Face mask body making machine

A technology for manufacturing machines and bodies, applied in clothing, clothing, protective clothing, etc., can solve problems affecting work efficiency, low adjustment efficiency, and poor mask quality, and achieve high automation, high work efficiency, and good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

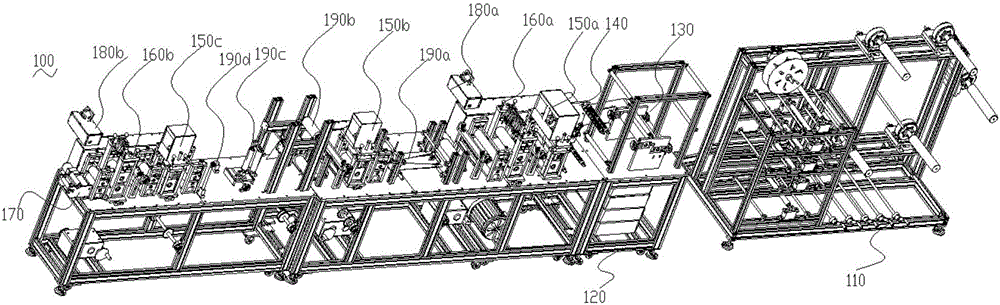

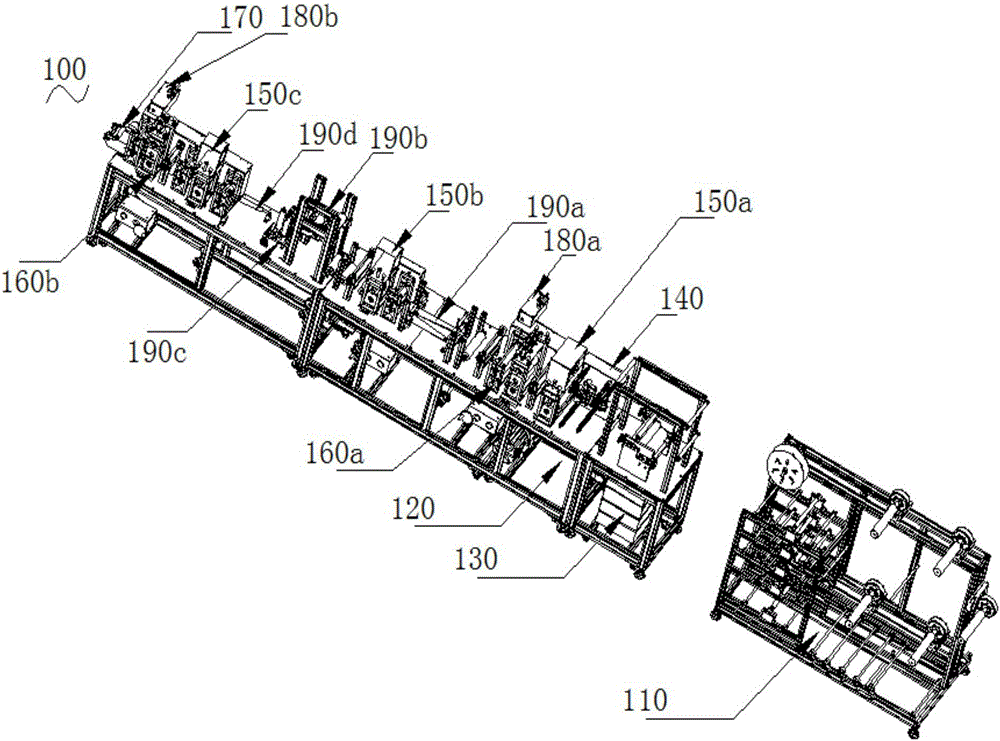

[0033] Such as figure 1 and figure 2 As shown, it is a perspective view of different viewing angles of the present invention.

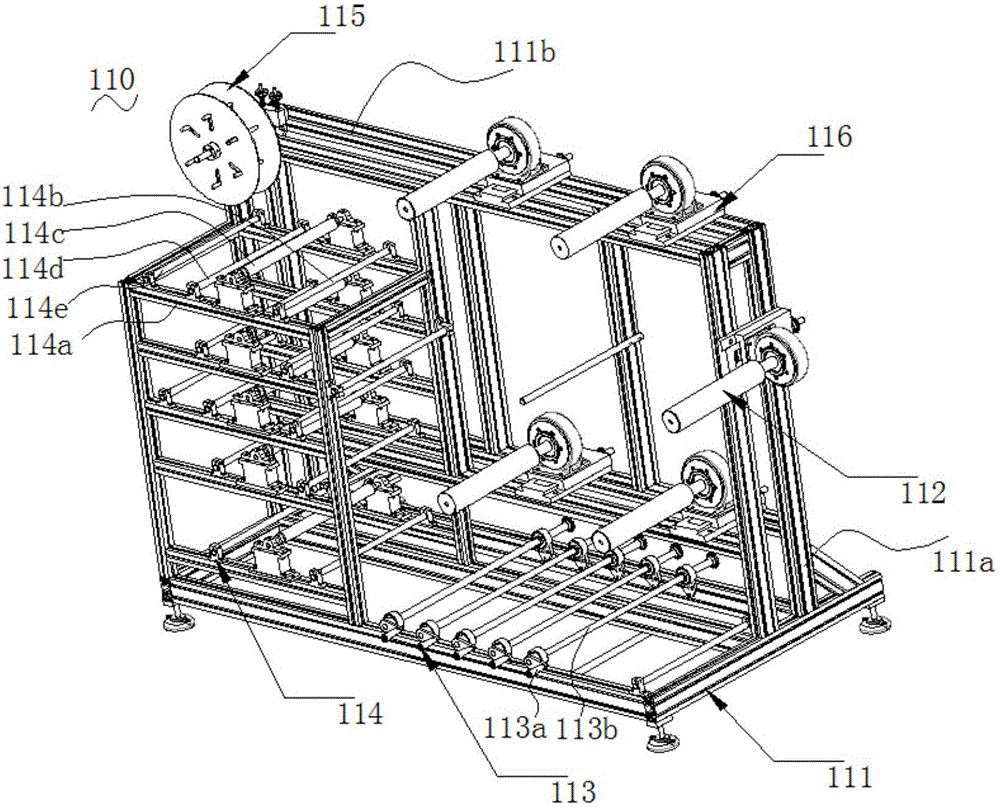

[0034] The mask body manufacturing machine 100 includes a discharge mechanism 110 for feeding non-woven fabrics and nose bridge strips, a frame 120, a printing mechanism 130 for printing on non-woven fabrics, and is used to weld nose bridge strips to non-woven fabrics. The fixed nose bridge mechanism 140, the pattern mechanism 150 for forming patterns on non-woven fabrics, the cutting mechanism 160 for cutting off the corners of non-woven fabrics with patterns, and the waste collection mechanism for recycling corner waste 180 and the discharging mechanism 170 for finished mask discharging, printing mechanism 130, fixed nose bar mechanism 140, pattern mechanism 150, cutting mechanism 160, waste collecting mechanism 180 and discharging mechanism 170 are all installed above the frame 120, and All are located at the rear of the discharging mechanism 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com