Patents

Literature

80results about How to "Realize the cutting function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

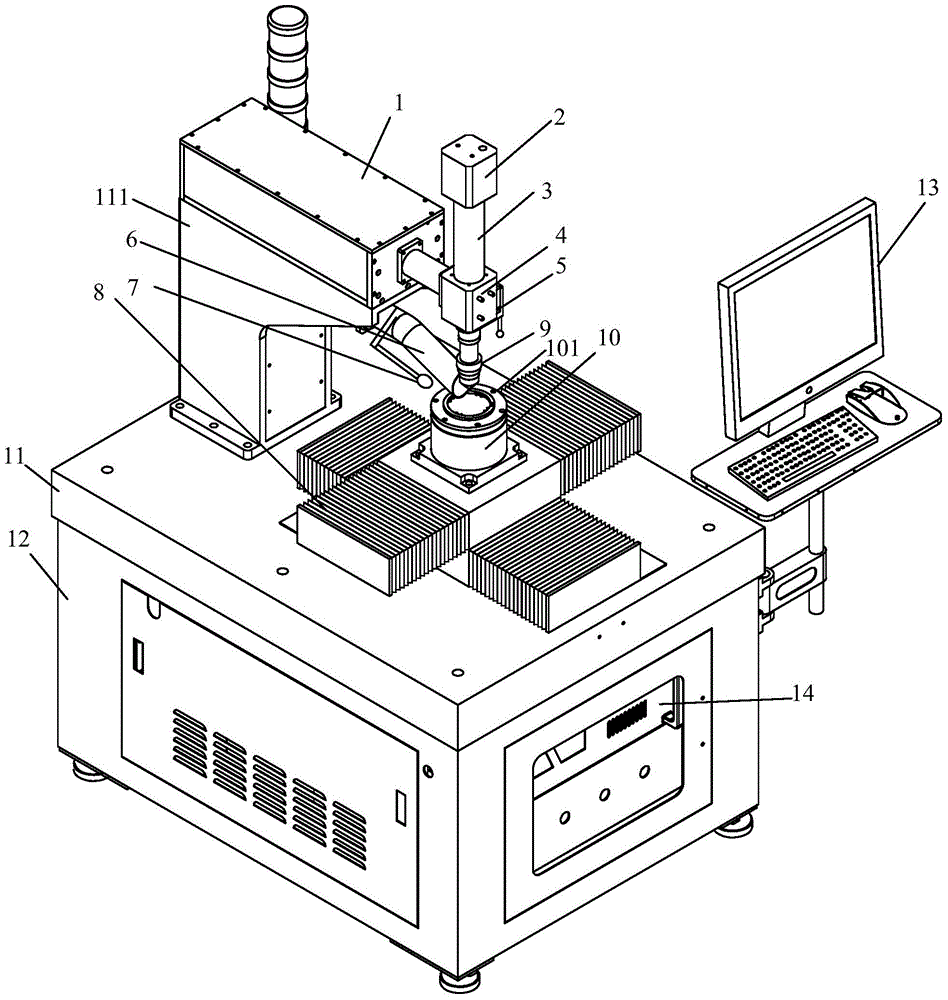

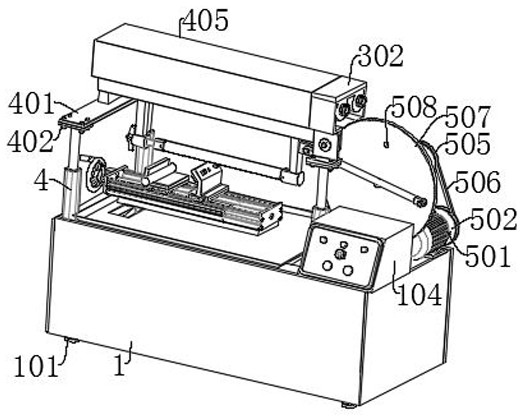

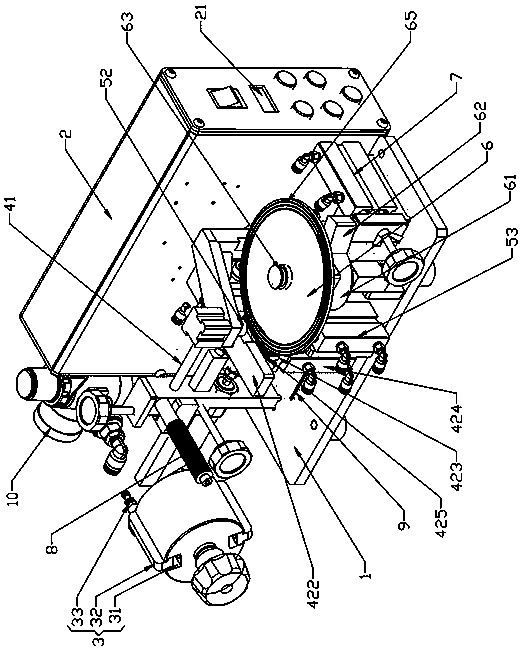

Laser drilling and cutting system for semiconductor material

ActiveCN105057893ASuck away in timeLaser drillingMetal working apparatusLaser beam welding apparatusSemiconductor materialsDisplay device

The invention discloses a laser drilling and cutting system for a semiconductor material. The laser drilling and cutting system comprises a laser path subsystem, a motion platform subsystem, a vision positioning and detection subsystem and an industrial personal computer. The laser path subsystem is composed of a reflector, a laser unit arranged beside the reflector and a focusing mirror arranged below the reflector. The vision positioning and detection subsystem is composed of a displayer, an imaging lens cone, a camera, a focusing mirror and a lighting lamp. The imaging lens cone and the camera are located above the reflector on the same vertical line, the focusing mirror is located below the reflector, and the lighting lamp is arranged beside the focusing mirror. The camera is connected with the reflector through the imaging lens cone. The reflector can reflect lasers and also can conduct light transmittance of an imaging light source. Laser synchronous drilling, machine vision positioning secondary re-drilling, drilling form and position error detection, laser cutting and other functions are integrated and achieved for the semiconductor material in the motion process, and through hole and blind hole drilling, laser cutting, vision detection and other functions can be achieved for the semiconductor material in the motion process.

Owner:SHANGHAI MICRO SEMI WORLD

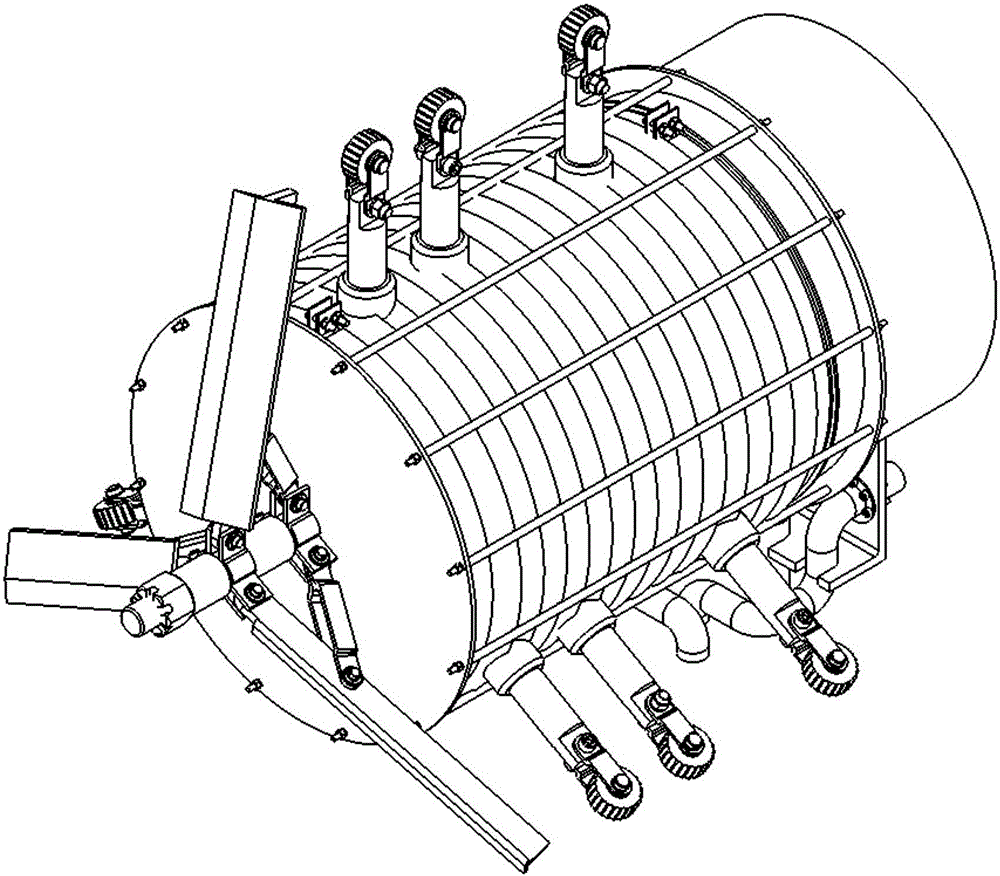

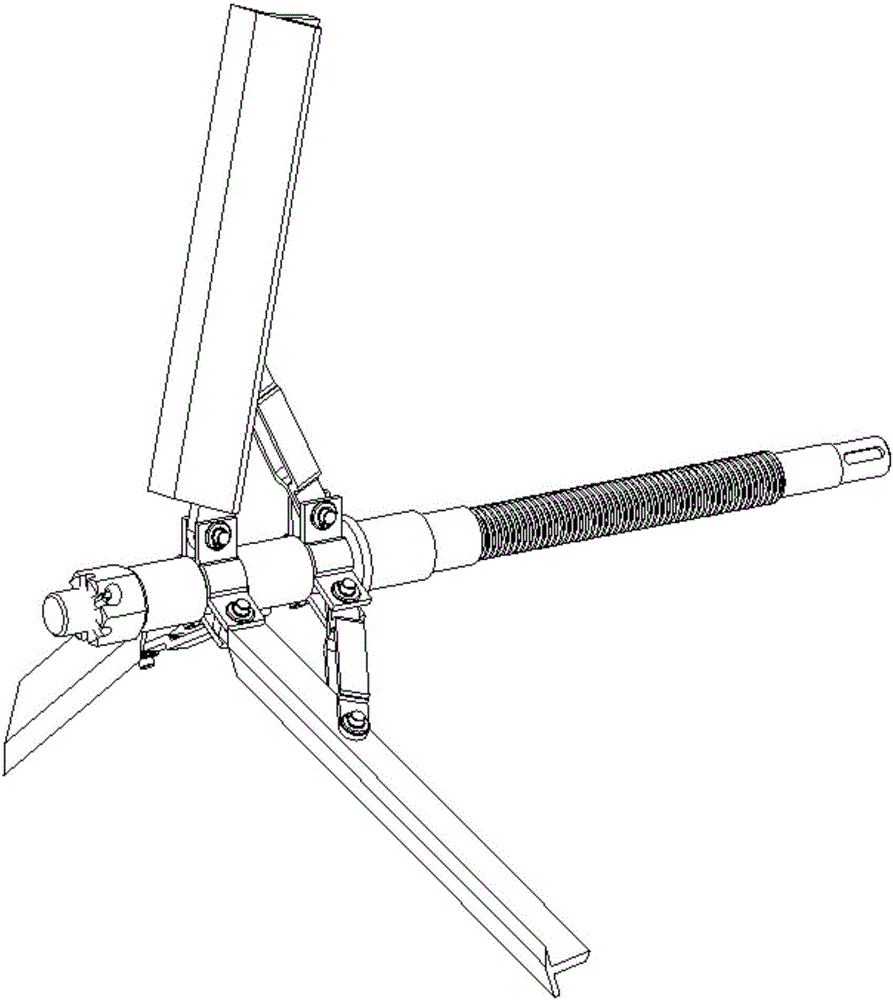

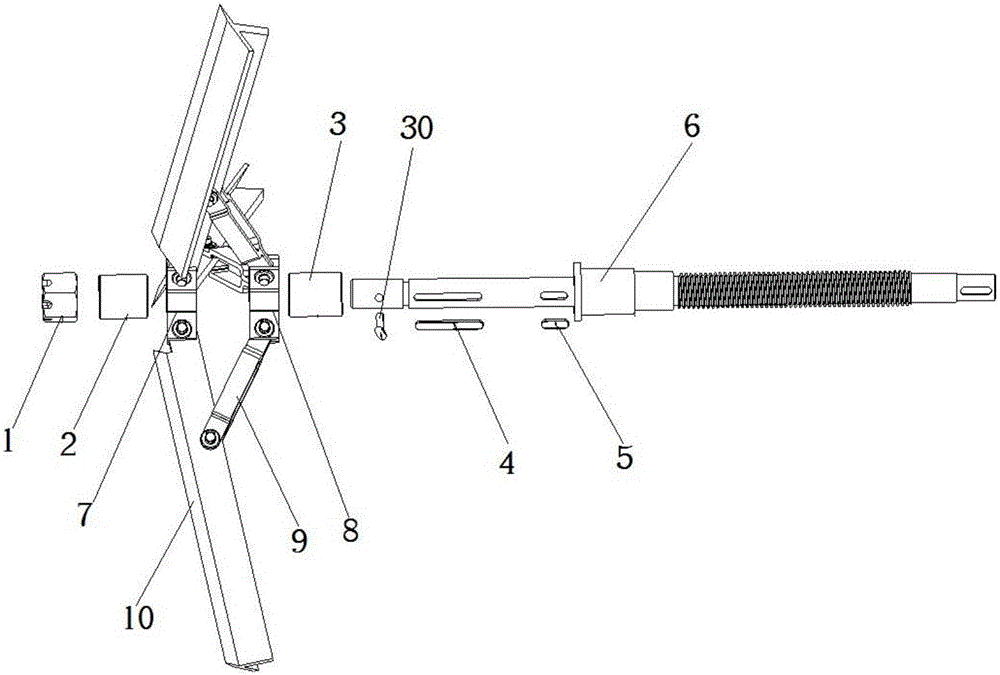

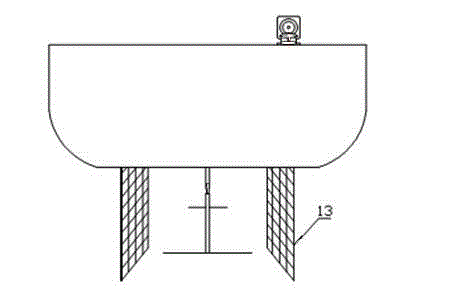

Novel underground drainage pipeline sewage disposal device

ActiveCN105149300AEffective dredgingProtection securityHollow article cleaningSubsurface drainageSewage

The invention discloses a novel underground drainage pipeline sewage disposal device which comprises a cutting mechanism, a self-walking mechanism, a waterproof mechanism and a sewage disposal mechanism. The self-walking mechanism is arranged on the periphery of the cutting mechanism and externally provided with the waterproof mechanism. The sewage disposal mechanism is arranged at the end of the outer side of the waterproof mechanism. By means of the self-walking mechanism, the novel underground drainage pipeline sewage disposal device can go ahead in a pipeline in a creeping mode and cut and remove sewage in the pipeline in the walking process. Cutter heads and the walking mechanism are adjustable, and the requirement for different pipe diameters is met. The functions of cutting, sewage disposal and self-walking are achieved. Robot operation with water is achieved. The two hands of a worker can be relieved through a drainage pipeline mechanical device, manual interference is reduced, manual sewage disposal is replaced completely, worker safety is guaranteed, and the drainage pipeline is efficiently dredged.

Owner:TIANJIN CHENGJIAN UNIV

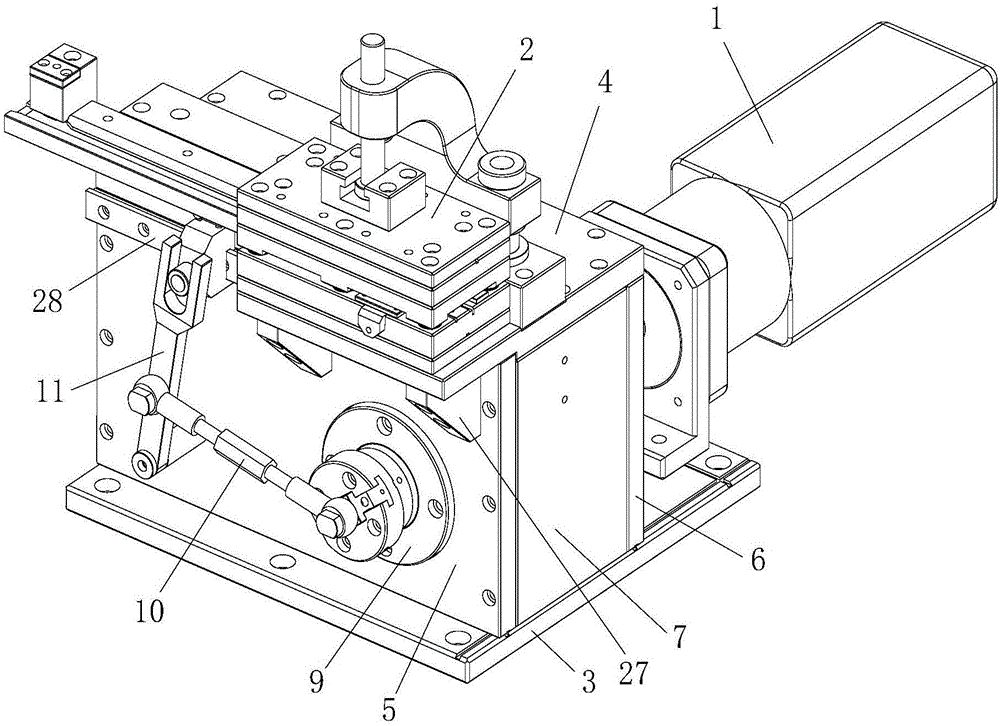

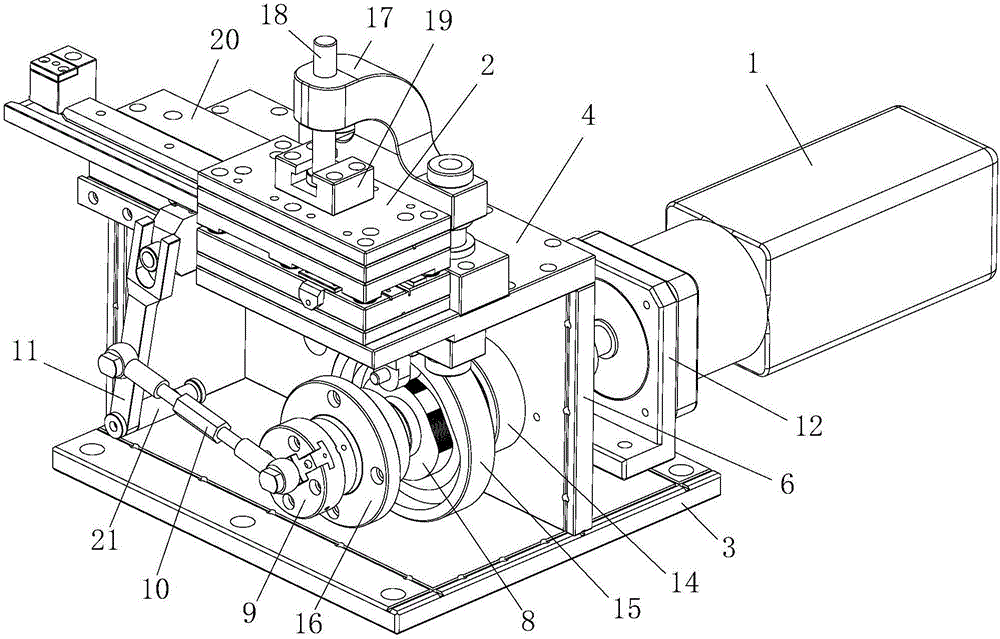

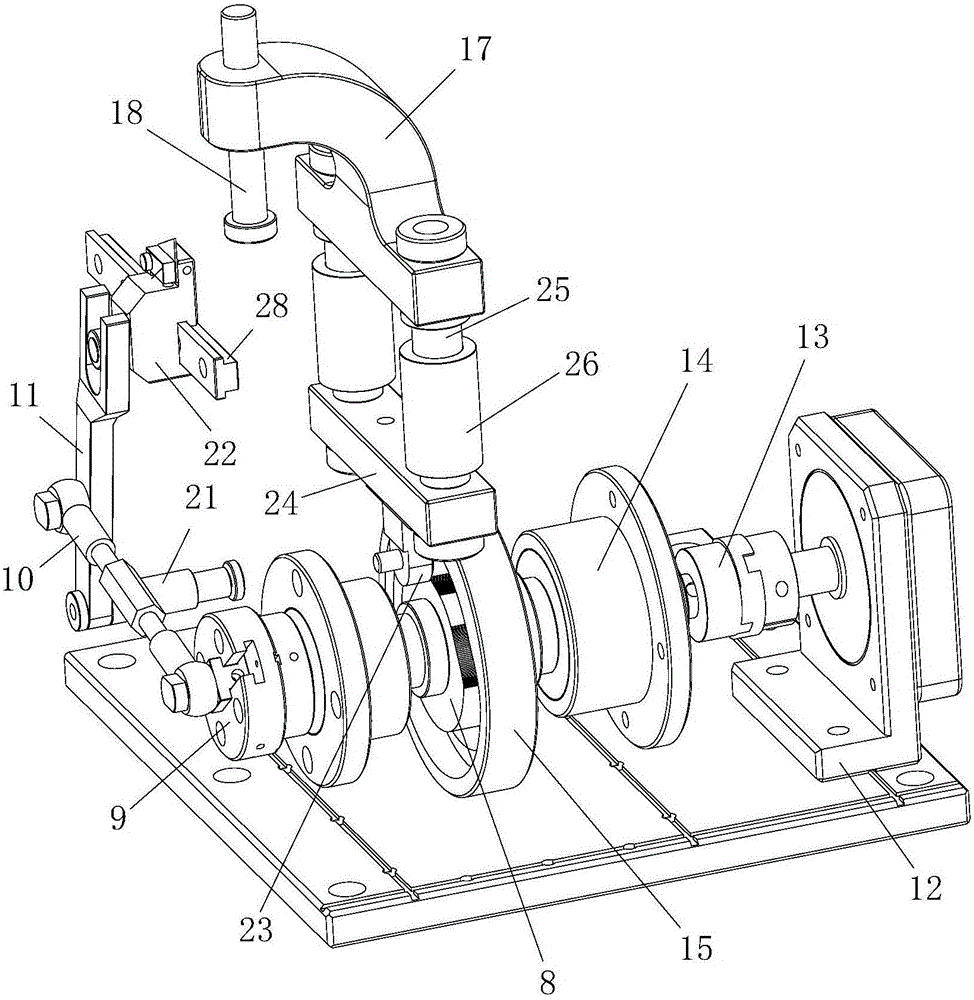

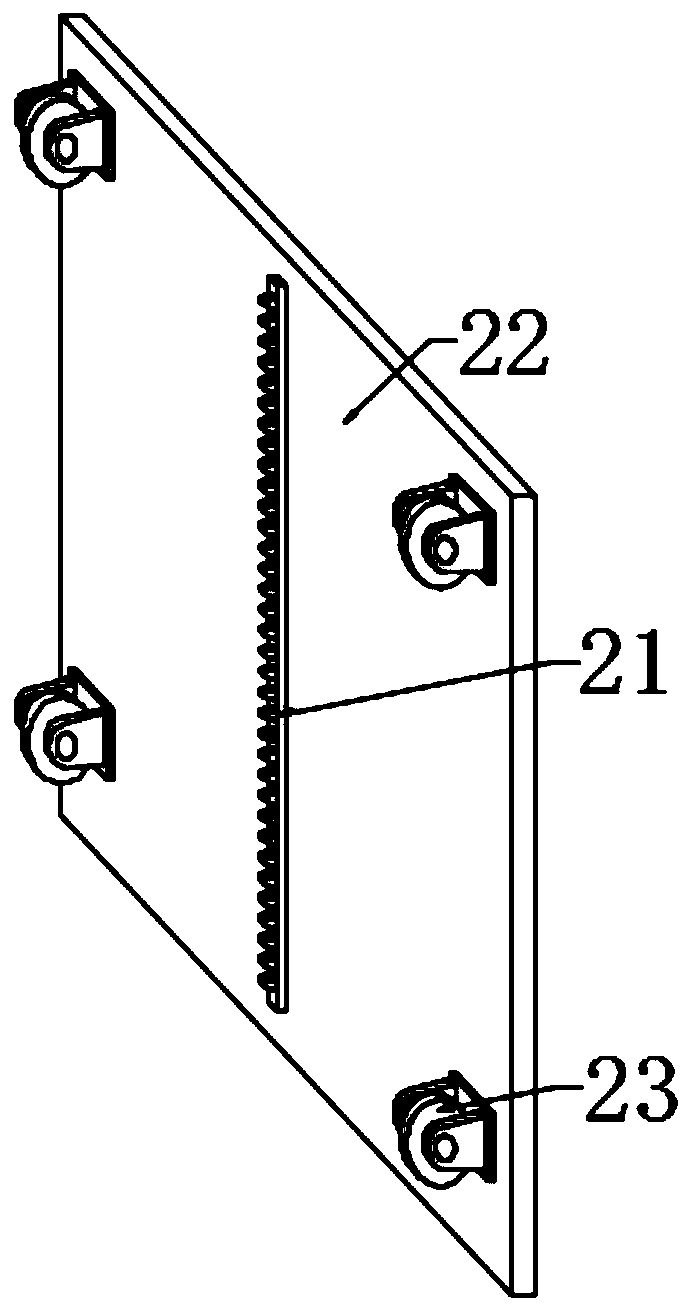

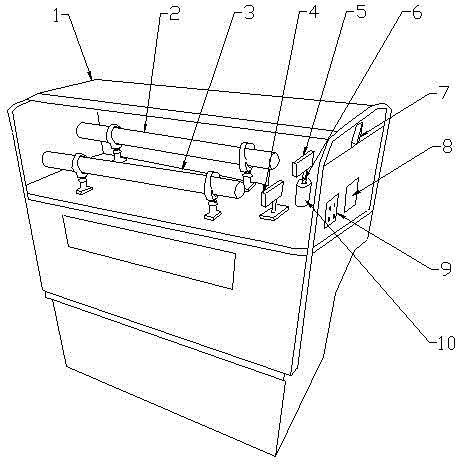

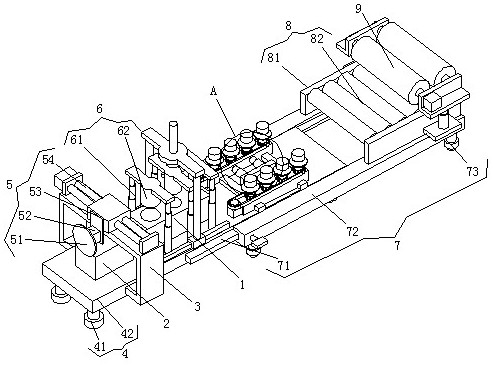

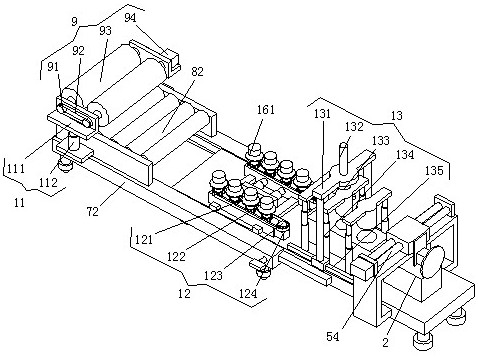

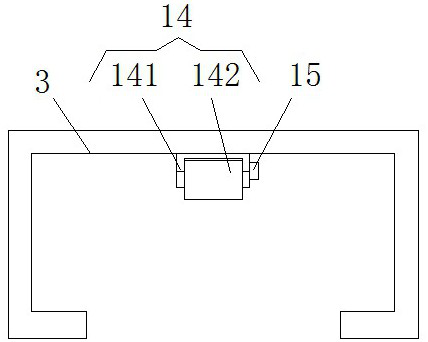

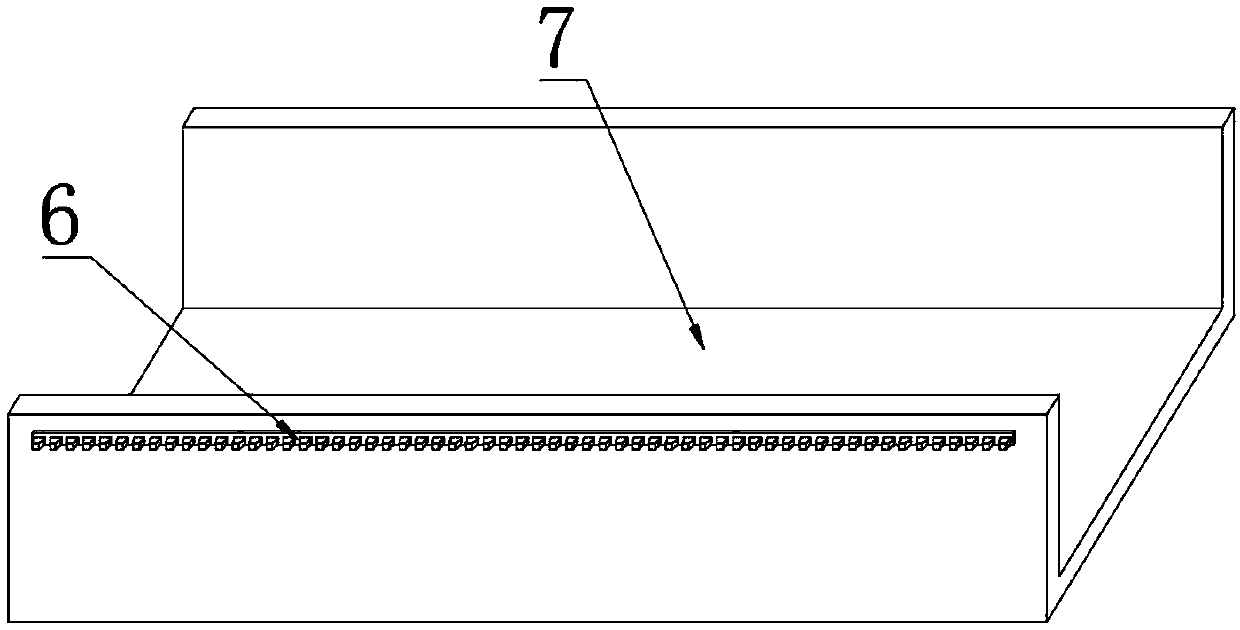

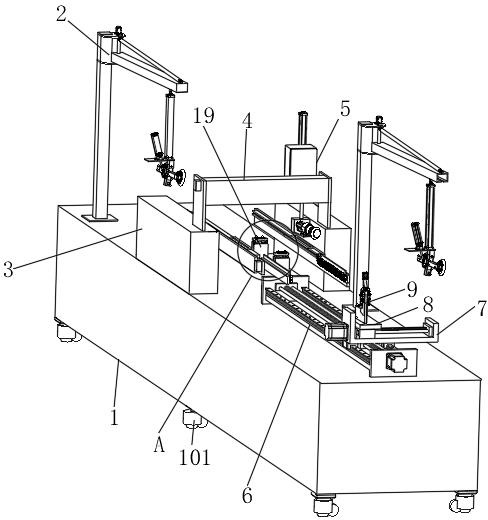

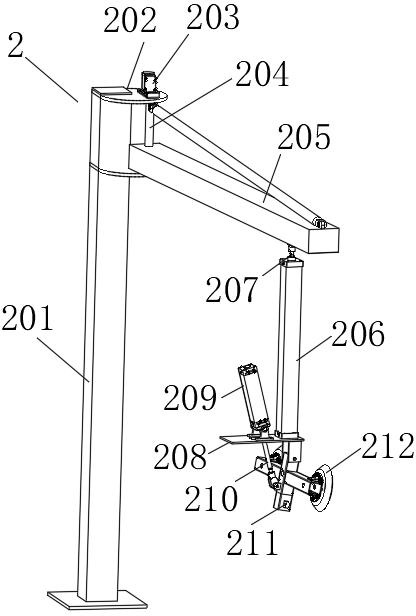

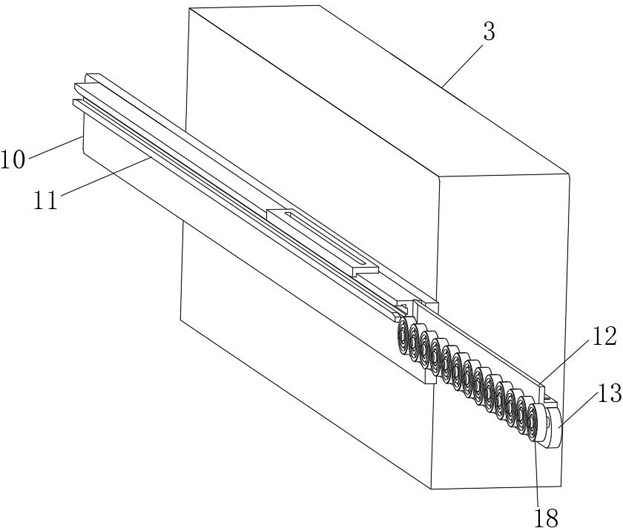

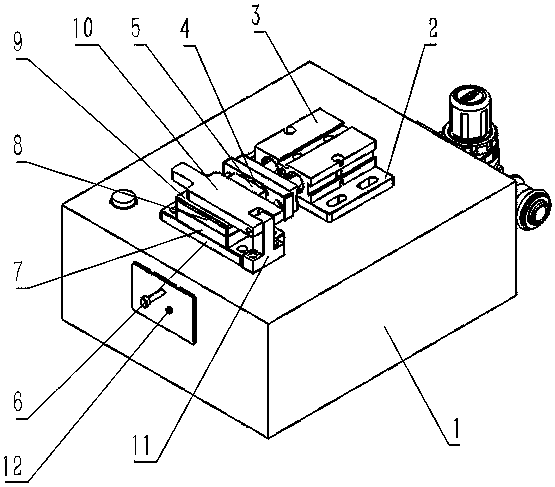

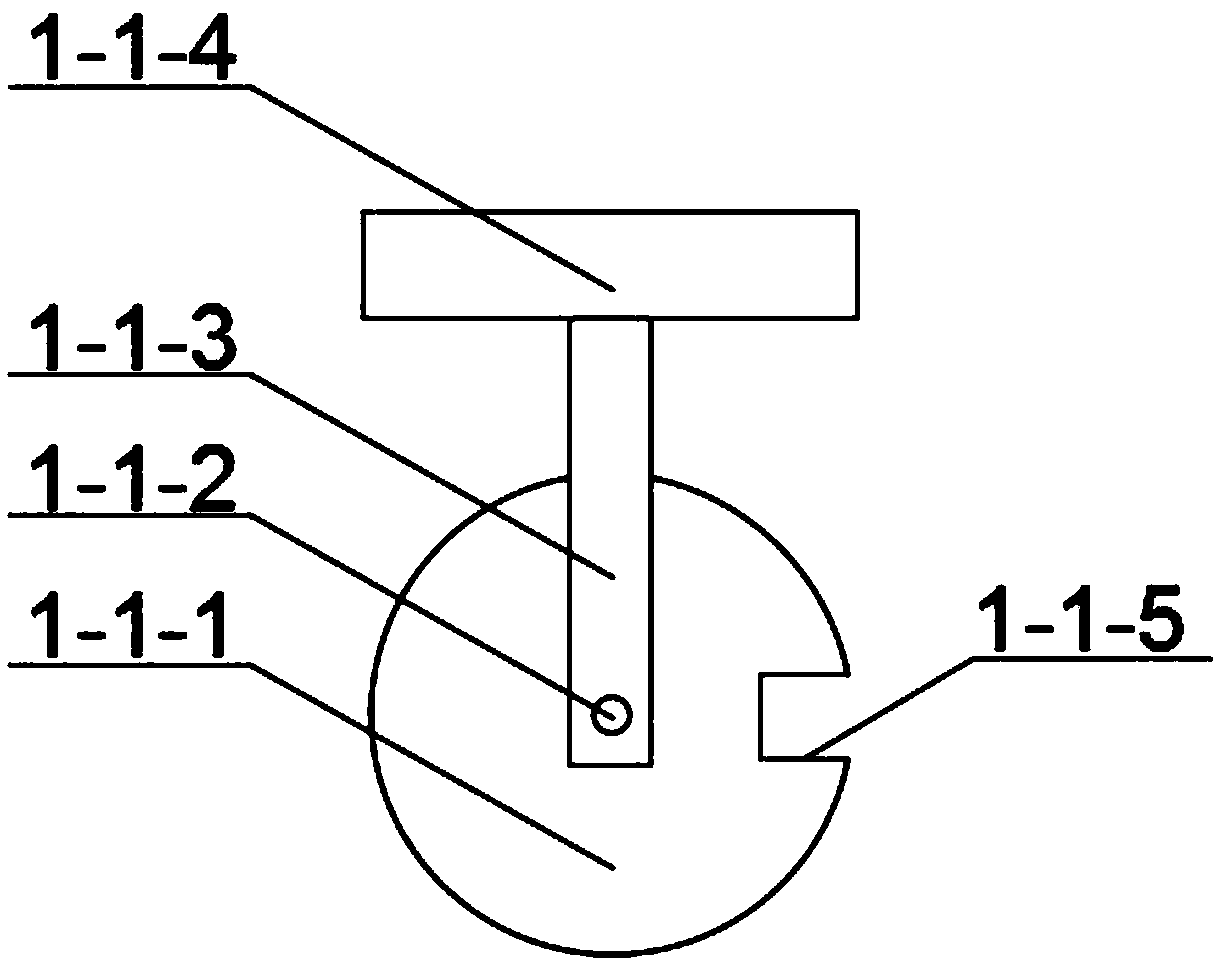

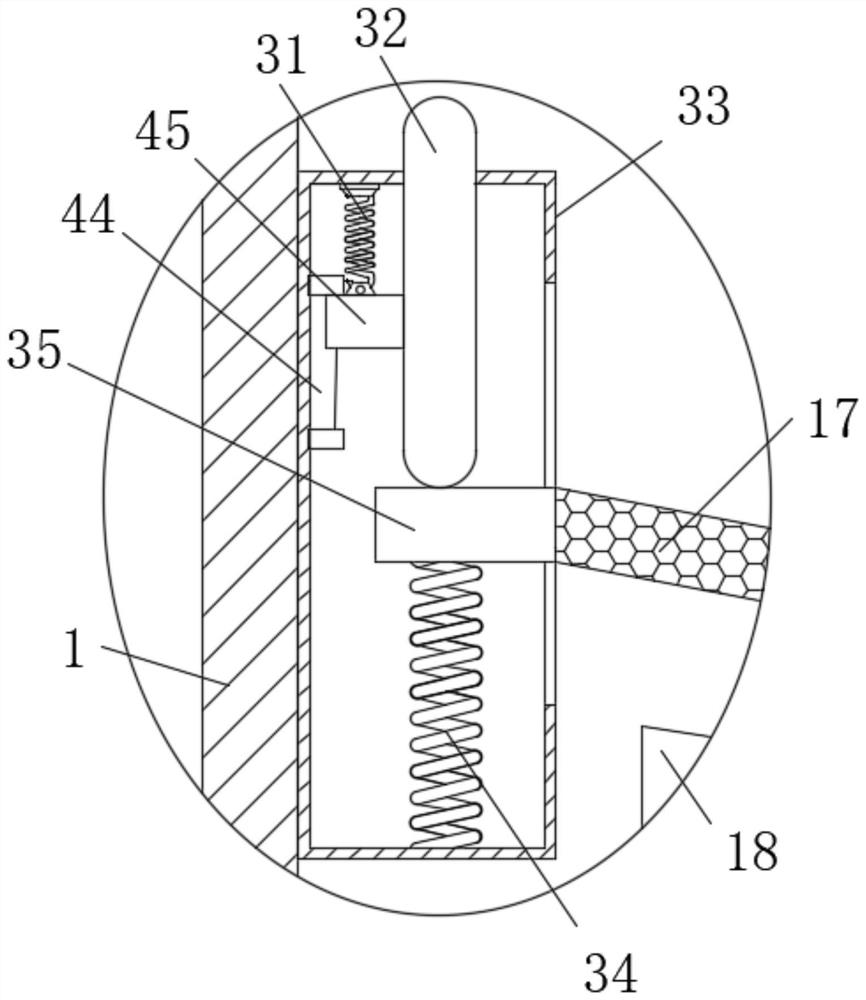

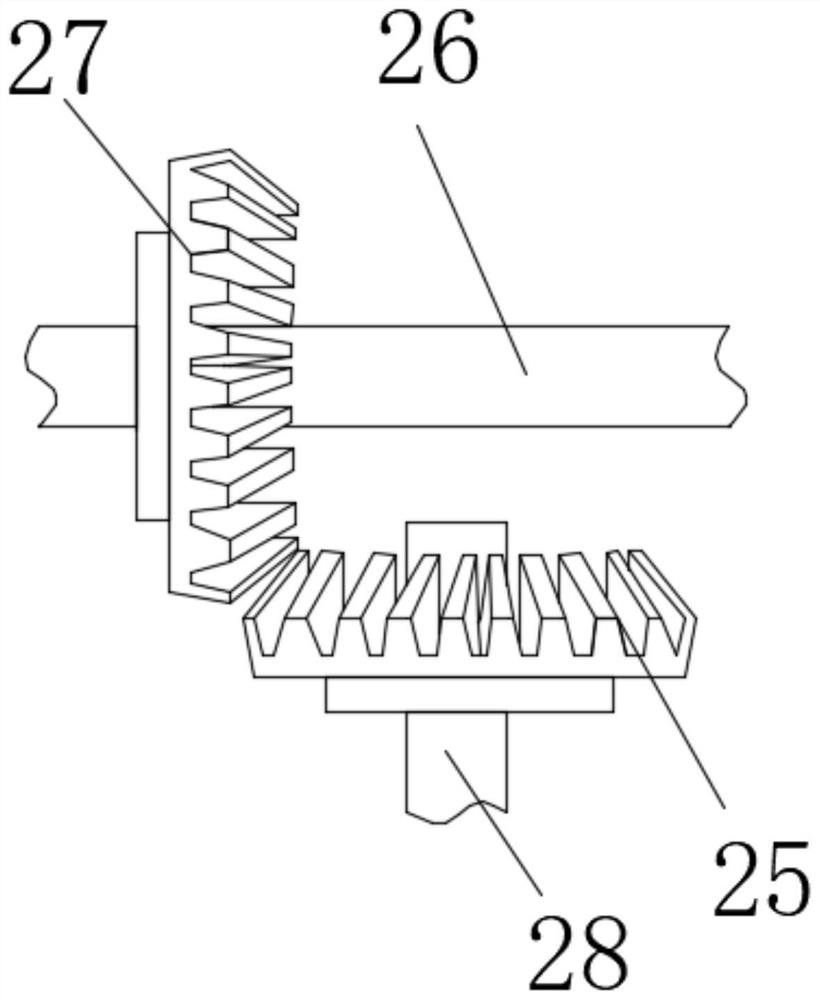

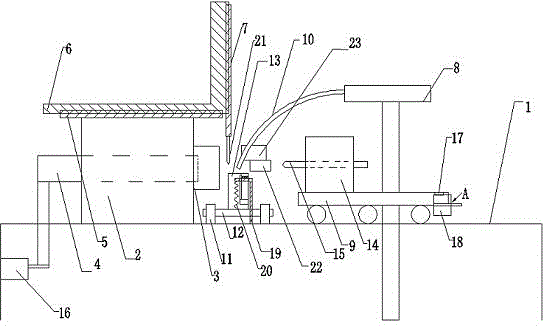

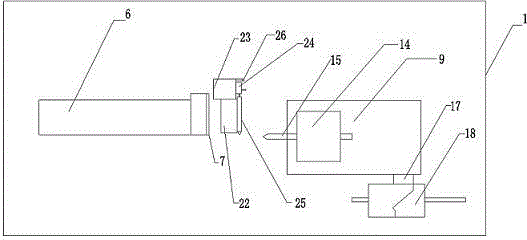

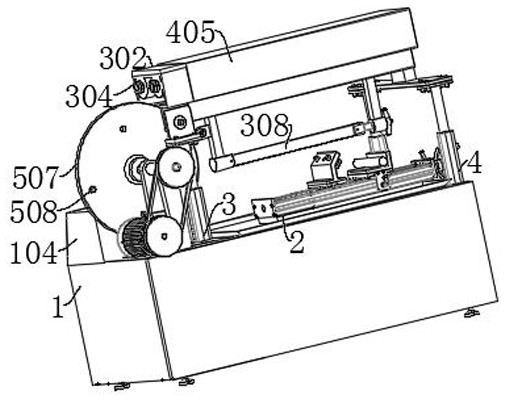

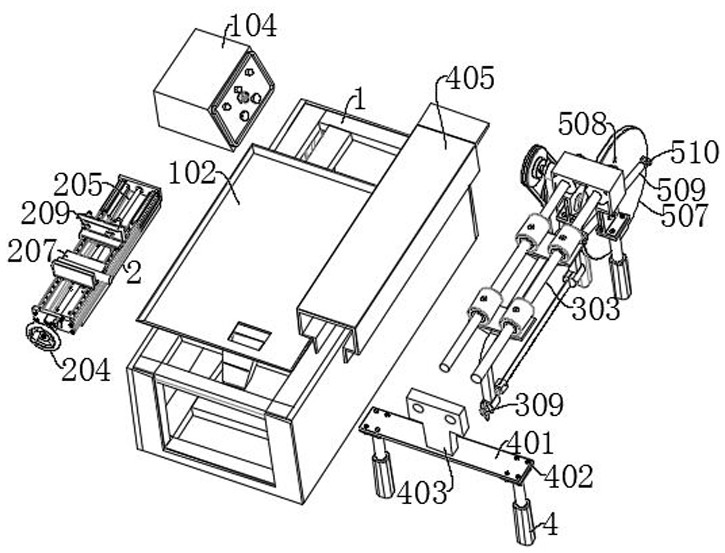

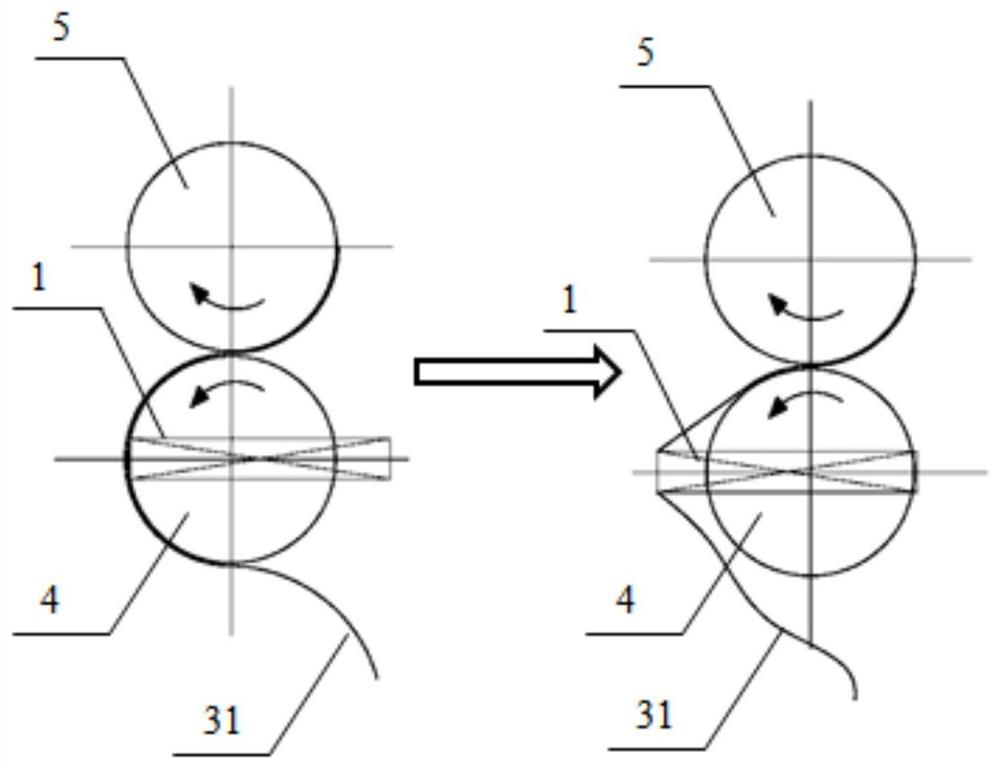

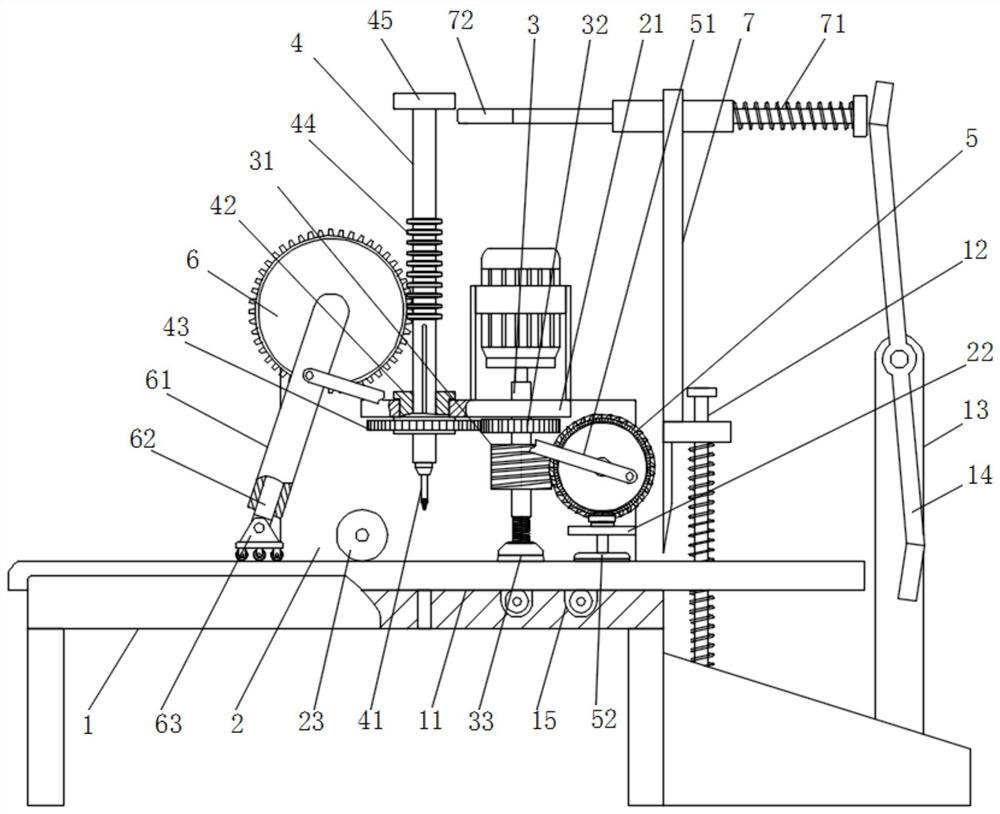

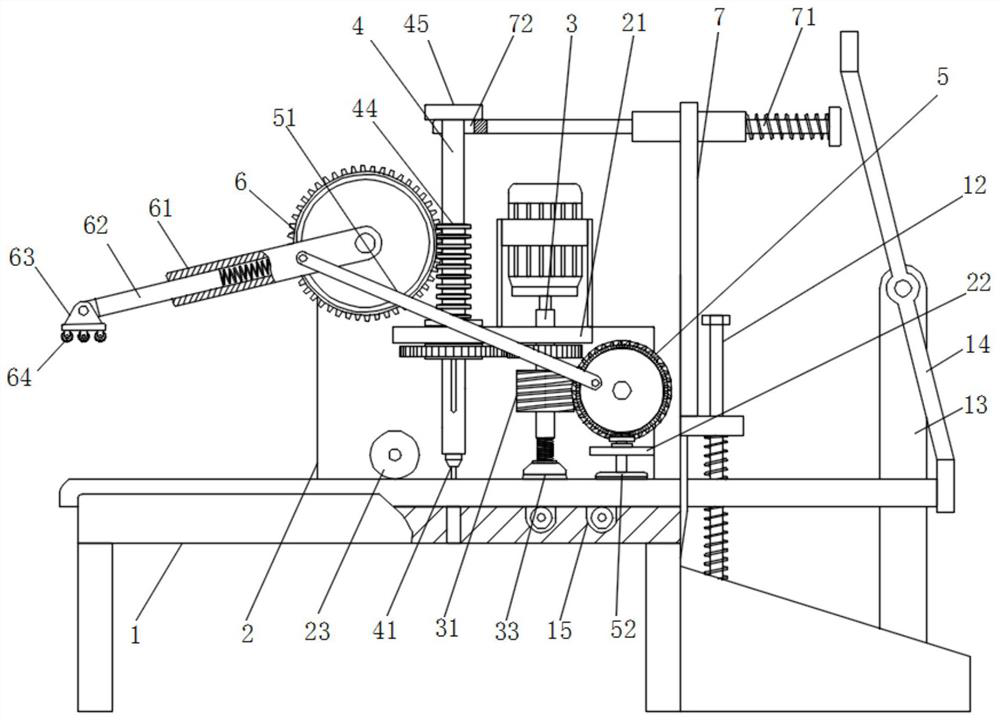

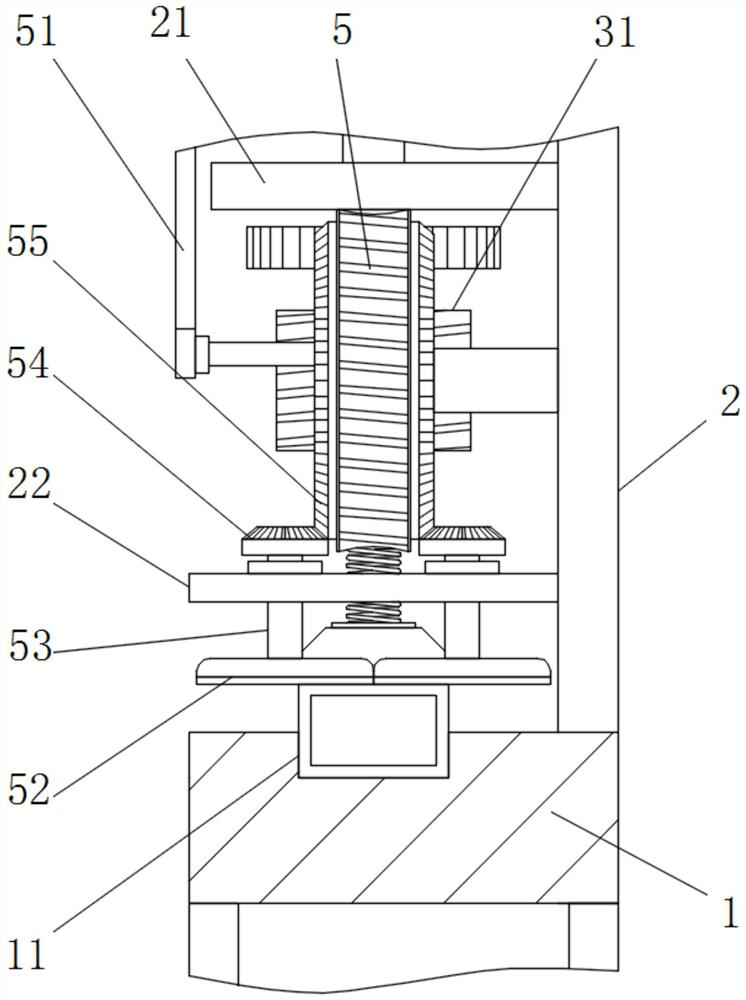

Integrated feeding and cutting mechanism

ActiveCN106363698ARealize the cutting functionImprove cutting effectMetal-working feeding devicesMetal working apparatusButt jointDrive shaft

The invention discloses an integrated feeding and cutting mechanism which comprises a machine body, a stepping motor, a cutting mold, a feeding mechanism and a cam mechanism. The feeding mechanism comprises a feeding claw, a swing arm, a connecting rod and an eccentric wheel. The stepping motor is connected with the cam mechanism and the eccentric wheel through a transmission shaft in the extending direction of the transmission shaft, the cam mechanism is connected with the cutting mold, and the feeding mechanism is in butt joint with the cutting mold. One end of the connecting rod is eccentrically connected with the eccentric wheel, and the other end of the connecting rod is connected to the middle of the swing arm. The feeding claw is mounted at the head end of the swing arm, and the tail end of the swing arm is connected with the machine body through a rotating shaft. The stepping motor, the cam mechanism and the cutting mold are matched to achieve a cutting function; and one power mechanism is used for driving the connecting-rod feeding mechanism to achieve a feeding function, the cutting mold and the feeding mechanism share one power source and are connected in a linkage mode, and therefore the integrated feeding and cutting mechanism has the advantages of being good in cutting effect, good in equipment synchronism, simple in structure, high in control precision, lower in cost and the like.

Owner:GUANGDONG EVERWIN PRECISION TECH

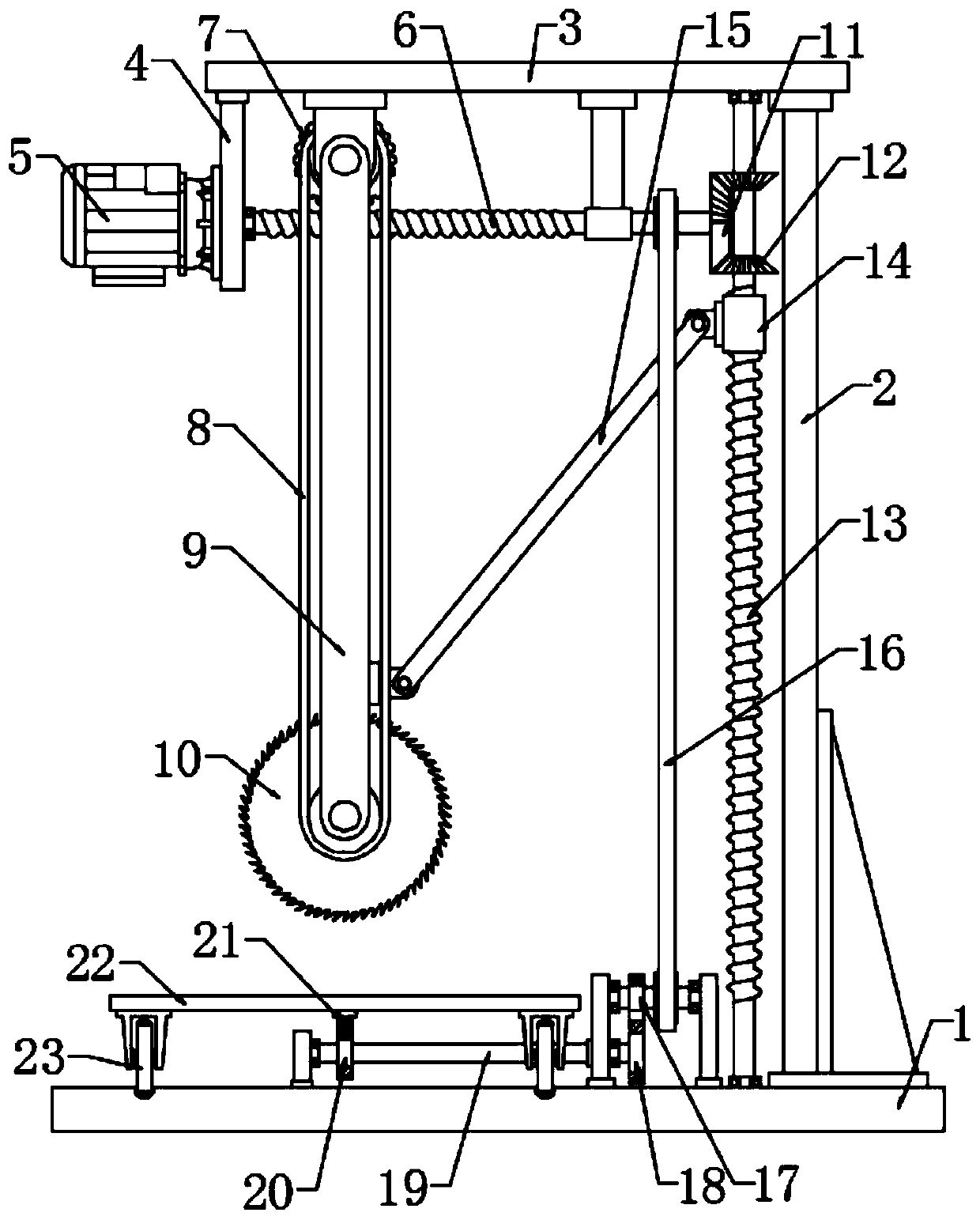

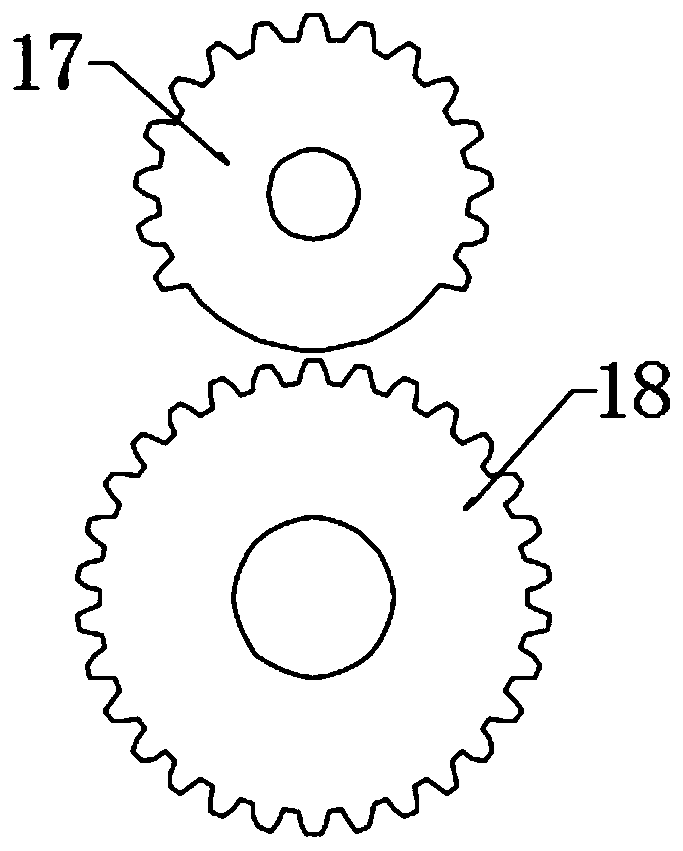

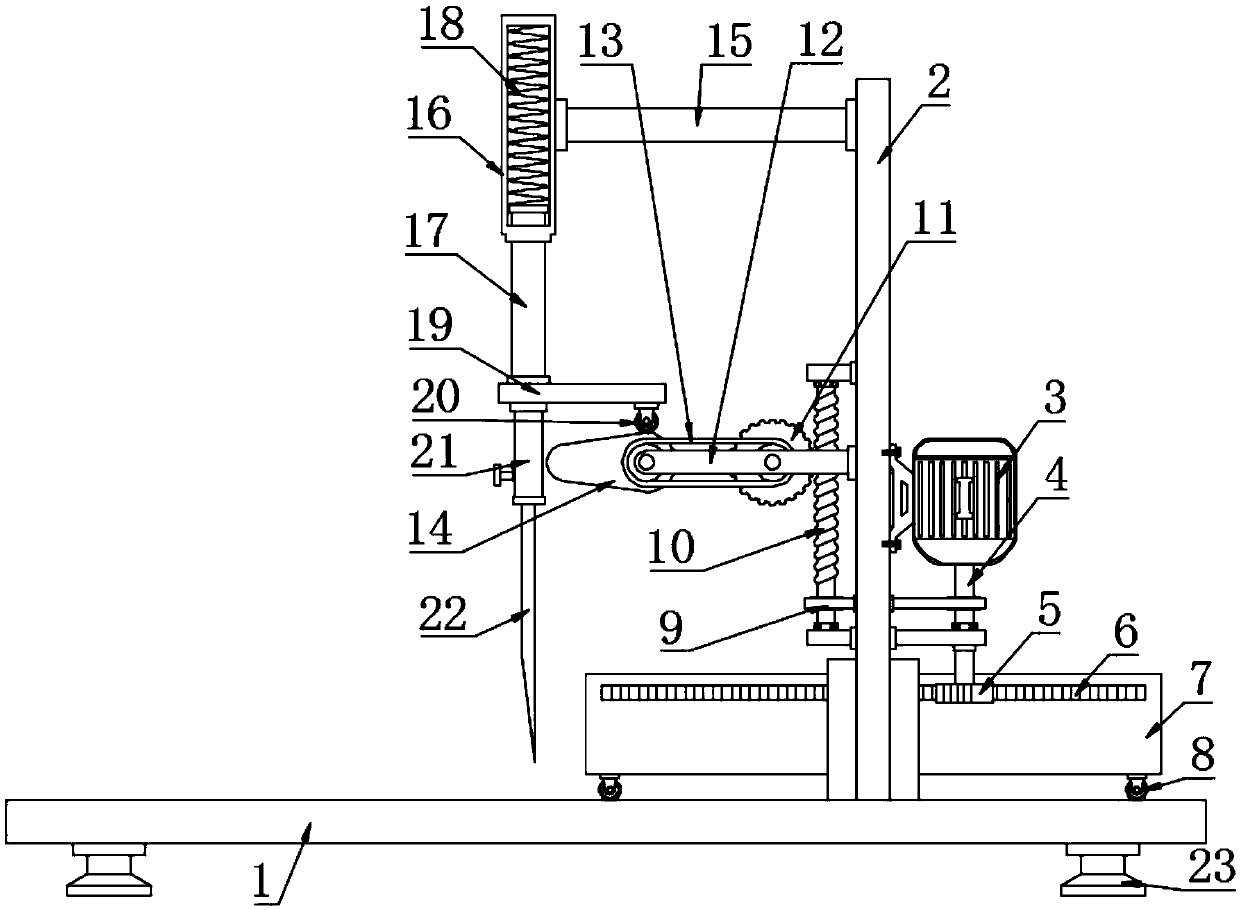

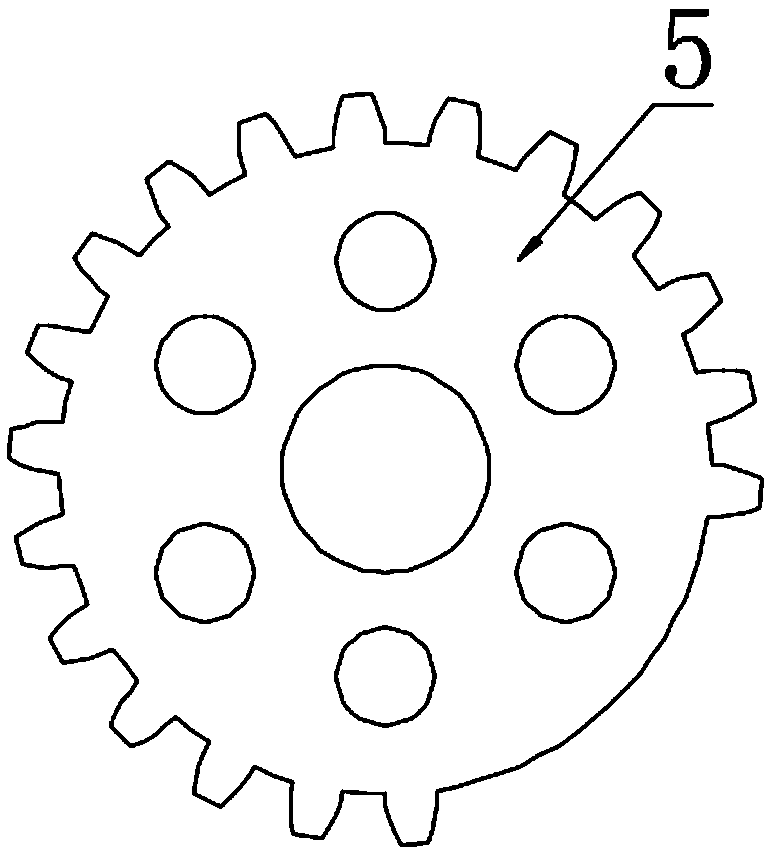

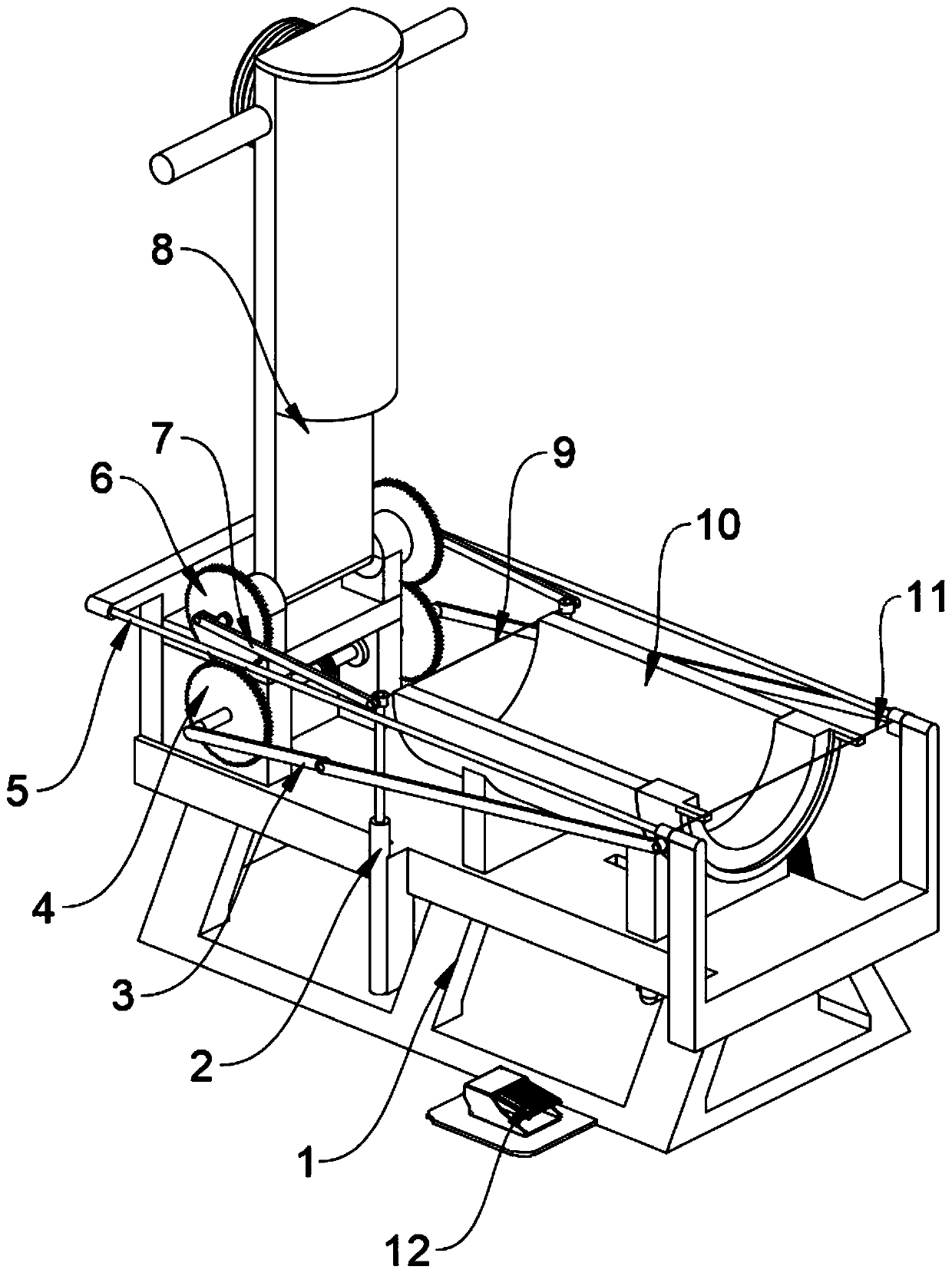

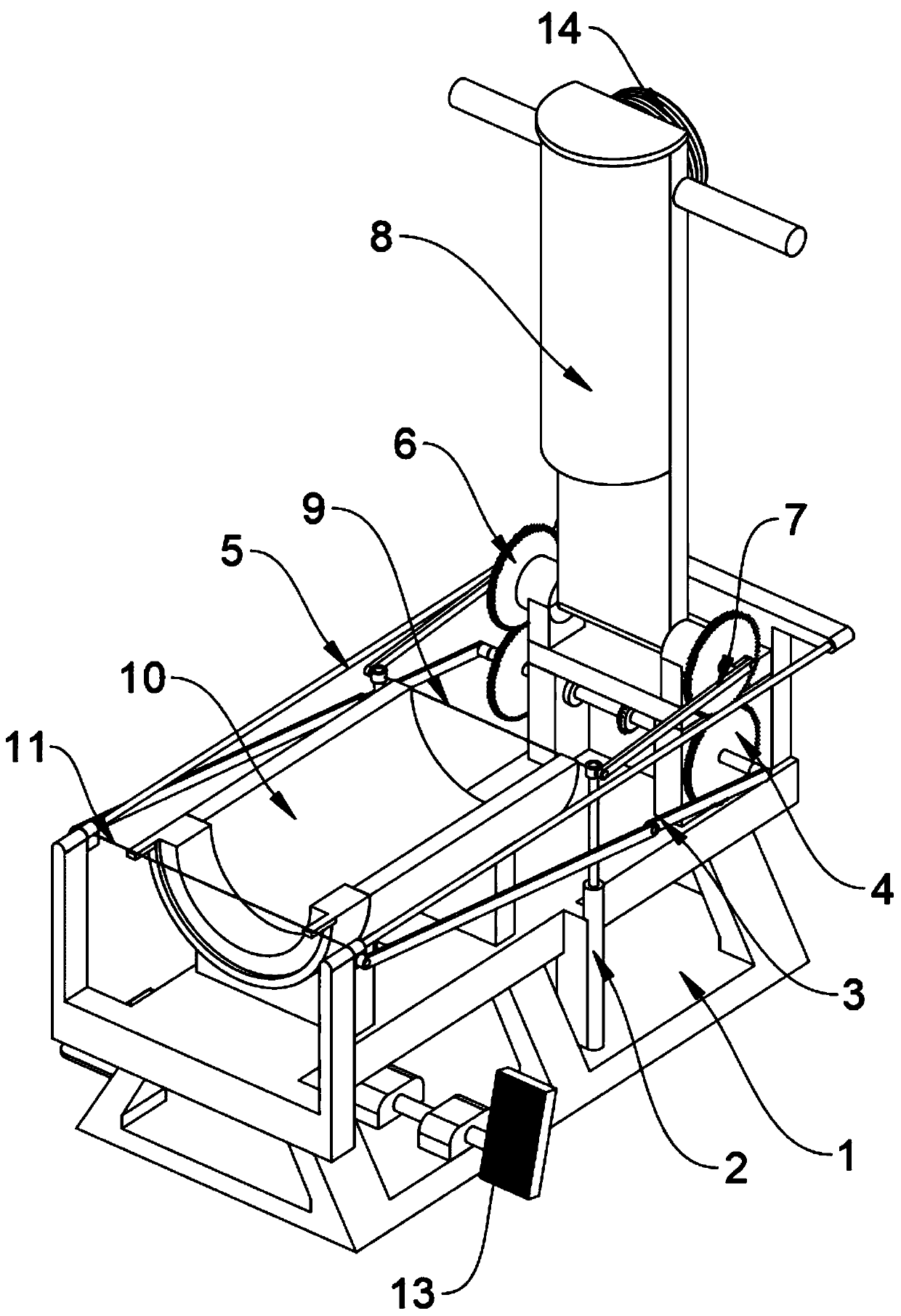

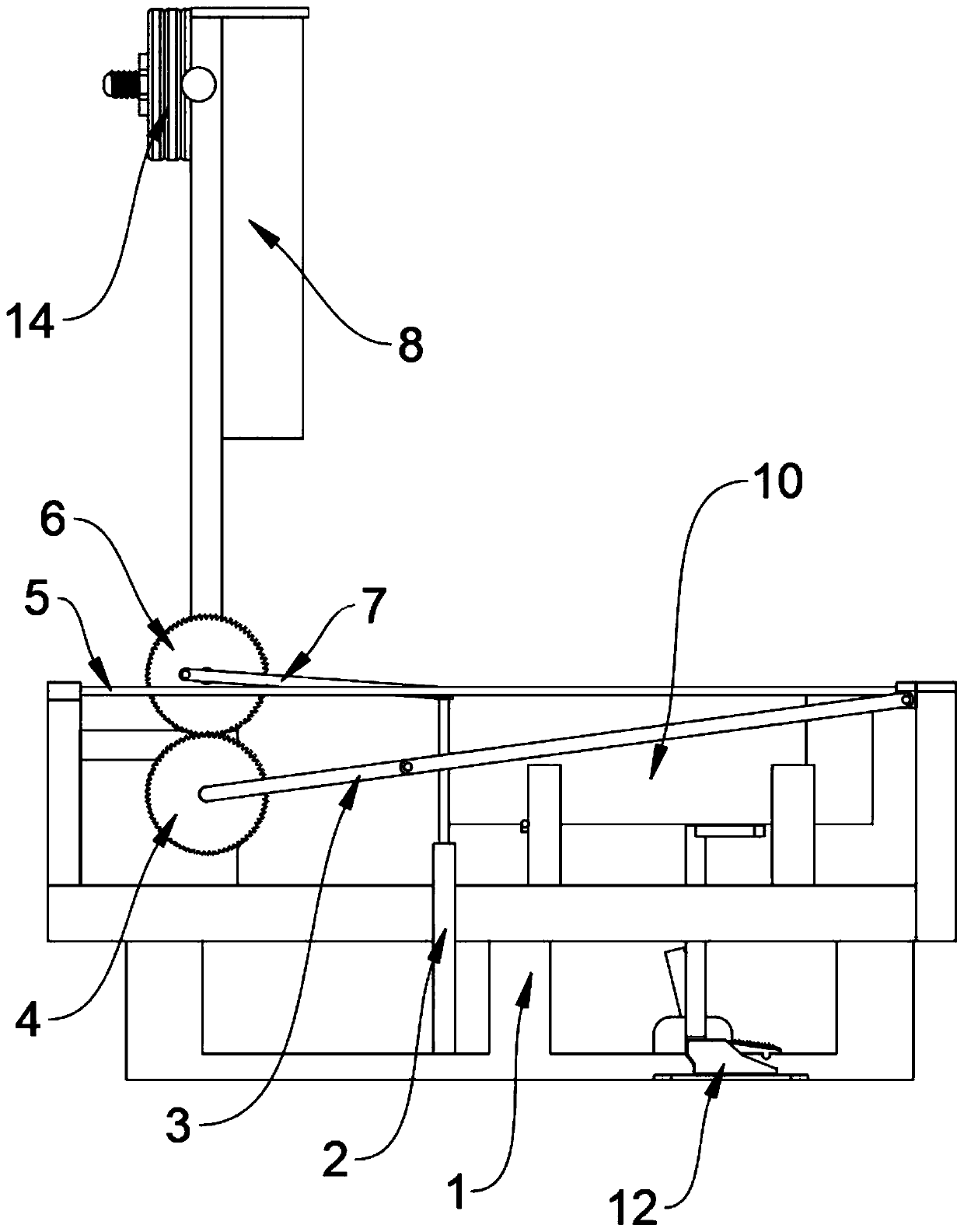

Swing type full-automatic steel sectional cutting machine

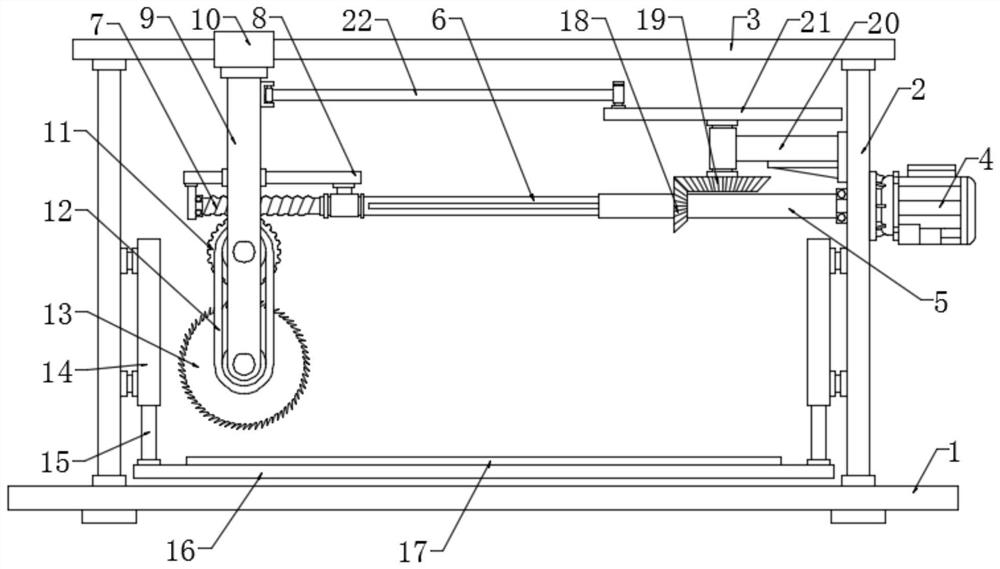

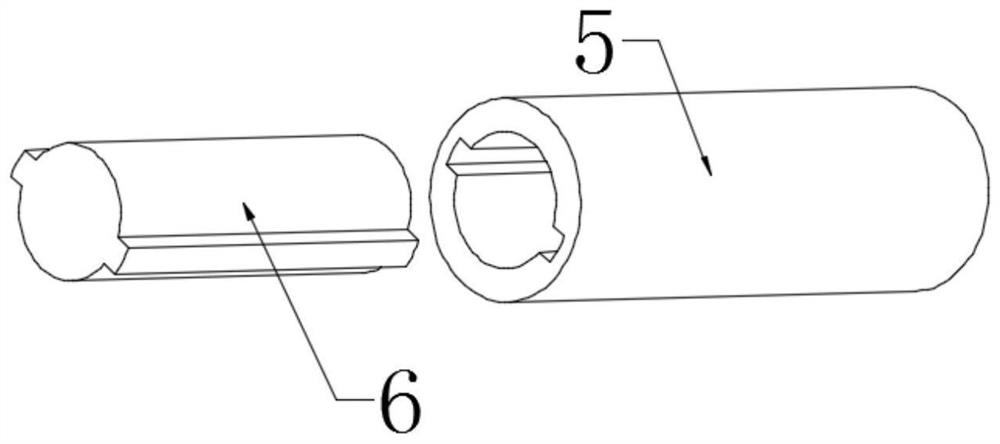

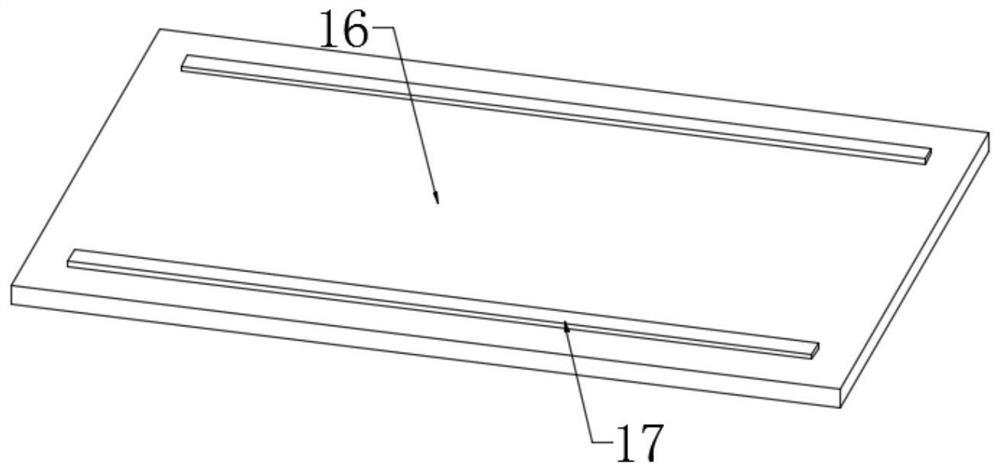

InactiveCN109759636ARealize reciprocating swing cutting functionRealize the cutting functionStock shearing machinesShearing machine accessoriesWorking environmentEngineering

The invention discloses a swing type full-automatic steel sectional cutting machine, in particular to equipment capable of carrying out automatic sectional cutting on steel. According to the swing type full-automatic steel sectional cutting machine, a worm drives a worm wheel to rotate so as to drive a synchronous belt to drive a cutter head to rotate, and the cutting function is realized; meanwhile, the rotating worm drives bevel gears at the upper part and the lower part to drive a screw rod to do reciprocating forward and reverse rotation by utilizing a semi-bevel gear, the screw rod whichdoes reciprocating forward and reverse rotation drives a threaded sleeve to move up and down so as to drive a swing arm to swing through a connecting rod, and the reciprocating swing cutting functionof the cutter head is realized; and a movable supporting plate is arranged above a workbench plate, the automatic intermittent feeding function is realized through the cooperation among gears, a residual gear and a rack, and the defects that in the case of most existing steel cutting machines, execution mechanisms are controlled to move by virtue of electrical equipment to realize the cutting function, the requirement on the working environment is relatively high, especially for the production of the steel in a building, the construction site is large in raised dust, electronic devices in machines can be prone to damage, and the fault rate is high are overcome.

Owner:戎珊珊

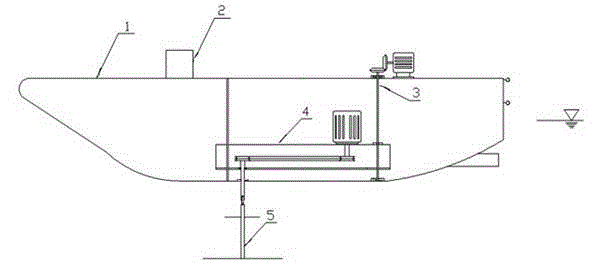

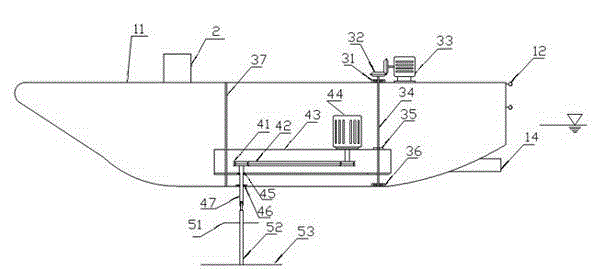

Novel underwater mowing machine

InactiveCN102714969AImprove mowing efficiencySimple structureHarvestersAgricultural engineeringElectric machinery

The invention belongs to the field of mowing machines, in particular to a novel underwater mowing machine. The underwater mowing machine comprises a carrier which is used as a mowing machine body frame, a lift part which is composed of a screw rod and bearing steel capable of going up and down in a straight line along the screw rod, a rotatable mowing power part which is arranged on the bearing steel, a mowing part which is in rotatable connection with the mowing power part and provided with a mowing blade, and a grass collection part which is connected with the carrier. According to the underwater mowing machine, the bearing steel can be driven to go up and down through rotation of the screw rod, so as to adjust the mowing depth; the motor drives a transmission rod and a central shaft to rotate at a high speed through a belt, so that the mowing function is realized; and the grass collection part is connected with a boat body through a latch and a tail ring, and mowed waterweeds are collected when the mowing machine moves to mow grass.. The mowing machine has the advantages of simple structure, convenience in operation and high mowing efficiency, and is suitable for various water areas, so that the labor intensity is greatly reduced.

Owner:昆山德纳普数控科技有限公司

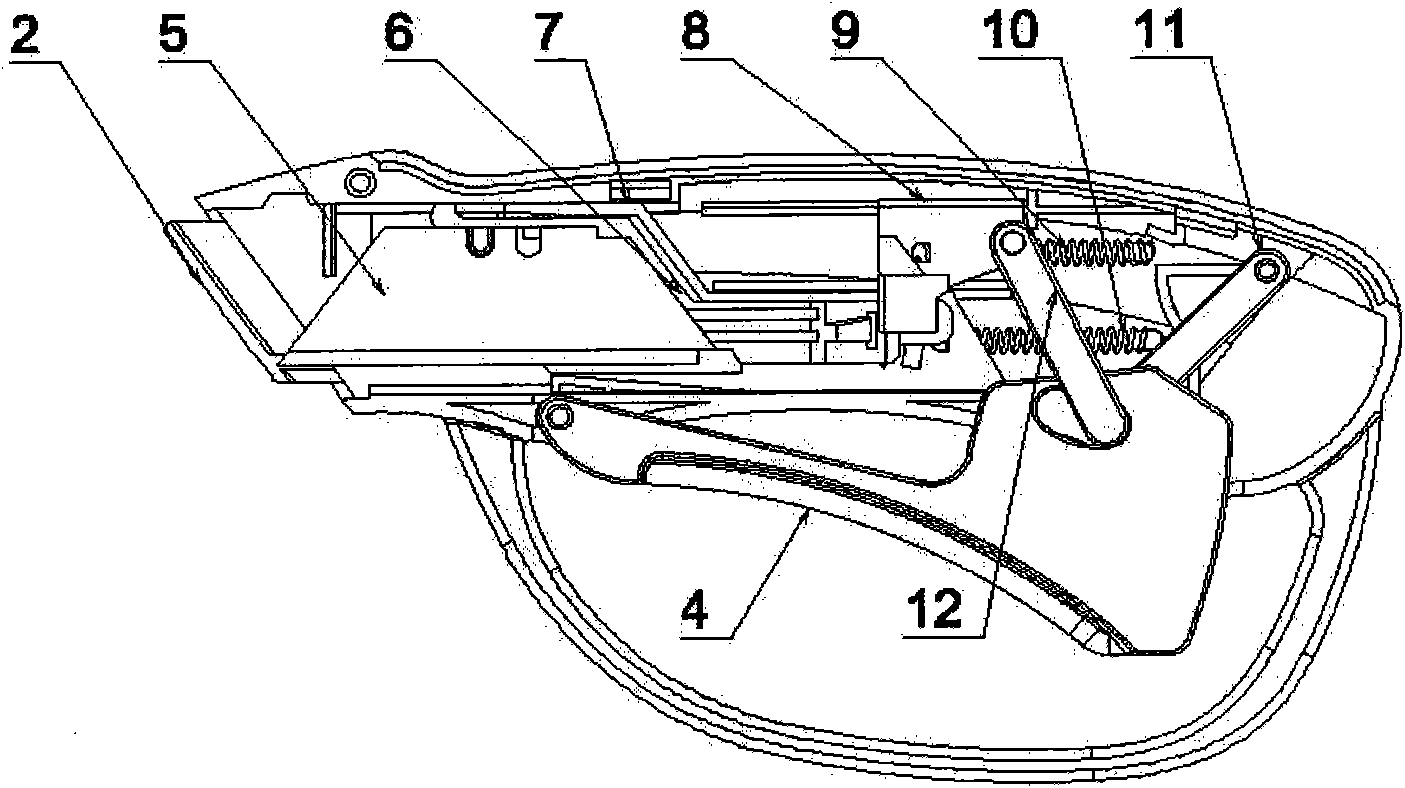

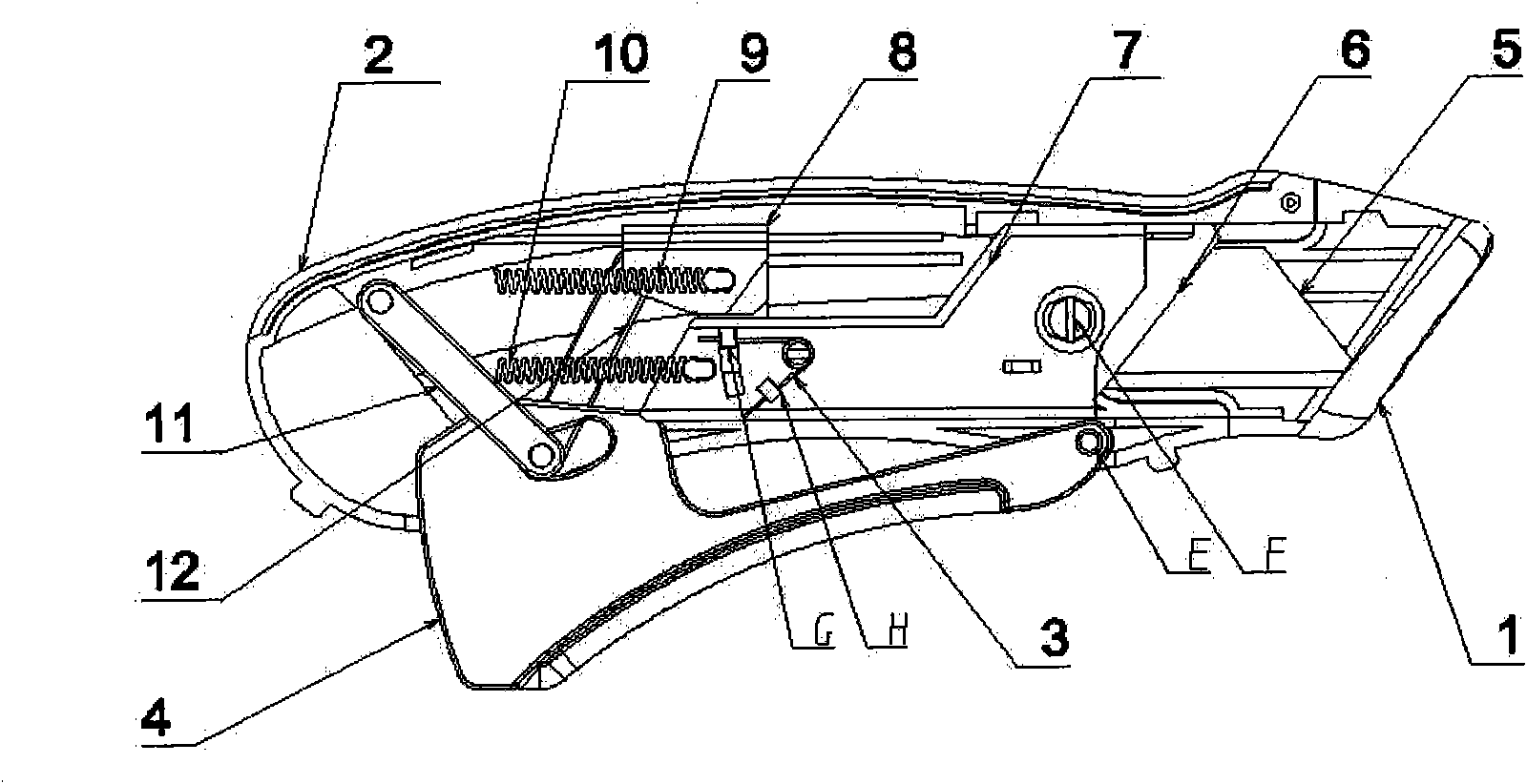

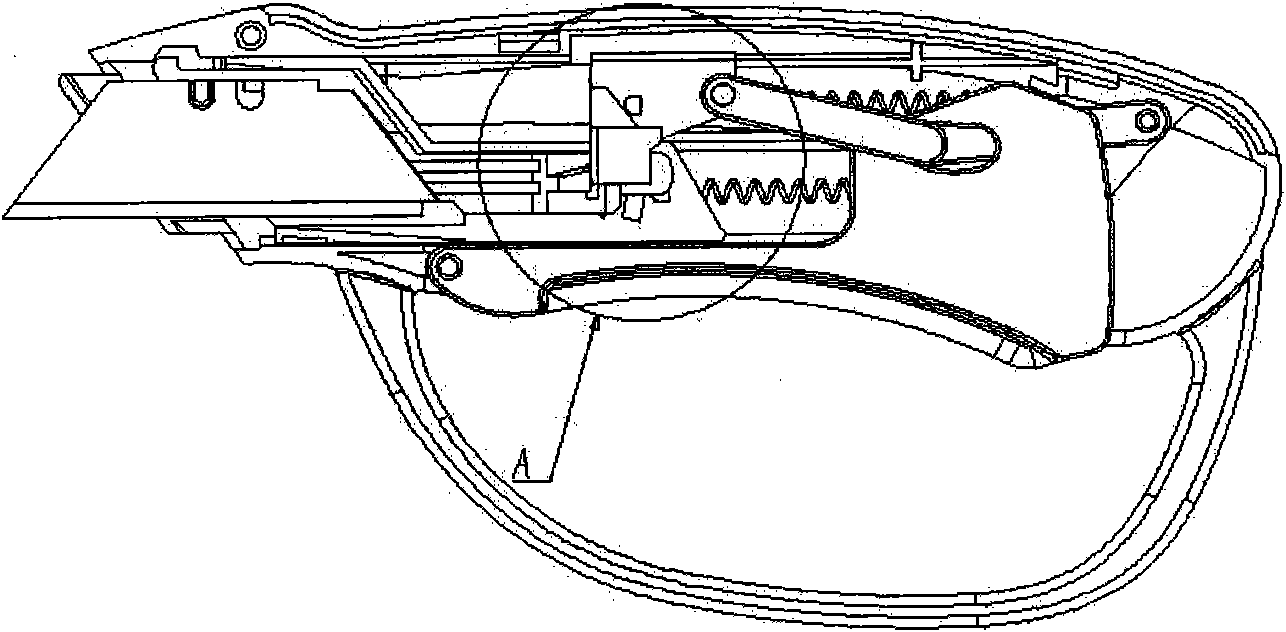

Safety cutter

InactiveCN101885183ACause some damagesRealize the cutting functionMetal working apparatusKnife bladesSupport point

The invention belongs to the technical filed of tools, which relates to a safety cutter and is characterized in that two ends of a tension spring 1 in a cutter shell cavity are respectively connected with a shell and a slide fastener; two ends of a tension spring 2 are respectively connected with the shell and a slide rest; one end of a trigger is connected with the shell through a supporting point E; one end of a connection rod 2 is connected with the slide fastener, and the other end is connected with one end of a connection rod 1 through a round hole above the trigger; the other end of the connection rod 1 is connected with the shell; the slide rest is connected with a cylindrical embossment F on a rotary tool rest in a button placement mode and can rotate for an alpha angle around the cylindrical embossment F; two ends of a torsional spring are respectively connected with a salient point G of the rotary tool rest and a salient point H of the slide rest; and the slide fastener is connected with the slide rest in a slide mode, and can be jointed or separated with the abutting side of the rotary rest. The invention has the beneficial effect that a blade can automatically stretch out under the driving of the squeezed trigger, realize the cutting function, and is convenient to use; and when the cutting operation ends, the blade can automatically retract into the shell at once even the trigger is not loosened, thereby having no potential safety hazard.

Owner:MERIDIAN INT

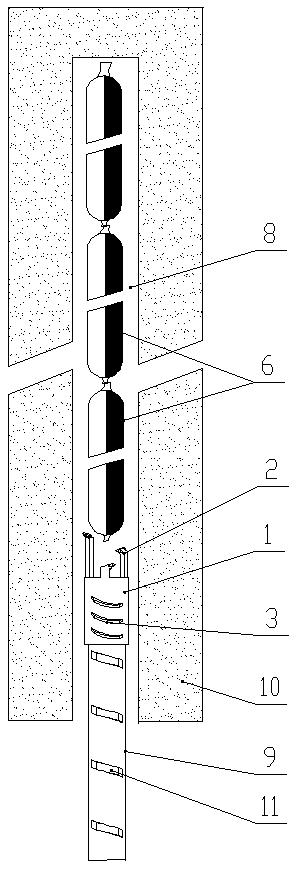

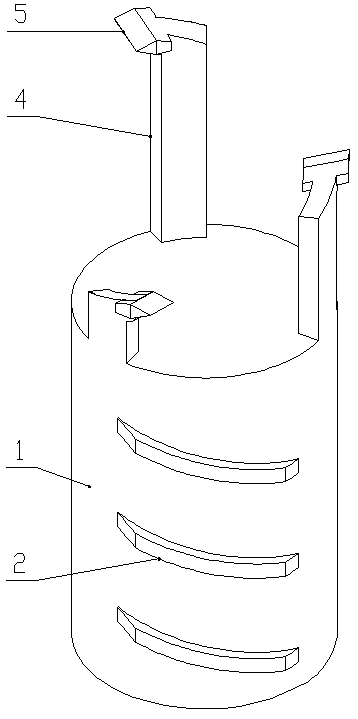

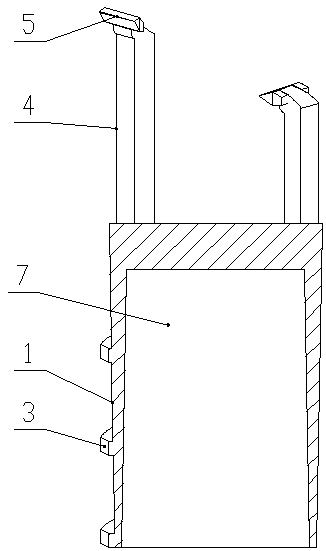

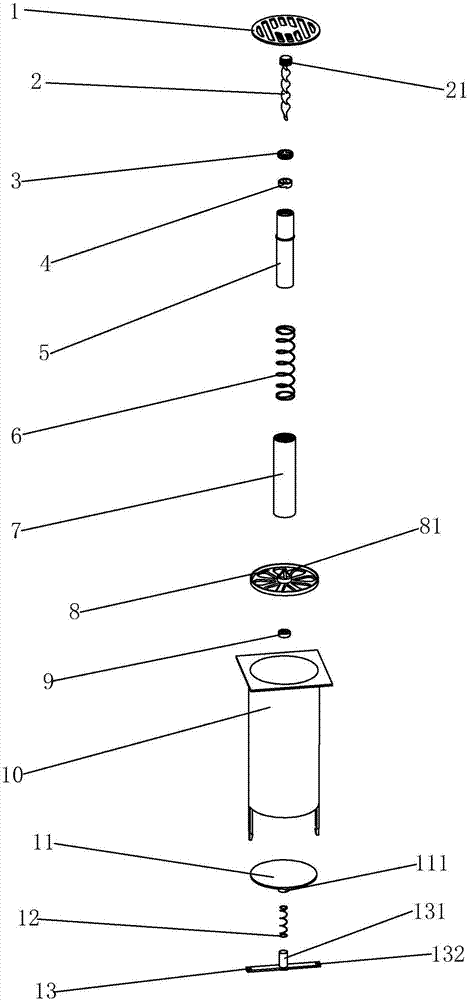

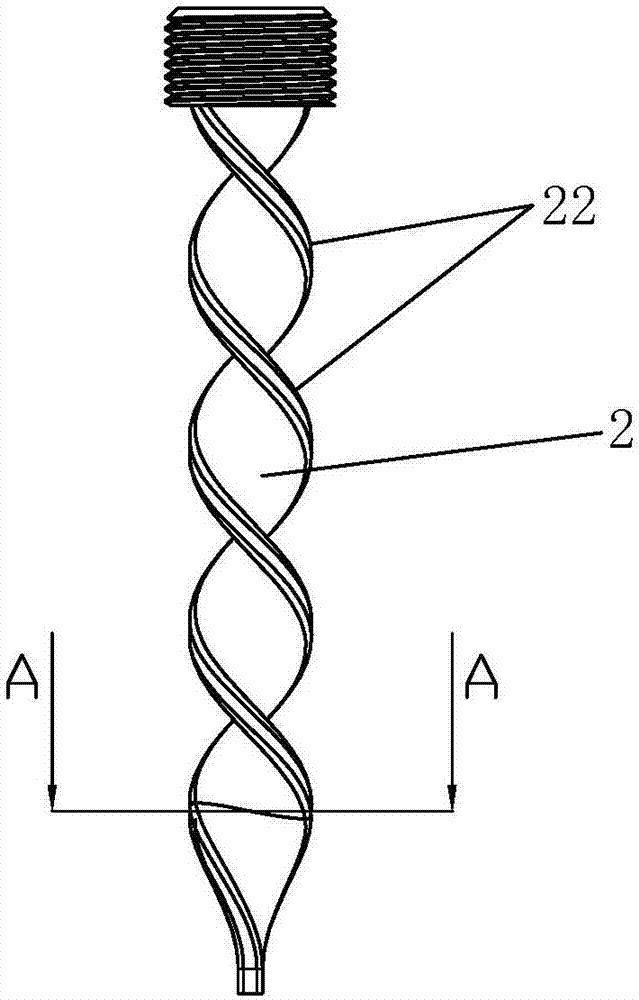

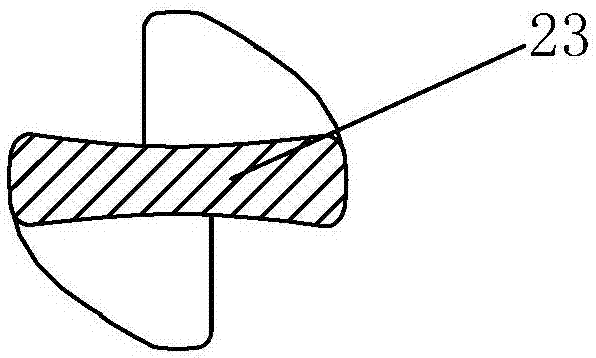

Resin anchoring agent bag breaking and stirring device and bag breaking and stirring method

The invention discloses a resin anchoring agent bag breaking and stirring device which comprises a sleeve. An opening is formed in the lower end of the sleeve, at least two breaking cutters are uniformly and fixedly arranged at the top of the sleeve along a peripheral direction, the maximum rotation diameter of each breaking cutter is equal to the outer diameter of the sleeve, and a plurality of screw stirring ribs are arranged on the periphery of the sleeve at intervals. The invention further discloses a resin anchoring agent bag breaking and stirring device method. The device is simple in structure, convenient to use, reasonable in design and high in practicability and can effectively solve the problems that breaking effects of resin anchoring agent bags are not ideal, and anchoring force is affected in a current anchor rod or anchor cable support. An efficient device is provided for breaking of the resin anchoring agent bags, stirring effects of resin anchoring agents can be effectively improved, materials in the resin anchoring agent are more sufficiently mixed, important guarantee is improved for improvement of quality of the anchor rod or anchor cable support, a constructionprocess of an anchor rod or anchor cable support technique is innovated, and the device has great social and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

Double-tube single-light-path laser engraving and cutting machine

InactiveCN104002047AAchieve engravingRealize the cutting functionLaser beam welding apparatusDouble tubeLaser engraving

The invention relates to the technical field of laser engraving and cutting, in particular to a double-tube single-light-path laser engraving and cutting machine. The laser engraving and cutting machine comprises a frame, a cross beam, a longitudinal beam, a second reflector, a third reflector and a laser head. An engraving laser tube and a cutting laser tube are parallelly arranged on the frame. The transmitting end of the engraving laser tube faces to the corresponding engraving reflector. The transmitting end of the cutting laser tube faces to the corresponding cutting reflector. The engraving reflector, the cutting reflector, the second reflector and the third reflector are on the same plane. The laser engraving and cutting machine has the advantages that functions of fine engraving and high-power cutting can be achieved on one machine, the two functions can be switched automatically, and the problems that one machine can only focus on engraving or cutting and is single in function are solved; the laser engraving and cutting machine is simple to operate, convenient to use, and applicable to non-metal engraving and cutting.

Owner:王勇

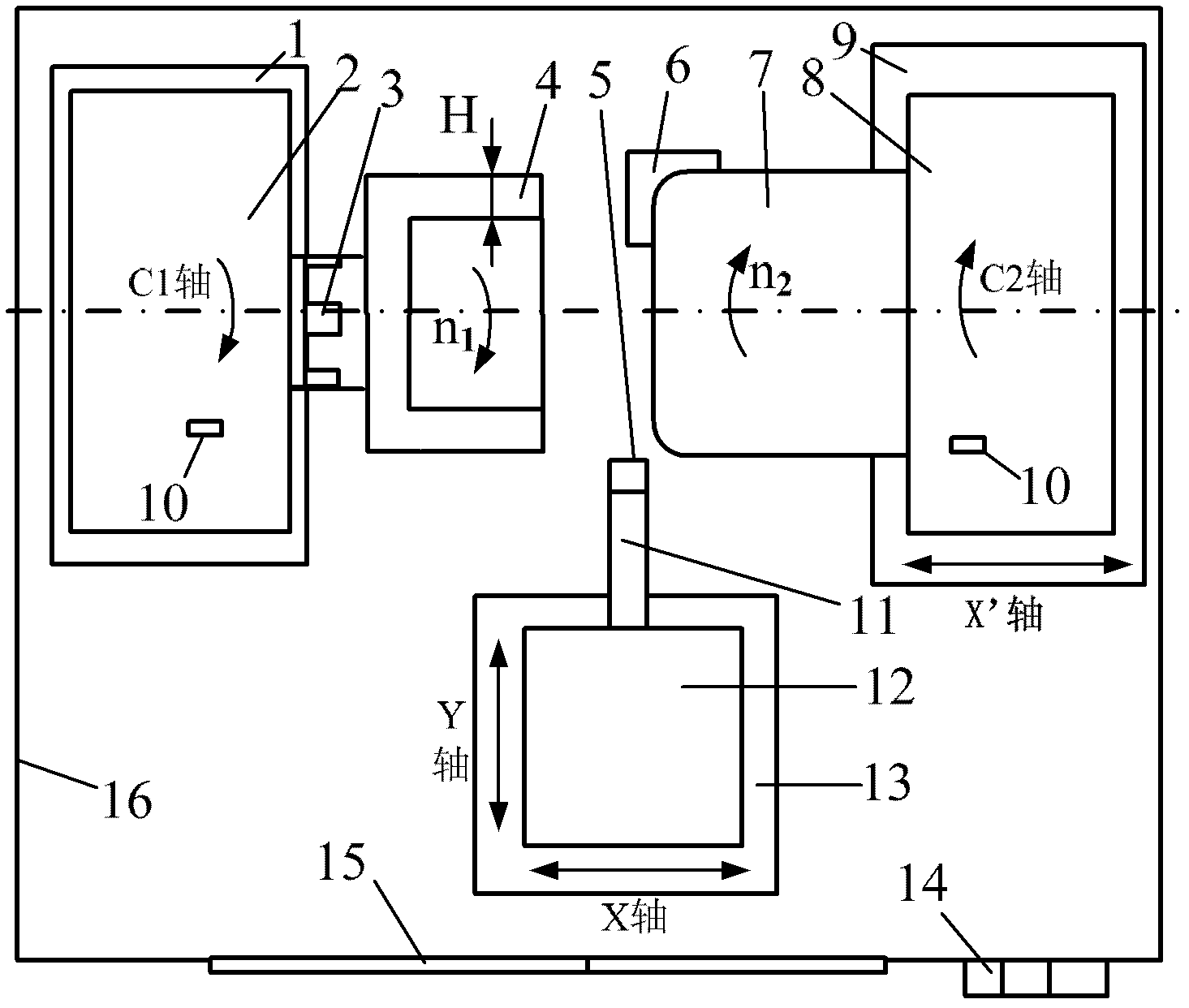

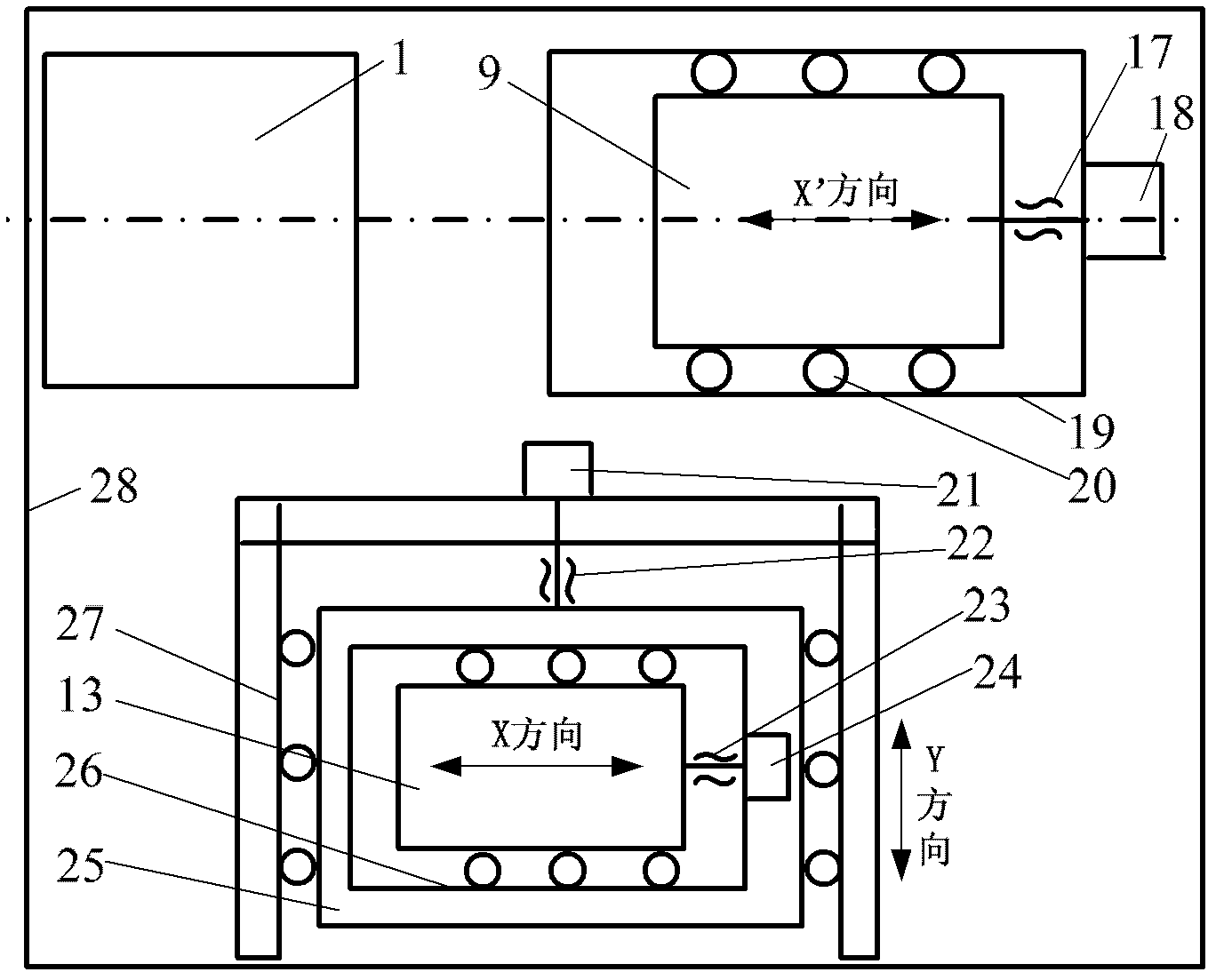

Multifunctional cutting device with ultra-high cutting linear velocity

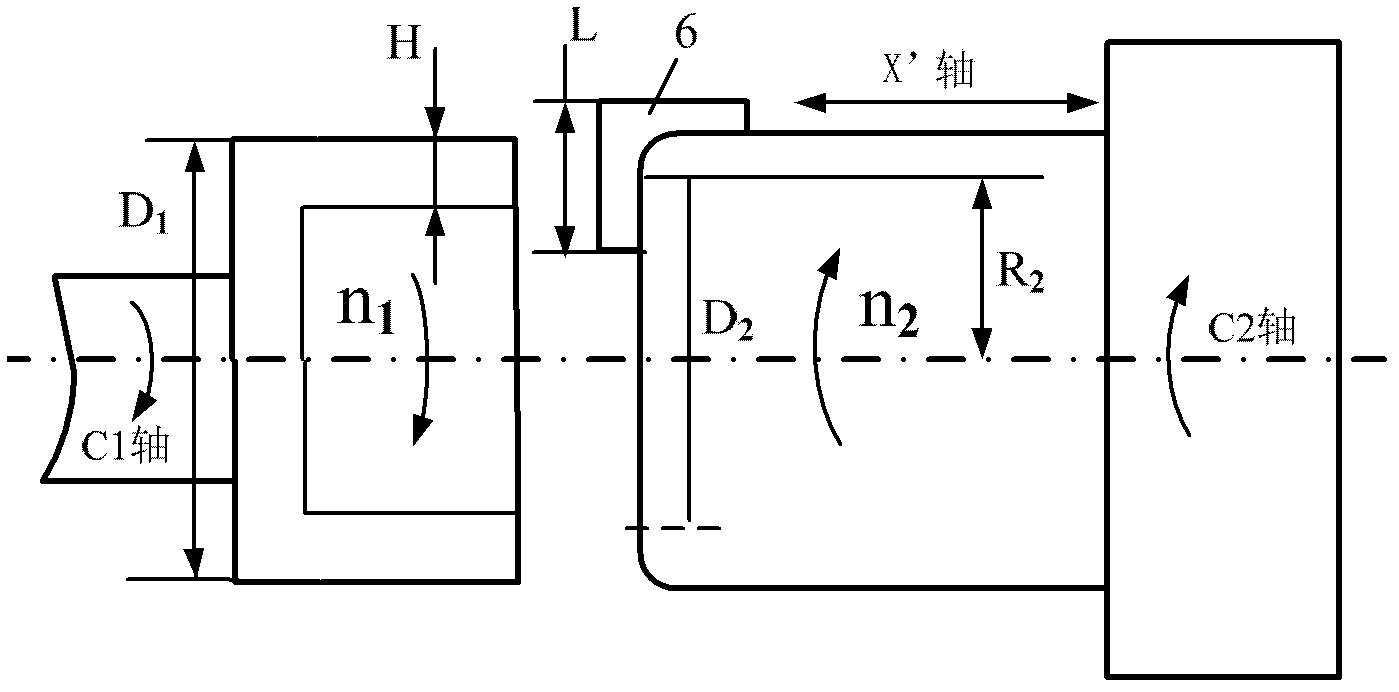

InactiveCN102615553ARealize milling (fly milling) processingAchieve ultra-high-speed boring machiningFeeding apparatusDriving apparatusUltra high speedCircular surface

The invention provides a multifunctional cutting device with ultra-high cutting linear velocity. The multifunctional cutting device comprises a first motorized spindle, a second motorized spindle, a turning tool holder and a base, wherein a fixed workbench of the first motorized spindle, a movable workbench of the second motorized spindle and the movable workbench of the turning tool holder are arranged on the base, the movable workbench of the turning tool holder is positioned at the front, and the first motorized spindle is fixedly mounted on the fixed workbench of the first motorized spindle; the second motorized spindle is fixedly mounted on the movable workbench of the second motorized spindle; the first motorized spindle and the second motorized spindle are coaxial and oppositely arranged; and the turning tool holder is mounted on the movable workbench of the turning tool holder. According to the multifunctional cutting device disclosed by the invention, a cutting tool and a workpiece are respectively mounted on the two sets of the motorized spindles, which are coaxially mounted, and the rotation directions of the two sets of the motorized spindles are reverse so as to increase the relative cutting speed of the cutting tool relative to the workpiece by times; and simultaneously, the multifunctional cutting device has a variety of cutting functions, such as ultra-high-speed milling of end surfaces, ultra-high-speed boring of inner circular surfaces, ultra-high-speed turning of outer circular surfaces and the like.

Owner:SHANDONG UNIV

Floor drain capable of rotatably cutting off hair and rotatable cutting method

PendingCN107060048ALabor-saving operationEasy to installSewerage structuresEngineeringHair characteristics

The invention discloses a floor drain capable of rotatably cutting off hair and a rotatable cutting method. The floor drain comprises a floor drain seat and a first cutting piece, wherein the first cutting piece is rotatably arranged around the axis in the floor drain seat, the floor drain further comprises screw blades and a rotating piece, the screw blades are arranged in the vertical direction, and are controlled to move downwards and reset upwards through a reset spring; the rotating piece is provided with a strip-shaped hole and matched with the first cutting piece; the screw blades penetrate through the strip-shaped hole of the rotating piece, the screw blades move up and down to drive the rotating piece to rotate along the preset first direction and second direction, and the first cutting piece rotates when the rotating piece rotates along the first direction and / or the second direction. The frictional force between the screw blades and the rotating piece is very small, the rotating piece is easily driven to rotate only by moving the screw blades up and down, so that the cutting function of the first cutting piece is realized, in addition, the operation saves labor, the installation is convenient, and the energy is saved.

Owner:JOMOO KITCHEN & BATHROOM

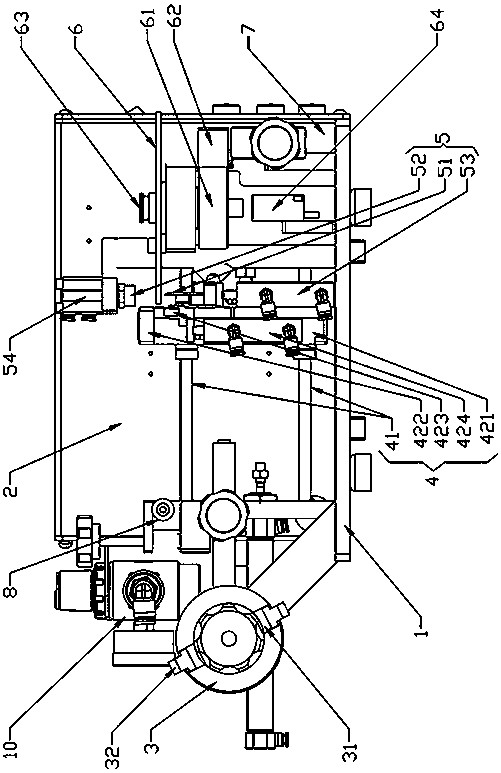

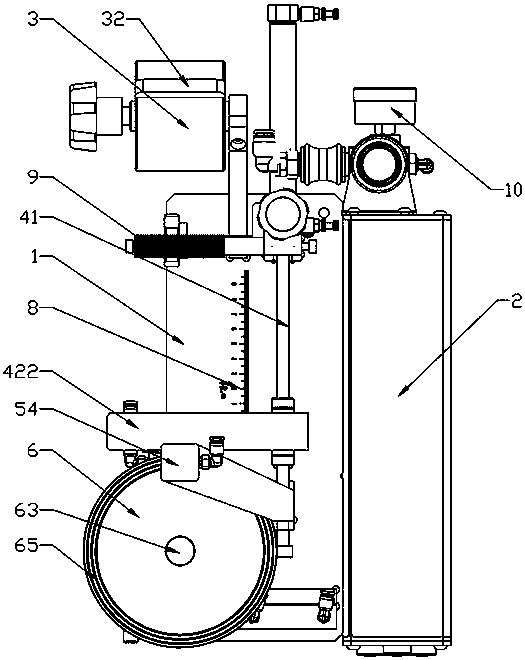

Flat iron channel steel punching and cutting combined automatic machining device

ActiveCN112894392APrecise feedingThe punching position is accurateMeasurement/indication equipmentsStock shearing machinesPunchingStructural engineering

The invention discloses a flat iron channel steel punching and cutting combined automatic machining device. The automatic machining device comprises a supporting base, a cutting assembly, a punching head assembly, an adjusting support, a workpiece supporting piece, a pressing conveying piece, up-down adjusting frames, a feeding driving piece, a punching driving piece, a cutting pressing piece and a feeding assembly, wherein the supporting base comprises a supporting table; and supporting legs are arranged at the four corners of the lower surface of the supporting table, the feeding assembly, the punching driving piece and a cutting support are sequentially arranged on the upper surface of the supporting table, the adjusting support is arranged at one end of the supporting table, the workpiece supporting piece is arranged on the adjusting support and located on one side of the feeding assembly, and the two up-down adjusting frames are arranged on the workpiece supporting piece. The flat iron channel steel punching and cutting combined automatic machining device is simple in structure, automatic positioning in the workpiece conveying process can be achieved, different hole machining can be carried out on the workpiece, the cutting function can be achieved, and convenience is provided for people.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

Tofu processing slitting device with automatic pushing function

The invention discloses a tofu processing slitting device with an automatic pushing function. The upper part of a bottom plate is fixedly connected with a support. The right side of the support is provided with a drive motor. The lower part of the drive motor is rotationally connected with an output shaft. The lower part of the output shaft is fixedly connected with an uncompleted gear. One part of the uncompleted gear is provided with teeth, and the other part of the uncompleted gear is not provided with teeth. One side of the uncompleted gear is attached to a rack plate, the tooth part of the uncompleted gear is engaged with the rack plate, the rack plate is fixed to the outer side wall of a loading vehicle, and movable wheels are attached to the upper surface of the bottom plate. The left side of the support is rotationally connected with a worm, the worm and the output shaft are connected through a first synchronous belt, the worm is engaged with a worm wheel, the worm wheel is rotationally connected with a cross beam, and the cross beam is fixedly connected with the left side of the middle of the support. The left end of the cross beam is rotationally connected with a cam, andthe cam and the worm wheel are connected through a second synchronous belt. The loading vehicle is driven by the tooth part of the uncompleted gear to move in an intermittent manner, meanwhile, the worm is used for driving the worm wheel to rotate so that rotation of the cam can be achieved, and a sleeving plate drives a tool to do reciprocating movement up and down so that a tofu block slittingfunction can be achieved.

Owner:刘景岳

Glass cutting and edge sealing equipment for building decoration and use method

InactiveCN112793015AAvoid Broken AccidentsEasy to fixLiquid surface applicatorsWorking accessoriesHydraulic cylinderMaterials science

The invention relates to the technical field of glass processing, in particular to glass cutting and edge sealing equipment for building decoration and a use method. The glass cutting and edge sealing equipment comprises a base table, a supporting table, a supporting frame, a cutting assembly, a first moving assembly, a second moving assembly and an edge sealing assembly, wherein top blocks are driven to extrude a piece of glass by using a fifth hydraulic cylinder, fixing of glass needing to be processed is achieved, the processed glass can be stabler in a cutting process, and therefore the cutting accuracy of the device is improved, meanwhile, the accident that the glass is broken due to the fact that the glass is not firmly fixed in the glass cutting process is avoided, the using safety of the equipment is improved, plastic pads are arranged at the tops of the top blocks, a buffering effect is achieved, the top blocks are prevented from bumping the glass, meanwhile, the plastic pads also has an anti-skid effect, the fixing effect on the glass can be further improved, and therefore the cutting accuracy and safety of the equipment are further improved.

Owner:胡芳艳

Pin cutting device for electronic element

The invention discloses a pin cutting device for an electronic element. The pin cutting device comprises a bottom box, wherein the upper end of the bottom box is provided with an air cylinder installing plate; the upper end of the air cylinder installing plate is provided with a cutting air cylinder; the front end of the cutting air cylinder is provided with a guide plate; the upper end of the guide plate is provided with a cutting knife; a seat plate is arranged in front of the air cylinder installing plate; the upper end of the seat plate is provided with a support plate; the upper end of the support plate is provided with a cutting plate; the upper end of the cutting plate is provided with a placing plate; a press plate is arranged above the placing plate; the right end of the press plate is provided with a support seat; a dust gathering box is arranged on a front side plate of the bottom box. Generally, the pin cutting device has the advantages that the structure is simple; the investment cost is low.

Owner:张义英

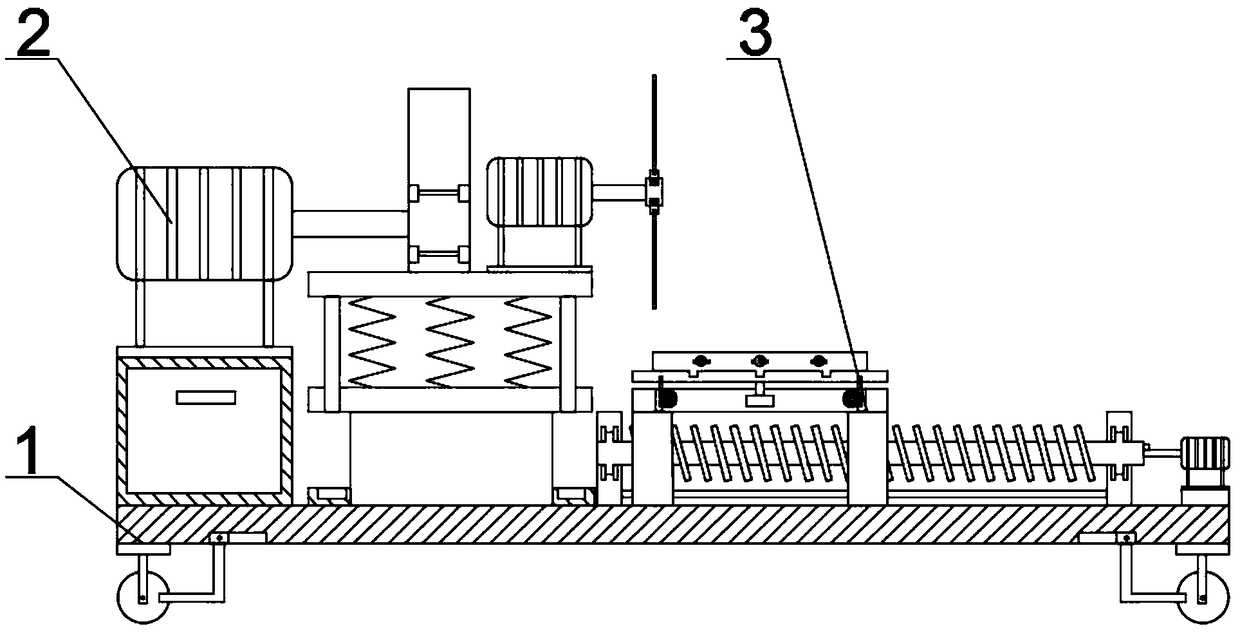

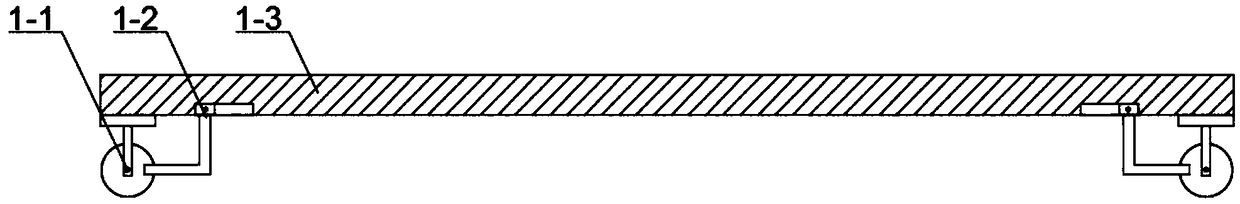

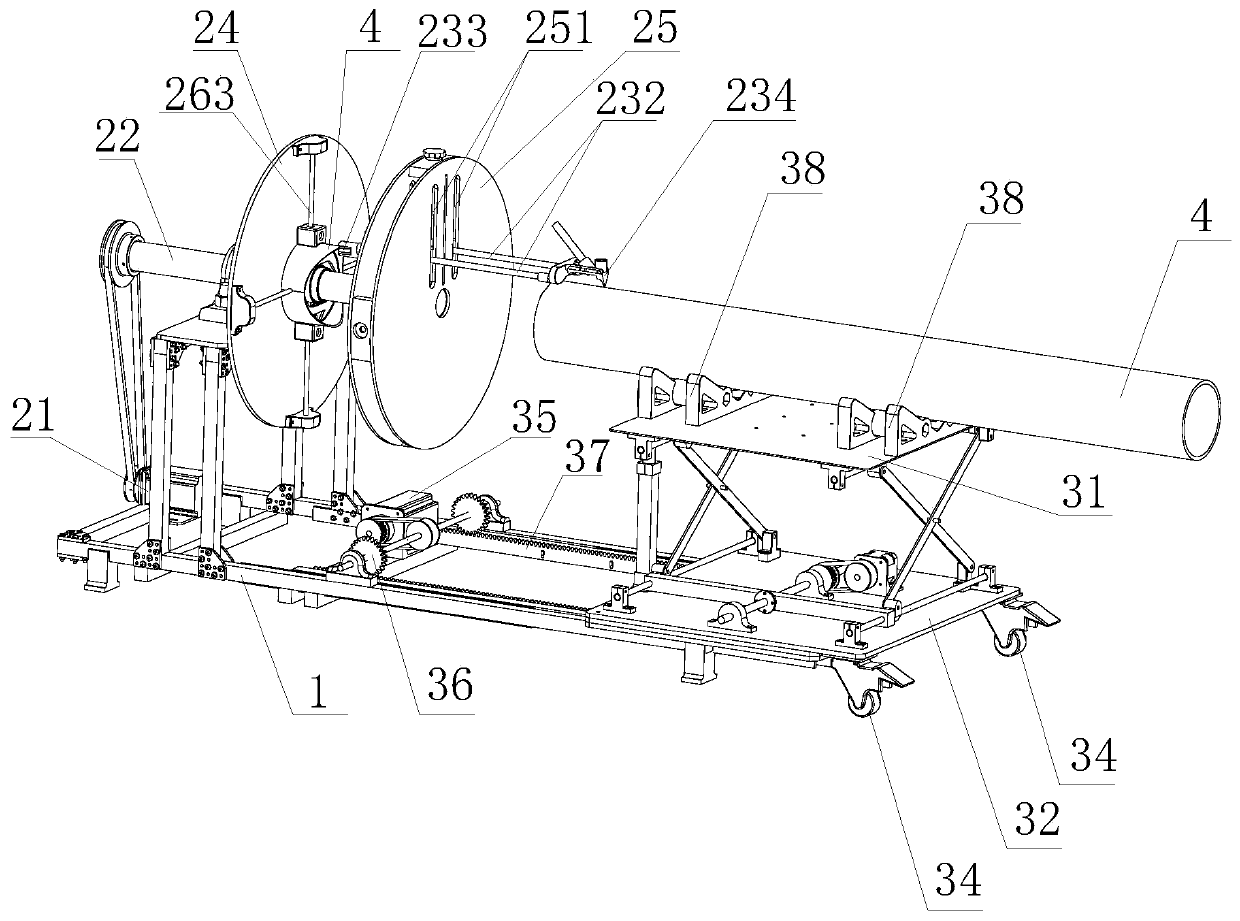

Multifunctional cutting device for building decoration

InactiveCN109079216ARealize the cutting functionRealize the parking functionShearing machinesEngineeringBuilding construction

The invention relates to a cutting device, in particular to a multifunctional cutting device for building decoration. The multifunctional cutting device comprises a moving bottom frame mechanism, a lifting cutting mechanism and a movable cutting platform mechanism. The multifunctional cutting device can realize a cutting function, and a cutter can ascend and descend automatically; the multifunctional cutting device can move a plate to conduct cutting, can rotate the plate to conduct cutting, can store construction utensils, can move and can realize a parking function; the lifting cutting mechanism is located above the moving bottom frame mechanism and connected with the moving bottom frame mechanism through bolts; and the movable cutting platform mechanism is located on the upper portion of the moving bottom frame mechanism and connected with the moving bottom frame mechanism through bolts.

Owner:刘丽军

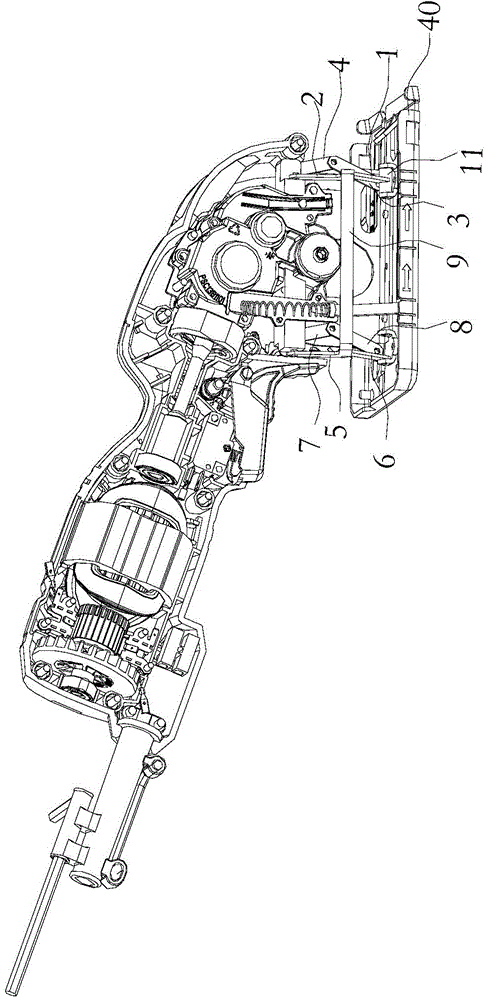

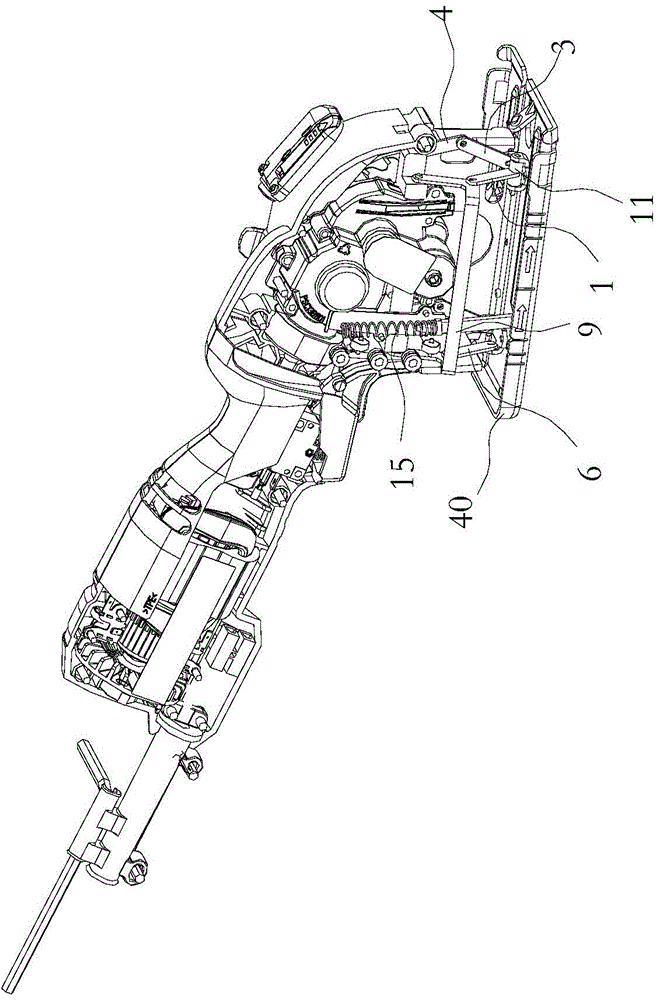

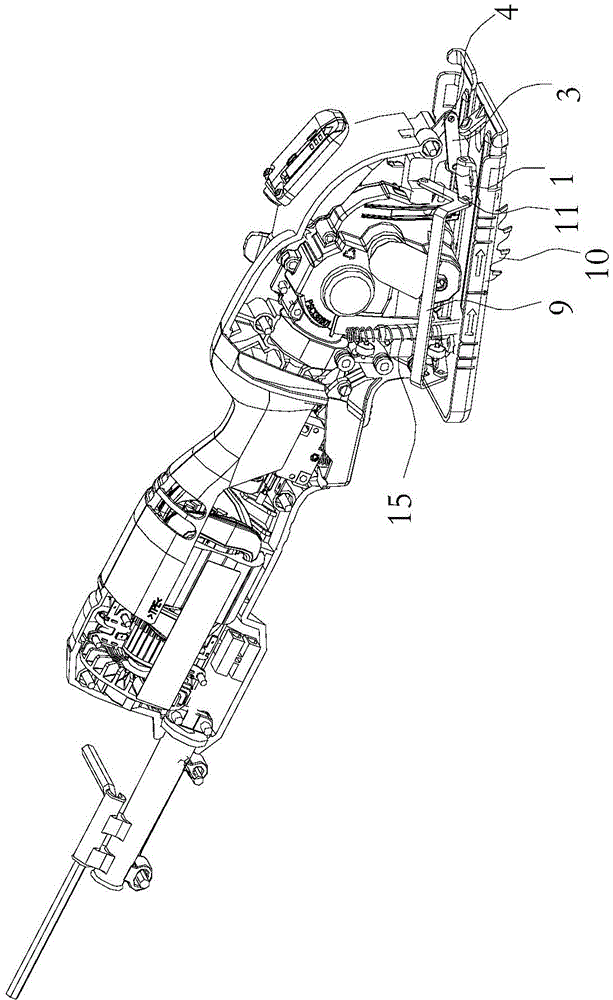

Electric circular saw cutting control device

ActiveCN105690331ARealize the cutting functionChanging the motion track to an arcMetal sawing devicesPortable power driven sawsVisibilityCircular saw

The invention discloses an electric circular saw cutting control device. The electric circular saw cutting control device is fixed to a bottom plate of an electric circular saw and comprises a saw blade supporting assembly which is connected with the bottom plate and a saw blade assembly. The saw blade supporting assembly controls the moving track of the saw blade assembly relative to the bottom plate to be perpendicular through a connecting rod and a hinge mechanism connected with the connecting rod. The saw blade supporting assembly comprises a first end supporting assembly and a second end supporting assembly, wherein the first end supporting assembly is used for supporting the front end of the saw blade assembly so that the moving track of the front end of the saw blade assembly relative to the bottom plate can be perpendicular, and the second end supporting assembly is used for supporting the rear end of the saw blade assembly so that the moving track of the rear end of the saw blade assembly relative to the bottom plate can be perpendicular. A saw blade moves perpendicularly relative to the bottom plate during cutting of the electric circular saw, the situation that the moving track of a saw blade in the prior art is an arc is changed, and therefore cutting can be more accurate and precise, the visibility effect is improved through the simple connecting rod design, and the cutting process is convenient to control.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

A reciprocating steel plate cutting device based on the principle of crank slider

ActiveCN109865883BAchieve reductionHeight adjustableMetal sawing devicesFeeding apparatusMachineBevel gear

The invention discloses a reciprocating steel plate cutting device based on the principle of a crank slider, and relates to a device capable of automatically walking and reciprocatingly cutting steel plates. The device drives a stepped shaft and a worm to rotate through a sleeve, and the rotating worm drives a worm wheel to rotate to drive The cutting wheel rotates to realize the cutting function. At the same time, the rotating sleeve drives the rotating shaft and the turntable to rotate through the first bevel gear and the second bevel gear. Cutting function, and, through the cooperation of the cylinder and the piston rod, the height of the workbench can be adjusted to realize the cutting of steel plates of different thicknesses. The present invention effectively solves the problems of complex structure of the existing steel plate cutting machine, the cutting function needs to be realized through synergy of multiple power mechanisms at the same time, and the problems of high manufacturing and use costs.

Owner:广西桂盾人防工程有限公司

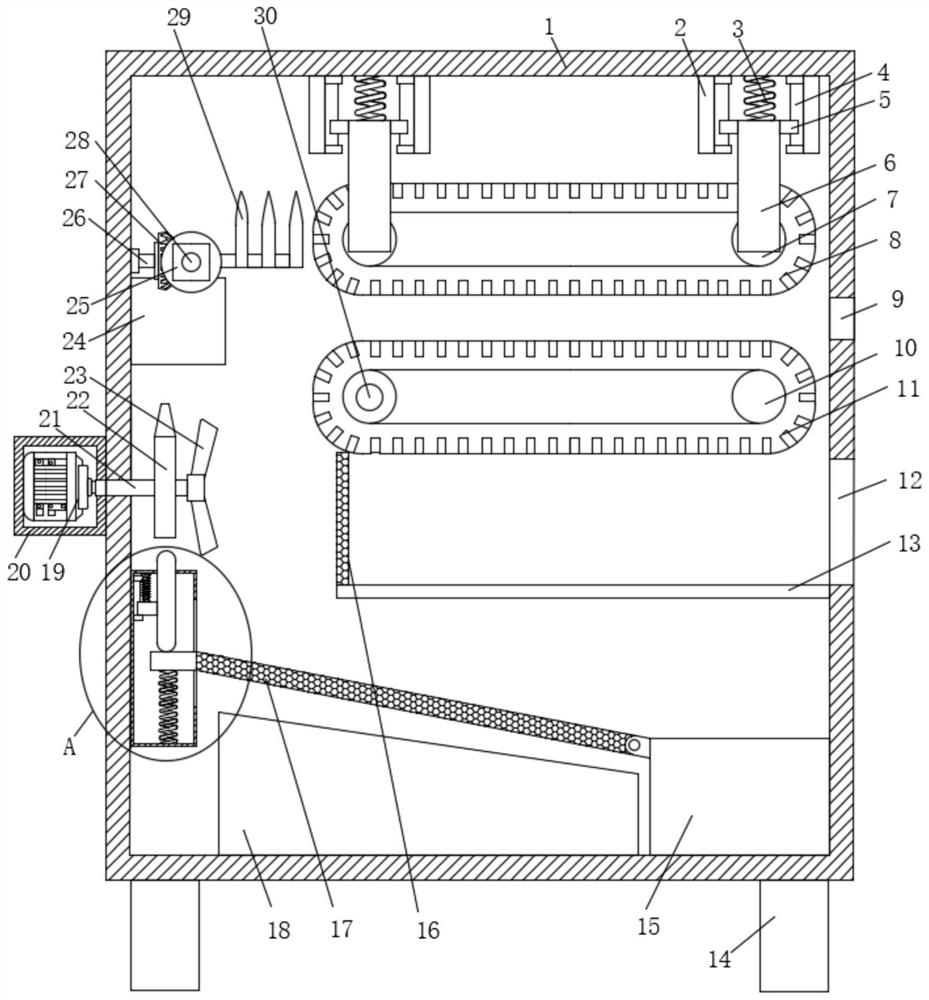

Intelligent traditional Chinese medicinal material slicing machine and traditional Chinese medicinal material processing technology

ActiveCN113211520AEasy to cutSimple structureGas current separationMetal working apparatusMedicinal herbsProcess engineering

The invention discloses an intelligent traditional Chinese medicinal material slicing machine and a traditional Chinese medicinal material processing technology and aims to solve the problems that existing traditional Chinese medicinal material need to be manually cut during slicing, use of operators is unsafe, potential safety hazards exist, the automation degree is lower, slice thicknesses are different, slices are uneven, manual classified collection is needed according to the sizes of traditional Chinese medicinal tablets, due to the fact that slicing powder dust is attached to the surfaces of the traditional Chinese medicine tablets, manual powder dust removal must be conducted after processing is completed, and the dust removal effect is poor. The following scheme is provided that the machine comprises a slicing box, two second rotating rollers are rotationally connected to the inner walls of the two sides of the slicing box, and the outer walls of the two second rotating rollers are sleeved with the same second belt. According to the intelligent traditional Chinese medicinal material slicing machine, traditional Chinese medicinal materials are conveyed through the second belt, the traditional Chinese medicinal materials are pressed through a pressing assembly and then clamped through a clamping assembly, cutting of a cutting assembly is facilitated, the cut traditional Chinese medicinal materials are subjected to dust removal through a dust removal assembly, finally, the traditional Chinese medicinal materials are screened and collected through a screening assembly, the structure is simple, and operation is convenient.

Owner:昭通市鑫水月商贸有限公司

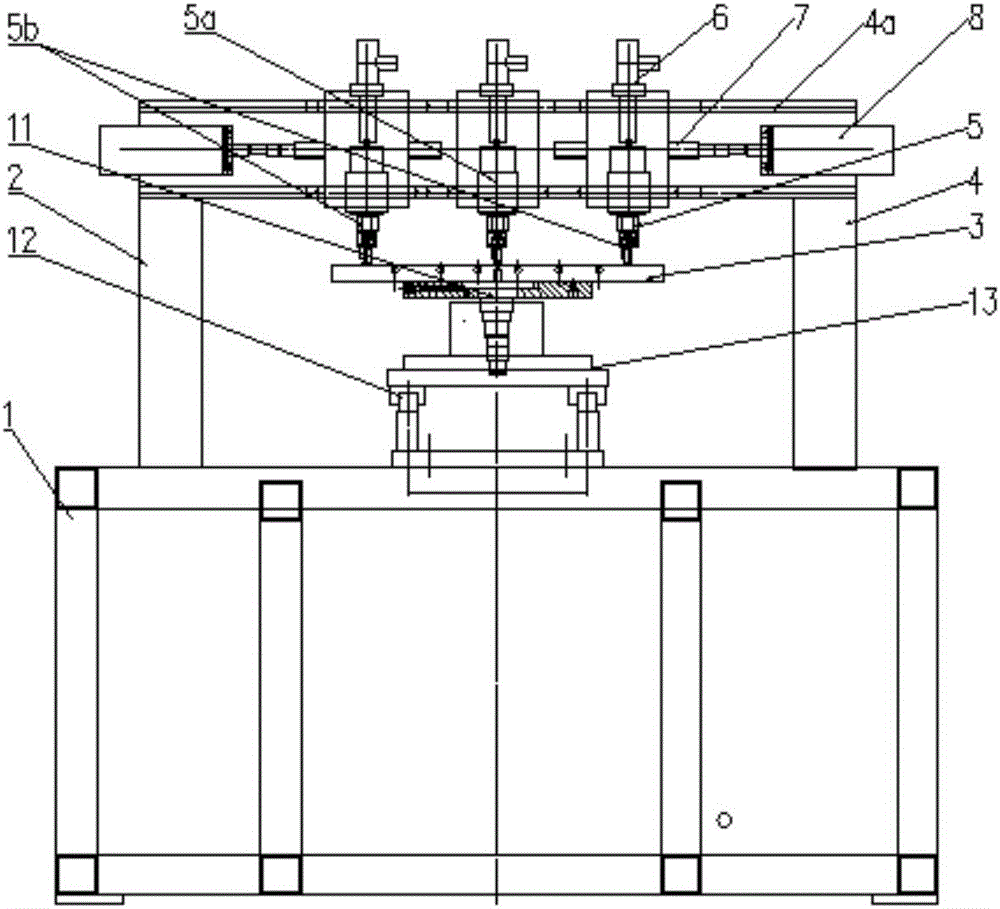

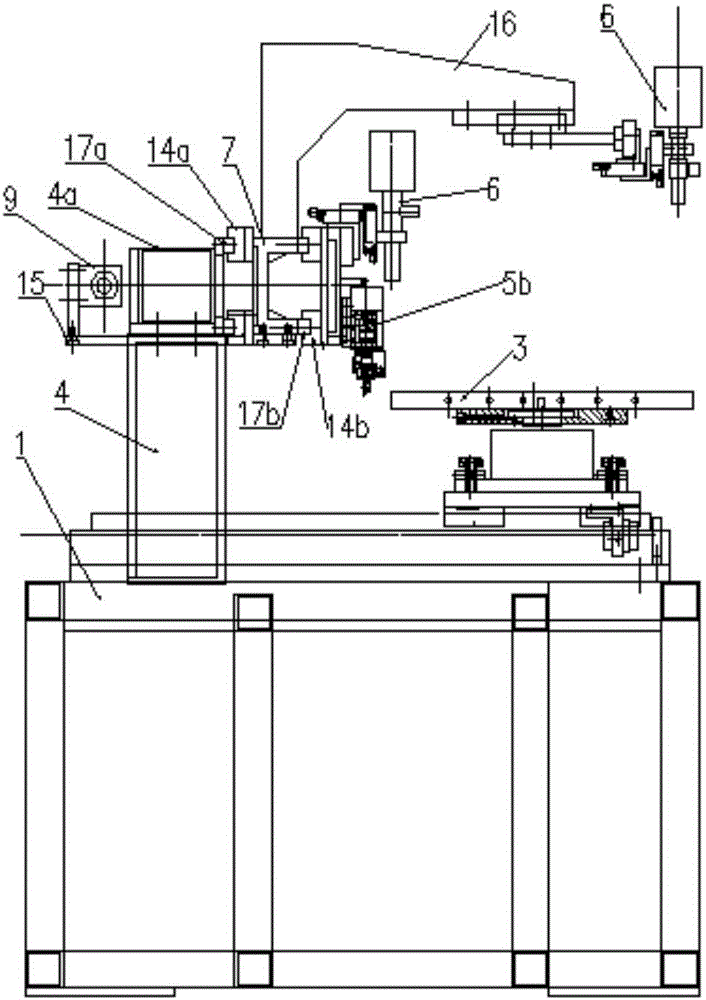

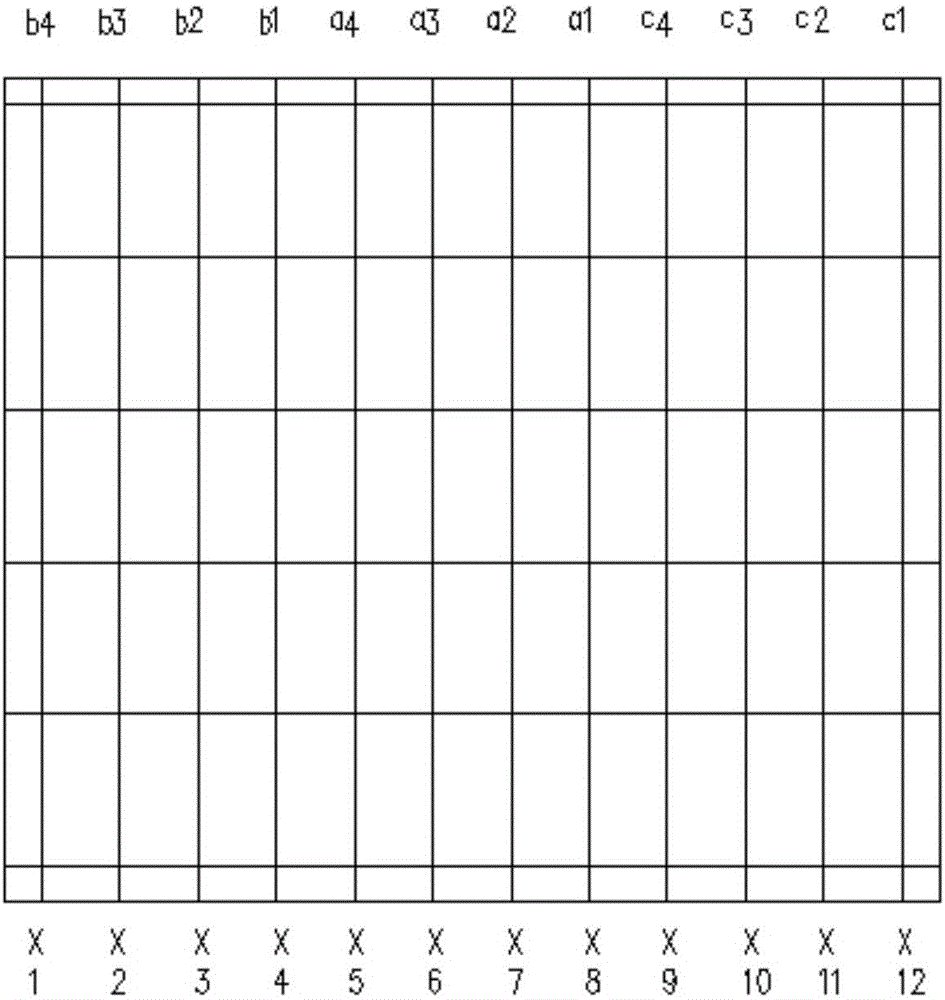

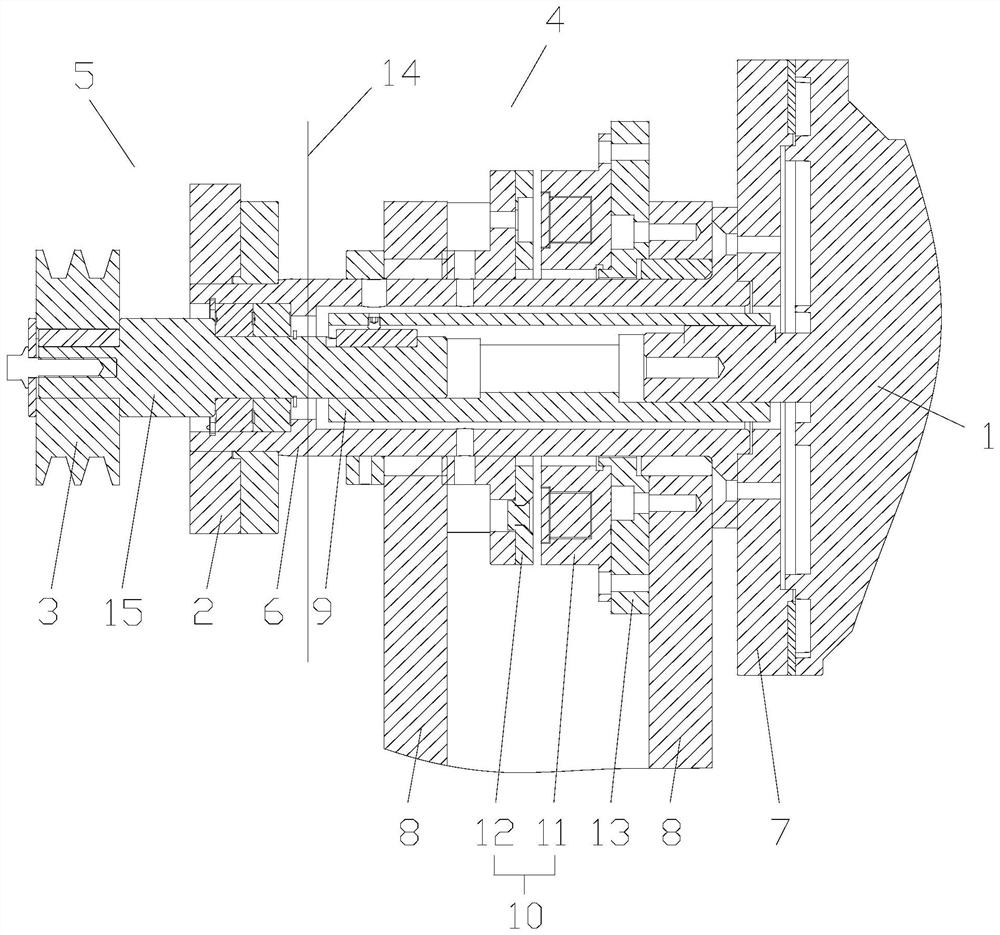

Three-in-one punching and milling machine for adapter

ActiveCN104440091ARealize the function of thread cuttingRealize the cutting functionOther manufacturing equipments/toolsLarge fixed membersEngineeringWorkbench

The invention provides a three-in-one punching and milling machine for an adapter. A punching machine comprises a workbench. One side of the workbench is provided with a clamping and rotating device. The clamping and rotating device comprises a clamping base fixed to the workbench. The punching machine further comprises a material disc arranged on one side of the workbench. The material disc conveys materials to a feeding device through a conveying belt. The other side of the workbench is provided with a punching device. The adapter is placed on the clamping and rotating device through the feeding device, then the adapter is punched through the punching device, and thread manufacturing is conducted on the adapter through a thread device while punching is conducted. According to the three-in-one punching and milling machine, automation is achieved from feeding to discharging after punching is conducted, three holes are integrated to conduct operation at the same time, punching is accurate, the production speed is high, the machine is suitable for mass production, automated production is achieved, the production speed is increased, production efficiency is improved, meanwhile the economical benefits of enterprises are increased, and the position and size of an inner diameter hole, a threaded hole and a milling groove are accurate.

Owner:江苏锦上精密齿条制造有限公司

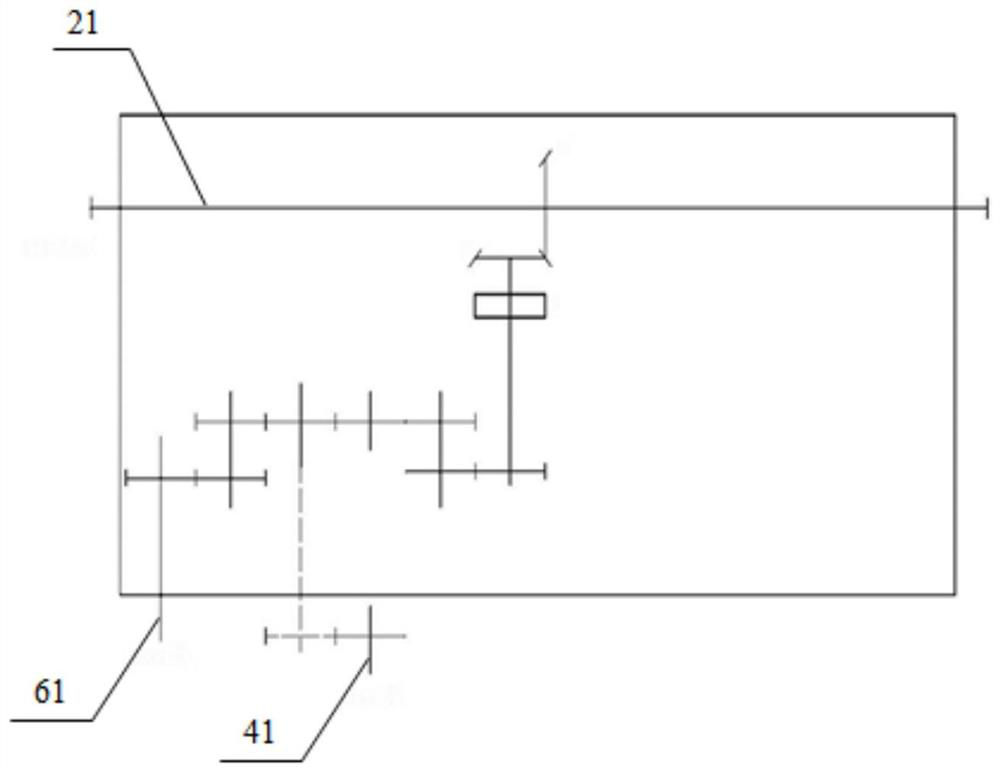

Automatic blank cutting device for civil building glazed tile production

ActiveCN111283849AEasy to moveEasy to operateAuxillary shaping apparatusConstruction engineeringStructural engineering

The invention discloses an automatic blank cutting device for civil building glazed tile production. The automatic blank cutting device for civil building glazed tile production comprises a glazed tile bottom blank die, wherein the glazed tile bottom blank die is arranged at a position of the top side of a support base; a bottom blank die ejection pedal is coupled to and arranged at the right sideof the support base, and the other shaft end of the bottom blank die ejection pedal is abutted against the bottom of the glazed tile bottom blank die; and a glazed tile top die blank-pressing deviceis rotationally connected to a part at one side adjacent to the glazed tile bottom blank die, of a top side support of the support base. Two limit slide rods are symmetrically arranged on supports atthe two ends of the top side of the support base of the automatic blank cutting device for civil building glazed tile production, a transversal cutting wire is slidably installed on the limit slide rods in a limit manner through slide blocks at the two ends, and moreover, a transversal cutting stroke of the transversal cutting wire and the top wall of the glazed tile bottom blank die are bonded inparallel, so that limit movement for the transversal cutting wire on the limit slide rods is benefited, and then the transversal cutting wire is enabled to always stably carry out cutting operation on the top wall and the bottom wall of the glazed tile bottom blank die.

Owner:安徽华丰建筑装饰有限公司

Cutting sawing machine for short bar machining

PendingCN113953584AAdjustable lengthEasy to useMetal sawing devicesMetal sawing accessoriesCircular discStructural engineering

The invention provides a cutting sawing machine for short bar machining and belongs to the technical field of cutting. The cutting sawing machine for the short bar machining comprises a base, a chip liquid containing disc and a rotating mechanism, wherein the chip liquid containing disc is fixedly connected to the upper end of the base, a first fixing table is fixedly connected to the upper end of the chip liquid containing disc, and a sliding table is fixedly connected to the upper end of the first fixing table; and the rotating mechanism comprises a fixing frame, a rotating shaft, a disc, a mounting groove, a connecting rod and a third bolt, the fixing frame is fixedly connected to the upper end of the base, the rotating shaft is rotatably connected to the side end of the fixing frame, the disc is fixedly connected to the side end of the rotating shaft, the mounting groove is formed in the side end of the disc, the connecting rod is connected to the side end of the disc, and the third bolt is connected in the mounting groove in a threaded manner. According to the cutting sawing machine for the short bar machining, a self-made and cast lathe bed is used as the base, the precise hard rail sliding table is added, a reasonable clamp and a reliable saw blade clamping part are further arranged, the length can be adjusted freely and conveniently, use is easy to operate, and potential safety hazards do not exist.

Owner:临沂市鲁蒙水表制造有限公司

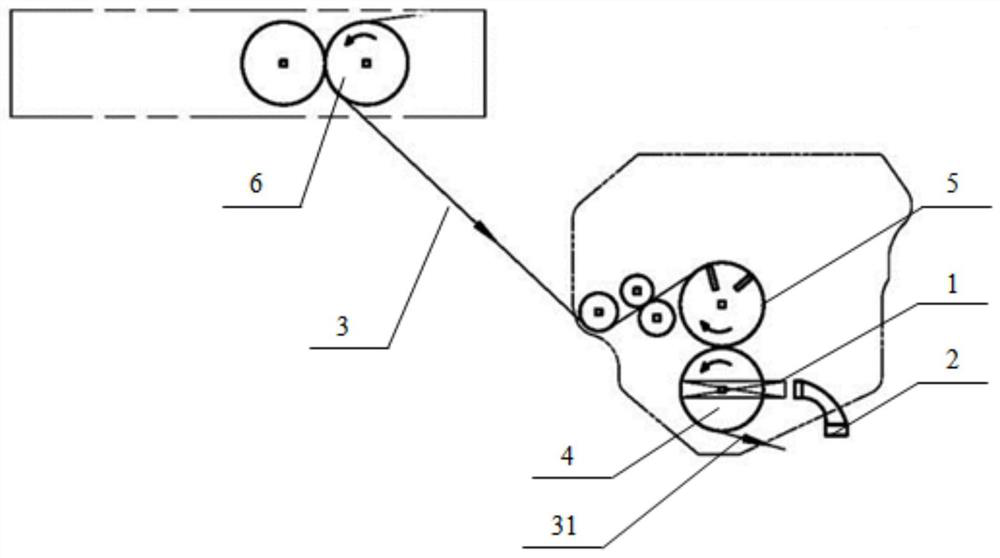

Cigarette lining paper cutting and conveying device and working method thereof

InactiveCN112407481ASolve the sliding problemImprove packaging qualityPackaging automatic controlControl systemMechanical engineering

The invention provides a cigarette lining paper cutting and conveying device. The cigarette lining paper cutting and conveying device comprises a cigarette pushing handle, a driving device, a first rotary driving device, a second rotary driving device and a control system, an encoder is arranged on an output shaft of the driving device, and the cigarette pushing handle is driven by a transmissionmechanism to push a cigarette group to enter a reserved space in the middle of a conveying roller; the first rotary driving device drives the conveying roller to rotate, and the second rotary drivingdevice drives an embossing roller to rotate; and the encoder, the first rotary driving device and the second rotary driving device are all connected with the control system. The invention further provides a working method of the cigarette lining paper cutting and conveying device. The device has the beneficial effects that the embossing roller and the conveying roller are correspondingly driven bythe two independent rotary driving devices, and the embossing roller and the conveying roller are matched with the encoder arranged on the output shaft for driving the cigarette pushing handle to act, so that the problem of relative sliding between lining paper and the surface of the cigarette group is solved, and the cigarette packet packaging quality is improved.

Owner:SHANGHAI TOBACCO MACHINERY

Fiber reinforced epoxy resin profile cutting equipment

ActiveCN113442215ARealize forward interval conveying functionRealize the cleaning functionMetal working apparatusEpoxyDrive shaft

The invention discloses fiber reinforced epoxy resin profile cutting equipment, and relates to the technical field of profile processing. The fiber reinforced epoxy resin profile cutting equipment comprises a rack, the top of the rack is provided with a conveying pipe guide groove, the middle of one side of the top of the rack is fixedly provided with a side vertical plate, the top of the middle of the side vertical plate is fixedly provided with a first transverse frame, a driving shaft is rotationally installed in the first transverse frame, the top end of the driving shaft is driven by a driving motor, and the bottom end of the driving shaft extends to the bottom of the first transverse frame and is fixedly provided with a worm. According to the fiber reinforced epoxy resin profile cutting equipment, the driving shaft is driven to continuously rotate, a worm gear is driven to continuously rotate, and then a material pushing rod swings left and right once and drives a drill rod to ascend and descend once in the period of one-circle rotation, so that the conveying function is achieved, the drilling and burr scraping functions are also achieved, the practicability and functionality of the equipment are greatly improved, and the processing efficiency of fiber reinforced epoxy resin material type square tubes is greatly improved.

Owner:SHENYANG UNIV

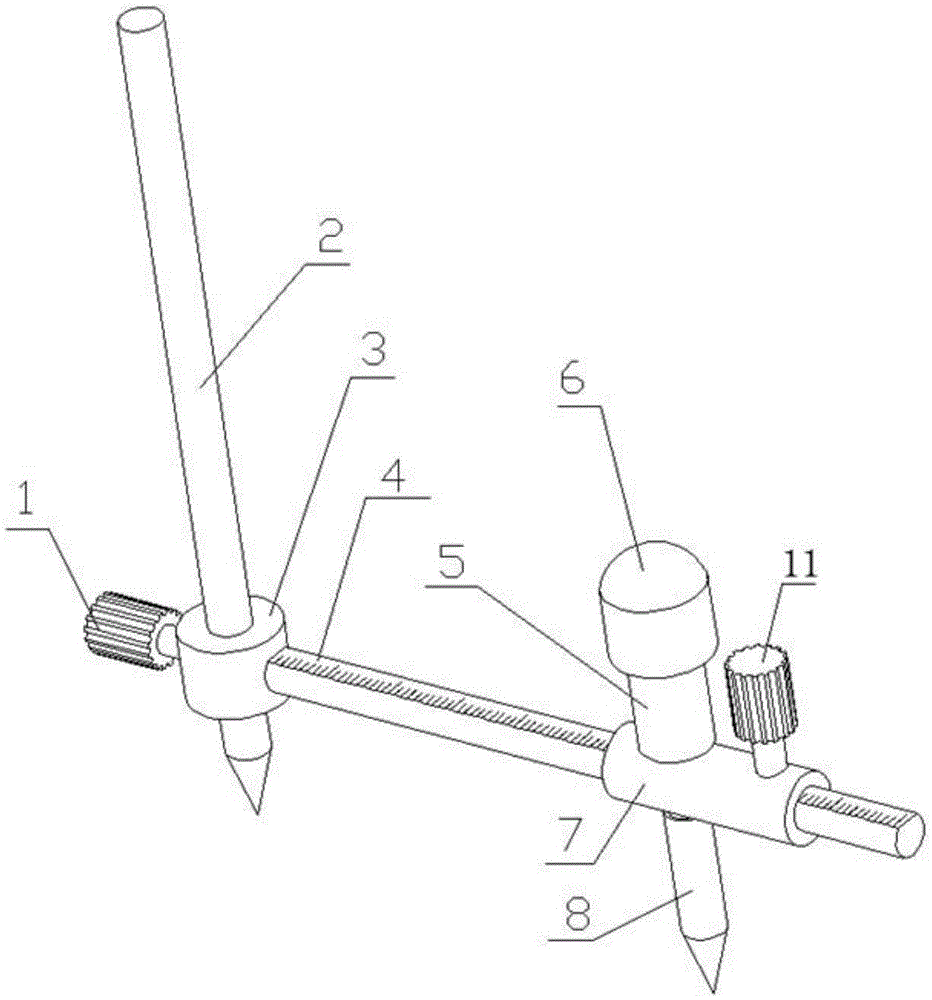

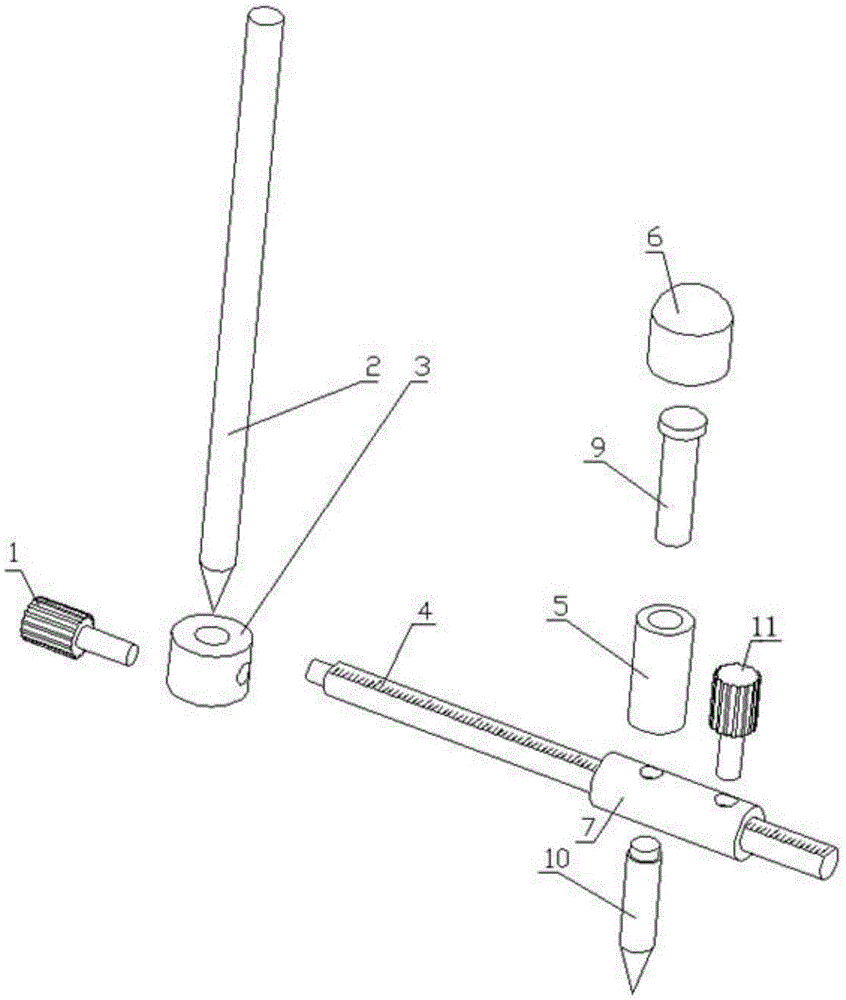

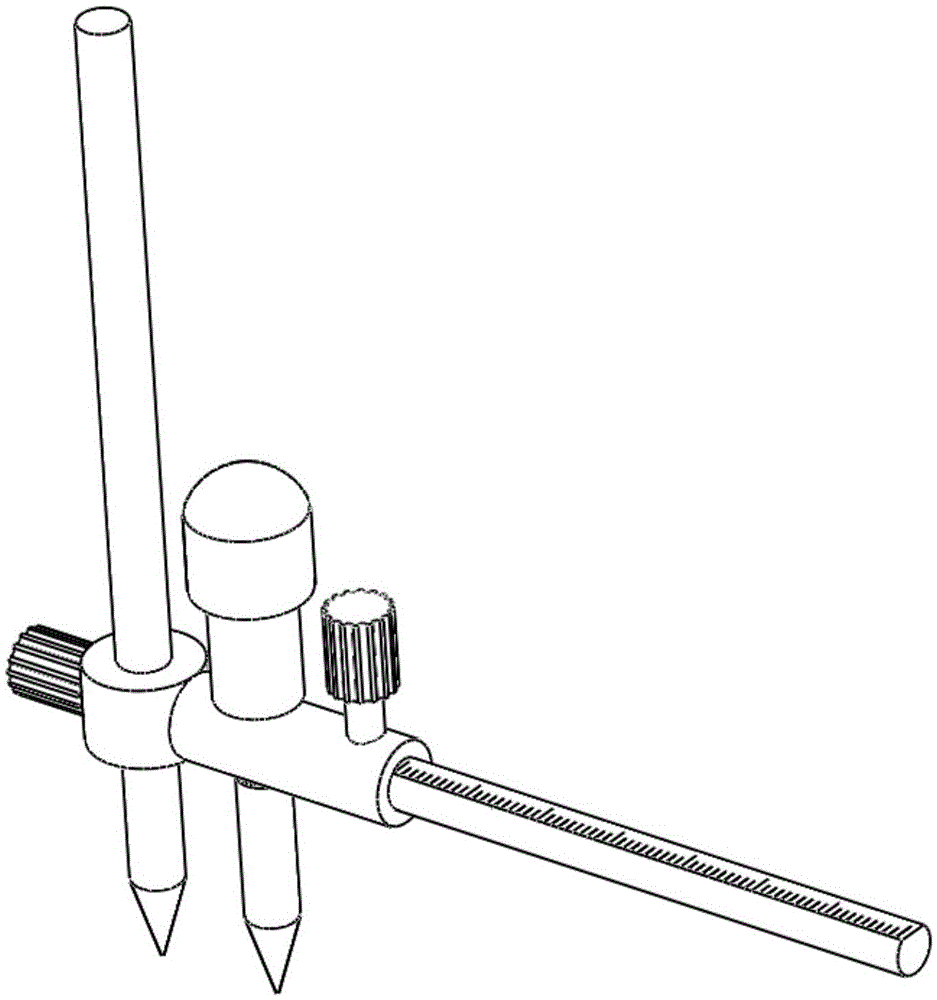

A kind of multifunctional adjustable diameter compass with graduated scale

InactiveCN104191873BEasy to adjustRealize the cutting functionCircular curve drawing instrumentsEngineeringRadius rod

The invention relates to multifunctional radius-adjustable compasses with scales. The multifunctional radius-adjustable compasses with the scales are characterized by comprising a first scale positioning bolt, a second scale positioning bolt, a pen, a pen holder, a radius rod, a fixing tube and a circle center fixing needle, wherein the pen is connected with the radius rod through the pen holder and the first scale positioning bolt; the circle center fixing needle is connected with the radius rod through a fixing tube; and the fixing tube is also provided with the second scale positioning bolt. The circle center fixing needle can move along the radius rod with length scale values, so that the radius can be accurately adjusted; circles and arcs can be conveniently scratched on surfaces of parts made of different materials; and the parts can be trimmed along the circles or the arcs.

Owner:HOHAI UNIV CHANGZHOU

Adhesive tape machine

PendingCN107840183ARealize the cutting functionSimple structureFinal product manufacturePrimary cellsEngineeringMechanical engineering

The invention discloses and provides a desktop adhesive tape machine which is simple in structure, low in manufacturing cost and high in efficiency. The adhesive tape machine comprises a mounting bottom plate, an electrical system box arranged on one side of the mounting bottom plate, a material hanging reel, an adhesive tape pulling assembly, an adhesive tape cutting assembly and a discharge platform, wherein the material hanging reel, the adhesive tape pulling assembly, the adhesive tape cutting assembly and the discharge platform are sequentially arranged on the mounting bottom plate from back to front; the adhesive tape pulling assembly comprises longitudinal rails arranged between the material hanging reel and the discharge platform and an adhesive tape clamping device in sliding fitwith the longitudinal rails; the adhesive tape cutting assembly comprises a cutter and a pressing block matched with the discharge platform and located over the discharge platform; the adhesive tape clamping device and the adhesive tape cutting assembly are both electrically connected with the electrical system box. The adhesive tape machine can be applied to the technical field of adhesive tape machines.

Owner:钟丙华

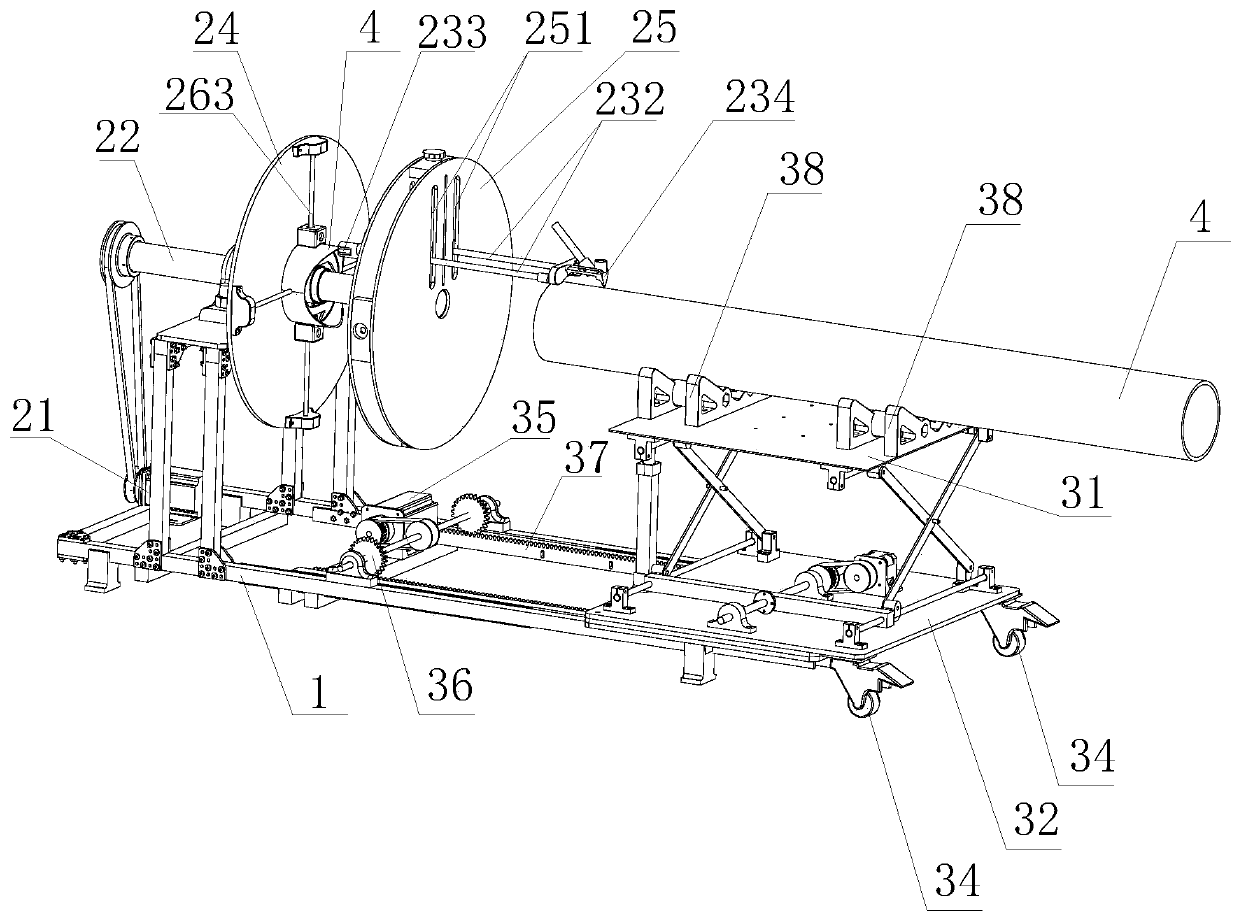

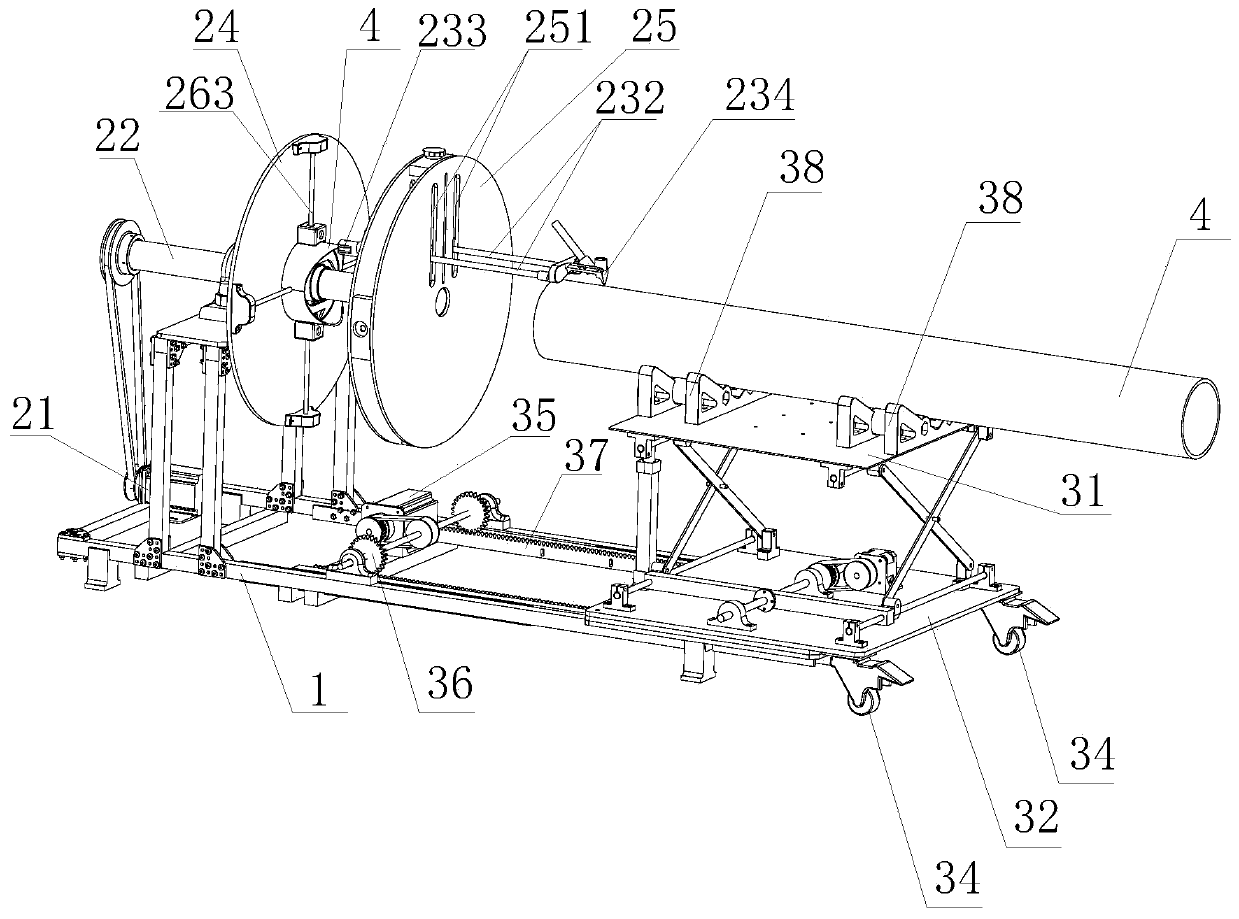

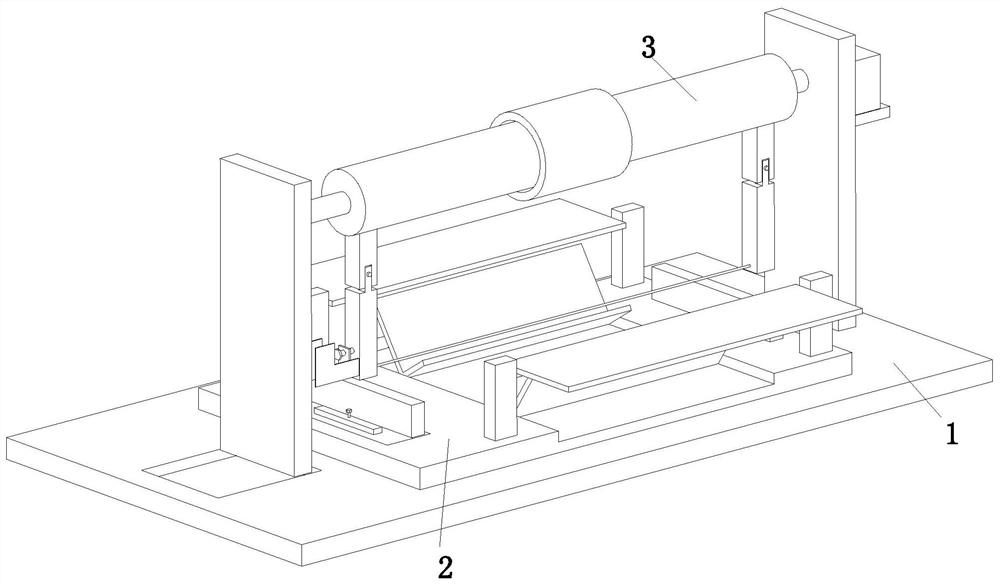

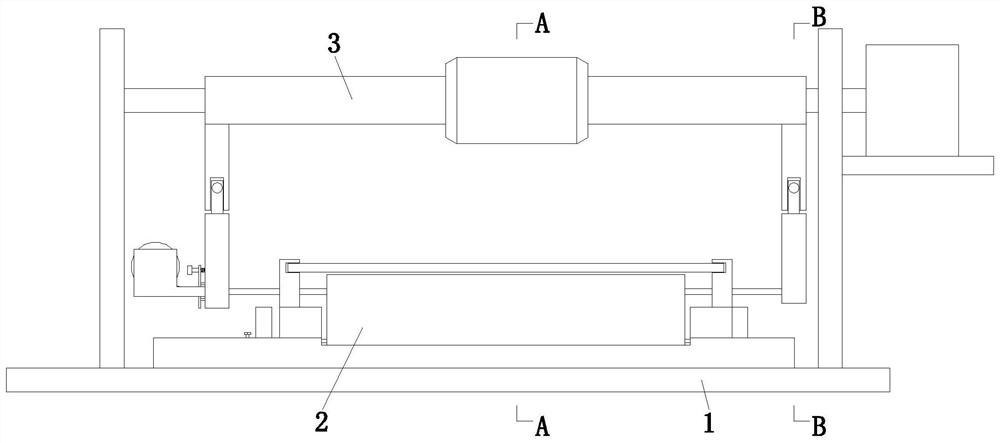

Simple rotating plasma cutter

PendingCN110253122AImprove cutting accuracyEfficient cuttingPlasma welding apparatusEngineeringPlasma cutting

The invention relates to a simple rotating plasma cutter which comprises a plasma cutting machine. The simple rotating plasma cutter is characterized by further comprising a rack, a rotary cutting mechanism and a pipeline bearing mechanism. The rotary cutting mechanism and the pipeline bearing mechanism are fixed to the rack. The rotary cutting mechanism comprises a first power part, a connecting shaft, a cutting assembly, a first rotating disc and a second rotating disc, wherein the first rotating disc and the second rotating disc are arranged coaxially. A pipe type cutting module is arranged on the front end face of the first rotating disc. The front end face of the pipe type cutting module is of an intersecting line shape. The pipeline bearing mechanism is arranged ahead of the rotary cutting mechanism. The pipeline bearing mechanism comprises a bearing platform, a base and a lifting mechanism. The simple rotating plasma cutter has the advantages that the cutting precision is high, cutting is efficient, the function of cutting pipelines with the different pipe diameters can be achieved on the same equipment by replacing the pipe type cutting module, and the cost of cutting the pipelines with the different pipe diameters can be reduced to the great extent.

Owner:NINGDE NORMAL UNIV

Polystyrene foam plastic board cutting process

ActiveCN112388705ARealize the cutting functionIncrease flexibilityMetal working apparatusPolystyreneMechanical engineering

The invention relates to a polystyrene foam plastic board cutting process. A polystyrene foam plastic board cutting device comprises a base, a fixing device and a slitting device, the fixing device isinstalled at the upper end of the base, the slitting device is arranged above the fixing device, and the slitting device is installed at the upper end of the base. The cutting process can solve the problems that when semicircular grooves are formed in polystyrene foam plastic boards, existing equipment cannot be adjusted at will according to the lengths of the foam plastic boards, so that the function of cutting the foam plastic boards of different sizes cannot be achieved, the flexibility of the equipment is reduced, meanwhile, the cutting radius cannot be adjusted, the semi-circular grooveswith different sizes cannot be cut in one equipment, the applicability of the equipment is reduced, the foam plastic boards cannot be ejected out after being cut, and therefore the foam plastic boards cannot be taken out of the equipment easily.

Owner:广东省科佳节能科技有限公司

Double-workstation three-knife glass cutter

ActiveCN106082618ASimple knife adjustmentSimple and scientific knife adjustmentGlass severing apparatusGlass productionGlass cutterComputer engineering

The invention discloses a double-workstation three-knife glass cutter which comprises a rack, a working platform arranged on the rack, a knife rest device and corresponding cutting knives. The knife rest platform comprises a fixed cross beam and a movable cutting knife cross beam connected to the fixed cross beam through a corresponding cross beam adjusting device, the cutting knives include a basic cutting knife fixedly connected to the movable cutting knife cross beam, and two deflection cutting knives respectively positioned on two corresponding sides of the basic cutting knife and connected to the movable cutting knife cross beam through corresponding cutting knife adjusting device. The double-workstation three-knife glass cutter is simple, scientific and reasonable in structure, automatic knife adjusting can be realized, preparation assisting time for production is reduced greatly, production efficiency is improved, and the double-workstation three-knife glass cutter is little in investment, small in occupied space, high in working efficiency and good in cutting effect.

Owner:王德胜

Power swing arm mechanism of cutting machine and cutting machine

PendingCN112903334ARealize the cutting functionExtended service lifeWithdrawing sample devicesShearing machinesDrive wheelTransmission belt

The invention provides a power swing arm mechanism of a cutting machine and the cutting machine, and relates to the technical field of cutting machines. The power swing arm mechanism of the cutting machine comprises a motor, a handle, a swing arm, a driving wheel, a driven wheel and a transmission belt. The motor is arranged in the dry cabin; a rotating shaft of the motor provides power for rotation of the cutting blade through the driving wheel, the driven wheel and the transmission belt; the motor is rotationally connected with the cutting machine, the motor can be pushed to rotate through the handle fixed to the motor, the swing arm fixed to the motor is driven to rotate, the set angle of the swing arm is changed, meanwhile, the driven wheel is rotationally arranged on the swing arm, and when the angle of the swing arm is changed, the position of the driven wheel is directly driven to change; the position of the cutting blade fixed on the driven wheel is changed, the cutting function of the cutting machine is achieved, meanwhile, the problem of dynamic sealing of holes in the prior art is avoided, the blocking effect on corrosive water mist is achieved, and the overall service life of the cutting machine is greatly prolonged.

Owner:上海刃安实业有限公司

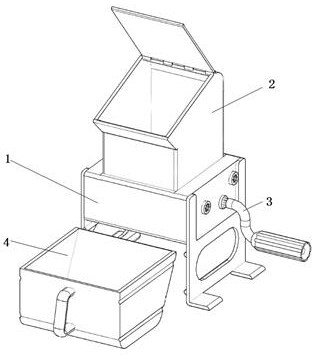

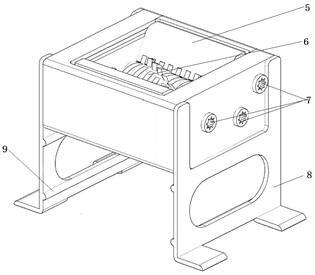

Hand-operated kitchen waste crusher

The invention provides a hand-operated kitchen waste crusher. The hand-operated kitchen waste crusher comprises a crushing main machine and a feeding hopper, wherein the feeding hopper is located at the upper part of the crushing main machine, a discharging opening is formed in the lower part of the crushing main machine, a pair of rotating shafts is mounted in a machine shell of the crushing main machine, each rotating shaft is provided with a cutting blade, and the cutting blades on the two rotating shafts are staggered to form a tool bit; and mutually meshed gears are mounted at one ends of the two rotating shafts to form a transmission gear set, and a crank handle is mounted at the other end of one rotating shaft to form a driving rotating shaft. The hand-operated kitchen waste crusher is simple in structure, low in manufacturing cost, low in noise and long in service life, and does not consume electric energy when being used.

Owner:HEILONGJIANG HONGSHENG AGRI SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com