Biological fermentation tank

A technology for biological fermenters and fermenters, which is applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biomass post-processing, etc., can solve the failure of raw materials, the influence of sampling analysis, and the influence of stirring blades and other problems to achieve the effect of preventing shedding, increasing wear resistance, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

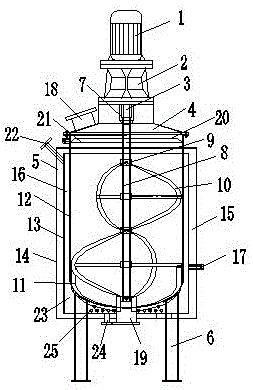

[0031] As can be seen in conjunction with the accompanying drawings, a biological fermenter includes a motor 1, a reducer 2, a stirring device 3, a loam cake 4, a fermenter 5 and a support 6, the lower end of the fermenter 5 is provided with a support 6, and the fermenter 5 The upper end is provided with a loam cake 4, the loam cake 4 is provided with a stirring port 7, the stirring device 3 is arranged in the stirring port 7, the motor 1 is connected with the stirring device 3 through a reducer 2, and the stirring device 3 Comprising a stirring shaft 8 and a stirring blade 9 arranged on the stirring shaft 8, the stirring blade 9 includes a first stirring blade 10 and a second stirring blade 11, and the second stirring blade 11 is arranged at the lower end of the stirring shaft 8, so The first stirring blade 10 is a Jiaolong rotating blade, the second stirring blade 11 is a frame-type stirring blade, the outside of the stirring blade 9 is provided with a coating, and the fermen...

Embodiment 2

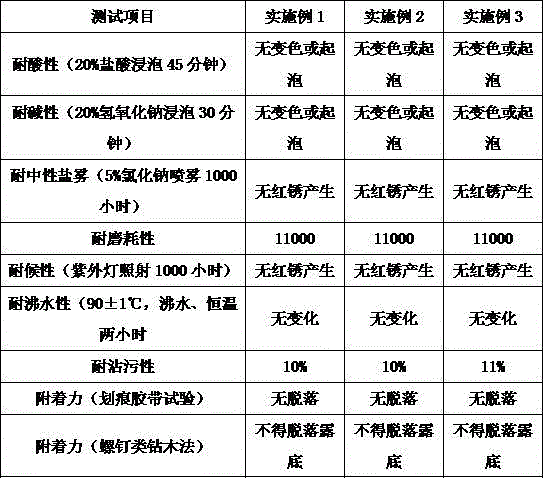

[0051] A coating is provided on the outside of the stirring blade 9, and the thickness of the coating is 1 mm.

[0052] The processing technology of the coating is as follows: 1) After cleaning the metal surface of the stirring blade 9 with acetone for 6 minutes, put the stirring blade 9 into the mixture of clear water, acetone and absolute ethanol, and clean the stirring blade 9 Perform ultrasonic treatment for 14 minutes, then put the stirring blade 9 into the distilled aqueous solution to clean the stirring blade 9 for 8 minutes; the weight ratio of the clear water, acetone and absolute ethanol is 3:5:3;

[0053] 2) Add 50 parts of deionized water to 38 parts of polyethylene and stir continuously, and add 5 parts of crosslinking agent during the stirring process and stir for 30 minutes;

[0054] 3) Put 5 parts of shell powder and 8 parts of bone powder into 42% ethanol solution, stir for 10 minutes, then filter, put the filtered mixture into a 0.8MPa high-pressure separator...

Embodiment 3

[0064] A coating is provided on the outside of the stirring blade 9, and the thickness of the coating is 1.2 mm.

[0065] The processing technology of the coating is as follows: 1) After cleaning the metal surface of the stirring blade 9 with acetone for 6 minutes, put the stirring blade 9 into the mixture of clear water, acetone and absolute ethanol, and clean the stirring blade 9 Perform ultrasonic treatment for 16 minutes, then put the stirring blade 9 into the distilled aqueous solution to clean the stirring blade 9 for 7 minutes; the weight ratio of the clear water, acetone and absolute ethanol is 3:5:3;

[0066] 2) Add 48 parts of deionized water to 41 parts of polyethylene and stir continuously, and add 8 parts of crosslinking agent during the stirring process and stir for 29 minutes;

[0067] 3) Put 6 parts of shell powder and 7 parts of bone powder into 42% ethanol solution, stir for 12 minutes, then filter, put the filtered mixture into a 0.8MPa high-pressure separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com