Method of designing minute flow rate controller with entrance throttle groove

A technology of flow control device and design method, applied in the direction of valve device, mechanical equipment, sliding valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Preferred Mode for Carrying Out the Invention

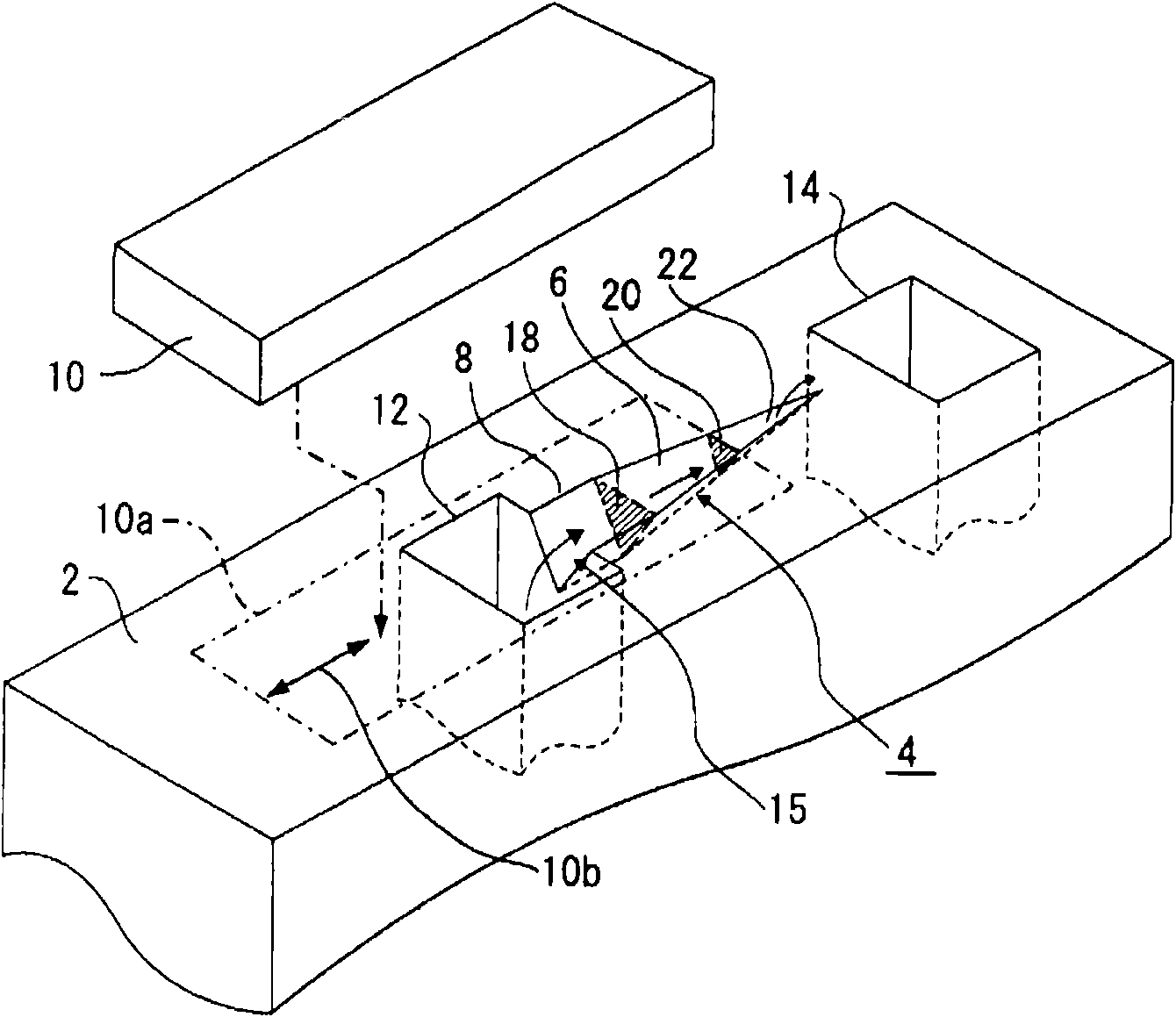

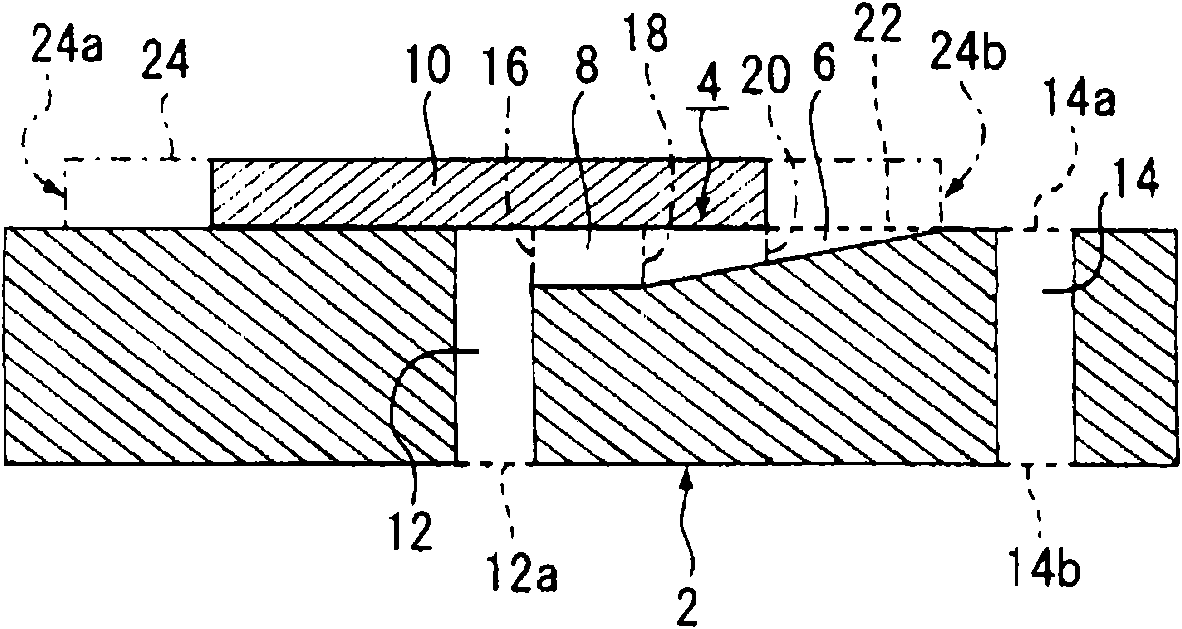

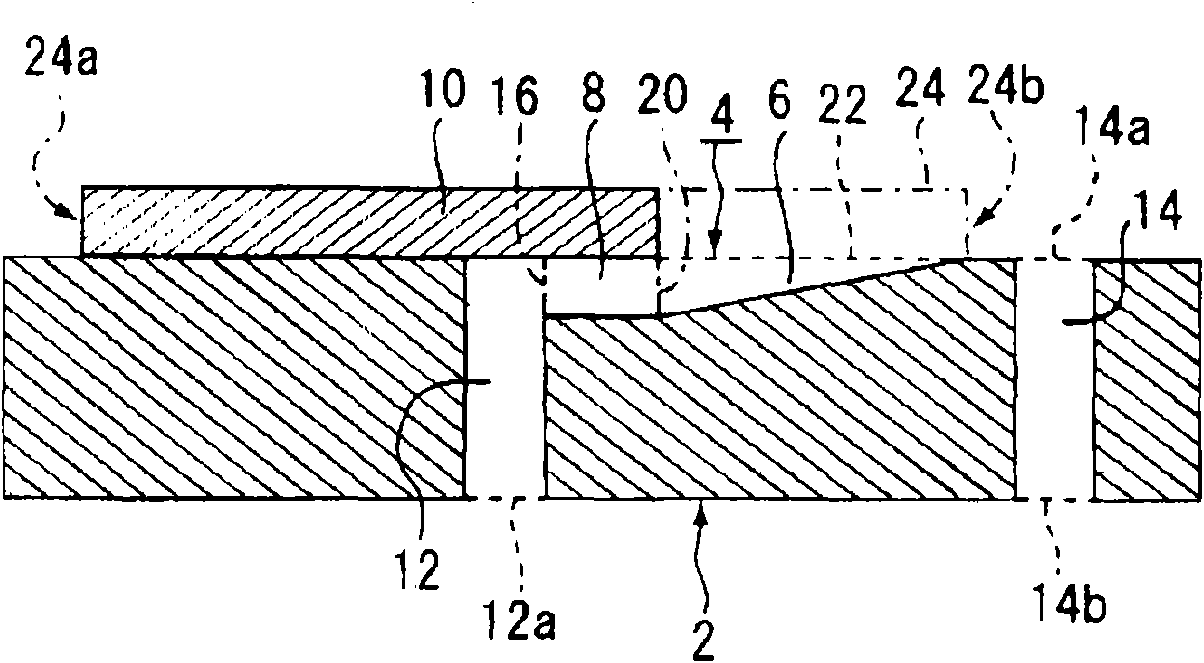

[0039] figure 1 It is a schematic explanatory diagram of the minute flow control device of the present invention. The basic structure of the micro-flow control device consists of a valve core 2 formed with a throttling groove 4 and a flow adjustment slider 10 sliding on the valve core 2 . The above-mentioned throttling groove 4 is composed of a main throttling groove 6 and an inlet throttling groove 8, and the above-mentioned flow adjustment slider 10 is in sliding contact with the upper surface of the valve core, and the above-mentioned main throttling groove 4 and the inlet throttling groove 8 function as a flow path. Features. When the above-mentioned flow rate adjustment slider 10 is located at the upper sliding contact position 10a of the valve core 2, the fluid flowing in from the inflow passage 12 flows into the inlet throttle groove 8 from the inflow portion 15, passes through the above-mentioned main throttle groove 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com