A reciprocating steel plate cutting device based on the principle of crank slider

A technology of crank slider and cutting device, which is applied to sawing machine, feeding device, metal sawing equipment, etc., can solve the problems of high labor intensity, large area and fire occurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

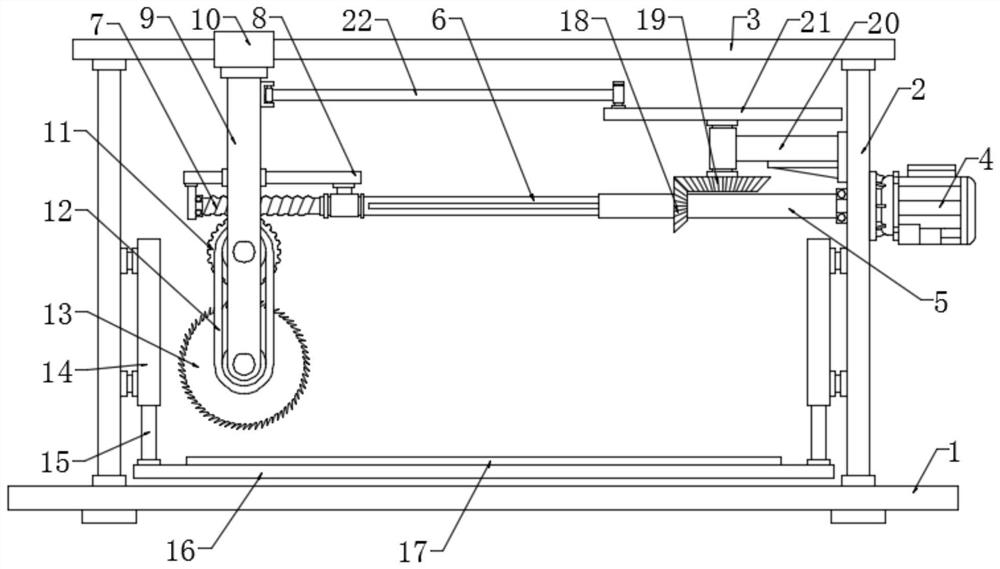

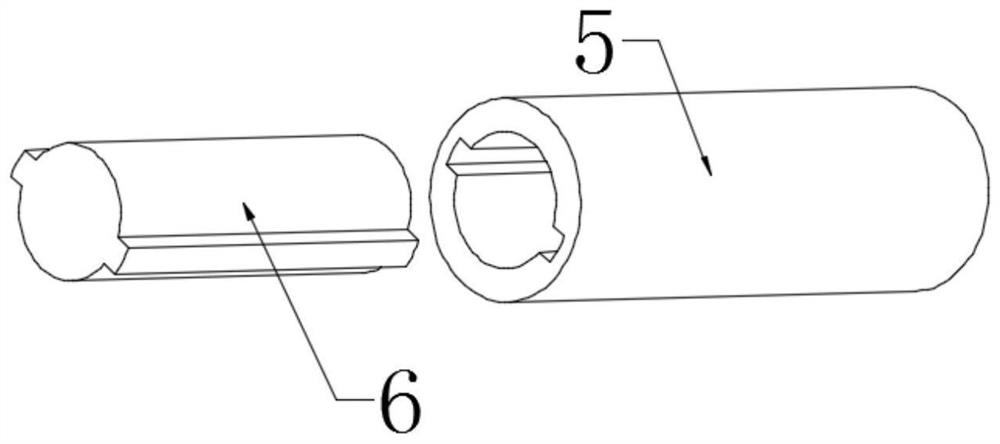

[0022] see Figure 1~3 , in an embodiment of the present invention, a reciprocating steel plate cutting device based on the slider crank principle includes a pallet 1, a sleeve 5, a boom 9, a cutting wheel 13 and a turntable 21; the two sides above the pallet 1 are respectively A column 2 is fixedly connected, and a guide rod 3 is fixedly connected between the columns 2 on both sides, and a drive motor 4 is fixedly installed on the flange of one side column 2, and the output end of the drive motor 4 rotates to connect the sleeve 5, and the sleeve 5 is socketed The stepped shaft 6, it should be noted that the sleeve 5 is a hollow shaft, two grooves are symmetrically arranged on its inner wall, and two convex lines are symmetrically arranged on the outer wall of the stepped shaft 6, and the convex lines are fitted on the inner wall of the sleeve 5 In the groove, the sleeve 5 can drive the stepped shaft 6 to rotate through the fitted convex strip and the groove, and the stepped s...

Embodiment 2

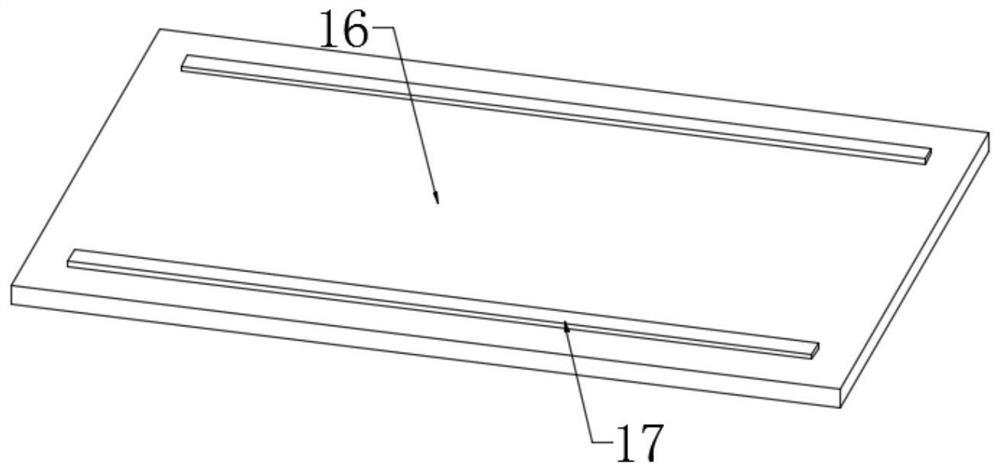

[0025] In order to further explain the above-mentioned reciprocating steel plate cutting device based on the principle of slider crank, the application provides another embodiment. The reciprocating steel plate cutting device based on the principle of slider crank in this embodiment has the following technical features: A workbench 16 is arranged above the supporting plate 1, and the top of the two sides of the workbench 16 is fixedly connected to the piston rod 15, and the upper part of the piston rod 15 is sealed and slidably connected to the cylinder 14, and the cylinder 14 is fixed on the columns 2 on both sides, and the front and rear sides of the workbench 16 The pads 17 are respectively fixedly connected, and the cylinder 14 drives the piston rod 15 to stretch and then drives the workbench 16 to move up and down to realize height adjustment, which is convenient for cutting steel plates of different thicknesses, and the pads 17 are used to pad the steel plates to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com