Carrying steel welding reinforcement measuring device

A welding reinforcement and measuring device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problem that the slow speed of weld universal energy gauge detection is unfavorable to welding production efficiency, and the inspector cannot find the welding base material and reading Or record errors and other problems to achieve the effect of easy promotion and use, reduction of mismeasurement, wear and tear on the mold, and small shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

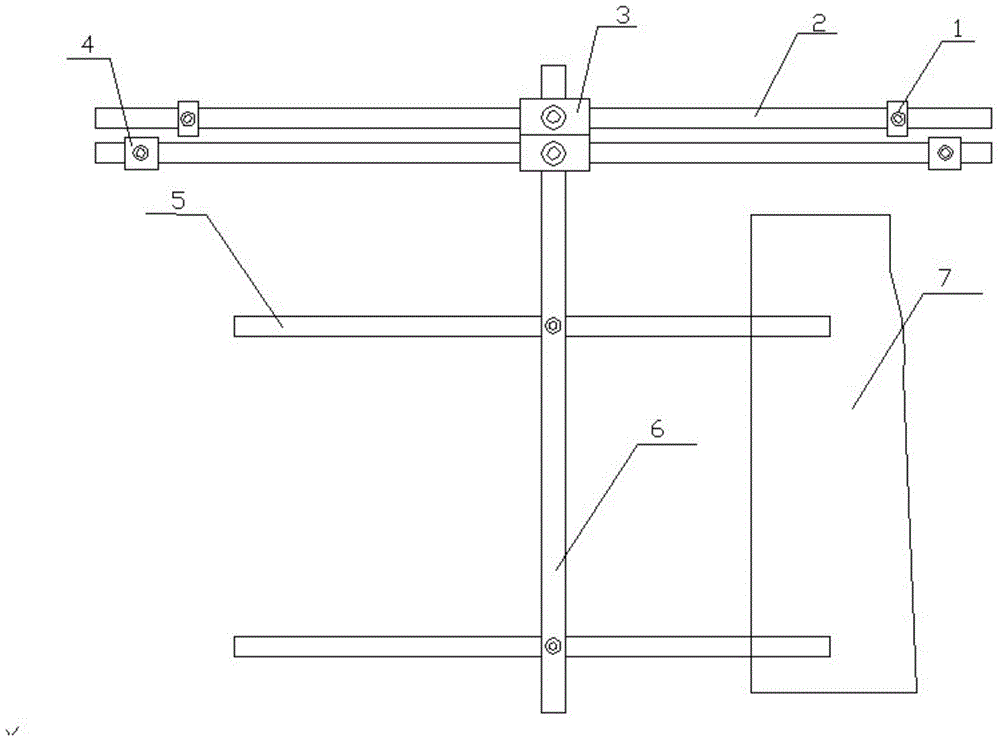

[0018] As shown in the drawings, the present invention is a welding reinforcement measuring device for bearing steel, which includes a central tube axis 6, and two horizontal tubes 2 that are parallel to each other and perpendicular to the center tube axis 6 are arranged on the top of the central tube axis 6. The horizontal pipes 2 are respectively fixed on the top of the central pipe shaft 6 by bolts through the bushings 3. The two ends of the upper horizontal pipe 2 are fixed with inner diameter sliders 1 for adjusting the upper horizontal plane, and the two ends of the lower horizontal pipe 2 are fixed with the inner diameter sliders 1 for adjusting the upper horizontal plane. The outer diameter slider 4, the middle part and the lower part of the central tube shaft 6 are respectively movably connected with adjustable stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com