Annular plate groove cutting mold, cutting system and cutting method

A technology of bevel cutting and moulding, which is applied in the field of semi-automatic flame cutting machines, can solve the problems of inconvenient beveling of circular steel members and single cutting method of semi-automatic flame cutting machines, and achieve the goal of improving production efficiency and quality precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific implementation examples in conjunction with the accompanying drawings.

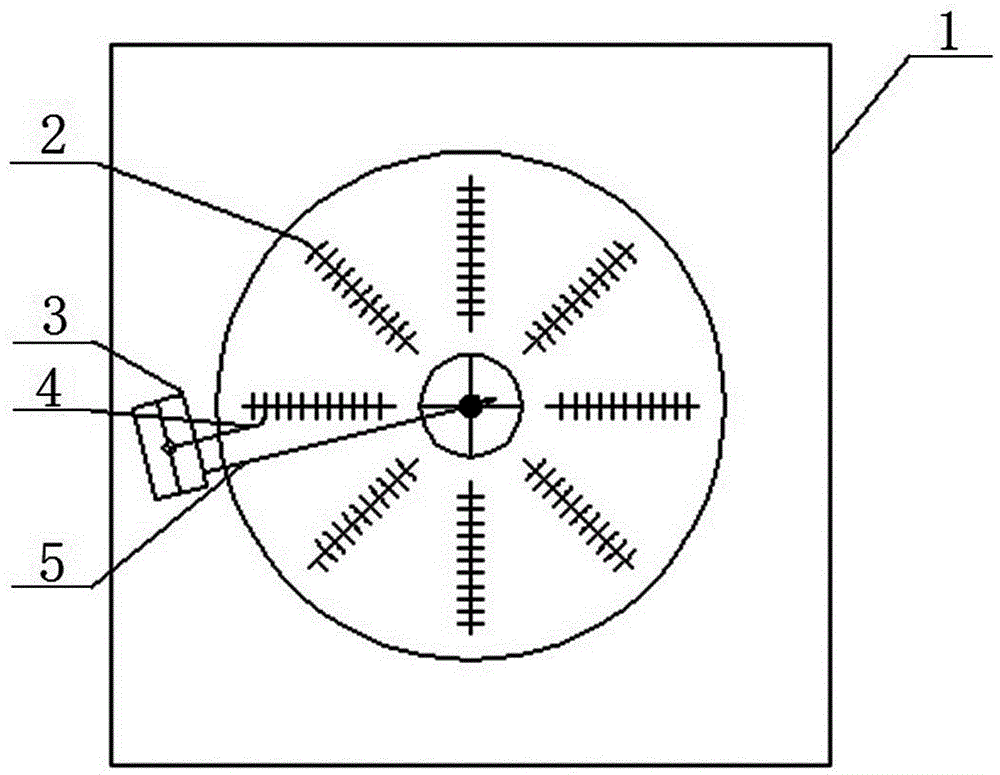

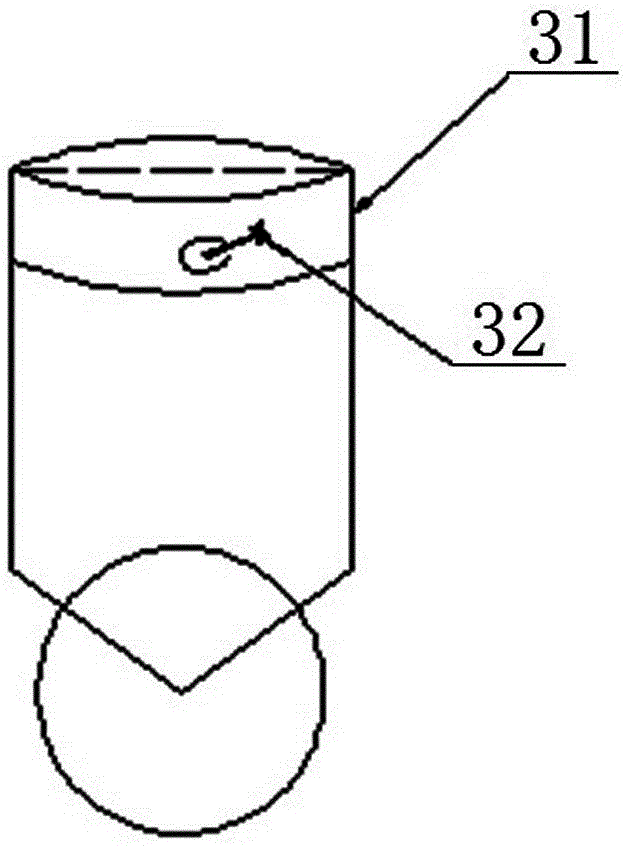

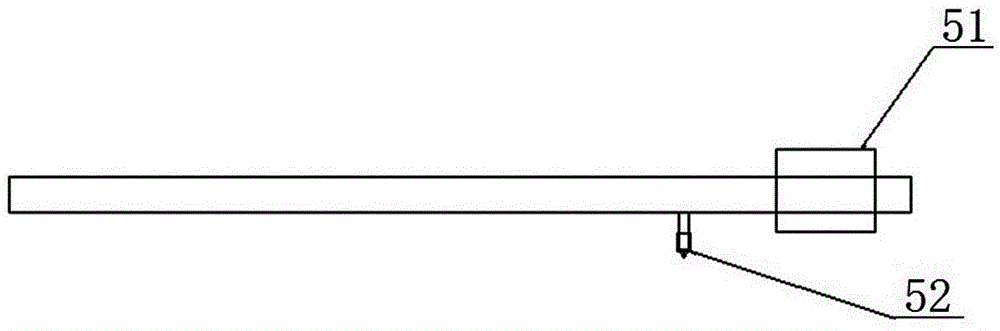

[0035] The application provides a ring plate bevel cutting mold, such as Figure 1 to Figure 3 As shown, the bevel cutting mold of the ring plate includes a mold base 1 and a mold dial 2, the mold dial 2 is arranged on the mold base 1, and the upper surface of the mold dial 2 It is used to place the ring plate, and the center position of the mold dial 2 is the positioning eye, and the scale line on the mold dial 2 is centered on the positioning eye, and extends outward along the radius of the mold dial 2 extend.

[0036] In this embodiment, as a preferred solution, at least two scale lines are arranged on the mold dial 2, and all the scale lines on the mold dial 2 are evenly distributed.

[0037] Through the above scheme, the bevel cutting mold for the ring plate can quickly and efficiently make the bevel for the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com