Hand-operated kitchen waste crusher

A kitchen waste and pulverizer technology, which is applied to grain processing and other directions, can solve the problems that the motor cannot work for a long time, the noise of pulverizing hard objects is large, and the power consumption is high, and the effect of simple structure, no power consumption and low manufacturing cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with examples in conjunction with the accompanying drawings.

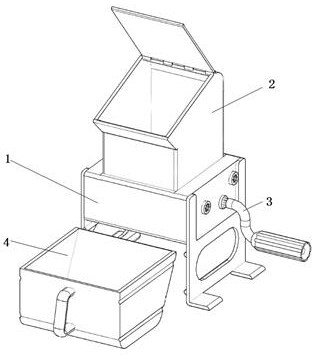

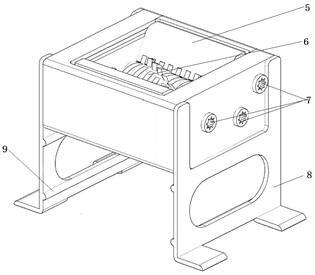

[0026] combine Figure 1 to Figure 7 , the composition of the first embodiment of the hand-cranked food waste shredder of the present invention includes a crushing host 1 and a feeding hopper 2, the feeding hopper is located at the upper part of the crushing host, the lower part of the grinding host has a discharge port, and the machine of the grinding host A pair of rotating shafts are installed in the housing, and each rotating shaft has a cutting blade to form a first rotating shaft 14 with a cutting blade and a second rotating shaft 18 with a cutting blade. The cutting blade is a windmill type formed by four blades. Blades, the cutting blades on the two rotating shafts are staggered to form the cutter head 6, and one end of the two rotating shafts is equipped with mutually meshing gears 12 and 13 to form a transmission gear set, and the other end of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com