Mechanical arm vibration abatement device and method

A vibration suppression and suppression device technology, which is applied in the direction of non-rotational vibration suppression, manipulators, manufacturing tools, etc., can solve the problems of increasing the weight and volume of the manipulator, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. The structure and working principle of the vibration suppression device of the manipulator

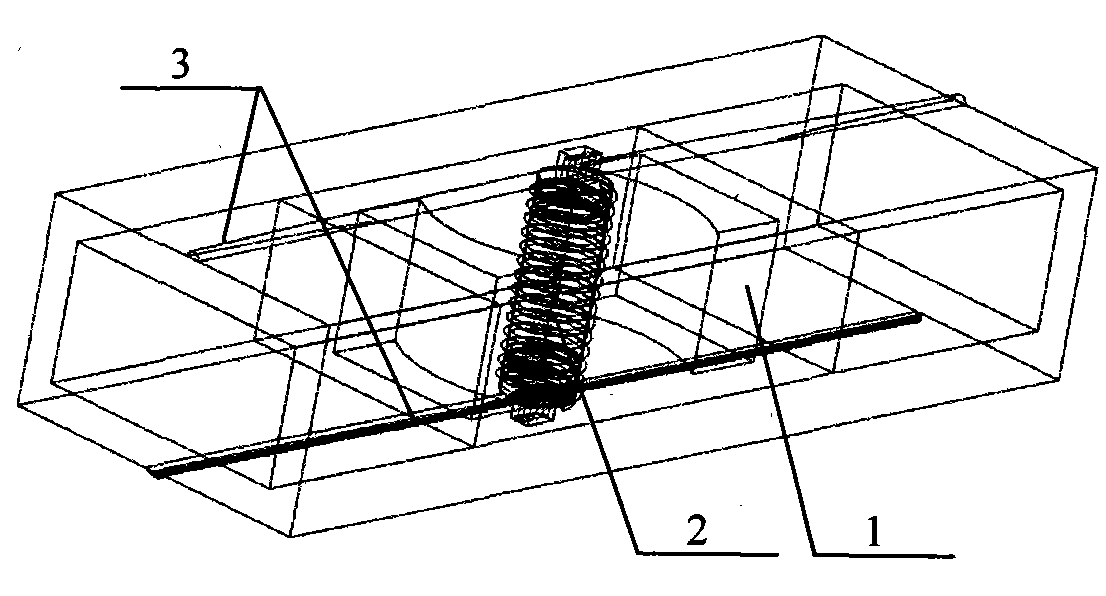

[0014] Such as figure 1 As shown, the vibration suppression device of the mechanical arm is composed of three parts: the motor (1), the lead screw (2) and the steel cable (3). The motor (1) is installed in the middle part of the mechanical arm, and its shaft is a hollow shaft, which can rotate forward and reverse. The hollow shaft is threaded on the inside. The leading screw (2) is a threaded cylinder, and the thread coincides with the thread on the inside of the hollow shaft of the motor (1). Both ends of the leading screw (2) are provided with cuboid-shaped threading columns, and slots are slotted in the middle of the threading columns for passing the steel cables (3). The two steel cables (3) are arranged on two opposite surfaces of the cuboid mechanical arm, and the two ends are respectively fixed on the two ends of the mechanical arm after being slotted through the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com