A reversible impact-resistant mechanical arm and its driving method

A mechanical arm and impact-resistant technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve the effect of reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

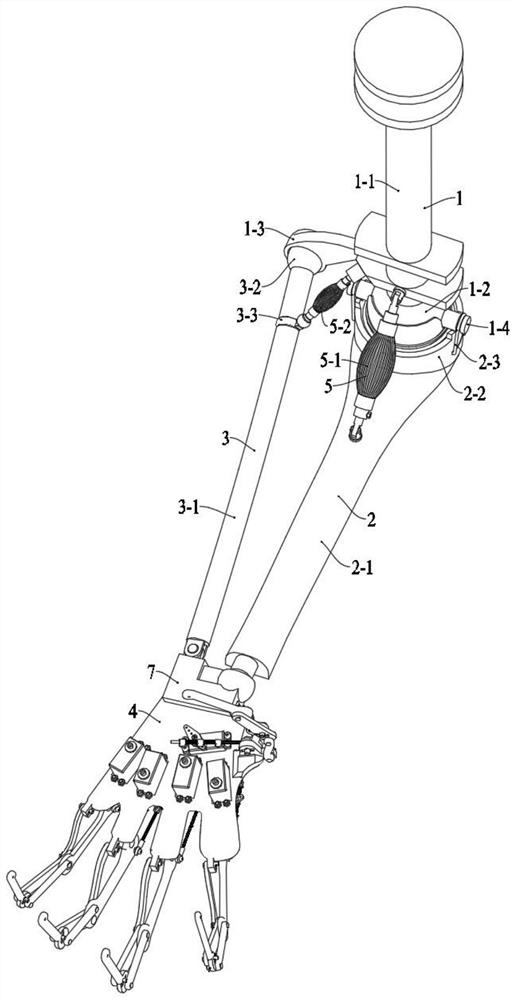

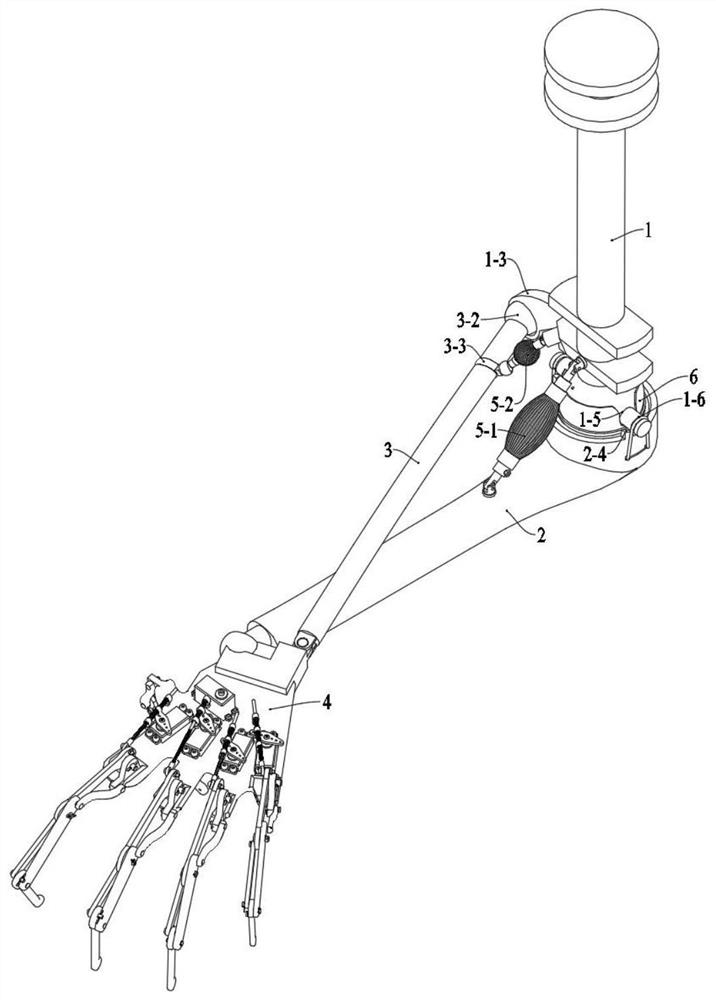

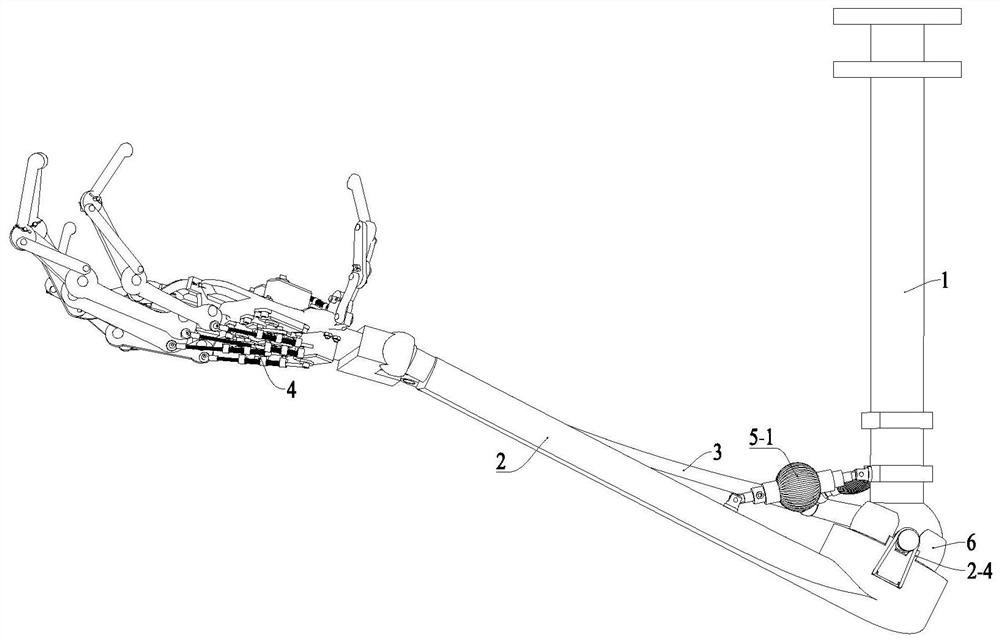

[0028] Such as Figure 1-5 As shown, a reversible impact-resistant mechanical arm includes a humerus imitation module 1 , an ulna imitation module 2 , a radius imitation module 3 , an actuator mounting block 7 , a manipulator module 4 and a manipulator driving module 5 . The manipulator module 4 is installed on the actuator mounting block 7 and has a grabbing function; one end of the imitation ulna module 2 and the imitation radius module 3 are connected with the imitation humerus module 1, and the other ends are connected with the actuator mounting block 7, respectively. To drive the actuator mounting block 7 to swing and turn over.

[0029] The imitation humerus module 1 includes a humerus rod 1-1, a humerus joint ball 1-2, a radial ball joint seat 1-3 and a pivot pin 1-4; the humerus joint ball 1-2 is fixed on the humerus rod 1-1 The lower end; the humerus joint ball 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com