Patents

Literature

30 results about "Radius rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A radius rod (also called a radius arm or a torque arm) is a suspension link intended to control wheel motion in the longitudinal (fore-aft) direction. The link is connected (with a rubber or solid bushing) on one end to the wheel carrier or axle, on the other to the chassis or unibody of the vehicle. Radius rods are also sometimes used in aircraft with fixed (non retractable) undercarriages.

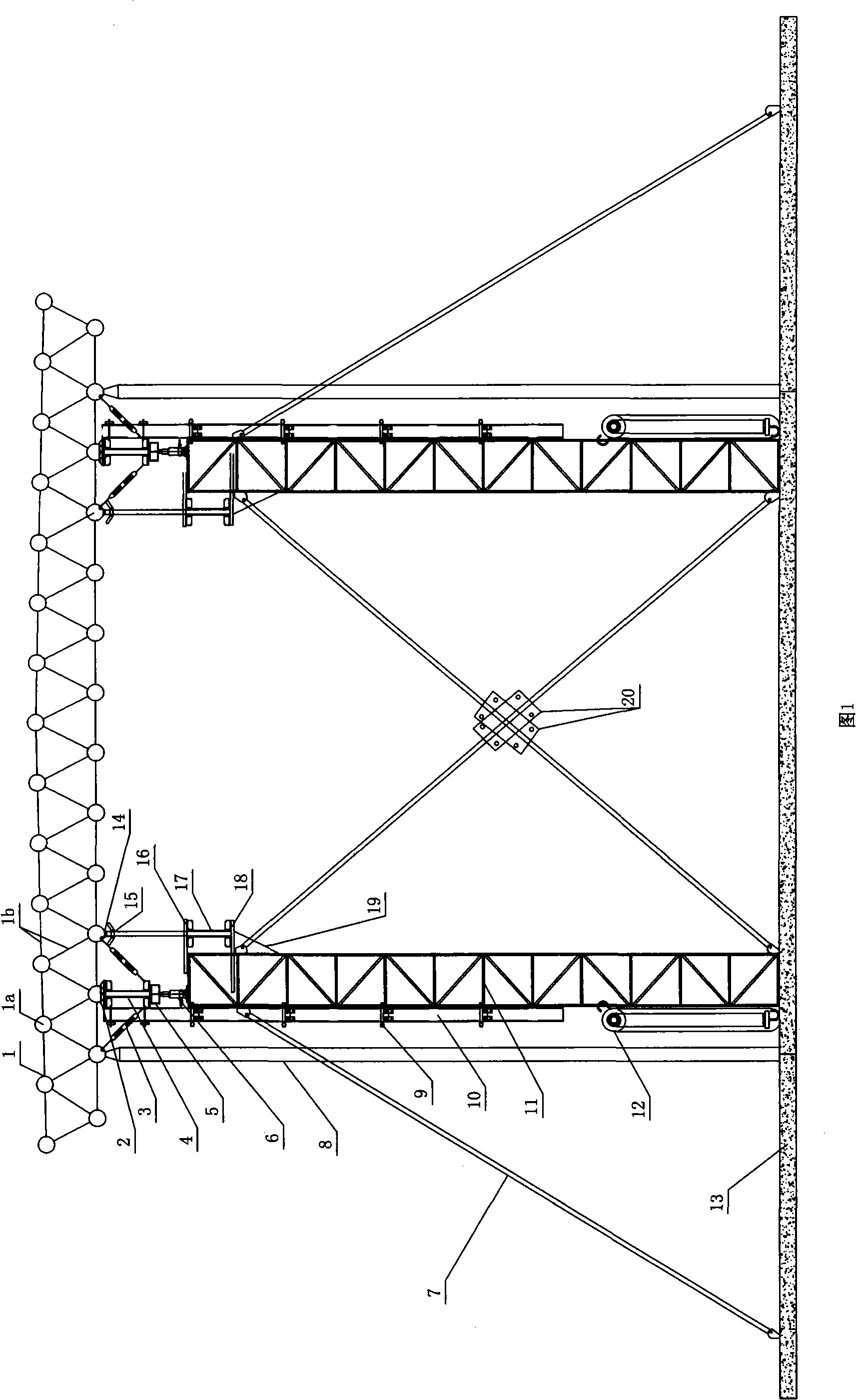

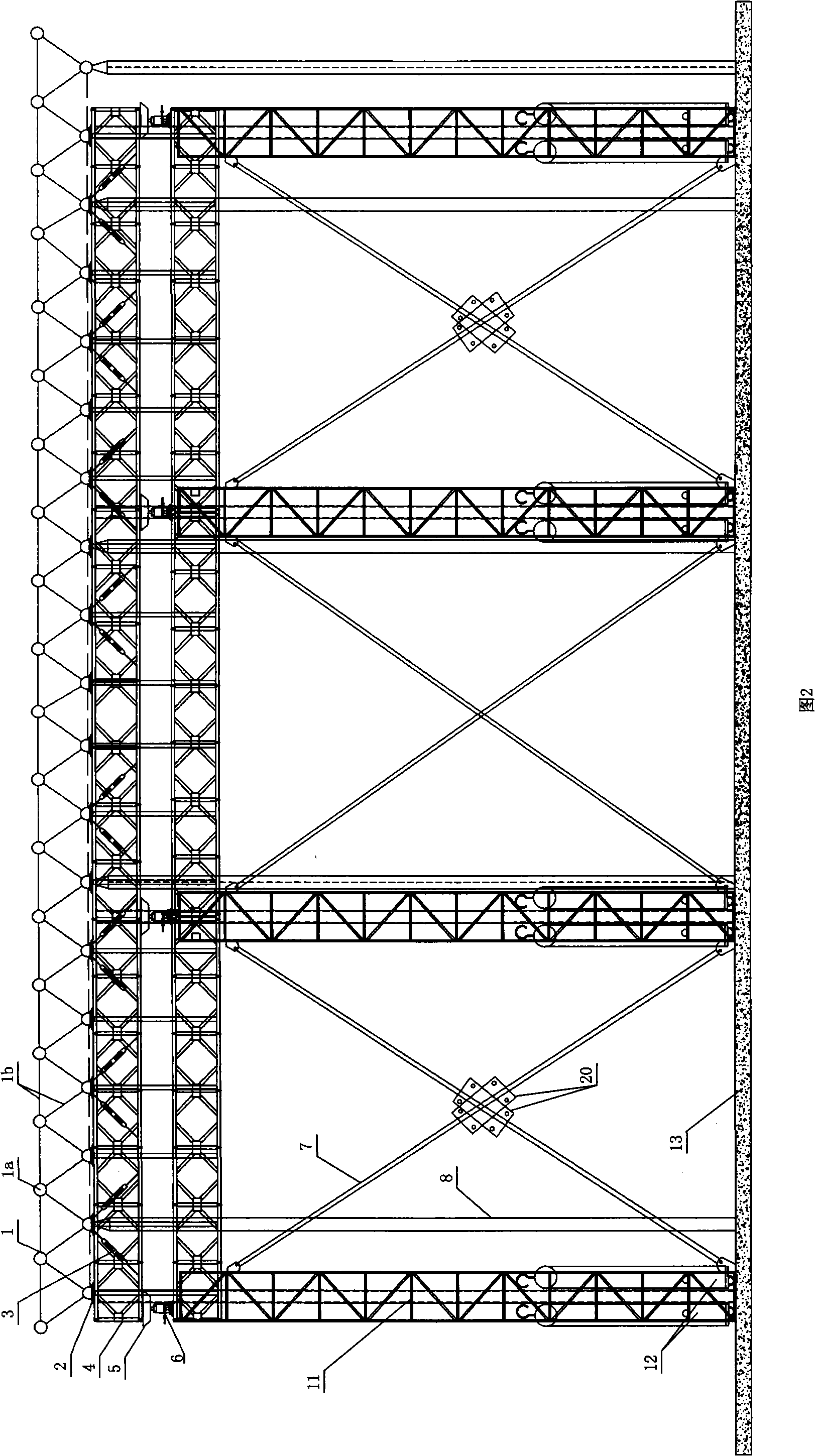

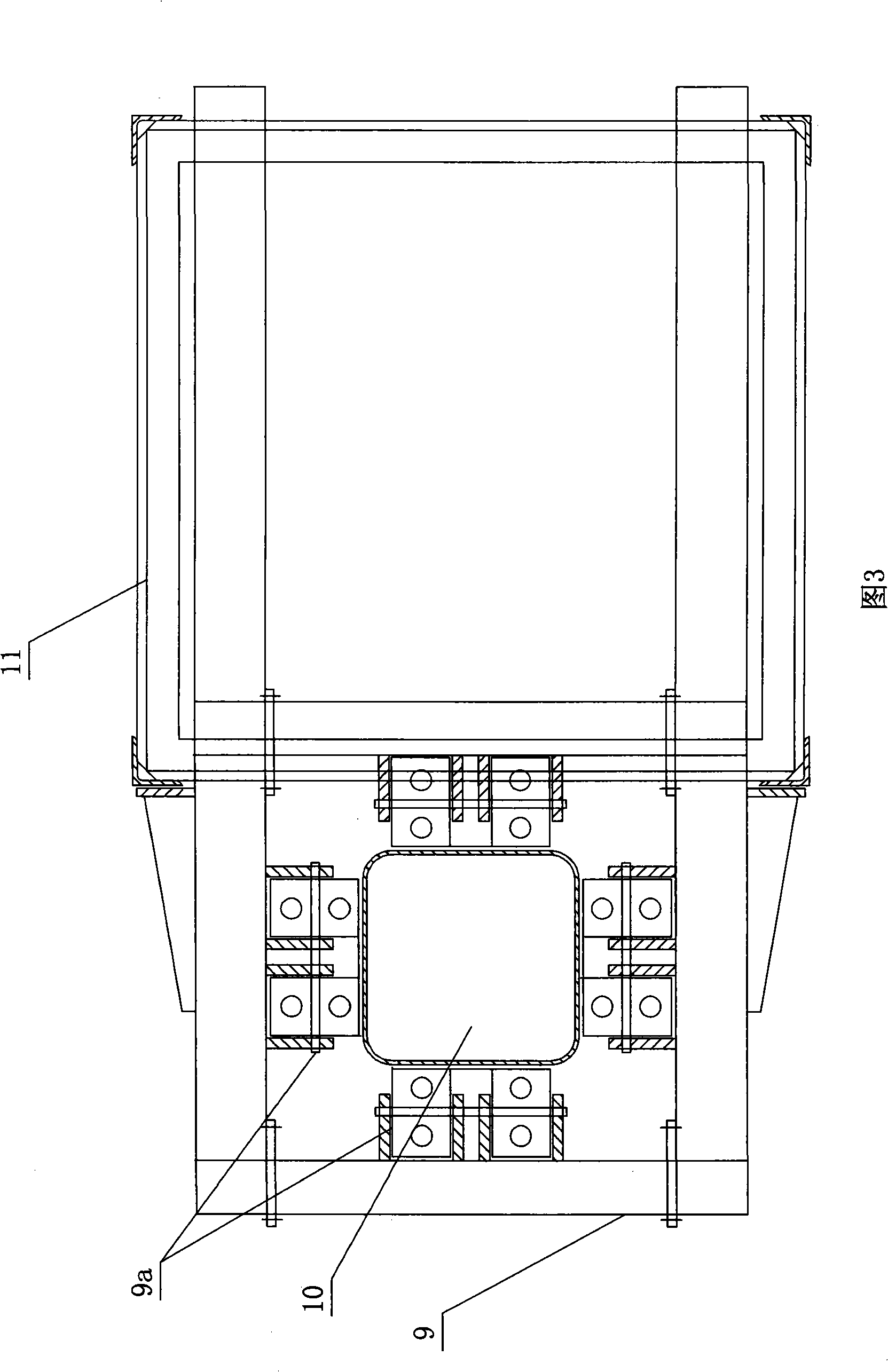

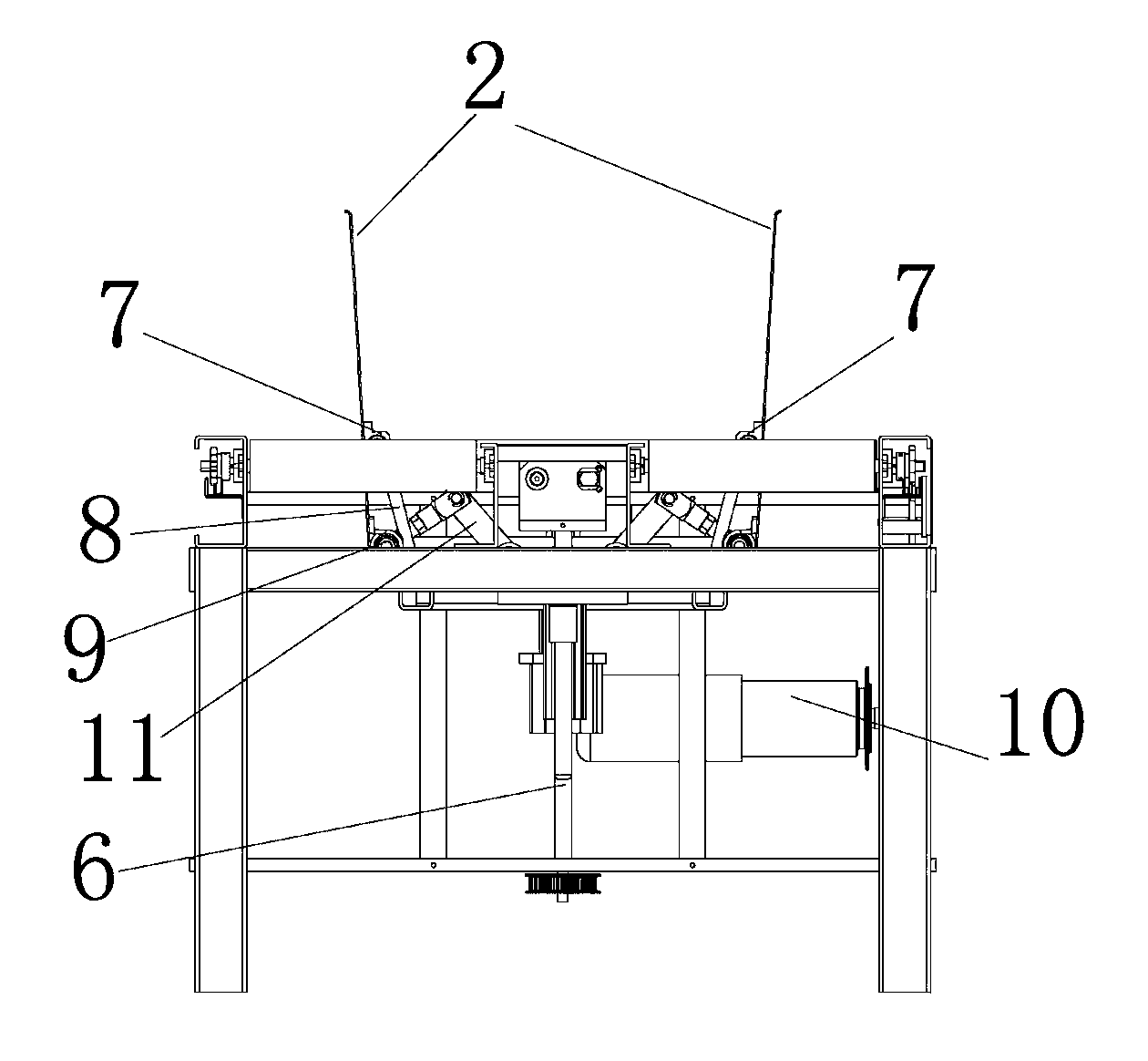

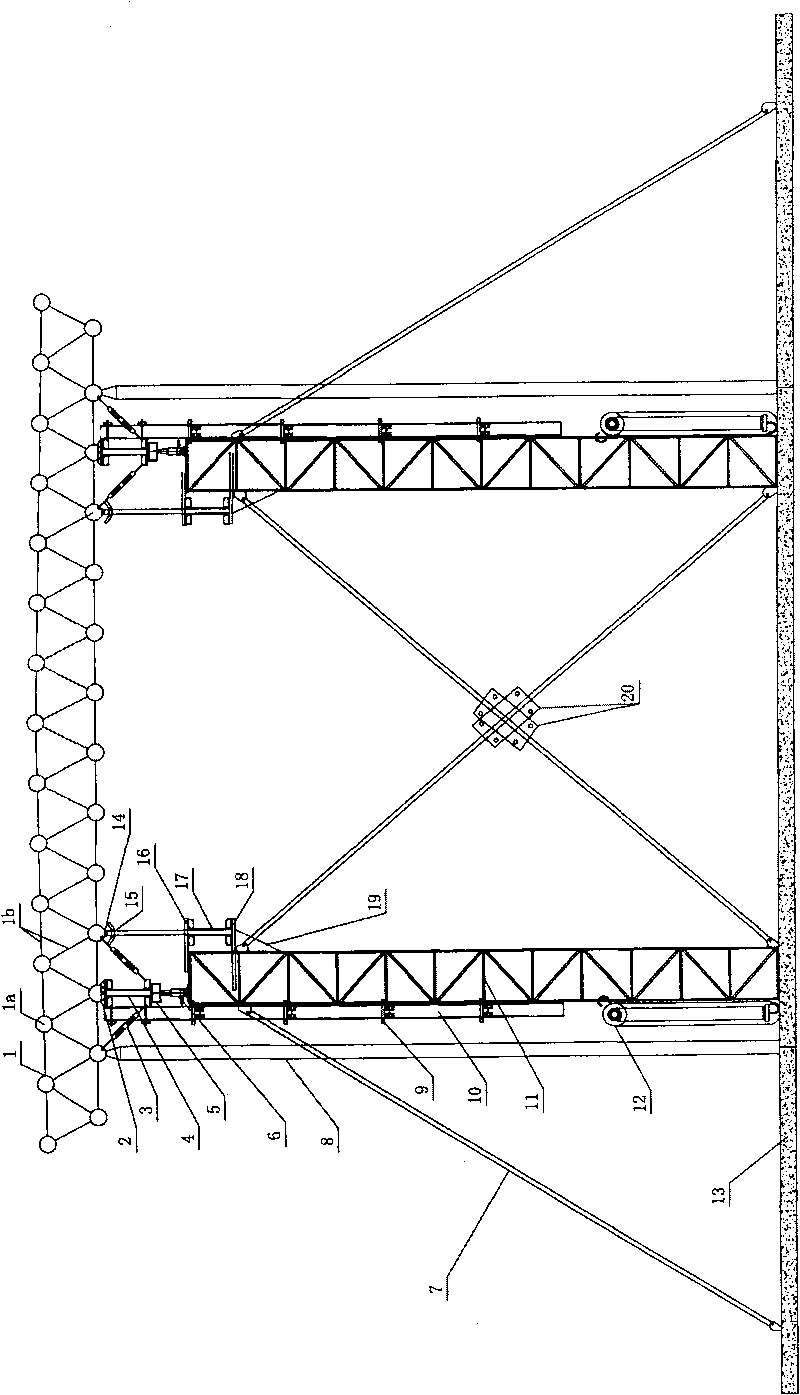

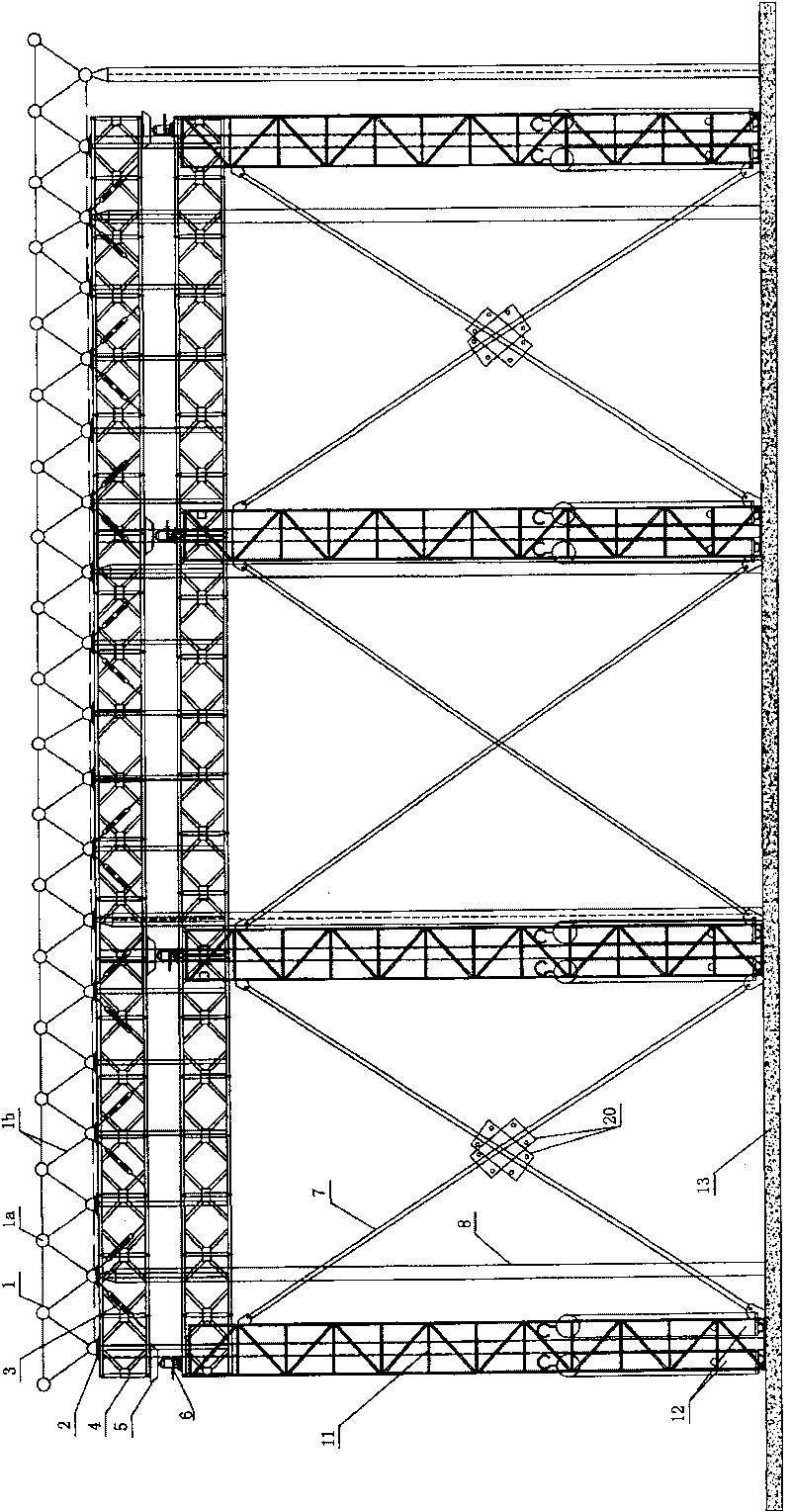

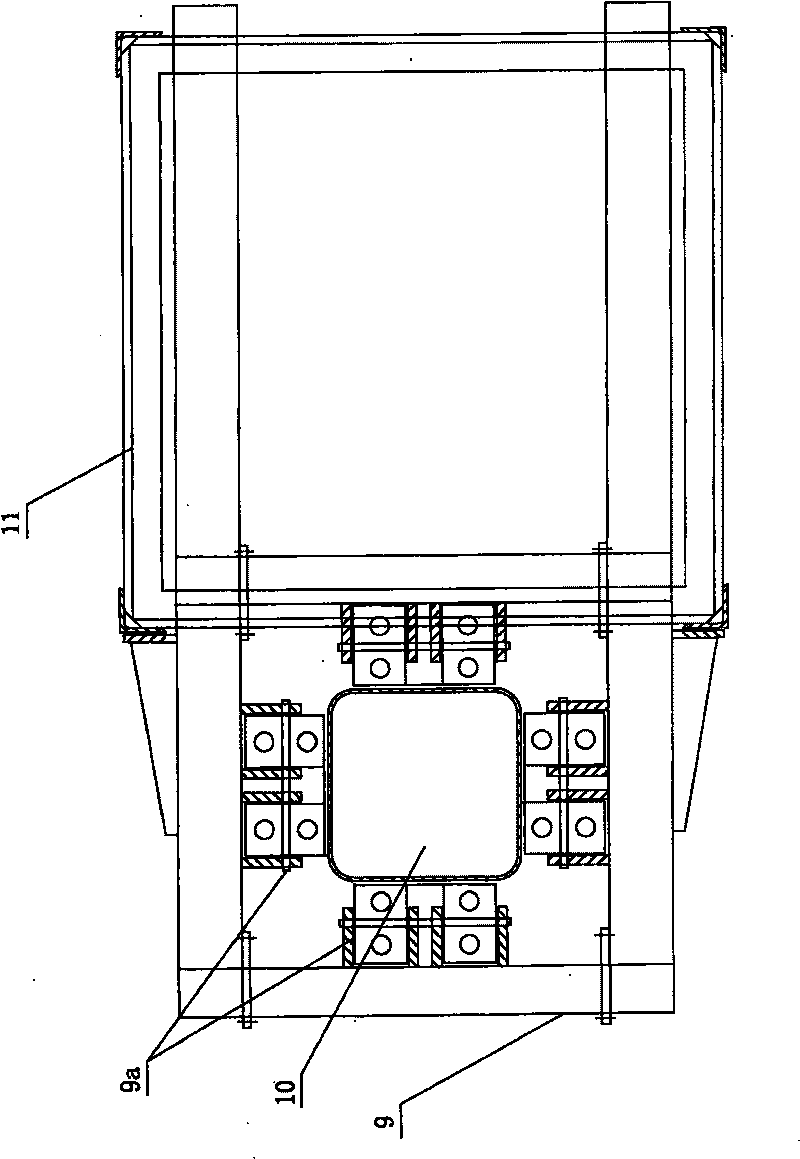

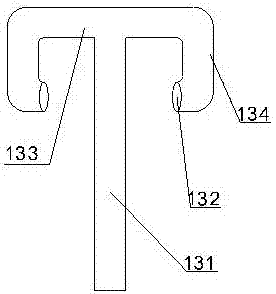

Network frame house cap integral lifting construction method

Disclosed is a construction method for lifting whole spatial grid roof structure, pertaining to the technical field of lifting a spatial grid roof structure. The spatial grid roof structure at which the method aims is composed of the connection of node spheres and tie bars; the whole spatial grid roof structure is supported and fixed by an upright column. The construction method is characterized by comprising the steps that: arranging a bearing upright column, connecting a lower girder, adjusting a radius rod, lifting an upper girder, installing a jack, arranging a bending- resistant lead, removing the original connection of the spatial grid roof structure, starting the jack to jack the whole spatial grid roof structure, padding the upper girder and jacking again, lengthening a connecting upright column and removing jacking facilities. The construction method adopts the combination of a hydraulic jack and girder multipoint supporting structure and directly jacks the whole spatial grid roof structure, which can shorten construction period, reduce construction amount as well as makes full use of the original structure; the construction method has components and equipment which are easy for manufacturing and convenient transportation and assembly, reduces project expenses, is fast and highly efficient, has low expense and is applicable to the heightening improvement of spatial grid roofs with various structures, such as circle, polygon, irregular odd shape, etc.

Owner:冯贵法

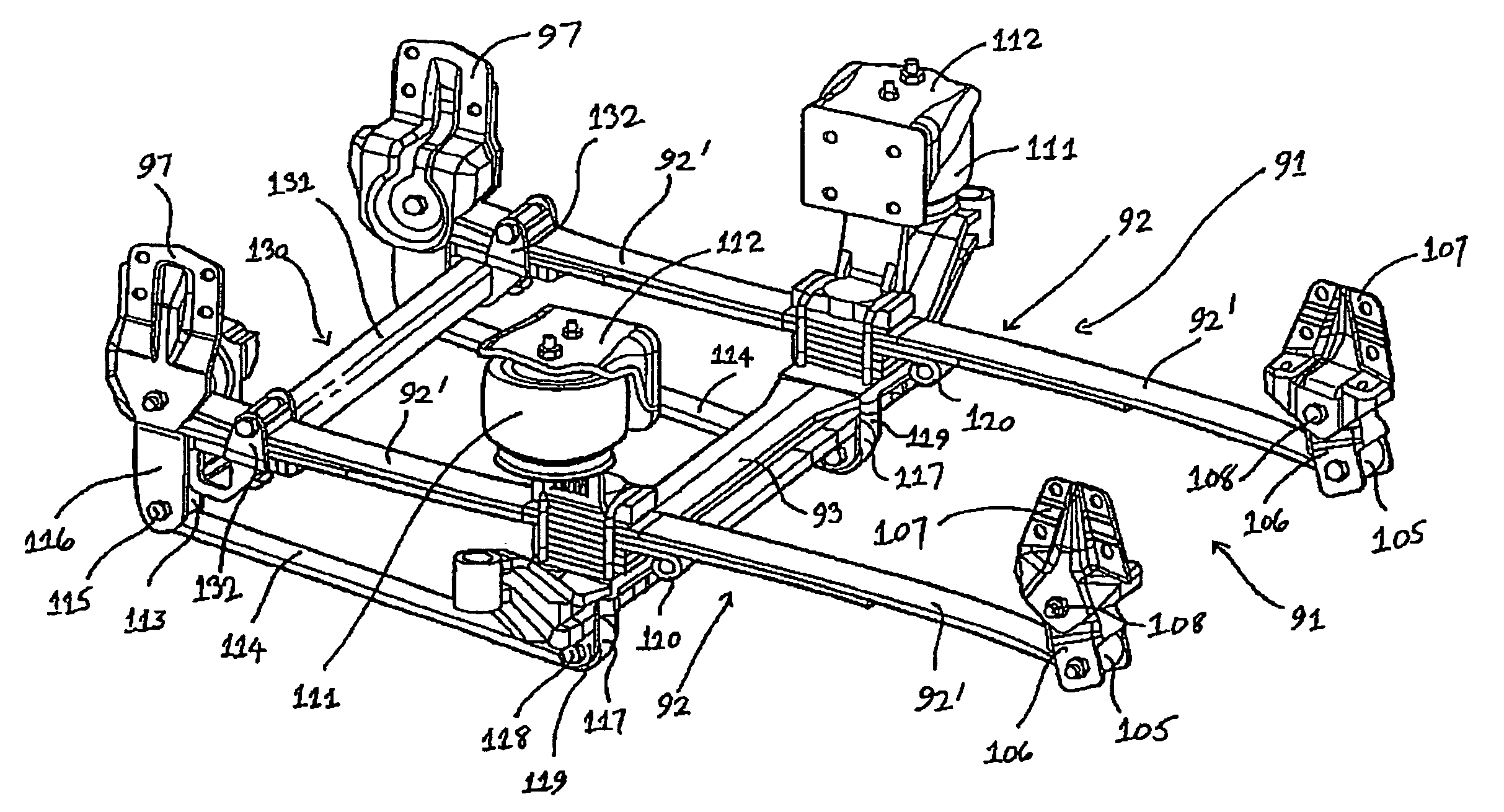

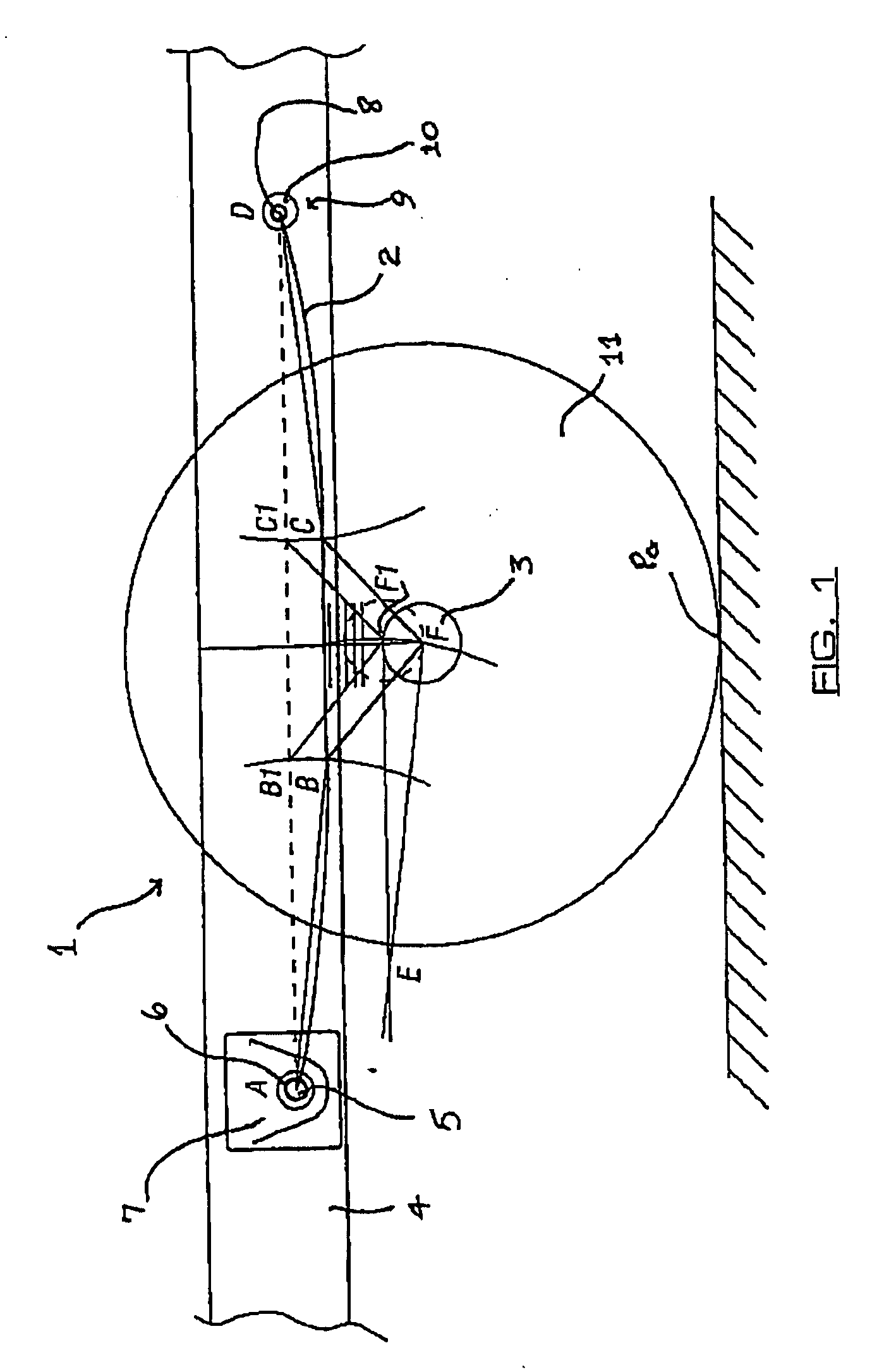

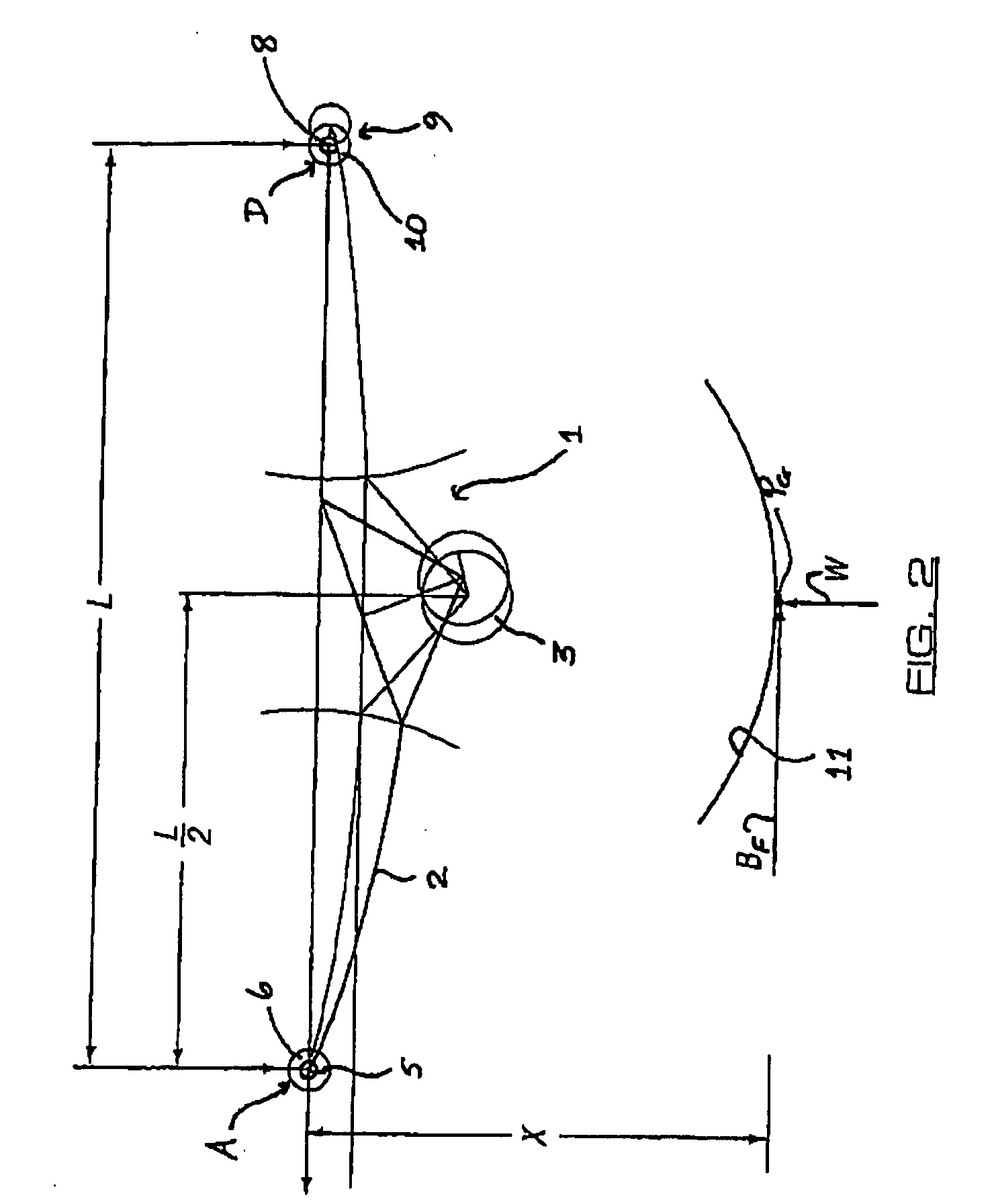

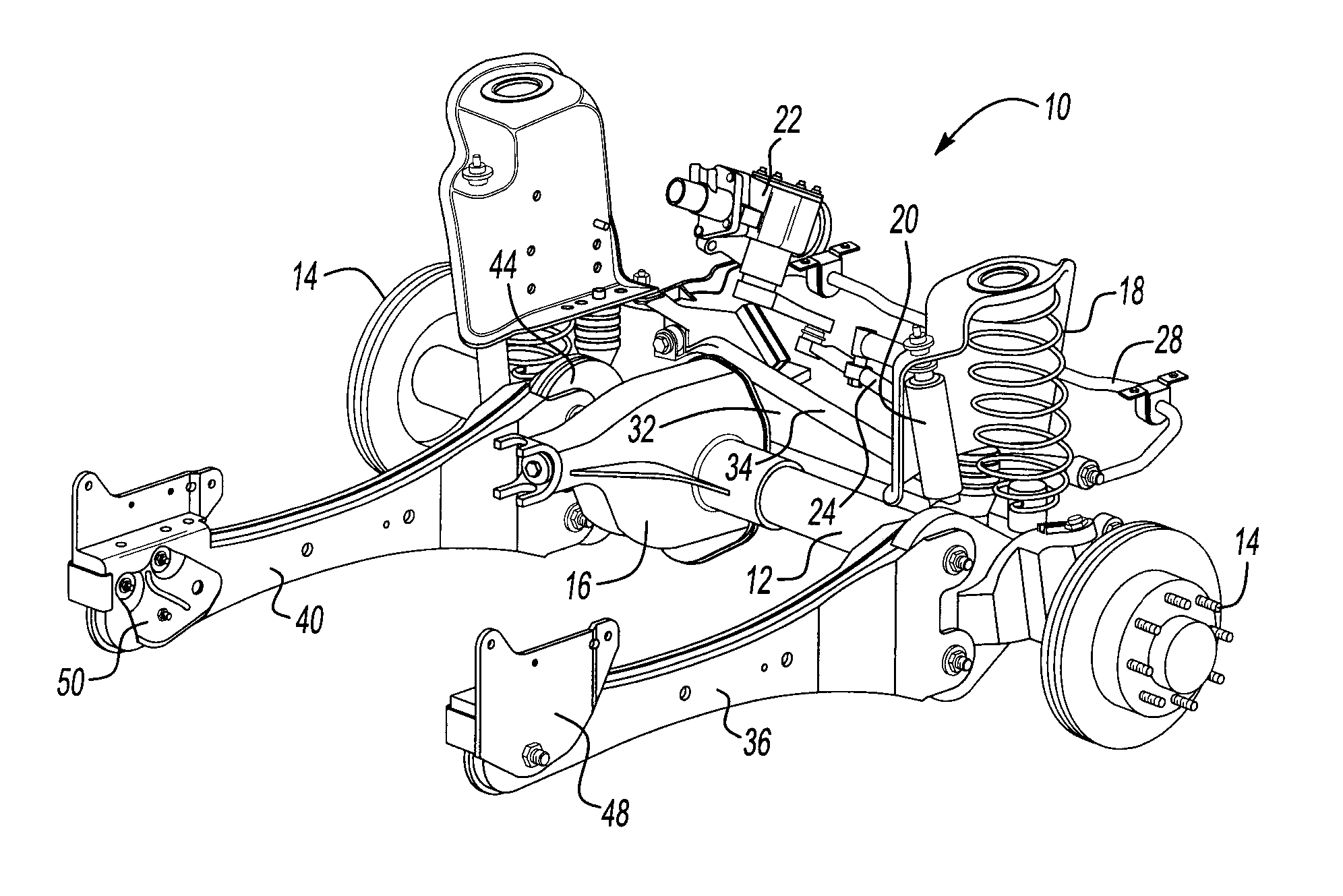

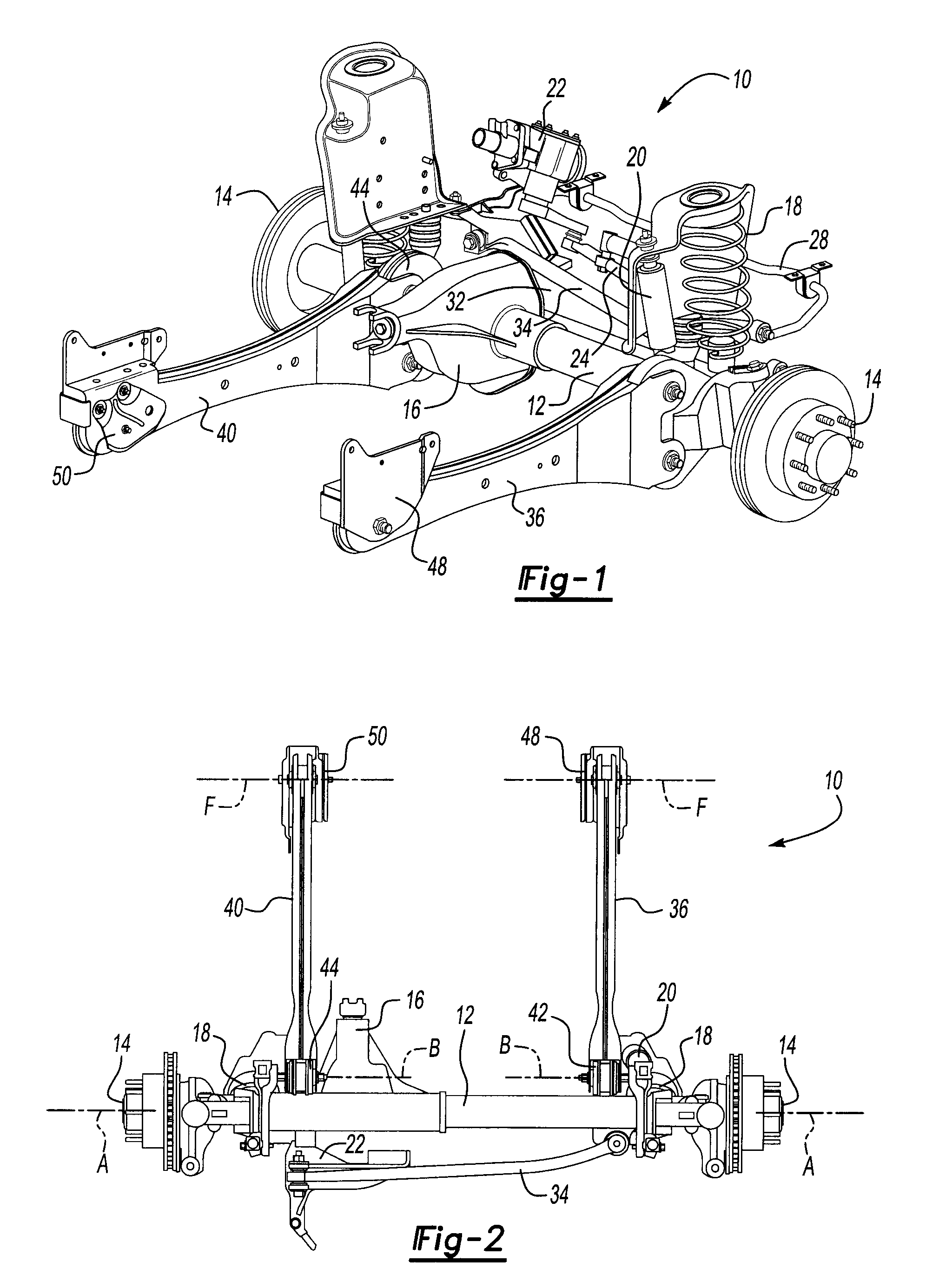

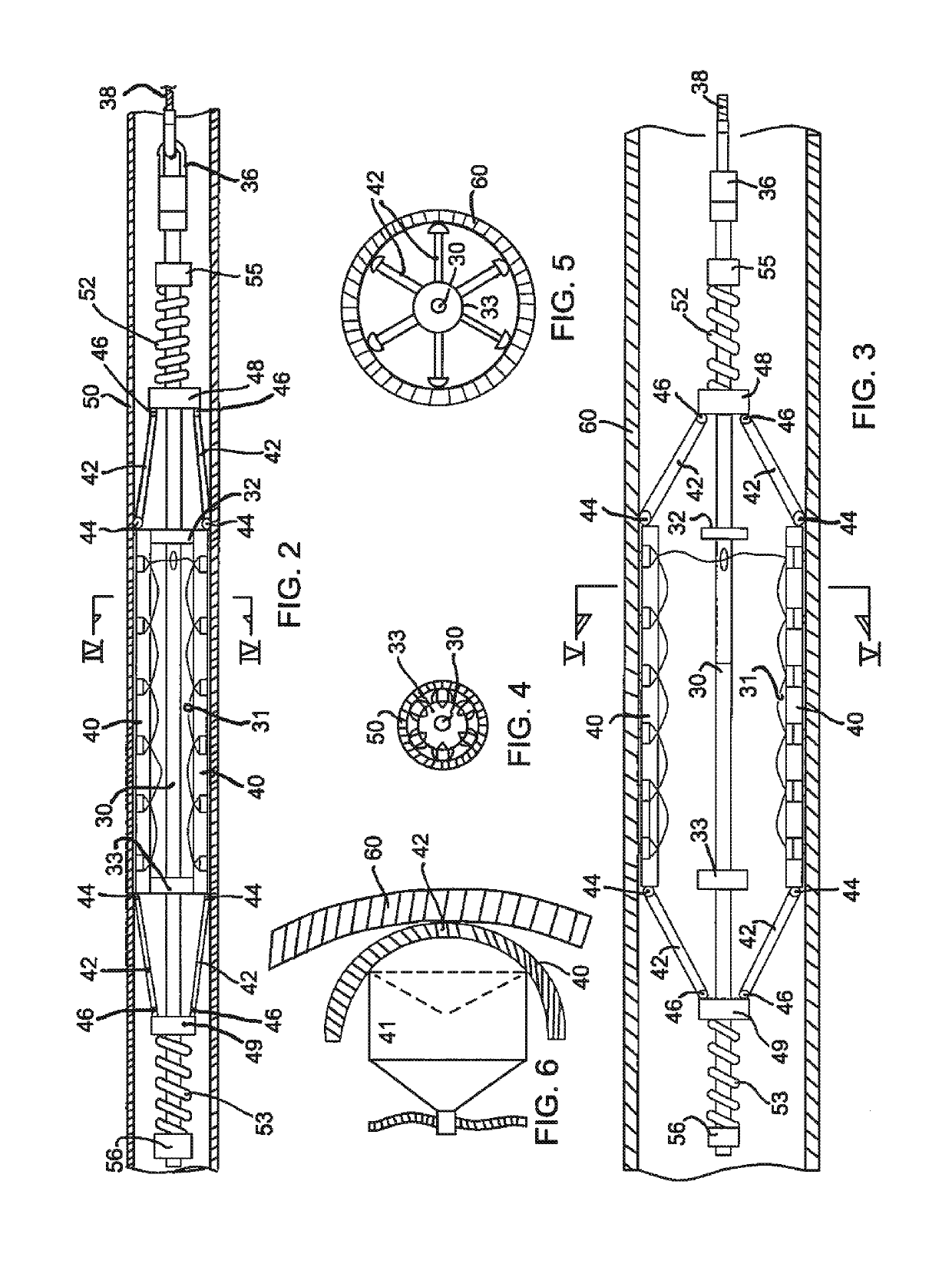

Vehicle leaf spring suspension with radius arms

A vehicle suspension comprising a pair of leaf springs arranged to extend longitudinally of the frame of a vehicle on opposed sides thereof with each leaf spring having one of its ends pivotally connected to the vehicle frame at a fixed location and which have an axle secured thereto between the ends thereof. A first bracket rigidly attaches each leaf spring at or adjacent the fixed location where the end of the leaf spring is connected to the vehicle frame. A radius arm extends longitudinally on each side of the vehicle frame and has one end thereof pivotally connected to the first bracket in a spaced-apart relationship to the fixed location. A second bracket is rigidly attached to the axle and is connected to the other end of the corresponding radius arm in a spaced relationship to the axle. Modified versions of the suspension are also disclosed.

Owner:GUTHRIE BRIAN SCOTT

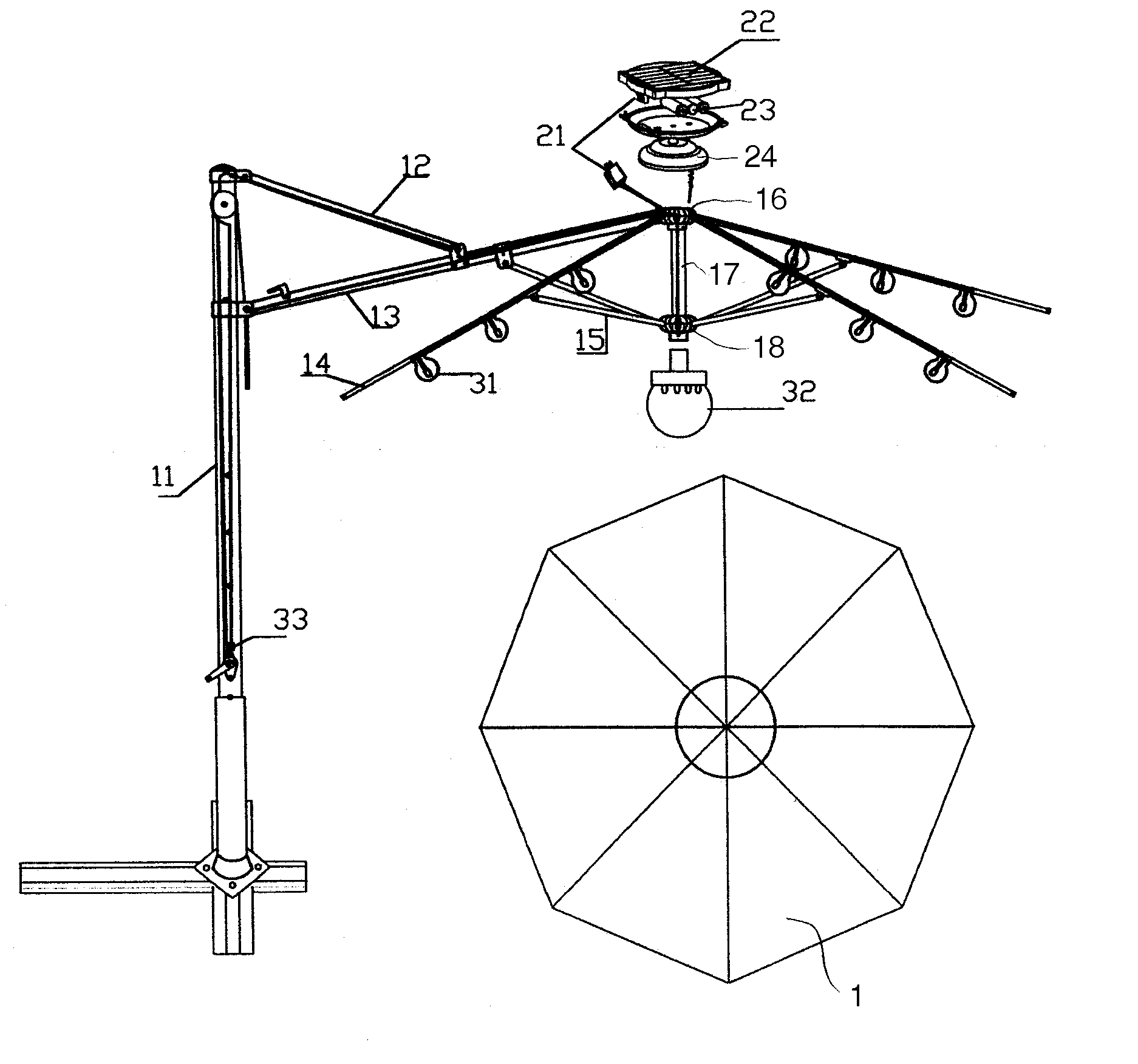

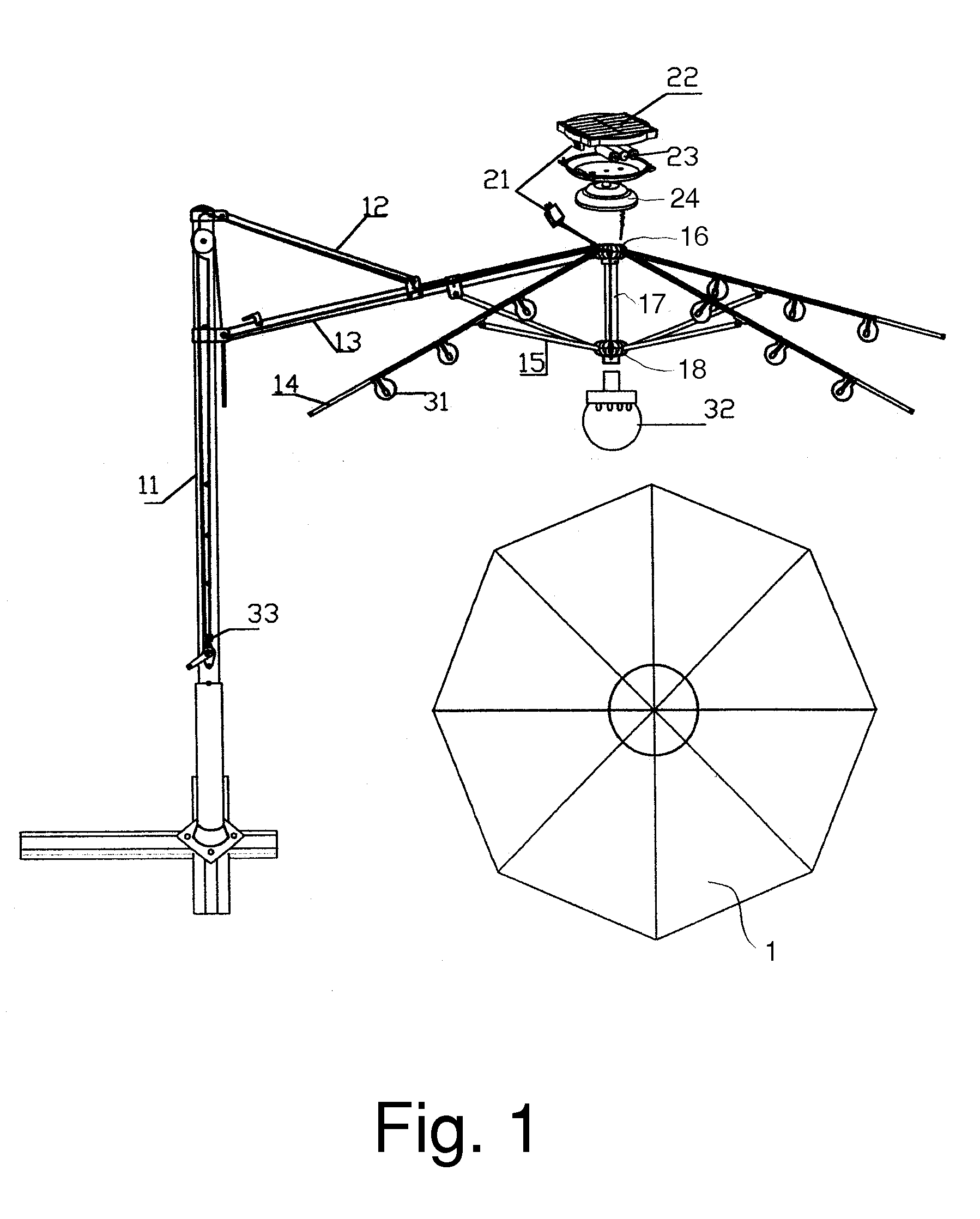

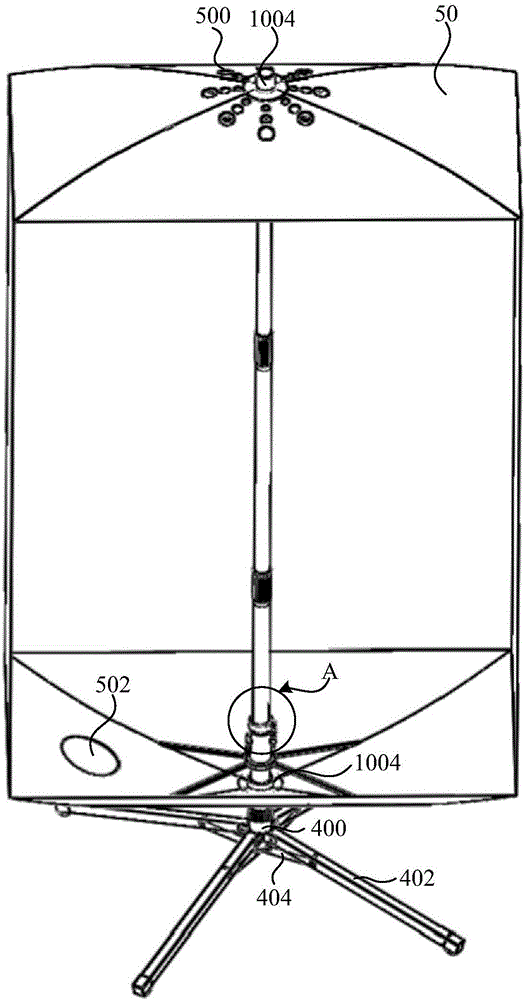

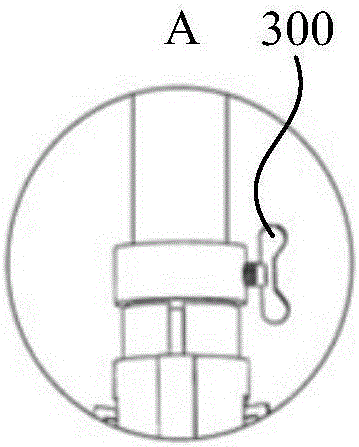

Sunshade with Illuminating Device

InactiveUS20060266398A1High level of light intensityHigh levelWalking sticksUmbrellasElectricityElectric machinery

The present invention relates to a sunshade with an illuminating device including a biased-arranging post and a canopy assembly having a upright central short pole (17) carrying a rib-mounting member, a runner, electric wiring and winding line; the rib-mounting member (16) mounted on top of a central short pole (17); a plurality of ribs (14) each having an upper end hinged on the rib-mounting member (16); a runner (18) slide-ably mounted on the central short pole (17) of the canopy assembly; a plurality of stretchers (15) each having an upper end pivotally connected to an intermediate portion of an associated rib and a lower end pivotally connected to the runner (18); a fabric covering surface supported by a plurality of ribs (14) forming a canopy of umbrella. An automated opening and closing system includes a motor, a transmission, a line-winding shaft, a pulley system, and a cable system; a pulley system is coupled to an electric motor, a switch (33) is electrically connected between a power-supply unit (22) and an electric motor; a main light member (32) is fixed at the bottom end of the central positioned short pole (17) of the canopy and energized by a self-contained power source. A cantilever connects with the biased post (11) as a radius rod suspends and supports the canopy assembly.

Owner:WU WEIDAN

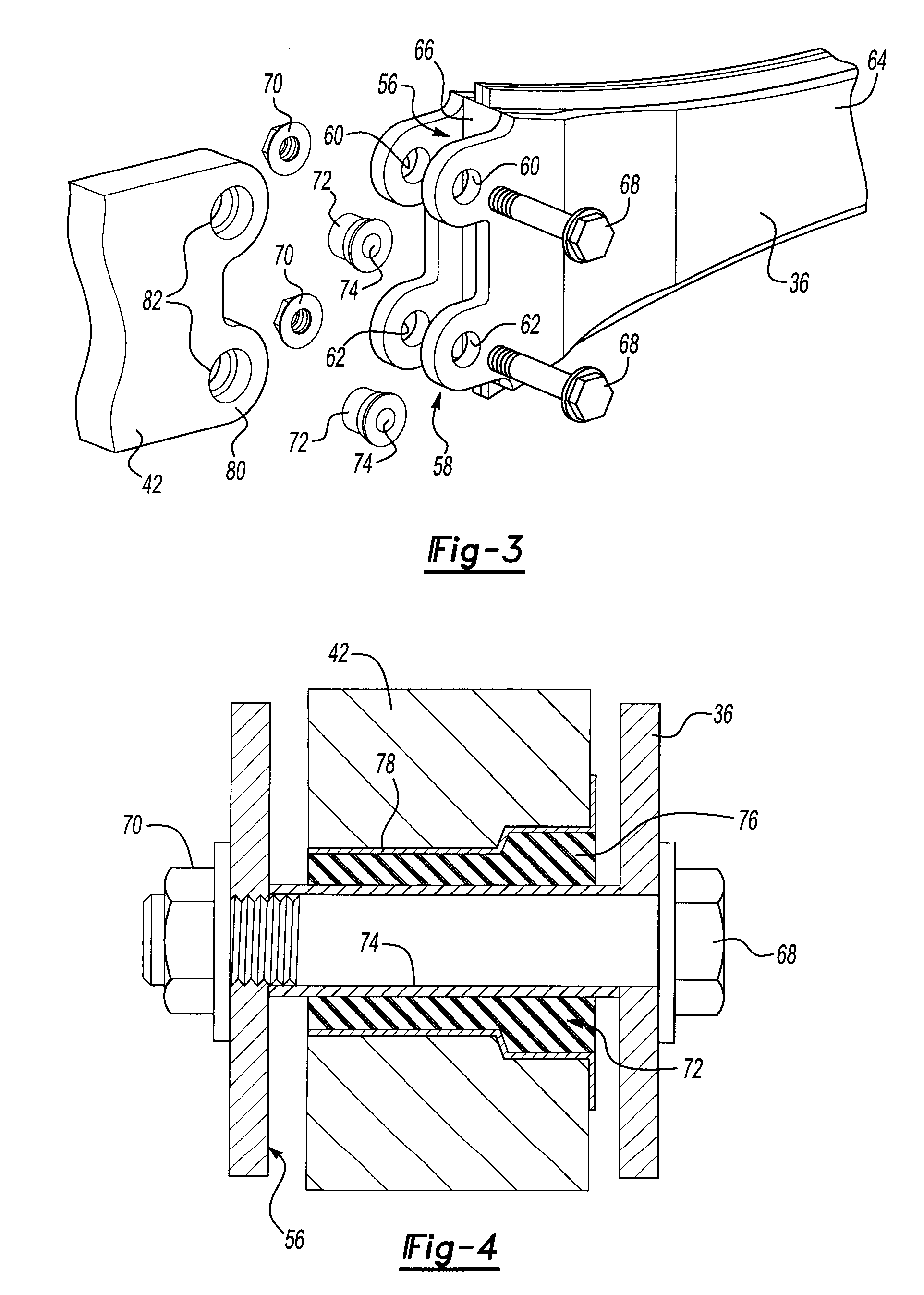

Vehicle suspension with improved radius arm to axle attachment

A vehicle suspension system having radius arms that are connected to axle brackets through vertically arranged bushings. A third link of the suspension system is a track bar that connects one end of the axle to a laterally spaced point on the frame of the vehicle. The radius arms are sheet metal fabricated members that are assembled in a clam shell arrangement.

Owner:FORD GLOBAL TECH LLC

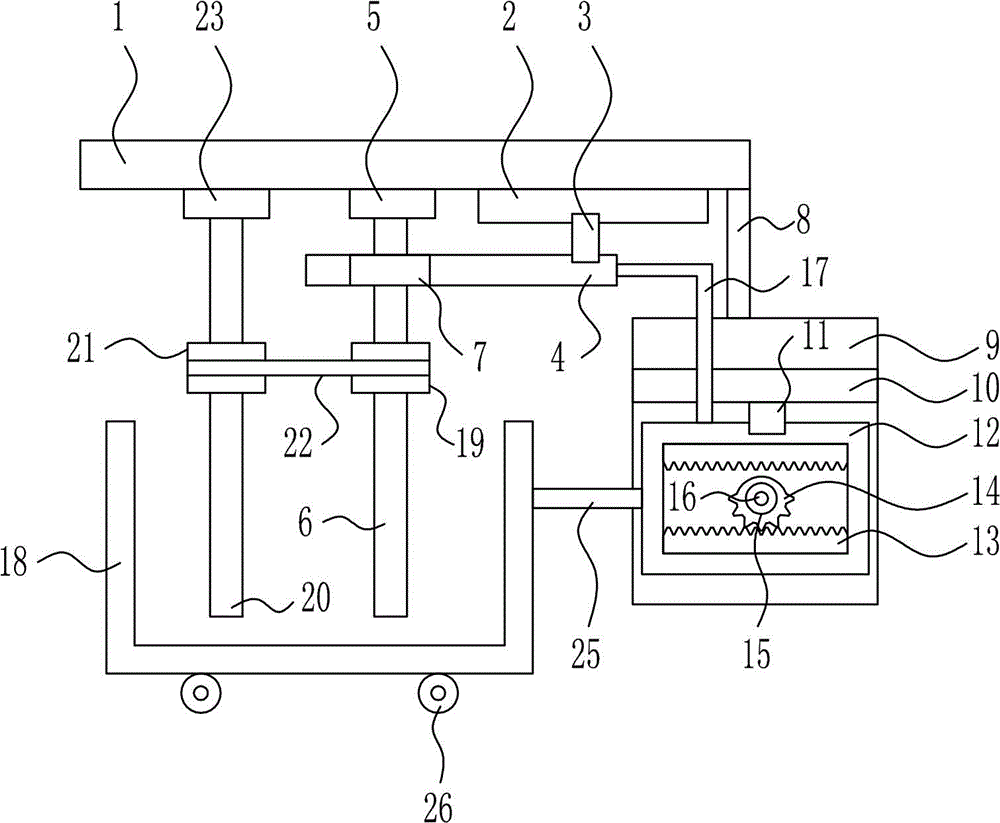

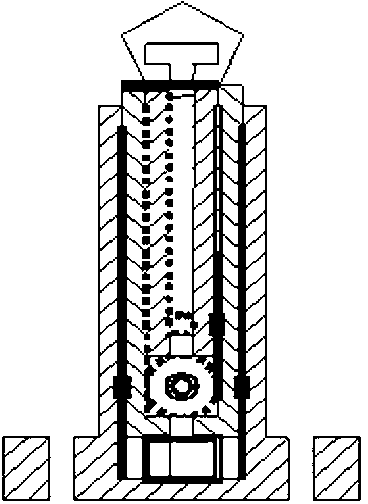

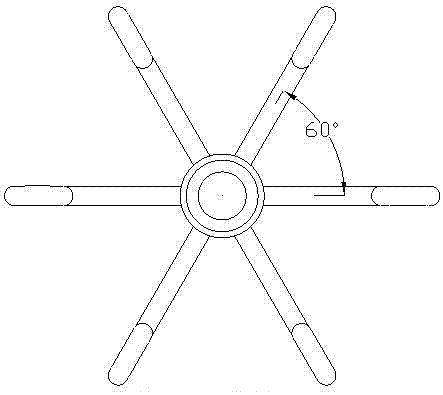

Highly-efficient multiple rods stirring type stirring equipment

InactiveCN106422919AStirring speed is fastImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingEngineeringRadius rod

The invention relates to stirring equipment, in particular to highly-efficient multiple rods stirring type stirring equipment. The invention aims to provide the highly-efficient multiple rods stirring type stirring equipment which has high stirring efficiency and a good stirring effect, and can brush aside stirring dead angles to the maximum. The highly-efficient multiple rods stirring type stirring equipment comprises a top plate, a first sliding rail, a first sliding block, a first rack, a first bearing pedestal, a first rotating rod, a first gear, a radius rod, a fixed plate, a second sliding rail and a second sliding block, wherein, the bottom of a stirring box is provided with wheels, the right side of the bottom of the top plate is connected to the first sliding rail through a bolt, the first sliding rail is connected to the first sliding block in a sliding mode, and the first sliding block coordinates with the first sliding rail. According to the stirring equipment, when materials are stirred, the first rotating rod and a third rotating rod can simultaneously rotate to stir the materials, and the stirring box can also continuously move left and right when the first rotating rod and the third rotating rod rotate.

Owner:荆门得道机械科技有限公司

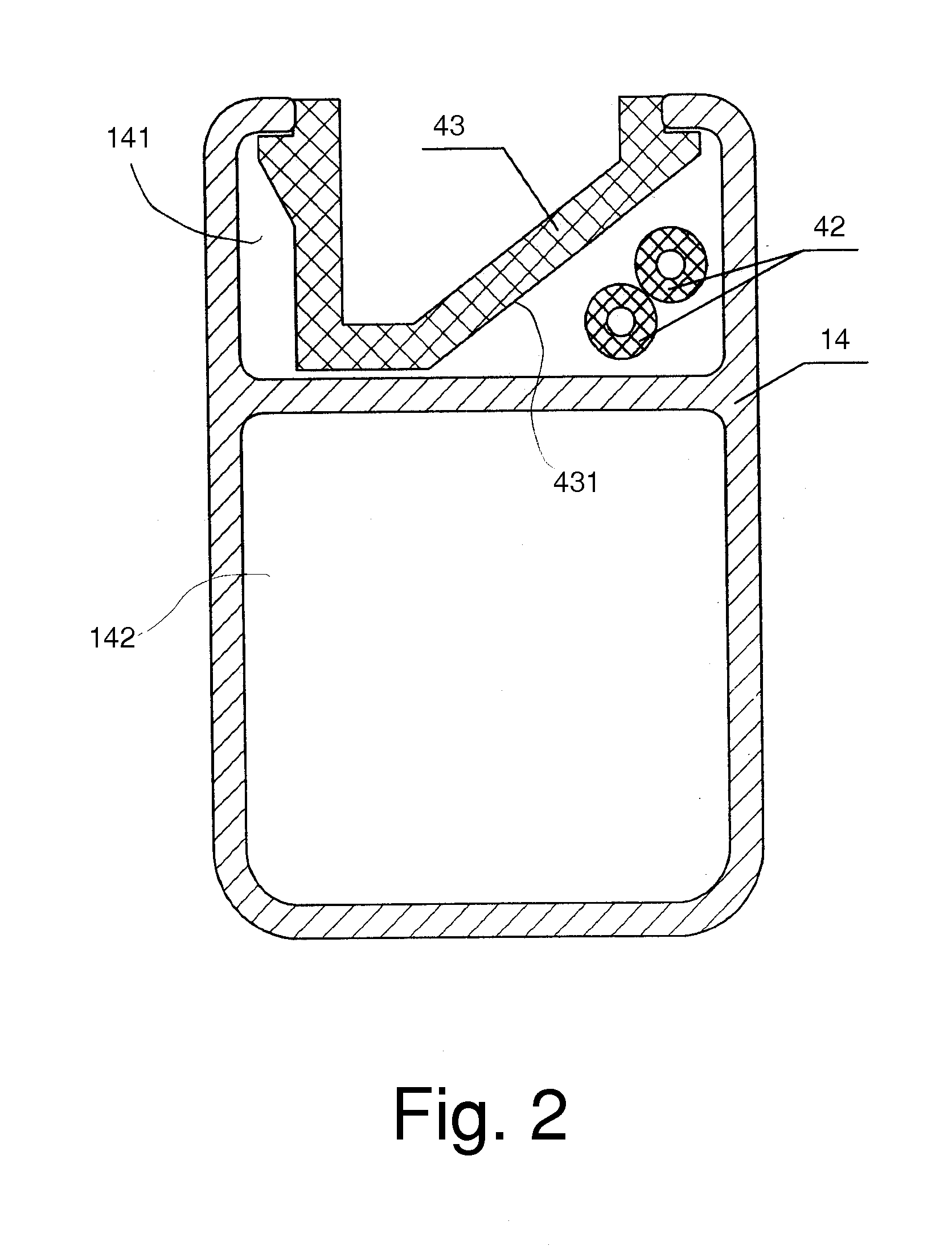

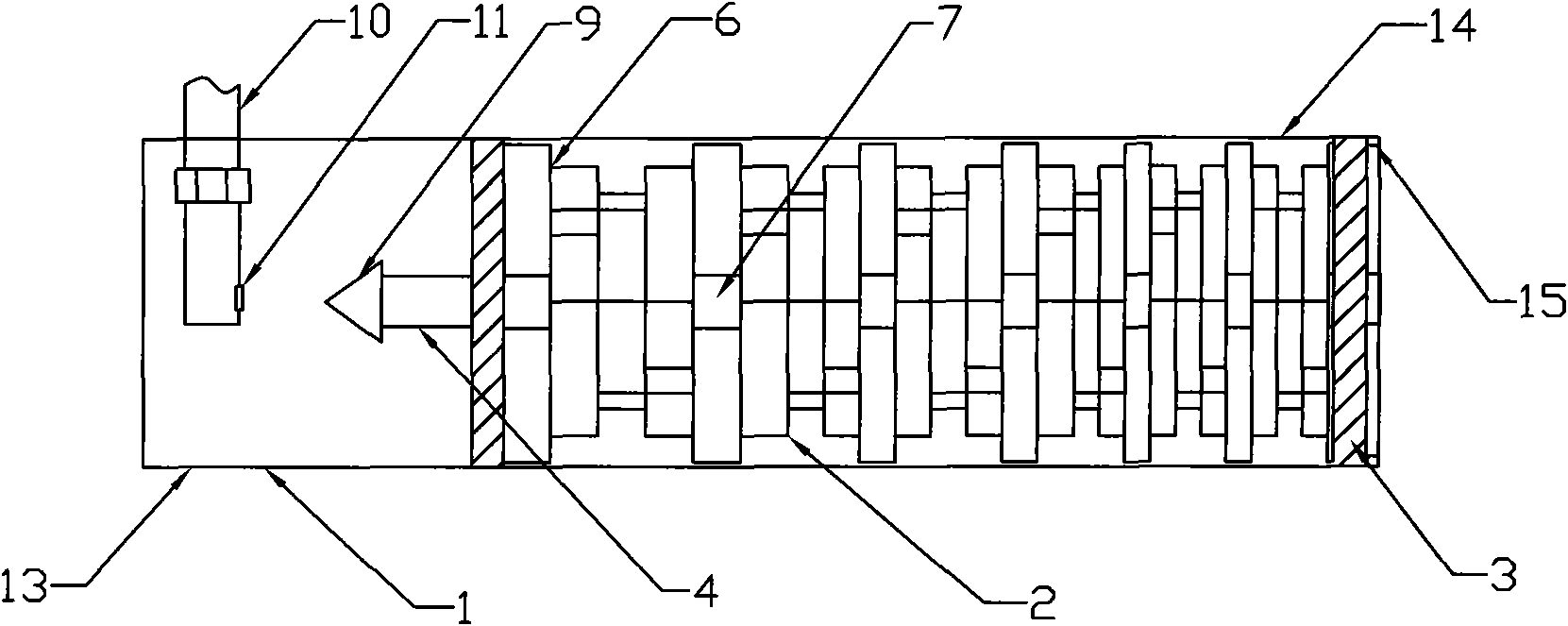

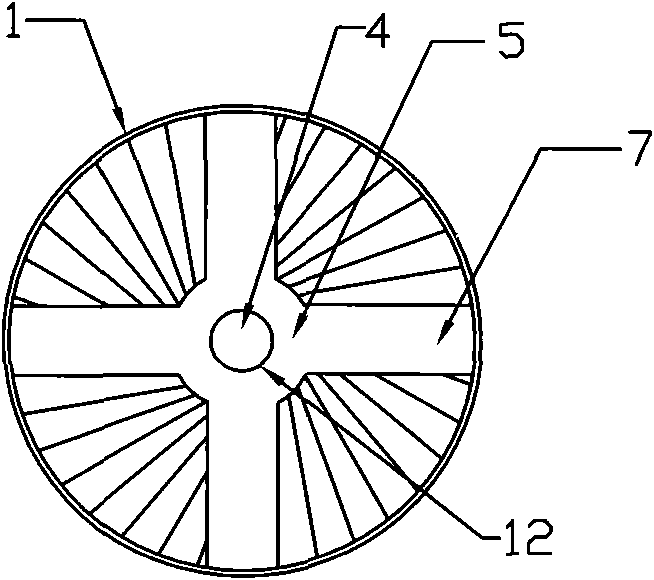

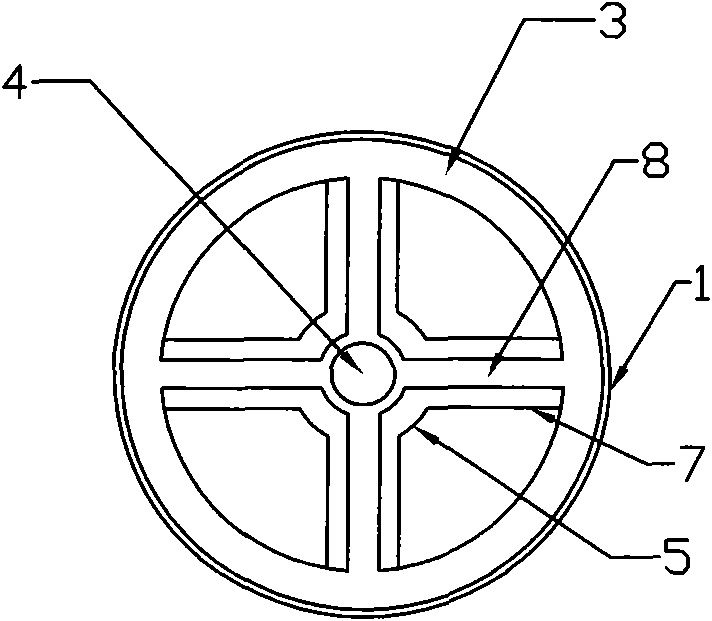

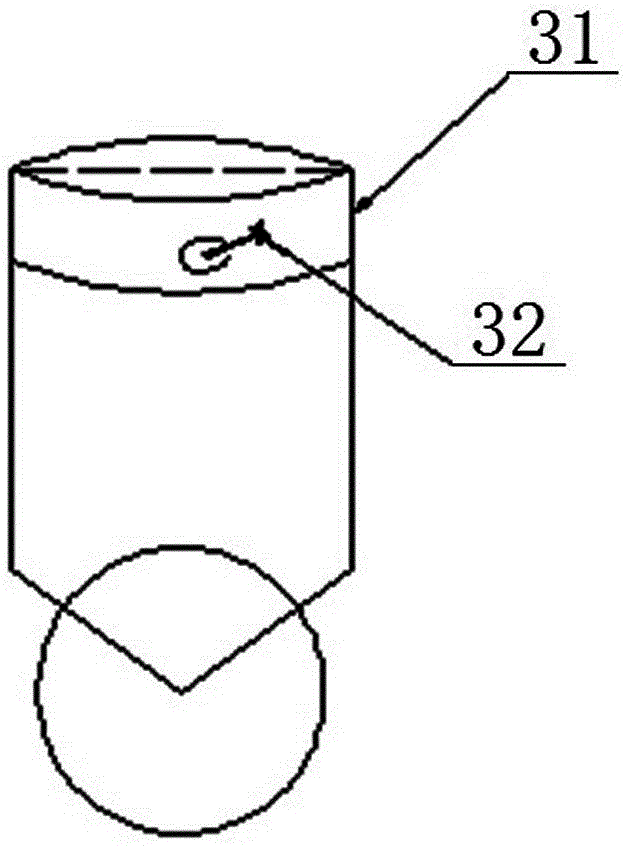

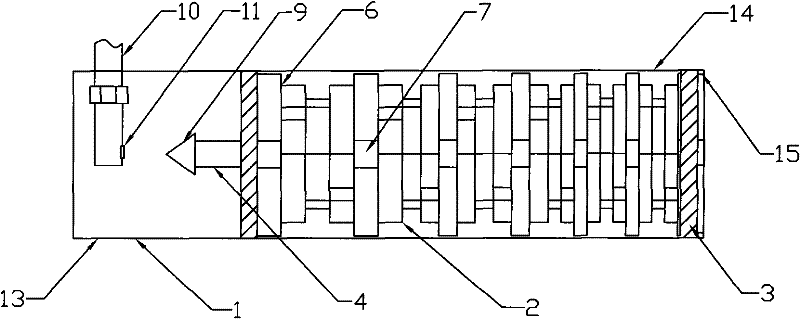

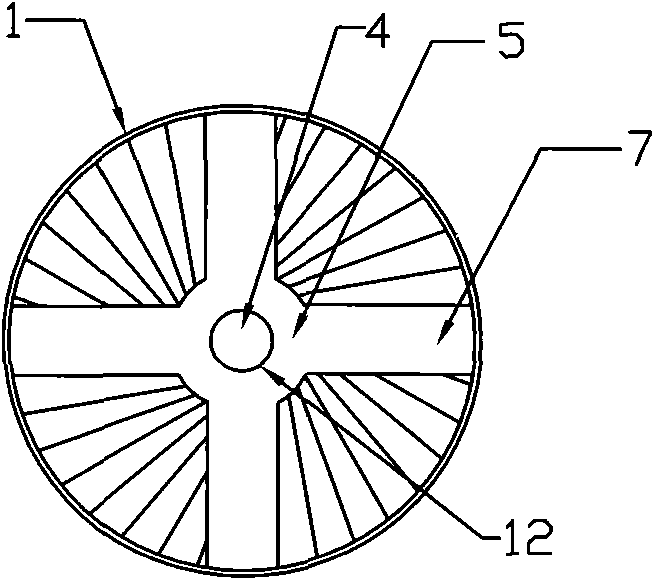

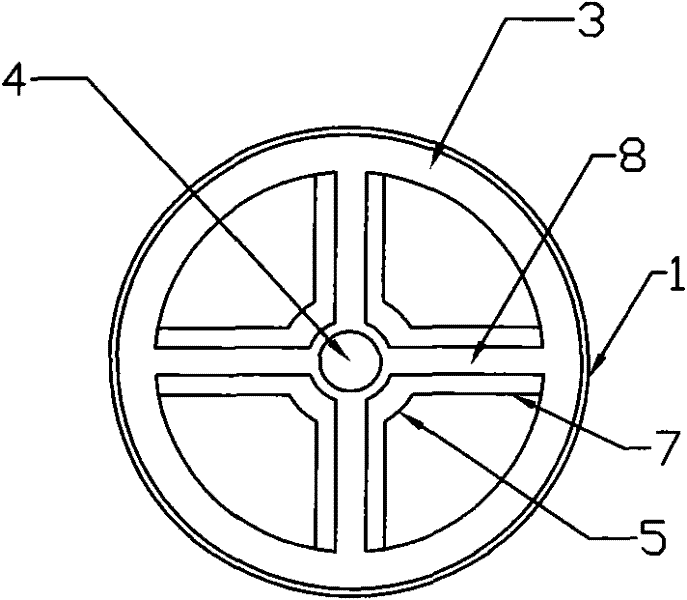

Fluid refining device

ActiveCN101658768AEasy to adjustAvoid mutual influenceFlow mixersMixing methodsCircular discEngineering

The invention relates to a fluid refining device, in particular relating to a device for refining mixed liquid. The device comprises a tubular housing and a spiral piece arranged in the tubular housing, wherein, the spiral piece is composed of a plurality of gaskets in an overlying manner; the intermediate shape of the gasket is a round disc; the periphery of the disc is provided with bulged blades to form a cross; each gasket in the rear and each gasket in the front stagger an angle to form a rotating spiral piece the screw pitch of which gradually diminishes from an inflow end to an outflowend; the entry end of a center shaft of the spiral piece is provided with a cone-shape screw cap; the two ends of the spiral piece are provided with support rings which are fixed with the center shaftthrough a radius rod. The scheme can be used in multiple liquid mixing modes, cancels a bearing seat, reduces the volume of the device, has convenient installation, utilizes the cone-shape screw capto reduce the resistance entering the liquid, and utilizes a gas filled tube to lead the mixing of gas and liquid to be more convenient. The scheme has simple structure, can adjust the screw pitch ofthe spiral piece according to actual condition, and reduces cost.

Owner:扈佳玉

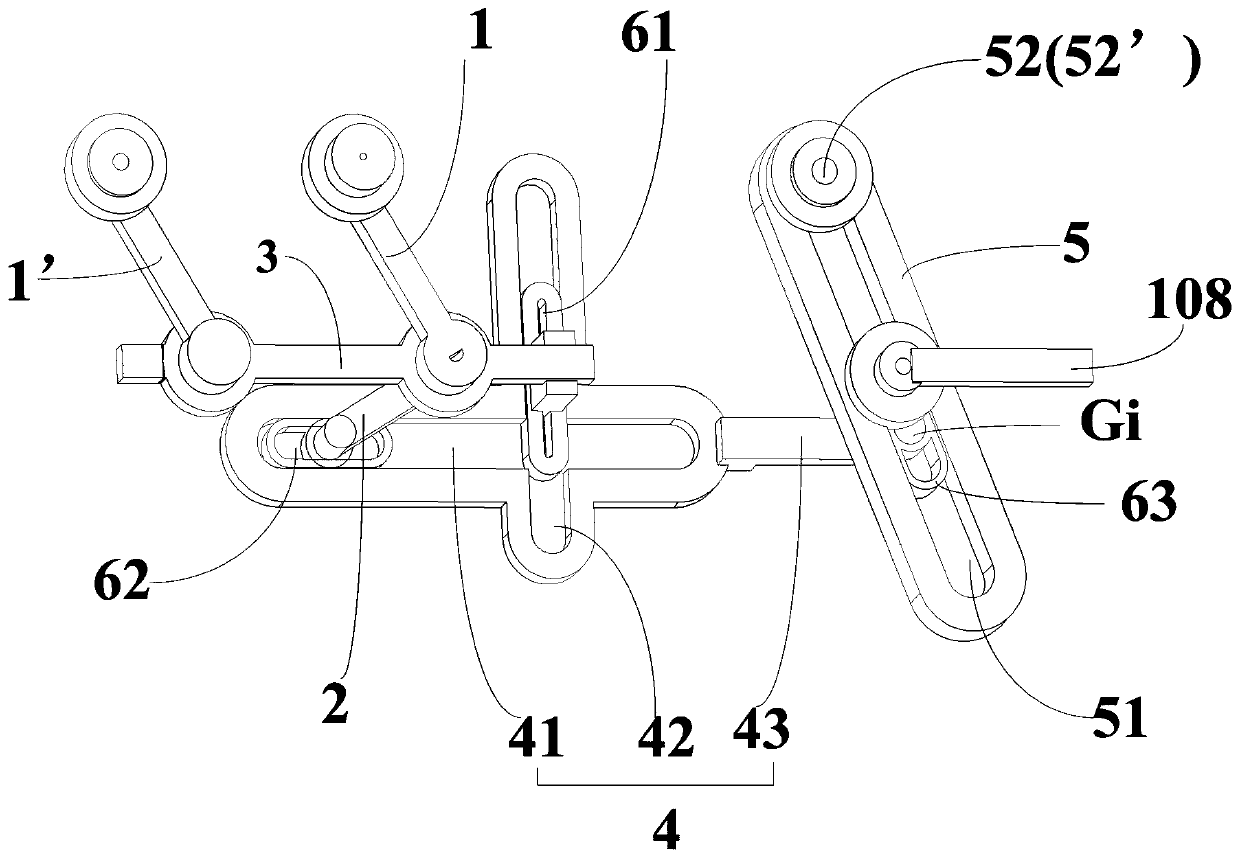

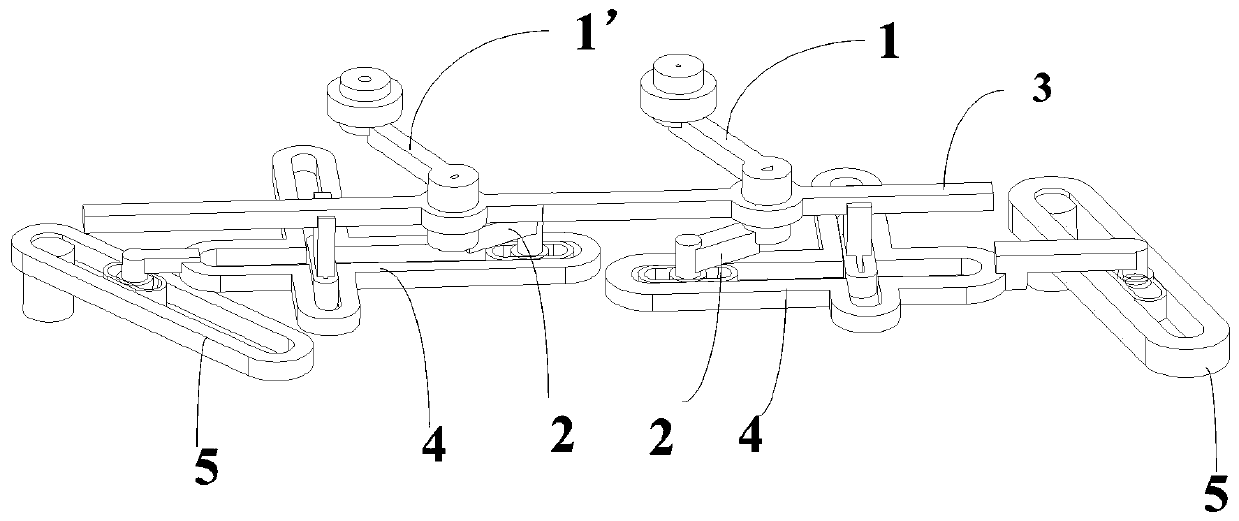

Constant steering control mechanism and method for radius rod connected trapezoidal swing arm and multi-wheel vehicle

InactiveCN110282011ASimple structureReduce manufacturing costSteering linkagesMechanical steeringCompensation effectTransverse groove

The invention relates to a constant steering control mechanism and method for a radius rod connected trapezoidal swing arm and a multi-wheel vehicle. The radius rod connected trapezoidal swing arm is in a right-angled triangle shape and forms an ellipsograph together with a two-dimensional synthetic control transmission arm of a cross-shaped chute formed by a transverse groove and a vertical groove; the length of the trapezoidal swing arm is R*M / H; along with a steering wheel rotation angle alpha, a radius rod connected trapezoidal swing arm end bearing generates an identical cosine compensation effect, R*cos beta i=R*cos alpha+ / -R*M / H* sin alpha, and the longitudinal cosine displacement is controlled by a sliding block sliding in the transverse groove; a right-angle end bearing is hinged with a connecting rod and then connected with the sliding block sliding in the vertical groove to control transverse sinusoidal displacement, the end bearing on the two-dimensional synthetic control transmission arm, namely a key control point bearing, draws a deflection elliptical track, and the hinged sliding block is connected with a vector control swing arm sliding groove to generate a steering angle beta i; and the electric potential of the electronic control differential speed mark of each wheel driving half shaft is obtained by a sliding resistor or a Hall induction brushless potentiometer arranged at a proper position.

Owner:刘海鹏

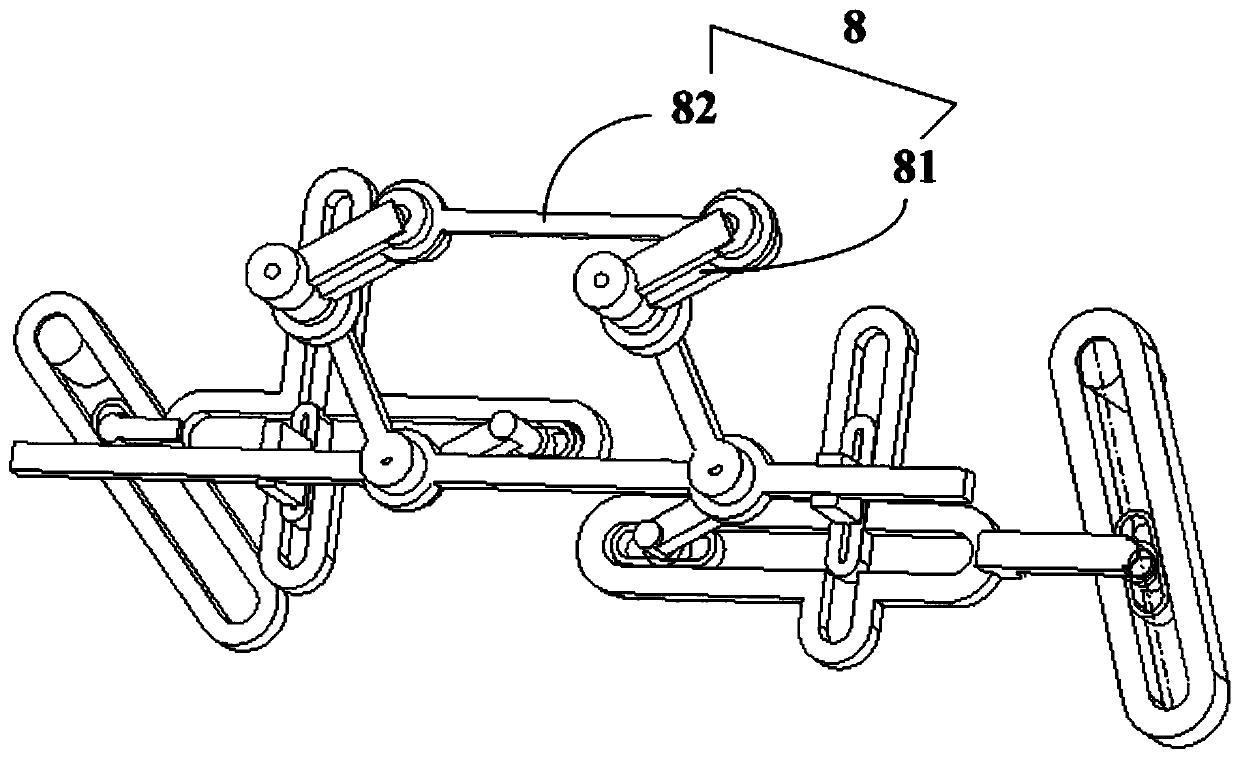

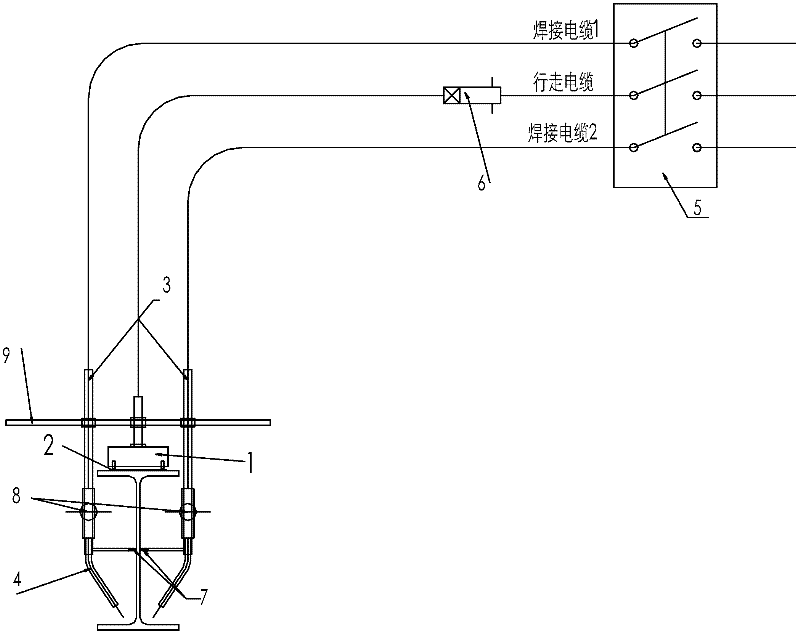

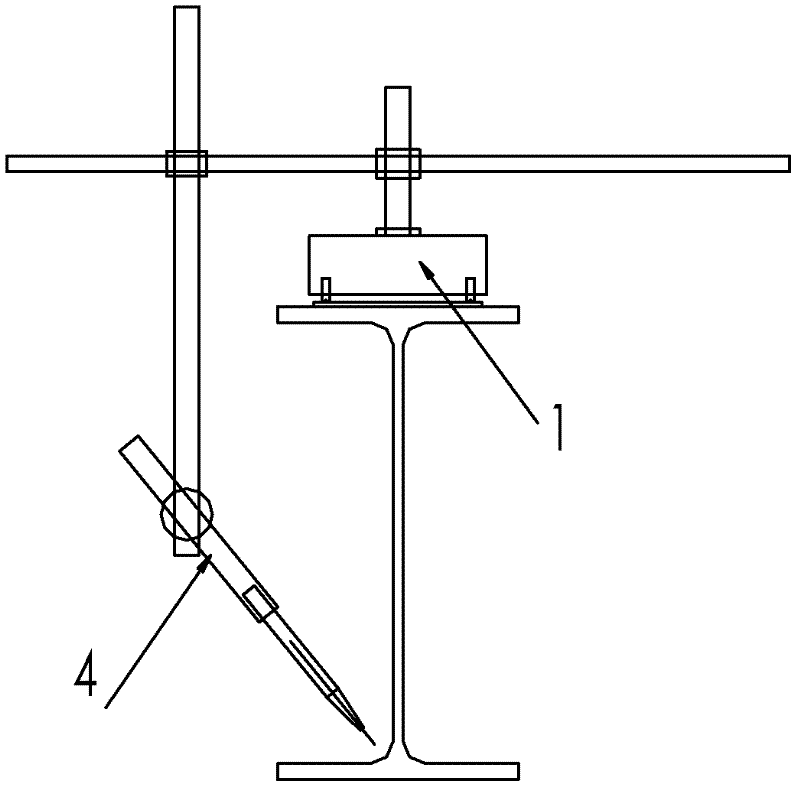

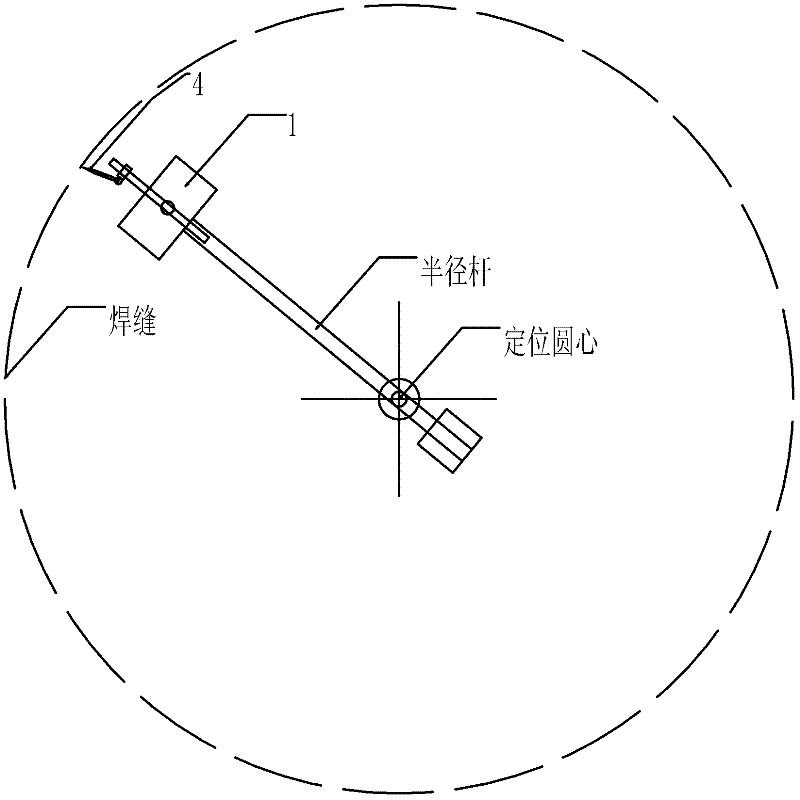

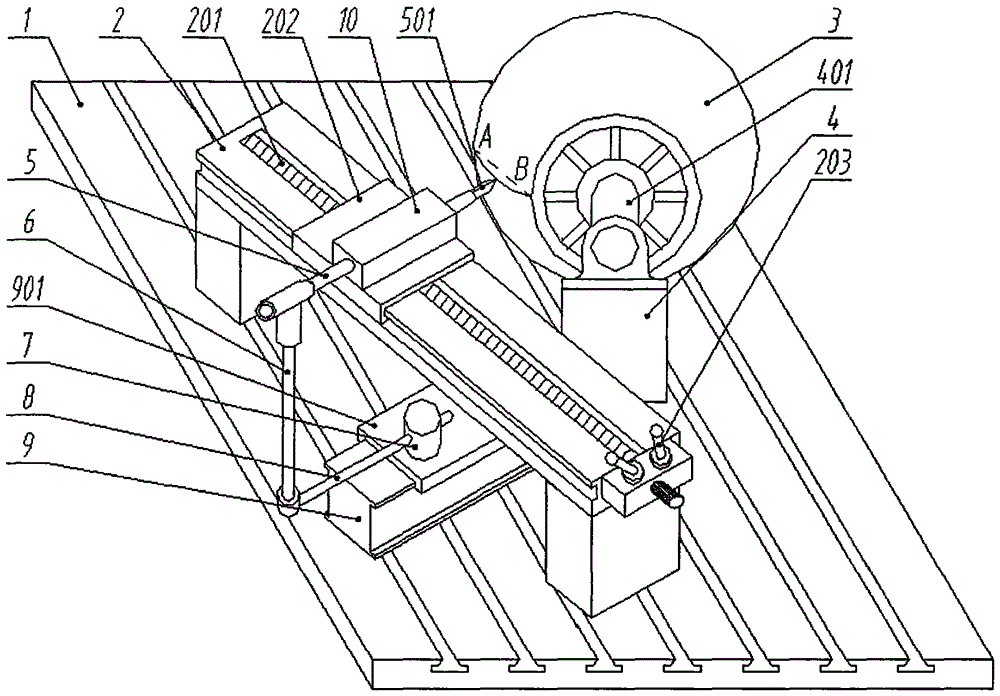

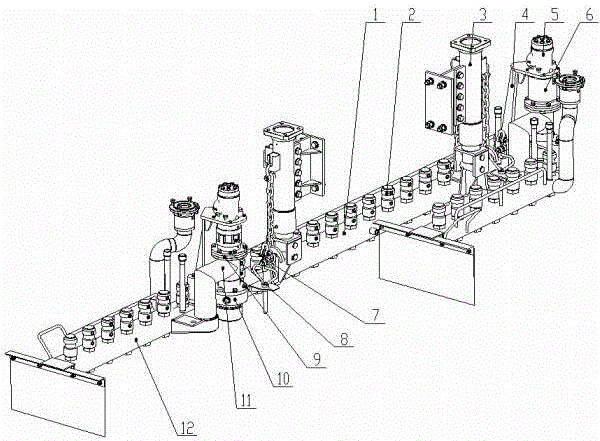

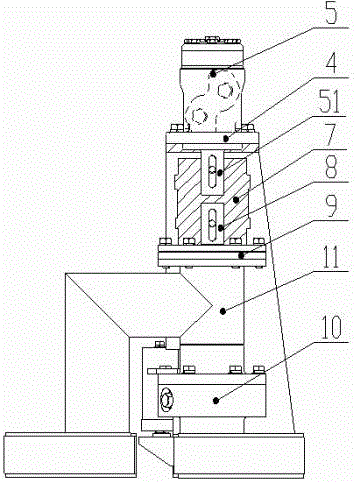

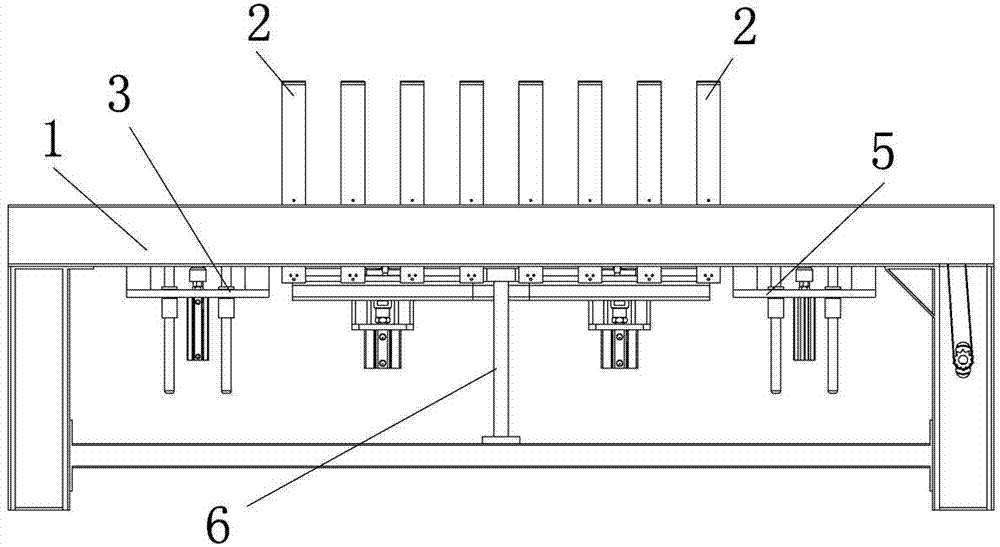

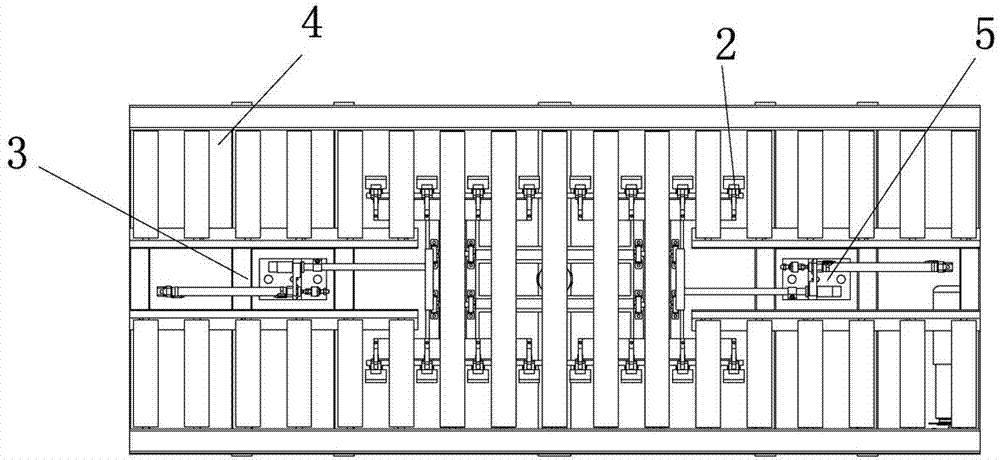

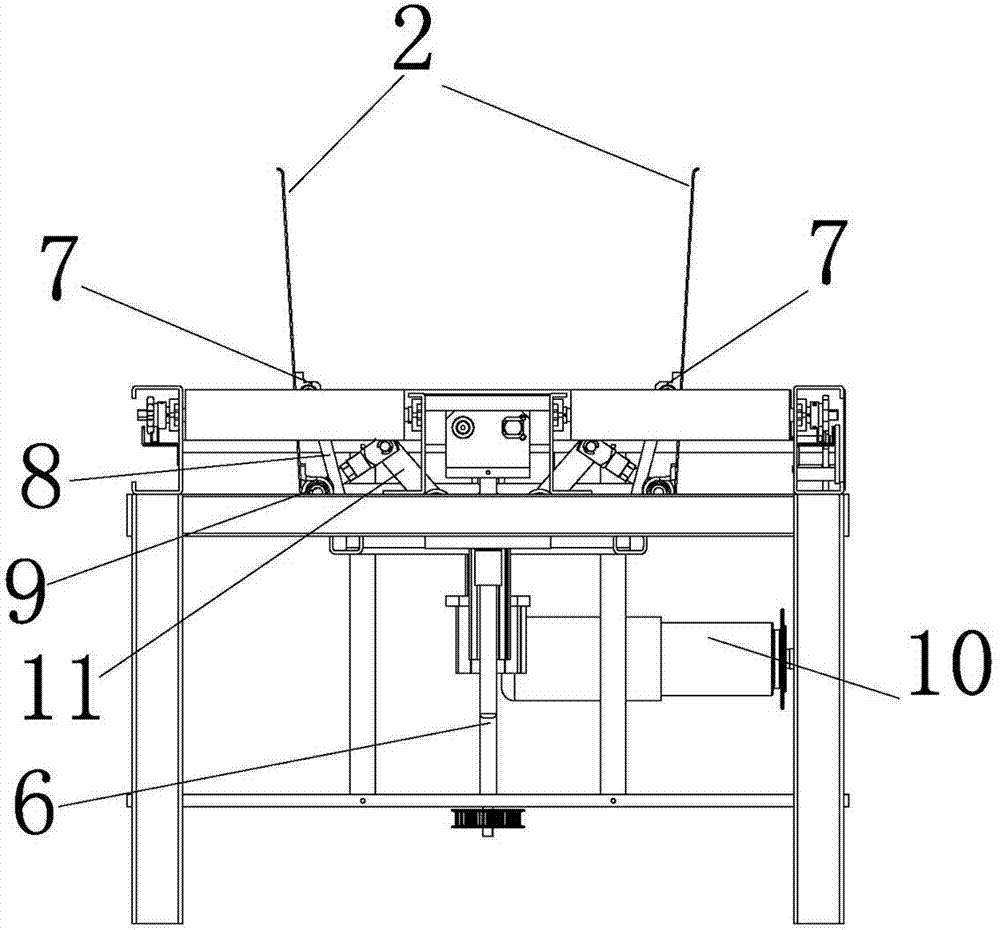

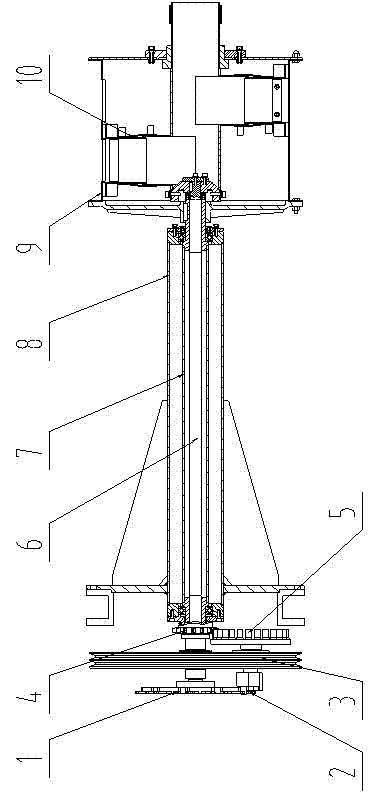

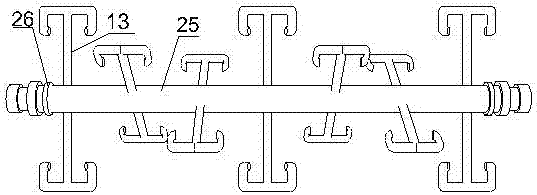

Semi-automatic double-head riding welding machine

InactiveCN102416521AAchieve regulationEasy to operateElectrode supporting devicesSemi automaticEngineering

The invention relates to a semi-automatic double-head riding welding machine, which is characterized by mainly comprising a switch controller, a connecting cable and a welding gun main body, wherein in the welding gun main body, a fixed support is arranged at the central point of a welding trolley and is provided with a horizontal welding arm of which the horizontal distance can be adjusted bidirectionally; one or two vertical welding arms with adjustable vertical height are arranged at one end or two ends of the horizontal welding arm; the lower end of each vertical welding arm is connected with a welding gun head through a gun head angle adjusting device; the switch controller is connected with the welding gun main body through the connecting cable; and the horizontal distance, the high-low travel and the angle of each welding gun head are adjustable. Welding craters can be avoided during arc striking and arc finishing; and arbitrary curved I-steel, H-steel and box beam can be welded through a flexible rail, and circular welding seams can be semi-automatically welded by arranging a radius rod.

Owner:CHINA FIRST METALLURGICAL GROUP

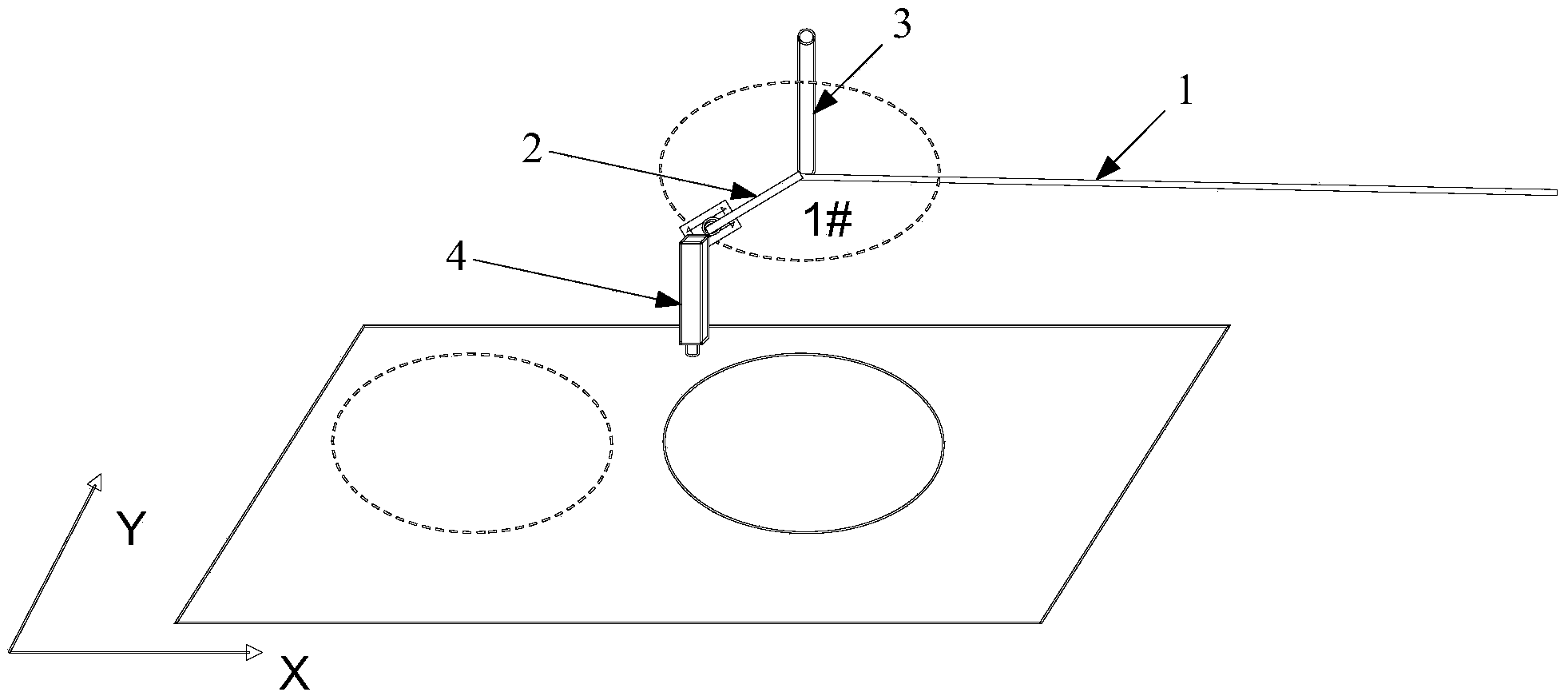

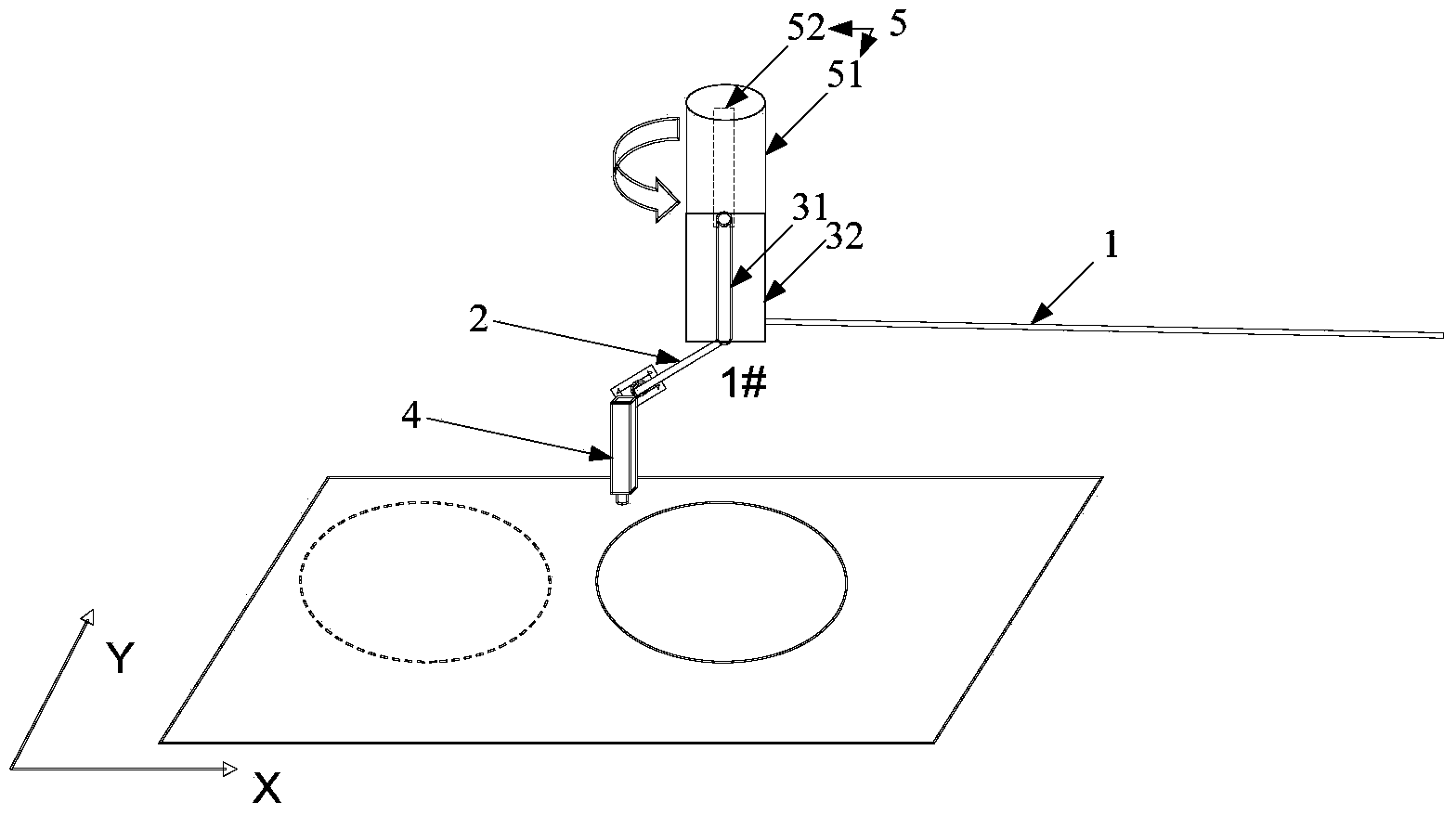

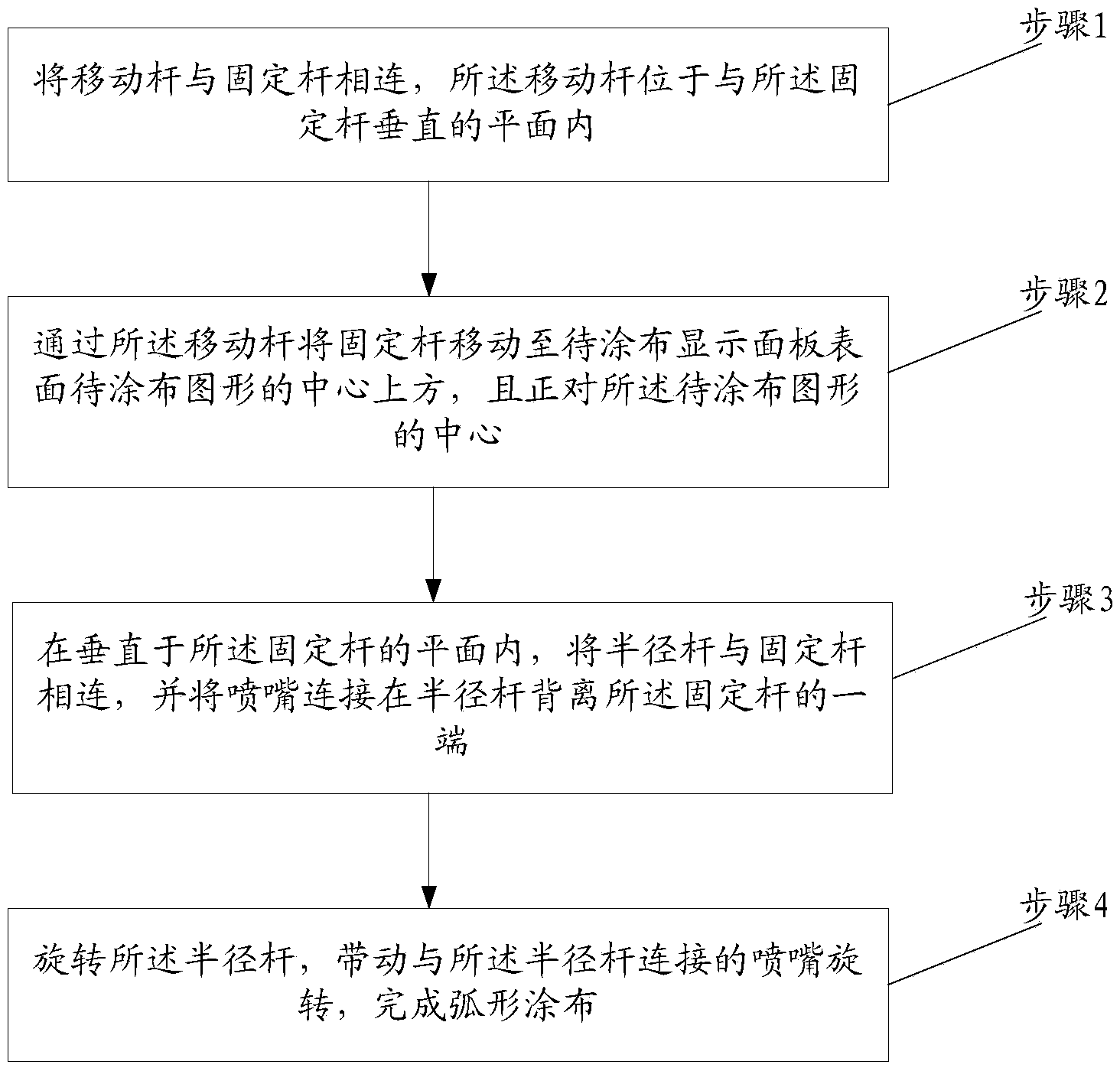

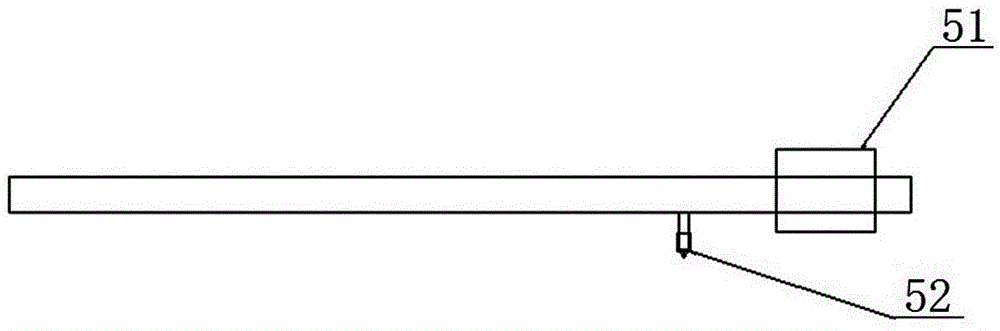

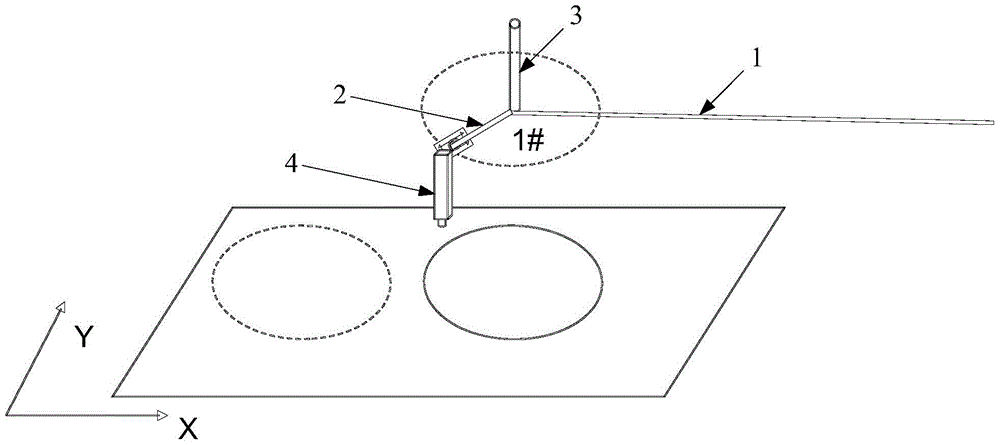

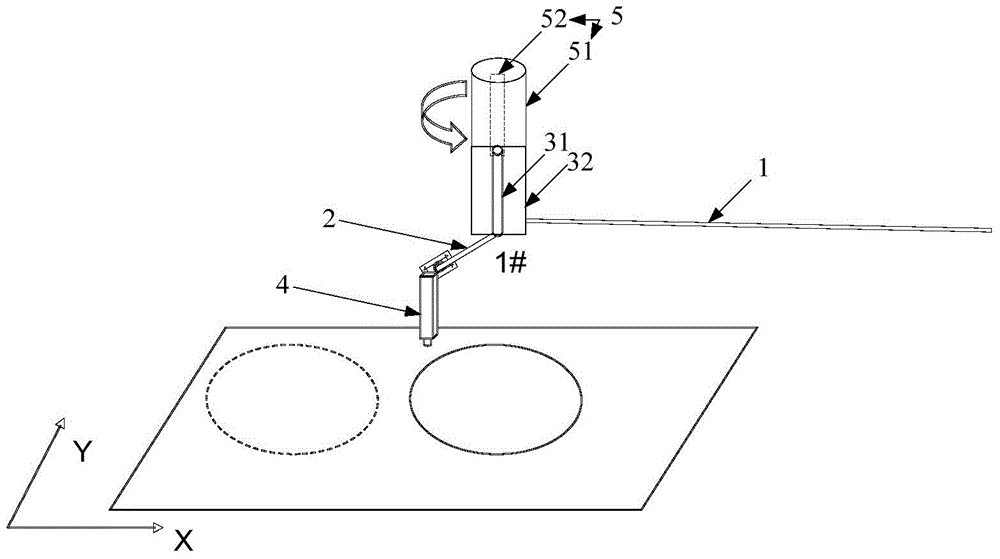

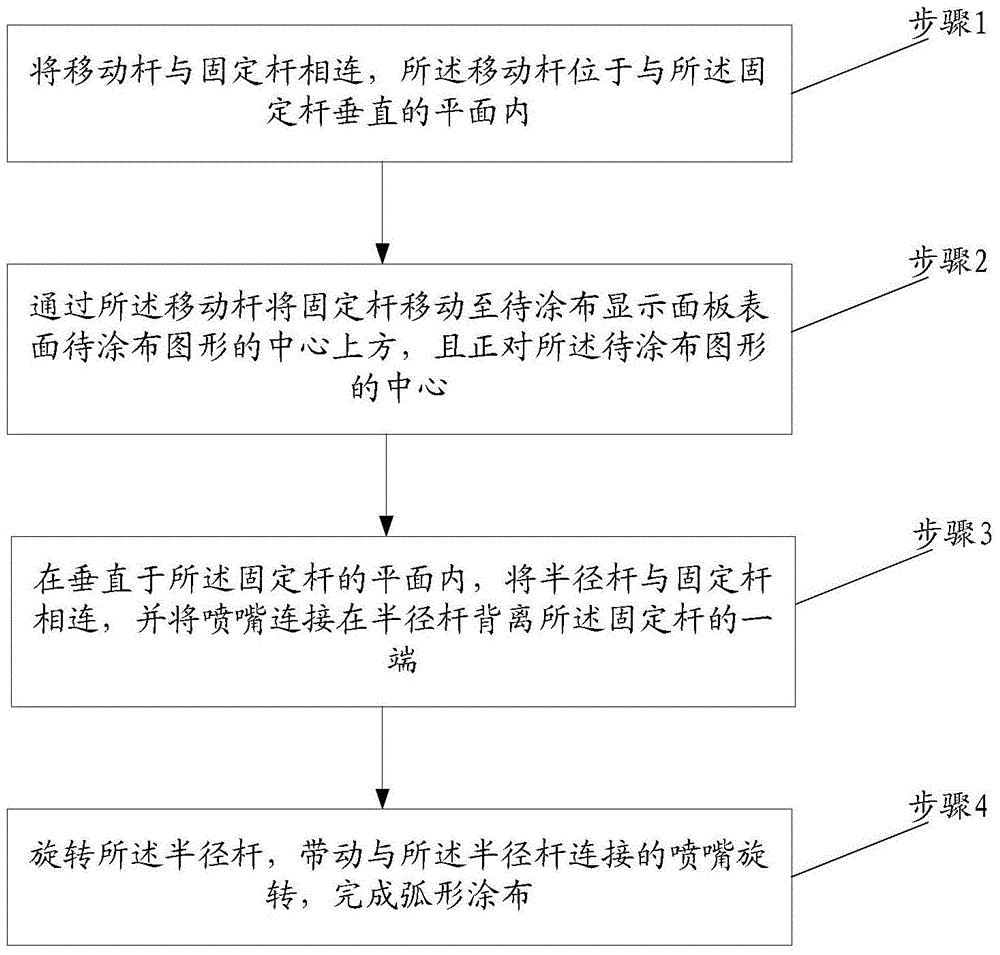

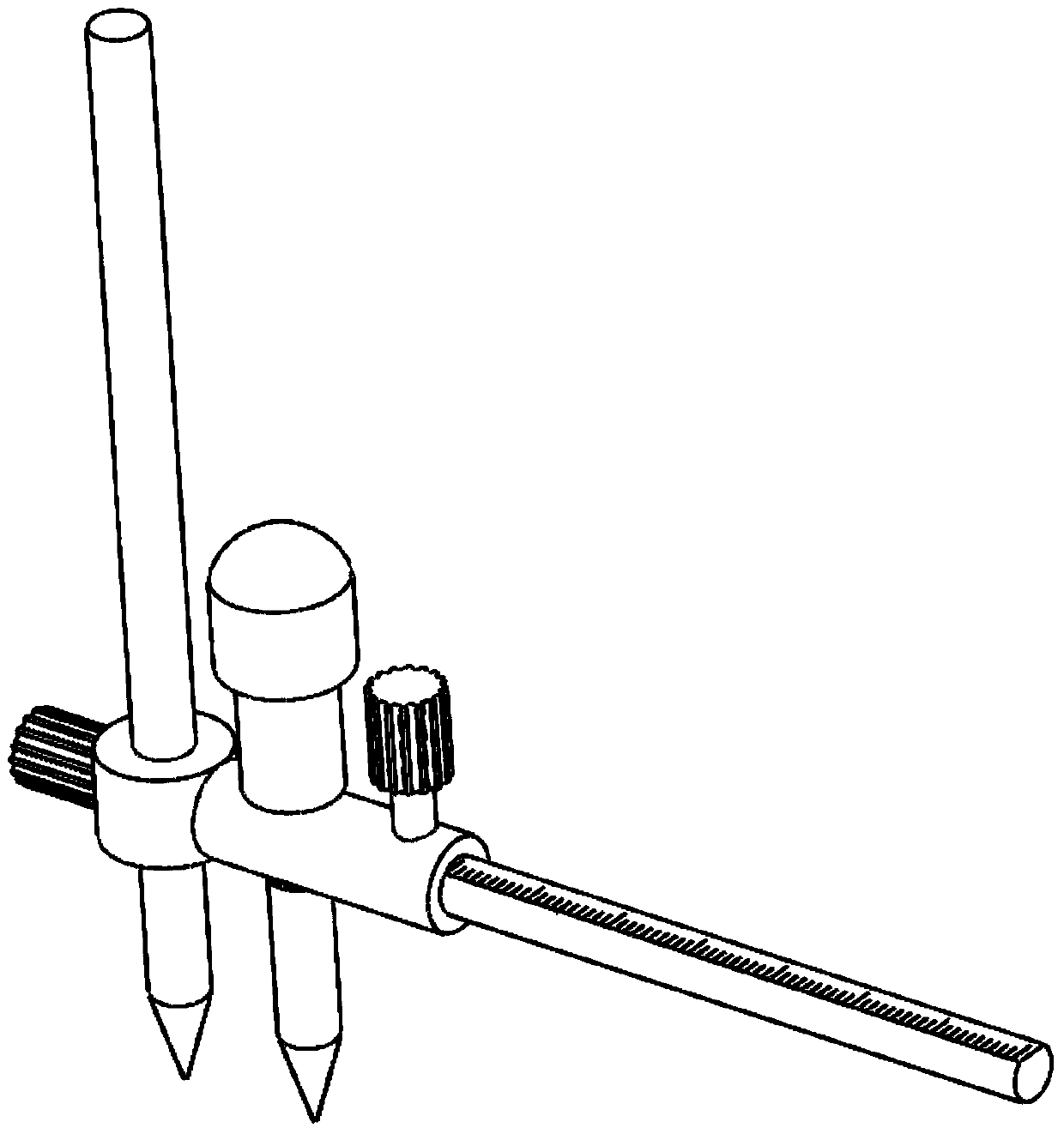

Spraying device and method for display panel

ActiveCN104307669AOvercome limitationsLiquid surface applicatorsSpraying apparatusEngineeringRadius rod

The embodiment of the invention provides a spraying device and method for a display panel. The spraying device comprises a moving rod, a radius rod, a fixed rod and a nozzle; the moving rod is positioned in a plane which is vertical to the fixed rod and is connected with the fixed rod; the radius rod is positioned in the plane vertical to the fixed rod; one end of the radius rod is connected with the fixed rod, and while the other end of the radius rod is connected with the nozzle; the radius rod drives the nozzle to rotate about the fixed rod. According to the spraying device, the radius rod can be rotated to drive the nozzle to rotate like an arc line about the fixed rod, in order to realize the coating of arc-shaped frame sealing glue; therefore, the limitation on the frame sealing glue spraying device in the coating of the arc-shaped frame sealing glue under the prior art can be overcome.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

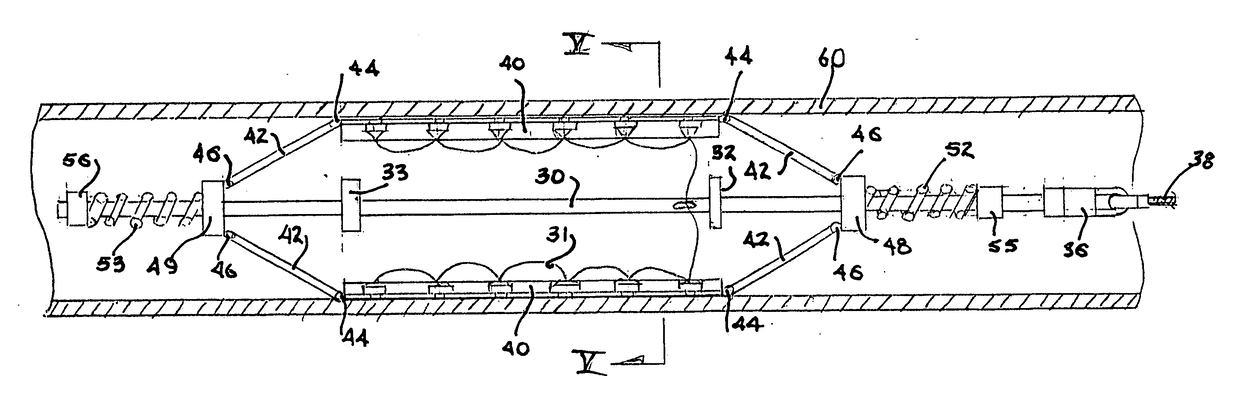

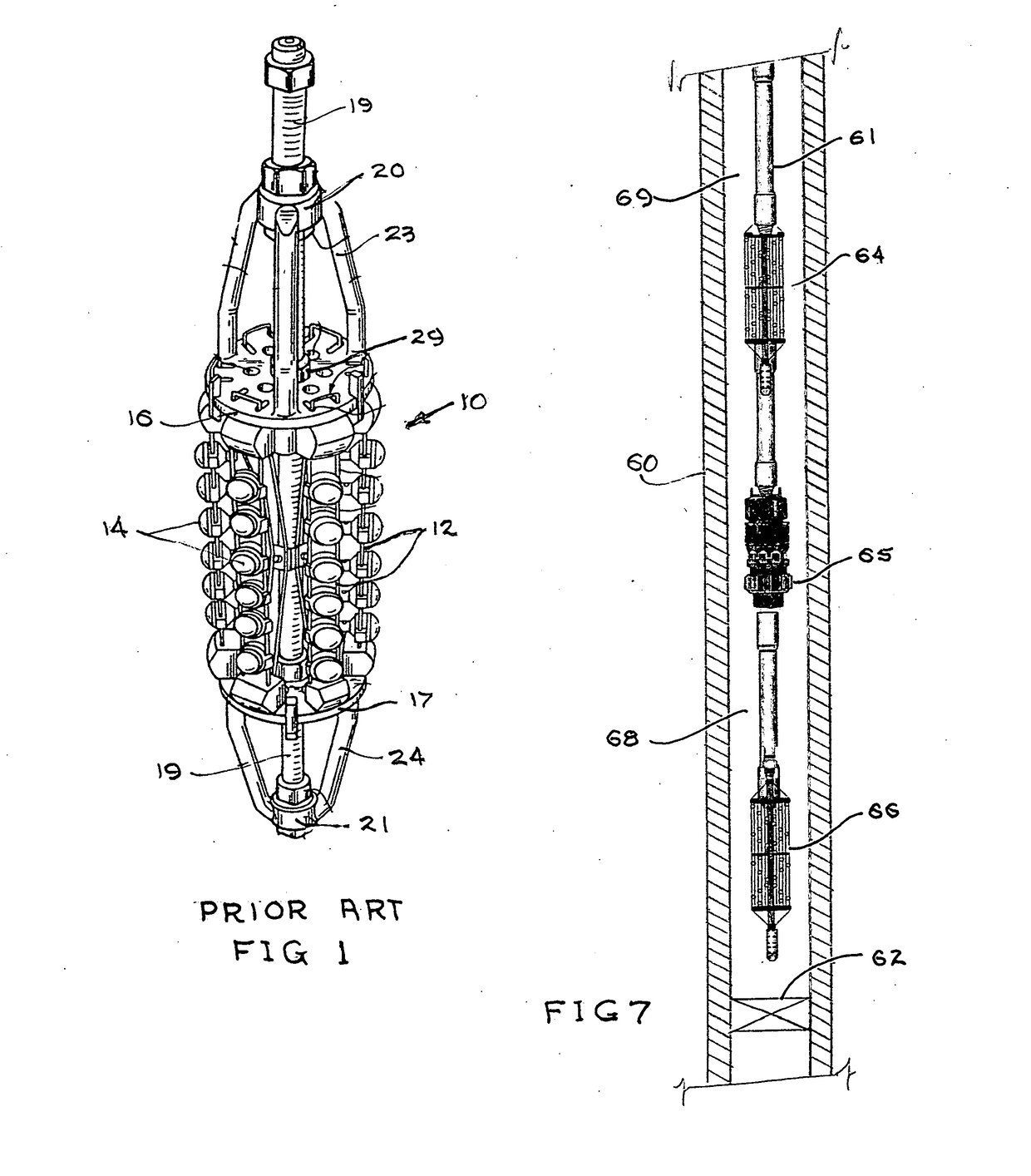

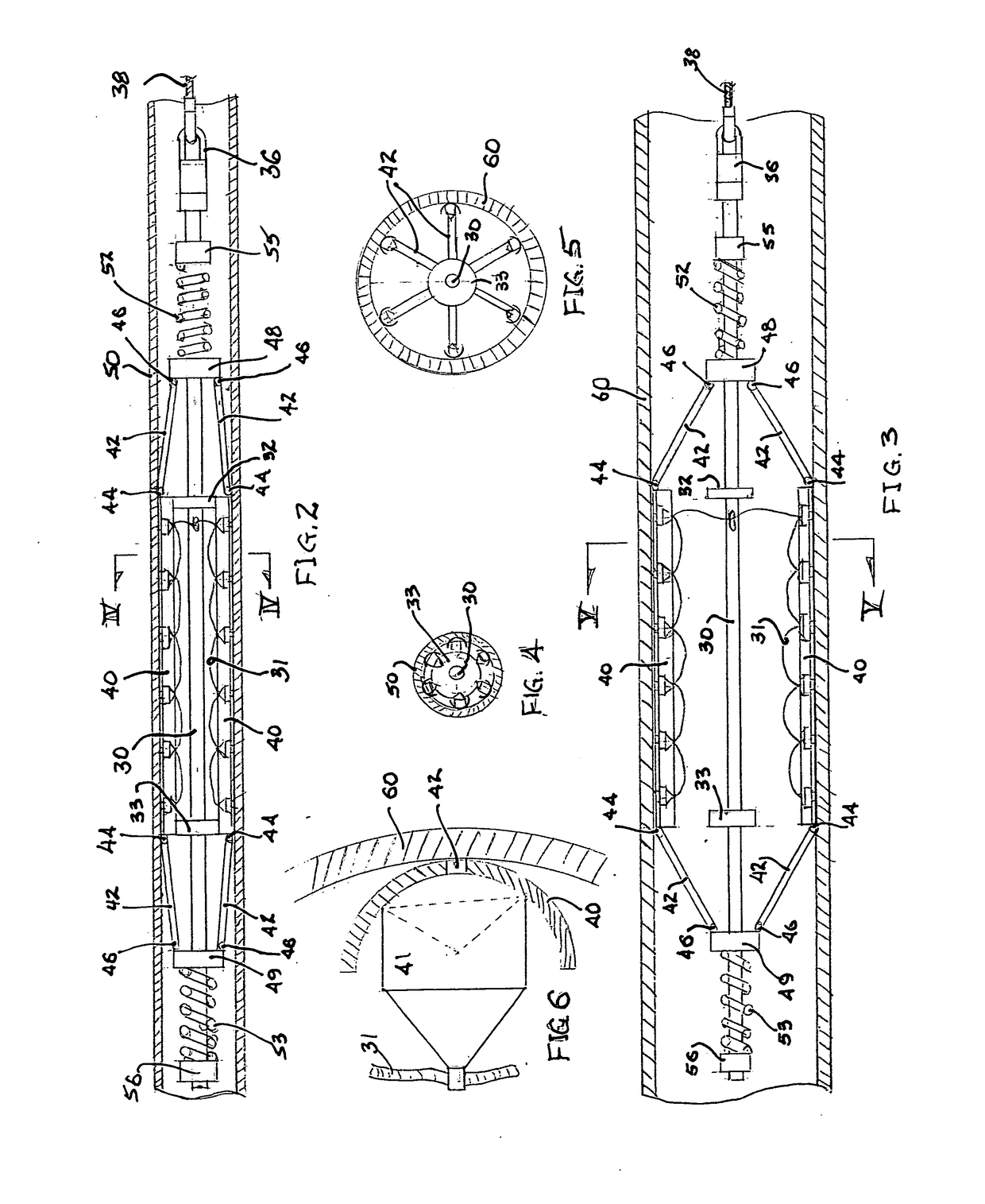

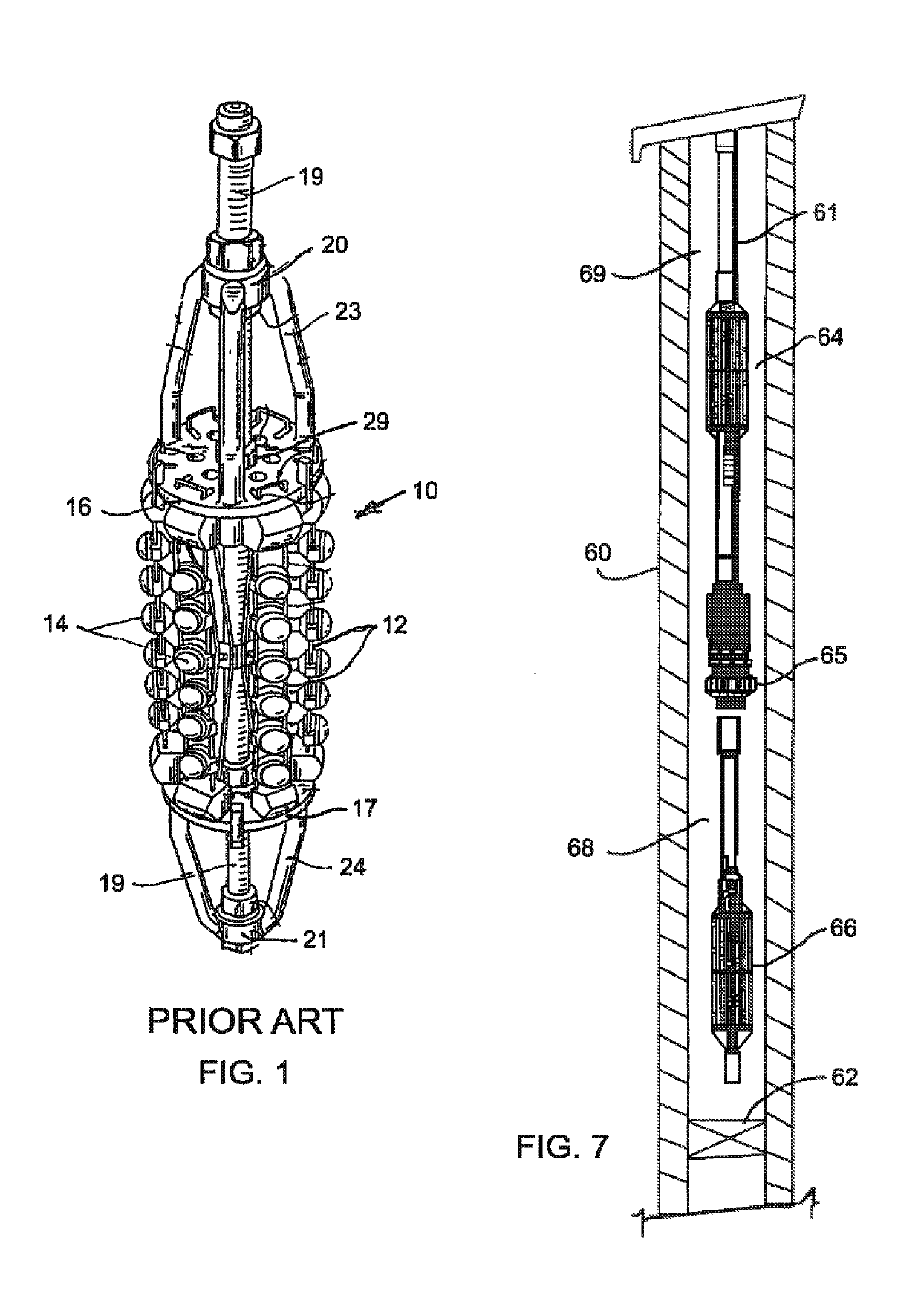

Total control perforator and system

A shaped charge carrier tool is provided that has particular utility for perforating well casing as a preparation for cement placement. A plurality, four or more elongated shaped charge carrier ribs having a high bending modulus are secured for radially expanded displacement around a central framing tube or rod. Radius rods link the ends of the carrier ribs to top and bottom hinge carriers. The hinge carriers encircle the framing tube and are free for axial translation along the framing tube. Articulating hinges connect the radius rods to the carrier ribs and to the hinge carriers. Opposed compressed coil springs provide a resilient bias on the hinge carriers to translate the carrier ribs radially outward against the interior surface of a well casing as the tool passes from a riser tube into a larger inside diameter well casing.

Owner:YELLOWJACKET OILFIELD SERVICES LLC

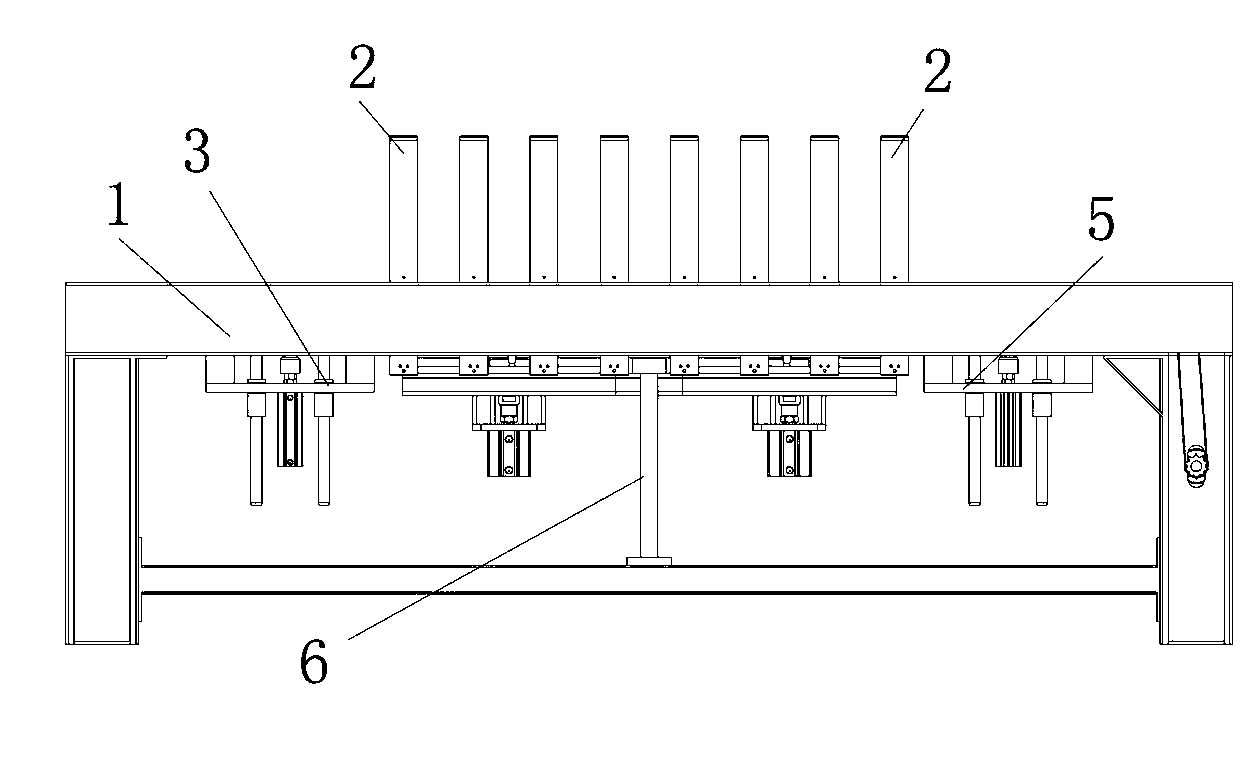

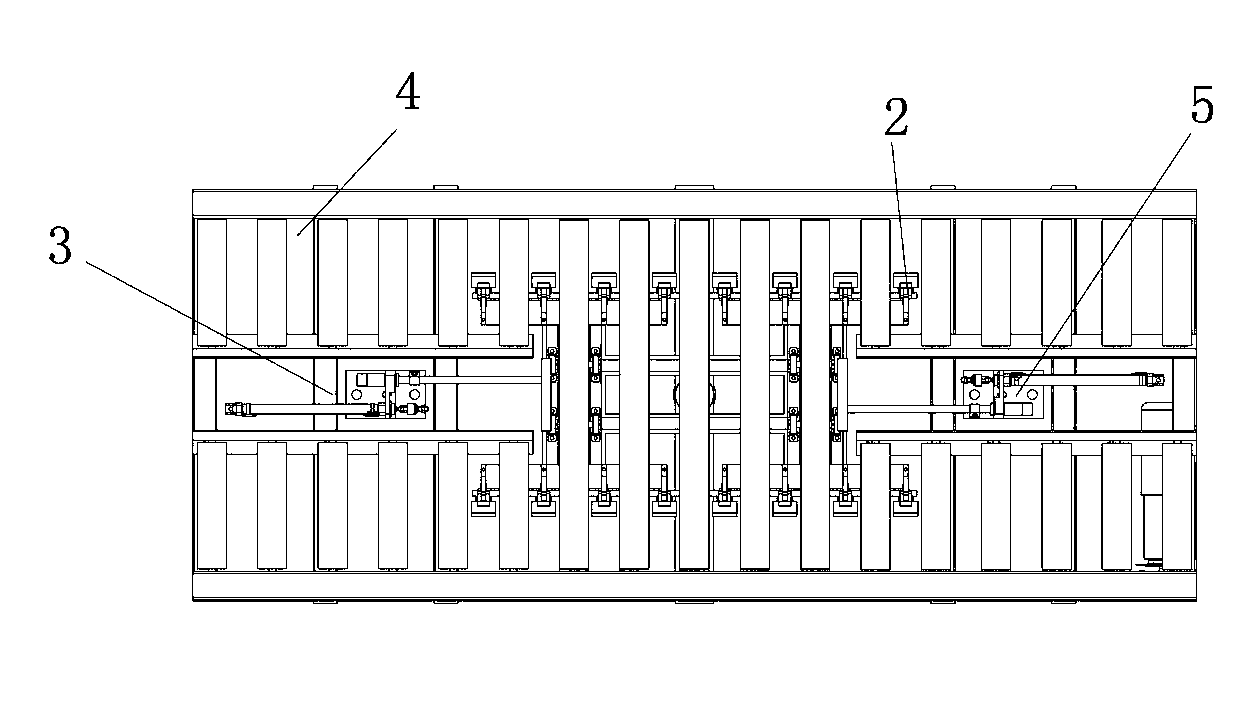

Locating mechanism for box packing device

The invention discloses a locating mechanism for a box packing device. The locating mechanism comprises a jacking support arranged on the middle portion of a drum-type transmission support, rotation shafts which are mutually parallel are arranged on two sides of the jacking support respectively, a plurality of location sheets are arranged on each rotation shaft at intervals, each location sheet can extends out from the position between adjacent rotary drums in the drum-type transmission support, a hinging seat is arranged on the middle portion of the lower section of each location sheet, a radius rod is connected onto the hinging seat, the other end of the radius rod is connected with the jacking support, a two-section-type connection arm construction member is arranged on each rotation shaft, the other end of the connection arm construction member is connected with the hinging seat fixed on the jacking support, the two-section-type connection arm construction member is connected with a driving motor below the jacking support, and a front locating mechanism and a back locating mechanism which are driven by a cylinder are respectively arranged at two ends of the jacking support. The locating mechanism can accurately locate electrical products on a production line and guarantees efficiency and quality of product packaging.

Owner:星派克智能装备(深圳)有限公司

Total control perforator and system

A shaped charge carrier tool is provided that has particular utility for perforating well casing as a preparation for cement placement. A plurality, four or more elongated shaped charge carrier ribs having a high bending modulus are secured for radially expanded displacement around a central framing tube or rod. Radius rods link the ends of the carrier ribs to top and bottom hinge carriers. The hinge carriers encircle the framing tube and are free for axial translation along the framing tube. Articulating hinges connect the radius rods to the carrier ribs and to the hinge carriers. Opposed compressed coil springs provide a resilient bias on the hinge carriers to translate the carrier ribs radially outward against the interior surface of a well casing as the tool passes from a riser tube into a larger inside diameter well casing.

Owner:YELLOWJACKET OILFIELD SERVICES LLC

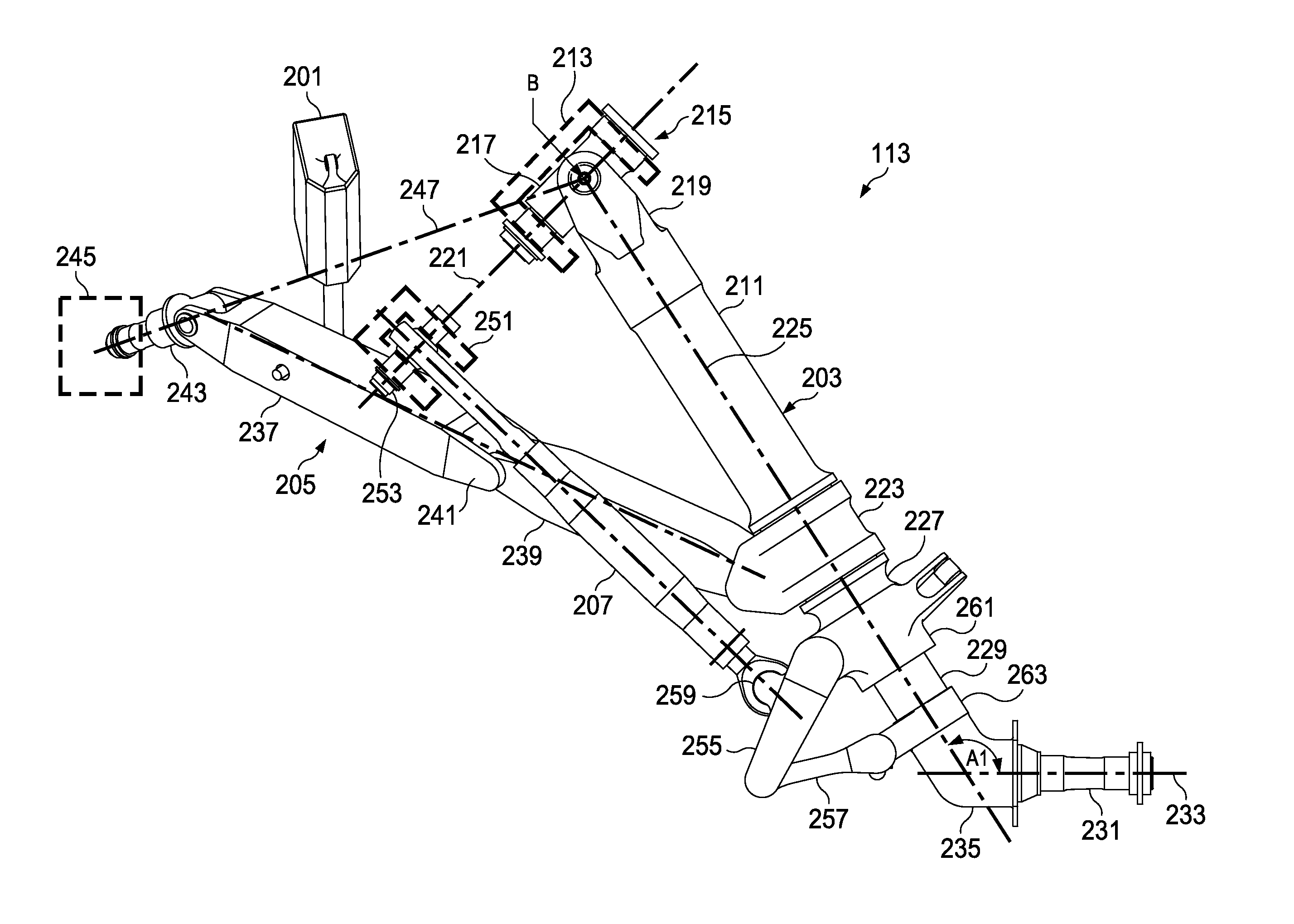

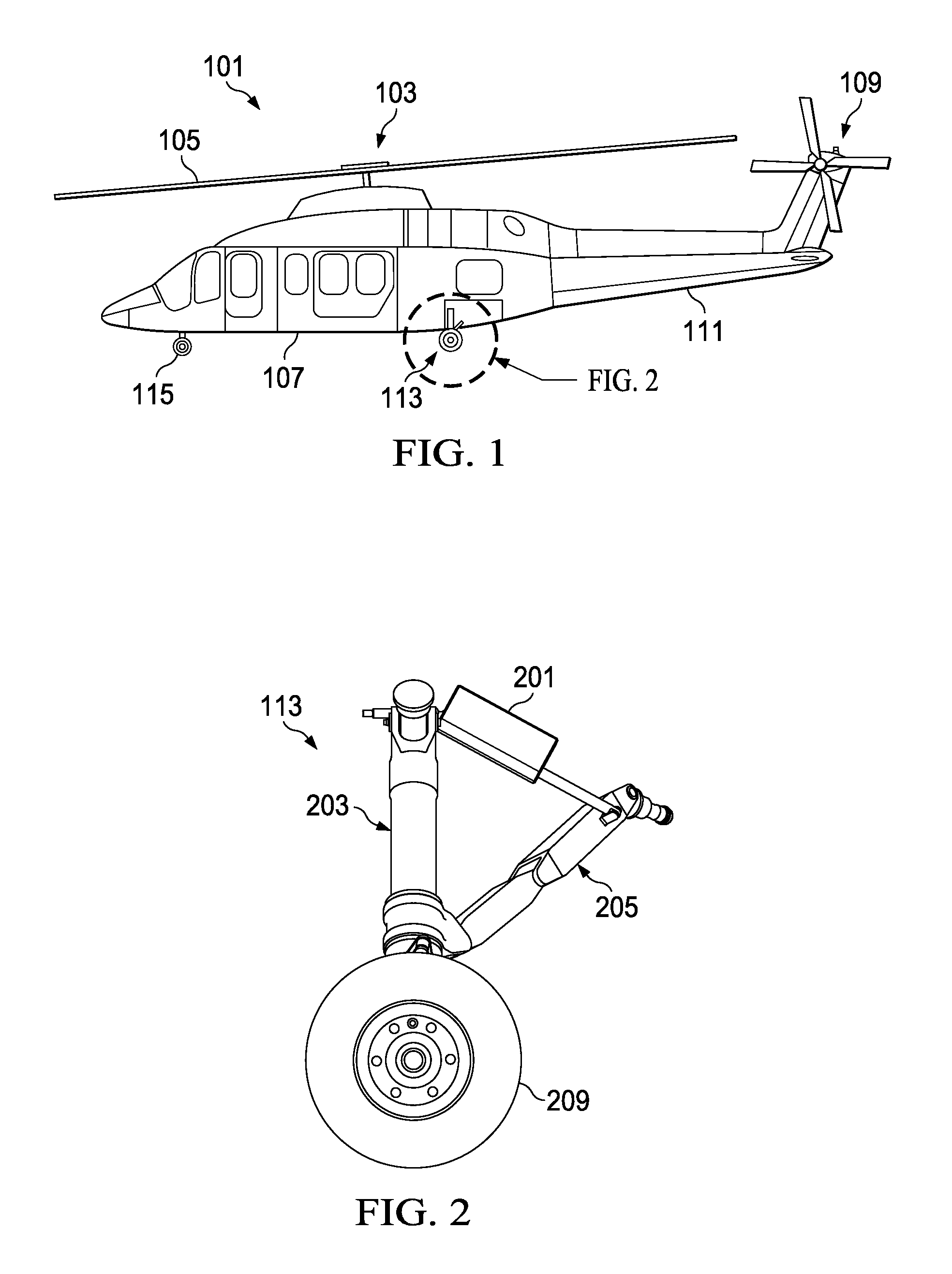

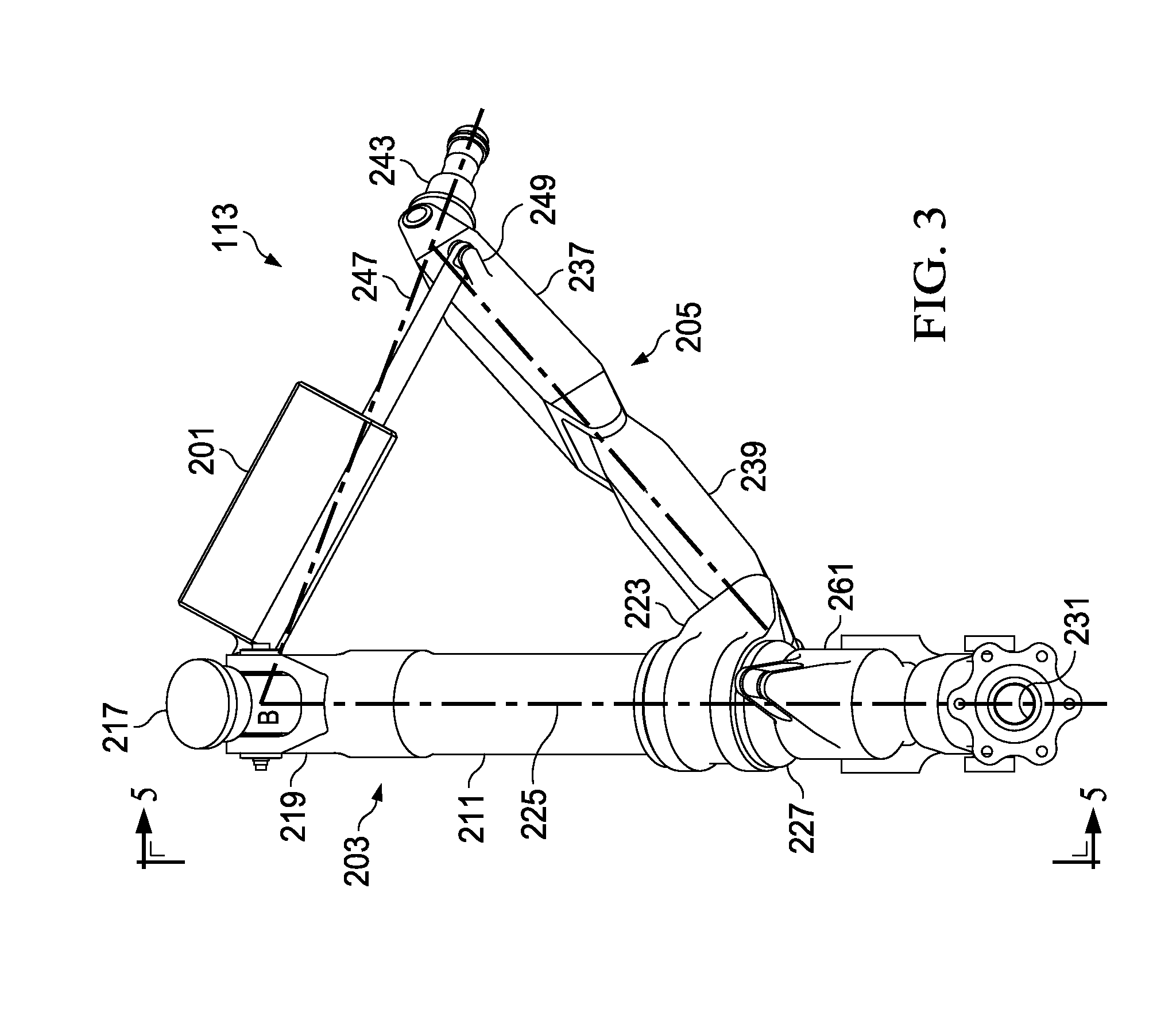

Semi-levered articulated landing gear system

The landing gear system for an aircraft includes a shock strut assembly that is coupled to the airframe with a universal joint. A tire member is mounted to the shock strut assembly. The landing gear system also includes a drag brace assembly coupled to an airframe of the aircraft with a spindle, the spindle being rotatable about a spindle axis. A radius rod is rotatably coupled to the airframe of the aircraft. The radius rod and the shock strut assembly are retractable about a retraction rotation axis. Further, the spindle axis has a common intersection point with the centerline axis and the retraction rotation axis. The orientation of the spindle axis causes a translation of the tire member to have a longitudinal component during a compression of the shock strut assembly.

Owner:BELL HELICOPTER TEXTRON INC

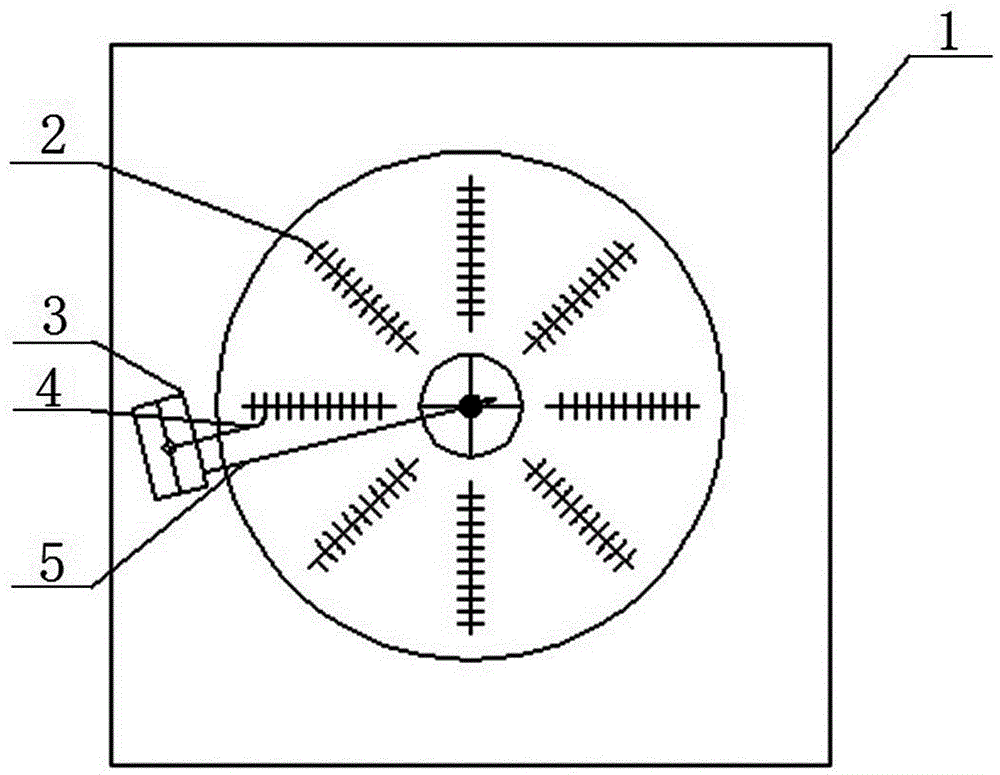

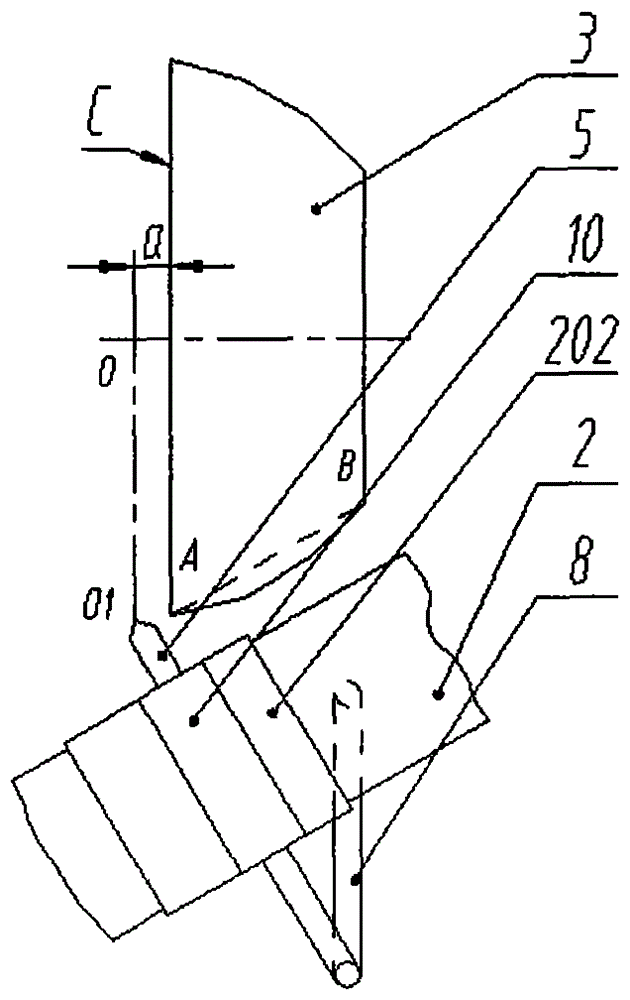

Annular plate groove cutting mold, cutting system and cutting method

InactiveCN106077887AFlexible positioningRapid positioningGas flame welding apparatusSteering wheelSemi automatic

The invention relates to the field of semi-automatic flame cutters, in particular to an annular plate groove cutting mold, a cutting system and a cutting method. The annular plate groove cutting system comprises a mold and a semi-automatic cutter; the mold includes a mold base, and a mold dial for placing an annular plate; the mold dial is arranged on the mold base; the center position of the mold dial is a positioning eye; a scale mark on the mold dial outwards extends along radius of the mold dial with the positioning eye as center; the semi-automatic cutter is positioned on the mold base, and includes a cutter body, a steering wheel, a cutting gun and a cutting circular radius rod; the cutting gun and one end of the cutting circular radius rod are both fixed on the semi-automatic cutter; and the other end of the cutting circular radius rod is put on the positioning eye. The mold and the semi-automatic cutter are reasonably joined, and the mold dial is flexibly applied, so that the position of the annular plate on the mold can be quickly positioned, the cutting point of a gun head can be quickly determined, and the production efficiency and the quality precision are greatly improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Radius Rod Spherical Surface Profiling Device

The invention discloses a radius rod spherical surface contour machining device. The radius rod spherical surface contour machining device comprises a sliding base, a sliding rod knife rest, a linkage rod, a radius rod and a rotary handle, and is characterized in that the sliding base is fixed on a large layer board of a large tool body and provided with the sliding rod knife rest; a cutting knife is arranged at one end of the sliding rod knife rest; the other end of the sliding rod knife rest is rigidly connected with the linkage rod; the other end of the linkage rod is hinged to one end of the radius rod; the effective length of the radius rod is equal to the radius of a workpiece spherical surface; the other end of the radius rod is rigidly connected to the rotary handle; the rotary handle is hinged to a small layer board of a small tool body. The radius rod spherical surface contour machining device is easy to machine, low in expense, high in universality, and capable of conveniently clamping parts, parts machined through the device are high in precision and low in cost, and the radius rod spherical surface contour machining device is an ideal contour machining device of large spherical surface parts.

Owner:SHAANXI UNIV OF TECH

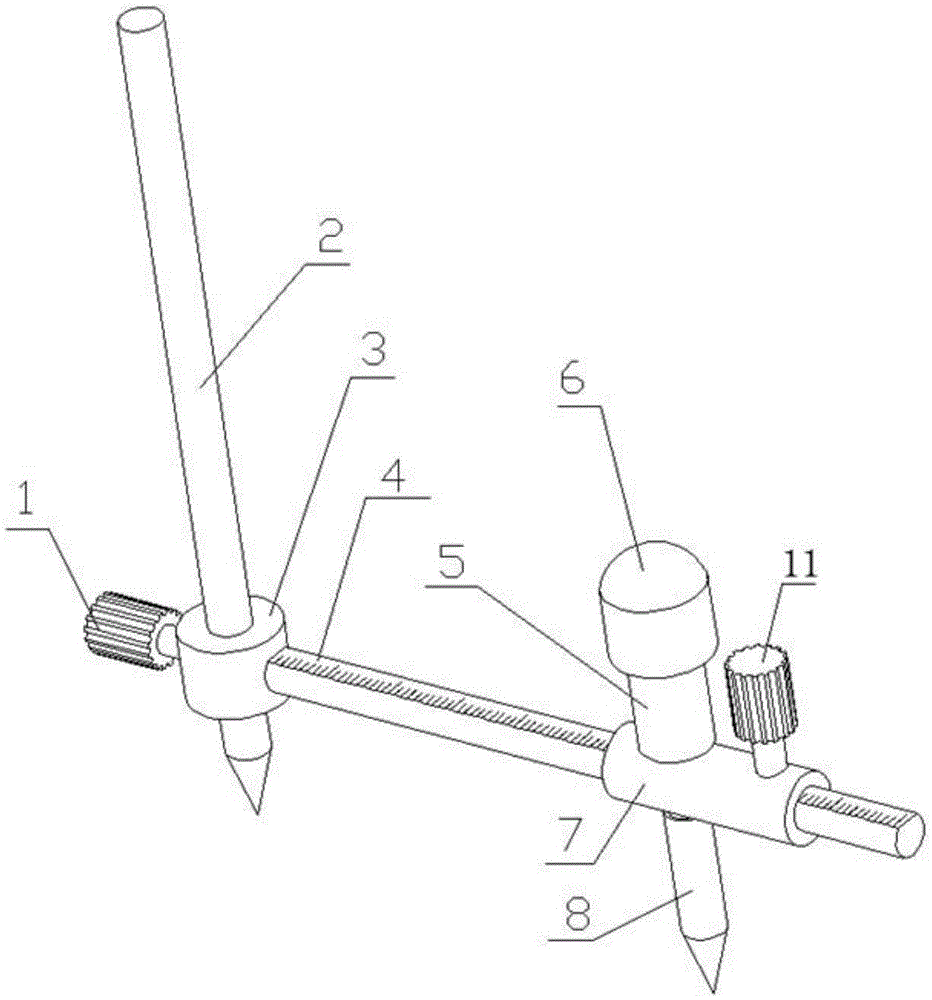

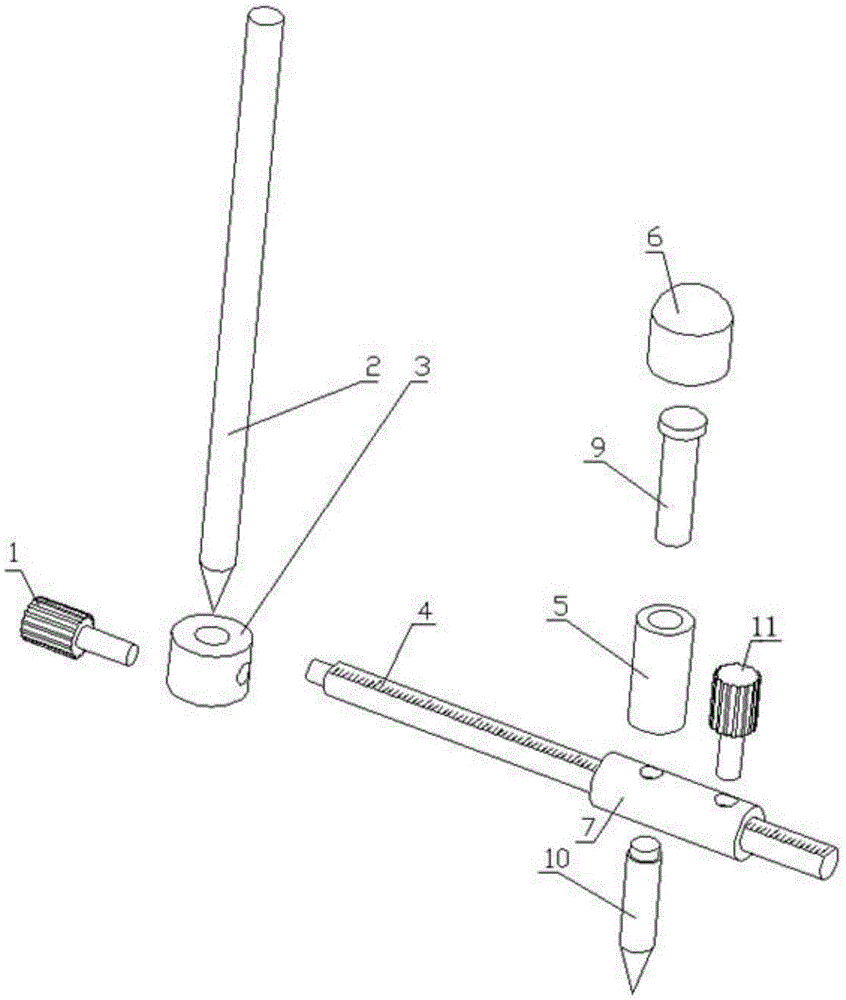

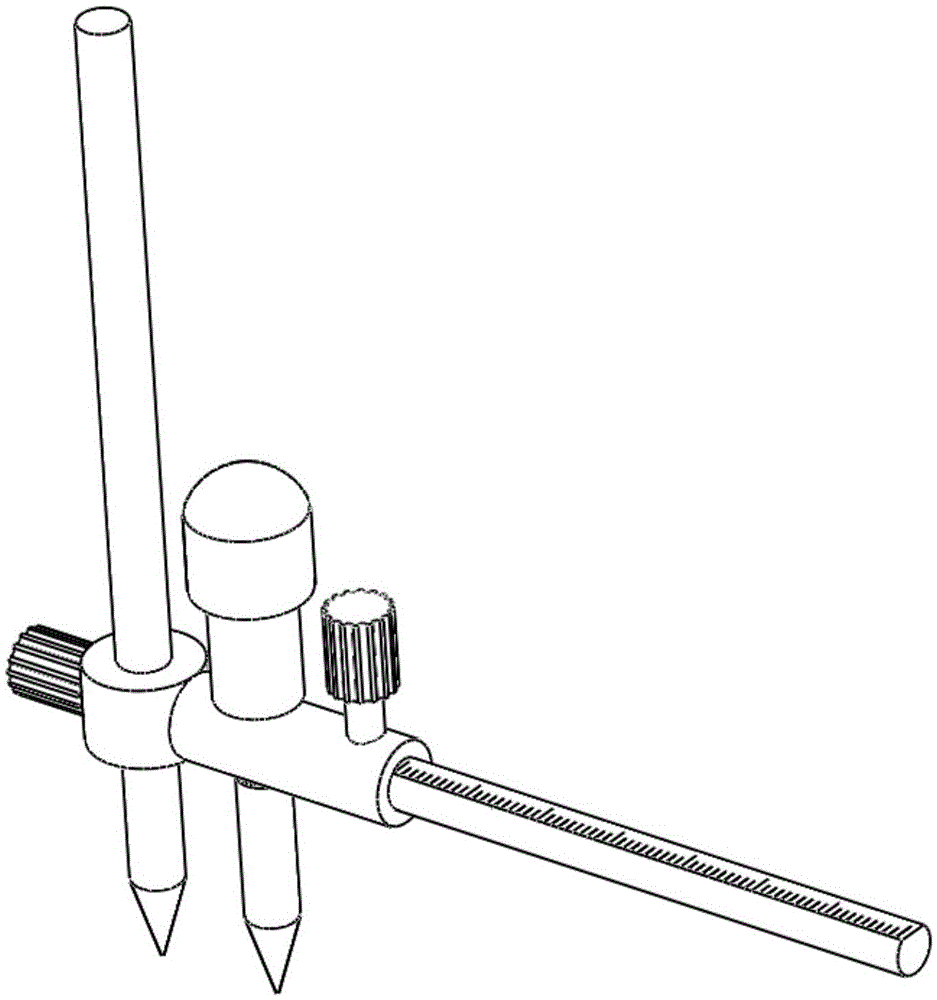

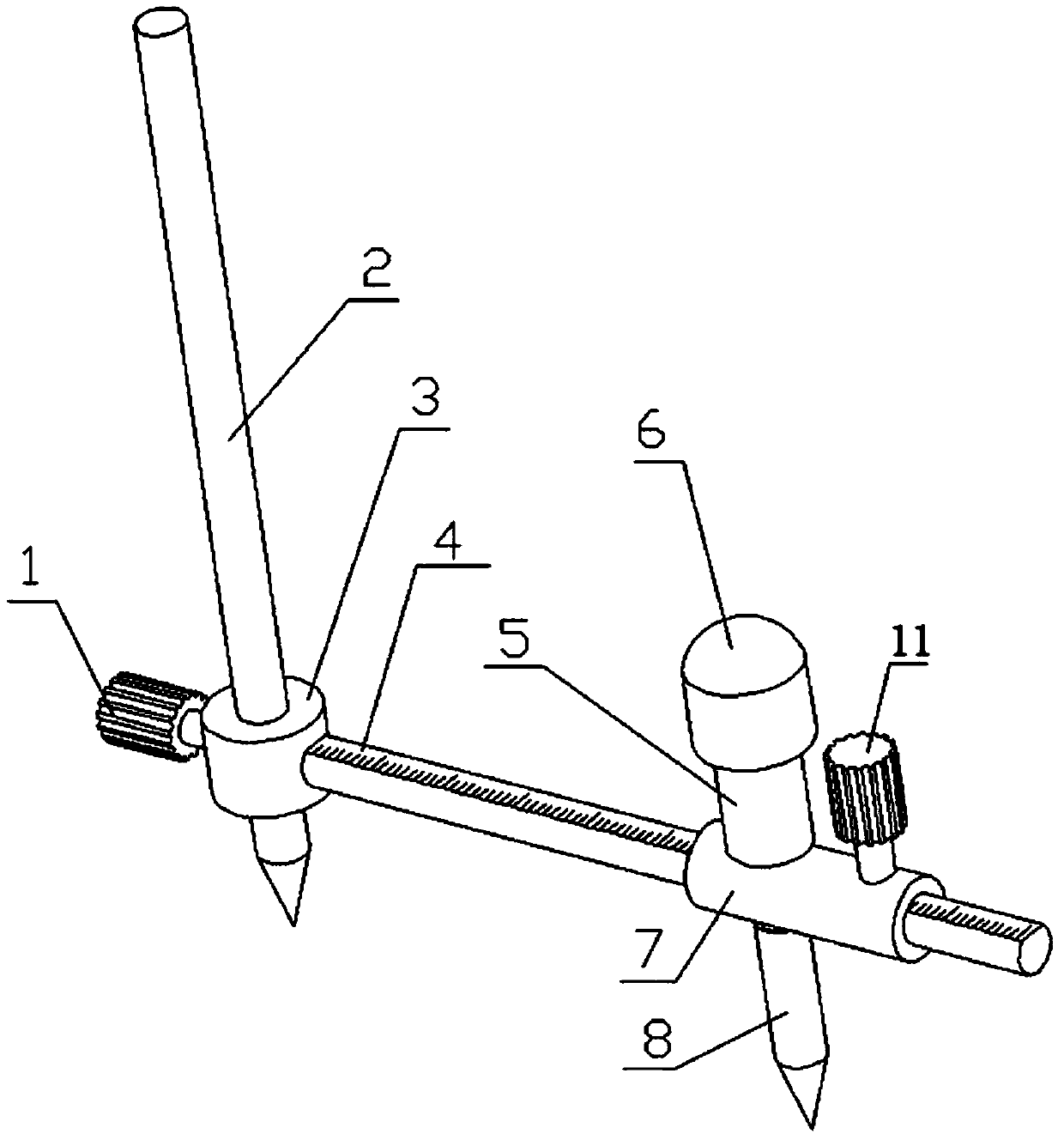

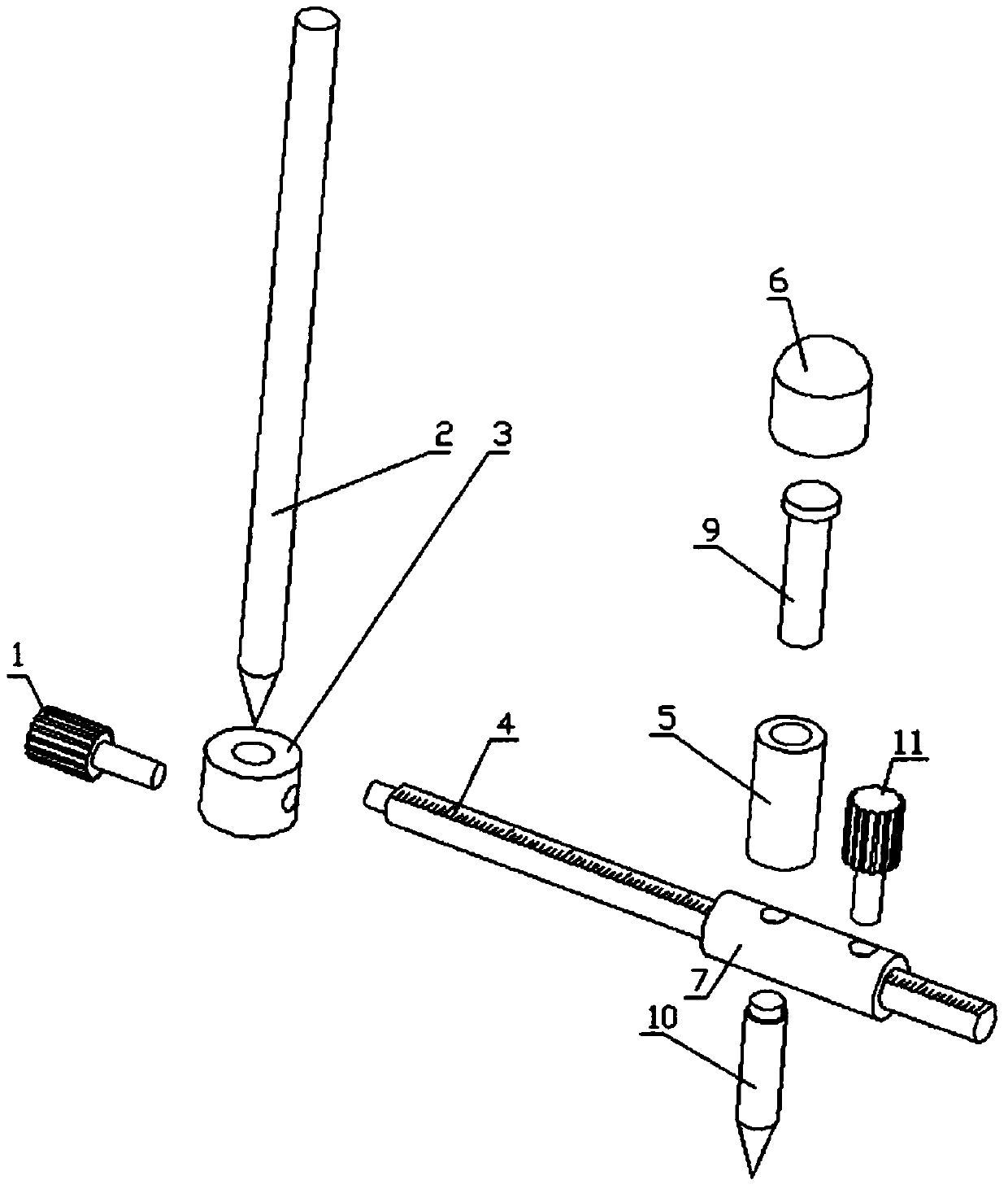

A kind of multifunctional adjustable diameter compass with graduated scale

InactiveCN104191873BEasy to adjustRealize the cutting functionCircular curve drawing instrumentsEngineeringRadius rod

The invention relates to multifunctional radius-adjustable compasses with scales. The multifunctional radius-adjustable compasses with the scales are characterized by comprising a first scale positioning bolt, a second scale positioning bolt, a pen, a pen holder, a radius rod, a fixing tube and a circle center fixing needle, wherein the pen is connected with the radius rod through the pen holder and the first scale positioning bolt; the circle center fixing needle is connected with the radius rod through a fixing tube; and the fixing tube is also provided with the second scale positioning bolt. The circle center fixing needle can move along the radius rod with length scale values, so that the radius can be accurately adjusted; circles and arcs can be conveniently scratched on surfaces of parts made of different materials; and the parts can be trimmed along the circles or the arcs.

Owner:HOHAI UNIV CHANGZHOU

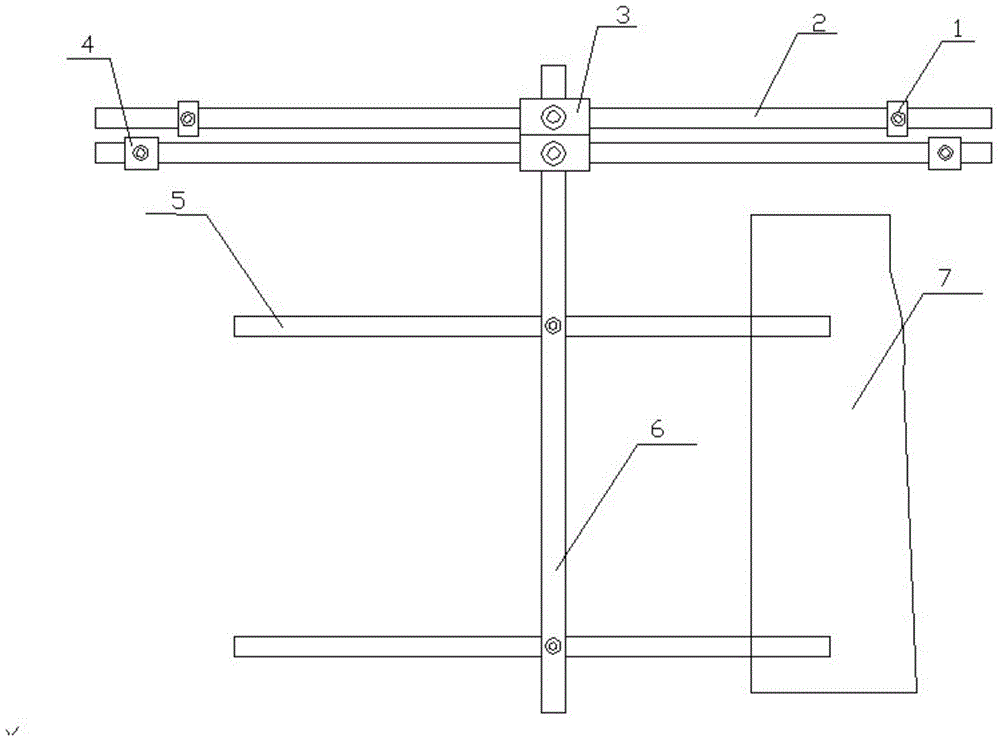

Carrying steel welding reinforcement measuring device

InactiveCN104677233ASimple structureNovel and reasonable designMechanical measuring arrangementsWeld seamEngineering

The invention provides a carrying steel welding reinforcement measuring device, which comprises a center pipe shaft and two mutually parallel horizontal pipes, wherein the two mutually horizontal pipes are arranged on the top end of the center pipe shaft and are vertical to the center pipe shaft, the horizontal pipes are respectively fixed on the top end of the center pipe shaft through shaft sleeves via screw bolts, the two ends of the upper horizontal pipe are fixedly provided with slide blocks for regulating the inner diameter of the upper horizontal plane, the two ends of the lower horizontal pipe are fixedly provided with slide blocks for regulating the outer diameter of the upper horizontal plane, and the middle part and the lower part of the center pipe shaft are respectively and movably connected with adjustable stainless steel radius rods through screw bolts. The carrying steel welding reinforcement measuring device has the advantages that the structure is simple, the design is novel and reasonable, the work reliability is high, the service life is long, the carrying steel welding reinforcement measuring device can be used for fast and conveniently completing the carrying steel inner wall reinforcement measurement, the workload of inspection personnel can be reduced, and the welding seam reinforcement can be accurately measured.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

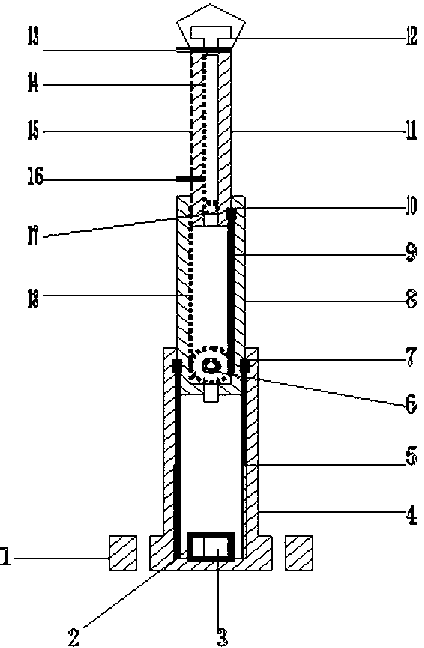

Automatic-control flag lifting device

The invention discloses an automatic-control flag lifting device. the automatic-control flag lifting device comprises an automatic controller, a storage battery, a lower chute, a lower gear, a sliding clamp, a middle chute, an upper sliding clamp, an upper gear groove, an upper gear, a middle gear groove, a fixing seat, a lower radius rod, a middle radius rod, an upper radius rod, a blower, an upper pull-tab, a blowing hole and a lower pull-tab, wherein the automatic controller and the storage battery is arranged in the inner side of the fixing seat. The lower chute is arranged at the inner side wall of the lower radius rod. The lower gear is arranged on the inner side of the middle radius rod. The middle sliding clamp is arranged at the lower end of the middle radius rod. The middle chute is arranged on the inner side of the middle radius rod. The upper sliding clamp is arranged on the lower side of the upper radius rod. The upper gear groove is arranged on the inner side of the upper radius rod. The upper gear is arranged on the inner side of the upper radius rod. The middle gear groove is arranged on the inner side of the middle radius rod. The fixing seat is connected with the lower radius rod. The lower radius rod is connected with the upper portion of the fixing seat, and the inner side of the fixing seat is sleeved with the outer side of the middle radius rod. The middle radius rod is sleeved in the lower radius rod. The upper radius rod is sleeved in the middle radius rod. The blower is sleeved with the upper radius rod. The upper pull-tab and the lower pull-tab are arranged at one side of the upper radius rod in a parallel mode, and the blowing hole is formed between the upper radius rod and the upper pull-tab.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

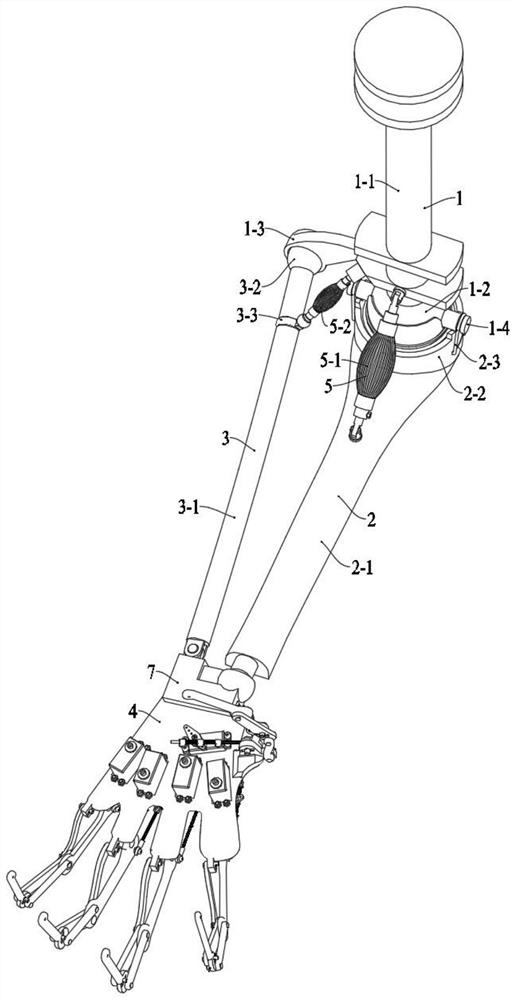

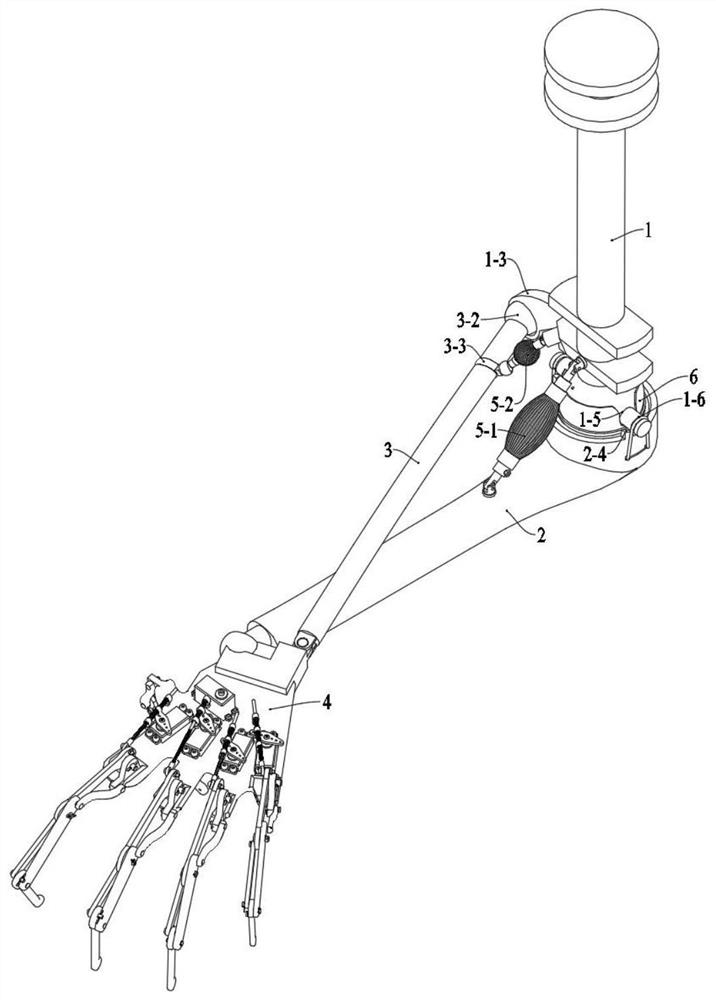

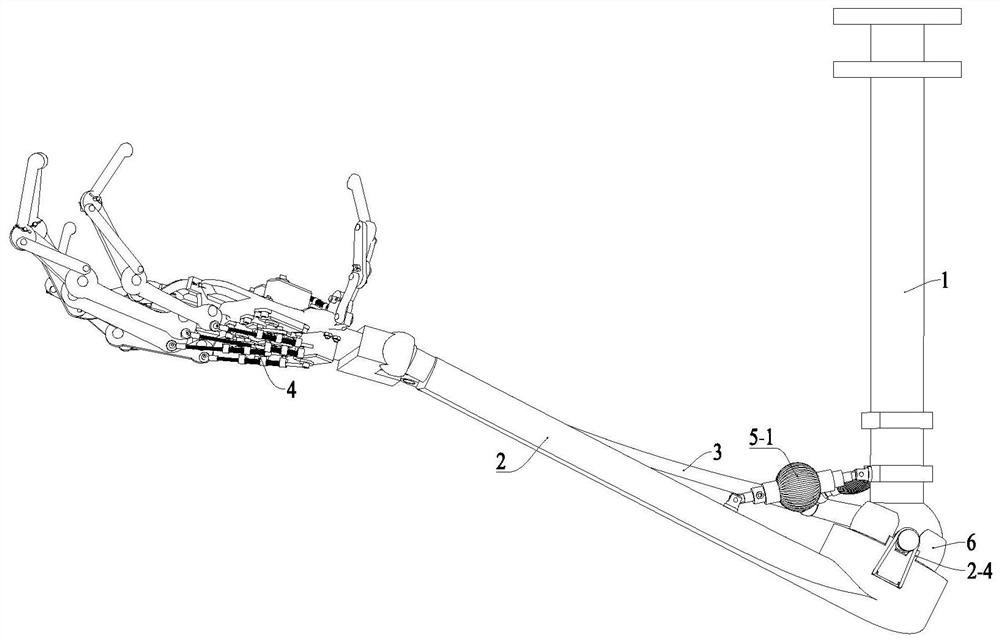

A reversible impact-resistant mechanical arm and its driving method

ActiveCN112720444BReduce harmDislocation is easy to recoverProgramme-controlled manipulatorGripping headsPhysical medicine and rehabilitationRobotic arm

Owner:HANGZHOU DIANZI UNIV

Automatically folding spraying rod

ActiveCN106436533AReduce the risk of workChange the way of drilling under the chassis of the synchronous gravel sealerRoads maintainenceAutomatic controlCoupling

The invention discloses an automatically folding spraying rod. The automatically folding spraying rod comprises a main spraying rod and spraying radius rods on the two sides of the main spraying rod, wherein motor supports and rotule are arranged on the two ends of the main spraying rod, motors are assembled on the motor supports, and motor output shafts are connected to input flanges through couplings; the input flanges are connected to the spraying radius rods through connecting pipes; torques of the motors are transmitted to the input flanges through the couplings and further to the rotule so as to make the connecting pipes drive the spraying radius rods to fold or unfold. The automatically folded spraying rod changes the method that workers have to get under a chassis of a synchronous surface dressing machine to work, achieves automatic control through a button over the spraying rod which is difficult and dangerous to operate and needs to be unfolded and folded through manual work, thus improving comfort of operation and reducing danger in work under the chassis. Through the coordination between electric and hydraulic pressure, multiple functions such as automatic folding and unfolding, location and stop of the spraying rod are achieved.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

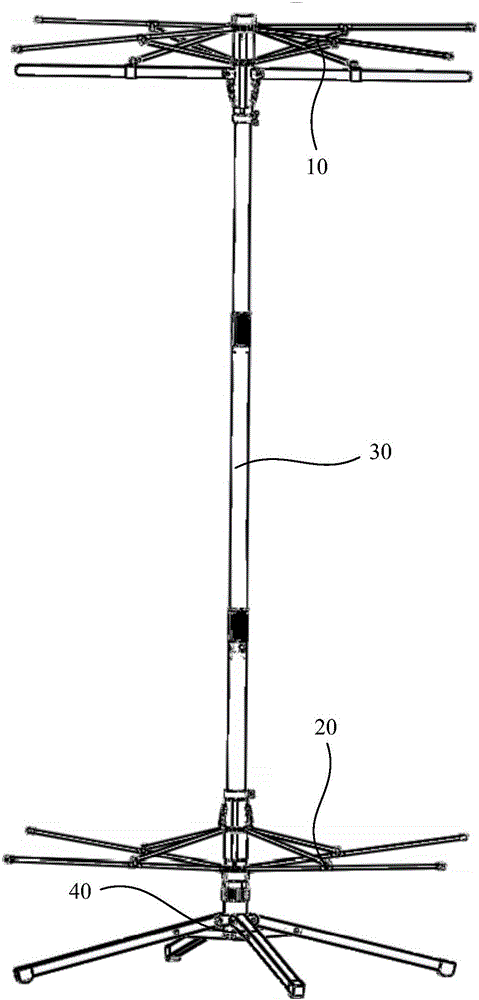

Folding drying cabinet

PendingCN106758070ASimple structureEasy to assemble and disassembleTextiles and paperLaundry driersSelf lockingEngineering

The invention discloses a folding drying cabinet. The folding drying cabinet comprises an upper framework, the upper framework is detachably arranged on the upper end of the drying cabinet and comprises a sliding sleeve, a fixed sleeve, an outer supporting rod, an inner supporting rod, a hanging radius rod, and a pulling rod, wherein the sliding sleeve and the fixed sleeve are connected through a sliding pair, the outer supporting rod and the inner supporting rod are connected to the fixed sleeve and the sliding sleeve through revolute pairs respectively, the hanging radius rod is rotationally connected to the sliding sleeve, the pulling rod is connected to the fixed sleeve through a revolute pair, the other end of the inner supporting rod is connected to a sliding cylinder which is arranged on the outer supporting rod in a sleeving mode through the revolute pair, the other end of the pulling rod is connected to a sliding bushing which is arranged on the hanging radius rod in a sleeving mode, and a self-locking switch is further arranged between the fixed sleeve and the sliding sleeve; the folding drying cabinet further comprises a lower framework, a telescopic supporting rod, a bottom support and fabric covering, wherein the lower framework is detachably arranged at the lower end of the drying cabinet, and the structure of the lower framework is the same with that of the upper framework but the lower framework is not provided with a hanging radius rod and a pulling rod; the upper and lower end of the telescopic supporting rod are fixedly connected to the upper framework and the lower framework respectively; the bottom support is located below the lower framework and supports the lower framework; the fabric covering covers the upper framework, the lower framework and the telescopic supporting rod so as to form drying space.

Owner:卢报新

Fluid refining device

ActiveCN101658768BEasy to adjustAvoid mutual influenceFlow mixersMixing methodsEngineeringGas-filled tube

The invention relates to a fluid refining device, in particular relating to a device for refining mixed liquid. The device comprises a tubular housing and a spiral piece arranged in the tubular housing, wherein, the spiral piece is composed of a plurality of gaskets in an overlying manner; the intermediate shape of the gasket is a round disc; the periphery of the disc is provided with bulged blades to form a cross; each gasket in the rear and each gasket in the front stagger an angle to form a rotating spiral piece the screw pitch of which gradually diminishes from an inflow end to an outflowend; the entry end of a center shaft of the spiral piece is provided with a cone-shape screw cap; the two ends of the spiral piece are provided with support rings which are fixed with the center shaft through a radius rod. The scheme can be used in multiple liquid mixing modes, cancels a bearing seat, reduces the volume of the device, has convenient installation, utilizes the cone-shape screw capto reduce the resistance entering the liquid, and utilizes a gas filled tube to lead the mixing of gas and liquid to be more convenient. The scheme has simple structure, can adjust the screw pitch ofthe spiral piece according to actual condition, and reduces cost.

Owner:扈佳玉

Positioning mechanism used in boxing devices

The invention discloses a locating mechanism for a box packing device. The locating mechanism comprises a jacking support arranged on the middle portion of a drum-type transmission support, rotation shafts which are mutually parallel are arranged on two sides of the jacking support respectively, a plurality of location sheets are arranged on each rotation shaft at intervals, each location sheet can extends out from the position between adjacent rotary drums in the drum-type transmission support, a hinging seat is arranged on the middle portion of the lower section of each location sheet, a radius rod is connected onto the hinging seat, the other end of the radius rod is connected with the jacking support, a two-section-type connection arm construction member is arranged on each rotation shaft, the other end of the connection arm construction member is connected with the hinging seat fixed on the jacking support, the two-section-type connection arm construction member is connected with a driving motor below the jacking support, and a front locating mechanism and a back locating mechanism which are driven by a cylinder are respectively arranged at two ends of the jacking support. The locating mechanism can accurately locate electrical products on a production line and guarantees efficiency and quality of product packaging.

Owner:星派克智能装备(深圳)有限公司

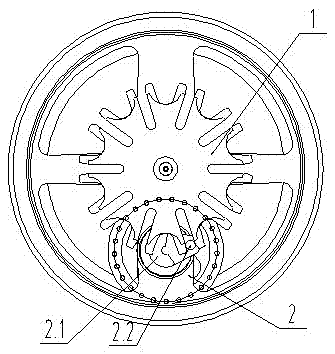

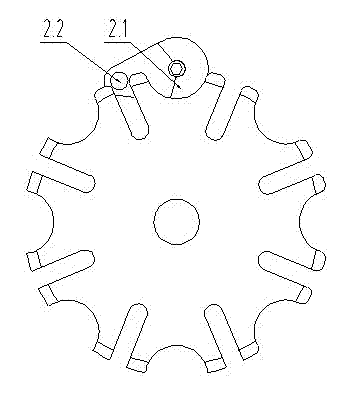

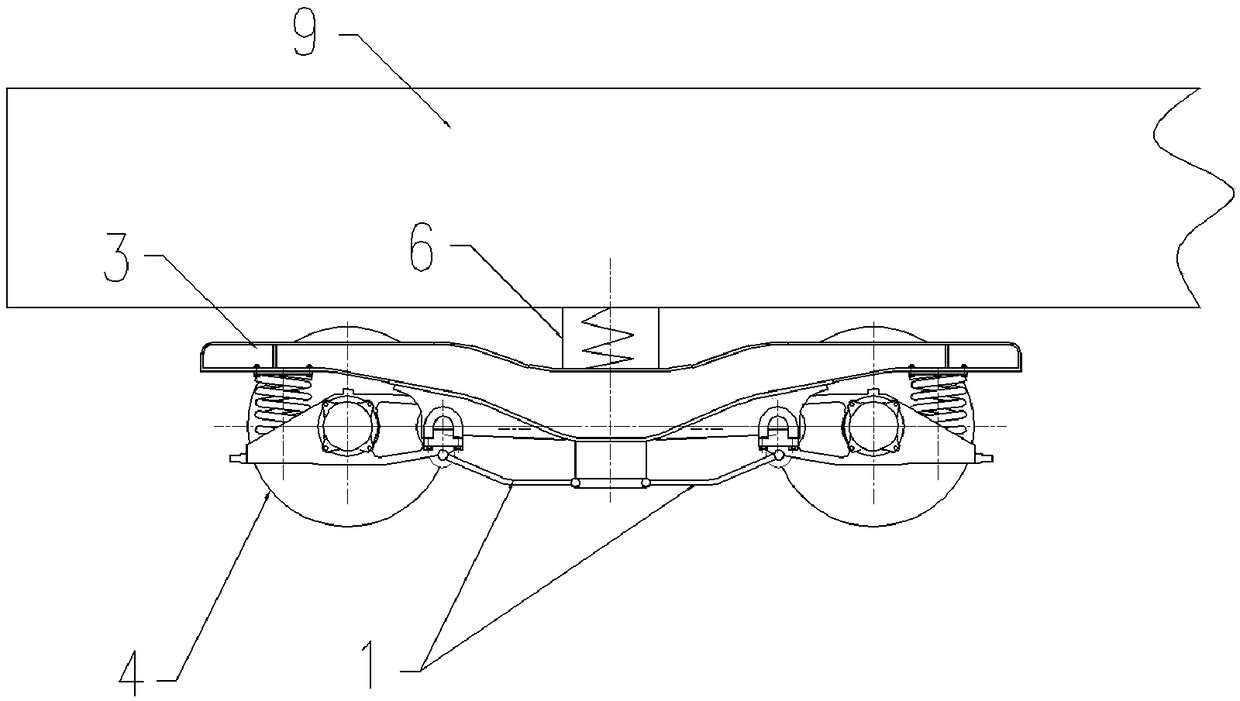

Spaced reversing grooved wheel mechanism

InactiveCN102767602AExtended guide sectionEliminate free zoneGearingGreat circleMechanical engineering

The invention belongs to the technical field of dust removing equipment, and relates to dust removing equipment, in particular to a spaced reversing grooved wheel mechanism for a single-suction dust removing unit. The spaced reversing grooved wheel mechanism comprises a grooved wheel (1) and a crankwheel (2), which are matched with each other. A limiting wheel (2.1) and stirring rods (2.2) are arranged on the crankwheel (2). The outer circle of the grooved wheel is step-shaped. The radius R of a small circle of the grooved wheel (1) remains unchanged, and the radius of a large circle of the grooved wheel (1) is increased to be a center distance a of the crankwheel (2). The spaced reversing grooved wheel mechanism comprises the grooved wheel (1) and the crankwheel (2), which are matched with each other, the limiting wheel (2.1) and the stirring rods (2.2) are arranged on the crankwheel (2), the outer circle of the grooved wheel (1) is step-shaped, the radius R of the small circle of the grooved wheel (1) remains unchanged, and the radius of the large circle of the grooved wheel (1) is increased to be the center distance a of the crankwheel (2).

Owner:JIANGSU JINGYA ENVIRONMENT TECH

A spraying device and spraying method for a display panel

ActiveCN104307669BOvercome limitationsLiquid surface applicatorsSpraying apparatusSpray nozzleEngineering

The embodiment of the invention provides a spraying device and method for a display panel. The spraying device comprises a moving rod, a radius rod, a fixed rod and a nozzle; the moving rod is positioned in a plane which is vertical to the fixed rod and is connected with the fixed rod; the radius rod is positioned in the plane vertical to the fixed rod; one end of the radius rod is connected with the fixed rod, and while the other end of the radius rod is connected with the nozzle; the radius rod drives the nozzle to rotate about the fixed rod. According to the spraying device, the radius rod can be rotated to drive the nozzle to rotate like an arc line about the fixed rod, in order to realize the coating of arc-shaped frame sealing glue; therefore, the limitation on the frame sealing glue spraying device in the coating of the arc-shaped frame sealing glue under the prior art can be overcome.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Multifunctional radius-adjustable compasses with scales

InactiveCN104191873AEasy to adjustRealize the cutting functionCircular curve drawing instrumentsEngineeringLength scale

The invention relates to multifunctional radius-adjustable compasses with scales. The multifunctional radius-adjustable compasses with the scales are characterized by comprising a first scale positioning bolt, a second scale positioning bolt, a pen, a pen holder, a radius rod, a fixing tube and a circle center fixing needle, wherein the pen is connected with the radius rod through the pen holder and the first scale positioning bolt; the circle center fixing needle is connected with the radius rod through a fixing tube; and the fixing tube is also provided with the second scale positioning bolt. The circle center fixing needle can move along the radius rod with length scale values, so that the radius can be accurately adjusted; circles and arcs can be conveniently scratched on surfaces of parts made of different materials; and the parts can be trimmed along the circles or the arcs.

Owner:HOHAI UNIV CHANGZHOU

Network frame house cap integral lifting construction method

Disclosed is a construction method for lifting whole spatial grid roof structure, pertaining to the technical field of lifting a spatial grid roof structure. The spatial grid roof structure at which the method aims is composed of the connection of node spheres and tie bars; the whole spatial grid roof structure is supported and fixed by an upright column. The construction method is characterized by comprising the steps that: arranging a bearing upright column, connecting a lower girder, adjusting a radius rod, lifting an upper girder, installing a jack, arranging a bending- resistant lead, removing the original connection of the spatial grid roof structure, starting the jack to jack the whole spatial grid roof structure, padding the upper girder and jacking again, lengthening a connectingupright column and removing jacking facilities. The construction method adopts the combination of a hydraulic jack and girder multipoint supporting structure and directly jacks the whole spatial gridroof structure, which can shorten construction period, reduce construction amount as well as makes full use of the original structure; the construction method has components and equipment which are easy for manufacturing and convenient transportation and assembly, reduces project expenses, is fast and highly efficient, has low expense and is applicable to the heightening improvement of spatial grid roofs with various structures, such as circle, polygon, irregular odd shape, etc.

Owner:冯贵法

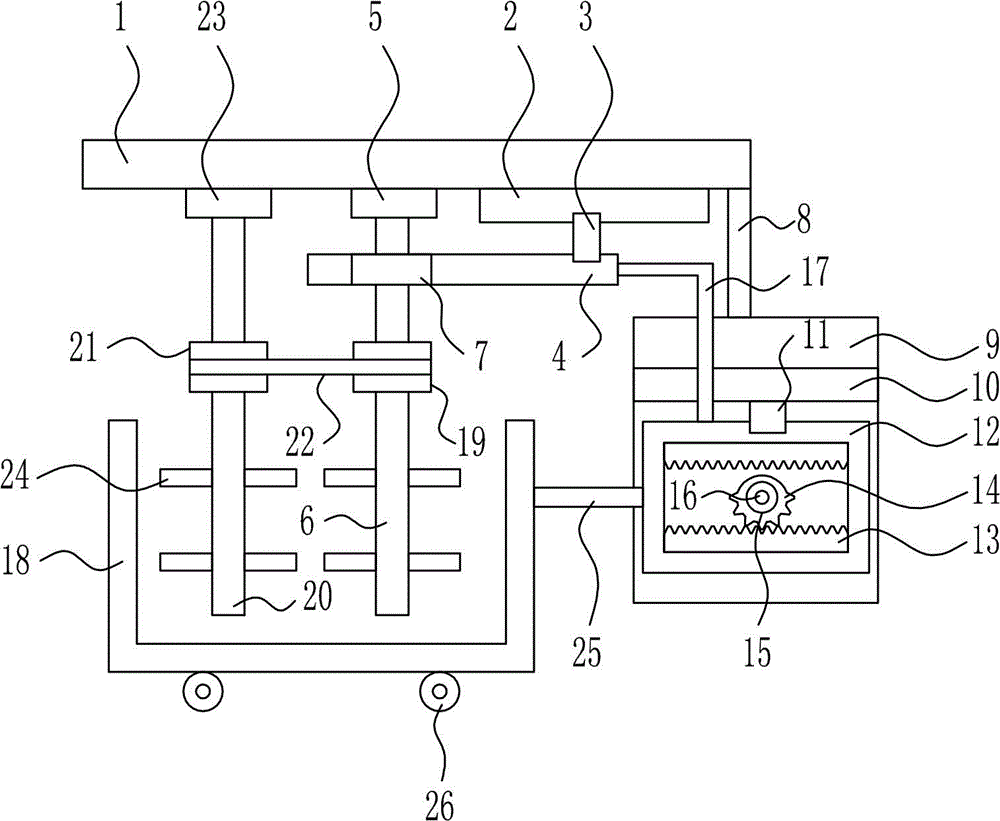

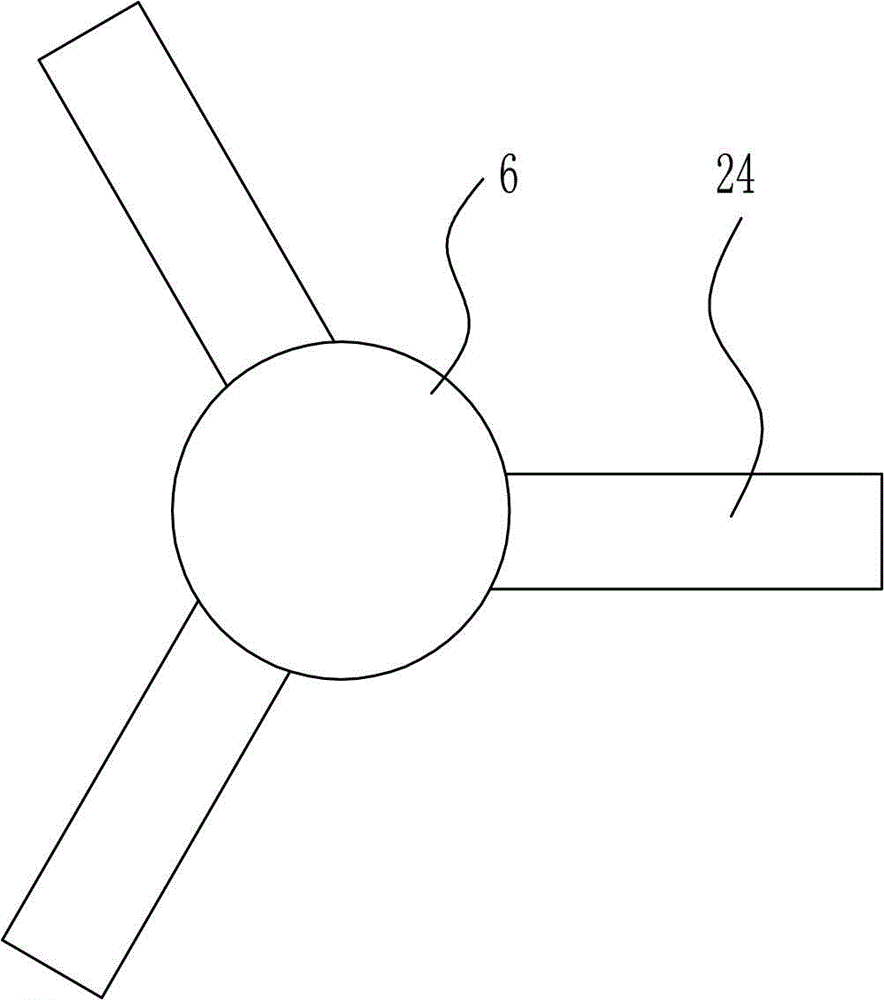

An anaerobic reaction tank for treating excrement from intensive cattle farms

InactiveCN104649728BSmall footprintMixed stronglyBio-organic fraction processingClimate change adaptationHeifer calfBiochemical engineering

The invention discloses an anaerobic reaction tank for processing intensive cattle farm excreta. The outer layer of the anaerobic reaction tank is designed with a jacket structure and the inside of the anaerobic reaction tank is provided with a stirring plate, wherein the stirring plate is composed of a stirring plate main rod, a stirring plate port, a stirring plate radius rod and a stirring plate wing rod; the stirring plate main rod is fixed on a rotary shaft; the included angle between the adjacent stirring plate main rods is 30-90 degrees; and two ends of the rotary shaft are provided with sealing rings and are connected with the tank body through a bearing. The anaerobic reaction tank is horizontally designed, and the draw ratio is 1: (1-4). The space between the jacket and the anaerobic reaction tank body is 20-40 mm; and the cross section of the stirring plate port is round or oval. The anaerobic reaction tank is in a jacket design for providing energy to preserve the heat so that the materials are uniformly heated; a plurality of stirring plates are in a cross-over design structure so that the stirring efficiency is effectively improved and the organic matters are completely metabolized.

Owner:XUZHOU UNIV OF TECH

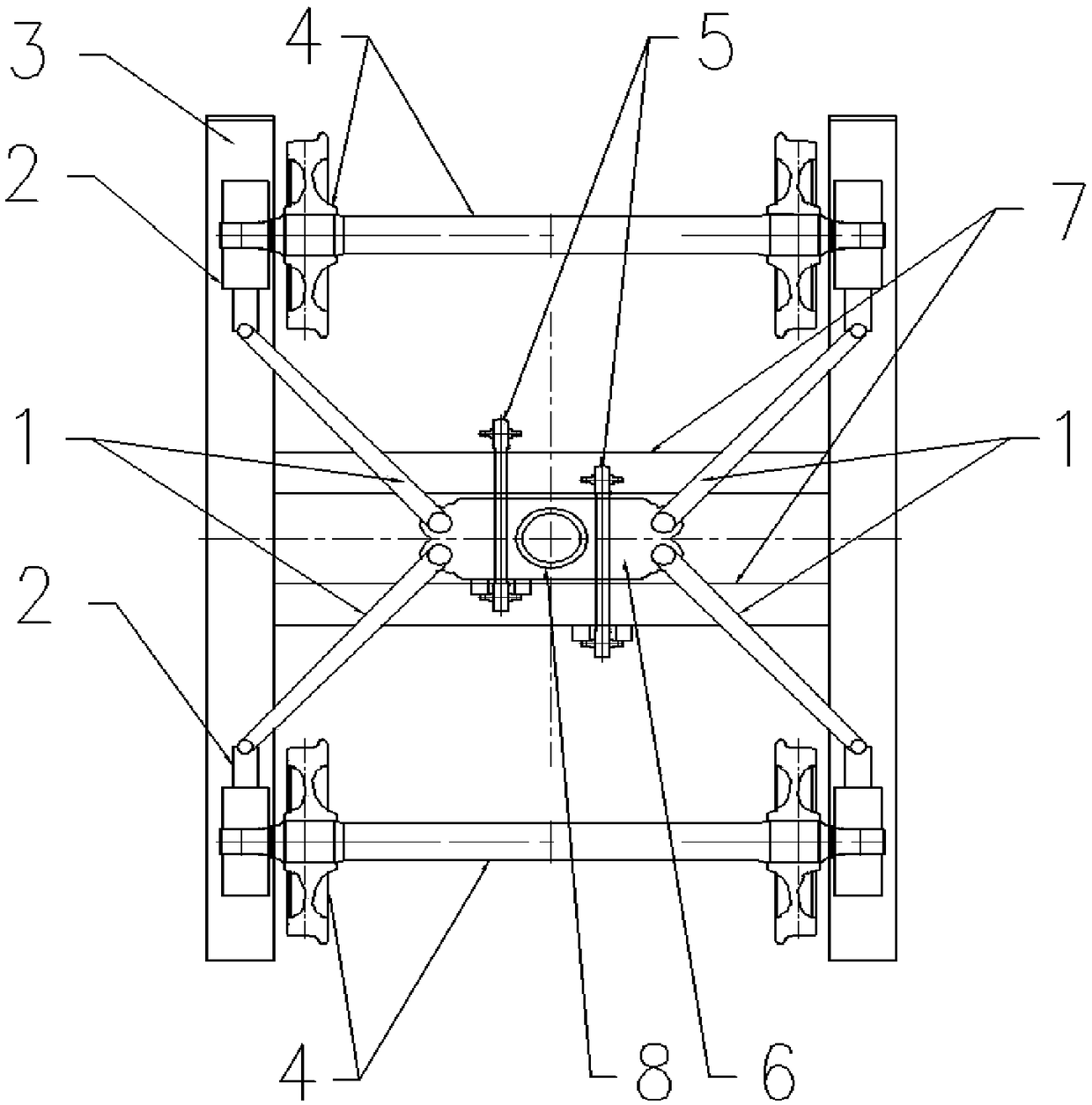

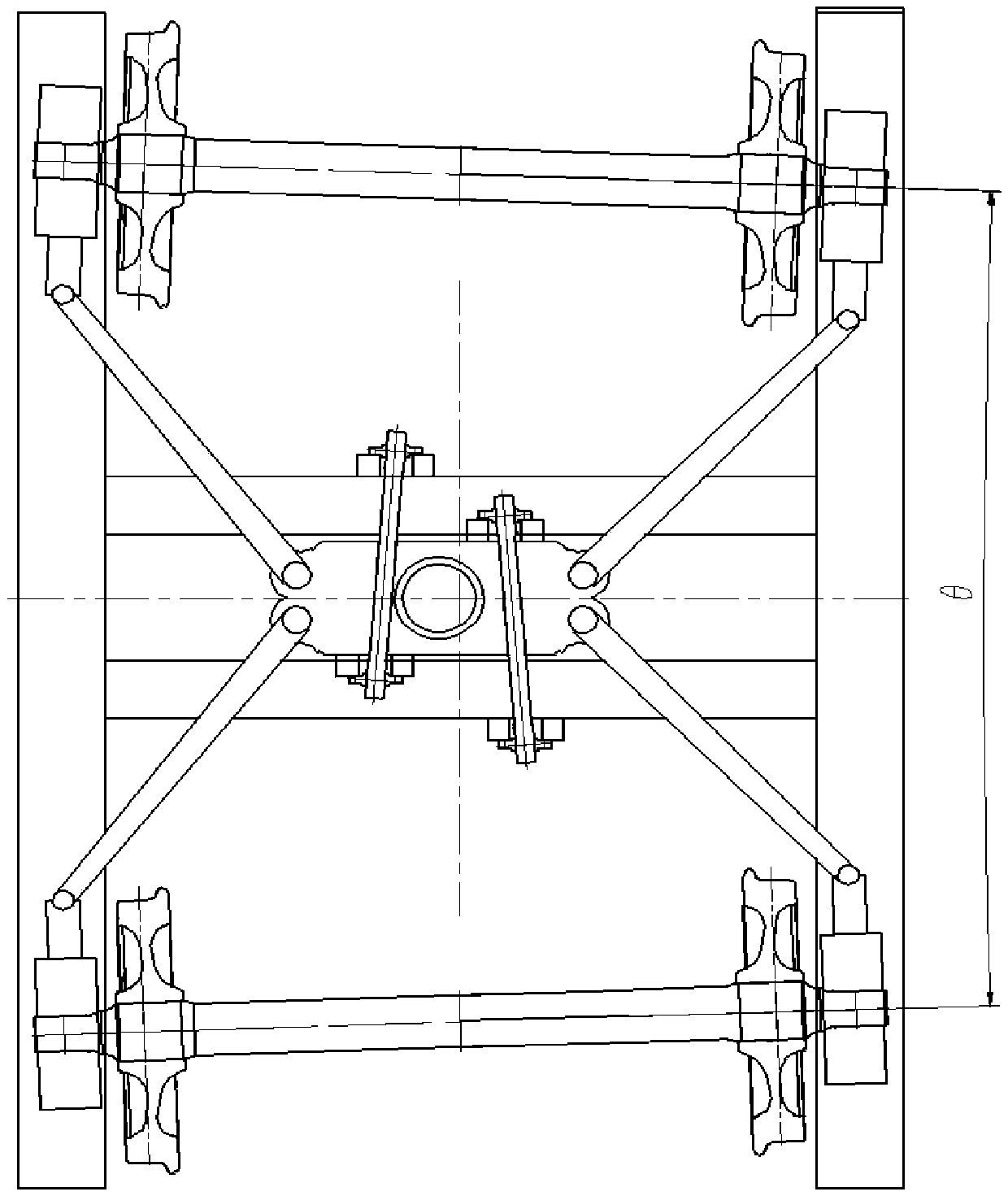

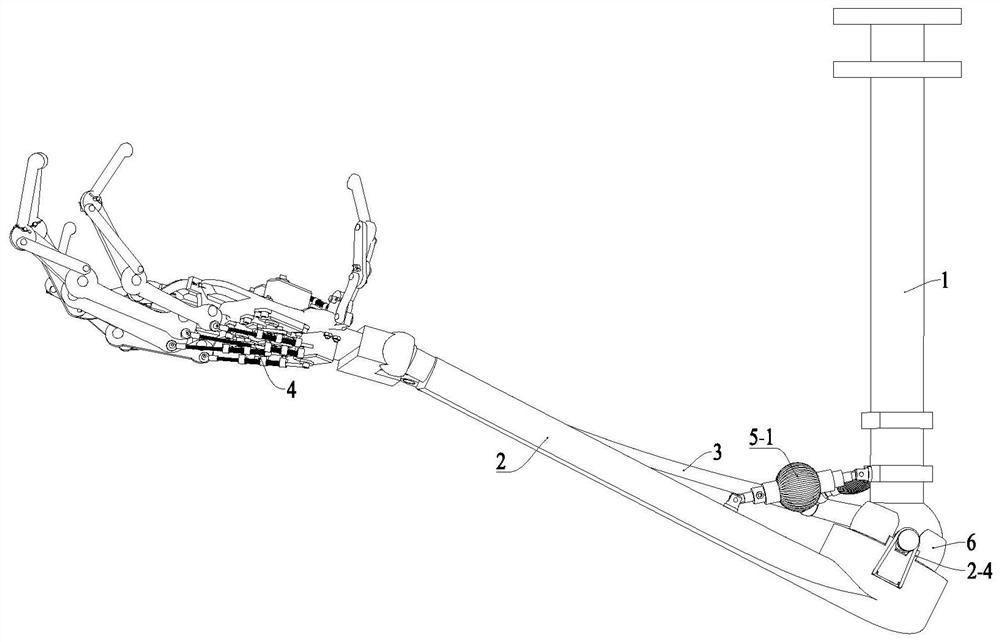

A rail vehicle and its forced guide radial bogie

ActiveCN106476840BSimple structureThe principle of action is simpleBogiesWheel axle self-adjustmentsBogieCentrifugal force

The invention discloses a rail vehicle and a forced steering radial bogie thereof. The forced steering radial bogie comprises a bogie body which is connected with a vehicle body through a traction device; the traction device is connected with a shaft box body of each wheel pair through a radial rod in a hinging manner; the bogie body generates one displacement amount in the transverse direction through a centrifugal force generated by the vehicle body at a curved line part; and the displacement amount drives the radial rods to act on the shaft box bodies of the wheel pairs through deviation of the traction device, so as to force an included angle theta to be formed between front and rear wheel shafts. By adopting the rail vehicle and the forced steering radial bogie thereof, the radial eccentric wear problem of the bogie is solved and a small space is occupied.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

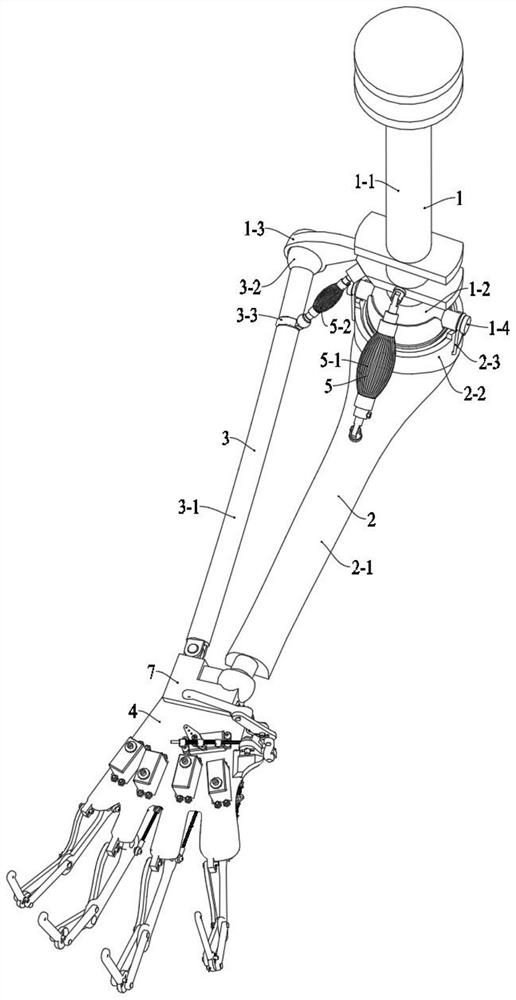

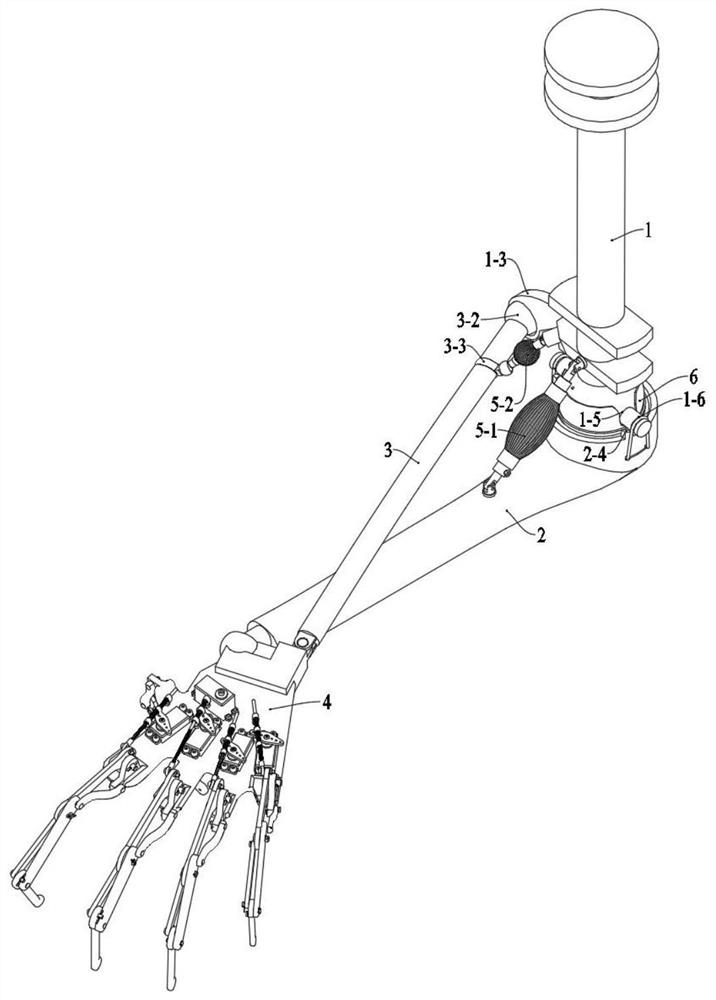

Reversible impact-resistant mechanical arm and driving method thereof

ActiveCN112720444AReduce harmDislocation is easy to recoverProgramme-controlled manipulatorGripping headsStructural engineeringMechanical engineering

The invention discloses a reversible impact-resistant mechanical arm and a driving method thereof. The reversible impact-resistant mechanical arm comprises a humerus-imitating module, an ulna-imitating module, a radius-imitating module, an actuator mounting block and a mechanical arm driving module, wherein one end of each of the ulna-imitating module and the radius-imitating module is connected with the humerus-imitating module, and the other end of each of the ulna-imitating module and the radius-imitating module is connected with the actuator mounting block and used for driving the actuator mounting block to swing and turn over, the humerus-imitating module comprises a humerus rod, the ulna-imitating module comprises an ulna rod, the radius-imitating module comprises a radius rod, the inner ends of the ulna rod and the radius rod and different positions of one end of the humerus rod respectively form spherical pairs, the outer end of the radius rod is hinged with the actuator mounting block, and the outer end of the ulna rod and the actuator mounting block form a spherical pair. By adopting the humerus-imitating module, the ulna-imitating module and the radius-imitating module, the reversible impact-resistant mechanical arm not only can realize buckling and stretching movement, but also can realize inward rotation and outward rotation movement.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com