Floor drain capable of rotatably cutting off hair and rotatable cutting method

A floor drain and hair technology, applied in waterway systems, buildings, water supply installations, etc., can solve the problems of unsmooth movement, energy-saving, inability to turn nuts and cutting parts, etc., to avoid sewer blockage, improve utilization, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

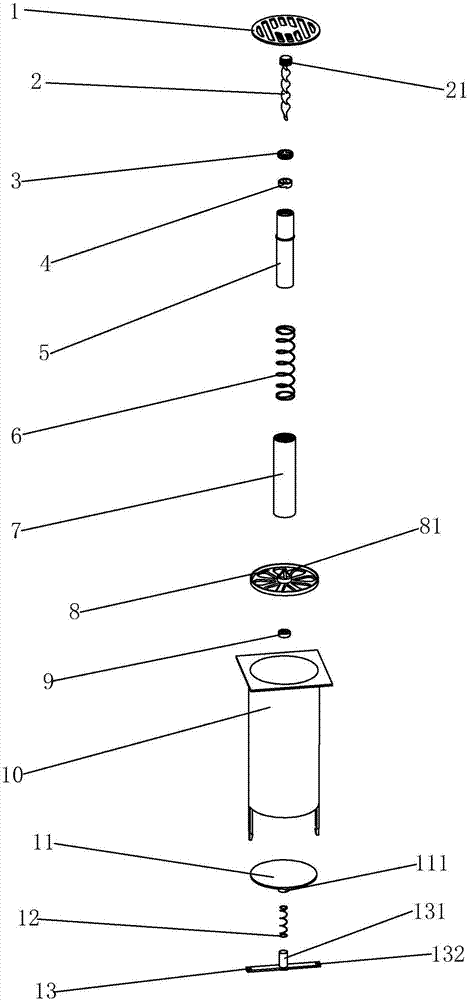

[0036] Examples, see Figure 1-Figure 12 As shown, a floor drain that can rotate and cut hair according to the present invention includes a floor drain seat 10 and a first cutting member 8, and the first cutting member 8 is rotatably arranged in the floor drain seat 10 around its axis; it also includes:

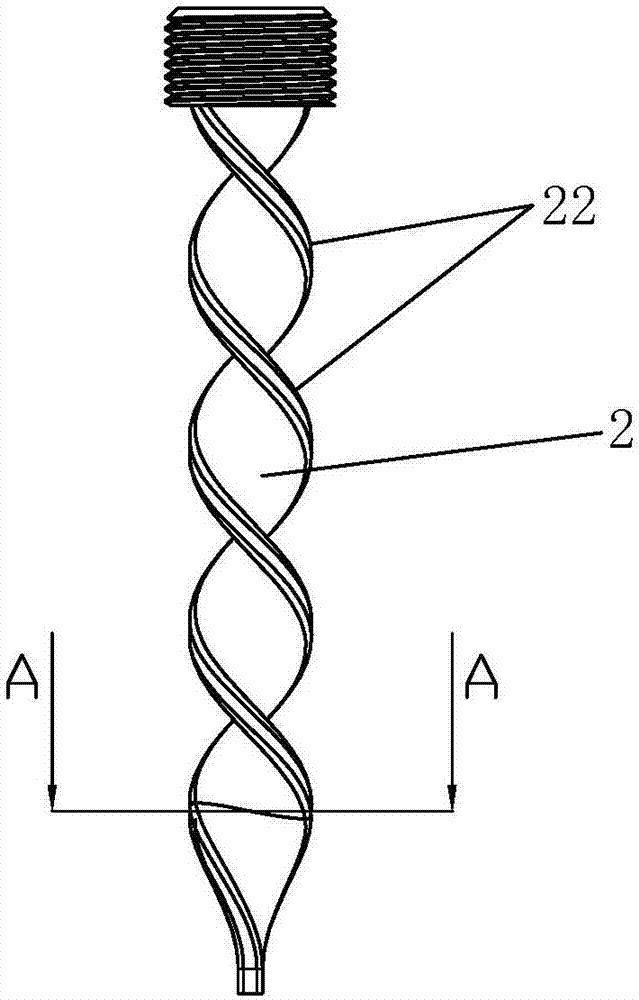

[0037] The spiral blade 2 is arranged in the up and down direction, and can be manipulated to move downward and reset upward through the reset elastic member 6;

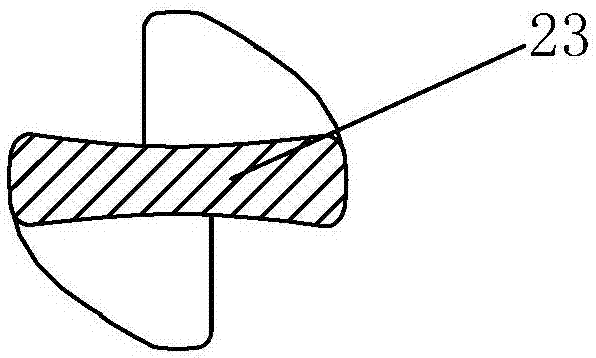

[0038] The rotating part 4 is provided with a strip-shaped hole 41, and cooperates with the first cutting part 8;

[0039] The spiral blade 2 passes through the strip-shaped hole 41 of the rotating member 4, and the rotating member 4 is driven to rotate around its axis along the preset first direction and the second direction through the up and down movement of the spiral blade 2, and the rotating member 4 rotates along the first and second preset directions. When rotating in one direction and / or in the second dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com