Cutting sawing machine for short bar machining

A technology for cutting saws and short bars, which is applied in sawing machine devices, metal processing equipment, attachment devices of sawing machines, etc., can solve the problem of inability to process and cut short bars, and achieves improved applicability and functionality, improved stability, and improved The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

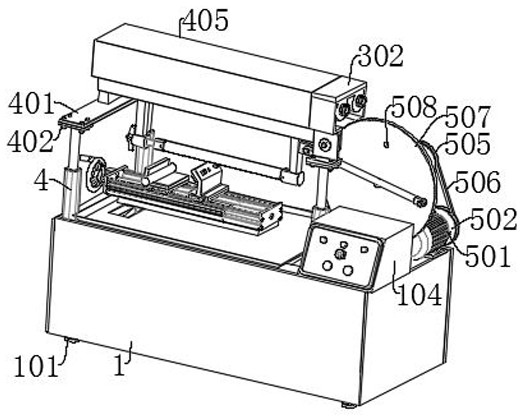

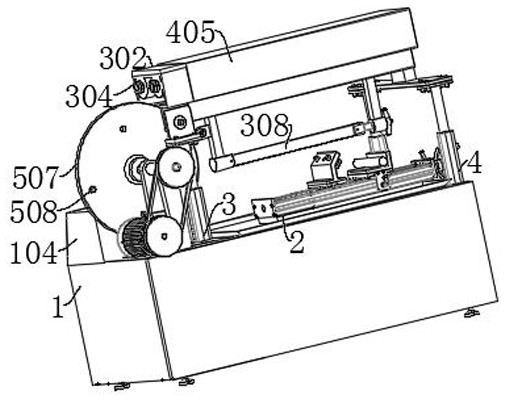

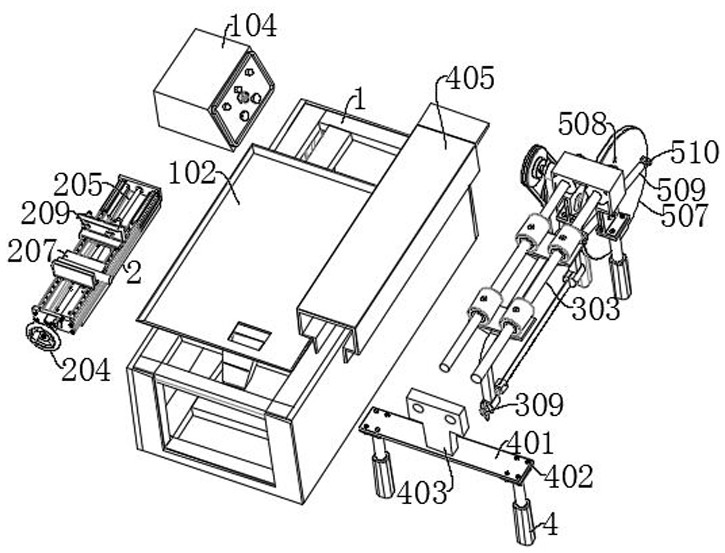

[0038] see Figure 1-Figure 9 , the present invention provides the following technical solutions:

[0039] A cut-off sawing machine for processing short bars, comprising:

[0040] base1;

[0041] The chip containing liquid pan 102, the chip containing liquid pan 102 is fixedly connected to the upper end of the base 1, the upper end of the chip containing liquid pan 102 is fixedly connected with the first fixed platform 2, and the upper end of the first fixed platform 2 is fixedly connected with the sliding platform 201; and

[0042]Rotation mechanism: The rotation mechanism includes a fixed frame 5, a rotating shaft 504, a disc 507, a mounting groove 508, a connecting rod 509 and a third bolt 510, the fixed frame 5 is fixedly connected to the upper end of the base 1, and the rotating shaft 504 is rotatably connected to the fixed frame 5 The side end, the disc 507 is fixedly connected to the side end of the rotating shaft 504, the installation groove 508 is opened on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com