Double-workstation three-knife glass cutter

A cutting machine and double-station technology, applied to glass cutting devices, glass production, glass manufacturing equipment, etc., can solve problems such as unfavorable organization and management, large production sites and personnel, high equipment investment and production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

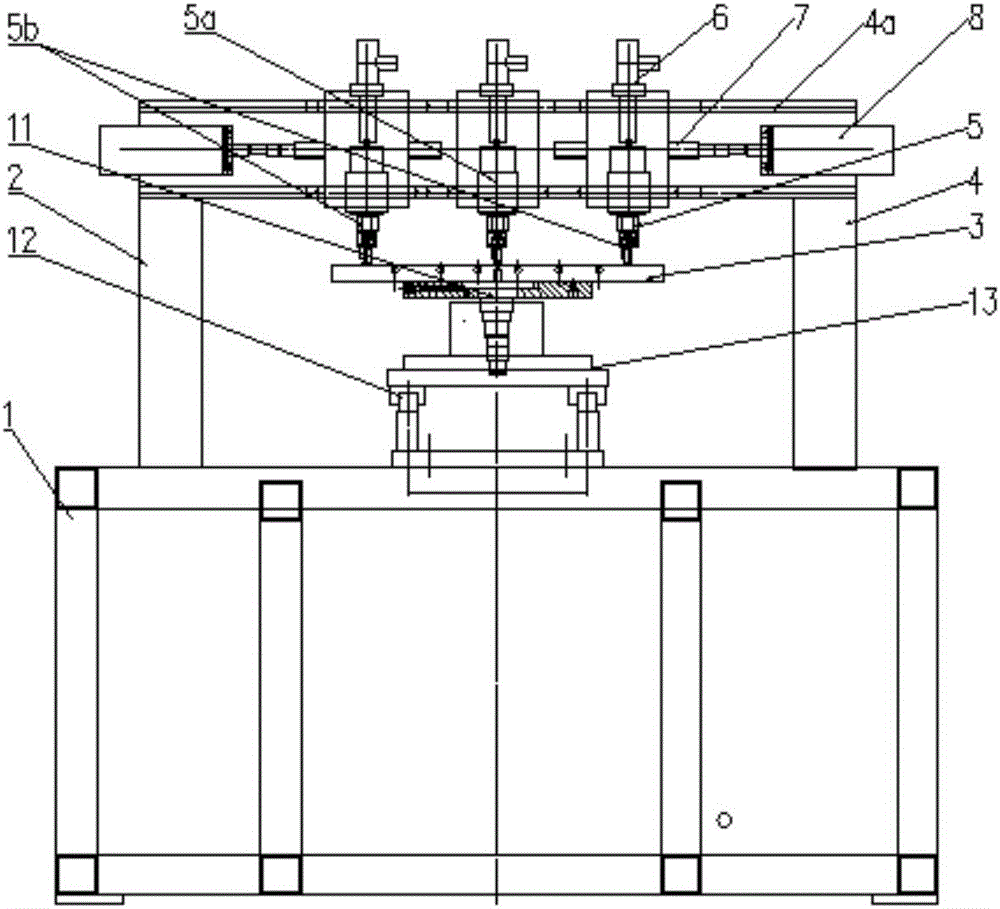

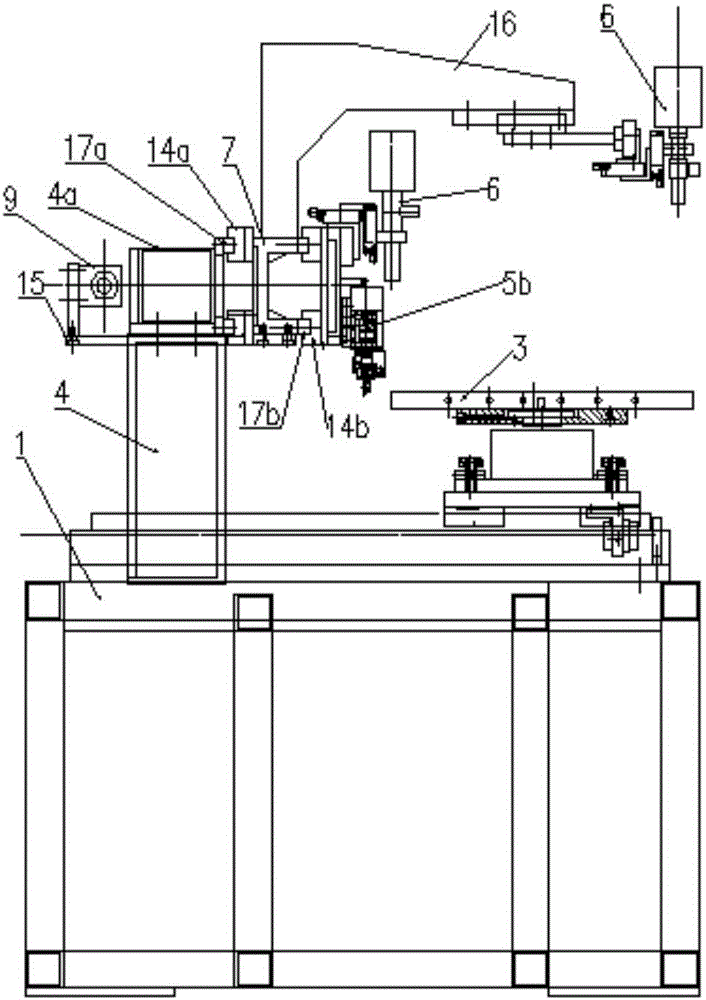

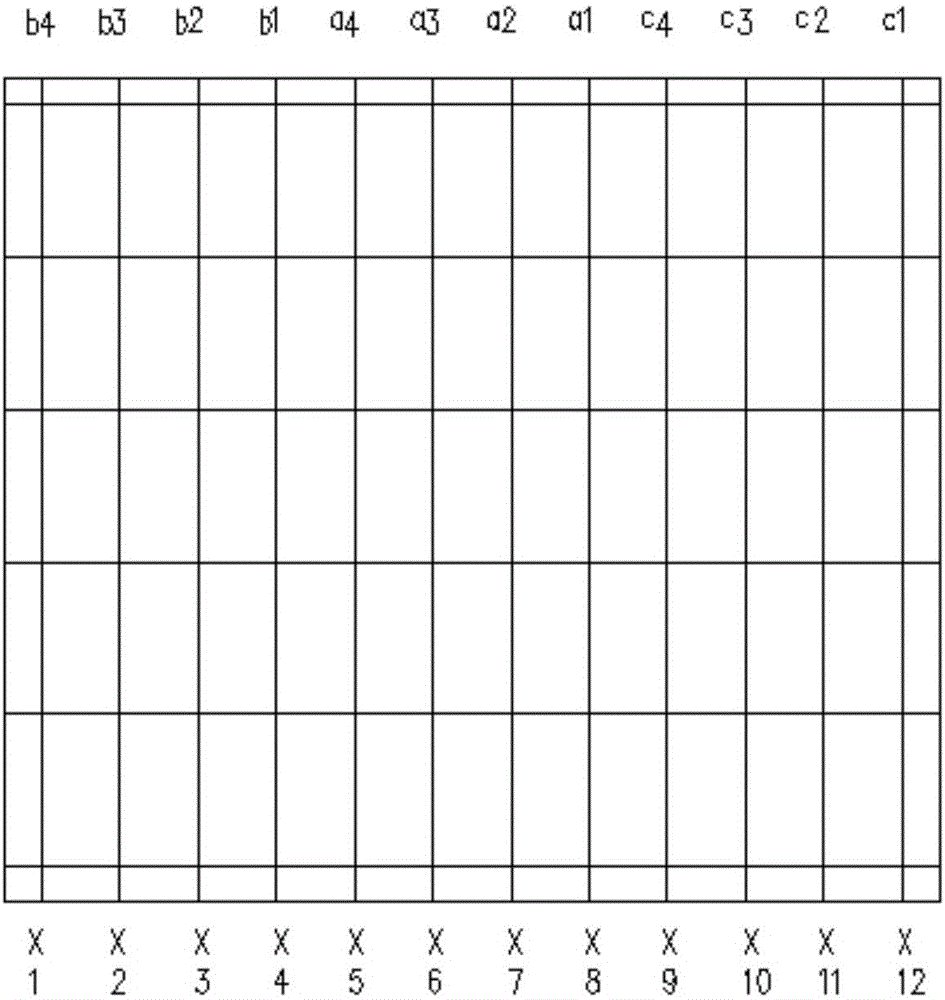

[0016] Such as figure 1 and 2 As shown, the double-station and three-knife glass cutting machine of this embodiment includes a frame 1, a working platform 3, a knife holder device, and three cutting knives 5 corresponding to the working platform 3, and the like. Its knife rest device comprises fixed crossbeam, the movable cutter crossbeam that is connected to fixed crossbeam by corresponding crossbeam adjusting device, and fixed crossbeam 4a is connected on the frame by left and right support 4, and movable cutter crossbeam 7 is positioned at the corresponding one of fixed crossbeam 4a. The side, whose length direction is the same as the length direction of the fixed beam, can move along the length direction of the fixed beam 4a through the corresponding beam adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com