Portable electric cutting device with blower mechanism

A cutting device, portable technology, applied in the field of portable electric cutting devices, can solve the problems of reducing the visibility of marking lines, catheter obstruction, and reduced assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

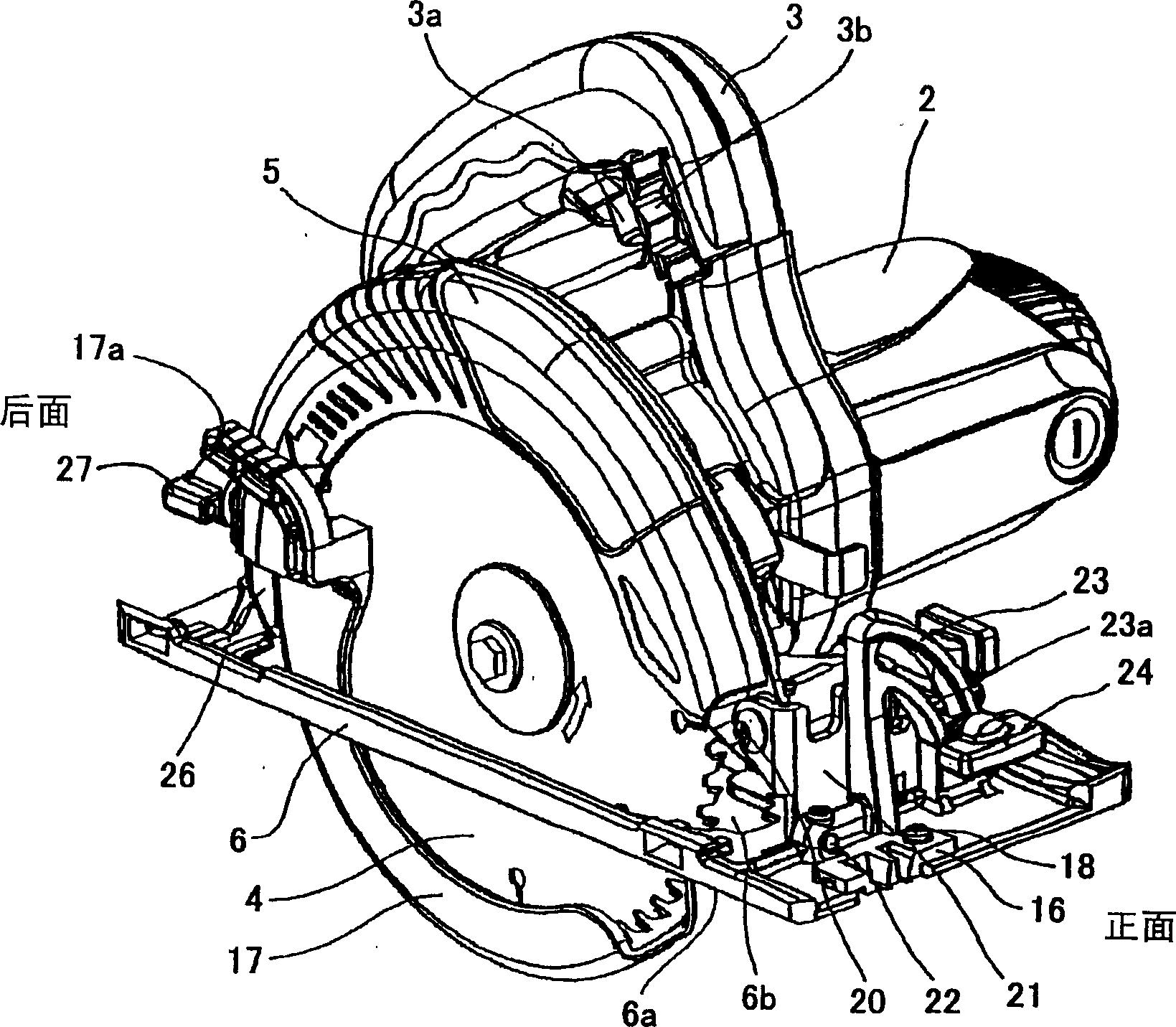

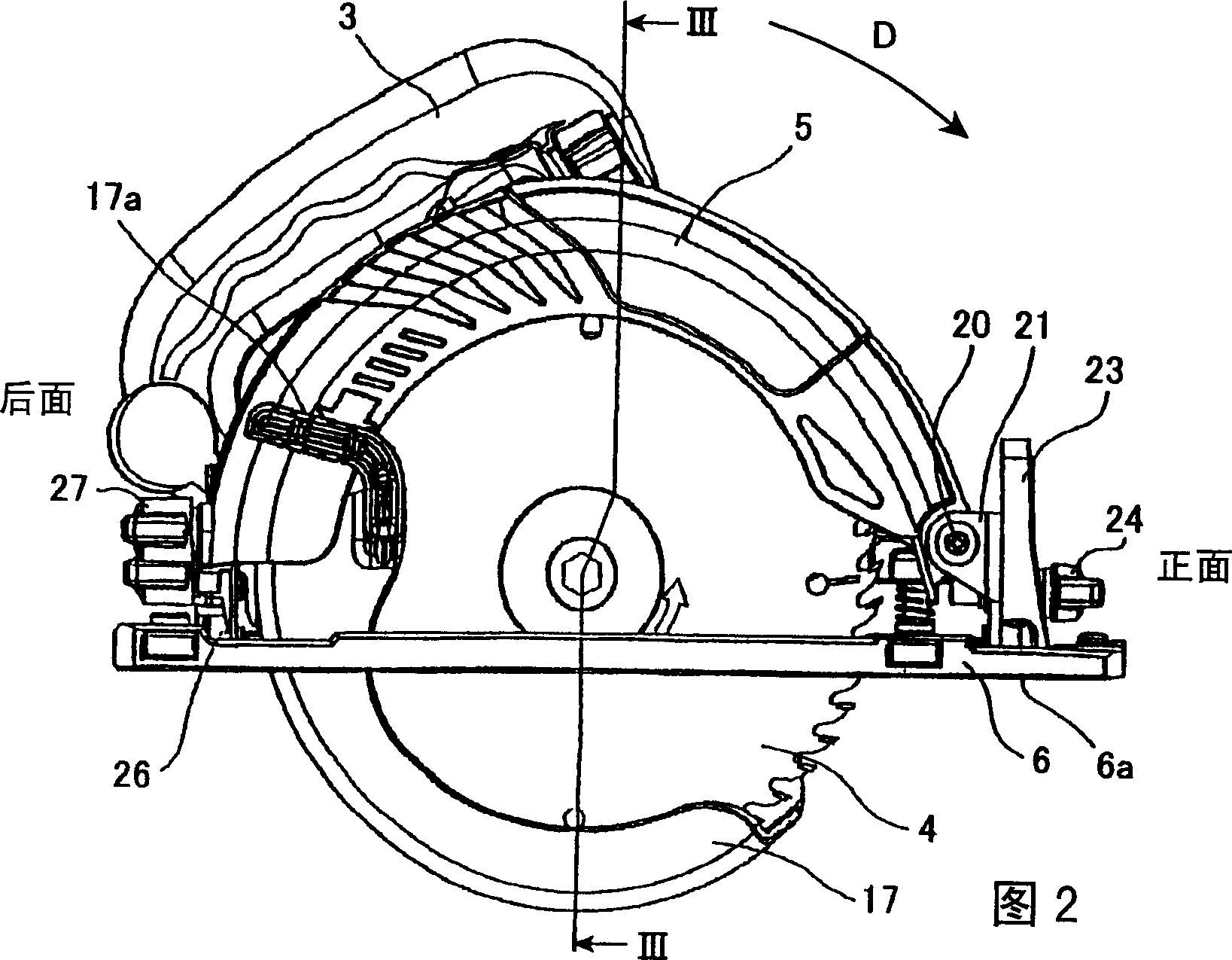

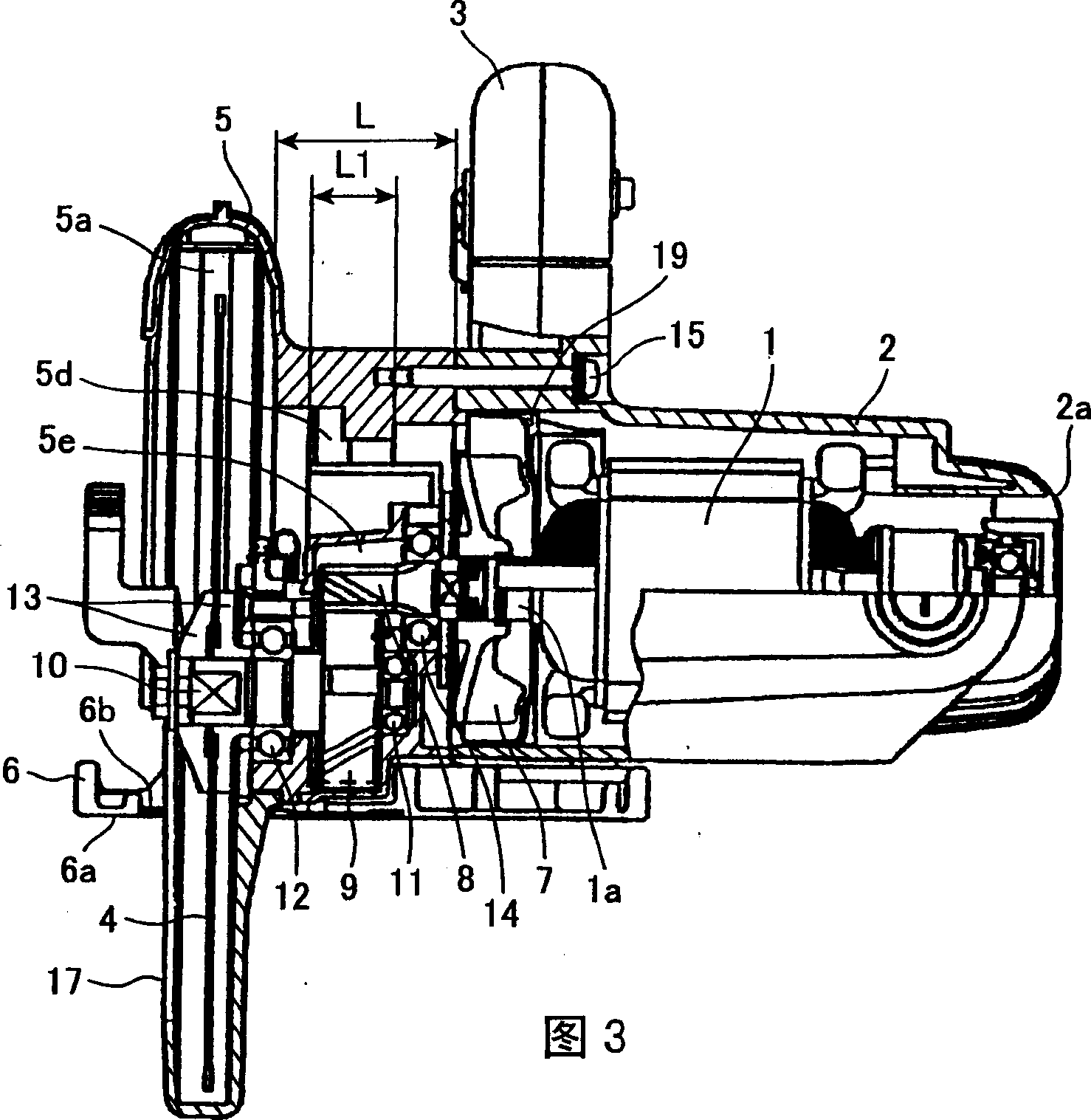

[0070] Next, a portable electric circular saw according to an embodiment of the present invention will be described with reference to the drawings. First, refer to Figure 1-28 A portable electric circular saw according to a first embodiment of the present invention will be described.

[0071] (1) Basic structure

[0072] like figure 1 As shown in FIG. 3 , the portable electric circular saw in this embodiment includes a motor 1 , a casing 2 , a handle 3 , a saw blade 4 , a saw cover 5 , a bottom plate 6 , and a fan 7 . The motor 1 drives the saw blade 4 to rotate. The housing supports and accommodates the motor 1 . The handle 3 is integral with the housing 2 or connected to the housing 2 as a separate component. The user can turn on or off the motor 1 by manipulating the switch 3 a of the handle 3 . The saw cover 5 is connected to the housing 2 and has a saw blade housing part 5a. The saw blade 4 has a fan-side flank facing the fan 7 and a housing part-side flank facing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com