Adhesive tape machine

A technology of adhesive paper machine and paper machine, which is applied in the field of adhesive paper machine, can solve the problems of increasing production cost, material consumption and high design cost of enterprises, and achieves the effects of convenient placement and transfer, increased production efficiency, and simple and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

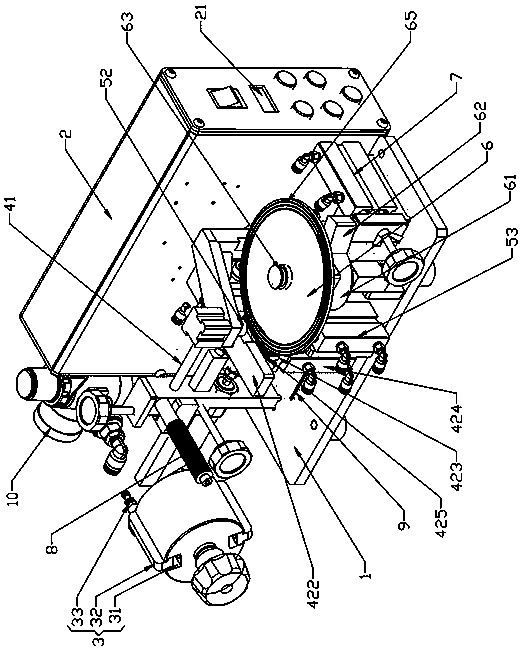

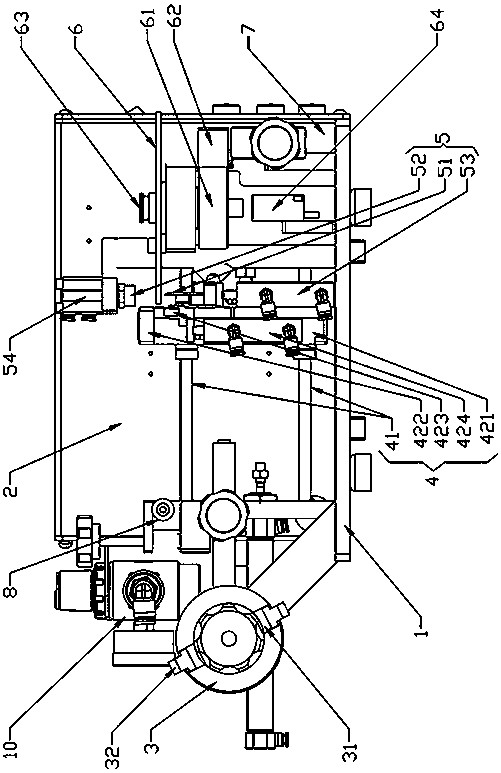

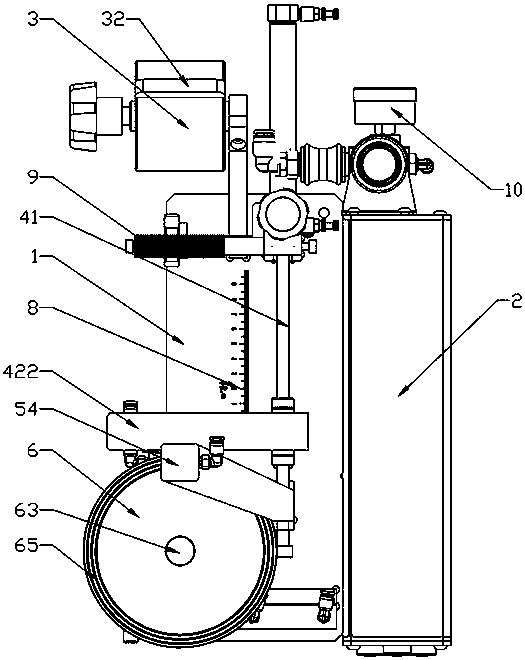

[0027] Such as Figure 1 to Figure 3 As shown, the specific embodiment of the present invention is: the present invention includes an installation base plate 1, an electrical system box 2 arranged on one side of the installation base plate 1, and an electrical system box 2 arranged on the installation base plate 1 and arranged in sequence from back to front Hanging tray 3, tape pulling assembly 4, tape cutting assembly 5, and discharge platform 6; an electrical control system is installed in the electrical system box 2, and a pressure regulating valve is provided in the rear of the electrical system box 2 10. Both the material hanging tray 3 and the discharge platform 6 are installed at a height position at a certain distance from the installation base plate 1 through a mounting frame; the glued paper assembly 4 includes a 3 and the longitudinal rail 41 between the discharge platform 6 and the clamping device slidingly matched with the longitudinal rail 41, the adhesive paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com