Spaced reversing grooved wheel mechanism

A reversing groove and sheave technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve problems such as mechanical interference of crank wheel levers, crank wheel breakage, etc., to avoid hidden dangers of mechanical interference and eliminate freedom. zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

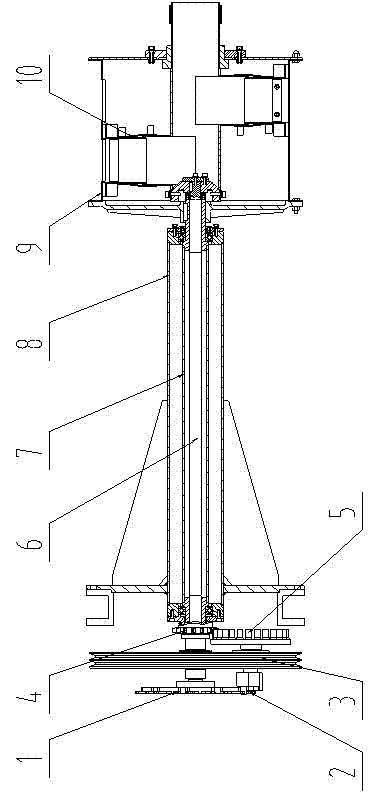

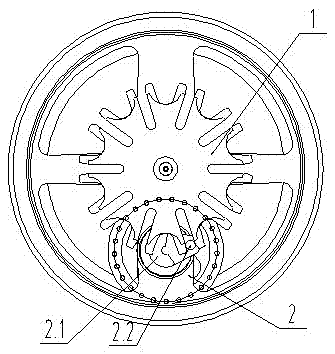

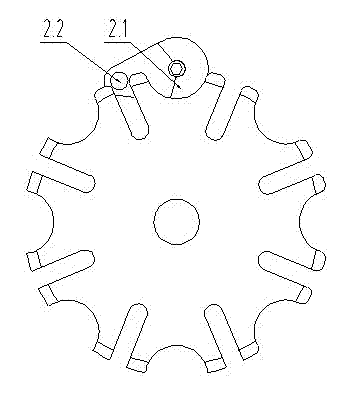

[0026] see Figure 1~Figure 4 , a gap reversing sheave mechanism of the present invention, which includes a cooperating sheave 1 and a crank wheel 2, the crank wheel 2 is provided with a limit wheel 2.1 and a lever 2.2, and the outer circle of the sheave 1 is stepped shape, the radius R of the small circle of the sheave 1 remains unchanged, and the radius of the major circle of the sheave 1 increases to the center distance a of the crank wheel 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com