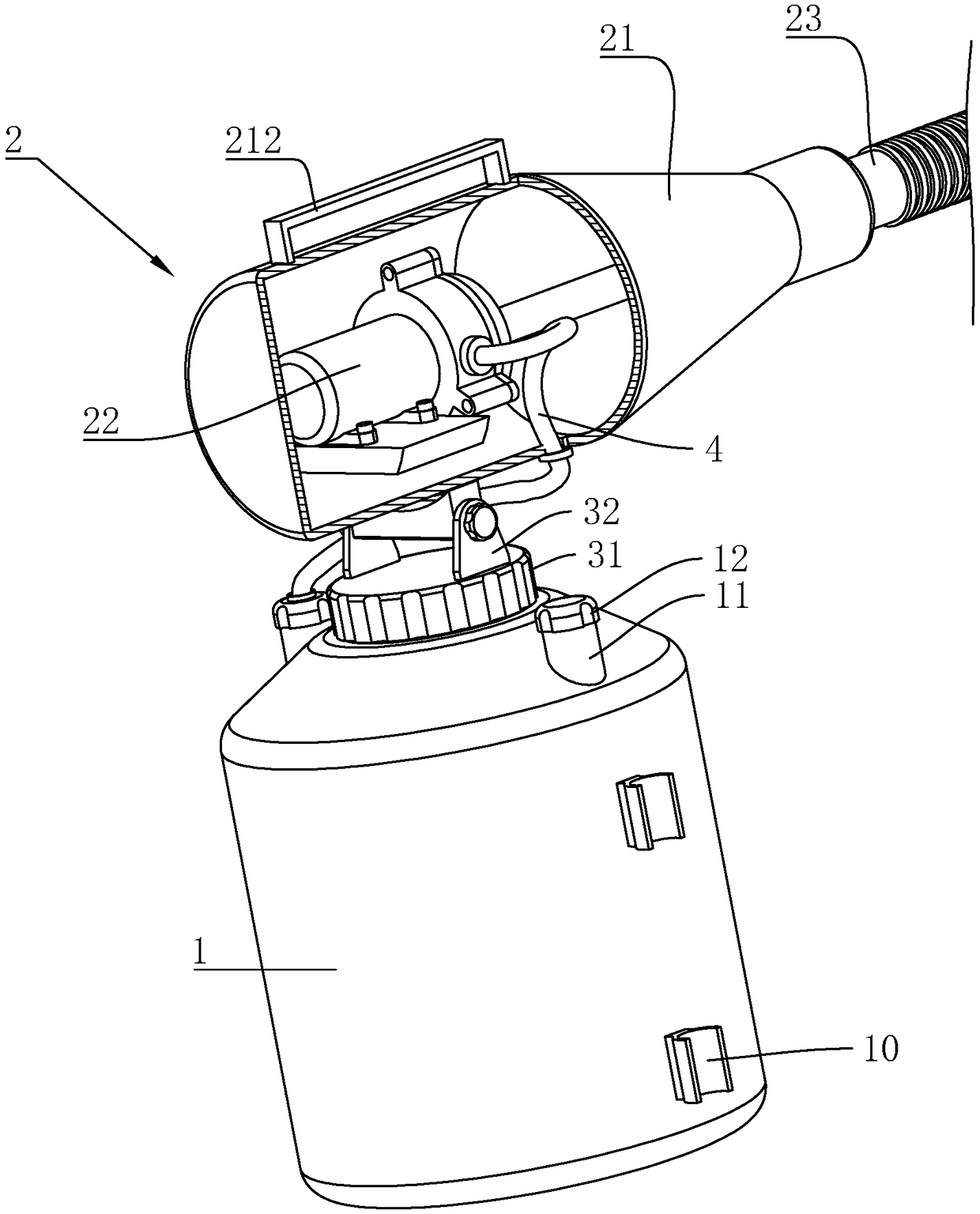

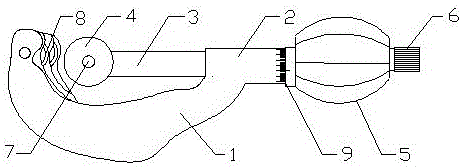

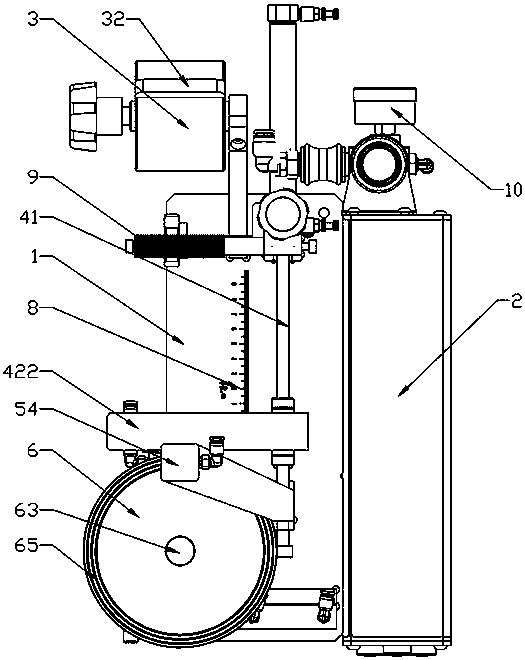

Ultralow-capacity atomizer

InactiveCN108787222ADetermine the lengthPrevent axial rotationLiquid spraying apparatusLiquid storage tankEngineering

The invention discloses an ultralow-capacity atomizer and belongs to the field of atomizers. The ultralow-capacity atomizer comprises a liquid storage tank and an atomizing device. The atomizing device is fixed to the top end of the liquid storage tank. The atomizing device comprises an atomizing tube. An atomizing pump and an atomizing pipe communicating with the atomizing pump are arranged in the atomizing tube. The atomizing pipe extends out of the atomizing tube to be exposed. The end, extending out of the atomizing tube, of the atomizing pipe is provided with an atomizing nozzle. The liquid storage tank communicates with the atomizing pump through a hose. The atomizing pipe is a length-adjustable flexible pipe body. The end, extending out of the atomizing tube, of the atomizing pipe is provided with a control lever. One end of the control lever is fixedly connected with the atomizing nozzle, and the other end of the control lever is the handheld end. The ultralow-capacity atomizerhas the advantage that the ultralow-capacity atomizer can conduct atomizing sterilization and deinsectization on a high place without using a climbing tool.

Owner:深圳市中大合顺生物科技有限公司

Large-scale curved surface modeling product mapping device

ActiveCN110017779ADetermine the lengthDetermine the widthUsing optical meansLaser rangingEngineering

The invention discloses a large-scale curved surface modeling product mapping device, which comprises a base, wherein two X-direction laser range finders are symmetrically arranged on the upper surface of the base, and two mounting grooves, a motor cavity and an equipment cavity are symmetrically arranged on the upper surface of the base, wherein, a first motor is arranged in the motor cavity, a threaded rod is horizontally arranged in each mounting groove, and one end of each threaded rod extends into the equipment cavity and is provided with a synchronizing wheel, wherein two of the synchronizing wheels are provided with a synchronizing belt together, each threaded rod is in threaded connection with a moving seat, and Y-direction laser range finders are arranged on the side walls of thetwo moving seats. The invention has the advantages that: the device is ingenious in structure, can measure the side wall positions and the upper surface positions of different positions of the special-shaped part, can measure large-scale curved surface products with complex surface structures, shortens the measuring time of the special-shaped part, and reduces the measuring process, so that the difficulty of measuring the special-shaped part is reduced.

Owner:安徽智时代软件服务有限公司

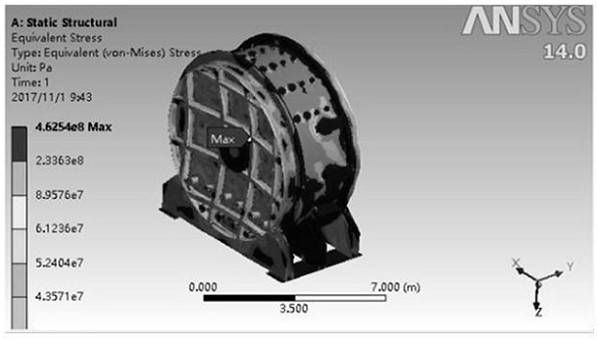

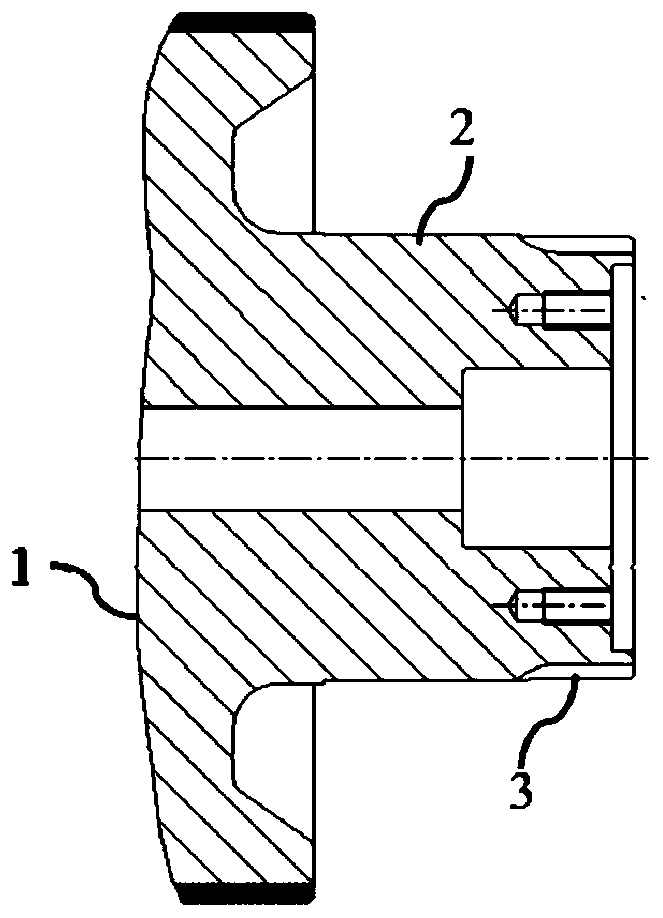

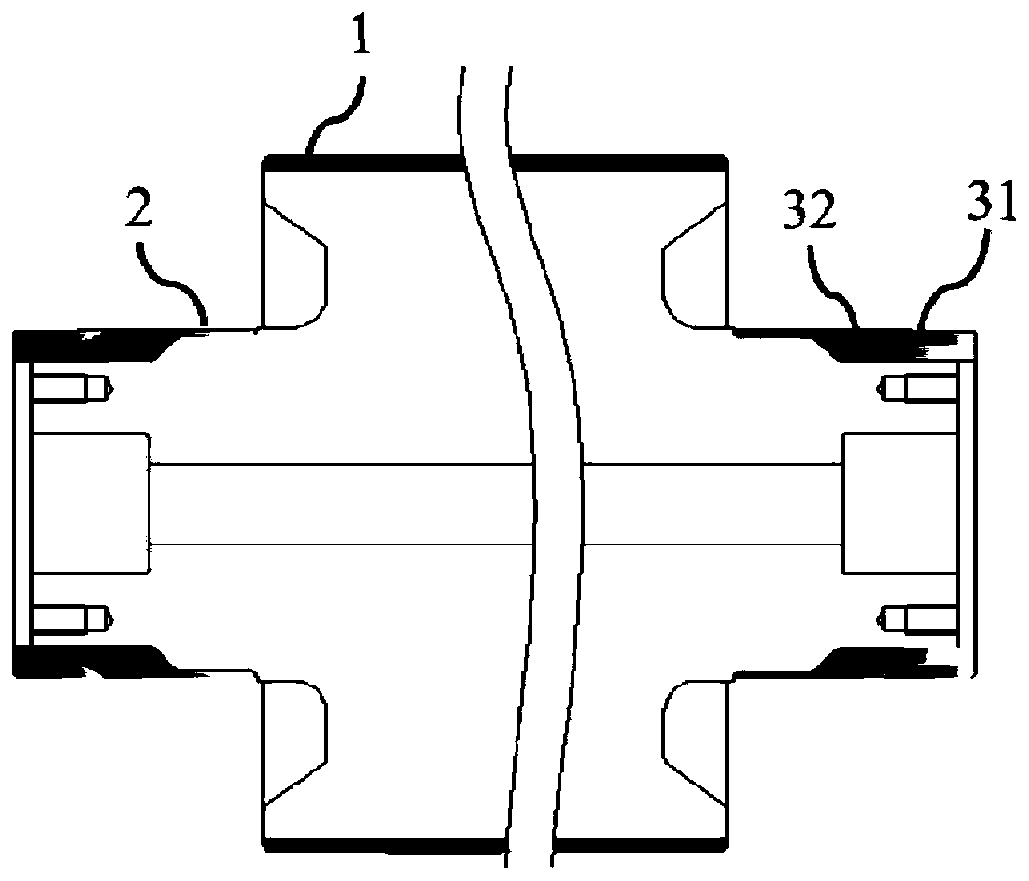

Continuous casting roller driving roller shaft spline repairing method

ActiveCN111331313AGood welding fusionGuaranteed machining allowanceStructural engineeringManufacturing engineering

The invention discloses a continuous casting roller driving roller shaft spline repairing method, and belongs to the technical field of spline repairing. The continuous casting roller driving roller shaft spline repairing method comprises the following steps that a welding material which is well welded and fused with a parent material and has chemical components close to those of the parent material is selected, integral surfacing is conducted to repair a spline, and after welding, a proper heat treatment mode is adopted to relieve stress and improve mechanical performance; and then stress analysis is carried out on the spline, the size of a stress-affected zone pitch tooth root is calculated, a finite element model is manufactured, the size of an outer circle of the spline subjected to overall turning is determined, and finally gear hobbing is carried out on the spline. The process of repairing the spline through the integral surfacing method comprises the steps of old tooth removing,integral surfacing and re-machining. According to the repairing method, the repaired spline can reach a new product standard, re-manufacturing is avoided, and the cost is saved.

Owner:安徽马钢重型机械制造有限公司

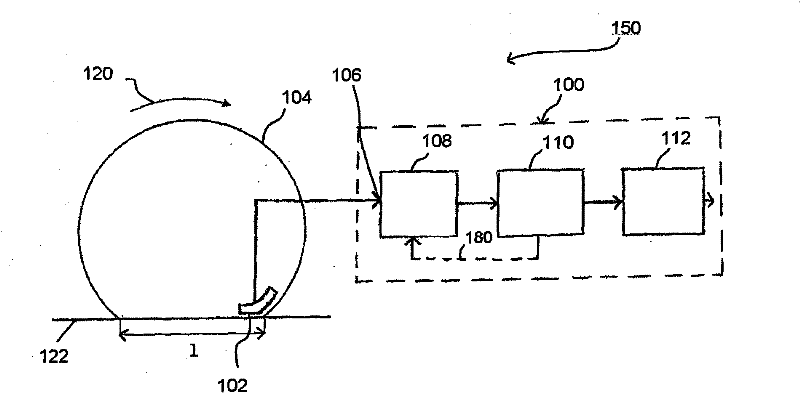

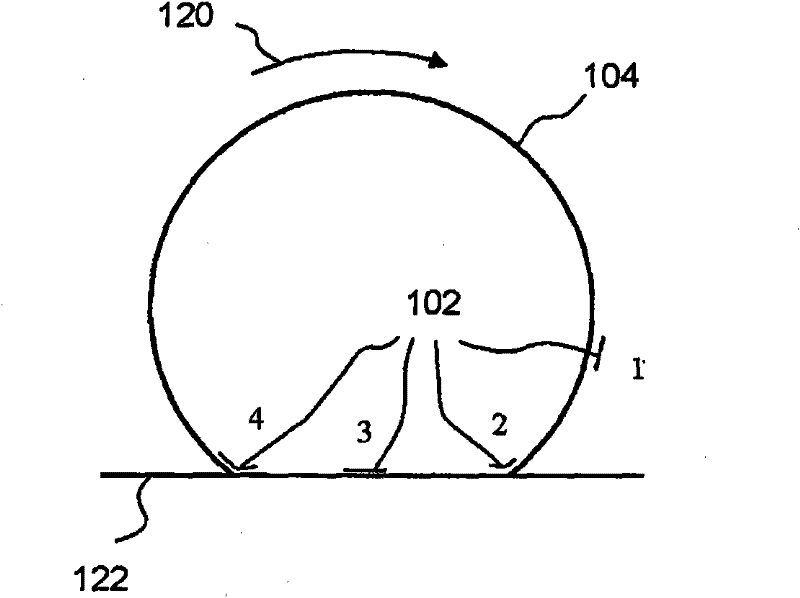

Latch-evaluation circuit for electromechanical transducer of a tire

InactiveCN102180070ADetermine the lengthAutomatically adjust input sensitivityTyre measurementsVehicle tyre testingElectricityElectromechanical transducer

The circuit (100) has a sensitivity adjusting mechanism (108) adjusting input sensitivity of the circuit based on strength of a time-dependent electrical sensor signal of an electromechanical converter (102) such that the full sensor signal is evaluated with adjusted input sensitivity. An evaluation device (110) generates an evaluation signal with the adjusted input sensitivity based on the provided sensor signal, where the evaluation signal indicates tread shuffle process of a tire (104). Independent claims are also included for the following: (1) a device for determining tread shuffle of a tire comprising an evaluation circuit (2) a method for evaluating a sensor signal of an electromechanical converter of the tire (3) a computer-readable storage medium comprising a set of instructions to perform a method for evaluating the sensor signal of the electromechanical converter (4) a program element for evaluating the sensor signal of the electromechanical converter.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Surface polishing and fixed-length cutting device for electromechanical equipment shell

InactiveCN112846791AErrorDetermine the lengthOther manufacturing equipments/toolsPolishingEngineering

The invention relates to the technical field of electromechanical equipment, and discloses a surface polishing and fixed-length cutting device for an electromechanical equipment shell, which comprises a shell; a polisher is movably connected in the shell; a fixed shell is fixedly connected in the shell; a screw rod is movably connected in the fixed shell, and a sliding bracket is movably connected outside the screw rod; and an electromagnetic valve is fixedly connected to the outer portion of the fixed shell. Under the interaction of all structures of the device, a plate can be polished in time through the polisher after entering the device, the plate is fixed through a push rod, and the required length of the plate can be accurately determined under the action of lamp beads and a photosensitive assembly, so that the effects that the plate can be automatically fixed, the surface of the plate can be polished, and the plate can be cut by a certain length according to different use requirements are achieved, and the device conforms to the technical concept of intelligent manufacturing.

Owner:杭州砥行机械自动化有限公司

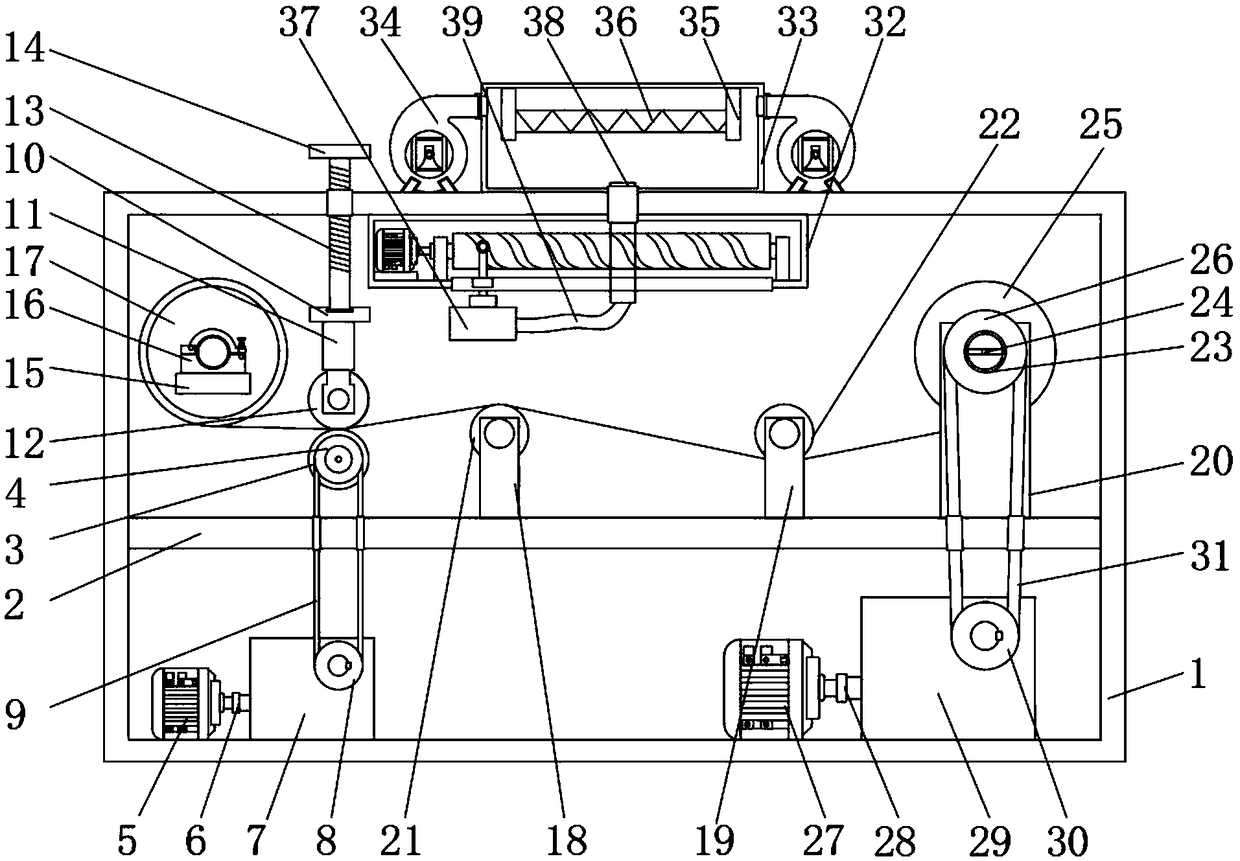

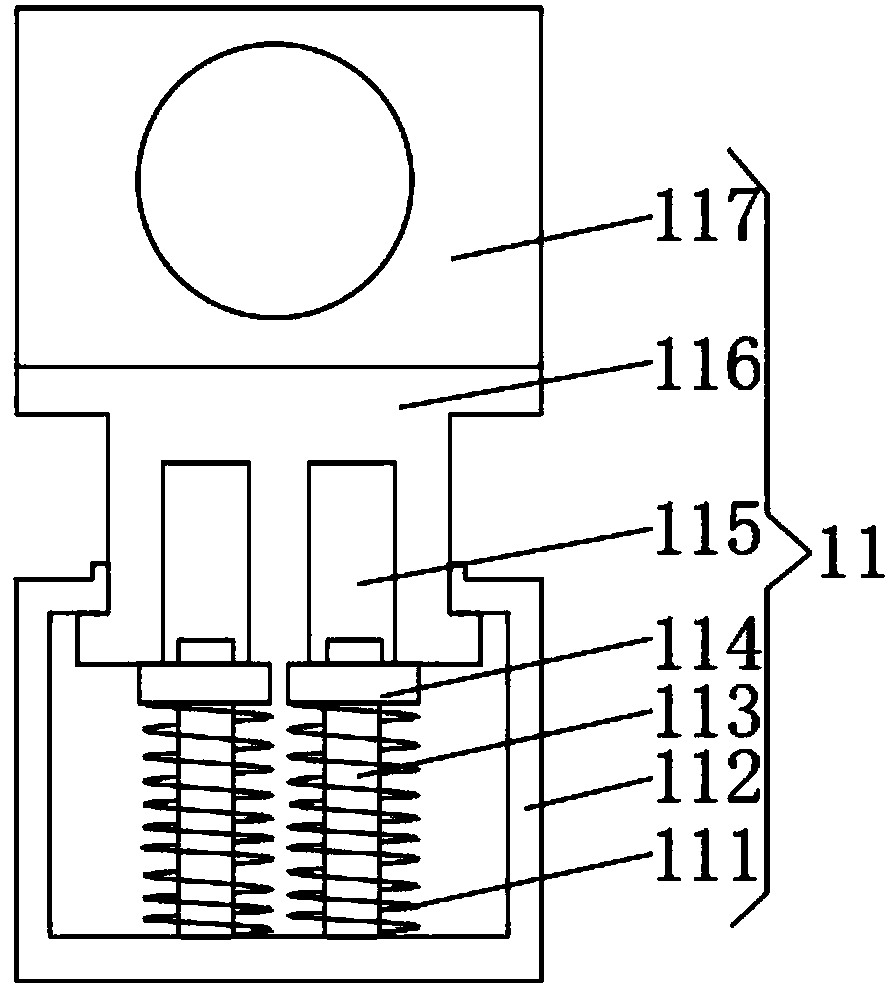

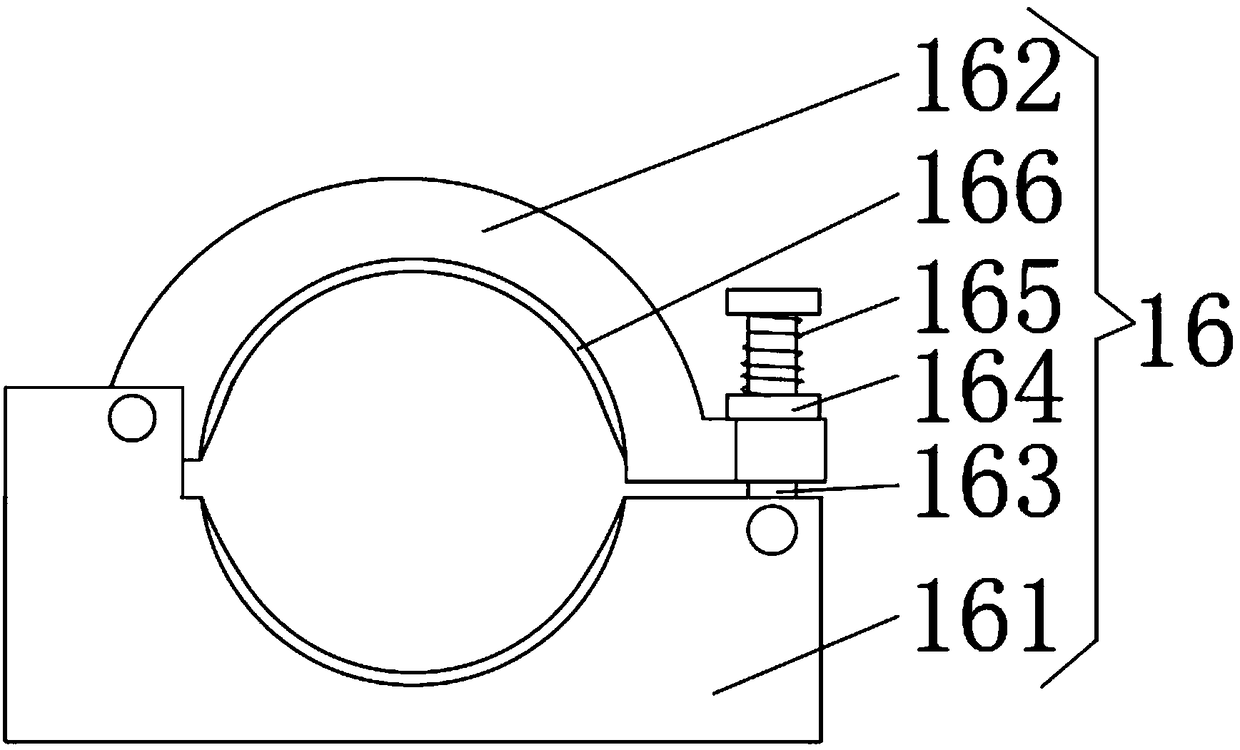

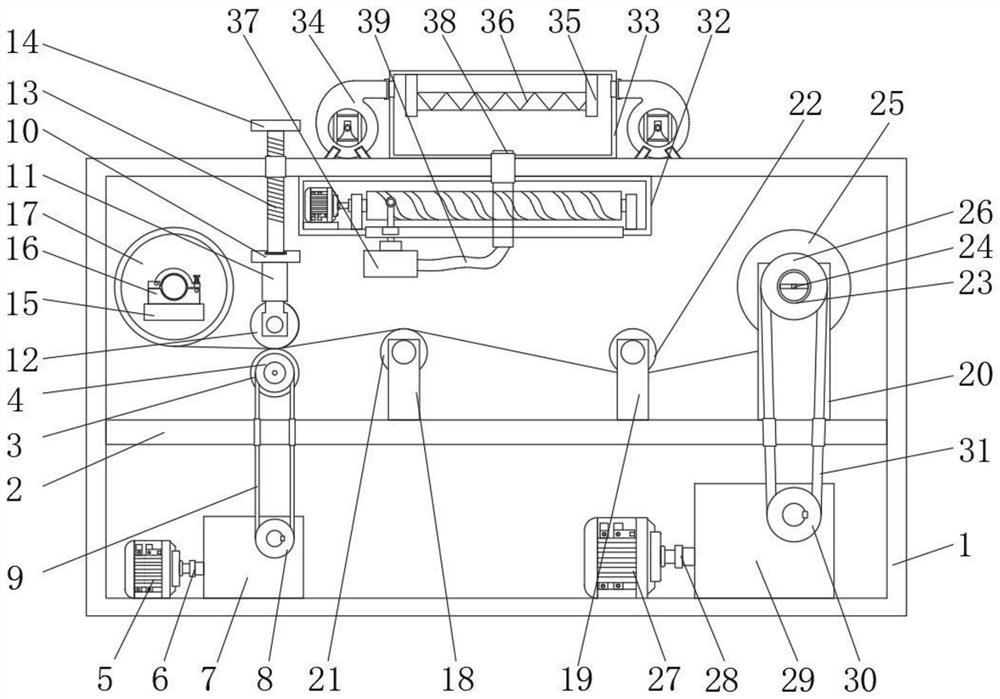

Ribbon drying and winding device used for coding machine

The invention discloses a ribbon drying and winding device used for a coding machine. The device comprises a box body. A driving roller is rotatably connected between two sides opposite to the inner wall of the box body. A slide plate is slidably connected to the corresponding position of the driving roller and is arranged between the two sides opposite to the inner wall of the box body. The bottom of the slide plate is fixedly connected to a buffer device. The center of the buffer device is rotatably connected to a driven roller. The two sides which are opposite to the inner wall of the box body are fixedly connected to a fixing block. The top of the fixing block is rotatably connected to a ribbon discharge roller through a rotation fixing device. The top of the inner wall of the box bodyis fixedly connected to a moving device. A heating box is fixedly connected to the corresponding position of the moving device on the top of the box body. The two sides of the heating box are connected to an air blower. The bottom of the moving device is fixedly connected to a ventilation plate. The device relates to the ribbon technology field. By using the ribbon drying and winding device usedfor the coding machine, a problem that existing drying and winding are performed separately is solved, and ribbon quality and work efficiency are increased.

Owner:诸暨叶蔓电子商务有限公司

Transverse defect verification method in eddy current testing and pipe cutting device with vernier adjustment knob

InactiveCN106680365AImprove accuracyLow costMaterial magnetic variablesEddy-current testingEngineering

The invention discloses a transverse defect verification method in eddy current testing, comprising the following steps: adopting an eddy current testing detection flow line; determining the position of a flaw on a steel wire; determining the initial scale of a flaw of the pipe cutting device with the vernier adjustment knob; determining the depth of the flaw on the steel wire; determining the length of the flaw on the steel wire; starting a drawing device for drawing the steel wire, and starting a flaw detection device to carry out flaw detection; if the flaw detection device can detect the flaw position and alarm for stoppage, proving that the flaw detection device satisfies requirements on sensitivity; and if the flaw detection device cannot detect the flaw position, proving that the flaw detection device is insufficient in sensitivity and needs repair. The transverse defect verification method adopts an on-line flaw cutting and on-line verification scheme, the flaw is cut with the pipe cutting device during the production process of the steel wire, the length and depth of the flaw are determined, then a detector is used for detecting the flaw for verifying the sensitivity of the detector, and the method is quick, high in accuracy, lower in cost and flexible and convenient in use due to controllable verification frequency and controllable defect size.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

A large-scale surface modeling product surveying and mapping device

ActiveCN110017779BDetermine the lengthDetermine the widthUsing optical meansLaser rangingElectric machinery

The invention discloses a large-scale curved surface modeling product mapping device, which comprises a base, wherein two X-direction laser range finders are symmetrically arranged on the upper surface of the base, and two mounting grooves, a motor cavity and an equipment cavity are symmetrically arranged on the upper surface of the base, wherein, a first motor is arranged in the motor cavity, a threaded rod is horizontally arranged in each mounting groove, and one end of each threaded rod extends into the equipment cavity and is provided with a synchronizing wheel, wherein two of the synchronizing wheels are provided with a synchronizing belt together, each threaded rod is in threaded connection with a moving seat, and Y-direction laser range finders are arranged on the side walls of thetwo moving seats. The invention has the advantages that: the device is ingenious in structure, can measure the side wall positions and the upper surface positions of different positions of the special-shaped part, can measure large-scale curved surface products with complex surface structures, shortens the measuring time of the special-shaped part, and reduces the measuring process, so that the difficulty of measuring the special-shaped part is reduced.

Owner:安徽智时代软件服务有限公司

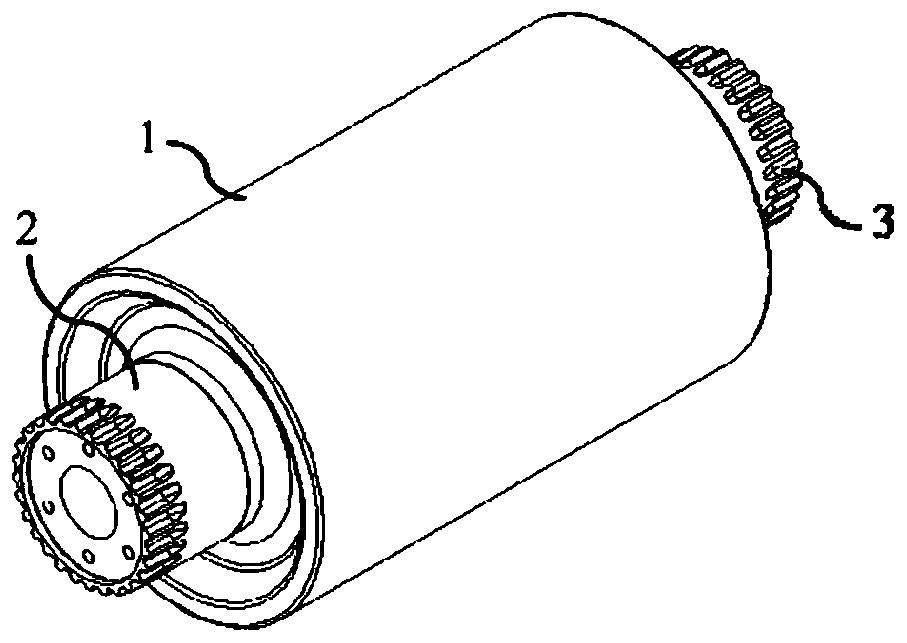

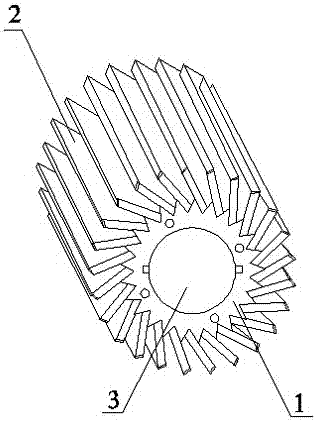

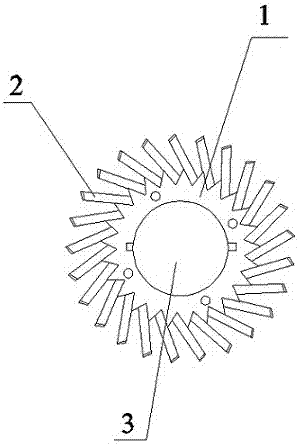

Combined shearing tool for plastic granulator

The invention provides a combined shearing tool for a plastic granulator. The combined shearing tool comprises a hollow cutter base, blades, a cutter shaft and limiting blocks. The hollow cutter base is connected with the blades and the cutter shaft. The outer edge of the hollow cutter base is of a sawtooth shape. Wheel teeth of the hollow cutter base are conical teeth. Each blade comprises a cutting edge mechanism, a connecting block and a locating block. Each cutting edge mechanism is provided with a first protruding block and a first screw hole. Each connecting block is provided with a first screw hole, a second protruding block and a first groove corresponding to the first protruding block. Each locating block is provided with a first screw hole, a third screw hole and a second groove corresponding to the second protruding block. The blades are fixed through the limiting blocks. Each limiting block is provided with a second screw hole. The hole diameter of each second screw hole is the same as that of each first screw hole. The shearing tool is of a combination type, the length of the blades is determined conveniently according to actual use, and meanwhile the interval between the blades can be adjusted. The combined shearing tool is reasonable in design, flexible and convenient to use and beneficial for improving production efficiency.

Owner:YANCHENG SHENYUAN PLASTIC

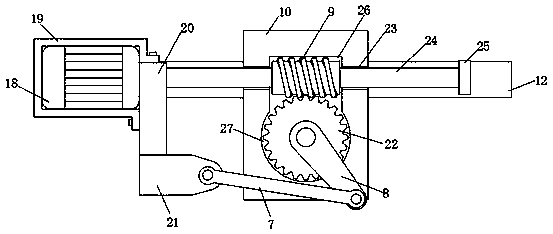

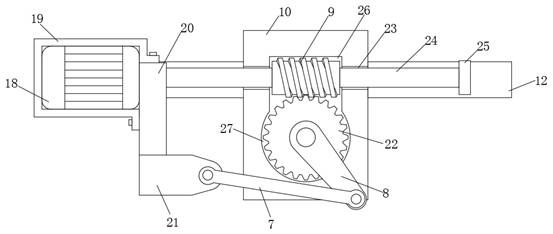

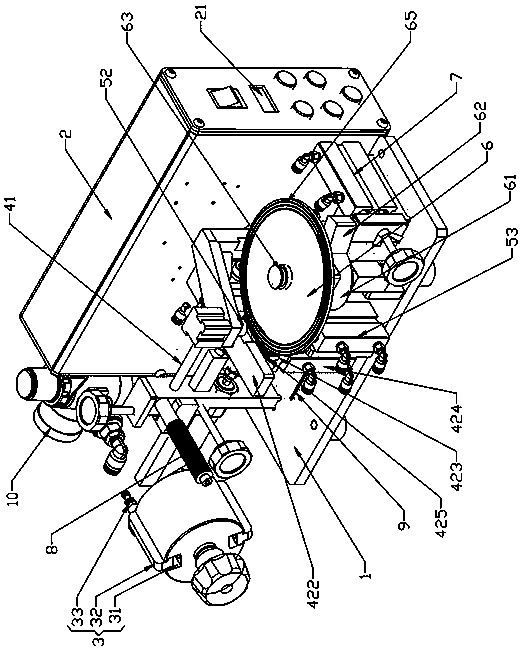

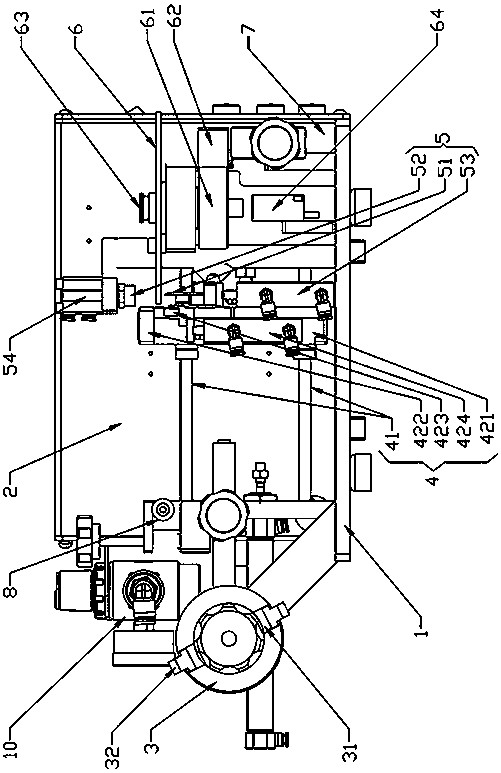

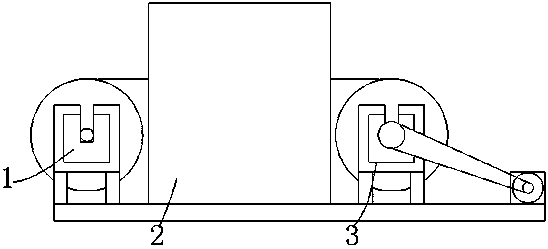

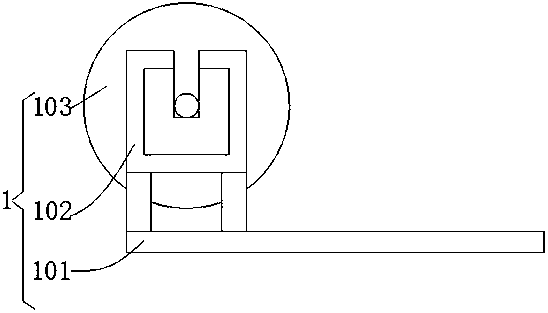

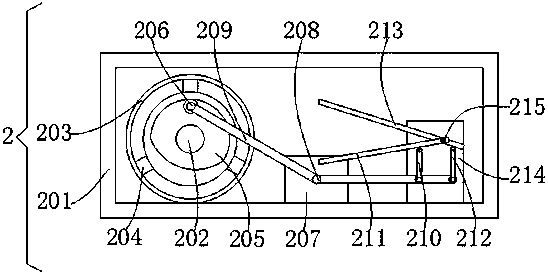

Adhesive tape machine

PendingCN107840183ARealize the cutting functionSimple structureFinal product manufacturePrimary cellsEngineeringMechanical engineering

The invention discloses and provides a desktop adhesive tape machine which is simple in structure, low in manufacturing cost and high in efficiency. The adhesive tape machine comprises a mounting bottom plate, an electrical system box arranged on one side of the mounting bottom plate, a material hanging reel, an adhesive tape pulling assembly, an adhesive tape cutting assembly and a discharge platform, wherein the material hanging reel, the adhesive tape pulling assembly, the adhesive tape cutting assembly and the discharge platform are sequentially arranged on the mounting bottom plate from back to front; the adhesive tape pulling assembly comprises longitudinal rails arranged between the material hanging reel and the discharge platform and an adhesive tape clamping device in sliding fitwith the longitudinal rails; the adhesive tape cutting assembly comprises a cutter and a pressing block matched with the discharge platform and located over the discharge platform; the adhesive tape clamping device and the adhesive tape cutting assembly are both electrically connected with the electrical system box. The adhesive tape machine can be applied to the technical field of adhesive tape machines.

Owner:钟丙华

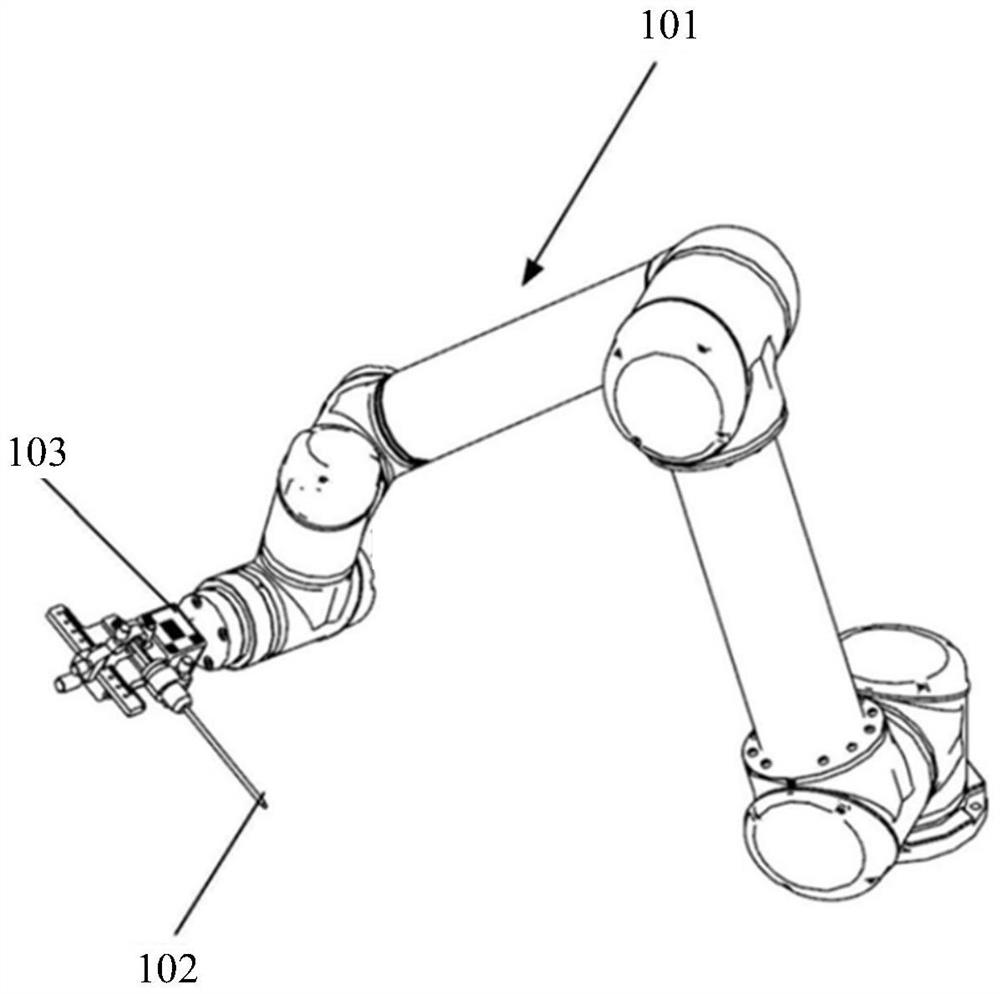

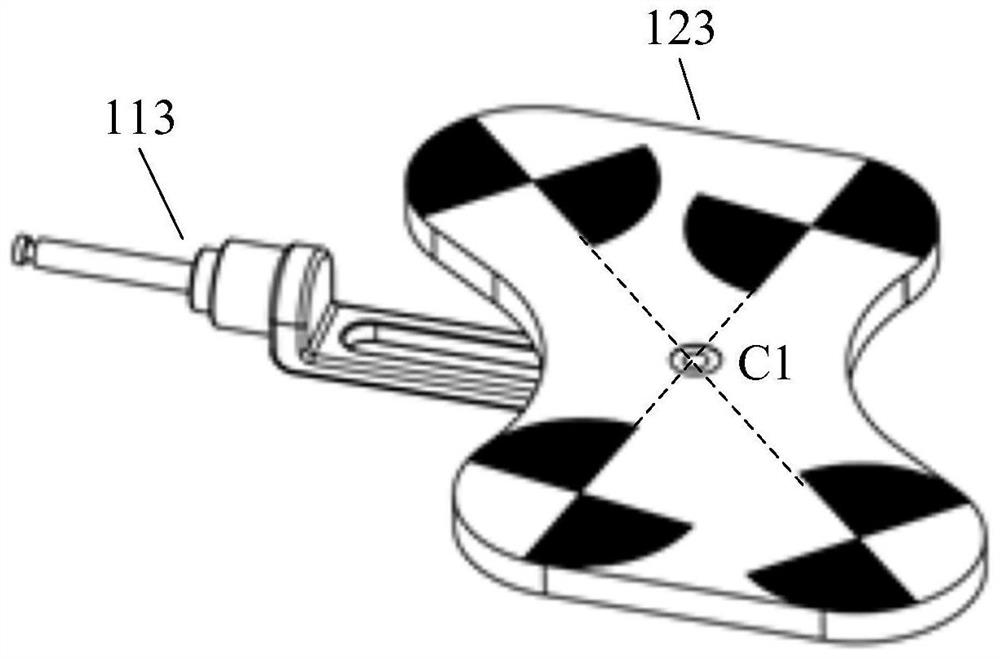

Length measuring system of marking block and surgical robot system

PendingCN114343848ADetermine the lengthGuarantee the effect of surgerySurgical robotsMechanical measuring arrangementsPhysical medicine and rehabilitationThree-dimensional space

The invention provides a length measuring system of a marking block and a surgical robot system.The length measuring system of the marking block comprises a fixing device used for fixing the marking block and enabling the marking block to do circular motion around a provided axis, when the marking block is fixed to the fixing device, the root of the supporting piece is located on the axis, so that the supporting piece drives the center of the marking body to rotate around the axis. The image shooting device is used for tracking the movement process of the marking block so as to record a plurality of three-dimensional space coordinates formed when the center of the marking body moves; the measuring host is used for determining the length of the marking block according to a plurality of three-dimensional space coordinates formed when the center of the marking body moves and a fitting circle center coordinate of the plurality of three-dimensional space coordinates, the length of the marking block is accurately determined, and therefore the operation effect is guaranteed.

Owner:BEIJING DIACRID MEDICAL TECH

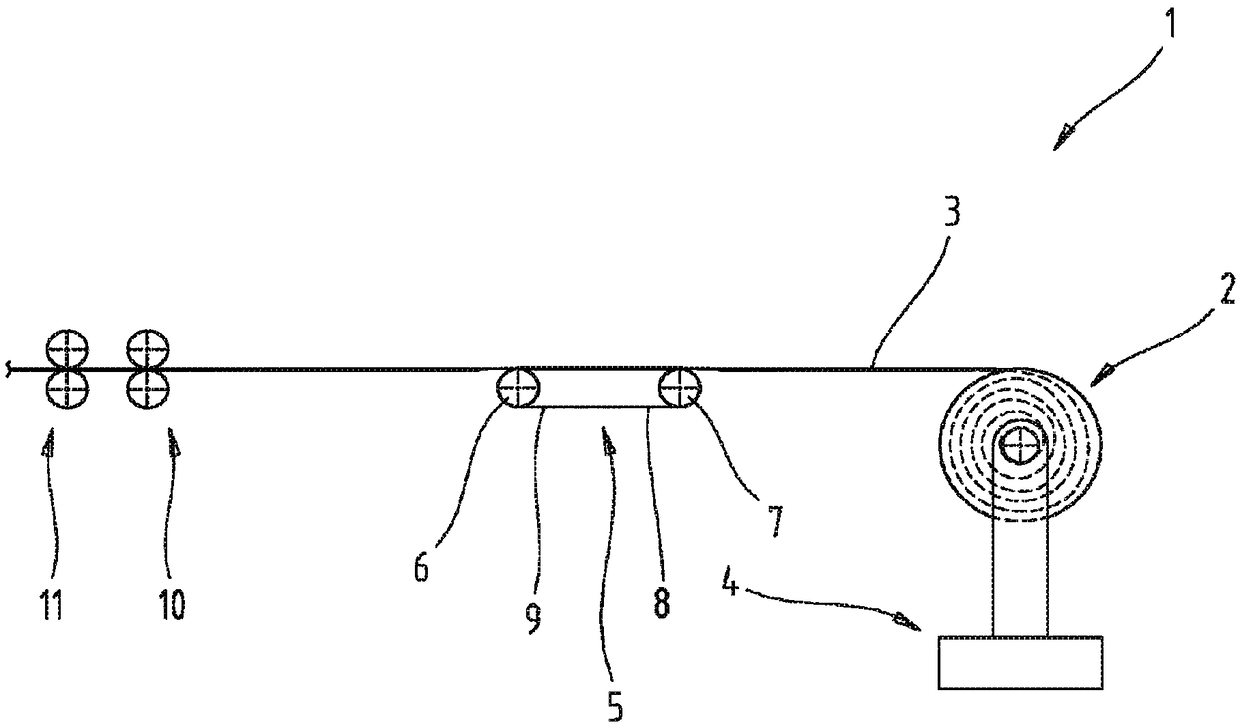

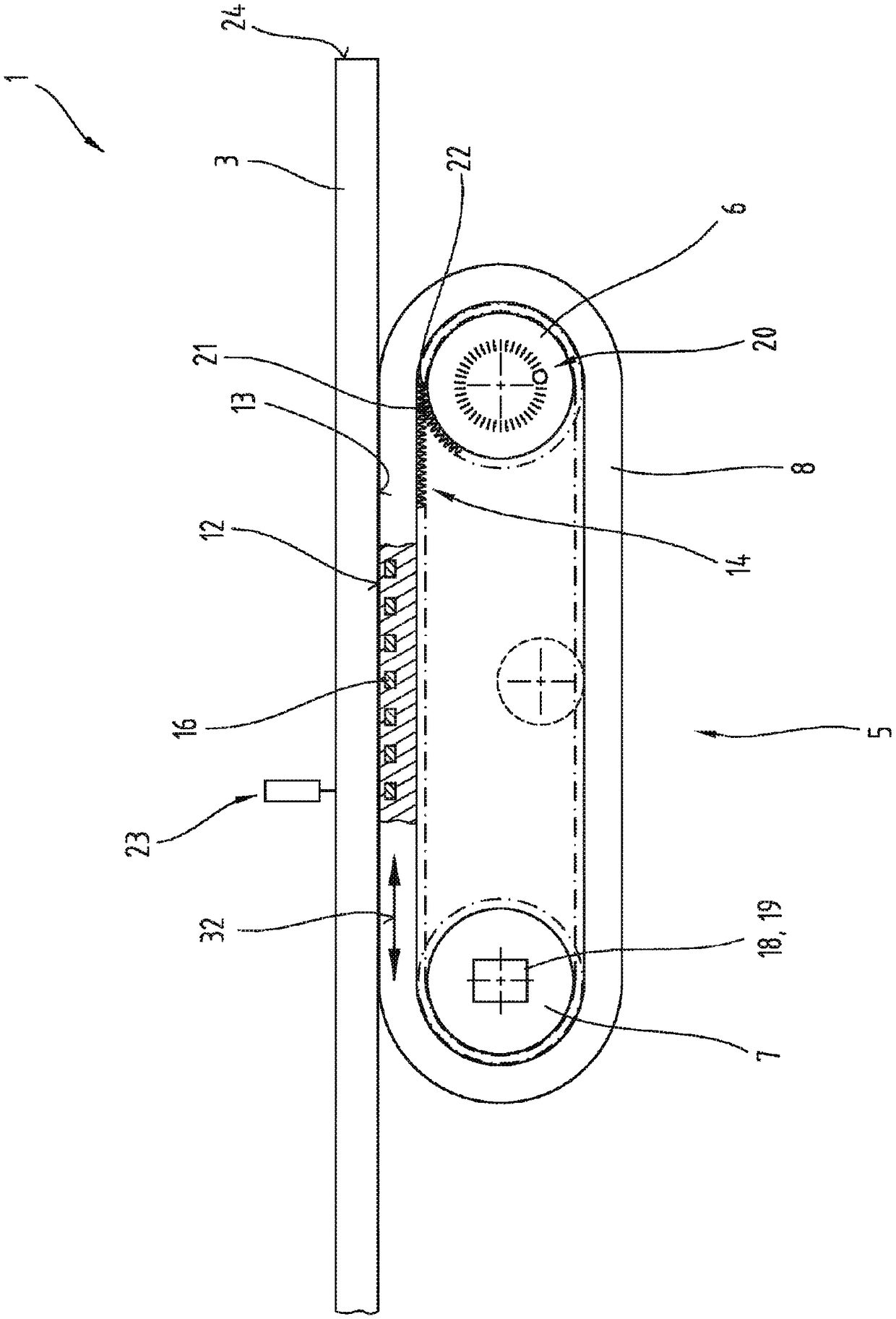

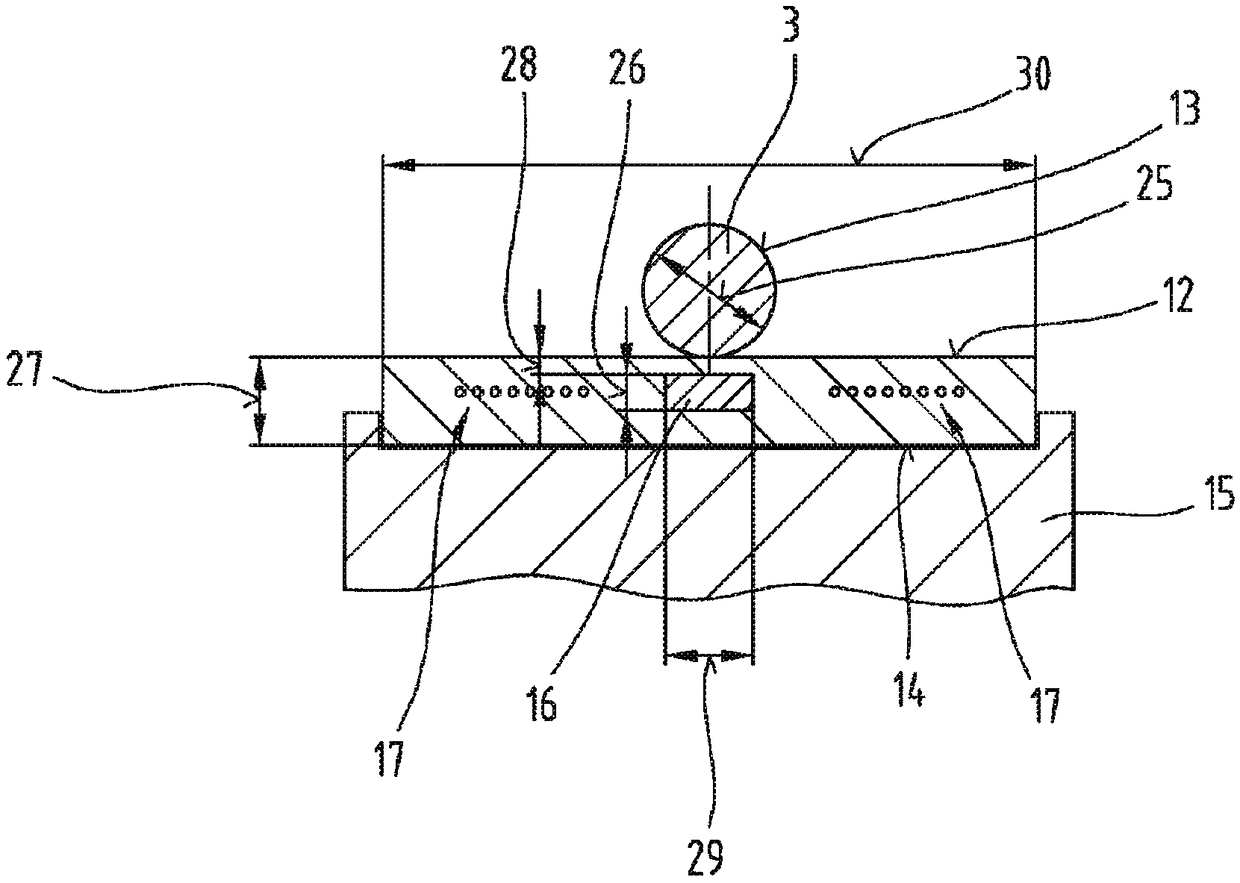

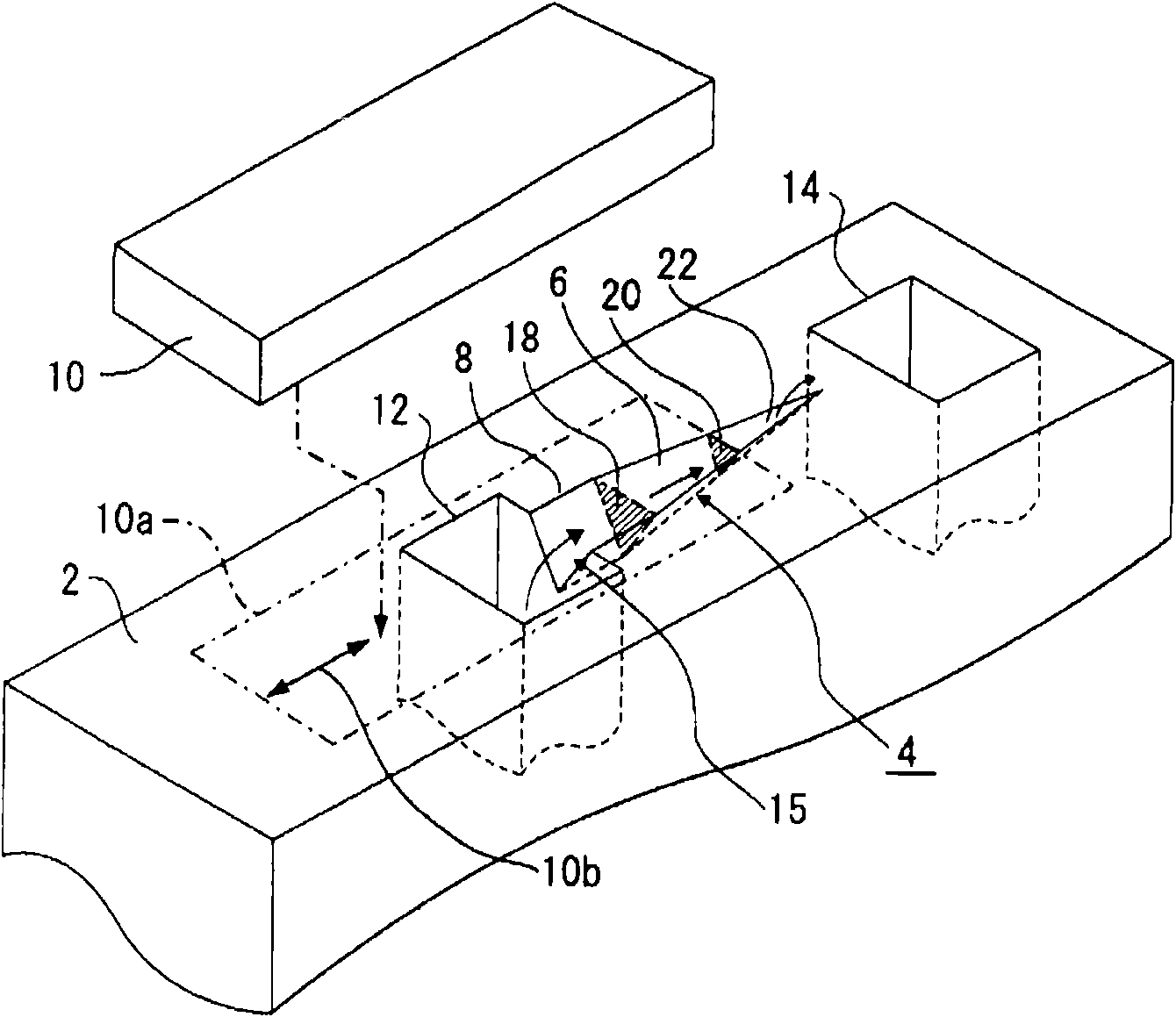

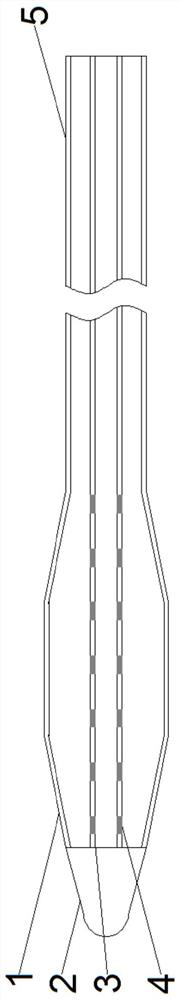

Production system for processing a wire material wound to form a wire reel, comprising a conveying means with permanent magnets

InactiveCN108883453AEasy to unwindReduce tensionConveyorsMetal-working feeding devicesWire rodEngineering

The invention relates to a production system (1) for processing a wire material (3) wound to form a wire reel (2), in particular reinforcing steel. The production system (1) comprises a receiving device (4) for receiving the wire reel (2); an unreeling device (5) for removing the wire material (3) on the wire reel (2); and a processing device (10) for processing the removed wire material (3). Theunreeling device (5) comprises a conveying means (8) surrounding a first deflection roller (6) and a second deflection roller (7), wherein permanent magnets (16) are arranged on the conveying means (8) and an increased frictional connection can be established between a surface (13) of the wire material (3) and an outer surface (12) of the conveying means (8) by means of the permanent magnets (16).

Owner:胡贝特拉佩斯托费尔

Method of designing minute flow rate controller with entrance throttle groove

InactiveCN101568754AEasy to controlDetermine dimensionless cross-sectional areaSlide valveMomentumControl theory

A method of designing a minute flow rate controller that is capable of accurately controlling the minute flow rate of a fluid and realizing desired valve characteristics without inducing any unsteadiness of fluid flow and has a simple configuration with respect to a throttle groove for controlling the fluid flow rate. With respect to a minute flow rate controller comprising inflow passage (12) for introducing a fluid, valve member (2) furnished with main throttle groove (6) for causing the introduced fluid to flow from a starting end toward a finishing end thereof, fluid outflow port (20) opened with an optional cross section by a flow rate regulating member and outflow passage (14) for leading out the fluid flowing out from the fluid outflow port (20), there is provided a method of designing the minute flow rate controller with entrance throttle groove, comprising providing entrance throttle groove (8) communicably preceding the starting end position of the main throttle groove (6), and, on the basis of a relational expression derived from the momentum equation of the fluid flowing through the entrance throttle groove (8) and the main throttle groove (6), determining the size of the entrance throttle groove (8) so as to exhibit a desired flow resistance.

Owner:FUJIKIN INC +1

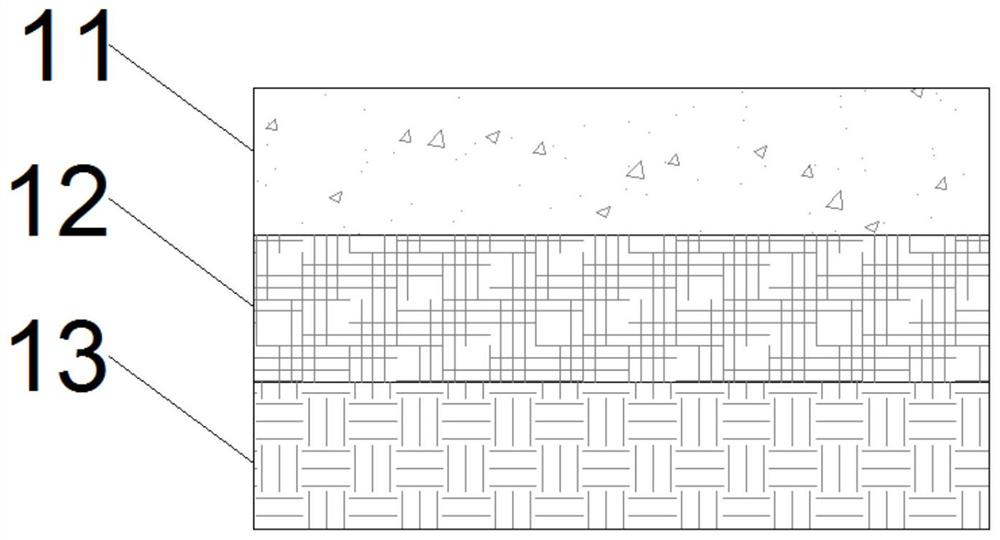

Dilation balloon catheter for pathological change of narrow digestive tract

InactiveCN112245773AEasy to useEasy to measureBalloon catheterSurgeryBalloon catheterAluminum coating

The invention discloses a dilation balloon catheter for a pathological change of a narrow digestive tract. The dilation balloon catheter comprises a balloon, wherein a catheter is arranged inside theballoon, the balloon is formed through combining a corrosion-resistant film, a stretching film and a nylon layer which are arranged sequentially from top to bottom, the corrosion-resistant film is formed through combining an upper-layer PET film, an aluminum coating, an anti-reflecting film, a lower-layer PET film and an EVA adhesive film which are arranged sequentially from top to bottom, and thestretching film is formed through combining a heat-insulating film, a transparent layer, a film layer, a transparent adhesive layer and a release film which are arranged sequentially from top to bottom. According to the dilation balloon catheter, the problem that only fuzzy narrow length and distance of the digestive tract can be judged when the existing dilation balloon catheter is used by working personnel is solved, the stability and accuracy are improved, the bendability and tensile and dimensional stability are further improved, and the practicability is high.

Owner:浙江桐轩医疗科技有限公司

Textile cloth dividing device

InactiveCN109183383AThe split mouth is neatDetermine the lengthSevering textilesEngineeringMechanical engineering

The invention provides a textile cloth dividing device, relates to the technical field of the textile cloth dividing device and aims to achieve the effect of cutting cloth through imitating the way ofscissors, achieve division without being tightened through external forces and achieve neat division edges. The device includes a laying device, a dividing device and a cloth collecting device, wherein the top of the laying device is fixedly equipped with the dividing device, and the top of the laying device is fixedly equipped with the cloth collecting device. The device is advantaged in that arotation disc is driven by a motor to rotate, a track is driven by the rotation disc through a connection rod to rotate, when convex blocks of the track contact with rotation wheels, the top of the rotation wheels moves downwards, the top of a support rod is made to move downwards, a bolt acts as a lever, the other end of the support rod rotates upwards, a first cutting plate and a second cuttingplate are meshed, so the cloth is divided, division can be achieved without being tightened through external forces, and the division edges are neat.

Owner:射阳县汇佳纺织有限公司

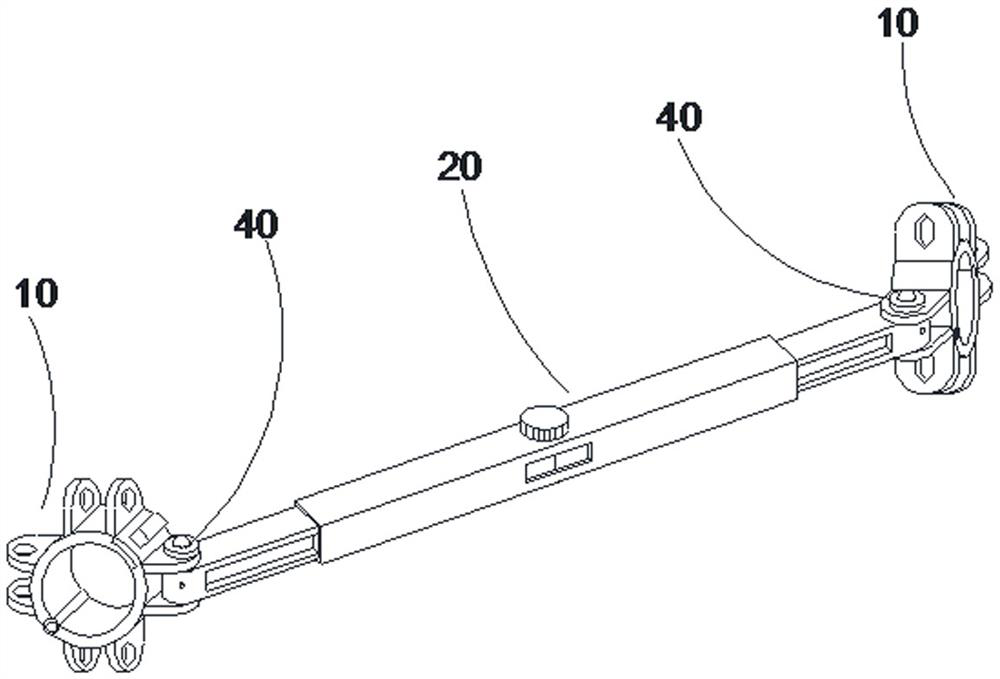

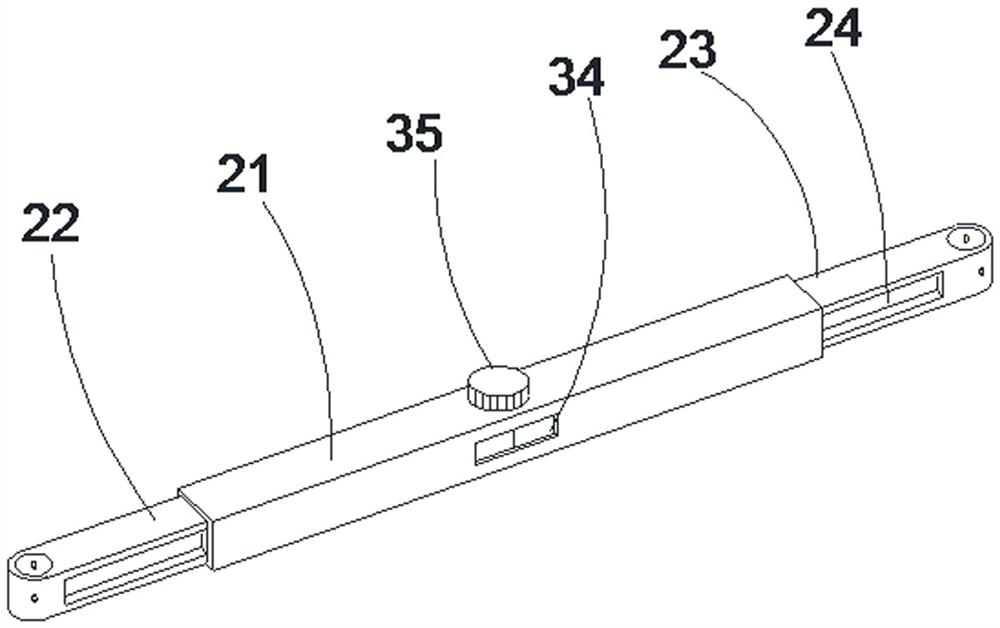

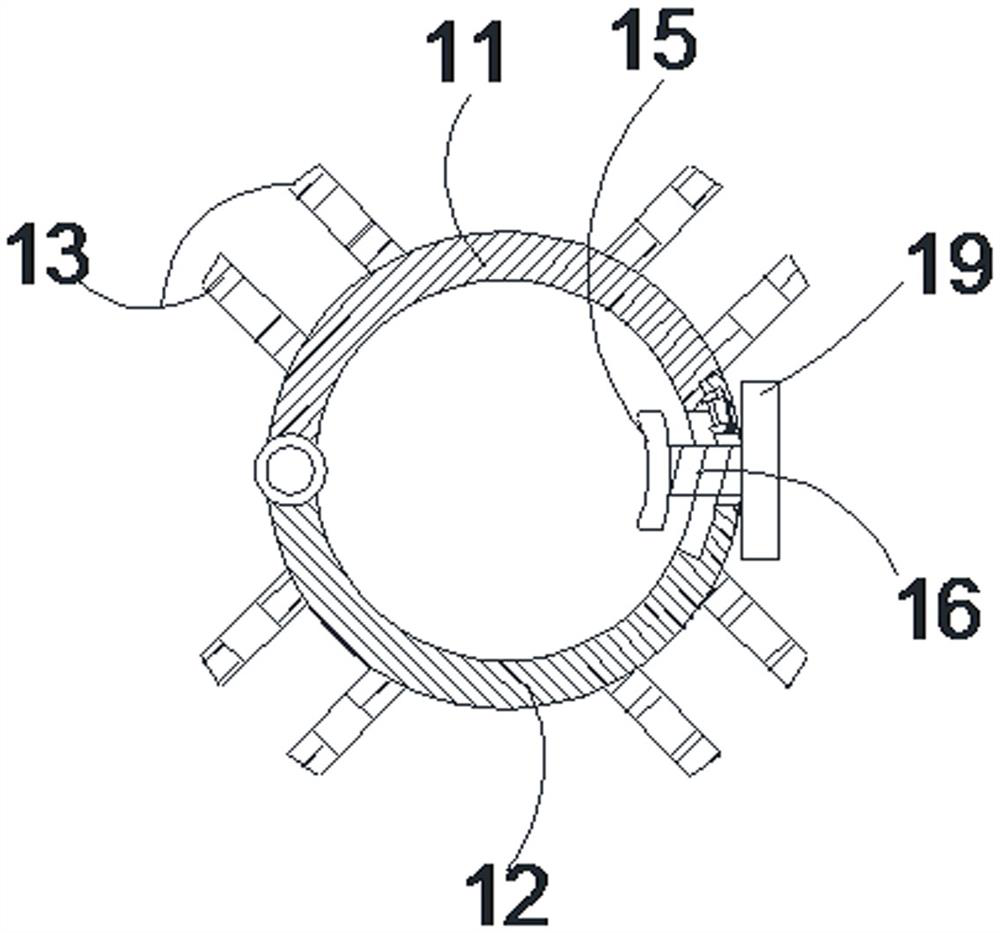

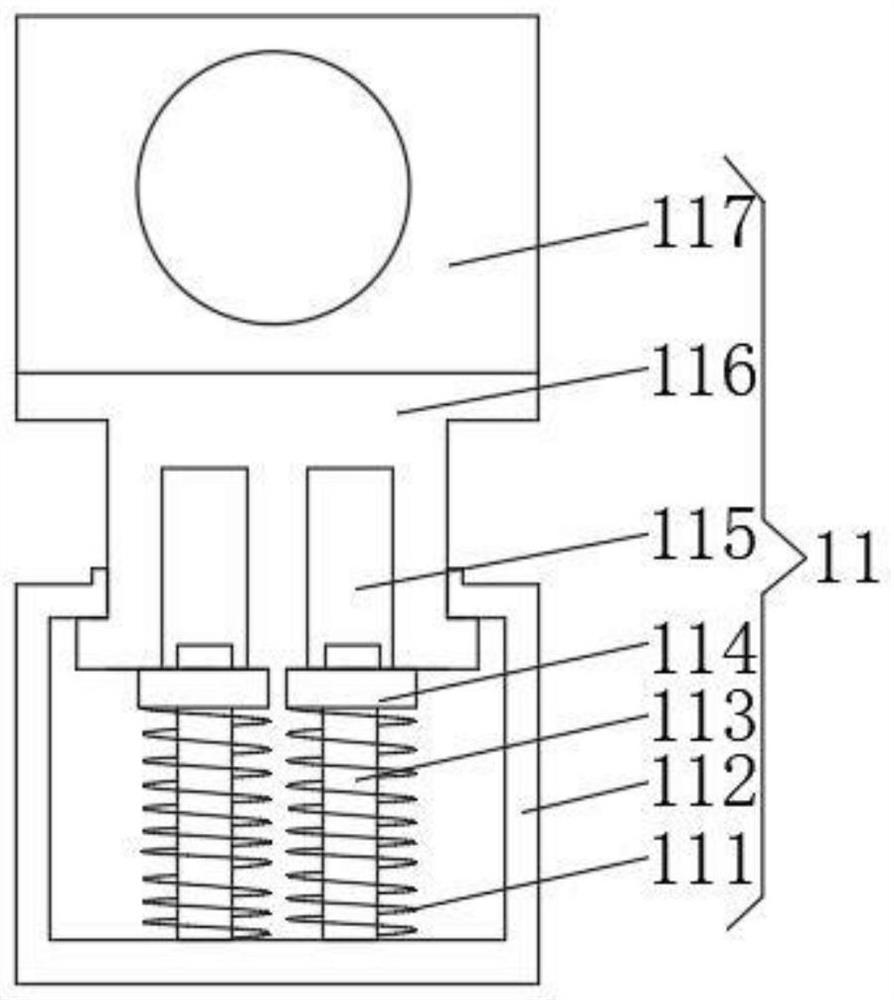

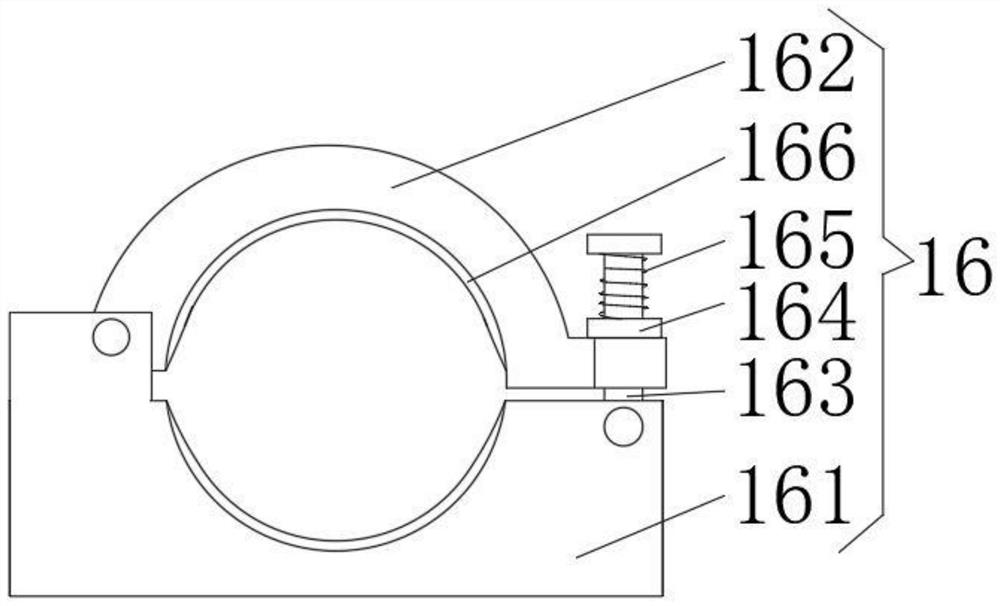

Quick release type scaffold stabilizer bar

ActiveCN113982245AEasy to assemble and disassemblePrevent slidingScaffold accessoriesEngineeringStructural engineering

The invention discloses a quick release type scaffold stabilizer bar which comprises a fixing sleeve, a supporting rod and a positioning piece, the fixing sleeve is used for sleeving and fixing a vertical rod or a transverse rod, the supporting rod comprises a middle sleeve, a first telescopic rod and a second telescopic rod, the middle sleeve is of a quadrangular tubular structure, and strip-shaped protruding guide strips are arranged on the front side wall and the rear side wall of a pipe hole respectively. An adjusting device and a length measuring device are arranged in a pipe hole of the middle sleeve, the first telescopic rod and the second telescopic rod are both of a pipe shell structure matched with the middle sleeve, the left end of the first telescopic rod and the right end of the second telescopic rod are provided with first fixing through holes, and first positioning holes are formed in the side walls of the first fixing through holes. Strip-shaped guide grooves are formed in the front side wall and the rear side wall of the first telescopic rod and the front side wall and the rear side wall of the second telescopic rod respectively, the right portion of the first telescopic rod and the left portion of the second telescopic rod are inserted into the middle sleeve respectively, the guide strips are inserted into the guide grooves, and the left end of the first telescopic rod and the right end of the second telescopic rod are fixedly connected with the fixing sleeve through positioning pieces respectively.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

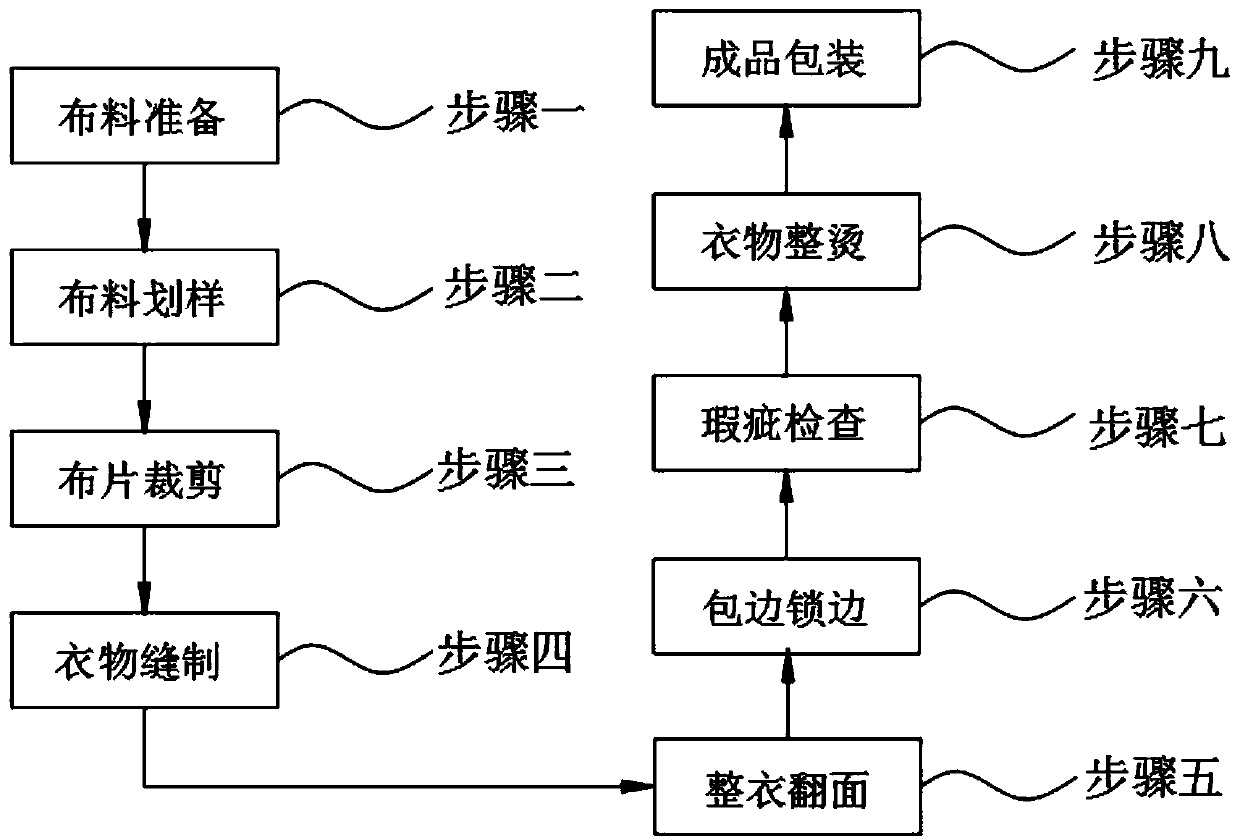

Clothes manufacturing process

InactiveCN111317211AImprove protectionDetermine the lengthClothes making applicancesIndustrial engineeringCotton material

The invention discloses a clothes manufacturing process. The process comprises the following steps: step 1, cloth preparation; 2, cloth marking; 3, cloth piece cutting; 4, clothes sewing; 5, whole clothes turning over; step 6, edge covering and locking; step 7, defect inspection; 8, clothes ironing; and 9, finished product packaging, wherein the cloth preparation step comprises the following steps: raw material selection, cloth weaving and cloth inspection; the step of clothes sewing comprises the following steps: sewing of cut pieces, sewing of sleeve pieces, sewing of whole clothes and seaminspection; the step of whole clothes turning over is characterized by making the rough edge of the seam facing outward; the step of edge covering and beautifying comprises edge covering and edge locking; the step of defect inspection is characterized by detecting the defects of clothes and detecting whether missing sewing and misalignment occur; ironing and shaping are conducted through a steam engine, and the ironed clothes are folded and packed. The process is smooth in process and convenient to operate; seam allowance at the seam joint of the clothes faces outwards, so that abrasion to skin can be avoided; and meanwhile, the clothes are tidy and attractive.

Owner:田娟

Mechanical arm vibration abatement device and method

ActiveCN103615495ADetermine the lengthLow costNon-rotating vibration suppressionManipulatorControl theoryAcceleration Unit

The invention relates to a mechanical arm vibration abatement device and method. By forward and backward rotation of a motor in the middle of a mechanical arm, a screw can be driven to way in two directions. The movement of the screw pushes and tensions the steel cable on one side of the mechanical arm to offset the opposite torque generated by tail end load accelerated movement. The projection, vertical to the steel cable mounting face, of the load inertia can be determined according to the tail end load mass and acceleration, and accordingly the movement direction and required extension length of the screw can be determined by the given screw required extension length formula.

Owner:南通静轩焊接科技有限公司

Ribbon drying and rewinding device for coding machine

The invention discloses a ribbon drying and winding device used for a coding machine. The device comprises a box body. A driving roller is rotatably connected between two sides opposite to the inner wall of the box body. A slide plate is slidably connected to the corresponding position of the driving roller and is arranged between the two sides opposite to the inner wall of the box body. The bottom of the slide plate is fixedly connected to a buffer device. The center of the buffer device is rotatably connected to a driven roller. The two sides which are opposite to the inner wall of the box body are fixedly connected to a fixing block. The top of the fixing block is rotatably connected to a ribbon discharge roller through a rotation fixing device. The top of the inner wall of the box bodyis fixedly connected to a moving device. A heating box is fixedly connected to the corresponding position of the moving device on the top of the box body. The two sides of the heating box are connected to an air blower. The bottom of the moving device is fixedly connected to a ventilation plate. The device relates to the ribbon technology field. By using the ribbon drying and winding device usedfor the coding machine, a problem that existing drying and winding are performed separately is solved, and ribbon quality and work efficiency are increased.

Owner:诸暨叶蔓电子商务有限公司

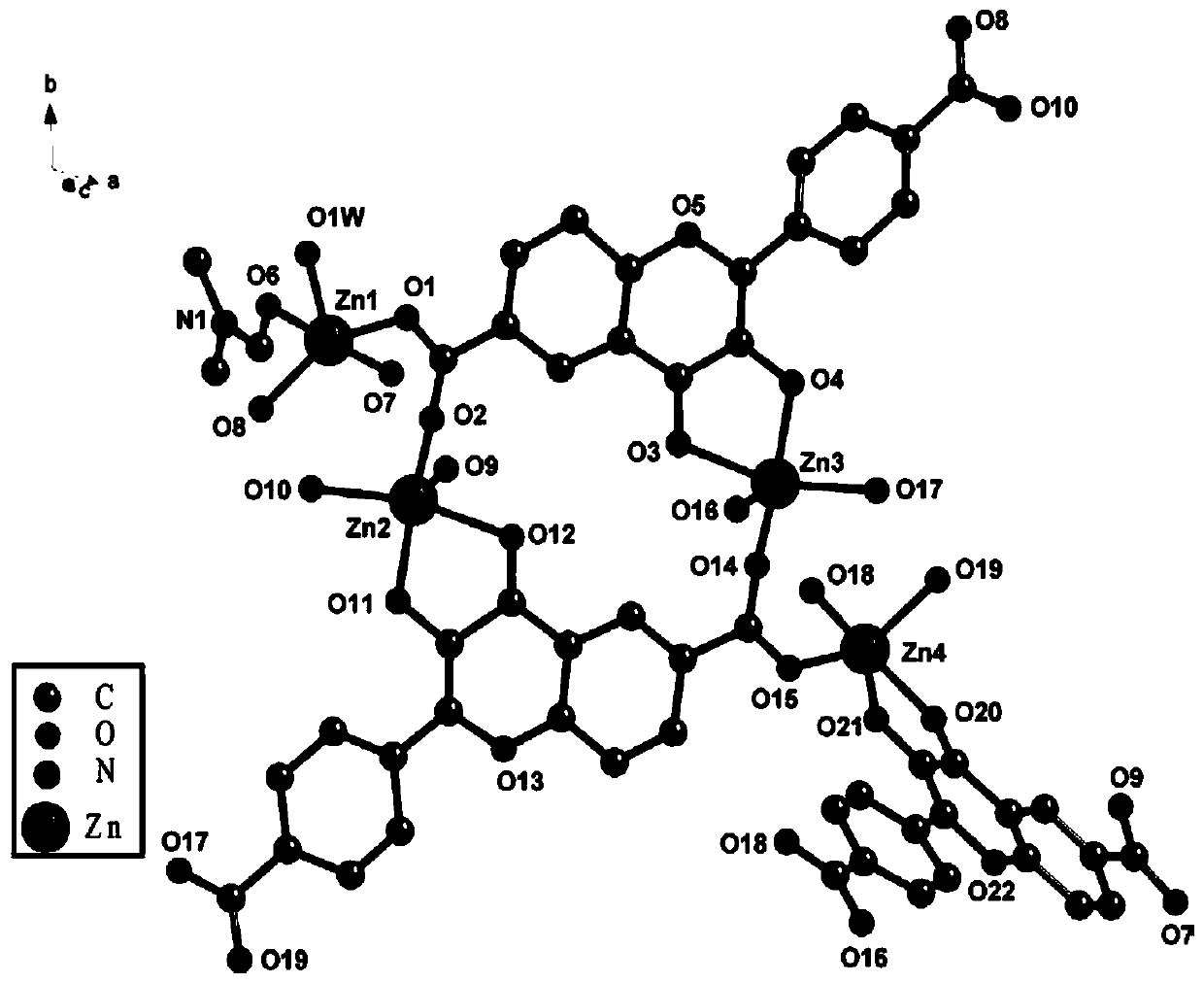

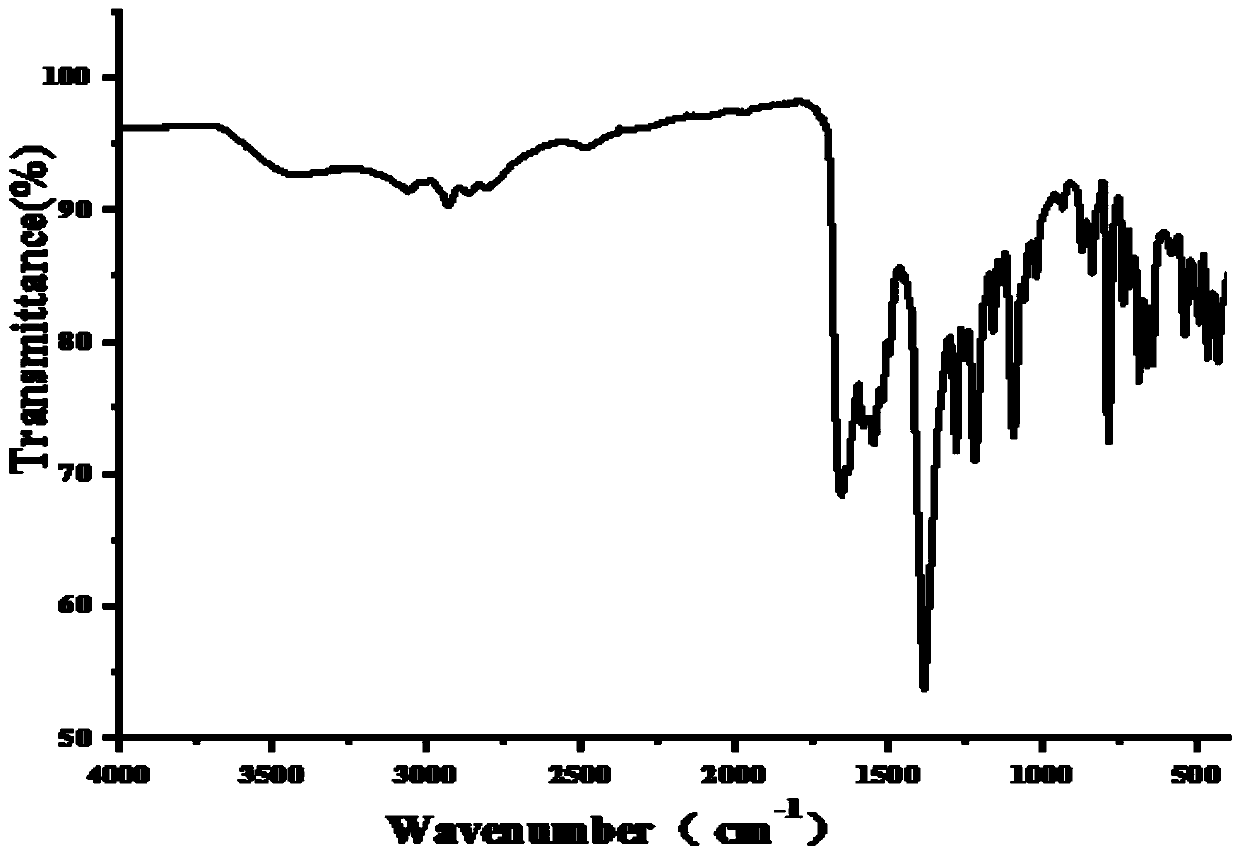

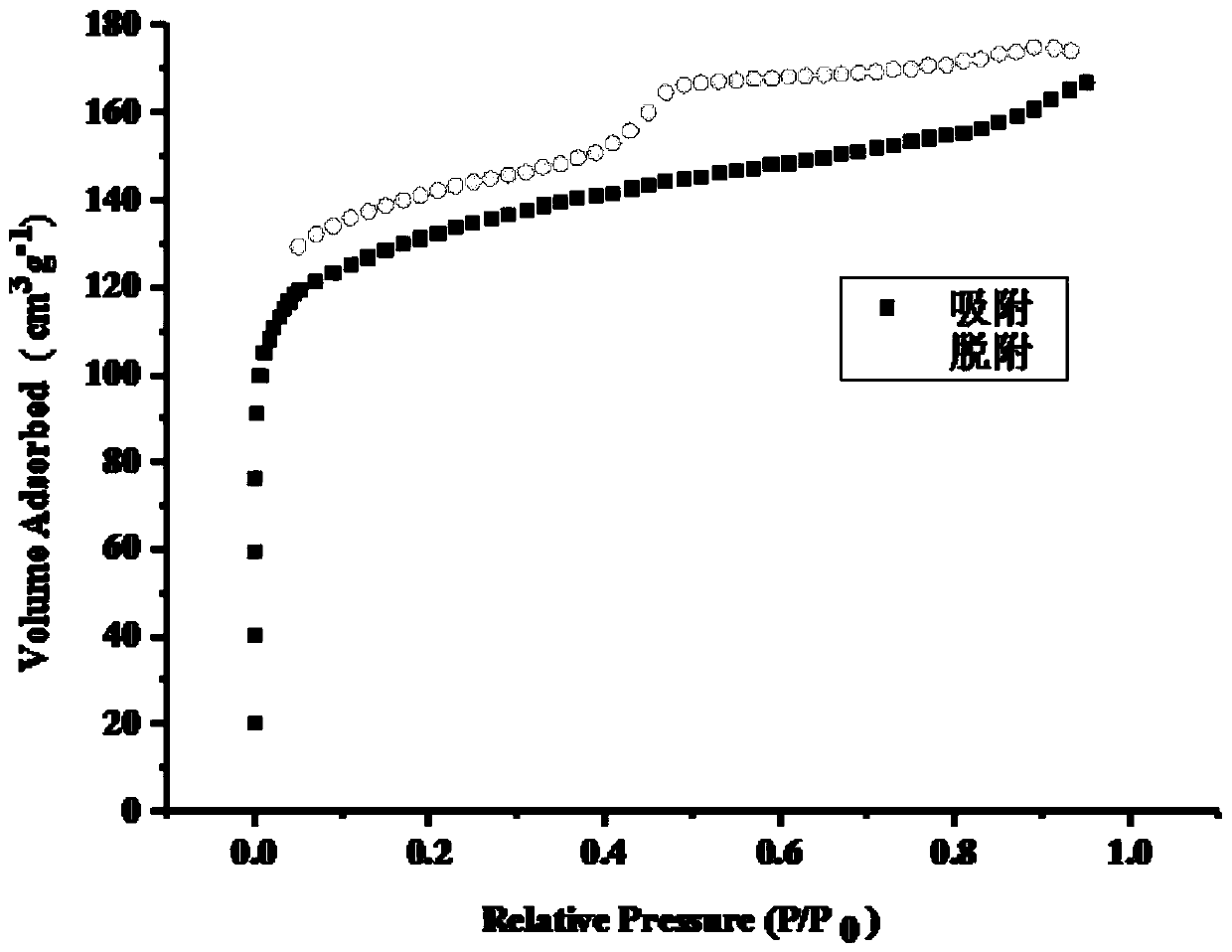

Flavone derivative-zinc complex and preparation method and application thereof

ActiveCN111393460ALow costHigh catalytic efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsGroup 2/12 organic compounds without C-metal linkagesPtru catalystNanoreactor

The invention relates to the field of material synthesis, and discloses a flavone derivative-zinc complex and a preparation method thereof. The preparation method comprises the following steps: S1, taking N, N-dimethylformamide and methyl alcohol and mixing, and obtaining a reaction solvent; S2, taking 3-hydroxy-6, 4 '-flavone dicarboxylic acid, a zinc salt crystal and the reaction solvent, mixing, and sealing to obtain a to-be-reacted substance; S3, sequentially carrying out heating, heat preservation and cooling treatment on the to-be-reacted substance to obtain yellow blocky crystals; and S4, washing and drying the yellow blocky crystals to obtain the complex. The invention also discloses an application of the complex in capturing and converting CO2 under normal pressure. The complex has a unique open Zn site and a smooth pore channel structure and can adsorb a large amount of CO2 at normal temperature and serves as a Lewis acid catalyst to become a nano reactor for reacting CO2 with an epoxy compound at normal temperature and normal pressure to generate cyclic carbonate; meanwhile, due to the high stability of the Zn site, the complex has excellent recovery performance in the catalytic reaction and separation process.

Owner:LUDONG UNIVERSITY

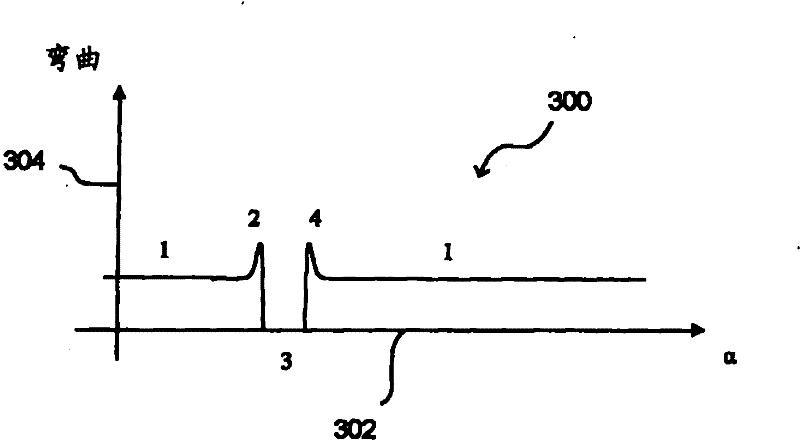

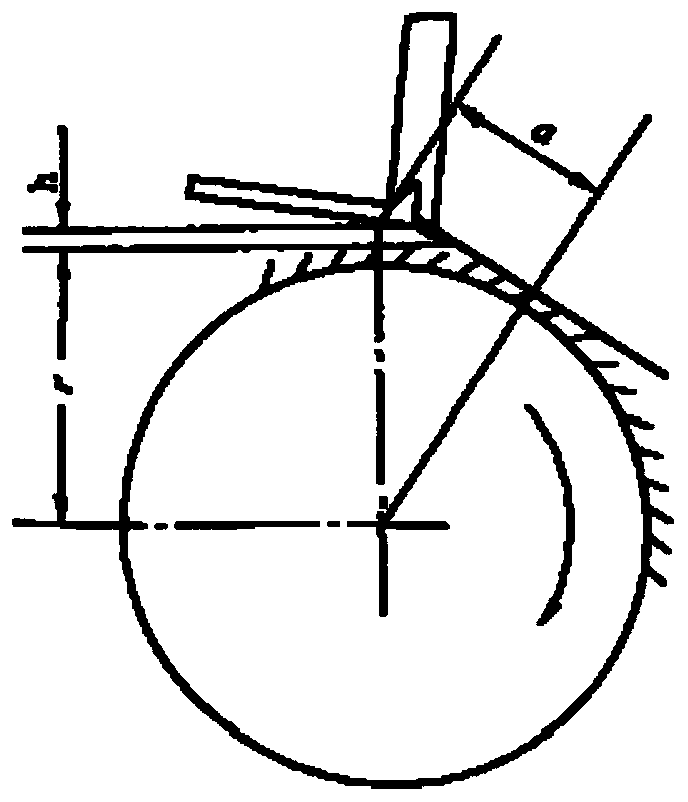

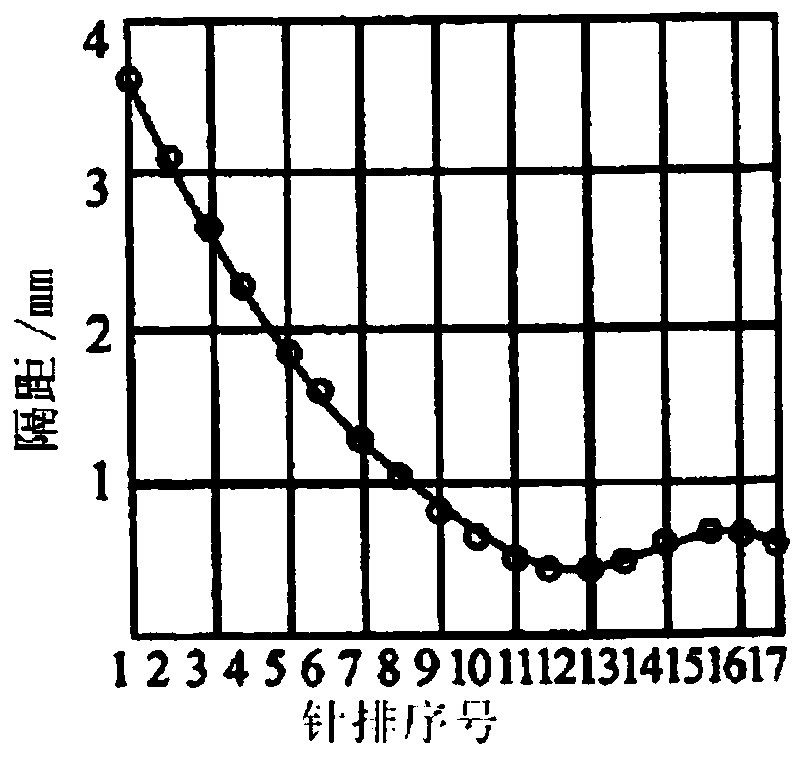

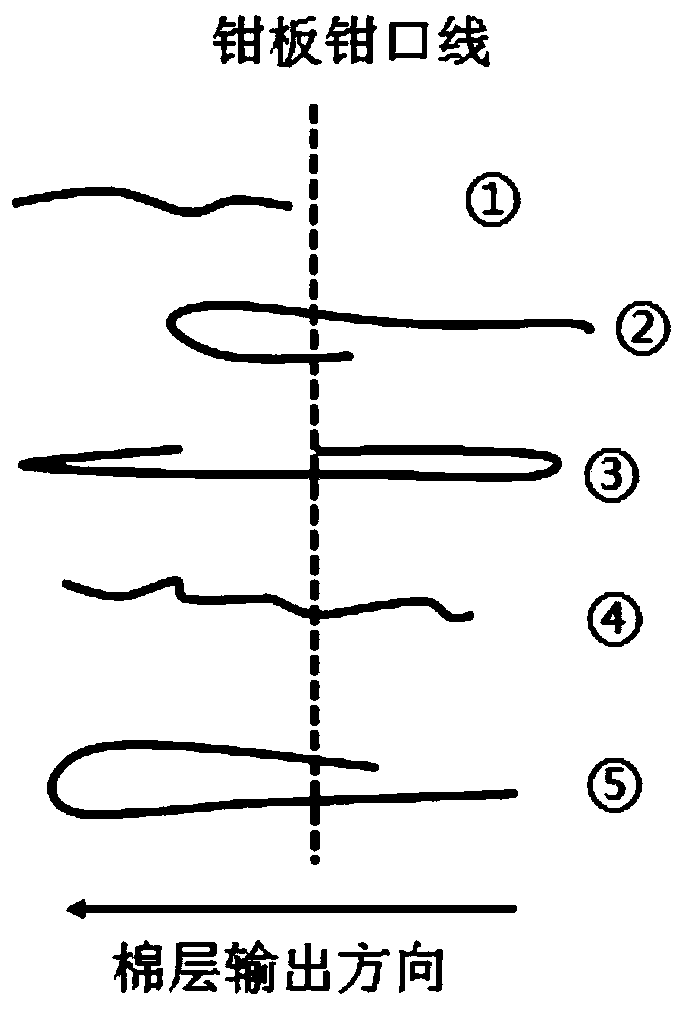

a combing method

The invention relates to a combing method. The dead zone length a meets the formula a=l*(1-eta*), wherein l represents the average fiber length, eta* represents the hook average straightness coefficient of fiber in a cotton layer fed for combing, the average fiber length l is obtained by conducting calculation after fiber grouping, and the hook average straightness coefficient of the fiber in thecotton layer fed for combing is obtained by adding colored fiber in cotton combing feeding, measuring the straightness coefficient of the colored fiber after the processes of cotton combing, pre-drawing and lap doubling and then conducting averaging. The combing method can solve the problems that in the prior art, a method for determining the dead zone length consumes much time and labor and easily causes serious damage to fiber in the combing process; by calculating the appropriate combing dead zone length according to the actual hook condition of the fiber in the cotton layer fed for combing, the combing effect is guranateed while the fiber damage is reduced.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com