Quick release type scaffold stabilizer bar

A scaffold and stabilizer rod technology, applied in the field of scaffolding, can solve the problems of unadjustable length of stabilizer rod, inconvenient quick disassembly and assembly, unstable length of retractable rod, etc., and achieves the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

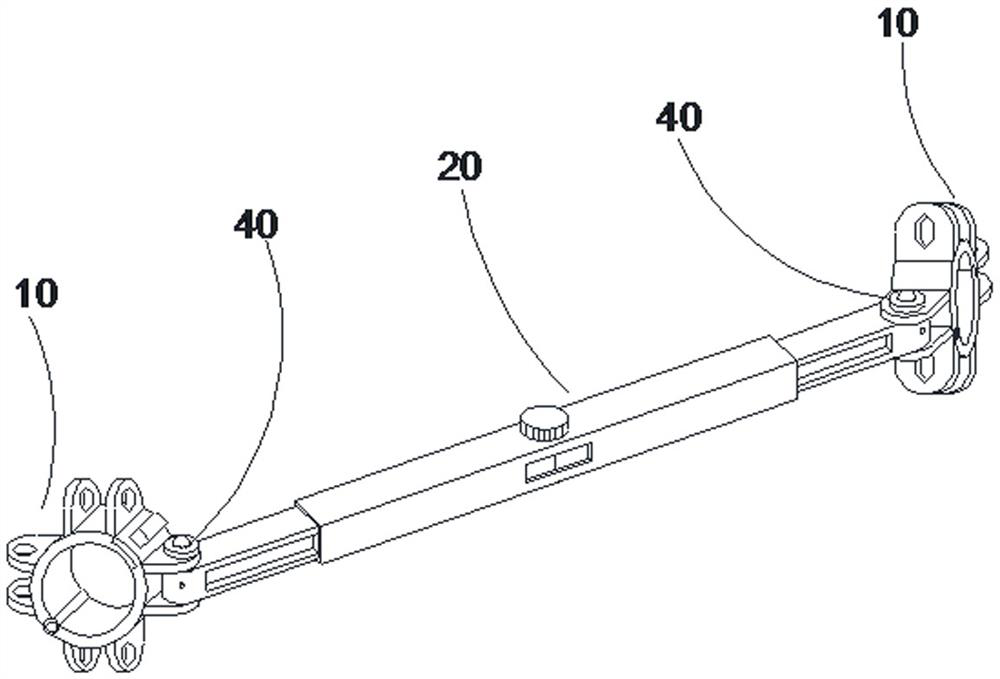

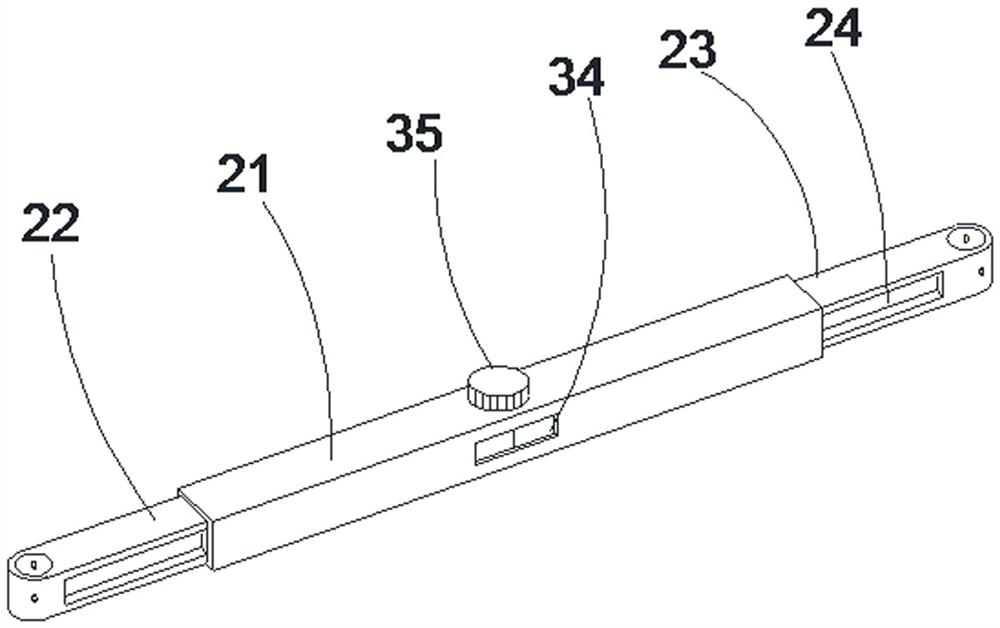

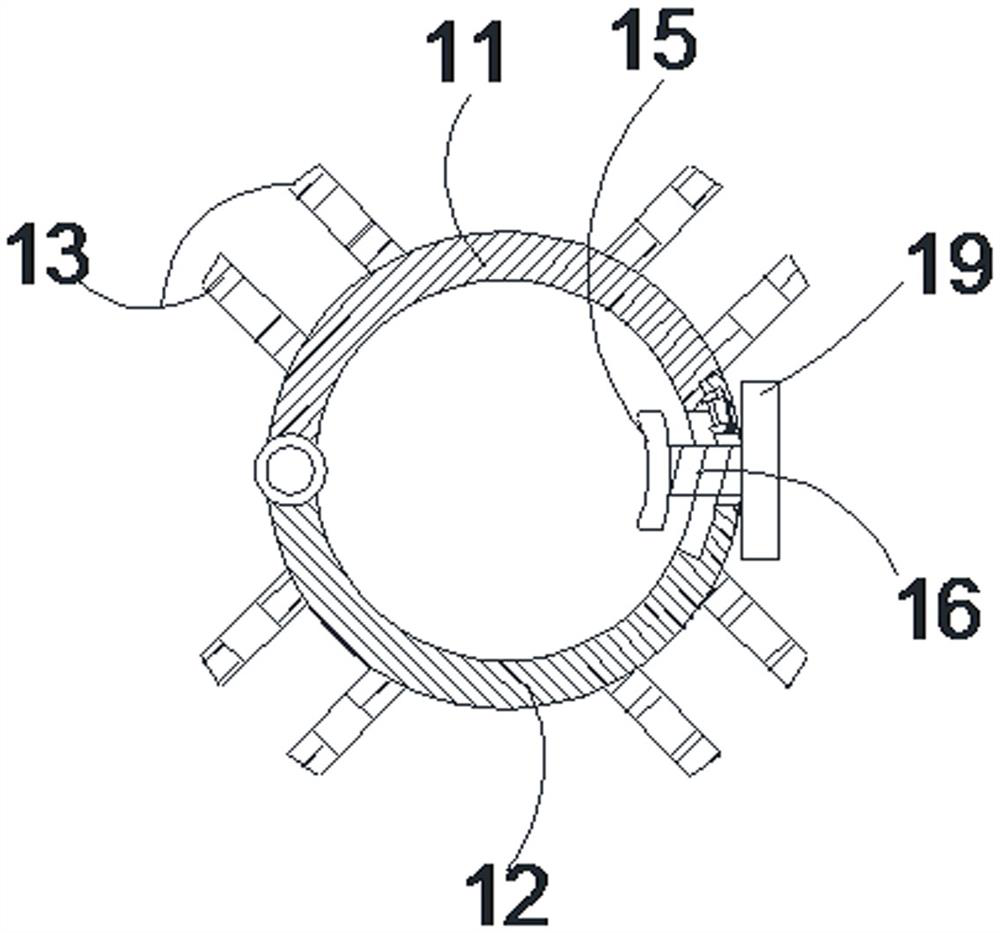

[0029] The quick-detachable scaffold stabilizer provided in this embodiment, such as Figure 1-10 As shown, it includes a fixed sleeve 10 , a support rod 20 , and a positioning member 40 . Specifically, the fixed sleeve 10 is used to be socketed and fixed on a vertical pole or a horizontal bar. The support rod 20 includes a middle sleeve 21, a first telescopic rod 22 and a second telescopic rod 23. The middle sleeve 21 is a tubular structure of a quadrangular prism. , and the front and rear side walls of the pipe hole are respectively provided with strip-shaped raised guide bars, and the pipe hole of the middle sleeve 21 is provided with an adjustment device and a length measuring device. The first telescopic rod 22 and the second telescopic rod 23 are all four Prismatic tube-shell structure. The left end of the first telescopic rod 22 and the right end of the second telescopic rod 23 are each provided with a circular first fixed through hole, the side wall of the first fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com