Swing type full-automatic steel sectional cutting machine

A fully automatic and swinging technology, which is applied in the direction of shearing device, device for shearing forming blank, and accessory device of shearing machine, etc. It can solve problems such as large dust, high requirements for working environment, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

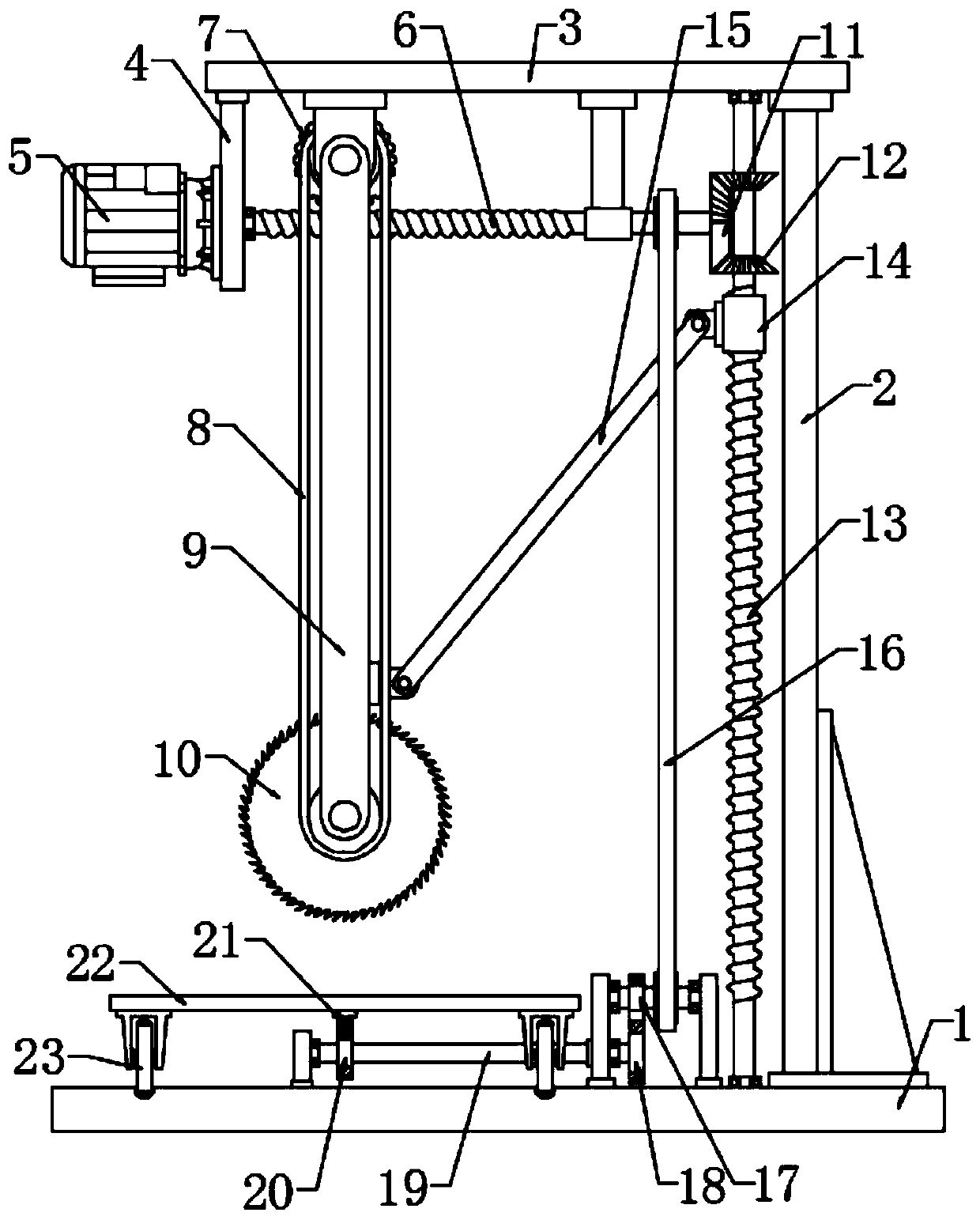

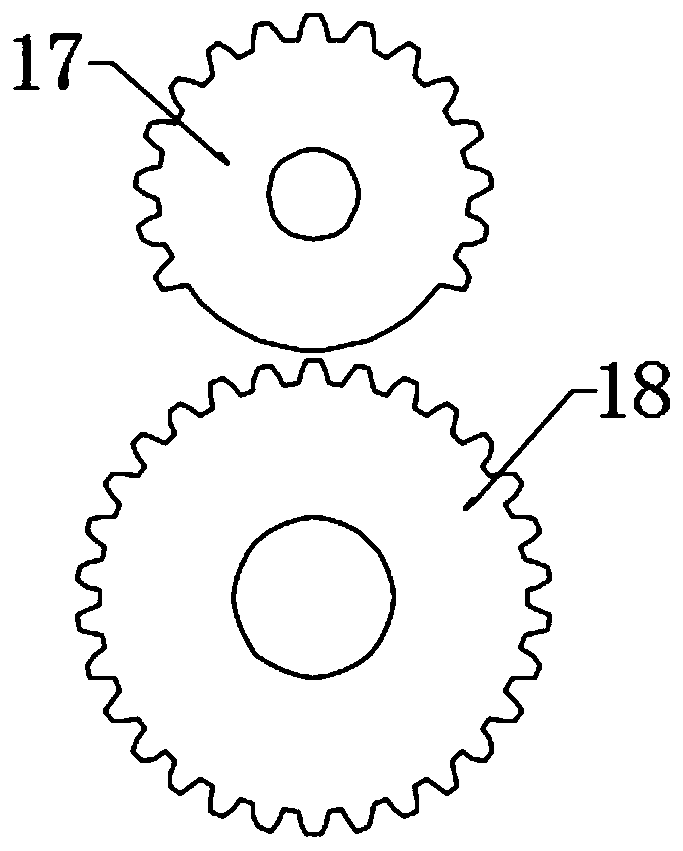

[0022] see Figure 1~3 , in an embodiment of the present invention, a swing-type fully automatic segmental cutting machine for steel, including a worktable 1, a worm 6, a swing arm 9, a cutter head 10, a screw 13 and a connecting rod 15; the worktable 1 The backboard 2 is fixed on one side by reinforcing ribs, the upper end of the backboard 2 is fixedly connected to the top 3, the mounting plate 4 is fixed below the end of the top plate 3, and the drive motor 5 is fixed on the flange of the mounting plate 4. It should be noted that the drive motor 5 The wire is connected to the power supply and the switch. The output end of the drive motor 5 is connected to the worm 6 by rotation. The worm 6 passes through the mounting plate 4 and is connected to the bearing for rotation. Pressing the switch makes the drive motor 5 energized to drive the worm 6 to rotate; the upper part of the worm 6 engages The worm wheel 7 is rotatably connected below the top plate 3, and the connection betw...

Embodiment 2

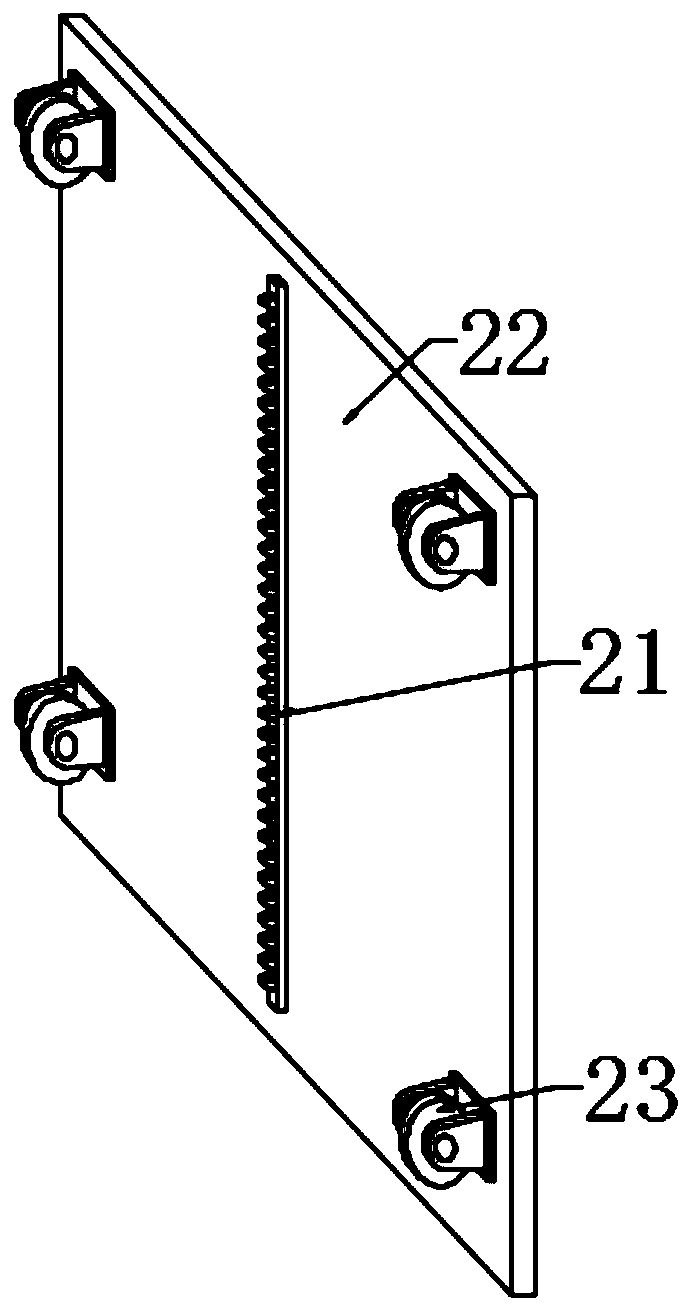

[0026] In order to further explain the above-mentioned oscillating fully automatic segmental cutting machine for steel, the application provides another embodiment, the oscillating fully automatic segmental cutting machine for steel in this embodiment has the following technical features: the moving pallet 22 There are support rods fixedly connected to the bottom of the two sides, the lower end of the support rod is fixedly connected to the slider, and the slider is slidably connected in the chute, the chute is arranged on both sides of the worktable 1, and the edge of the cutter head 10 is provided with a serrated cutting part, through the sliding The groove realizes the precise guiding function to the mobile pallet 22 .

[0027] According to the specific description of the above embodiment, it is easy to know that the working principle of the present invention is: press the switch to make the drive motor 5 energized to drive the worm 6 to rotate, the rotating worm 6 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com