Fluid refining device

A fluid and cone technology, applied in fluid mixers, chemical instruments and methods, dissolution, etc., can solve problems such as low refinement effect, unreasonable structure, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

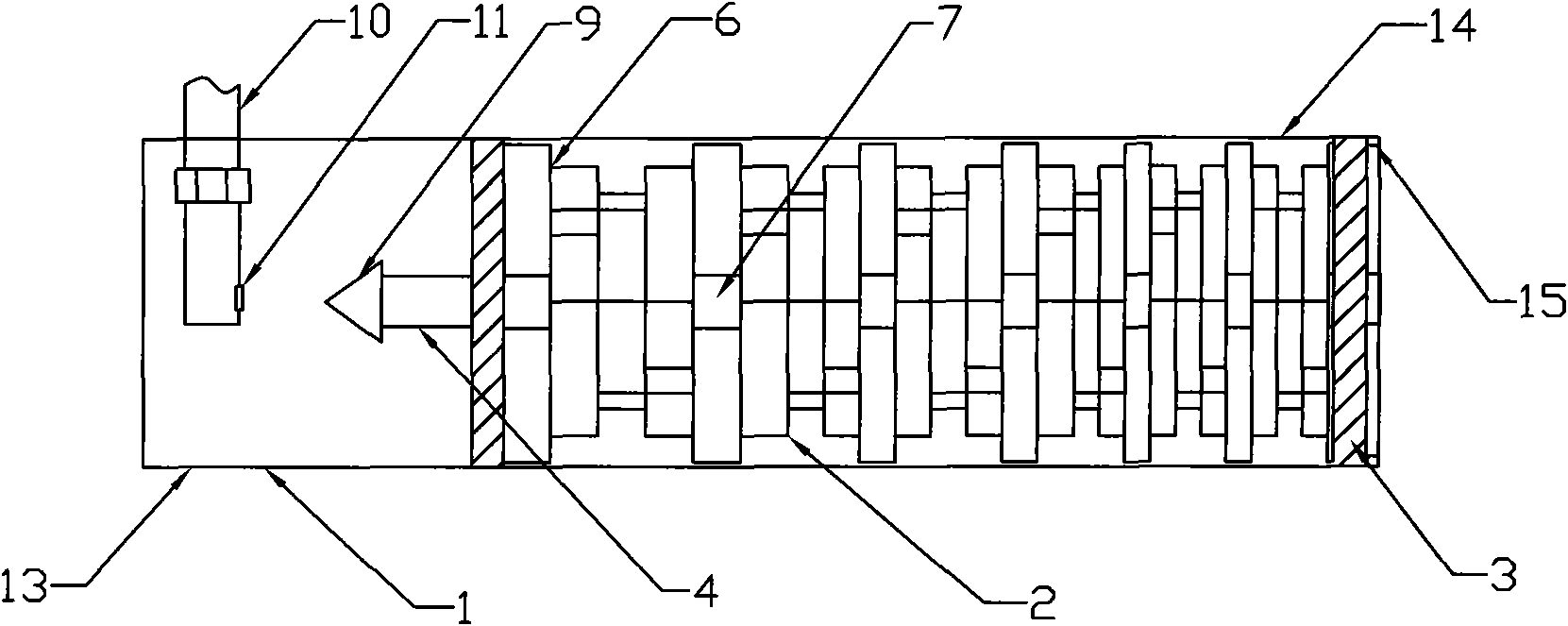

[0018] Such as figure 1 As shown, the shell of the thinning device of this technical solution is a circular tube shell 1, and the screw 2 is installed in the tube shell. There are external bayonet joints at both ends of the tube shell 1. Generally, screw ports are used, and clamping methods such as clamping can also be used. , as long as it can be tightly connected with the pipeline to be connected, according to the inflow direction of the fluid, the front end of the shell is defined as the inflow end 13, and the rear end is defined as the outflow end 14. The ratio of the inner diameter of the shell to its length is 1 / 2 to 3 / 10.

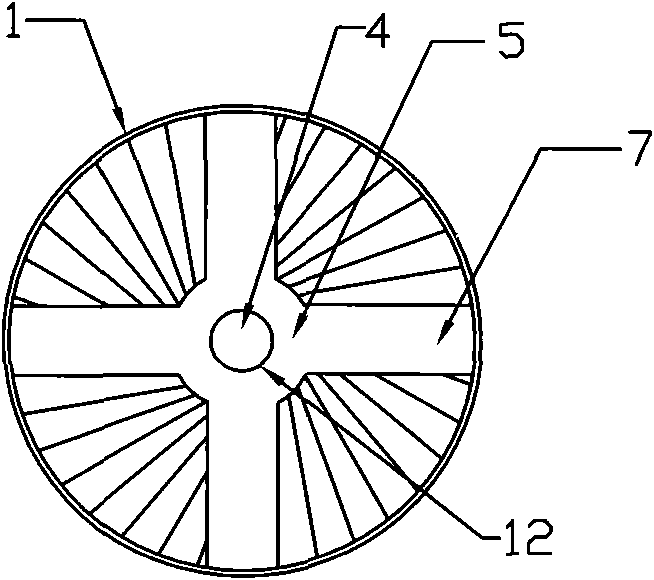

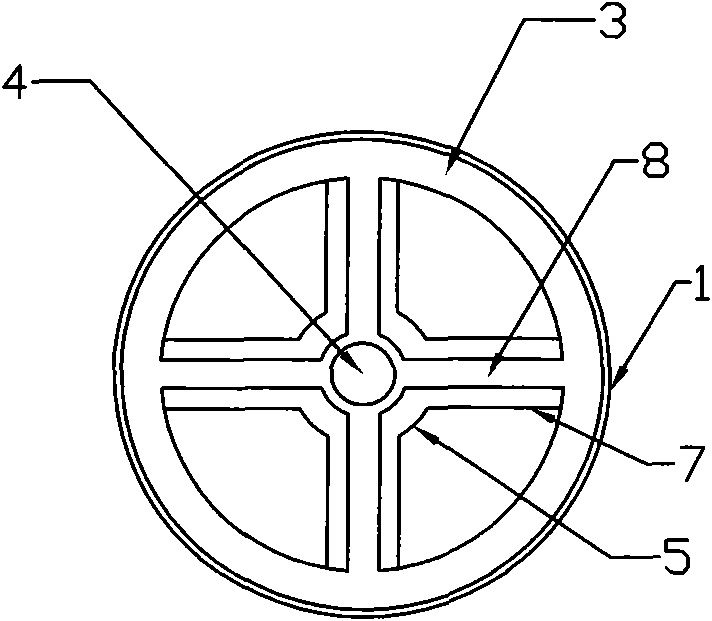

[0019] The spiral part 2 is composed of a plurality of gaskets 6 stacked together, such as figure 2 As shown, the shape of the gasket 6 is: a disc 5 in the middle, with a shaft hole 12 in the middle of the disc, and four raised blades 7 are evenly distributed on the outer circumference of the disc 5, and the four blades 7 are perpendicular to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com