Radius Rod Spherical Surface Profiling Device

A profiling processing and radius rod technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of high difficulty, high cost of parts, high cost, etc., and achieve strong versatility, convenient clamping and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

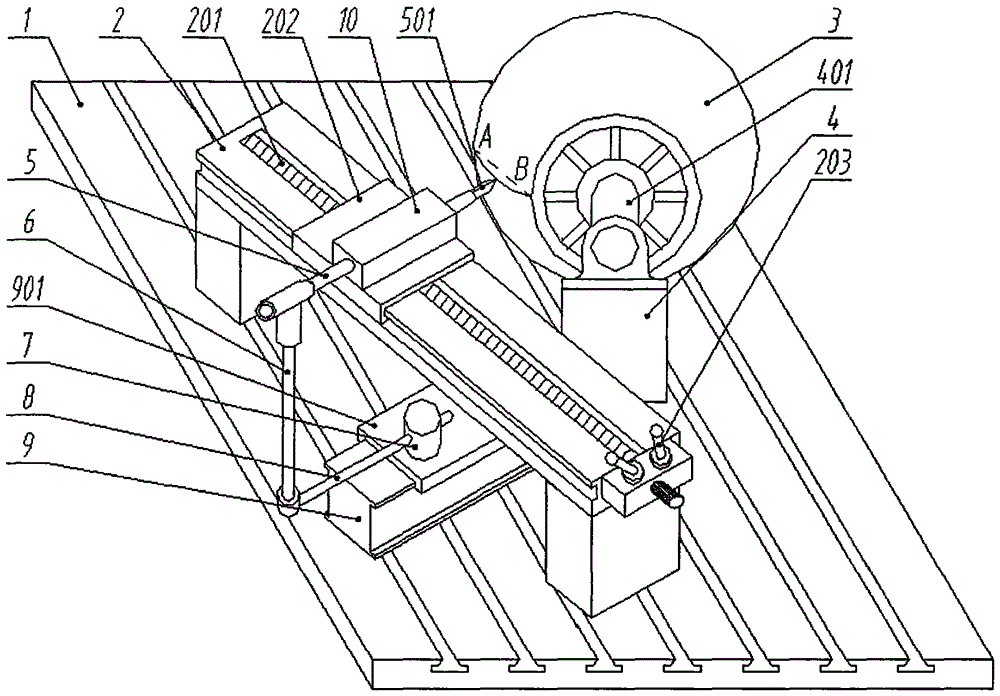

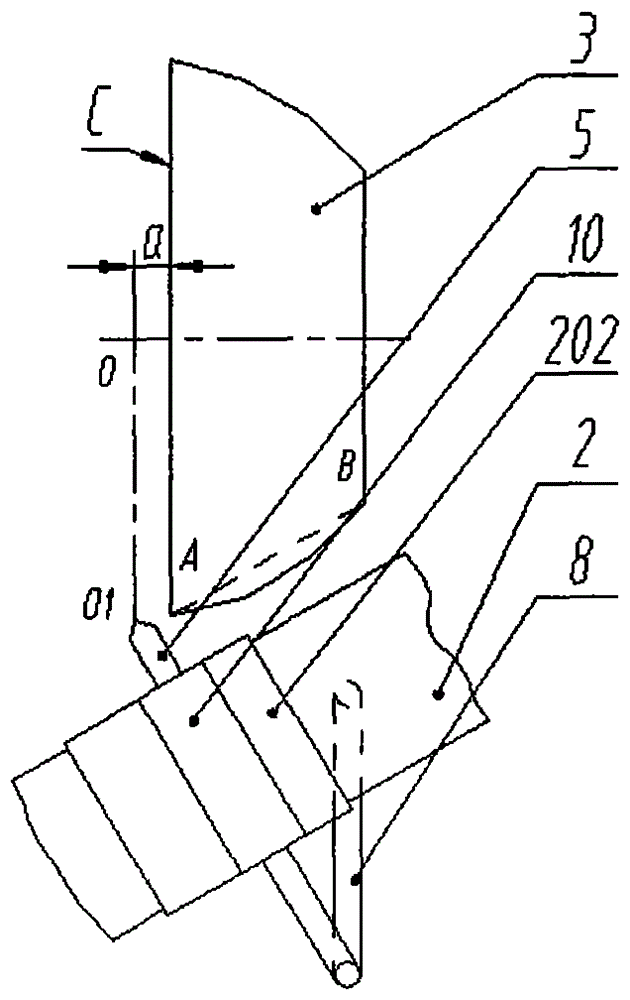

[0010] Such as figure 1 As shown, the present invention includes a sliding seat 10, a slide bar tool holder 5, a coupling rod 6, a rotating handle 7 and a radius rod 8; the large bed 2, the small bed 9 and the worm gear drive mechanism 4 are installed on a T-shaped groove. Base 1 for adjustment and fixation. It is characterized in that the sliding seat 10 is fixed on the large pallet 201 of the large bed 2, and by controlling the operating handle 203, the lead screw 201 will drive the large pallet 202 to advance, reverse or change speed; Rod tool rest 5, one end of slide bar tool rest 5 is provided with turning tool 501, and turning tool 501 moves along the bed direction of big bed 2 with big supporting plate 202 under the drive of slide seat 10, completes longitudinal feeding; The other end of the tool holder 5 is rigidly connected to the connecting rod 6, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com