Resin anchoring agent bag breaking and stirring device and bag breaking and stirring method

A technology of resin anchoring agent and stirring device, which is applied in the direction of earth drilling, bolt installation, mining equipment, etc. It can solve the problems of damage, unsatisfactory effect, and reduce the anchoring force of bolts (cables), so as to enhance the quality of support , Improve the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

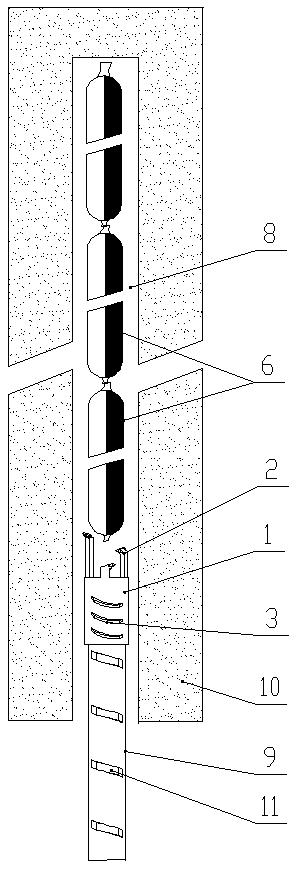

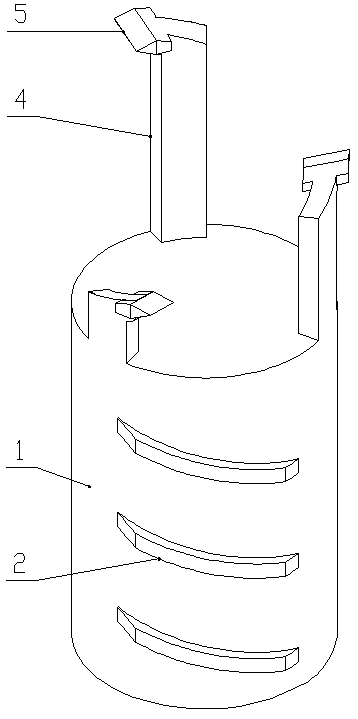

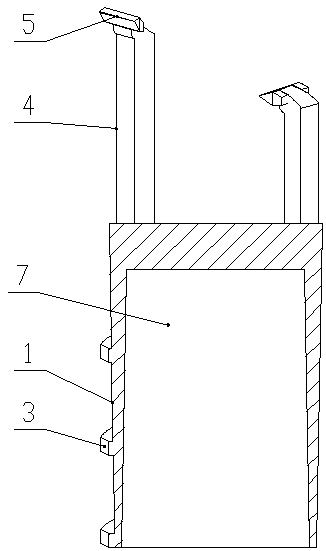

[0024] Such as figure 1 , figure 2 and image 3 As shown, the resin anchoring agent bag breaking stirring device of the present invention comprises a sleeve 1 with an open lower end, and at least two crushing knives 2 are evenly fixed on the top of the sleeve 1 along the circumferential direction, and the maximum rotation diameter of the crushing knives 2 is equal to that of the sleeve. The outer diameter of the barrel 1 and the outer circle of the sleeve 1 are provided with several spiral stirring ribs 3 at intervals.

[0025] There are three crushing knives 2, each of which includes a cutter bar 4 and a cutter head 5, the lower end of the cutter bar 4 is fixedly connected to the top of the sleeve 1, the cutter head 5 is fixedly connected to the upper end of the cutter bar 4, and the three crushing knives 2 The cutter heads 5 are staggeredly arranged in height, and each cutter head 5 is gradually inclined downward from the outside to the inside along the radial direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com