Safety cutter

A cutting knife, safety technology, applied in the direction of metal processing, etc., can solve the problems of damage, personal injury items, cutting edge safety, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

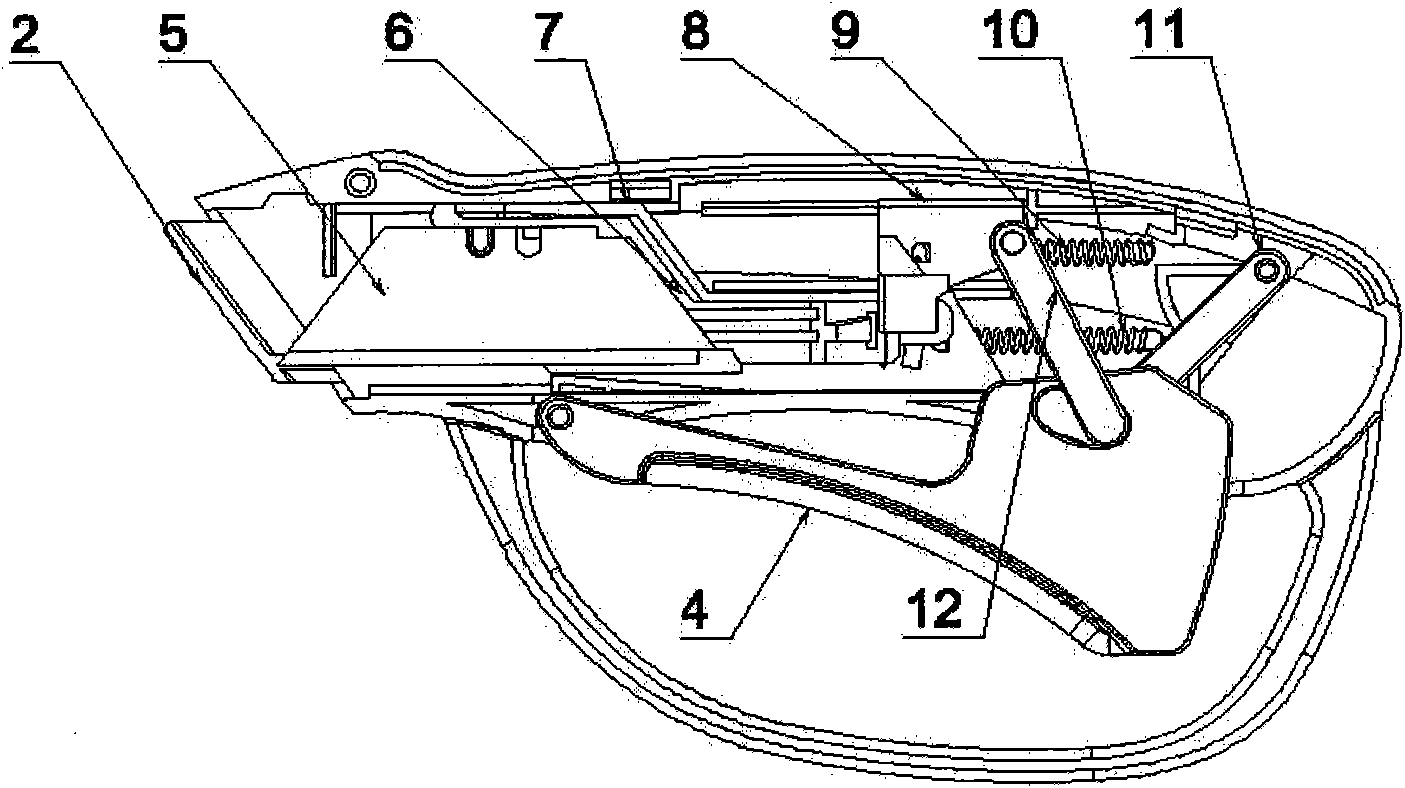

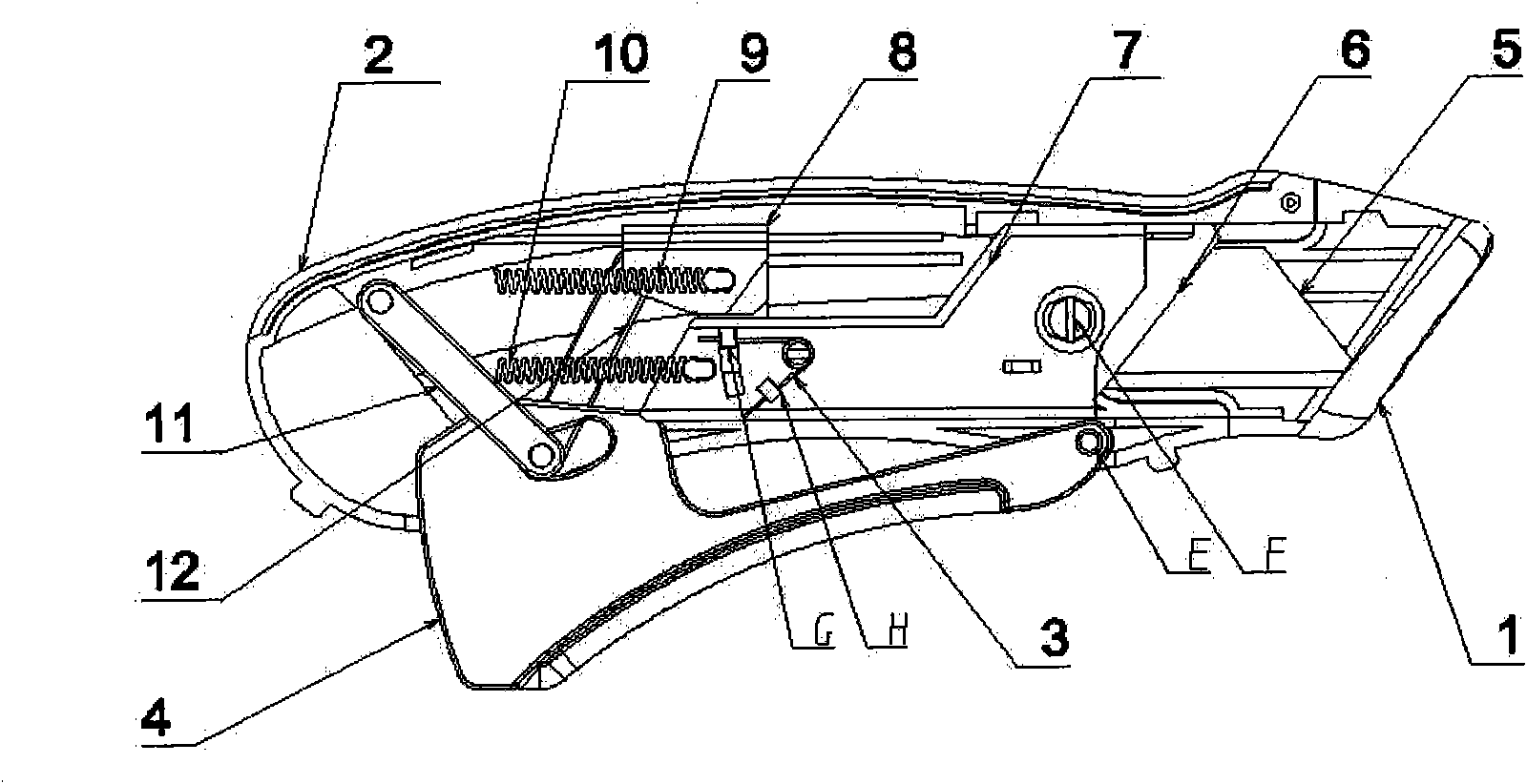

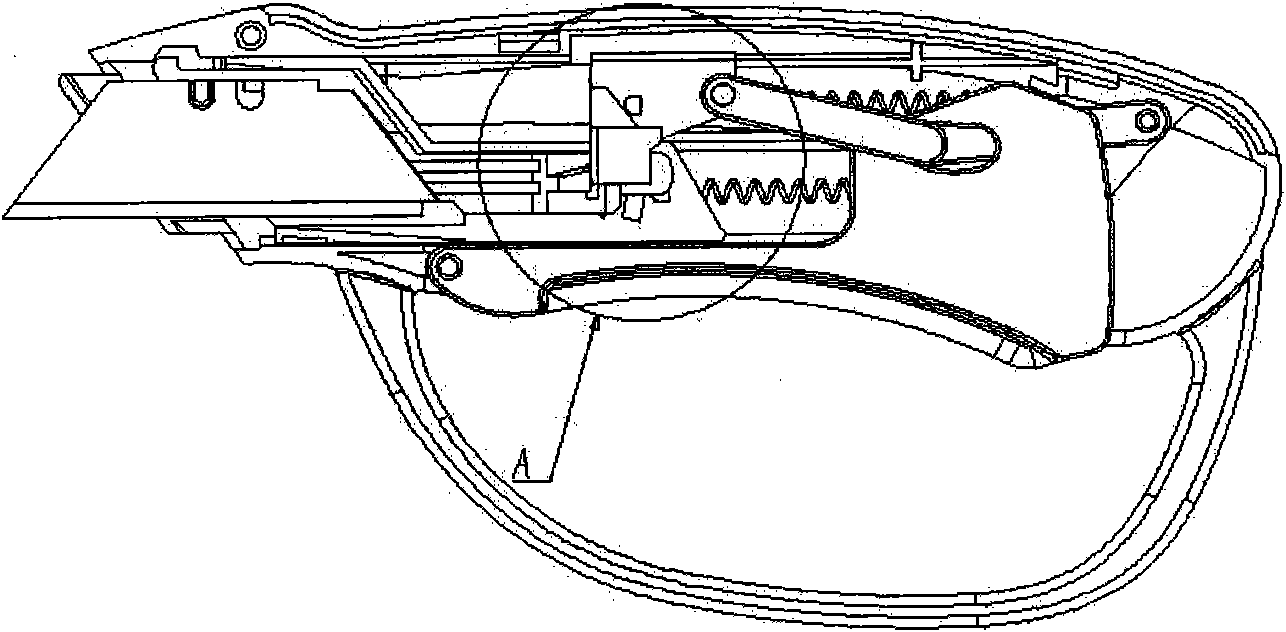

[0016] The casing 2 of the present invention is a snap-fit connection structure of left and right halves. In the figure, the surface layer casing is removed to clarify the internal structure of the present invention.

[0017] figure 1 with figure 2 It is a schematic diagram of the internal structure of the present invention. It can be seen from the figure that a safety cutting knife includes a housing 2, a detachable blade protective cover 1 placed at the end of the housing 2, and a fixed connection with the rotating knife rest 6. The blade 5 is characterized in that: the two ends of the tension spring one 9 in the cavity of the housing 2 are respectively connected to the housing 2 and the slider 8, and the two ends of the tension spring two 10 are respectively connected to the housing 2 and the sliding tool holder 7; one end of the trigger 4 Connected to the housing 2 through the fulcrum E, the other end of the trigger 4 can move up and down around the fulcrum E; It is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com