Simple rotating plasma cutter

A rotary cutting and plasma technology, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of difficulty in cutting the incision of the intersecting line of the pipeline, and achieve the effect of reducing cutting cost, high cutting precision and high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

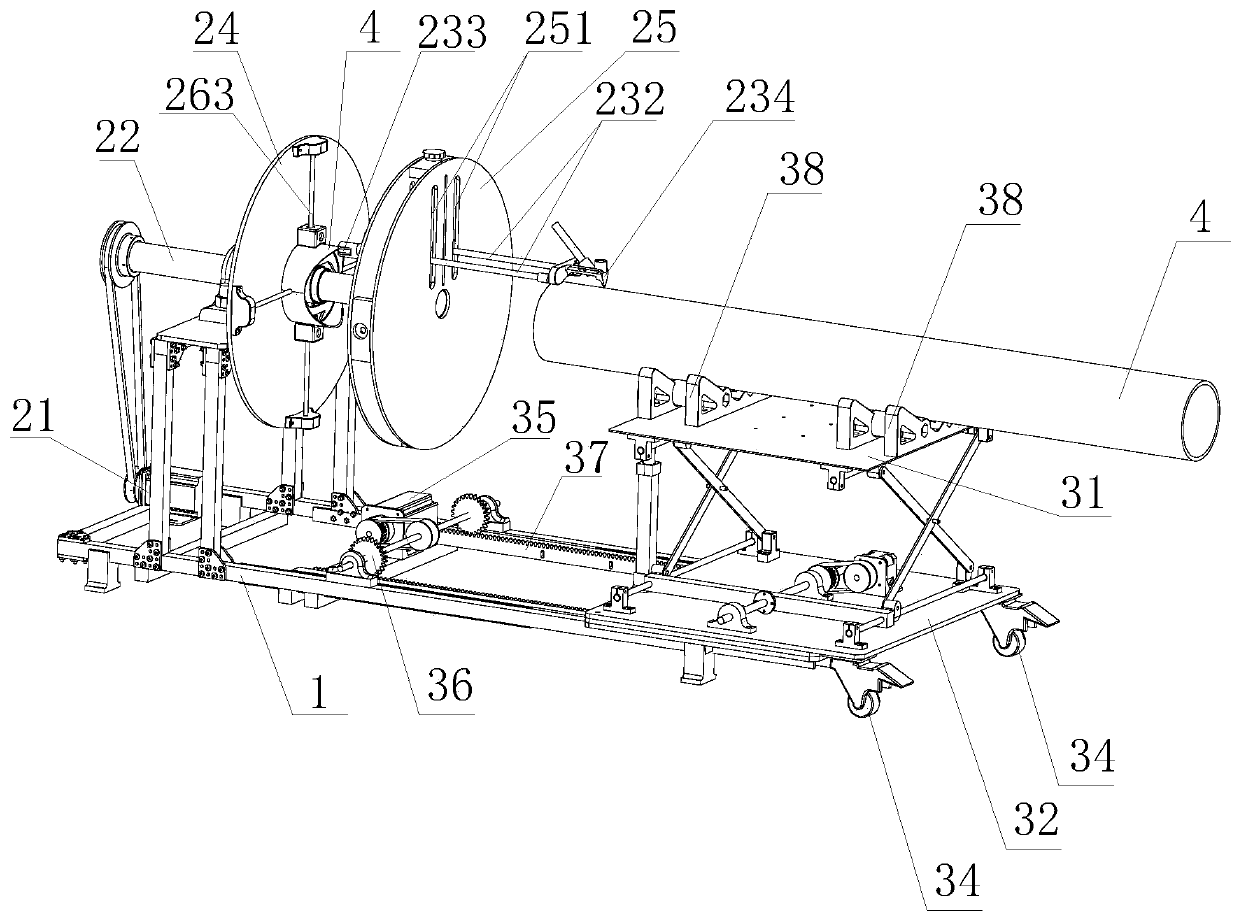

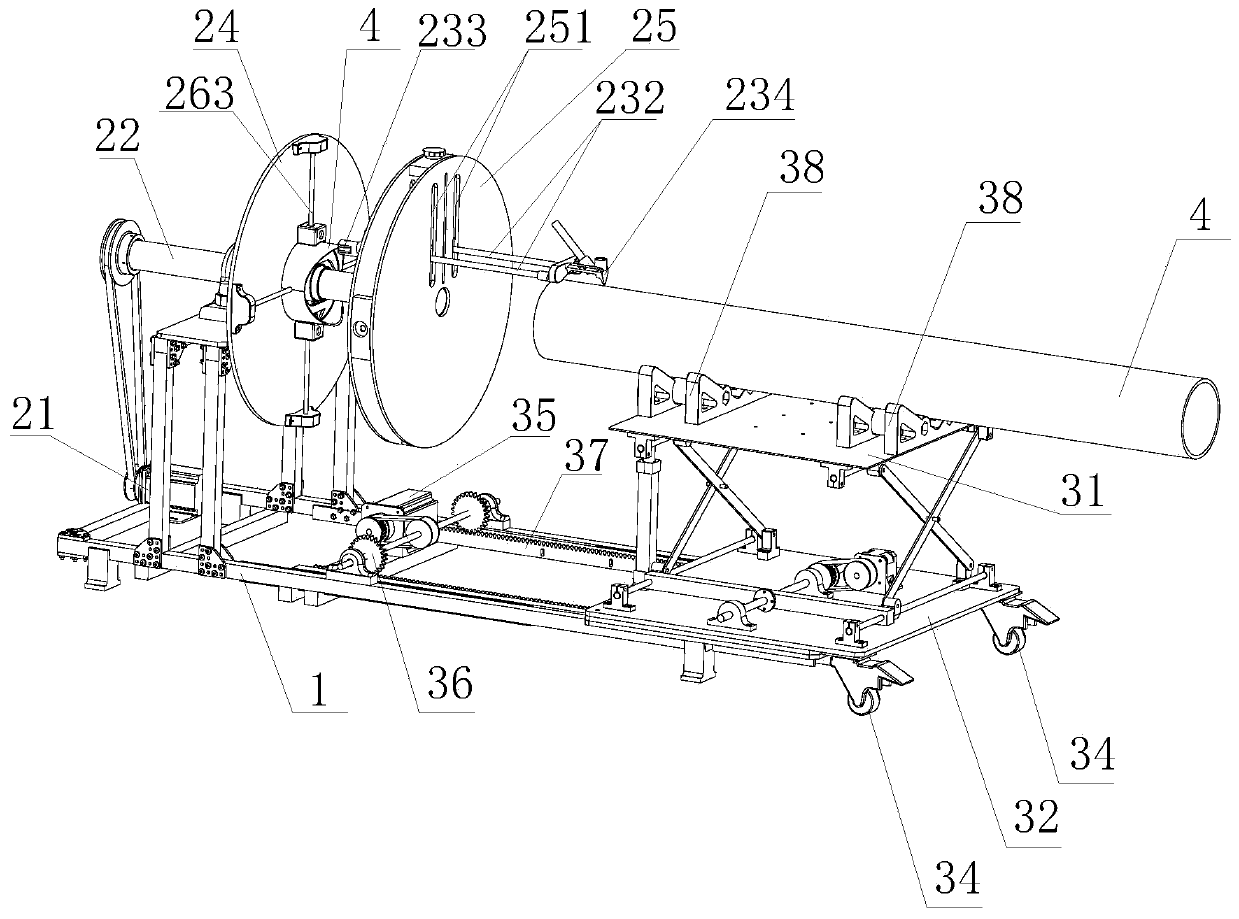

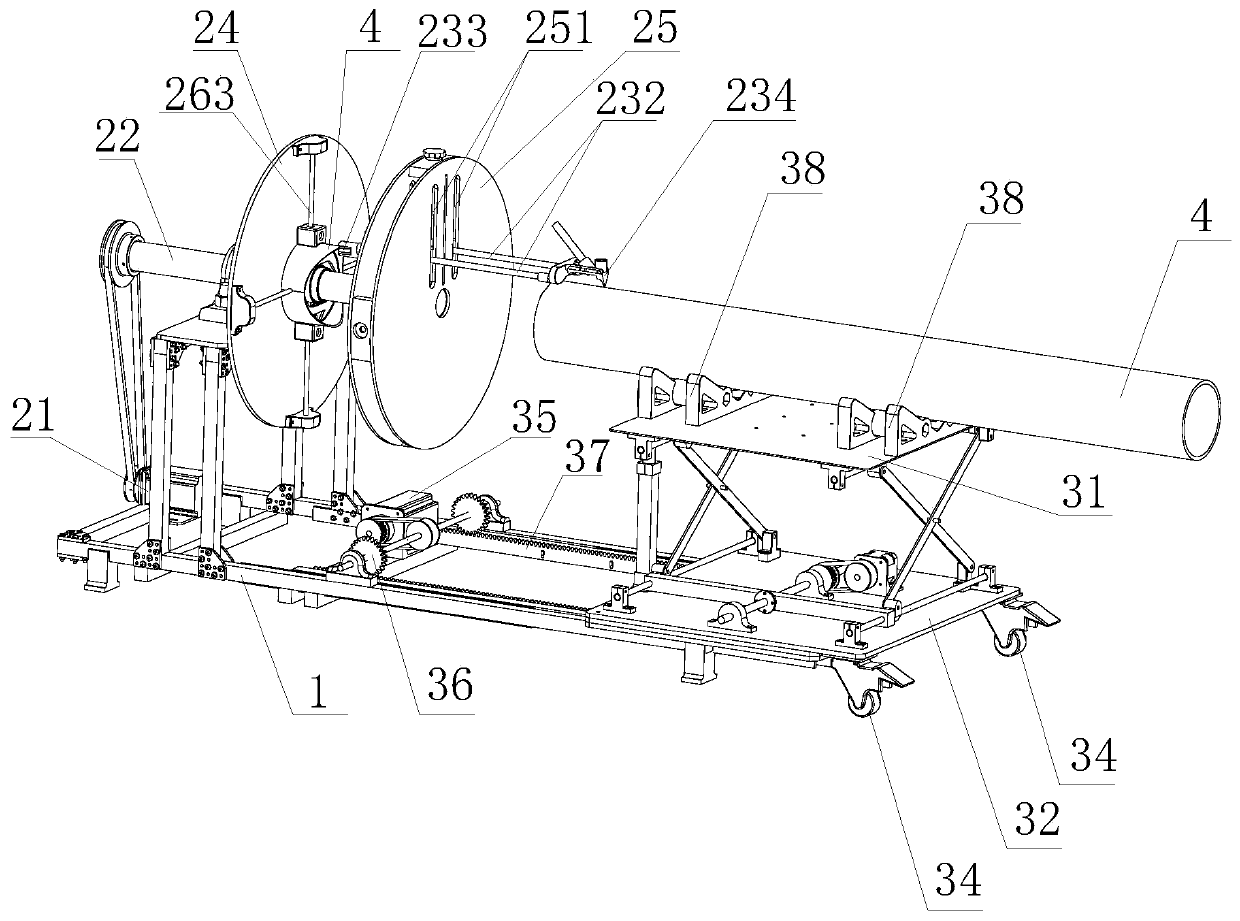

[0064] see Figure 1 to Figure 6 , The present invention provides a simple rotary plasma cutter, including a plasma cutter, which is a machine for processing metal materials by means of plasma cutting technology.

[0065] The shape of mechanical parts is often formed by combining more than two basic solids in different ways. Two solids intersect when they are combined. The intersection of two solids is called intersecting two solids, and the intersection line formed on their surfaces is called intersecting line. There are two cases of using the simple rotary plasma cutter to realize the intersecting line incision, one is to cut the intersecting line incision on the pipe wall, and the other is to cut the intersecting line incision on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com