Spraying device and method for display panel

A technology of spraying device and display panel, applied in the field of coating to achieve the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

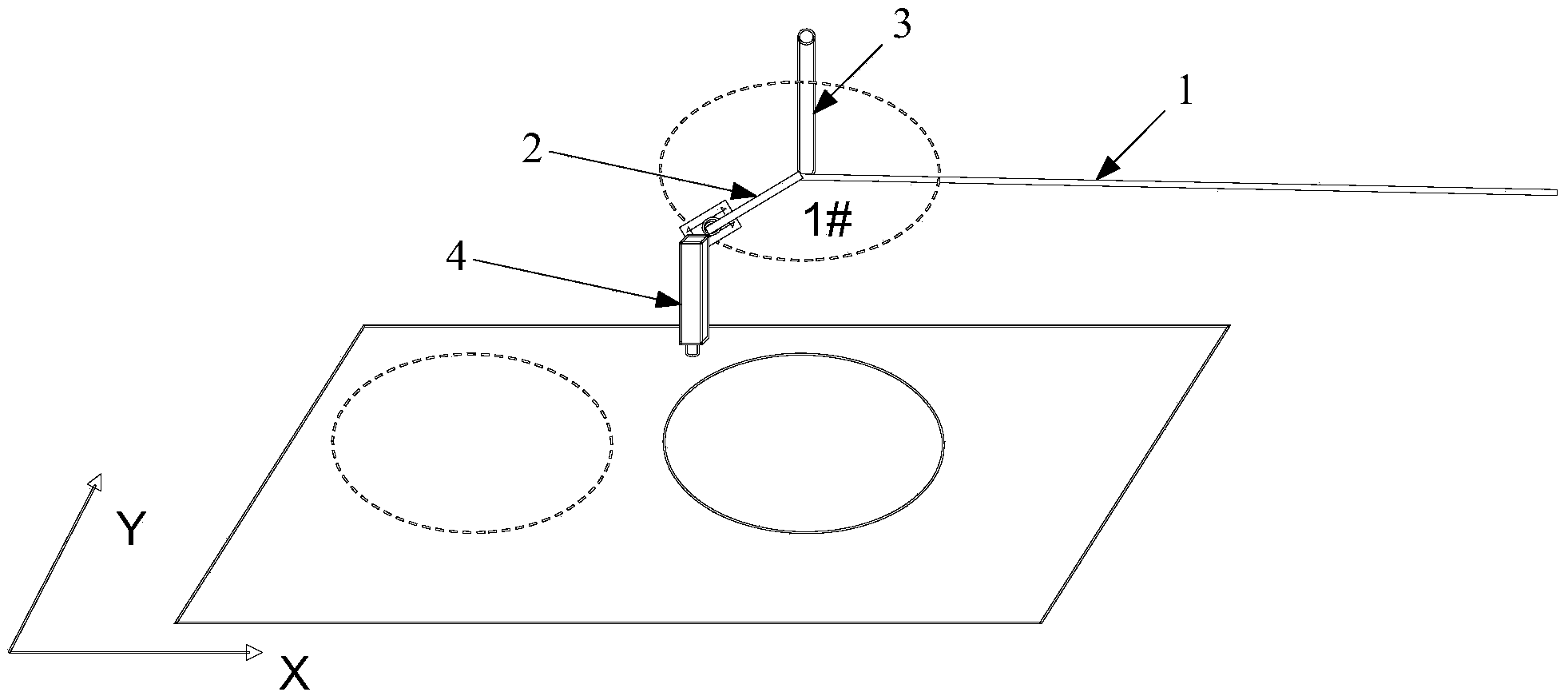

[0032] As mentioned in the background technology section, the frame sealant spraying device in the prior art has relatively large limitations when coating arc-shaped frame sealants. The inventor found that this is because the sealing glue spraying device in the prior art can only coat in the X direction or the Y direction, but cannot complete the arc coating with a certain inner diameter, which leads to the sealing glue in the prior art The spraying device has great limitations when applying arc-shaped sealant.

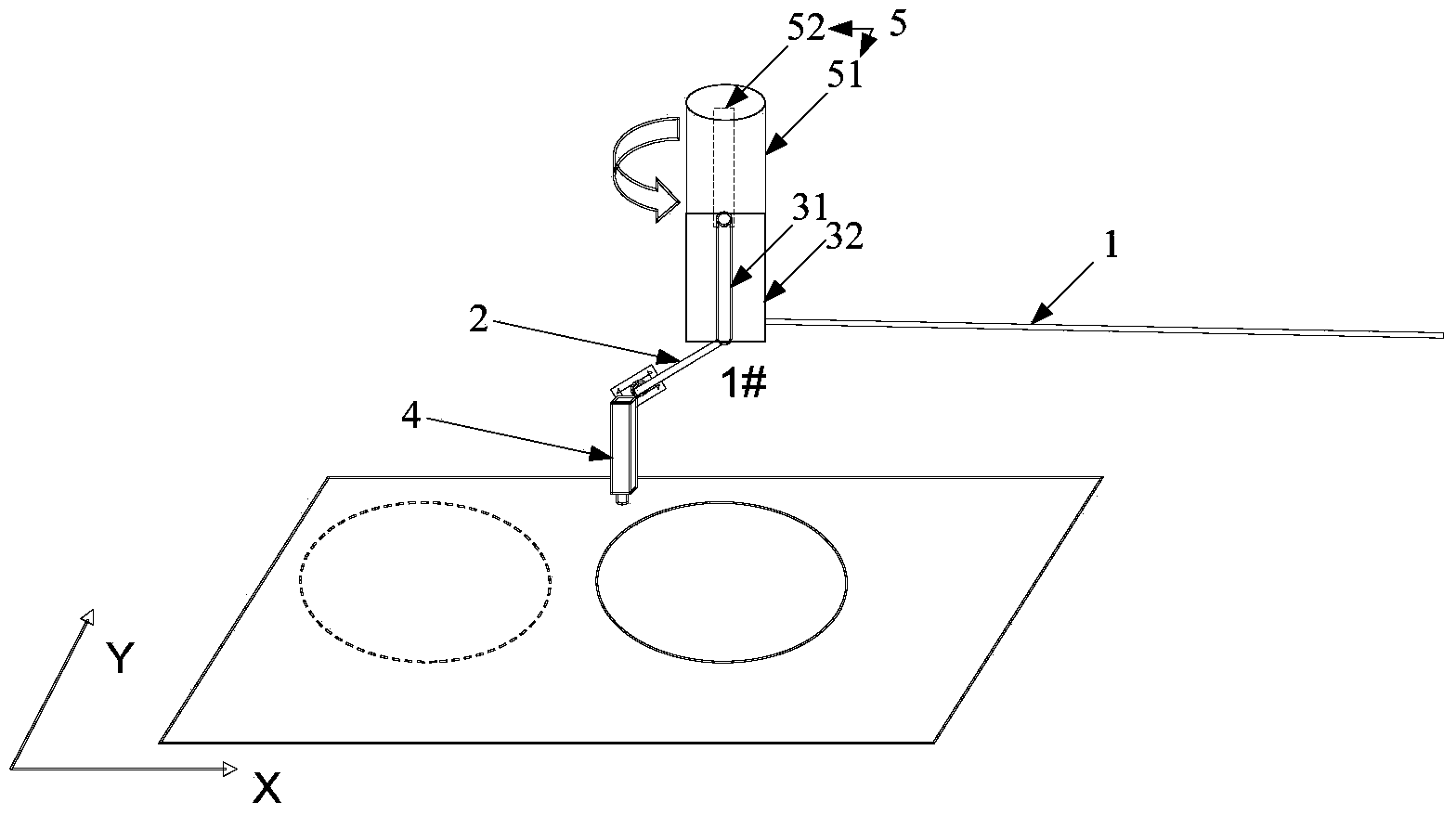

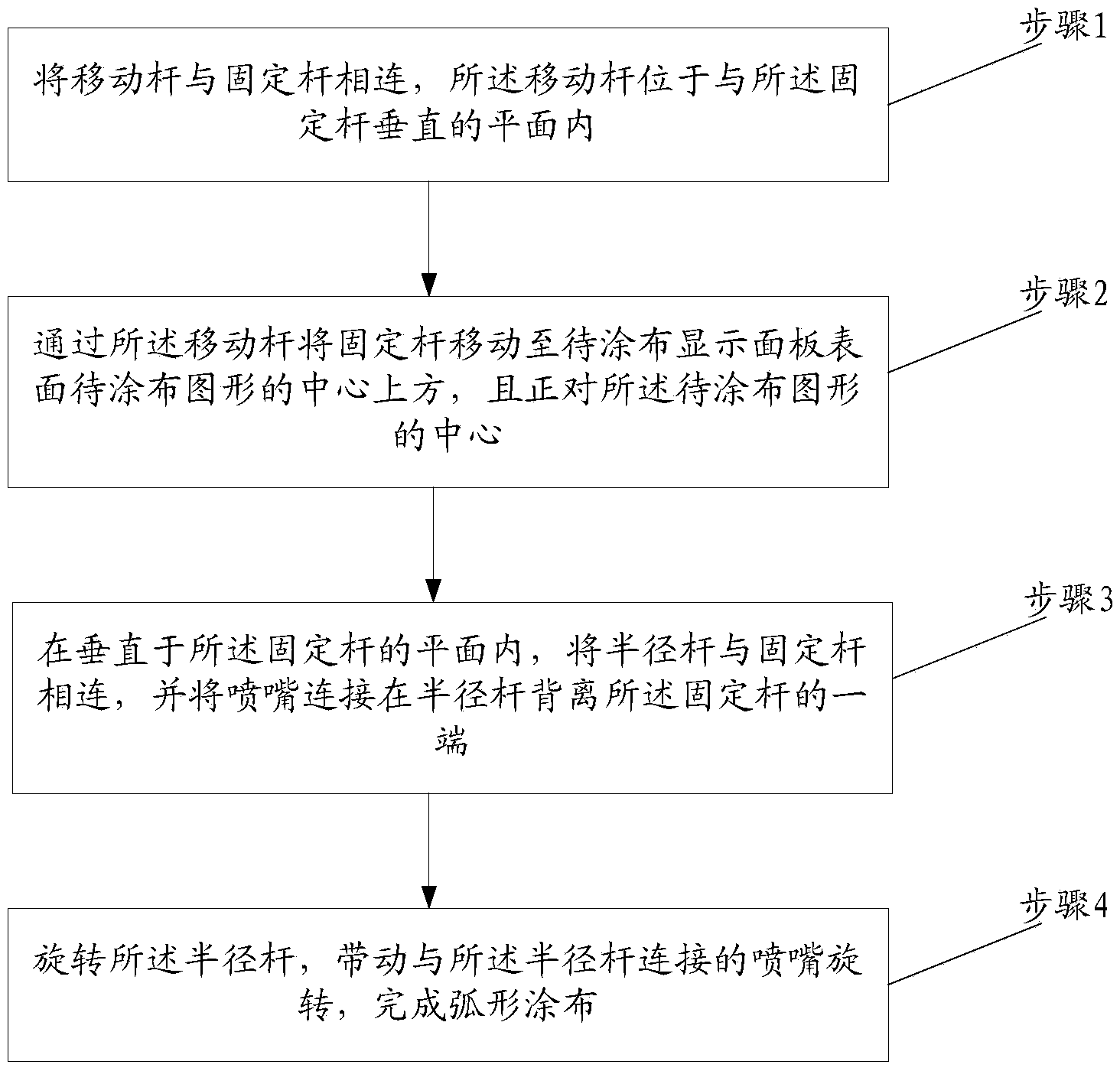

[0033] In view of this, an embodiment of the present invention provides a spraying device for display panels, including: a moving rod, a radius rod, a fixed rod and a nozzle, wherein,

[0034] The moving rod is located in a plane perpendicular to the fixed rod and connected to the fixed rod;

[0035] The radius rod is located in a plane perpendicular to the fixed rod, one end of which is connected to the fixed rod, and the other end is connected to the nozzle, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com