Highly-efficient multiple rods stirring type stirring equipment

A kind of mixing equipment and stirring technology, which is applied in the direction of dissolution, mixer, chemical equipment and methods, etc., can solve the problems of unable to eliminate the dead corner of stirring, low stirring efficiency, poor stirring effect, etc., to increase the stirring range, improve the stirring effect, Increase the effect of the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

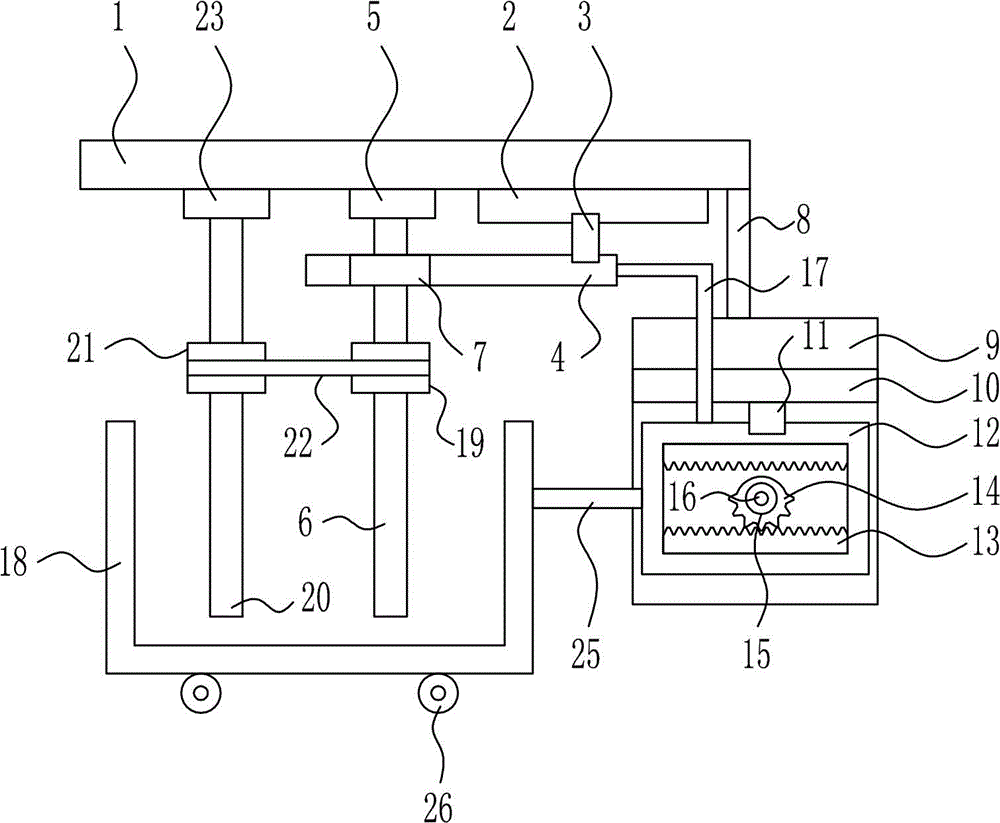

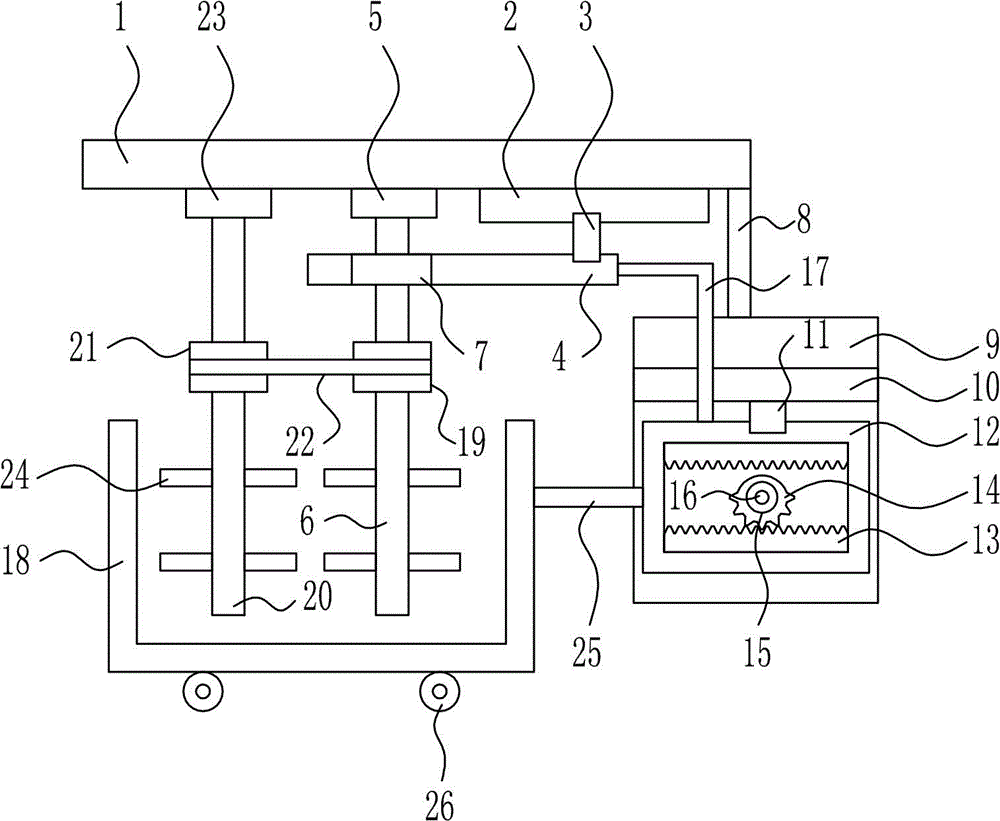

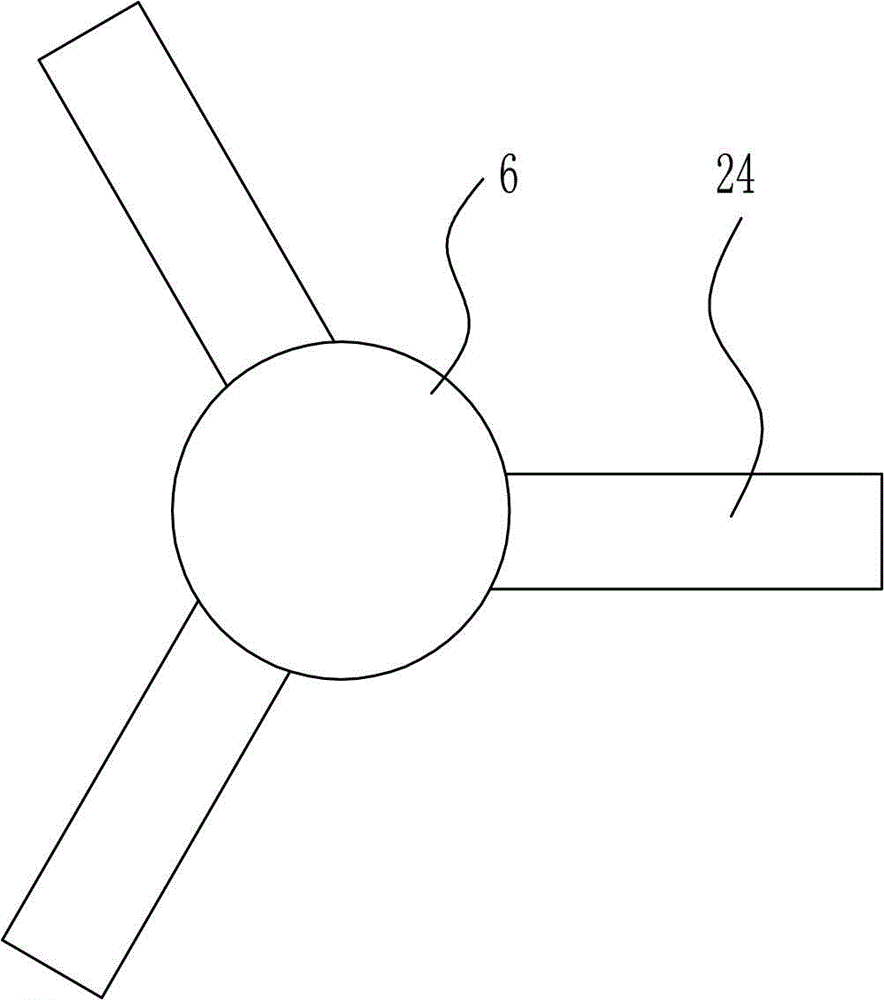

[0030] A high-efficiency multi-rod stirring type mixing equipment, such as Figure 1-5As shown, it includes a top plate 1, a first slide rail 2, a first slider 3, a first rack 4, a first bearing seat 5, a first rotating rod 6, a first gear 7, a pole 8, and a fixed plate 9 , the second slide rail 10, the second slide block 11, the moving frame 12, the second rack 13, the sector gear 14, the motor 15, the second rotating rod 16, the moving rod 17, the stirring box 18, the connecting rod 25 and the wheels 26 Stirring box 18 is placed on the left side below the top plate 1, the bottom of the stirring box 18 is provided with wheels 26, the first slide rail 2 connected by bolts on the right side of the bottom of the top plate 1, and the first slide rail 2 is slidably connected with the first slide block 3. The first slider 3 cooperates with the first slide rail 2. The bottom of the first slider 3 is welded to the first rack 4. The bottom of the top plate 1 is connected to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com