Cutter machine and its controlled circuit and controlled method

A technology for controlling circuits and cutting plotters, applied in the field of plotting plotters, can solve problems such as huge cost, achieve high-quality work performance, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

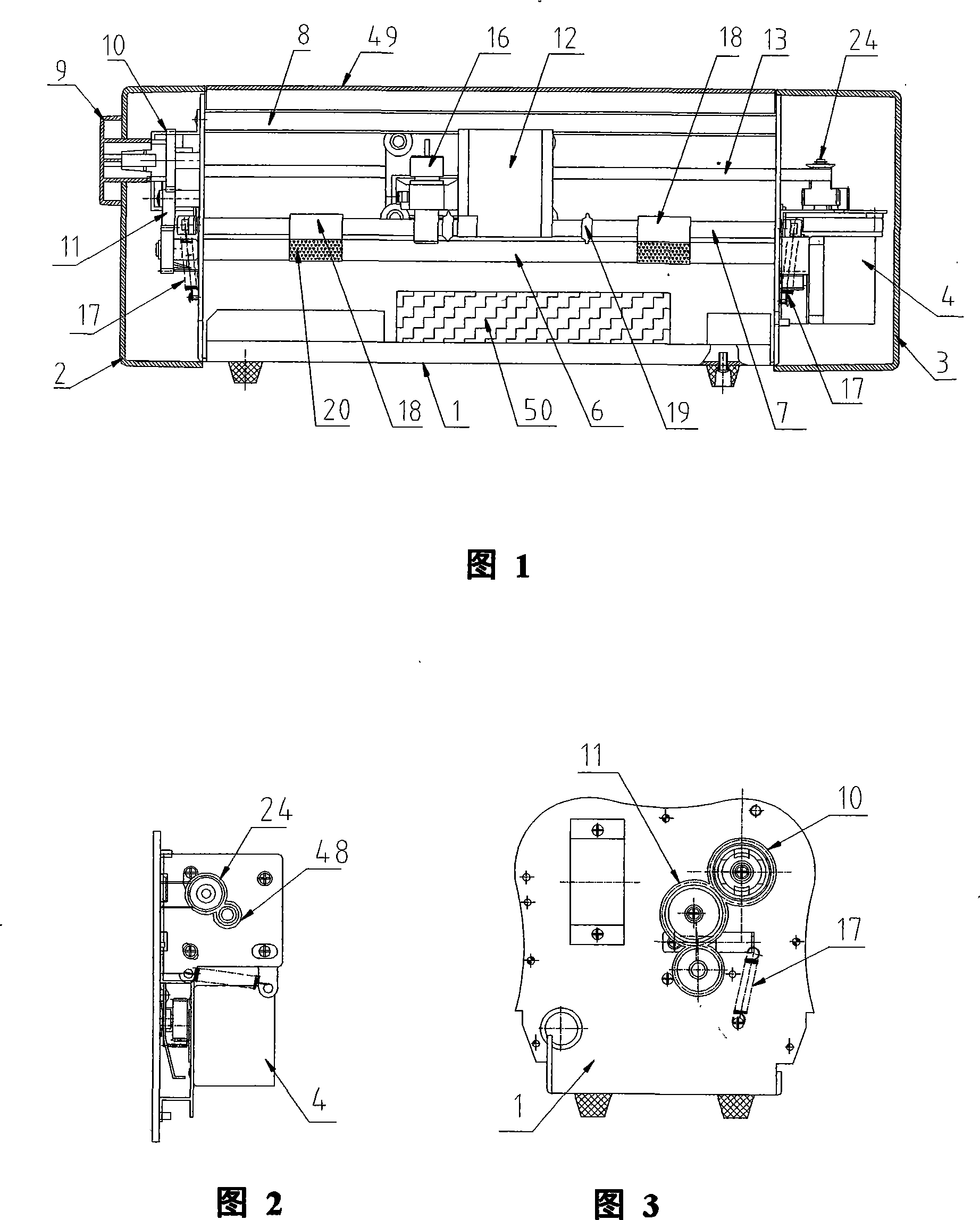

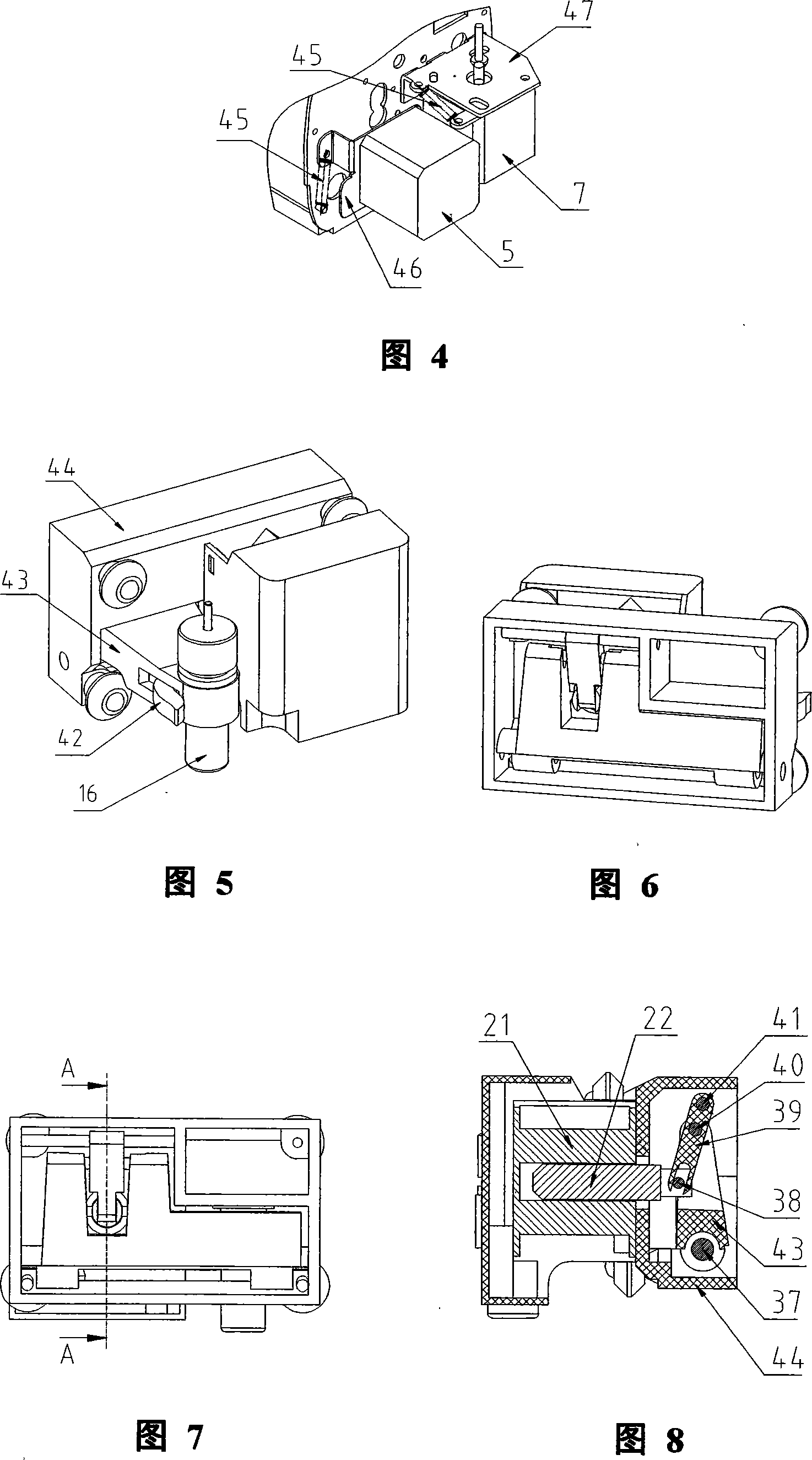

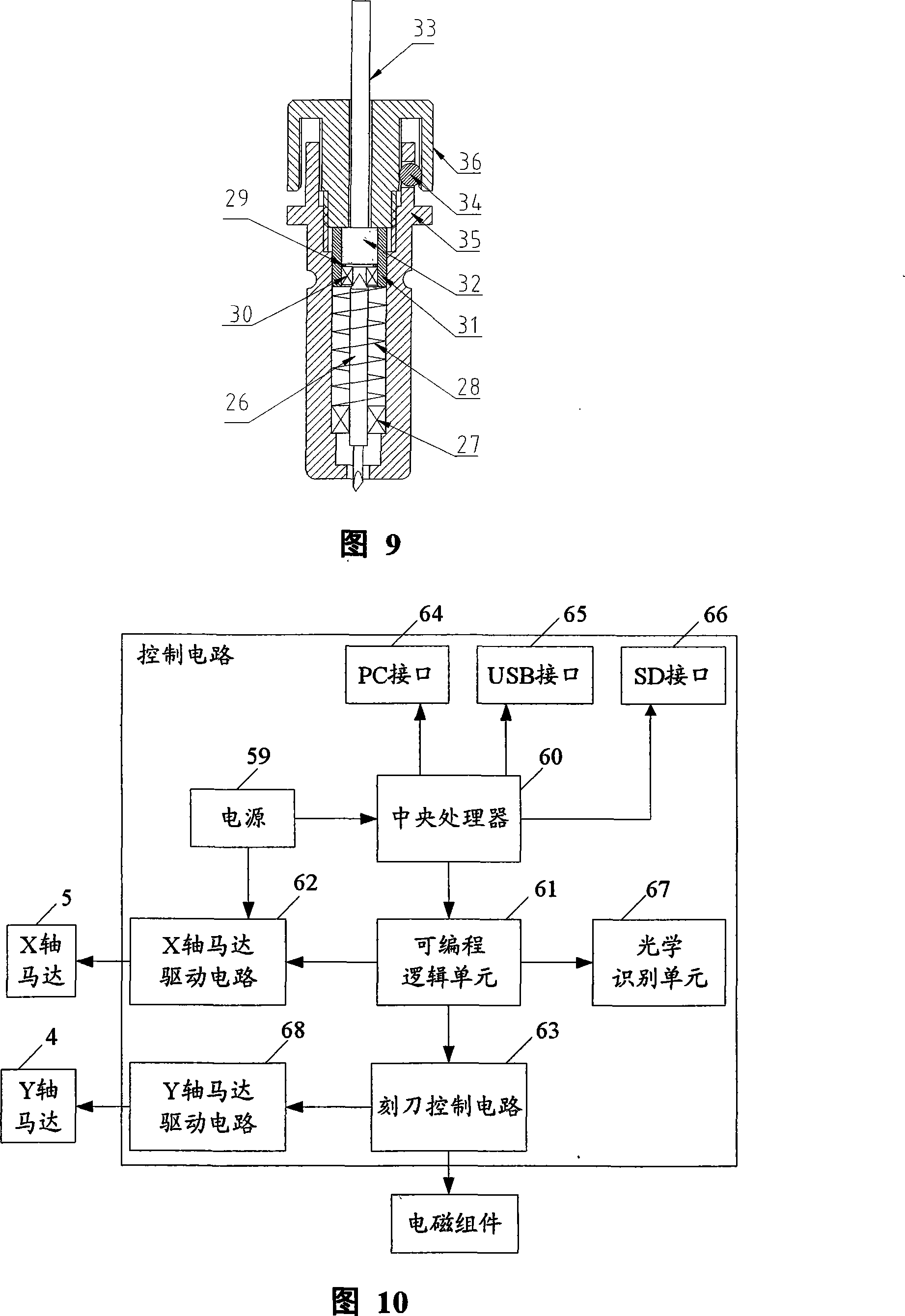

[0040] The basic structure of the new preferred embodiment shown in Fig. 1, Fig. 2 and Fig. 3, a kind of carving plotter, comprises by base 1 and is positioned at the left and right casing 2,3 of base 1 both sides and is positioned at base 1 The casing formed by the cover plate 49 above; the Y axis motor 4 and the X axis motor 5; The file to be written is read and analyzed, and then a control command is issued according to the analyzed content, and the Y-axis motor 4 and the X-axis motor 5 are driven to drive the carving knife through the transmission device to perform automatic lettering processing.

[0041] On the top of the base 1, between the left and right casings 2 and 3, there are mutually parallel paper feed shafts 6 linked by the Y-axis motor 4, a paper platen shaft 7 cooperating with the paper feed shafts 6, and a paper feed shaft 6 behind the paper feed shafts. Side beams 8. At the same time, as shown in Figure 2, a knob 9 is provided on the outer wall of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com