Locating mechanism for box packing device

A technology of positioning mechanism and boxing, applied in the direction of packaging, etc., can solve the problems of low labor efficiency, high cost, unstable packaging quality, etc., and achieve the effect of ensuring efficiency and quality, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

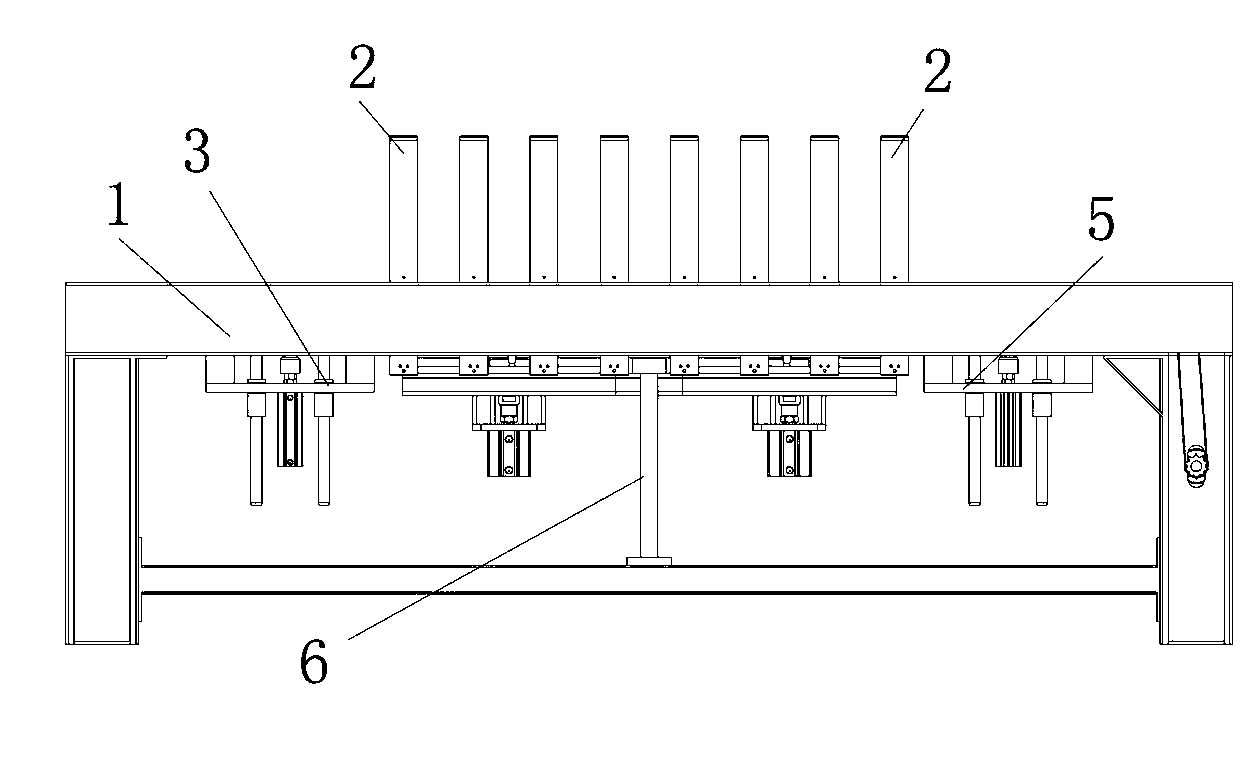

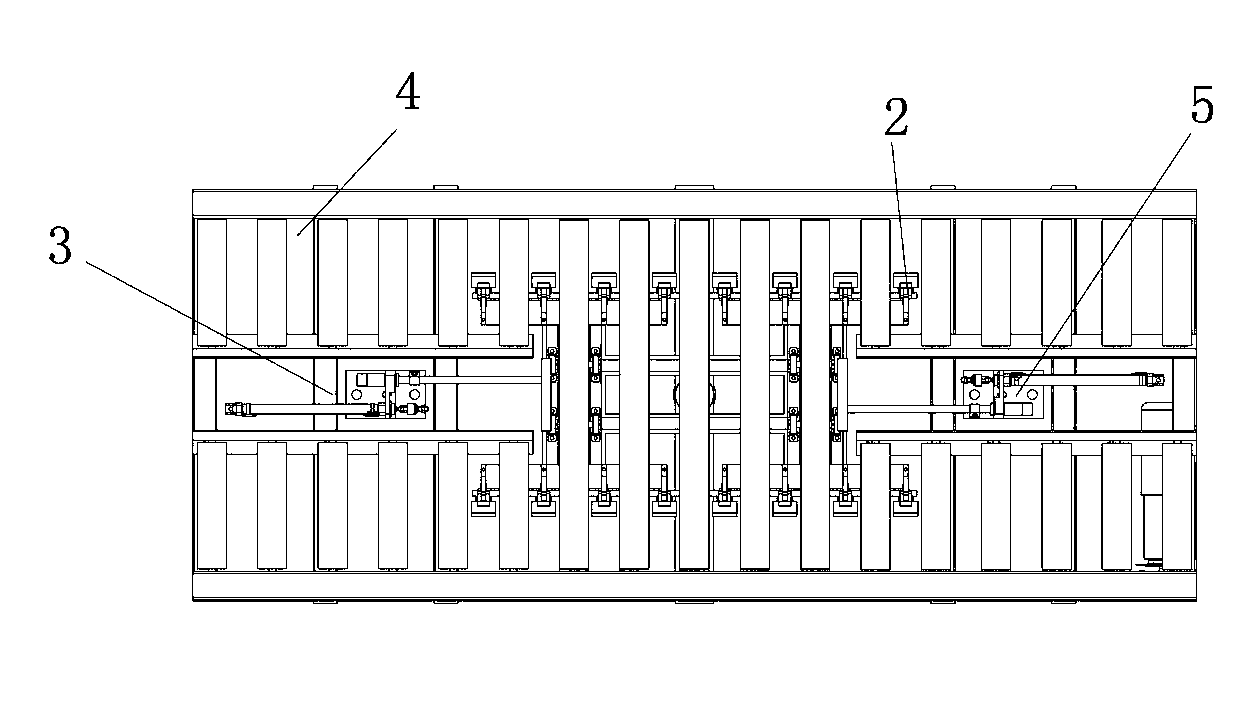

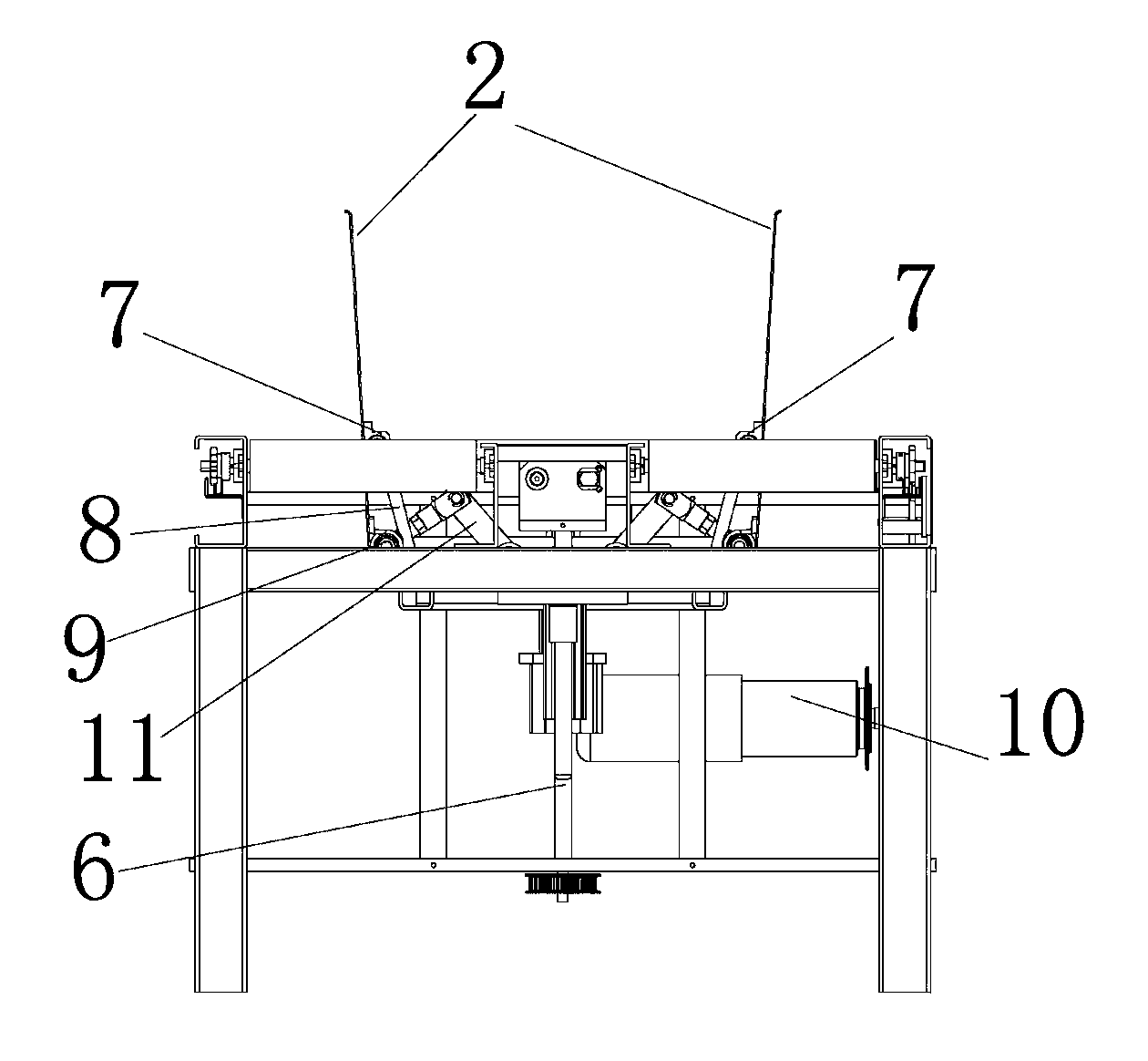

[0010] refer to figure 1 , figure 2 , image 3 As shown, a positioning mechanism for the casing device is designed, which is provided with a jacking bracket 6 arranged in the middle of the roller conveyor frame, and a rotating shaft 9 parallel to each other is provided on both sides of the jacking bracket 6, and on the rotating shaft 9 A plurality of positioning pieces 2 are arranged at intervals, and each positioning piece 2 can stretch out between two adjacent rollers 4 in the roller conveyor frame 1, and a hinged seat 7 is provided at the middle part of the lower section of each positioning piece 2, and a hinged seat 7 is arranged on the hinged seat 7. A pole 8 is connected, and the other end of the pole 8 is connected with the jacking bracket 6. A two-stage connecting arm member 8 is arranged on the rotating shaft 9, and the other end of the connecting arm member 8 is fixed on the jacking bracket 6. The hinge seat on the top is connected, the two-stage connecting arm me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com